Patents

Literature

633results about How to "Improve the pressing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

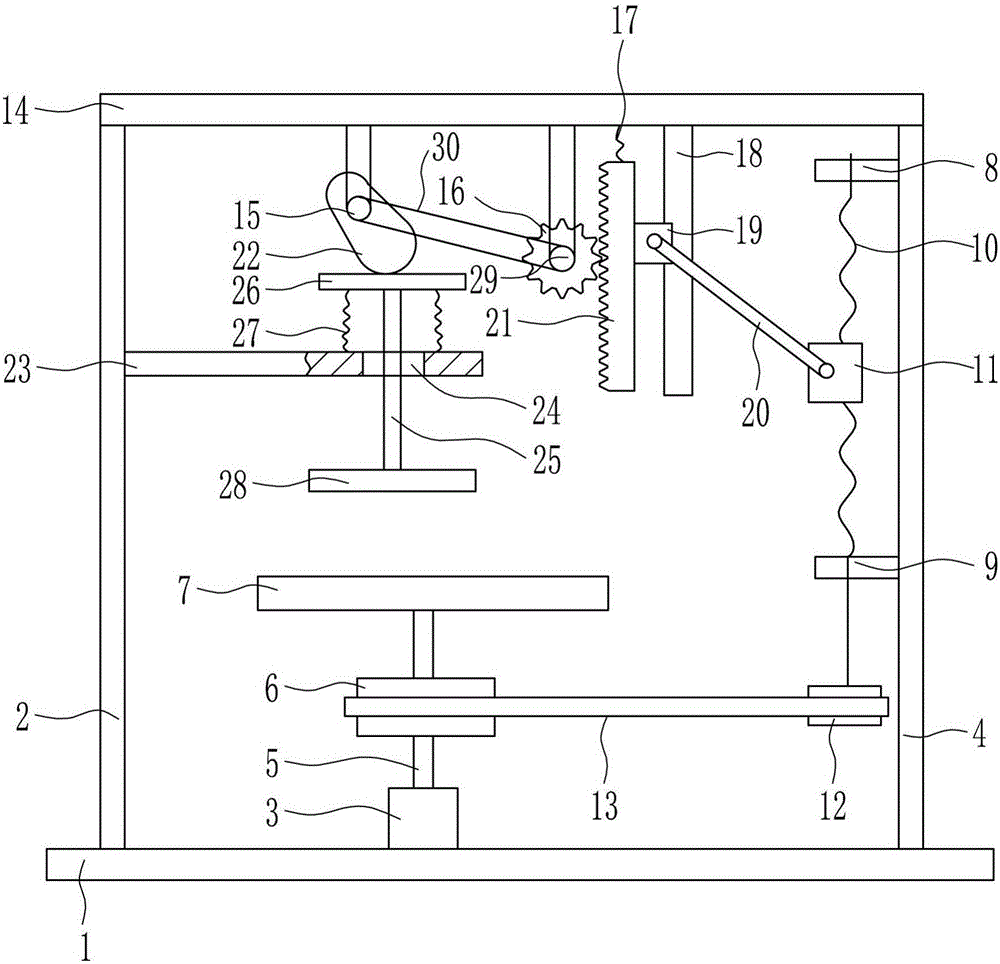

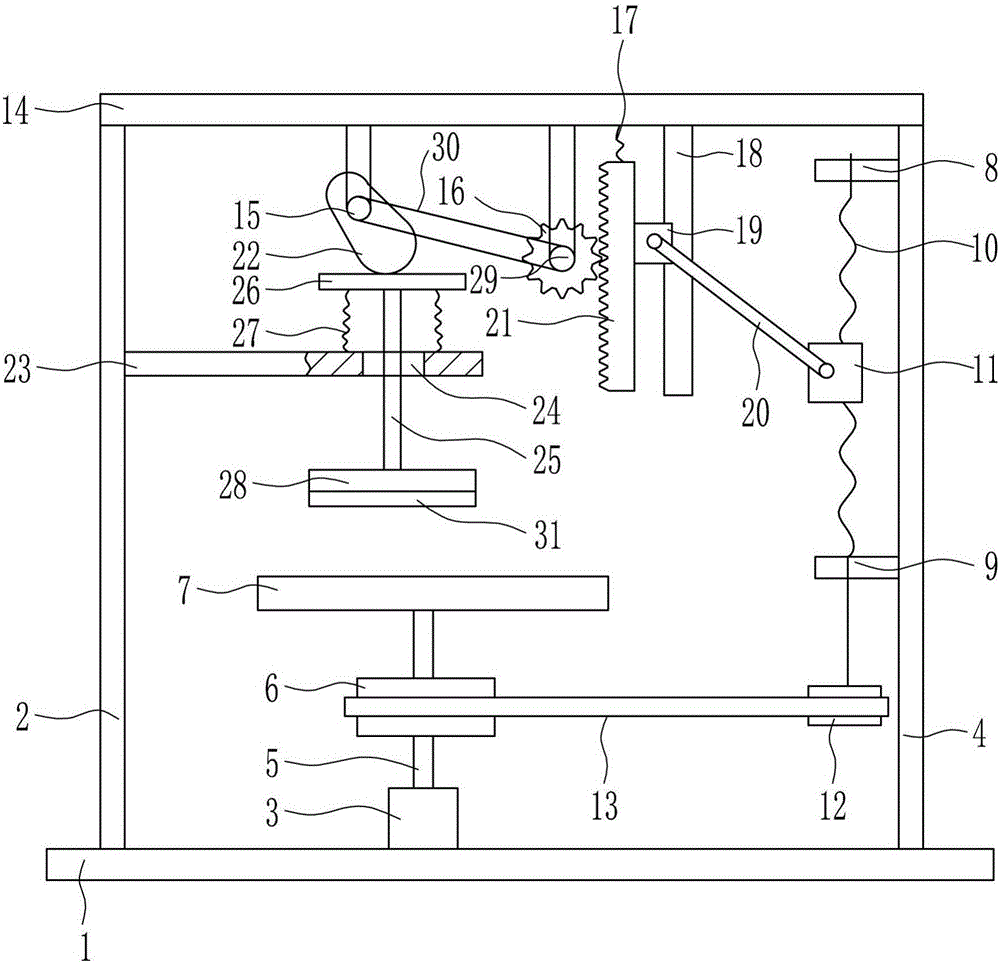

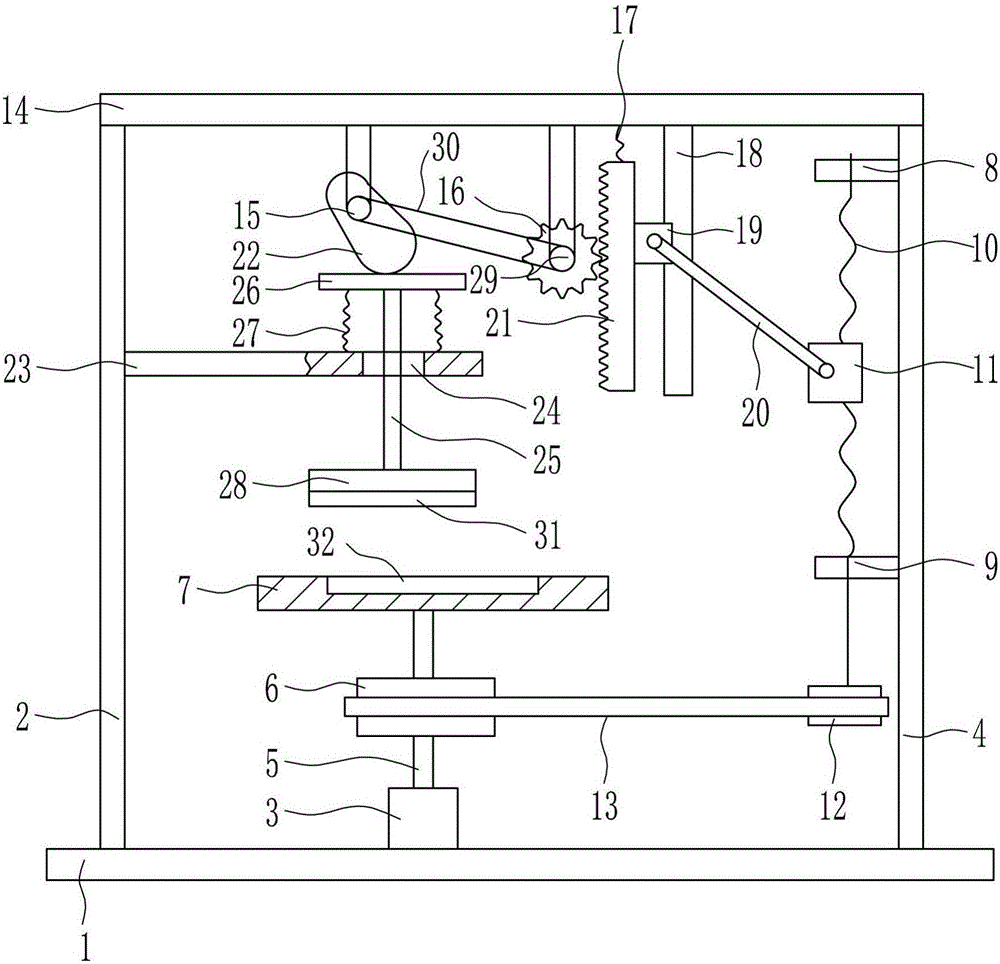

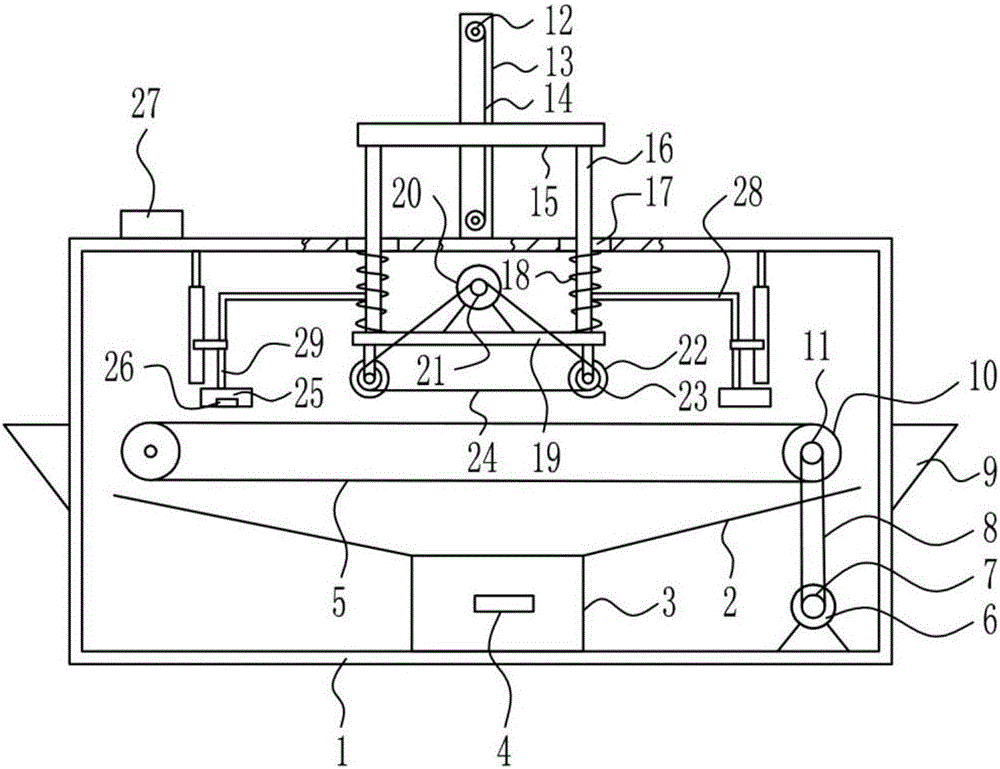

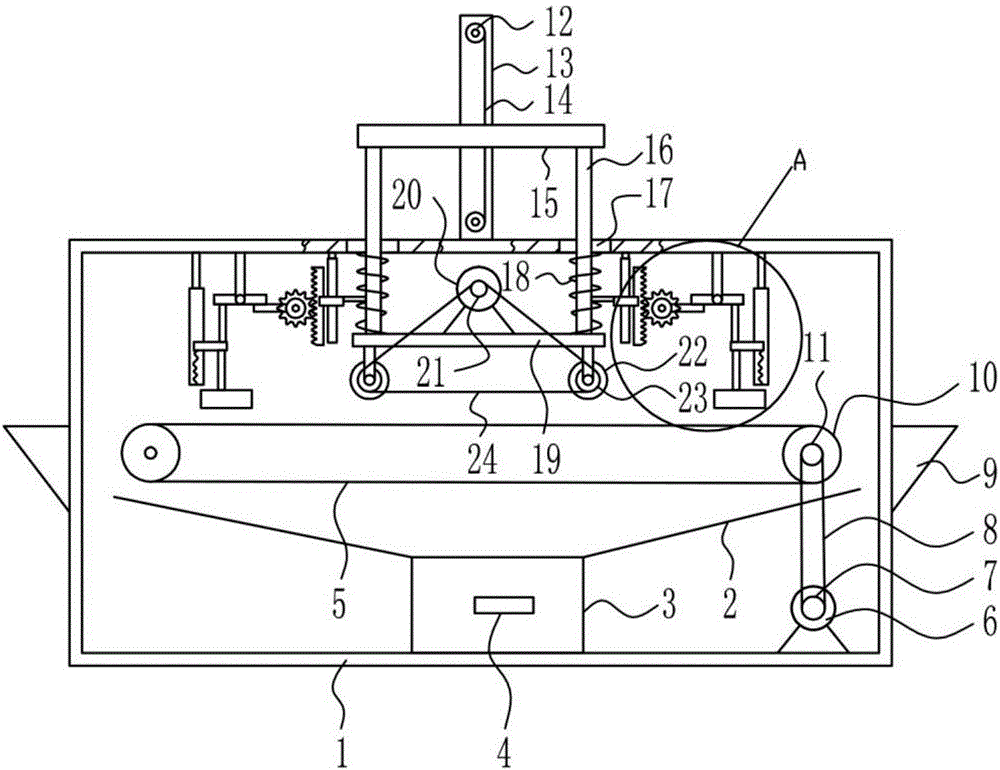

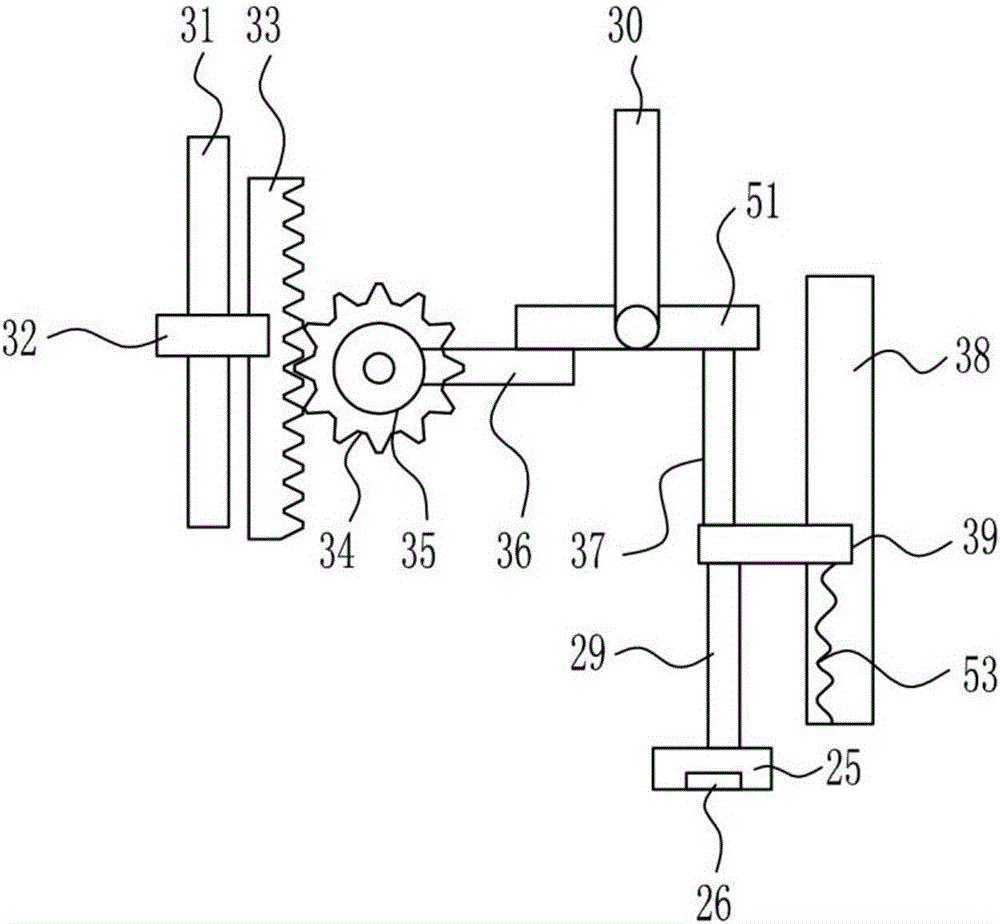

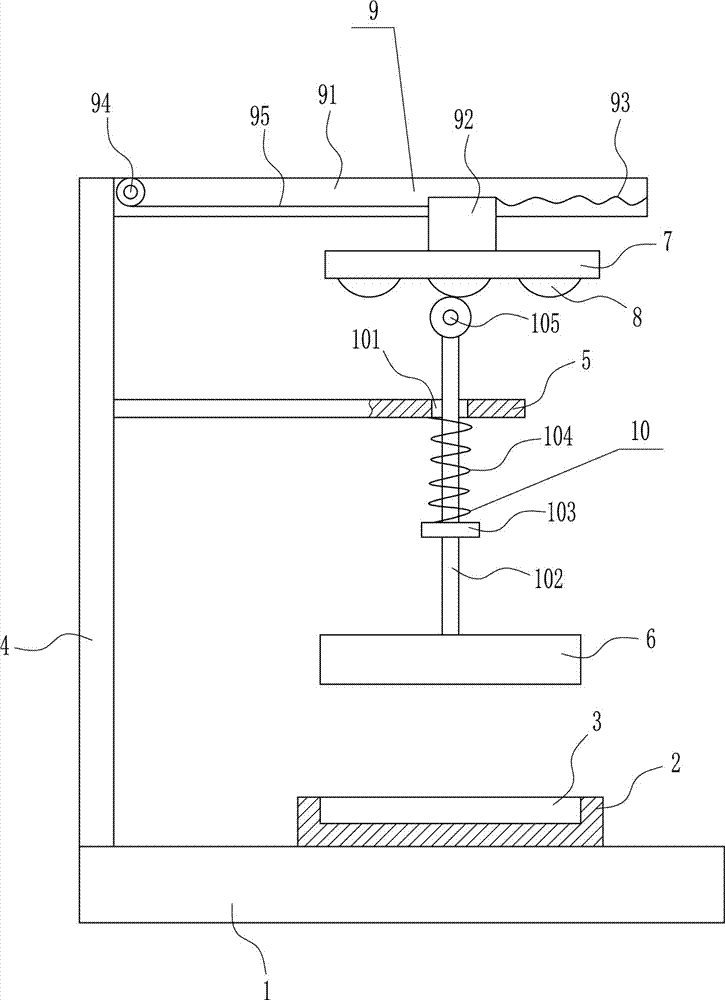

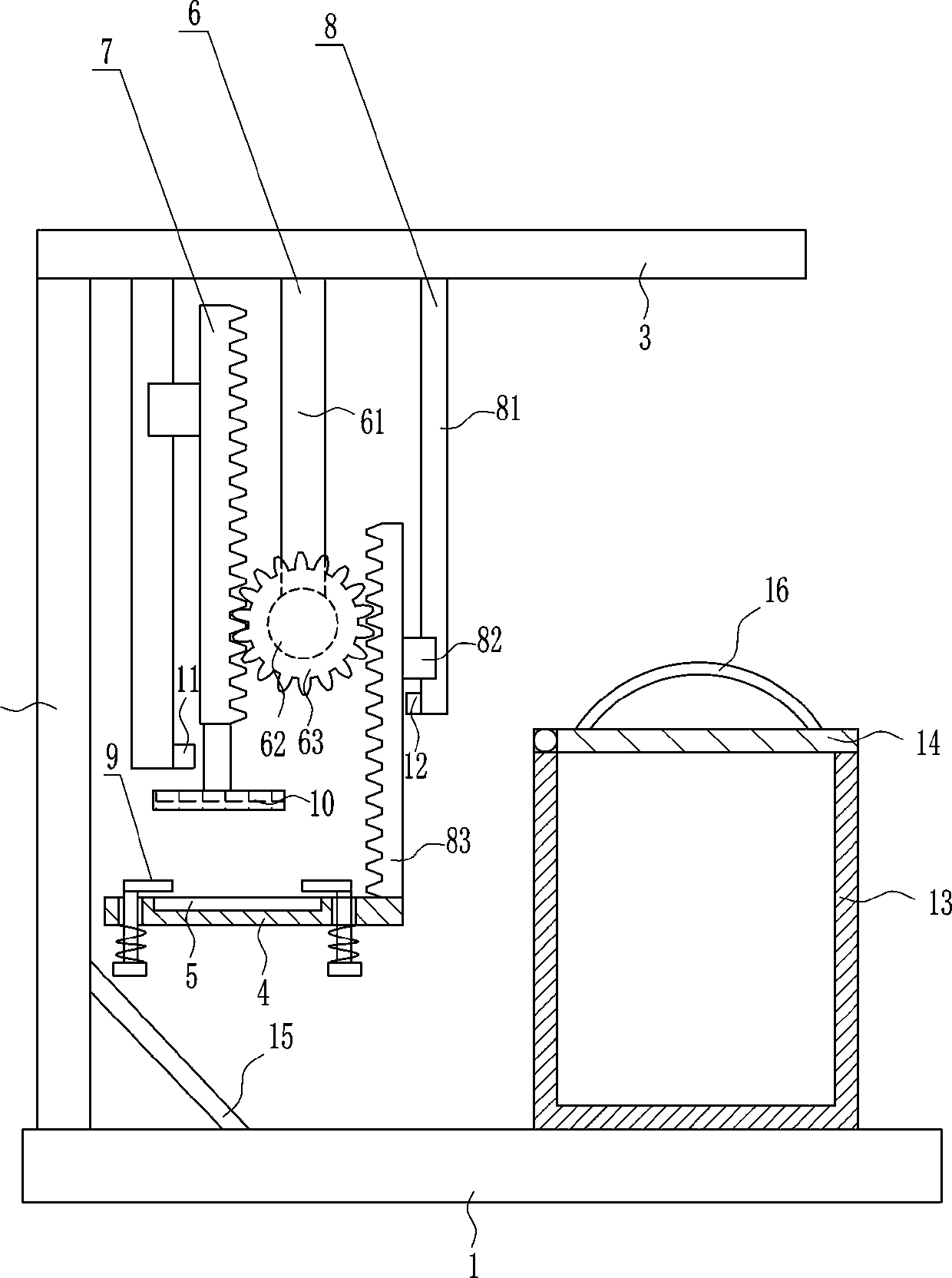

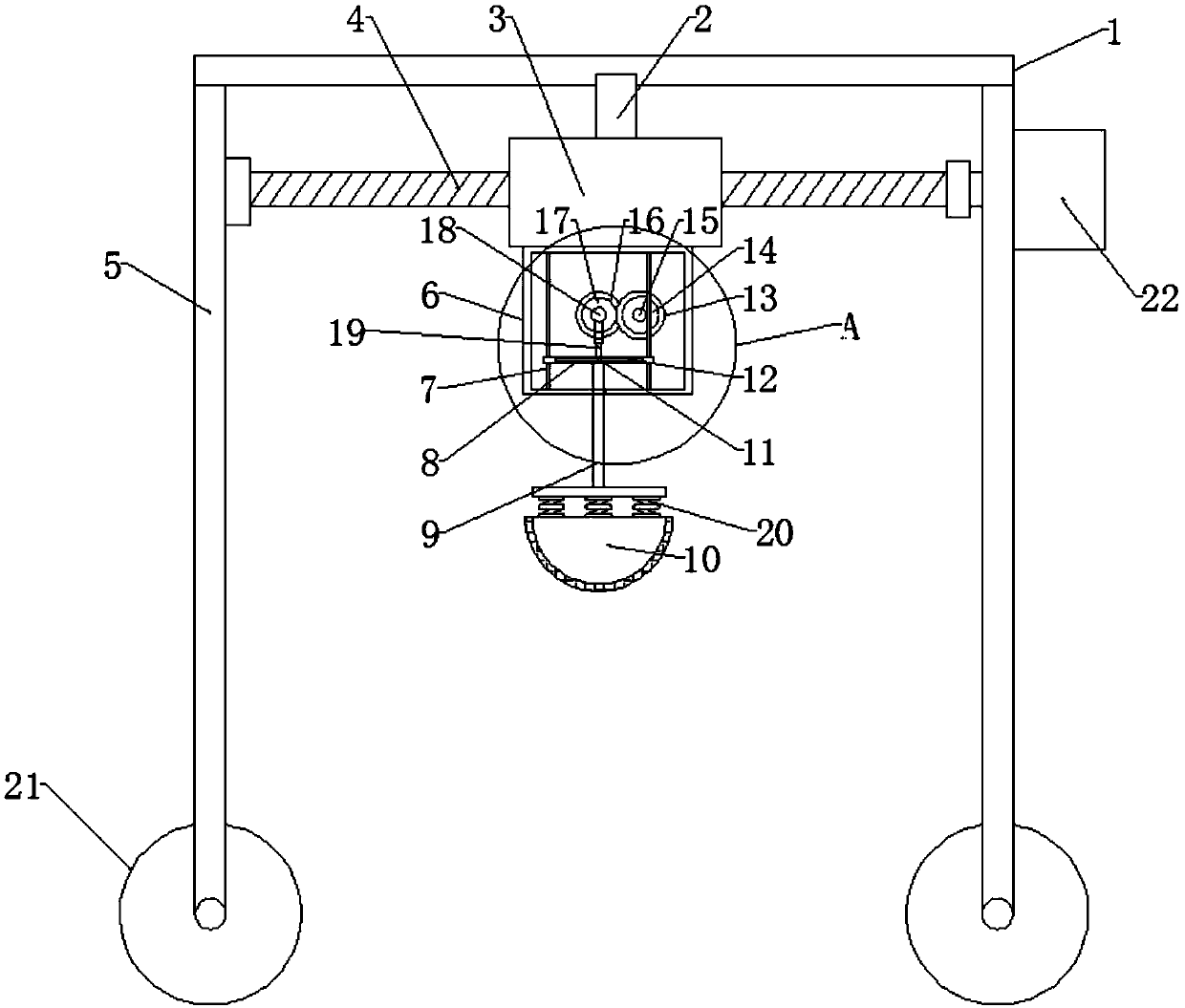

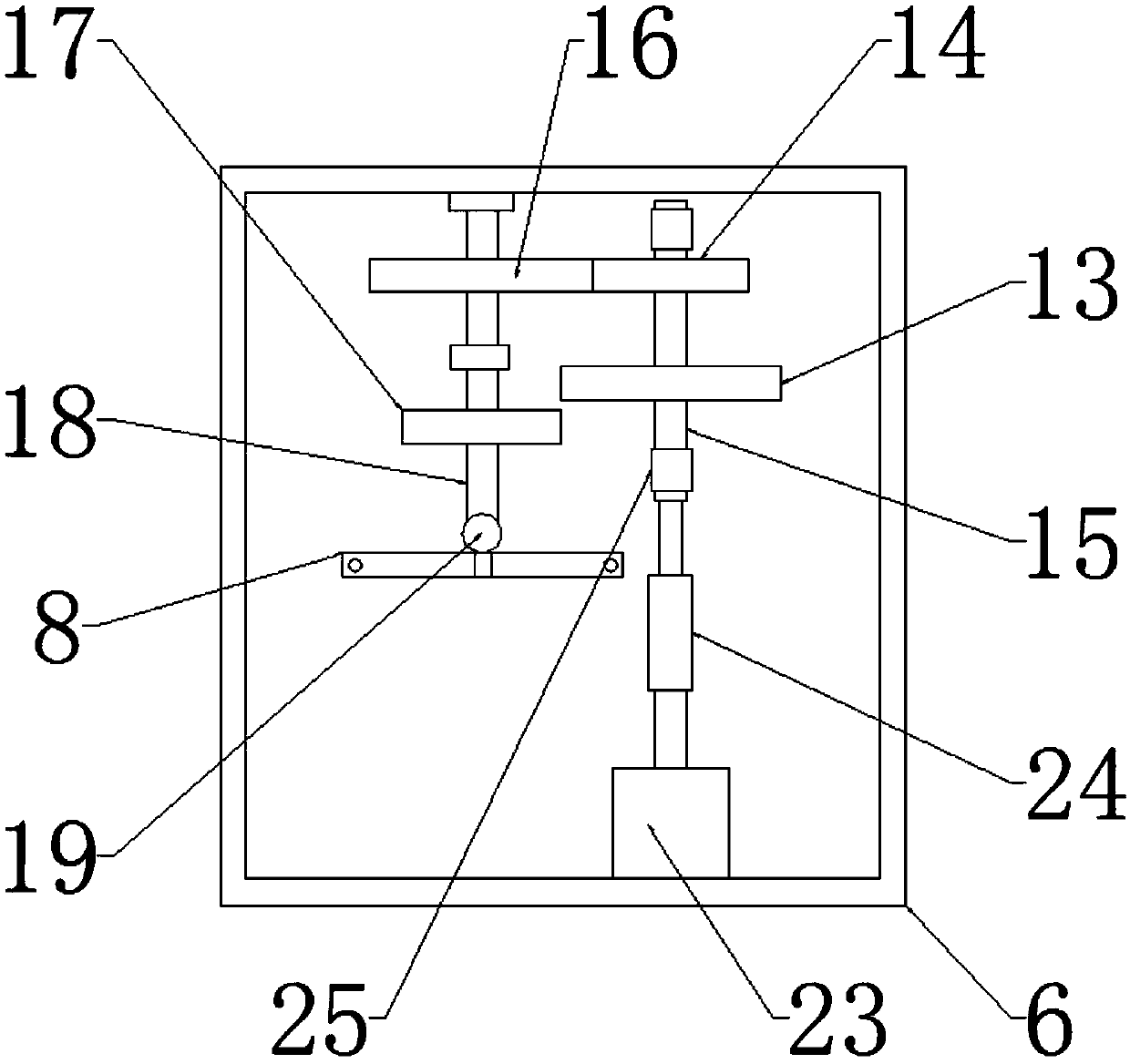

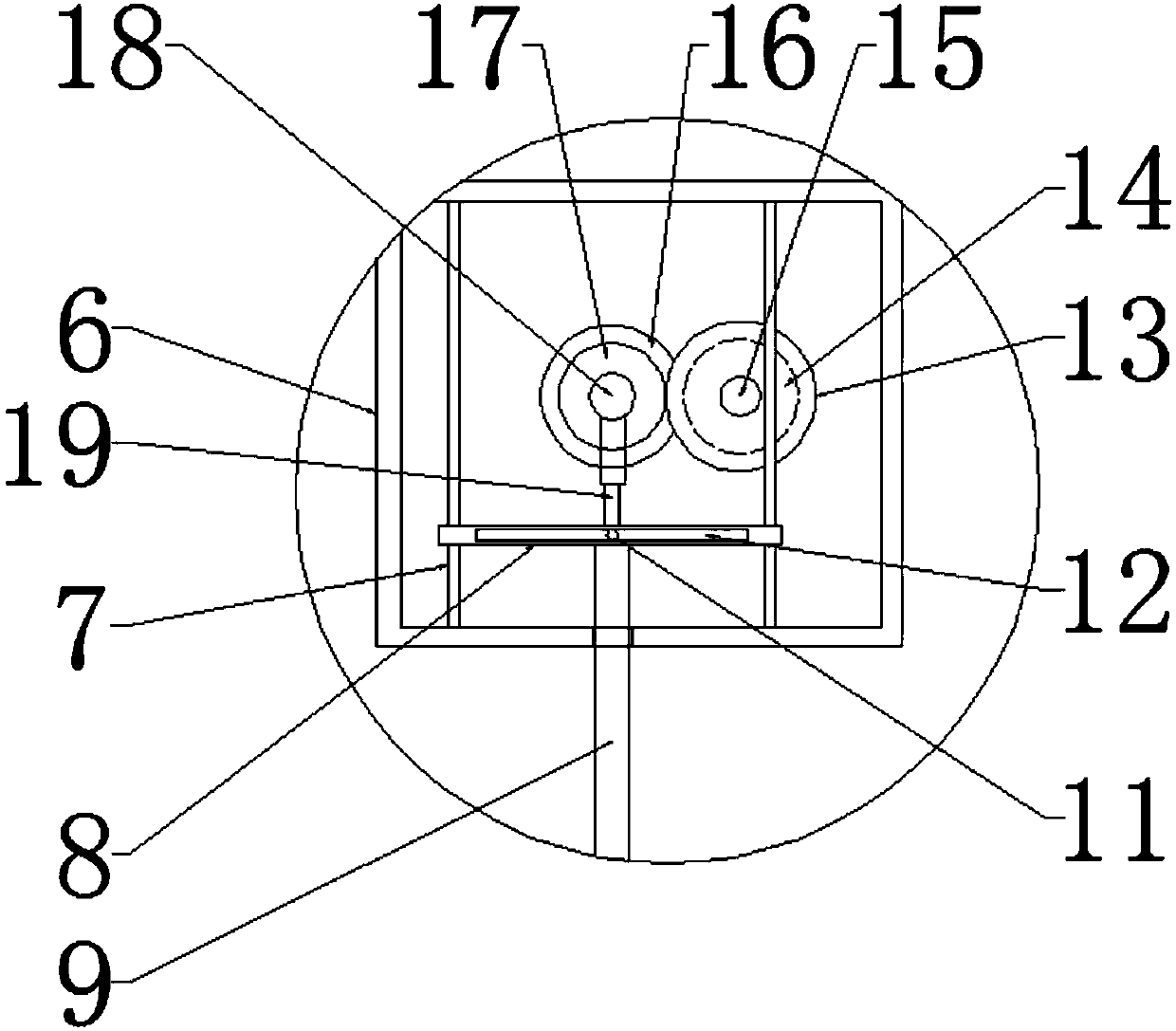

Rapid shoe sole press-fit device for shoe production

The invention relates to a shoe sole press-fit device, in particular to a rapid shoe sole press-fit device for shoe production. The technical problem to be solved in the invention is to provide the rapid shoe sole press-fit device for shoe production which is good in press-fit effect, easy to operate and high in working efficiency. In order to solve the technical problem, the rapid shoe sole press-fit device for shoe production provided by the invention comprises a bottom plate, a left side plate, a motor, a right side plate, a rotating shaft, a big belt pulley, a placement plate, an upper bearing block, a lower bearing block, a lead screw, a nut, a small belt pulley, a flat belt, a top plate, a driven wheel, a gear, a first spring, a sliding rail, a slide block, a connecting rod, a rack, a cam, a guide plate, a lifting rod, a movable plate, a pressure block, a driving wheel, a first belt and the like. According to the rapid shoe sole press-fit device for shoe production provided by the invention, with the adoption of a manner of the pressure block and the placement plate, the pressure block moves up and down to press the shoe sole with glue on the placement plate.

Owner:张浩杰

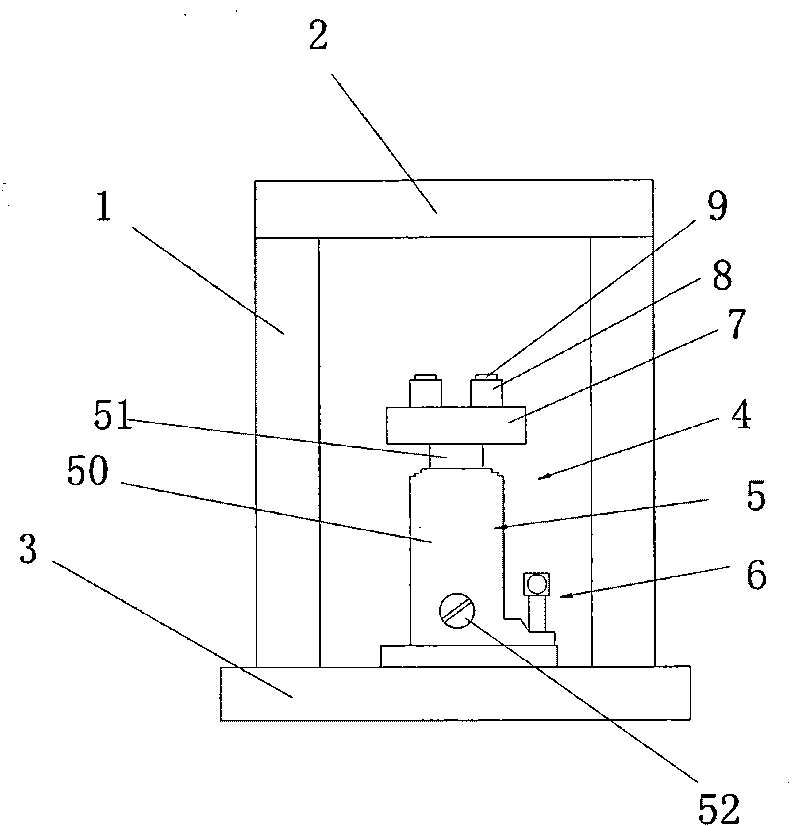

Press-mounting machine

InactiveCN101733627ASimple structureLow costMetal working apparatusMetal-working hand toolsTorchMechanical engineering

The invention relates to a press-mounting machine for compressing a press ring and assembling the press ring on a corresponding workpiece. The press-mounting machine comprises a base, a support frame with a top plate and a press-mounting device, wherein the support frame with the top plate is arranged on the base; the press-mounting device is arranged on the base and positioned below the top plate and comprises a hydraulic jacking device and a press-mounting tooling, wherein the press-mounting tooling is arranged at the top of the hydraulic jacking device and comprises a base plate and a plurality of convex columns arranged on the base plate; and the top ends of the convex columns are provided with lug bosses matched with pressing rings of the press-mounting tooling. The press-mounting machine has simple structure, low cost, good press-mounting effect, steady assembly and high production efficiency and is very convenient, used for pressing and mounting a metal ring to a part matched with the metal ring and especially suitable for pressing and mounting a conductive pressing ring to the bottom of an inner cavity of the head part of a electric torch.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

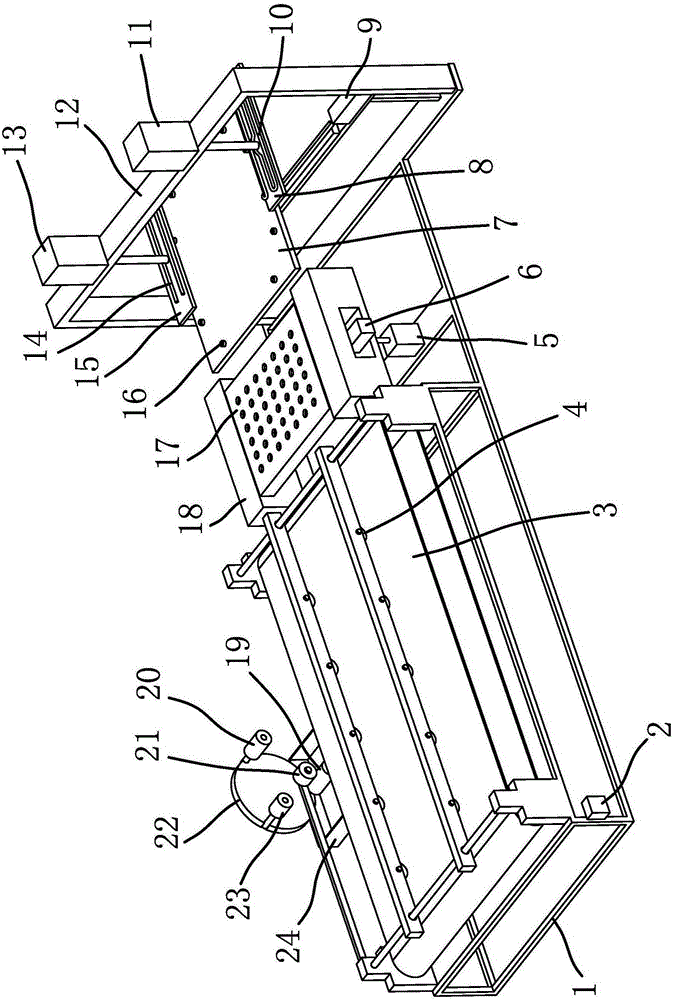

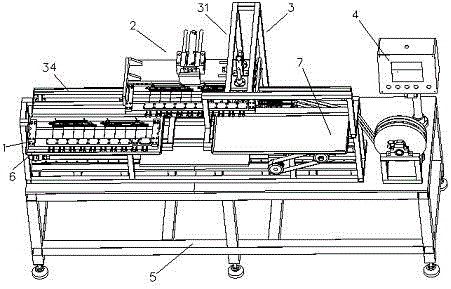

Carton glue coating and pressing all-in-one machine

InactiveCN105196609AIncrease productivityTo meet the needs of different widths of gluingPaper-makingBox making operationsCartonEngineering

The invention provides a carton glue coating and pressing all-in-one machine, which solves the technical problems that no pressing structure is arranged in the existing carton pasting device, and the manual one-by-one pressing is needed, so that the production efficiency is low, and the like. The carton glue coating and pressing all-in-one machine comprises a machine frame, wherein a glue coating device and a pressing device are arranged on the machine frame; the glue coating device comprises a conveying belt, a rotating shaft, a glue water box and a pressing wheel; the conveying belt is arranged on the machine frame through a conveying shaft; the glue water box is arranged on the machine frame through a first moving mechanism capable of driving the glue water box to vertically move; in addition, the glue water box is positioned at one side of the conveying belt; the rotating shaft is arranged on the machine frame in an axially fixed and peripherally rotating way; the rotating shaft and the conveying shaft are mutually parallel; one end of the rotating shaft is connected with a power mechanism capable of driving the rotating shaft to rotate; the other end of the rotating shaft is fixedly connected with a rotating disc; the rotating disc can be positioned in the glue water box; a first installing rod, a second installing rod and a third installing rod are respectively arranged on the side surface of the rotating disc. The carton glue coating and pressing all-in-one machine has the advantage of high production efficiency.

Owner:京山联德机械有限公司

Vacuum belt press filter

InactiveCN101612805AEasy to cleanRealize automatic continuous operationCleaning using liquidsPressesFiltrationPulp and paper industry

The invention relates to a vacuum belt press filter, comprising a rack, a vacuum filtration assembly, a press assembly and a filtration belt assembly, wherein the filtration belt assembly comprises an upper filtration belt, a lower filtration belt, and a cleaning device A and a cleaning device B which are used for respectively cleaning the upper filtration belt and the lower filtration belt; the cleaning device B comprises a front guide roller and a rear guide roller on the motion direction of the lower filtration belt, the front guide roller is arranged on the upper face the lower filtration belt, closely contacts the lower filtration belt and enables the lower filtration belt to form a V shape, the rear guide roller is arranged on the lower face of the lower filtration belt and is provided with a plurality of pinpricks, the size of each pinprick is matched with the size of a filtration pore of the filtration belt, and the rear guide roller contacts with the lower filtration belt by the pinpricks; and the cleaning device B is provided with a plurality of spray heads, and the spray heads are distributed on the upper face and the lower face of the lower filtration belt. The vacuum belt press filter of the invention has the advantage of favorable cleaning effect of the filtration belts, and belongs to the technical field of press machines.

Owner:HUZHOU HEHONG MACHINERY

Automatic bamboo machining device

InactiveCN106392800AReal-time monitoring of the degree of compressionAdjust the distance in timeGrinding carriagesGrinding feed controlEngineeringGrinding wheel

The invention relates to a bamboo machining device, in particular to an automatic bamboo machining device. The technical problem to be solved by the invention is to provide the automatic bamboo machining device with high pressing tightness degree, easy waste chip collection and high automation degree. In order to solve the technical problem, the invention provides the automatic bamboo machining device. The automatic bamboo machining device comprises a worktable, a first guide plate, a collecting drawer, a pull ring, a first flat belt, a first motor, a first belt wheel, a second flat belt, a second guide plate, a support wheel and the like; the back side of the collecting drawer is connected with the worktable through an extension part through a hanging hook connecting mode; the front end of the collecting drawer is connected with the pull ring through a screw mode; and the lower part in the worktable is welded with the first guide plate. The automatic bamboo machining device enables a pressing plate and a grinding wheel to synchronously ascend and descend, and is provided with a pressure sensor glued at the bottom of the pressing plate for timely monitoring the pressing degree between the pressing plate and bamboos and returning signals to a controller.

Owner:GUANGDONG IND TECHN COLLEGE

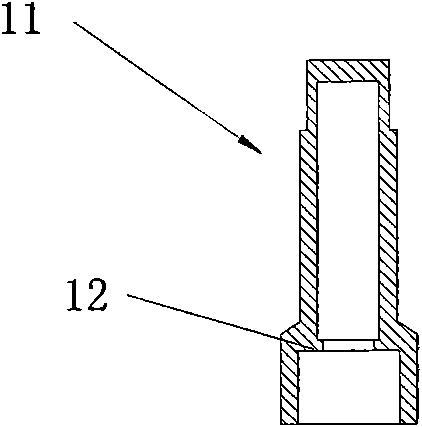

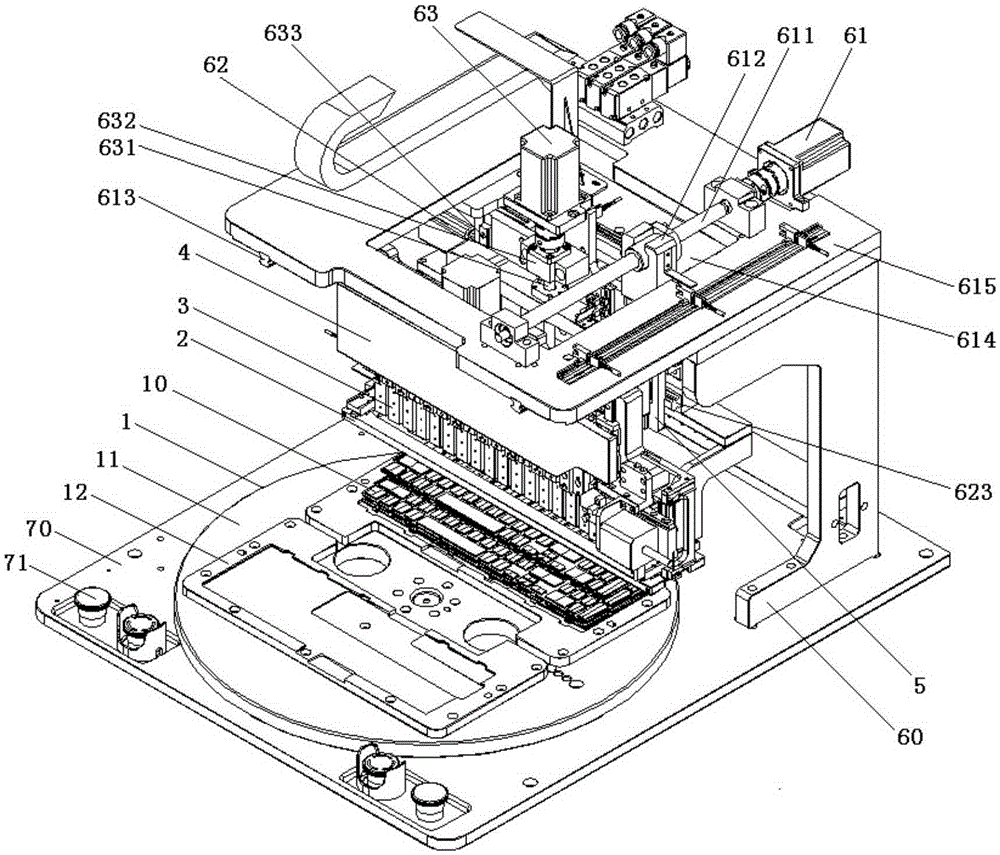

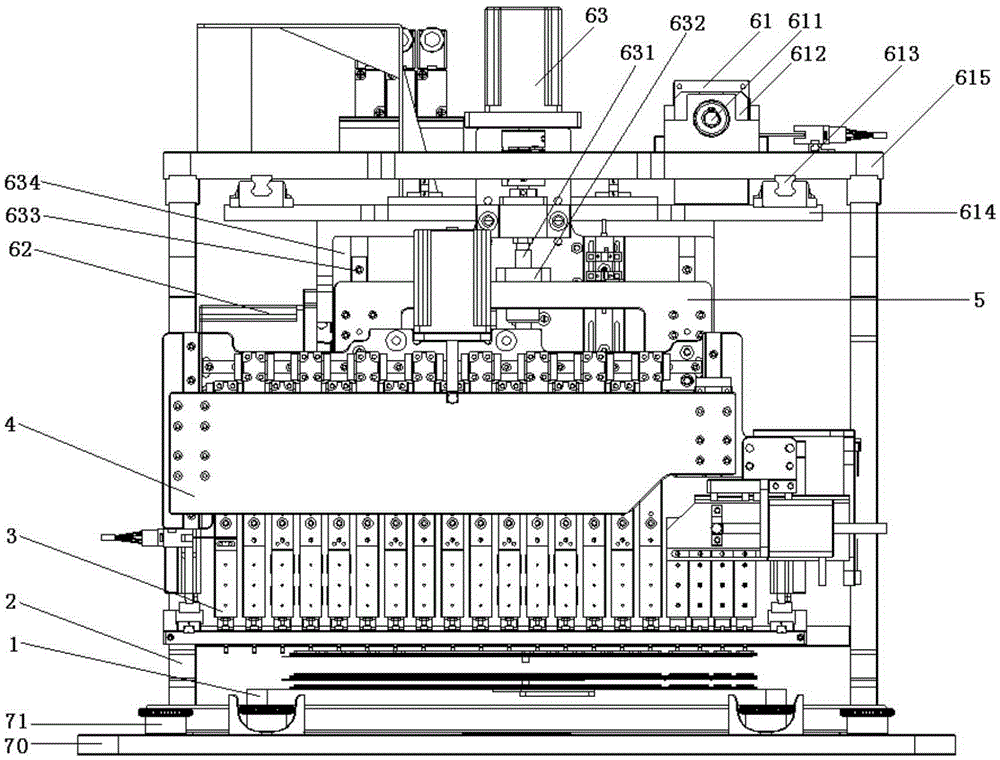

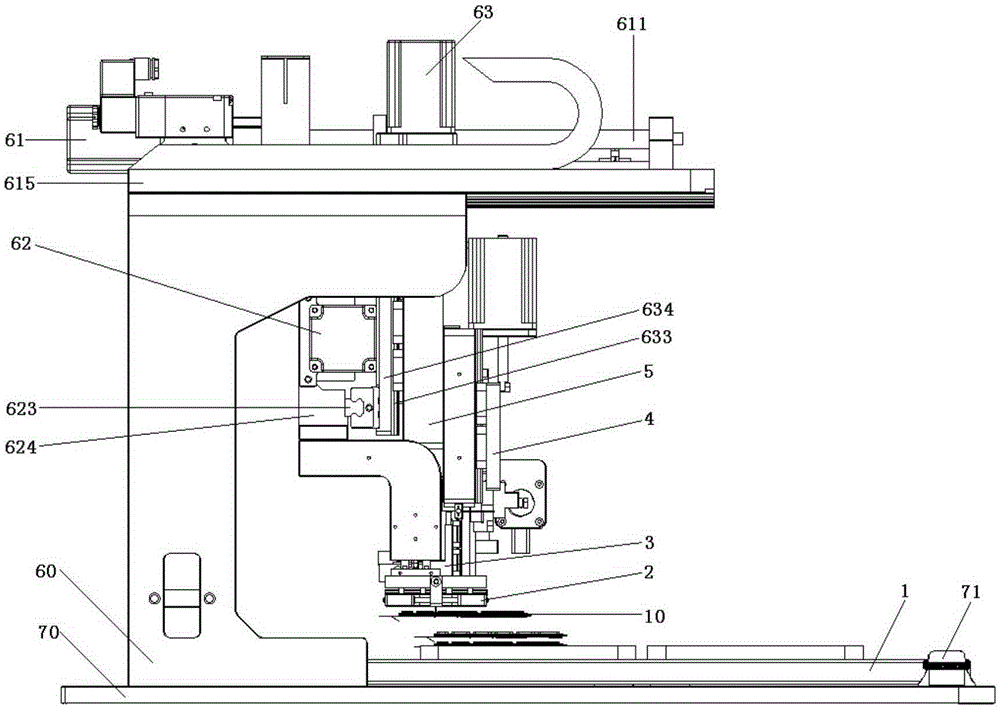

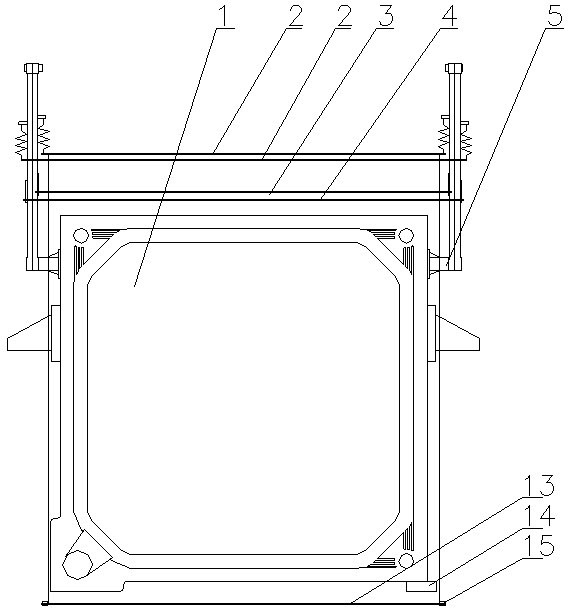

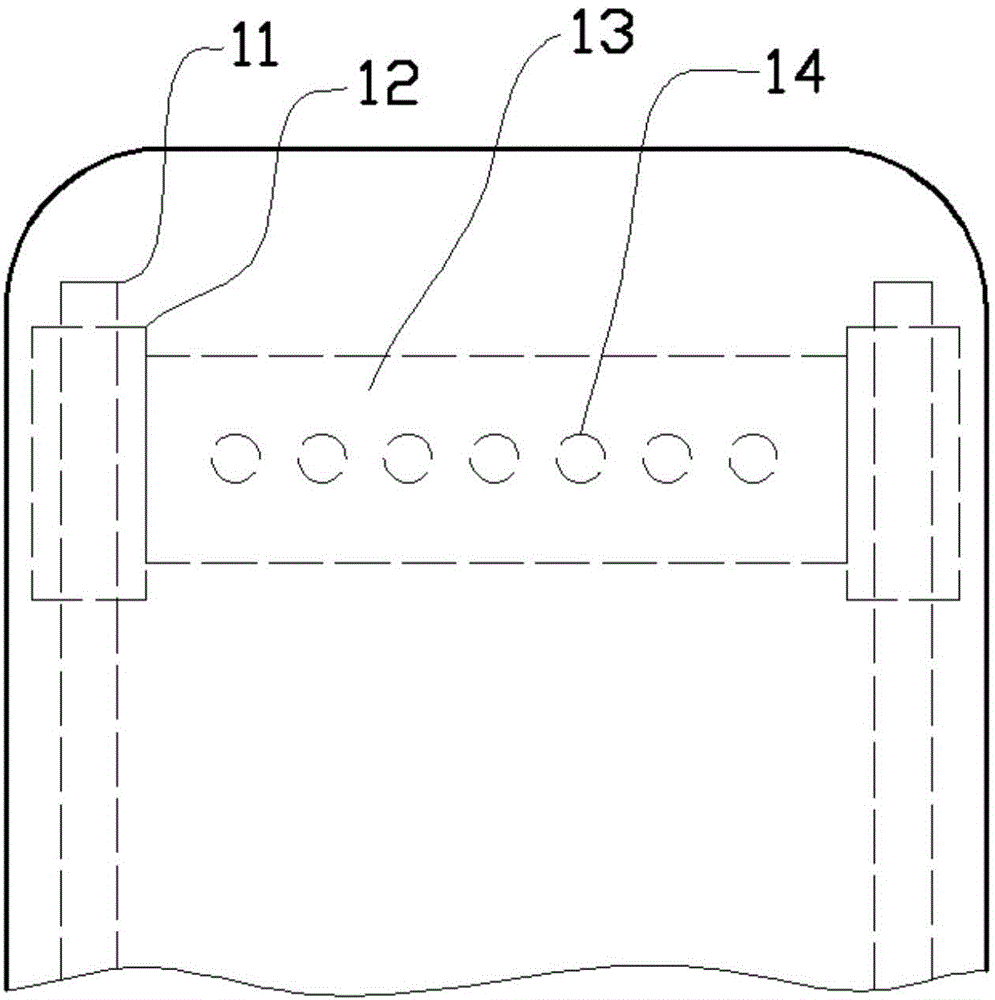

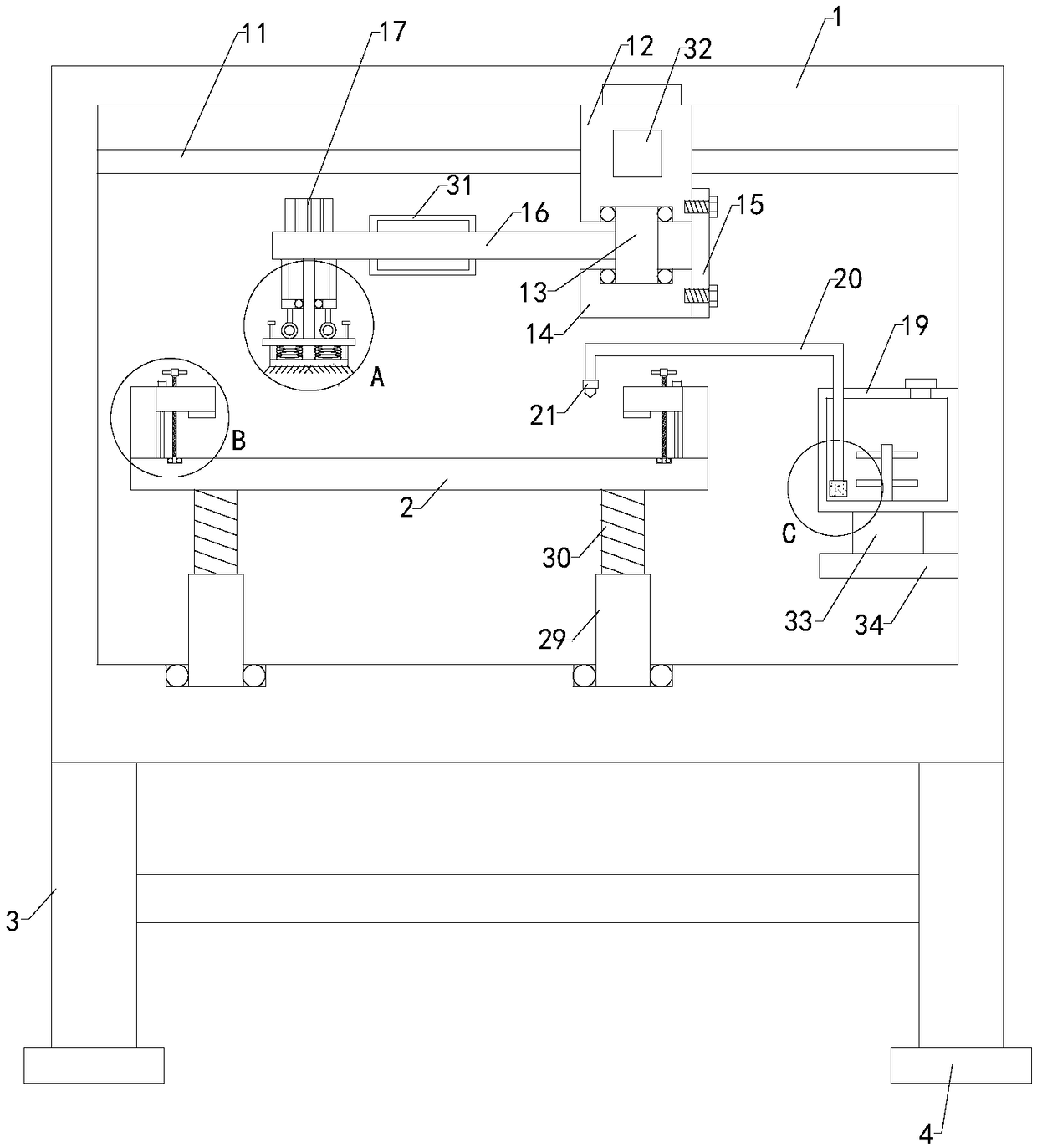

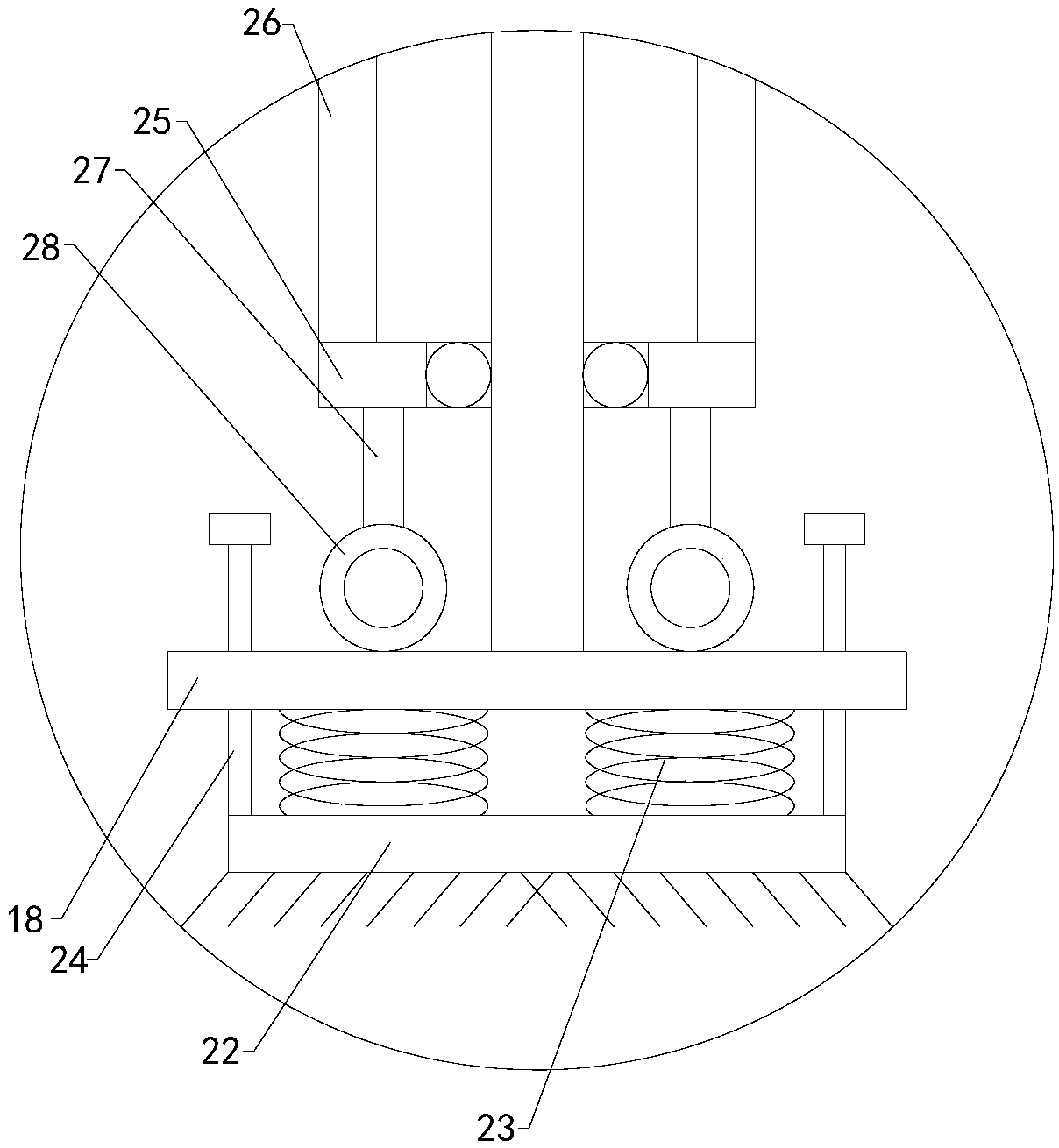

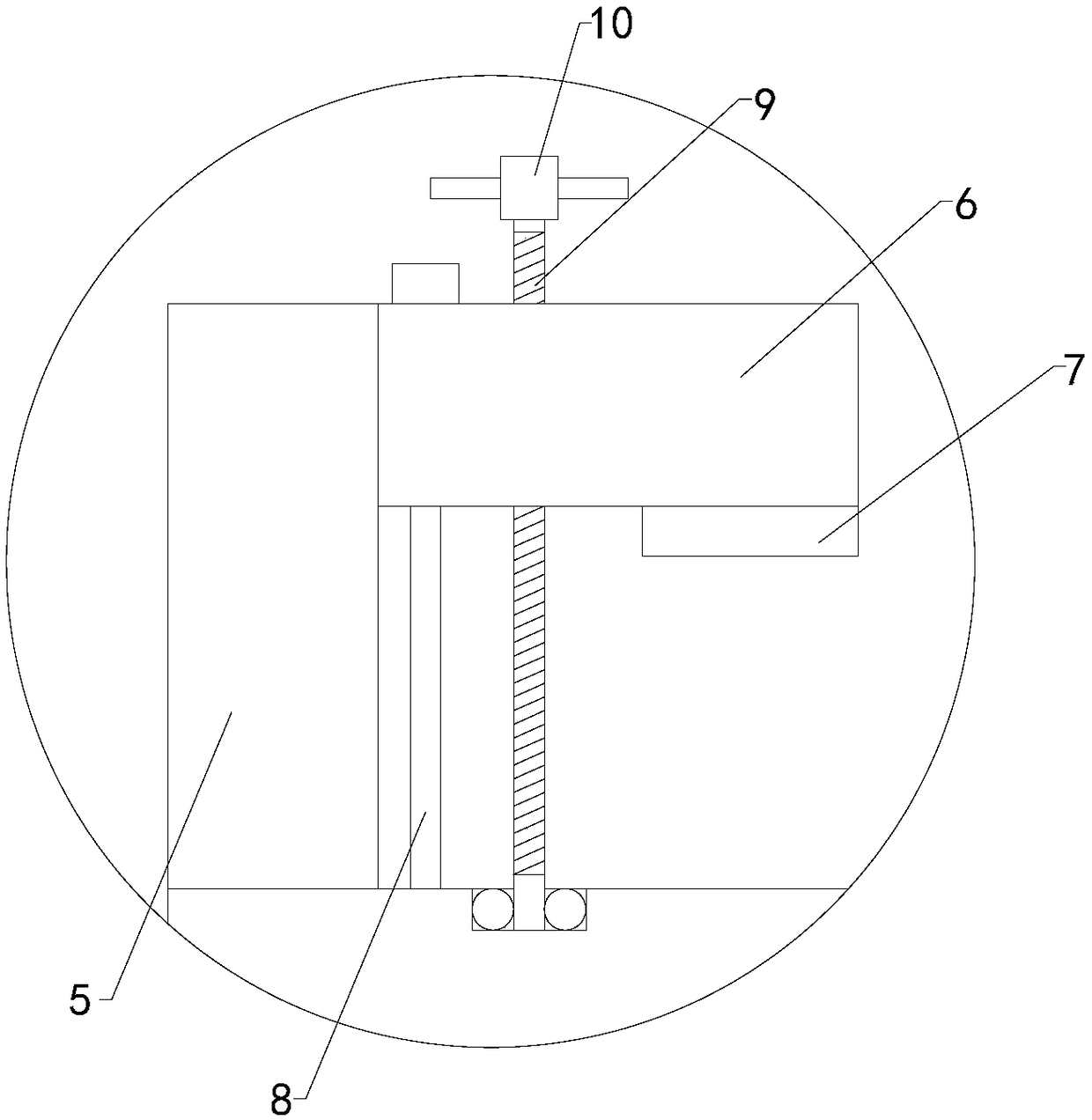

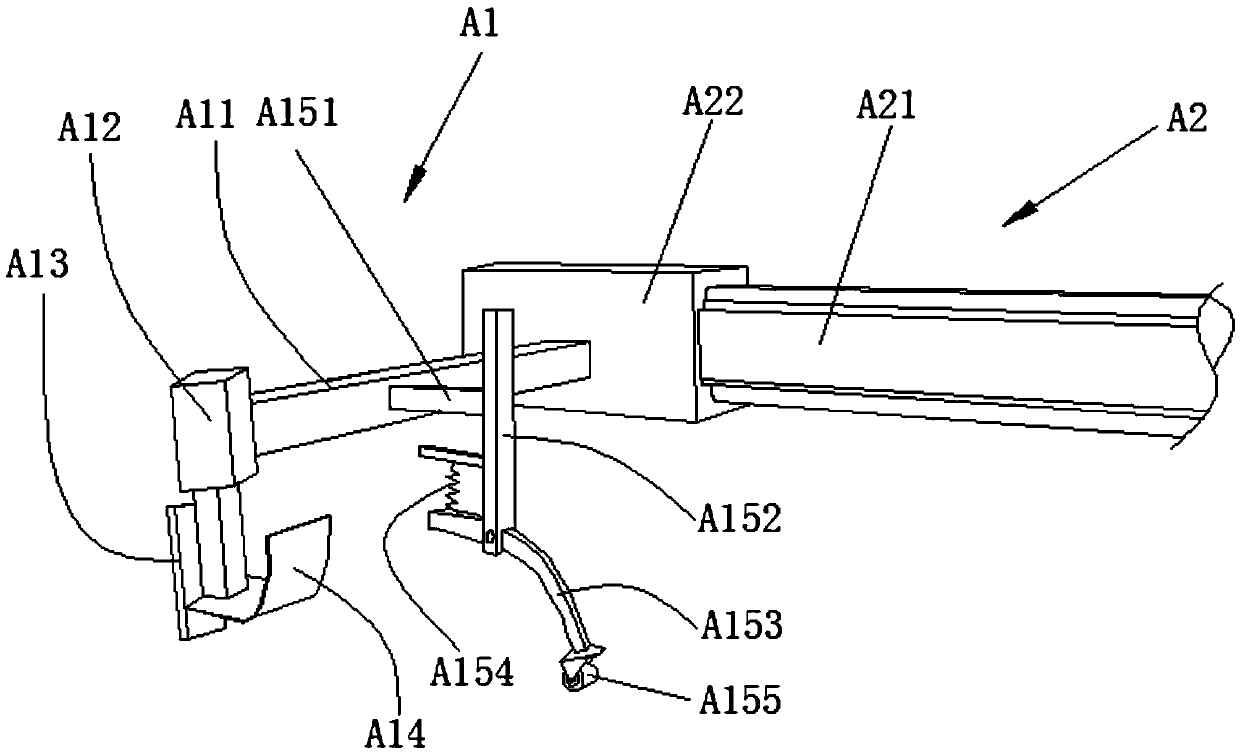

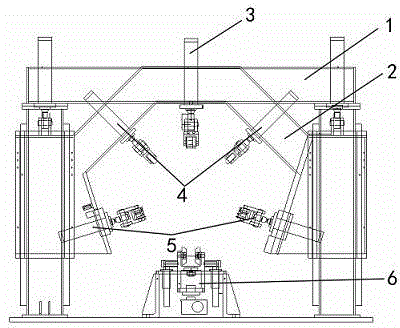

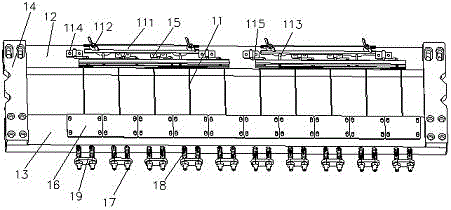

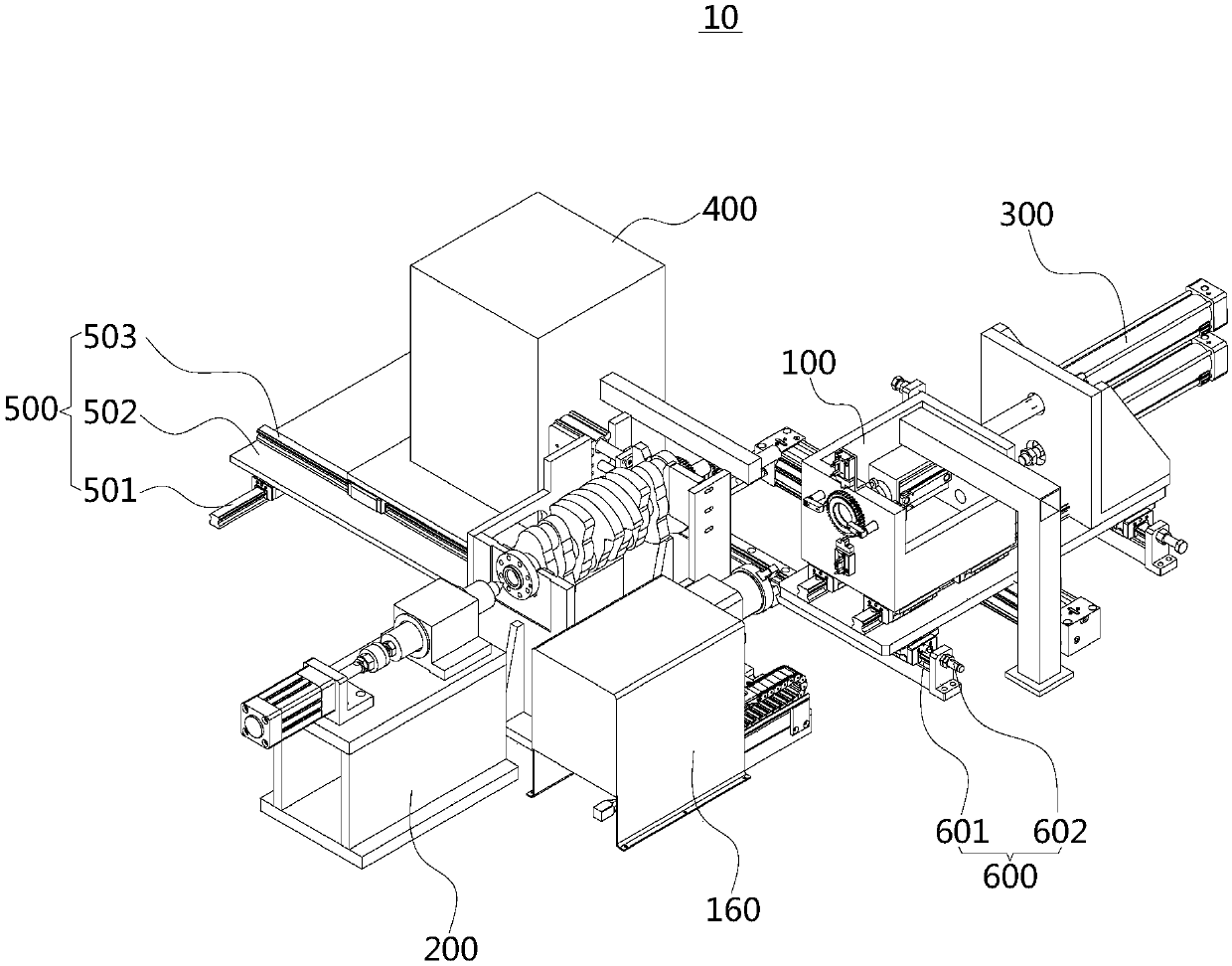

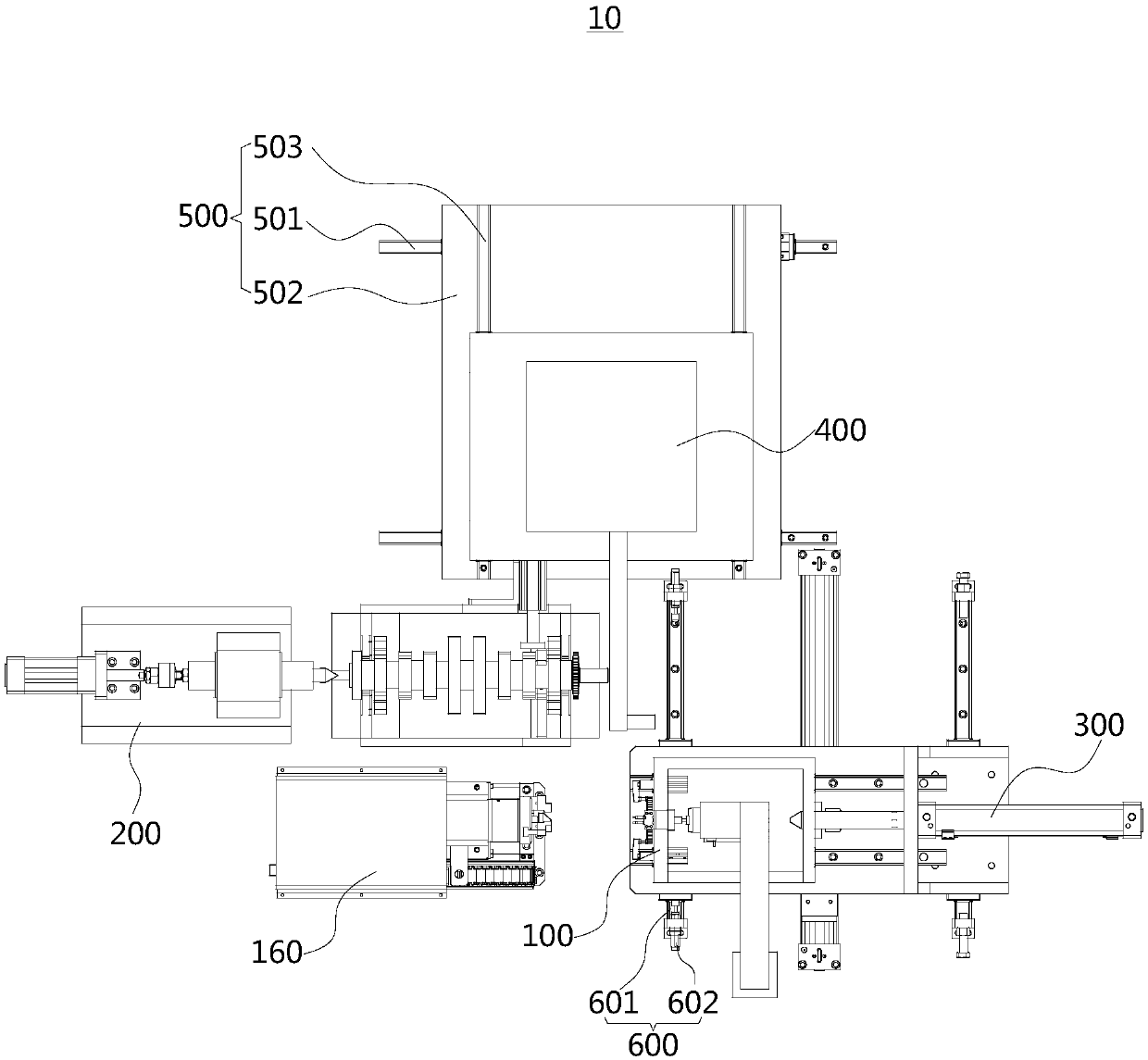

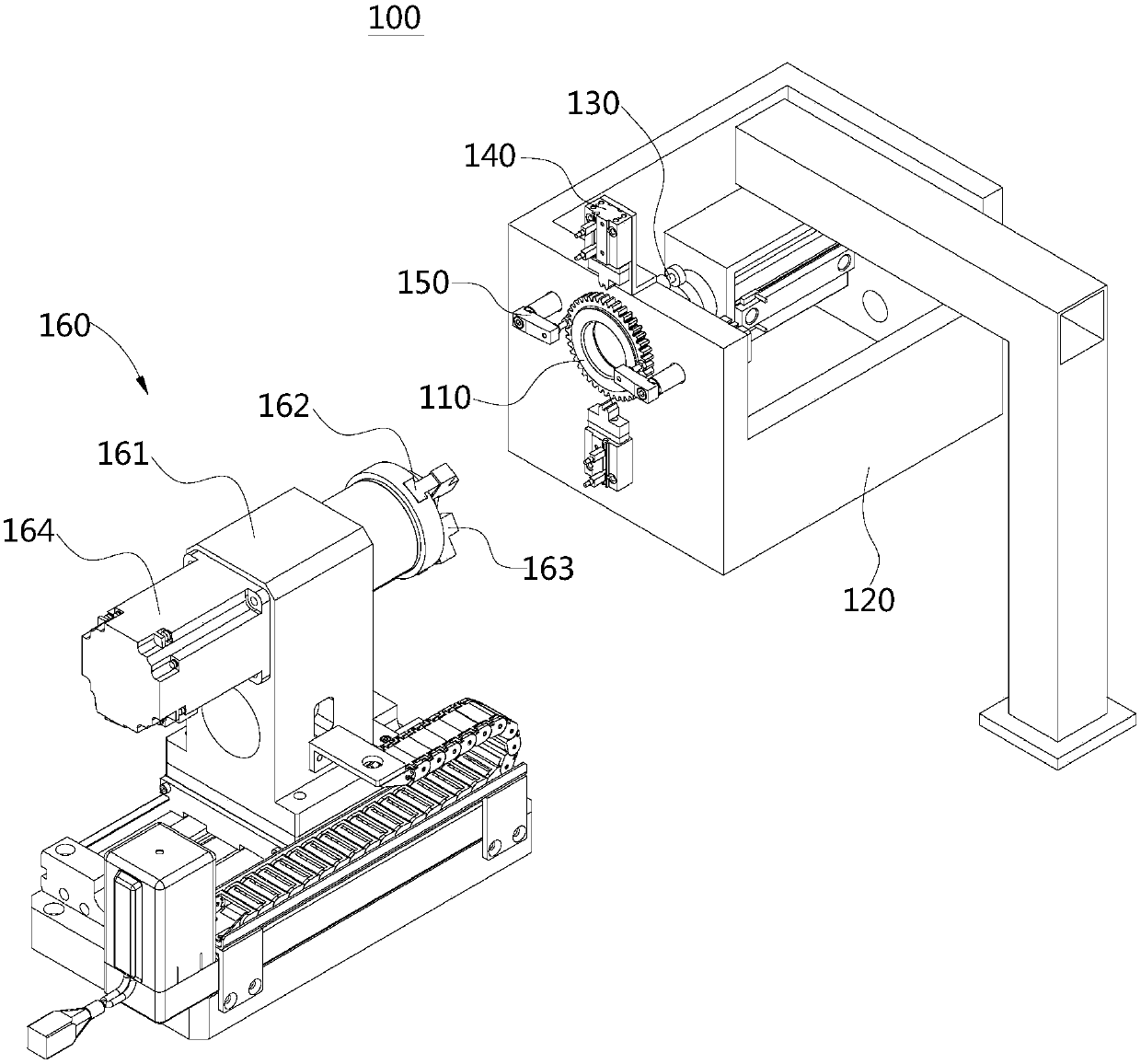

Pressing module for testing drawing force of keycap and test machine for drawing force of keycap

ActiveCN105258834AImprove the pressing effectStrong coordinationApparatus for force/torque/work measurementMechanical engineeringDetection rate

The invention discloses a pressing module for testing drawing force of a keycap and a test machine for the drawing force of the keycap. The pressing module comprises a pressing board, a pressing board cylinder, and a pressing board driver, which are connected in sequence from bottom to top, wherein the pressing board is used for pressing a keyboard; the pressing board cylinder is used for driving the pressing board to move up and down in a vertical direction; and the pressing board driver is used for driving the pressing board cylinder and the pressing board together to move in a Y-axial direction in a keyboard plane. The test machine for the drawing force of the keycap comprises: a keyboard placing device for placing and inputting a to-be-measured keyboard; a pressing module for testing drawing force of the keycap for pressing the keyboard, a drawing force measuring head module for measuring the drawing force of the pressed keycap in the keyboard; a telescoping module for hanging the measuring head module and performing interval adjustment; a substrate for fixing the telescoping module; and a driving device for driving the substrate to move along the X-axial, Y-axial, and Z-axial directions. The test machine is high in detection rate, low in misjudgement rate, good in versatility, and low in detection cost, and doesn't generate damage to a good keycap.

Owner:KUNSHAN HONGZHIXI AUTOMATION EQUIP

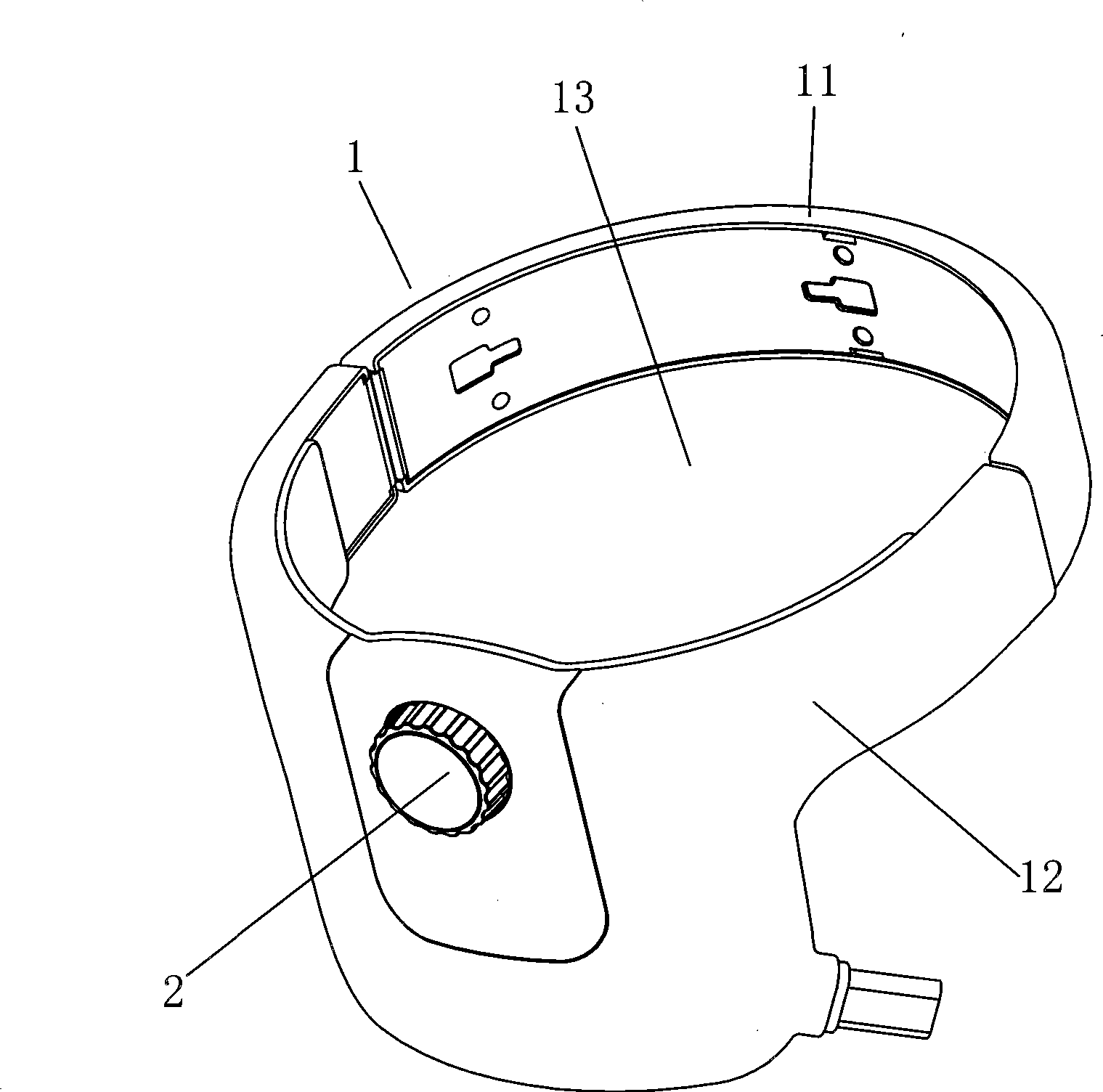

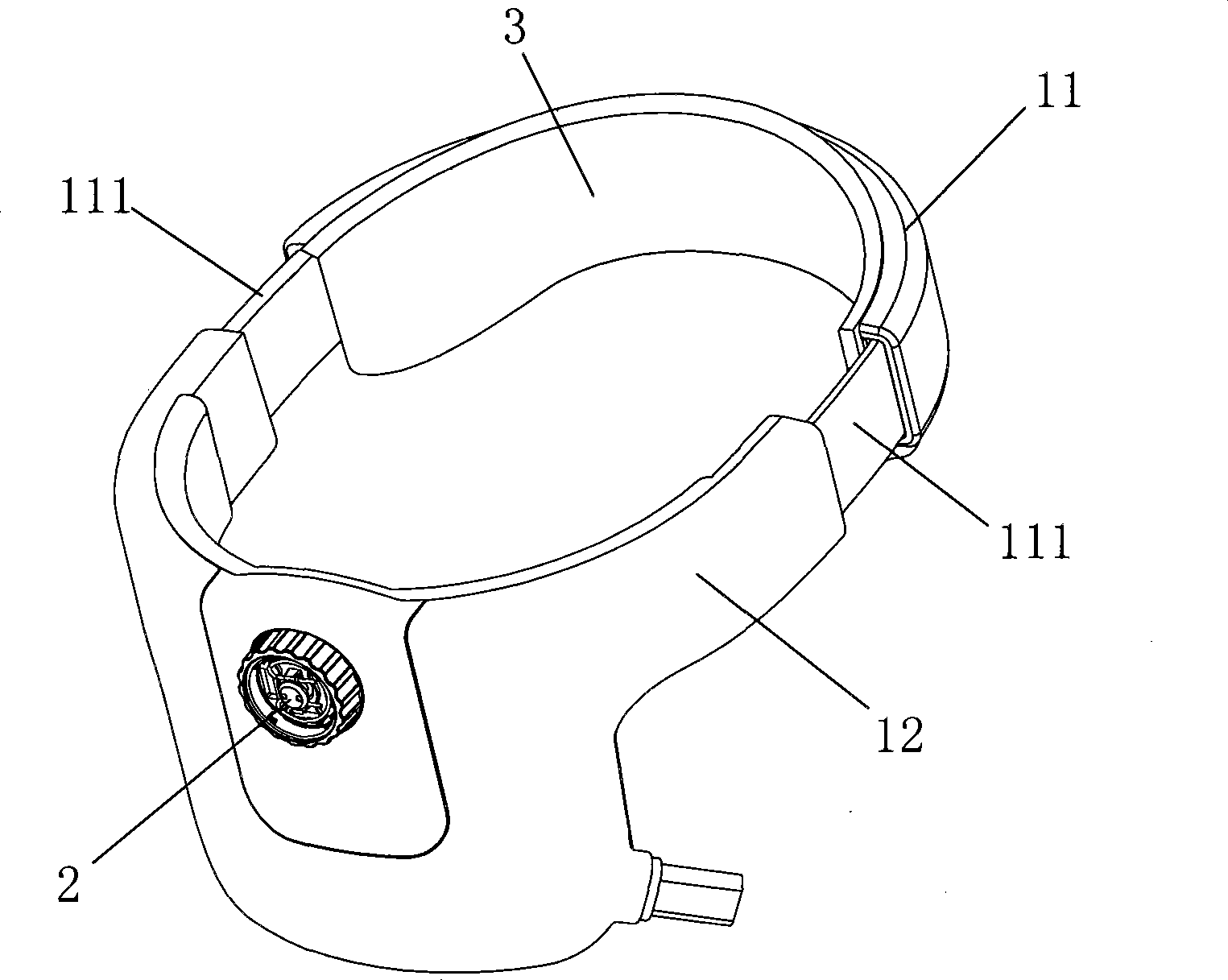

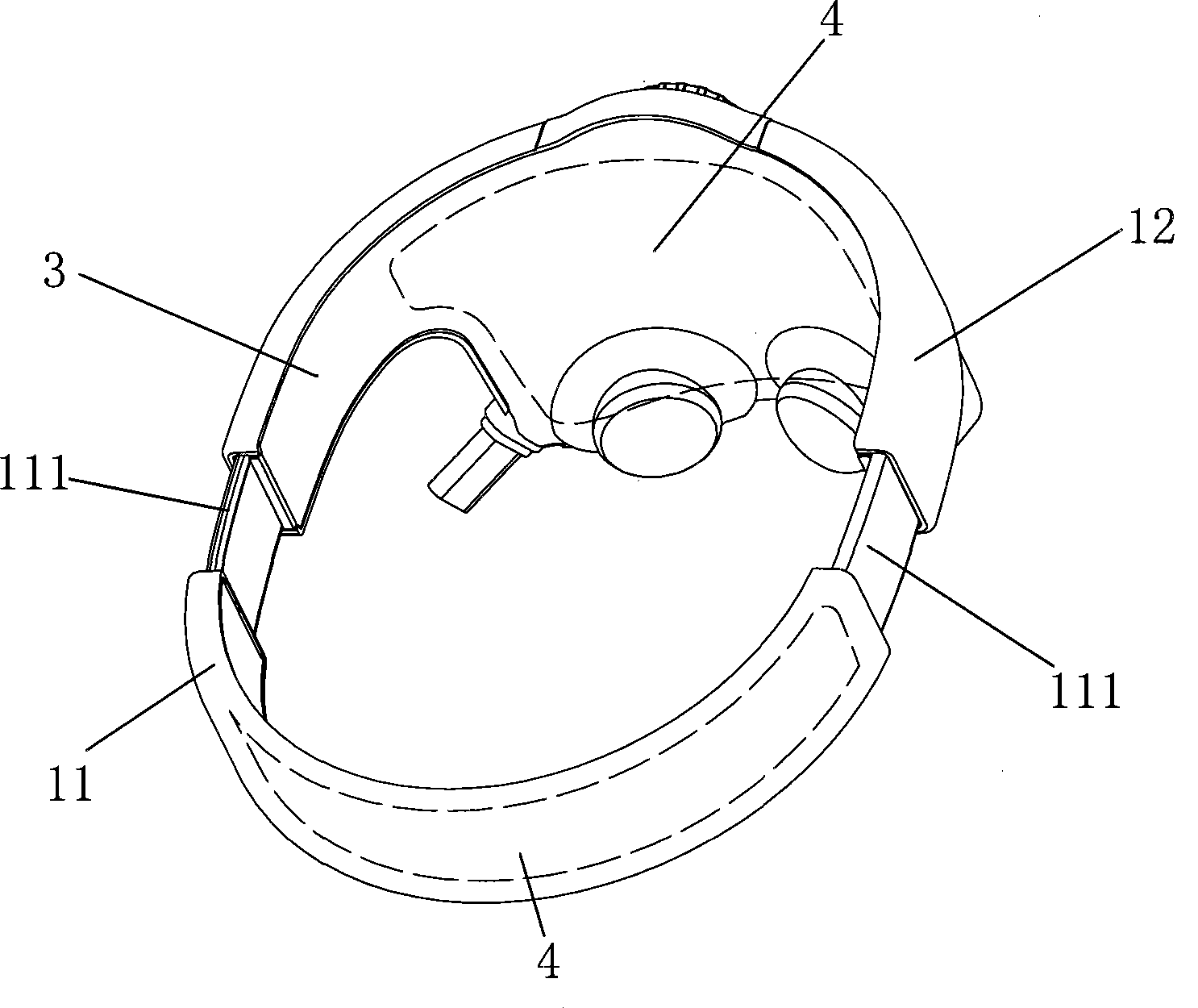

Head massager and helmet thereof

ActiveCN101390802AAchieve regulationEasy to adjustHelmetsSuction-kneading massageEngineeringHead circumference

Owner:SHENZHEN BREO TECH CO LTD

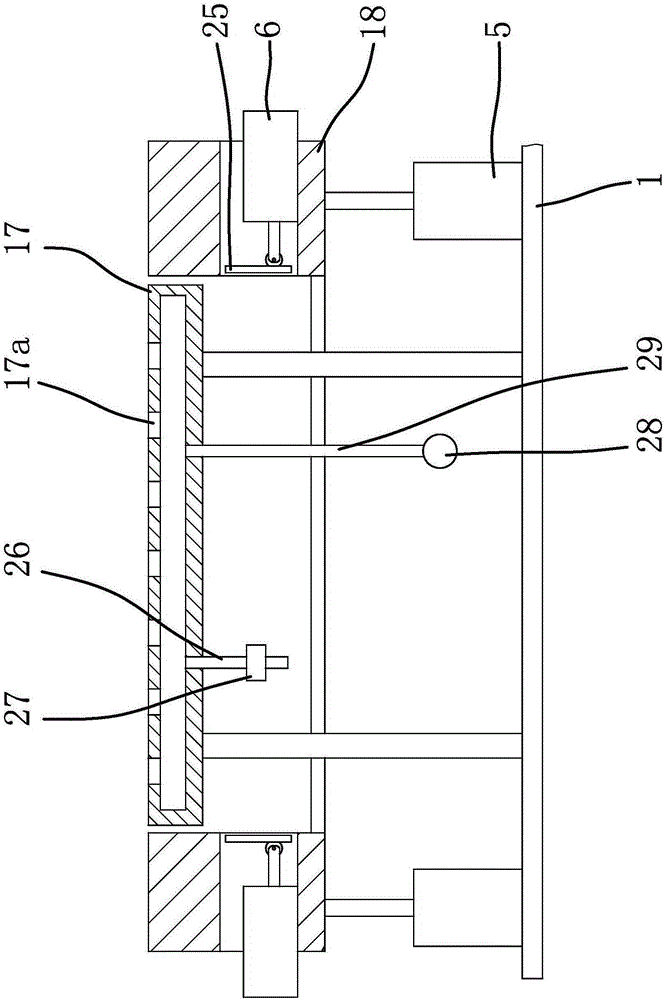

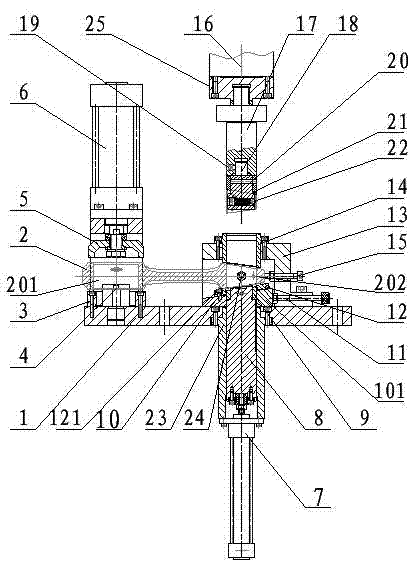

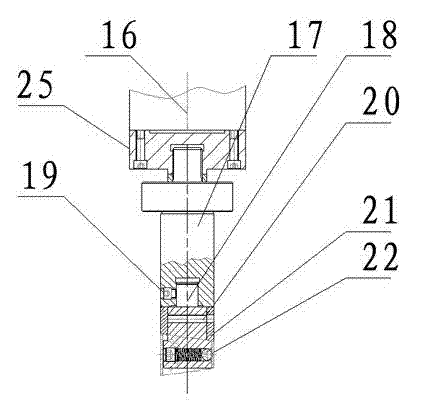

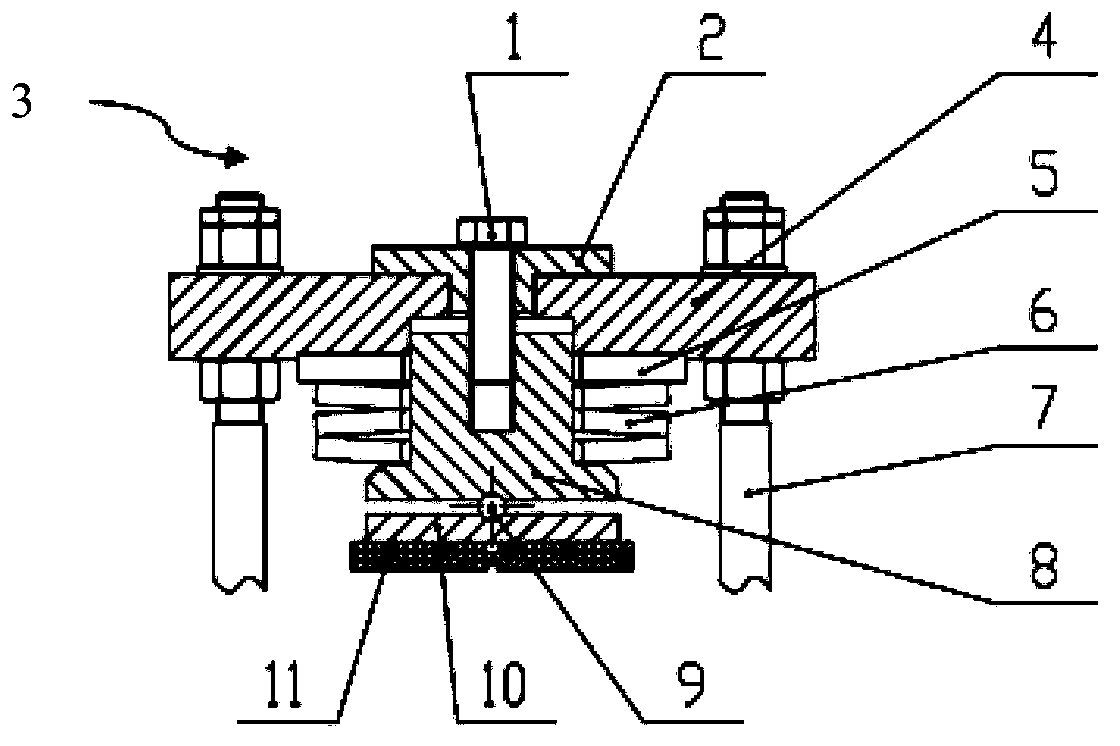

Wedged connecting rod bushing press fitting positioning mechanism

ActiveCN102729034AGuaranteed positioning accuracyImprove the pressing effectMetal working apparatusSet screwSurface phase

The invention relates to a wedged connecting rod bushing press fitting positioning mechanism, comprising a large-head positioning mechanism, a small-head positioning mechanism and a bushing press fitting positioning mechanism all arranged on the top of a worktable; the bushing press fitting positioning mechanism adopts a mandrel with a split structure for press fitting; a wedged bushing is mounted on the mandrel; a circumferential phase angle between the wedged inclined surface of a pressing sleeve and a positioning steel ball subjected to fine adjustment through a fastening screw; the wedge surface phase angle of the wedged bushing is adjusted through a hold-down screw; and the connecting rod bushing is press-fitted into a hole formed at the small head of the wedged connecting rod positioned by the large-head positioning mechanism and the small-head positioning mechanism. The wedged connecting rod bushing press fitting positioning mechanism is convenient for press fitting and accurate in positioning.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

All crank unloading device for press filter

The invention relates to an all crank unloading device for press filter. At present, there is no all crank unloading device for press filter with reasonable structural design and reliable performance. The device comprises plural all crank unloading mechanisms. The all crank unloading mechanism includes two lower-corner feeding filter plates, two outer crank arms, two inner crank arms, two long cloth supporting swing plates, two short cloth supporting swing plates, a long cloth supporting roll, a short cloth supporting roll, two crank arm connection shafts, two pieces of lower-corner feeding filter cloth, two filter cloth sinker rods, two balance blocks, a sinker rod locking unit, and a suspension vibrating mechanism. One outer crank arm and one inner crank arm on the same side of the lower-corner feeding filter plate are connected via one crank arm connection shaft, the two filter cloth sinker rods are connected at the lower parts of the two pieces of lower-corner feeding filter cloth in a penetrating manner, and adjacent two filter cloth sinker rods in adjacent two all crank unloading mechanisms are fixed through the sinker rod locking unit. The device provided by the invention has unloading assisting effects on both upper and lower half parts of a filter cake during crank unloading.

Owner:ZHEJIANG HUAZHANG TECH

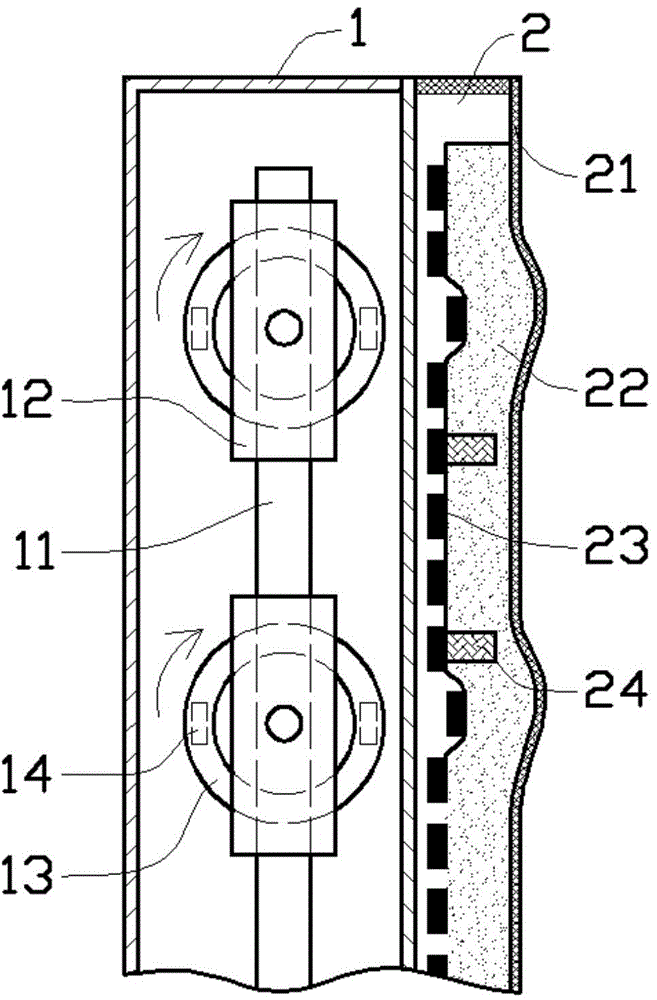

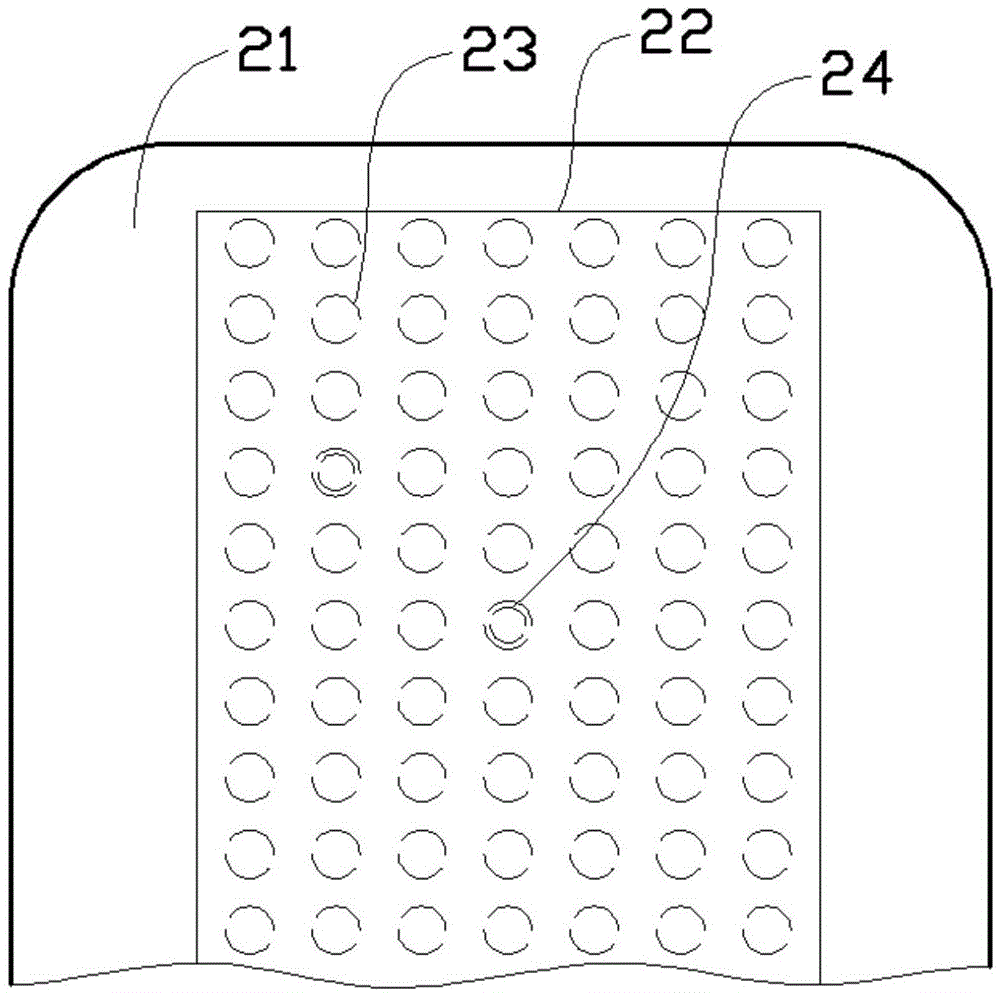

Massage backrest capable of pushing and pressing up and down

ActiveCN104586629AImprove the pressing effectExtended service lifeDevices for pressing relfex pointsRoller massageAcupunctureMagnetic poles

The invention provides a massage backrest capable of pushing and pressing up and down. The massage backrest comprises a movement box and a back cushion module, wherein the back cushion module is attached to the front surface of the movement box; back sin made of an elastic material is assembled on the front surface of the back cushion module; a massage back cushion is attached to the back surface of the back sin, and a front magnetic block of an array is attached to the inner side of the massage back cushion; vertical slide rails are symmetrically designed at the two sides of the movement box; slide blocks are assembled on the slide rails; a transverse roller is assembled between the two slide blocks; a rear magnetic block which is transversely placed in parallel and corresponding to the front magnetic block in front-rear direction is assembled on the transverse roller; opposite magnetic poles of the front magnetic block and the rear magnetic block are opposite. According to the massage backrest capable of pushing and pressing up and down, the back can be integrally pushed and pressed, different pressures can be applied to different massage acupuncture points, and quick point-pushing-pressing can be adopted.

Owner:哈尔滨昇悦生物科技有限公司

Flexible circuit board scrubbing device

InactiveCN108686986AImprove the pressing effectPrevent slidingCleaning using toolsCleaning using liquidsCost (economic)Engineering

Owner:YANCHENG SANDING ELECTRONICS TECH CO LTD

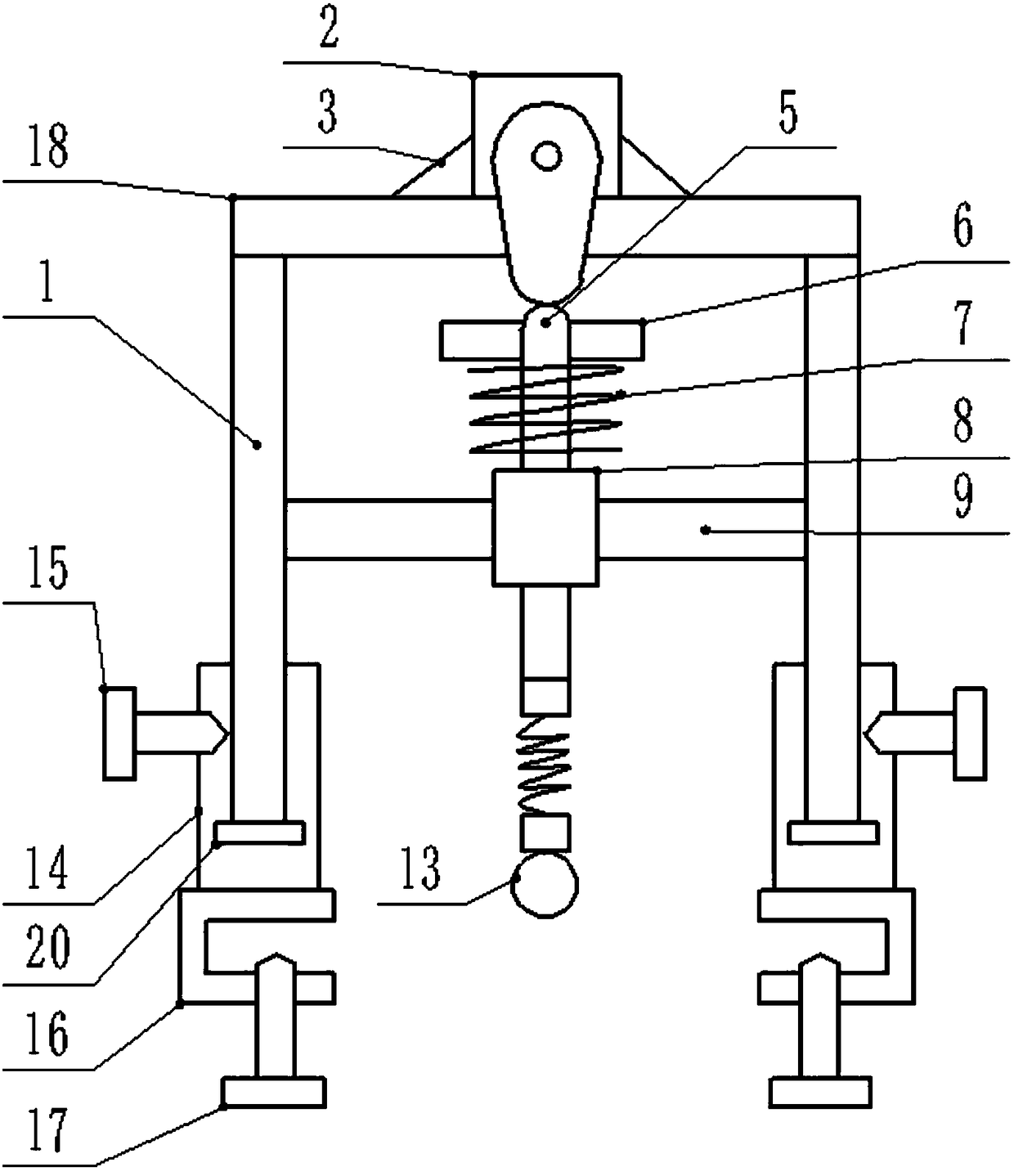

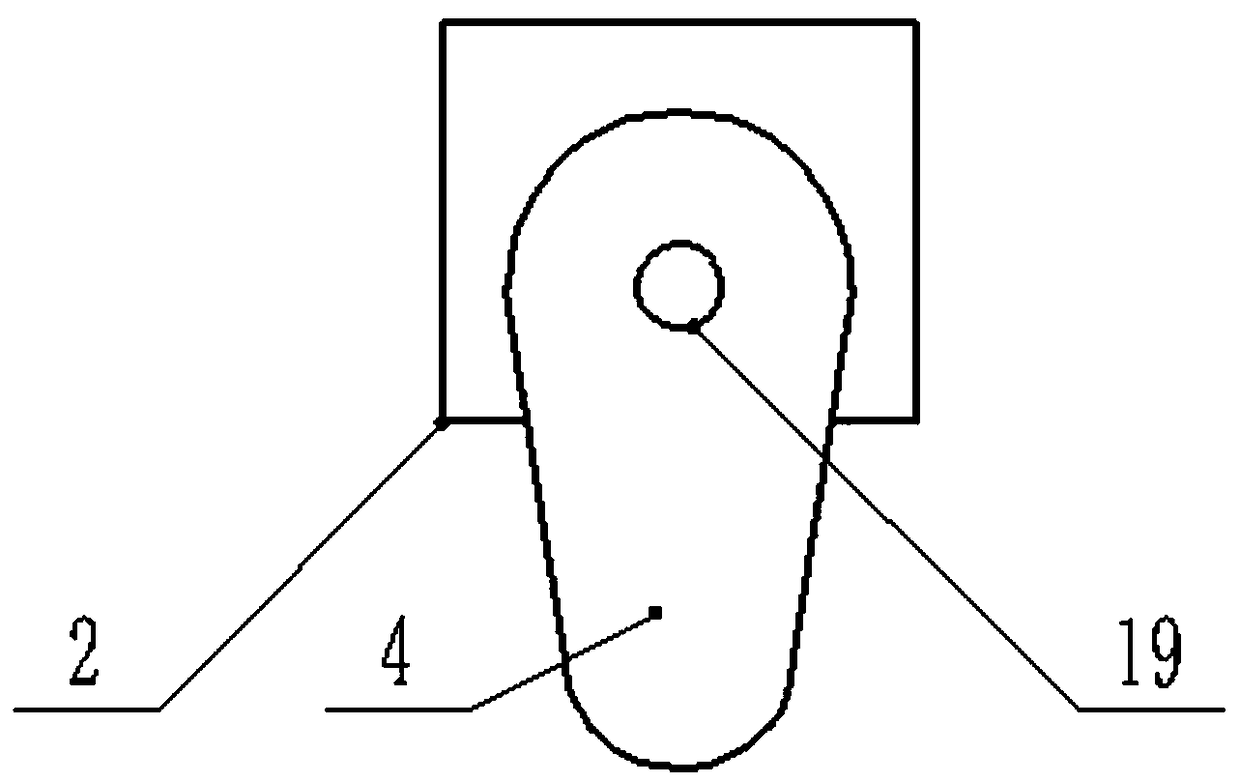

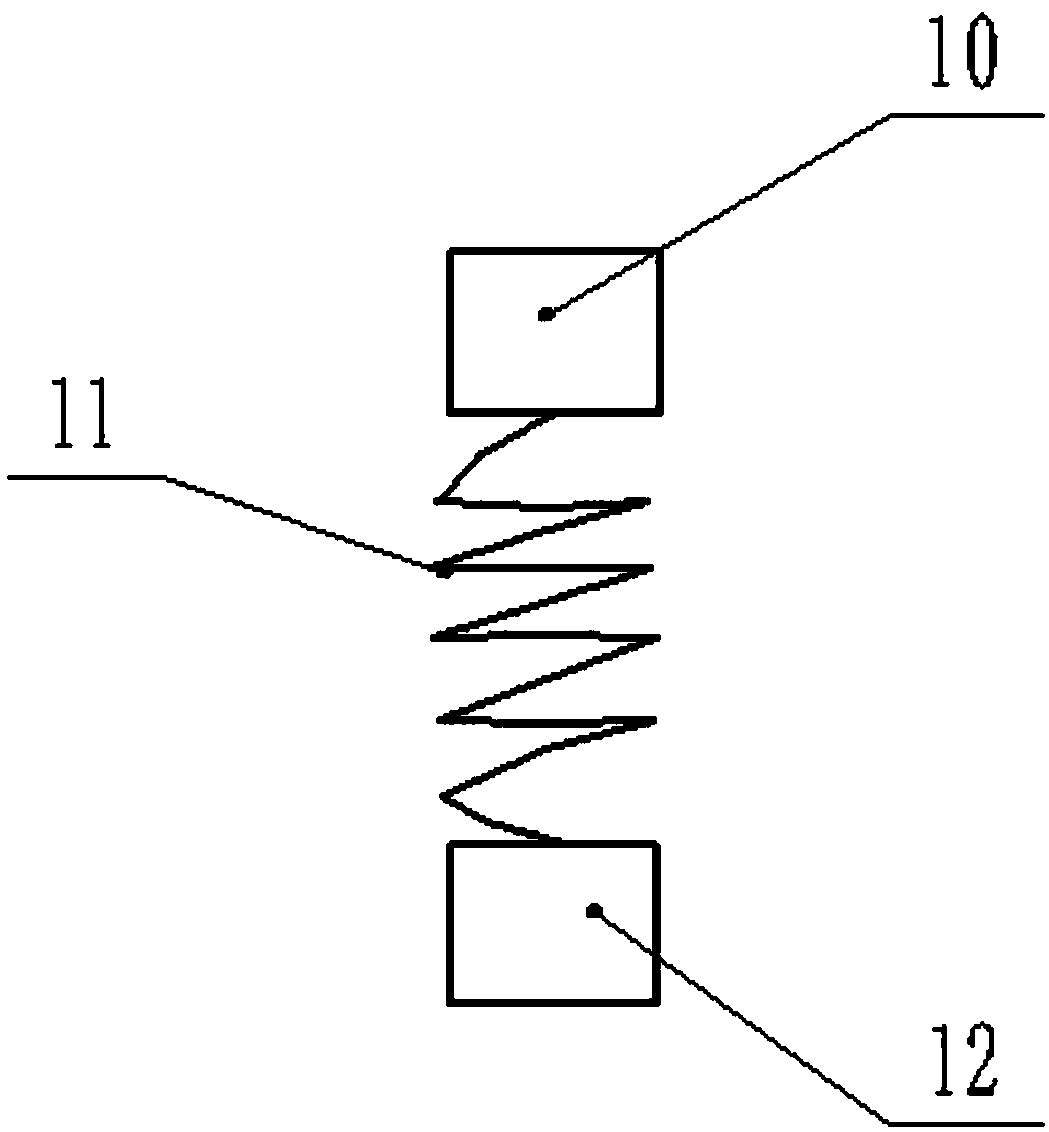

Cam-controlled back massage device

InactiveCN108158793AImprove the pressing effectSave manpower and material resourcesRoller massageSuction-kneading massageMassageMaterial resources

The invention discloses a cam-controlled back massage device. The device comprises clamping plates, the number of the clamping plate being two. The middle part of the lower part of the clamping plateis connected with a second thread fixing pin by threads. The middle part of the upper surface of the clamping plate is connected with a telescopic frame. A first thread fixing pin is connected with the upper part of the left side of the telescopic frame by threads. A support is connected in the middle part of the telescopic frame in a contact manner. The lower end of the support is connected witha limiting block. The upper end of the support is connected with a fixing plate. The middle part of the upper part of the fixing plate is connected with a motor. The left side and the right side of the motor are connected with motor supports. The middle part of the right front part of the motor is connected with a shaft rod. The motor is connected with a cam through the shaft rod. A push rod is connected with the lower part of the peripheral surface of the cam in a contact manner. The lower end of the push rod is connected with an upper connecting block. The lower end of the upper connecting block is connected with a second spring. The lower end of the second spring is connected with a lower connecting block. The device saves manpower and material resources, and solves a problem that manual work can hardly master pressing strength on a back, so pressing effect on a human back is more obvious, and pressing efficiency is high.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

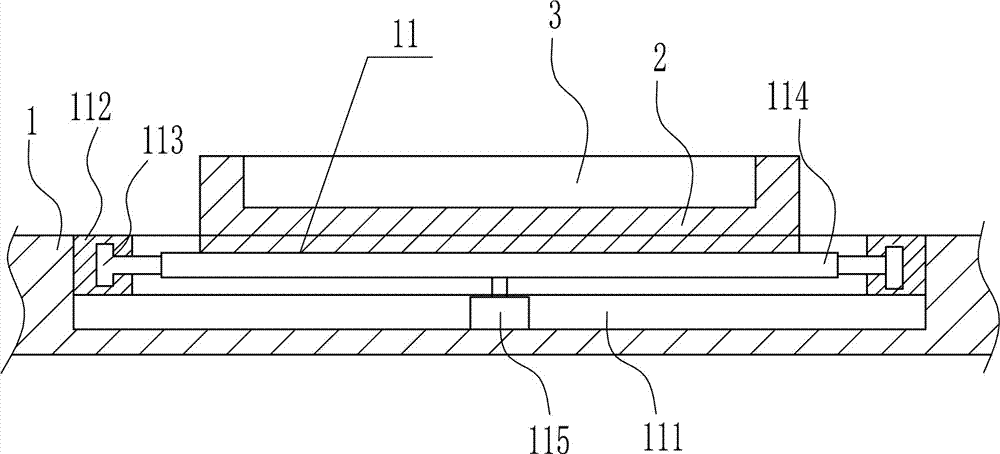

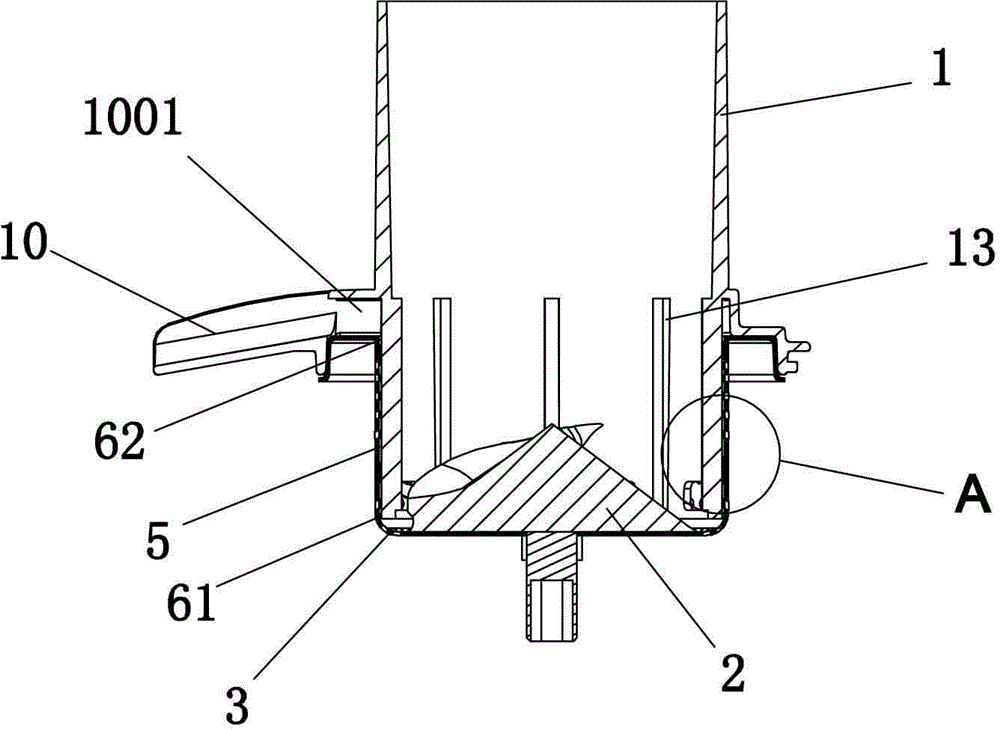

Sole press-fit equipment for shoemaking

InactiveCN106923446AImprove the pressing effectSpeed up pressingShoe gluingArchitectural engineeringTransverse plane

The invention relates to press-fit equipment, particularly to sole press-fit equipment for shoemaking. The technical problem to be solved by the invention is to provide sole press-fit equipment for shoemaking, which is time-saving, labor-saving and good in press-fit effect, does not influence the service lives of soles, and is simple and convenient to operate and small in size. In order to solve the above technical problem, the invention provides such sole press-fit equipment for shoemaking, comprising a base, a fixed block, a support plate, a transverse plate, a heavy block and a fixed plate; the fixed block is mounted at the right side of the top of the base in a bolt connection manner, a placing groove is formed in the middle of the top of the fixed block, the support plate is mounted at the left side of the top of the base in a bolt connection manner, and the transverse plate is mounted on the upper part of the right lateral surface of the support plate in a bolt connection manner. Air is ejected via an air outlet pipe to dry glue on a sole, so that the press-fit effect of the heavy block on the sole is better, and press-fit on the sole is accelerated at the same time.

Owner:邱艳

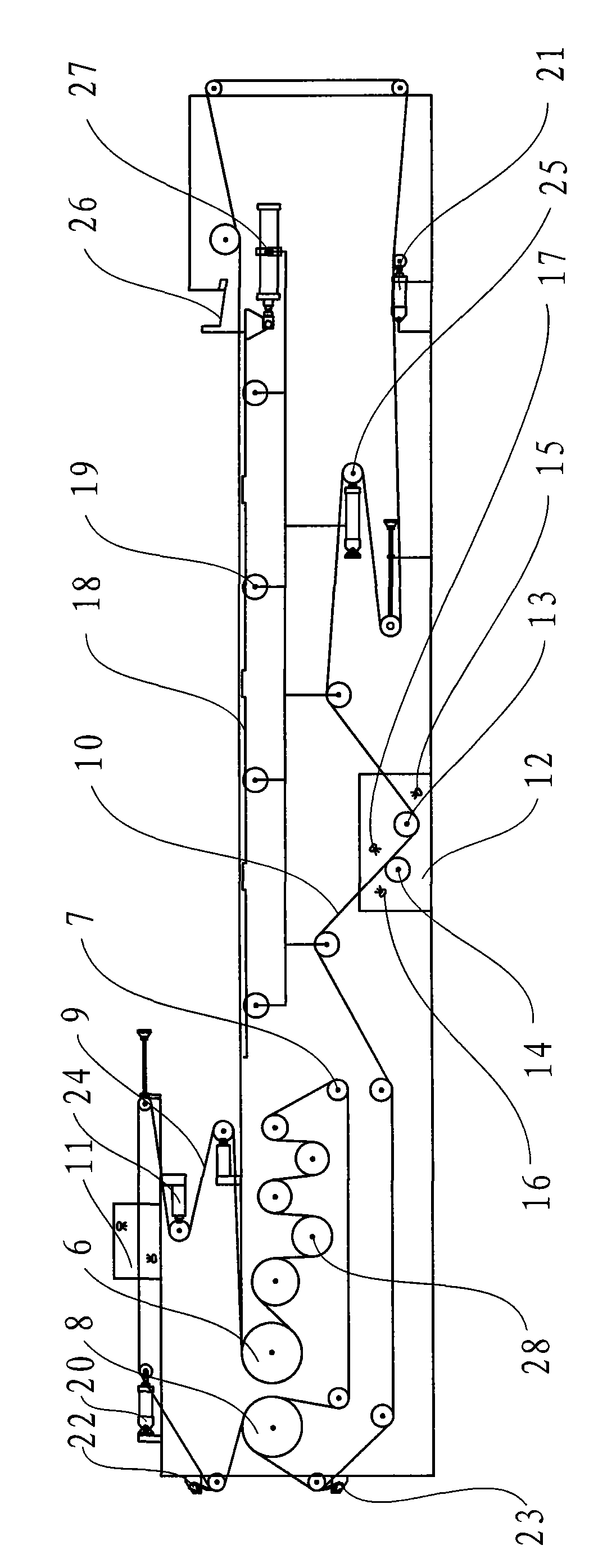

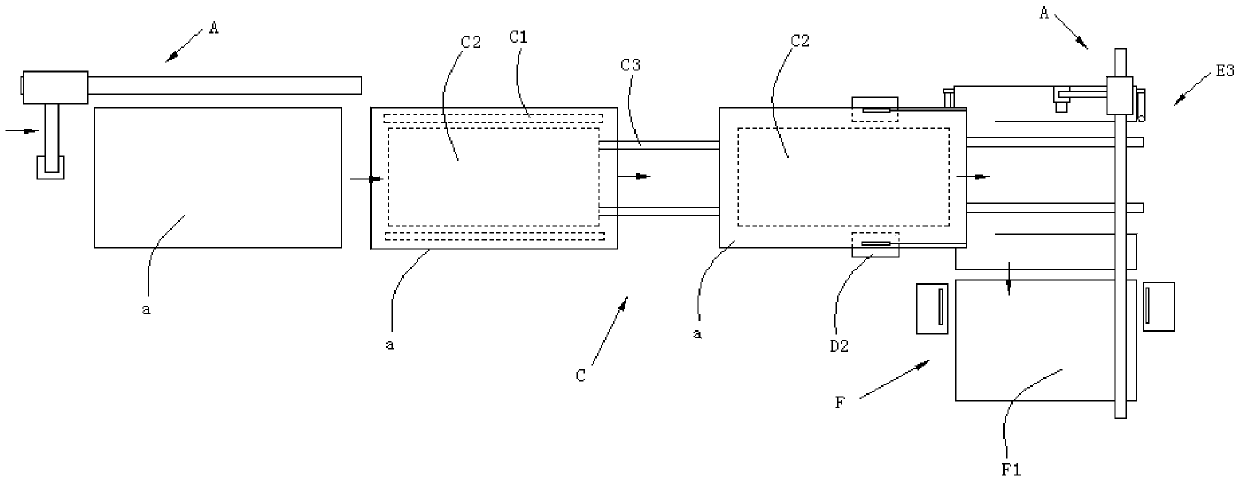

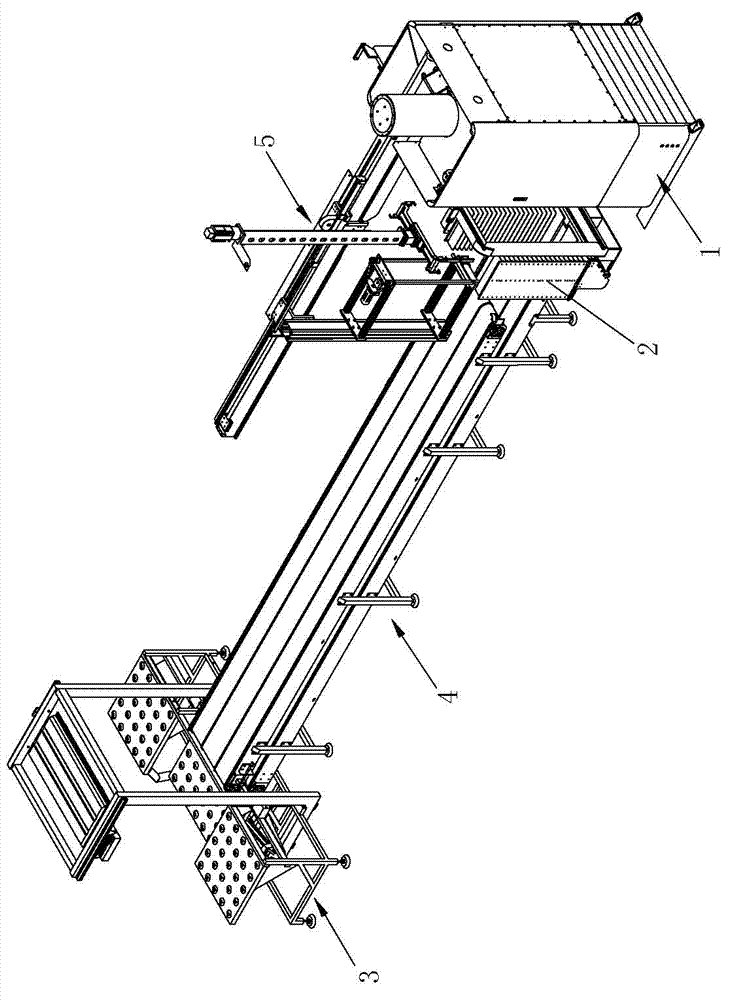

Full-automatic trimming machine

The invention provides a full-automatic trimming machine which comprises a feeding device, a long edge trimming device, a steering device and a short edge trimming device, wherein panels sequentially pass through the feeding device, the long edge trimming device, the steering device and the short edge trimming device; the long edge trimming device and the short edge trimming device are respectively positioned on the two adjacent sides of the steering device; and the horizontal-direction included angle of the long edge trimming device and the short edge trimming device is 90 degrees. Compared with the prior art, the trimming machine provided by the invention has the advantages that the structure is simple, the panel feeding is smooth, all the steps closely cooperate with each other, before the next step is carried out, the next work task is prepared in the precious step, the connection is close, and the working efficiency is high.

Owner:ANHUI ANSU WORLD HOME CO LTD

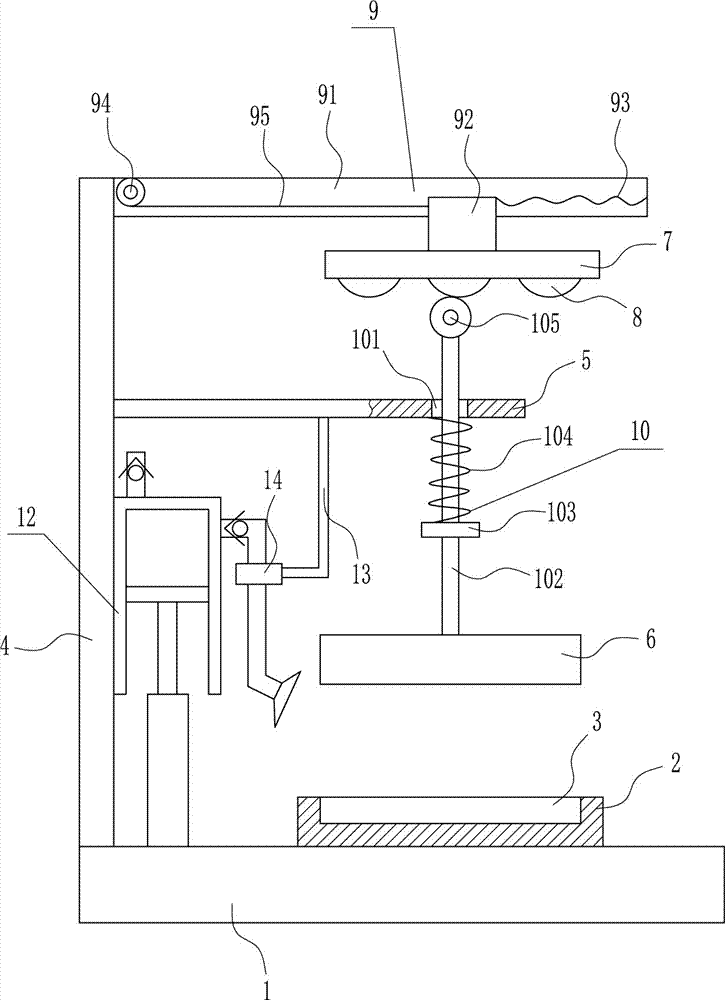

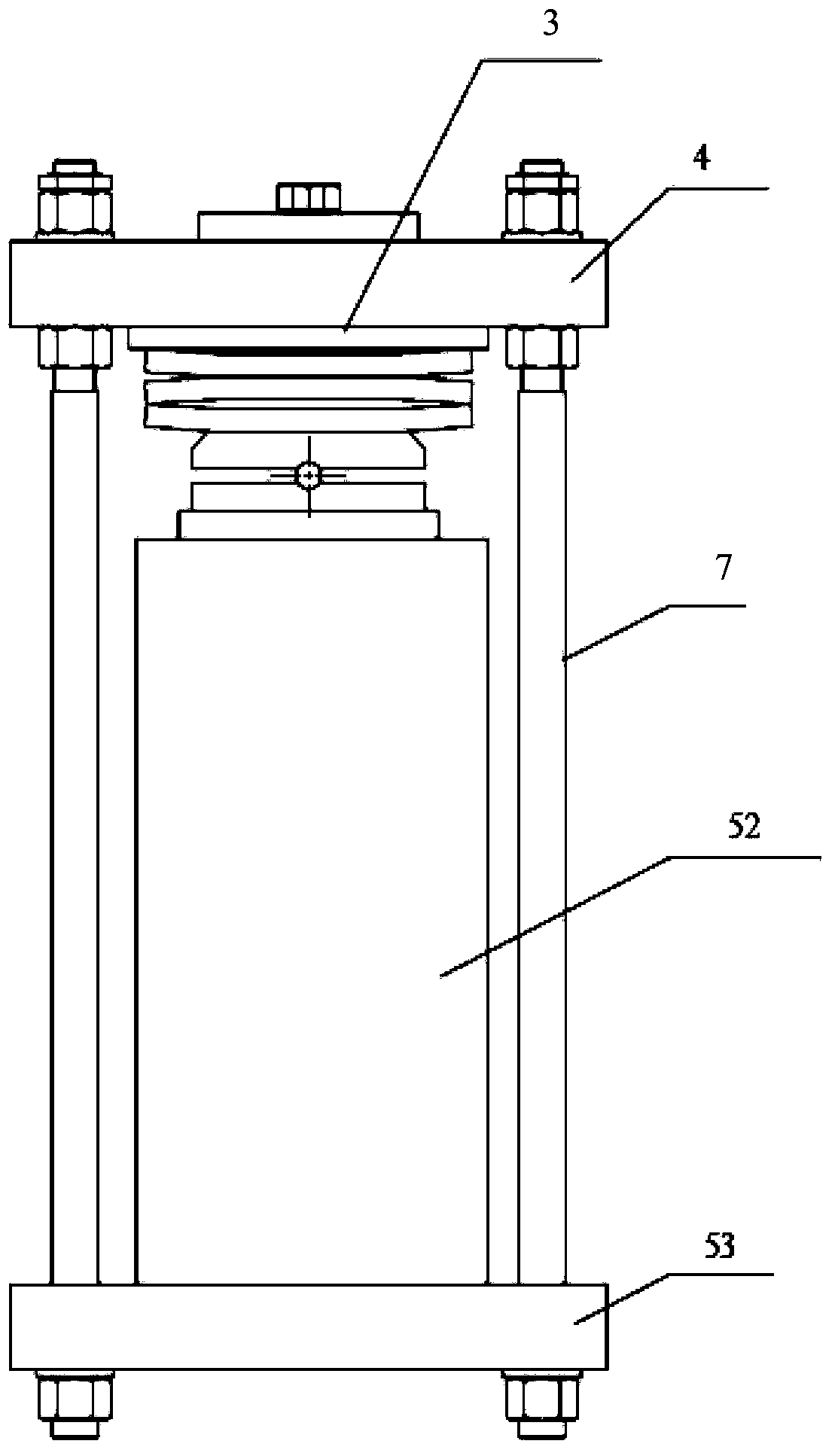

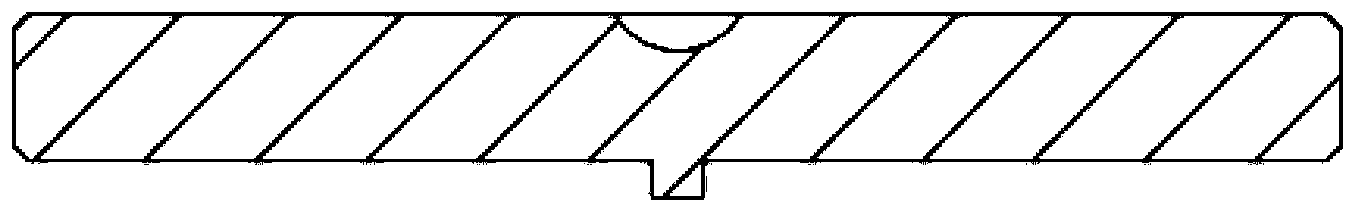

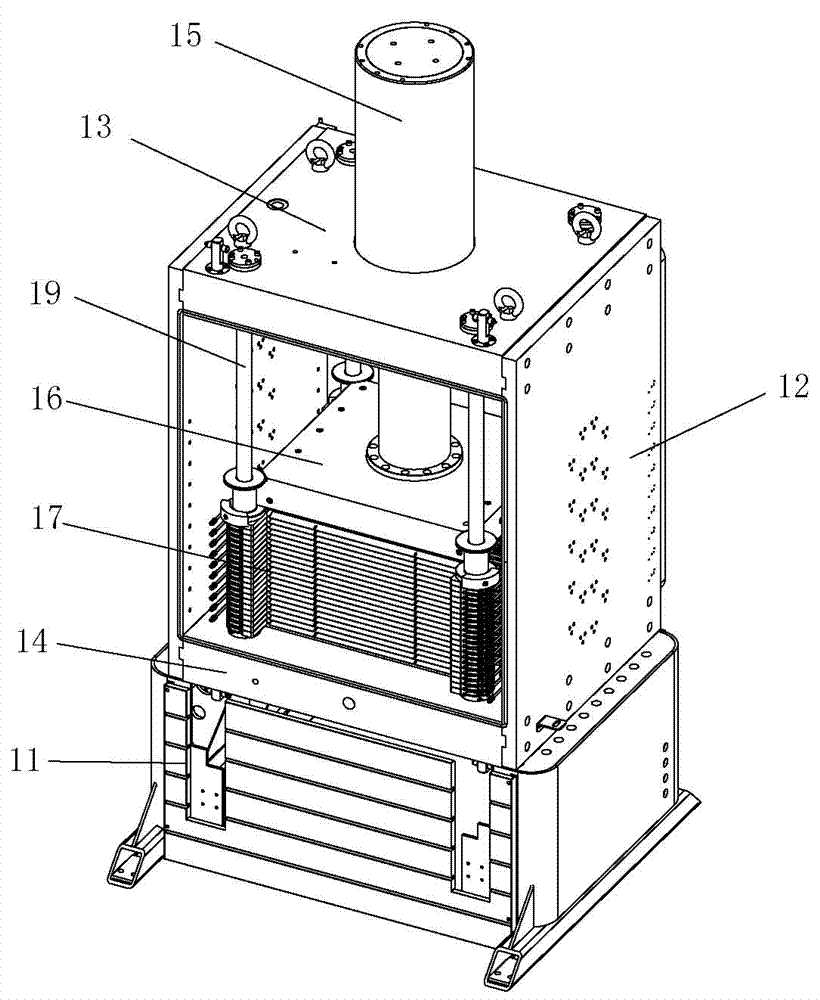

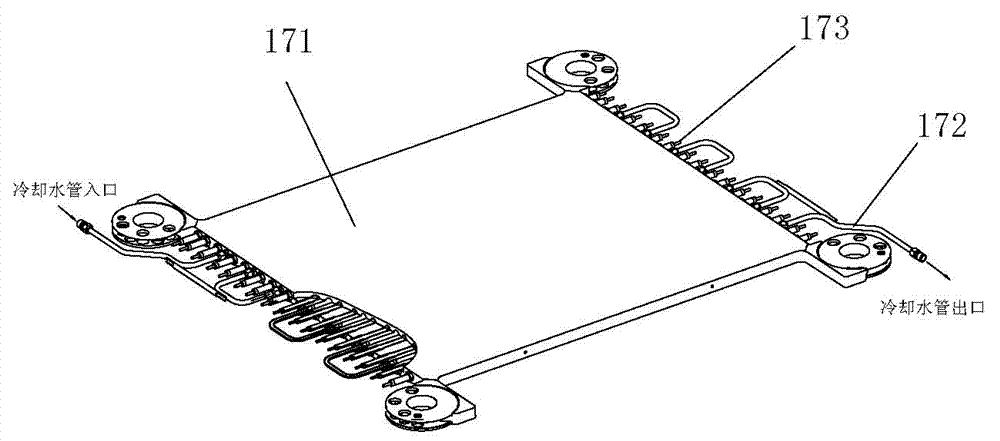

Device and method for press-fitting flat plate type semiconductor element on press-fitting equipment

ActiveCN103367276AIncrease the force areaPrecisely control the size of the pressing forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlange

The invention provides a device for press-fitting a flat plate type semiconductor element on press-fitting equipment. The device comprises a pressing plate, a pressing mechanism which is arranged on the pressing plate and comprises a central column body provided with an end flange, and an elastic element which is arranged between the end flange and the pressing plate, wherein the central column body can move along the direction vertical to the pressing plate by means of an adjusting element so that the elastic element remains under a preset pretightening force; the device is connected with the press-fitting equipment through the pressing plate so that the surface of the pressing mechanism is contacted with the surface of the flat plate type semiconductor element to be press-fitted; and the pretightening force of the elastic element is transferred onto the flat plate type semiconductor element through the pressing mechanism by releasing the adjusting element. The invention also provides a corresponding method. According to the method and the device disclosed by the invention, the accuracy of press-fitting force is ensured; and when the semiconductor element works normally, the influence on the press-fitting force caused by strong external vibration is prevented.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

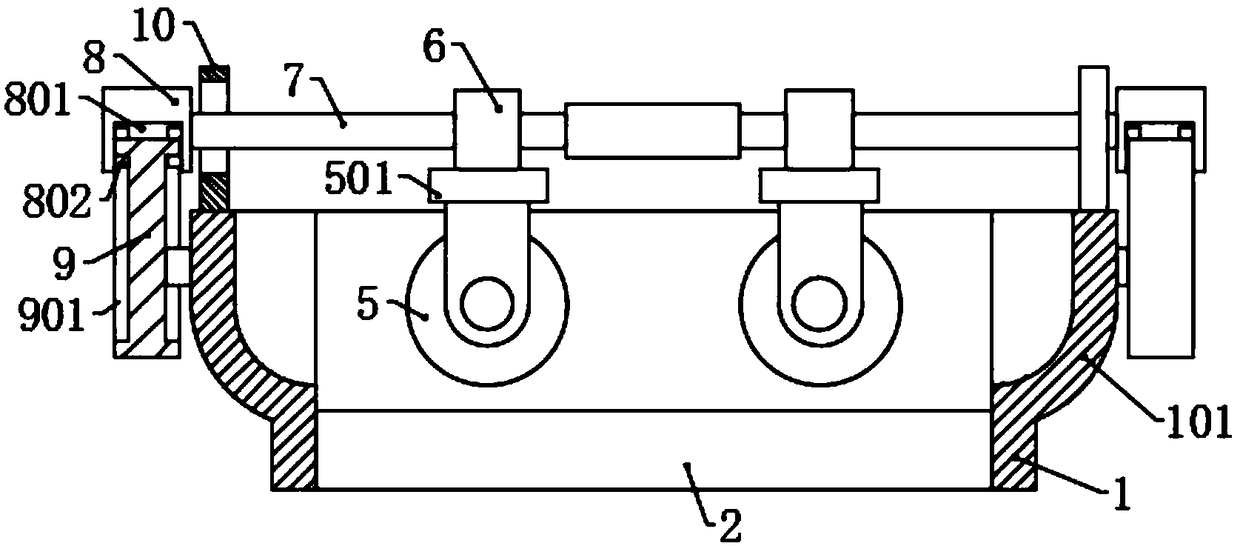

Circuit board laminating machine

InactiveCN102729572AEasy to operateReduce labor intensityLaminationLamination apparatusForms ControlEngineering

The present invention relates to the technical field of circuit board manufacturing equipment, and particularly to a circuit board laminating machine. The laminating machine comprises a control system, a laminating device, a lifting device for carrying out lifting operation on the circuit board after preparing the material, a conveying device having a double layer conveying structure, and a suspension arm type feeding and unloading device. The plate inlet of the laminating device is slidably connected with a material bracket. The lifting device, the conveying device and the laminating device are sequentially arranged. The suspension arm type feeding and unloading device is fixedly arranged on the top of the laminating device. The control system respectively forms control connections with the suspension arm type feeding and unloading device and the laminating device. The circuit board laminating machine of the present invention has the following advantages that: automation degree is high, control is reliable, a plate laminating effect is good, labor intensity can be reduced, and production efficiency can be improved.

Owner:特新电路材料(东莞)有限公司

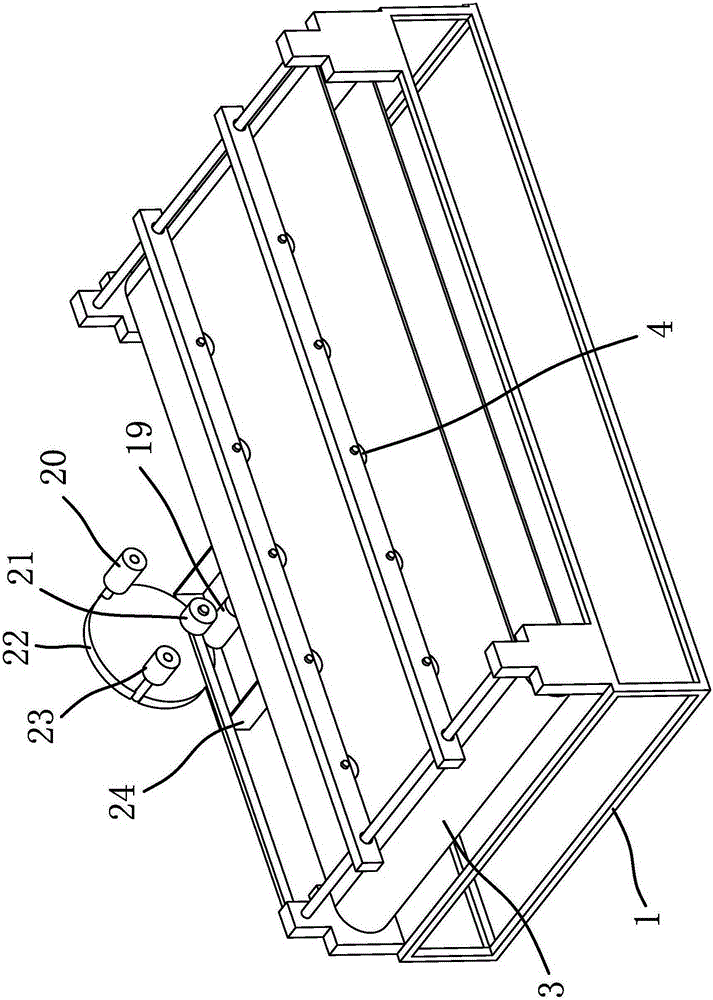

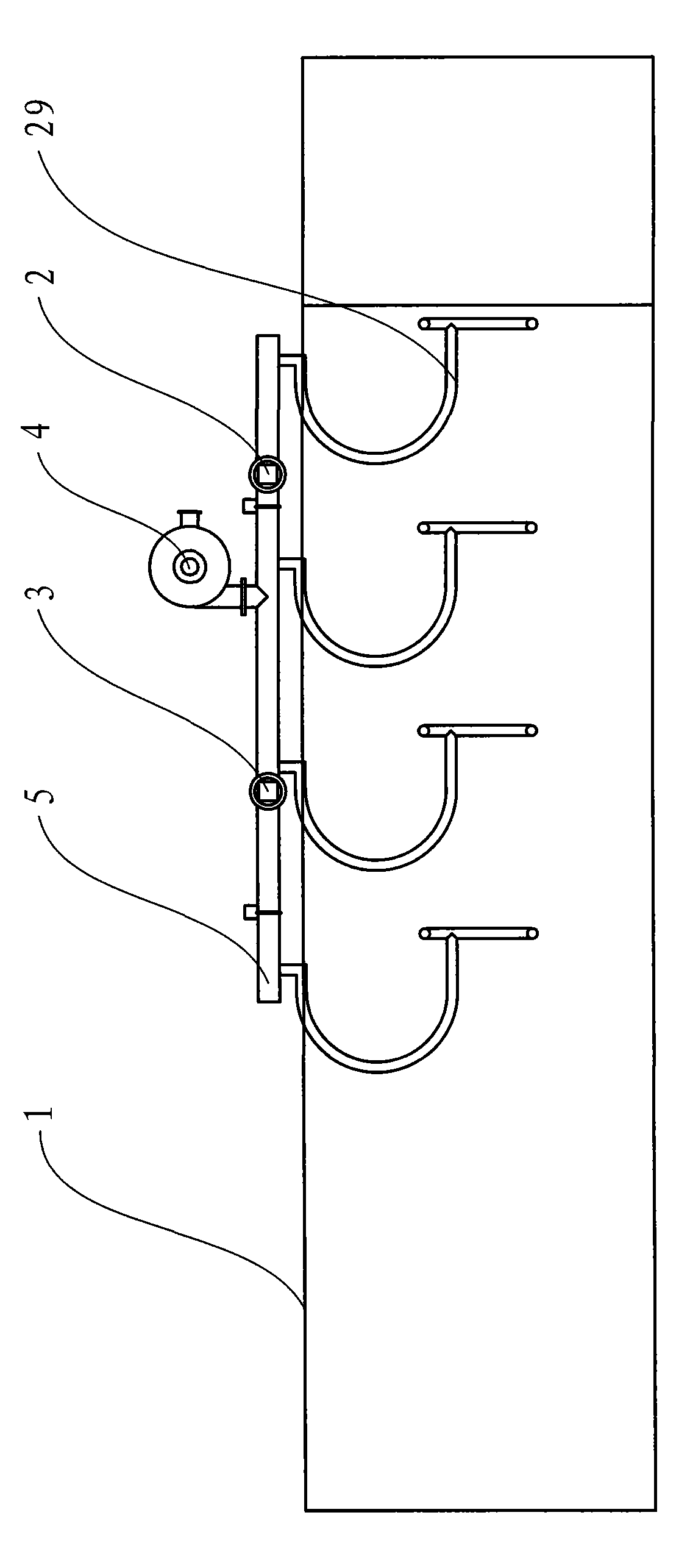

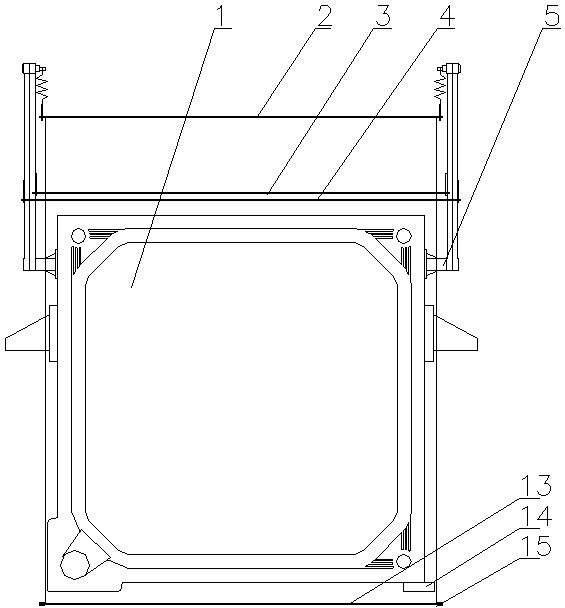

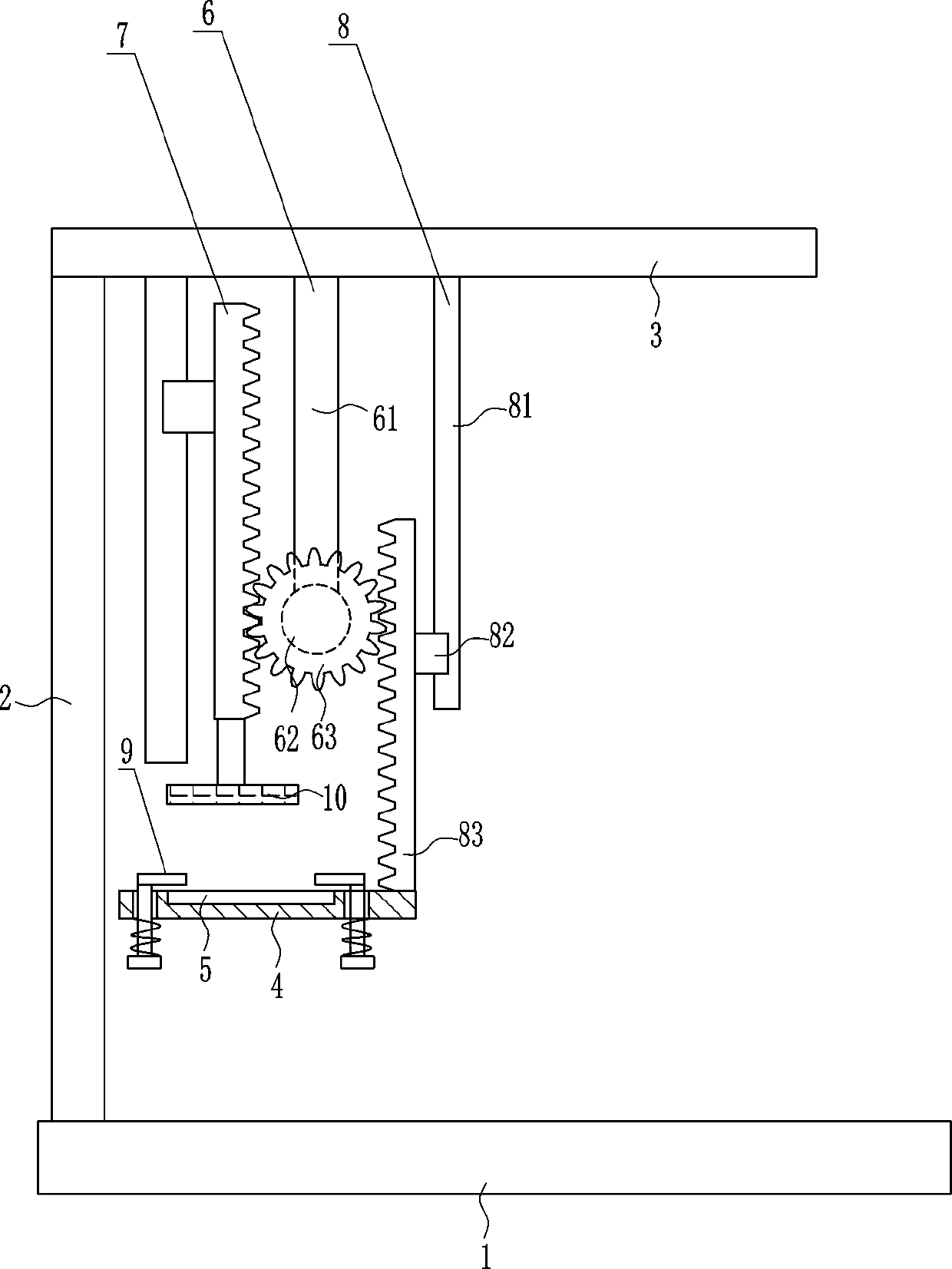

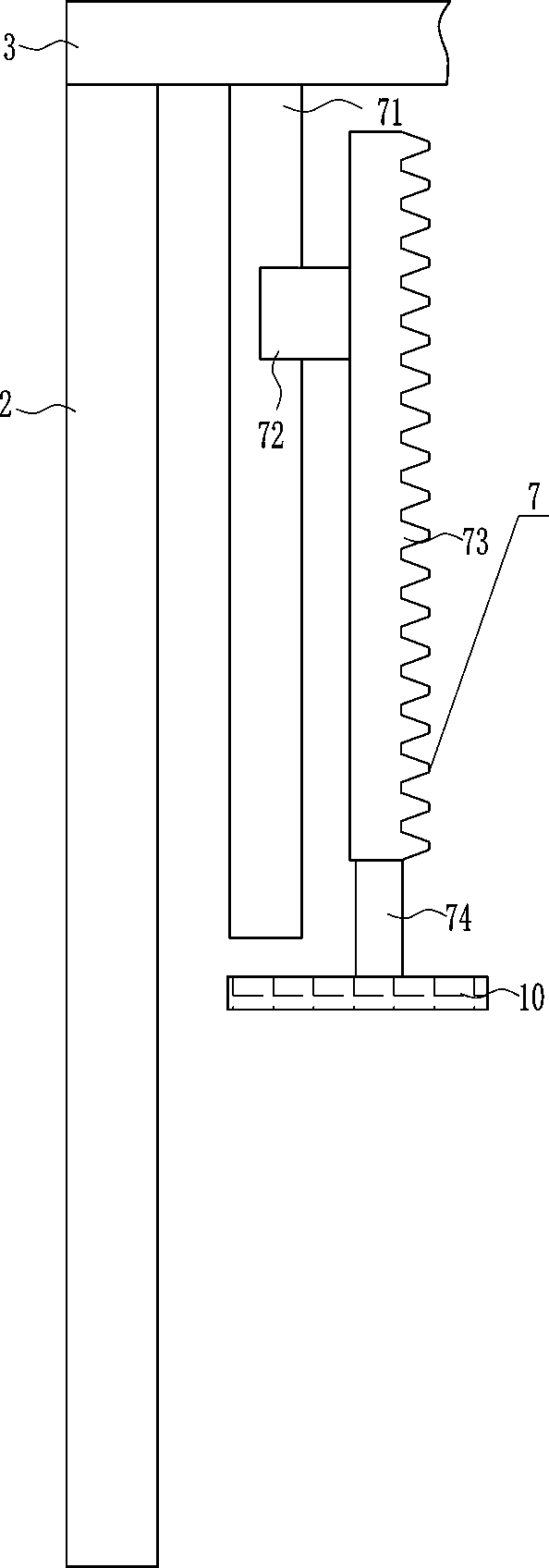

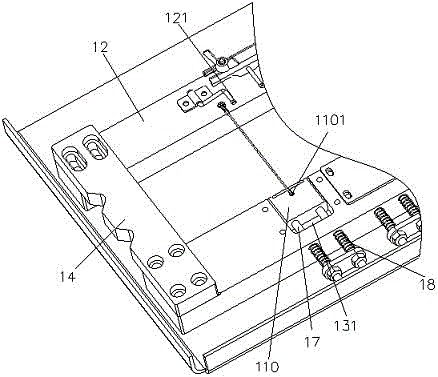

Prepressing device of plywood

ActiveCN108247773AImprove the pressing effectAvoid problems caused by large area laminationPlywood pressesVeneer pressesEngineeringCam

The invention discloses a prepressing device of plywood, and belongs to the technical field of plywood processing. The prepressing device comprises a fixing frame, a conveying roller, a first pressingroller, a second pressing roller and a side pressing roller. Through a rotating cam, a moving base and a screw are vertically moved, thus height of the side pressing roller is regularly changed; whenthe side pressing roller is upwards moved, the conveying roller is rotated so that a laminate to be pressed is moved; the first pressing roller can primarily press the middle part of the laminate; when the side pressing roller is located at the innermost side of the screw, the bottom end is just contacted with the laminate, the conveying roller stops movement, and the side pressing roller is moved from inside to outside to press the side of the laminate, thus the laminate is completely pressed, the pressing effect is good; after being pressed by the first pressing roller and the side press roller, the laminate is secondly pressed by the second press roller, thus the pressing effect is further improved; by adopting a division pressing method, every part can be uniformly pressed, thereby effectively avoiding the problem caused by large area pressing; the prepressing device is simple in structure and low in production cost.

Owner:和县薛氏木制品制造有限公司

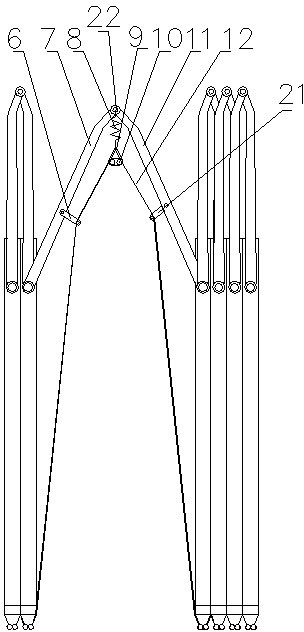

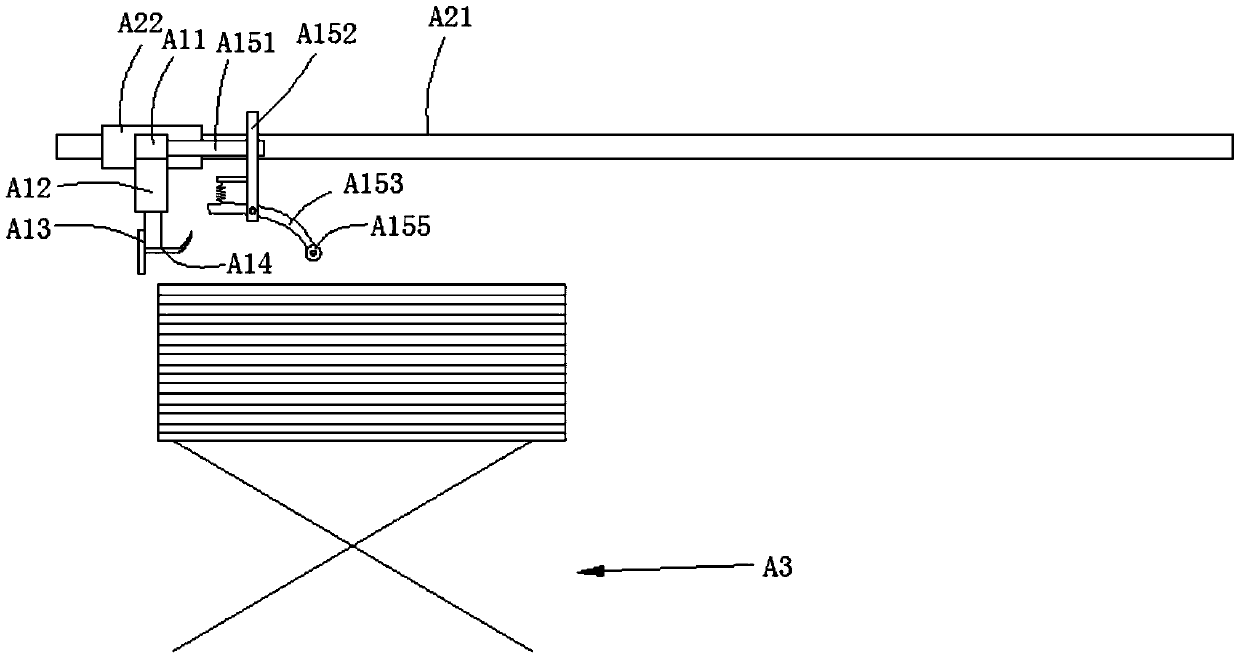

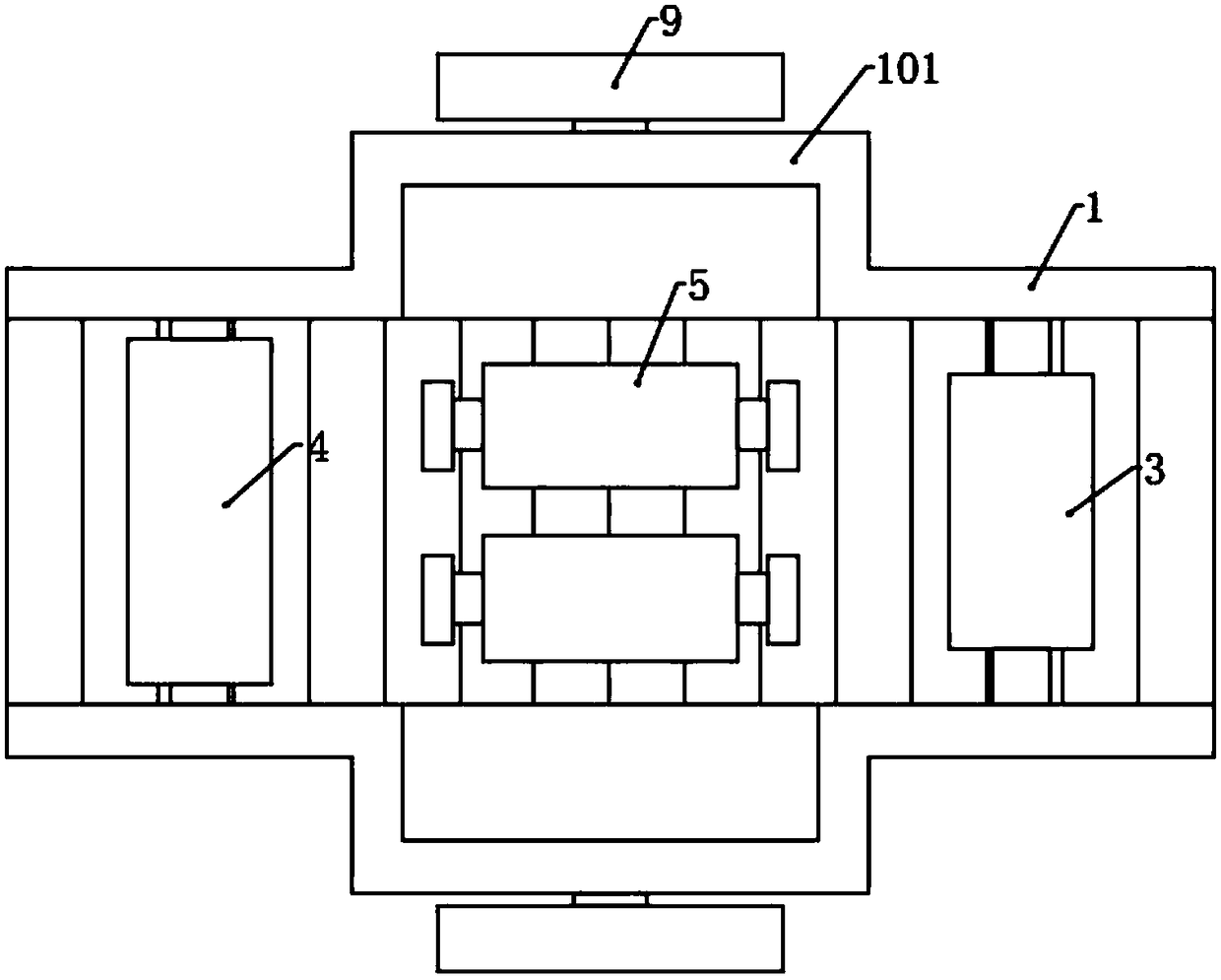

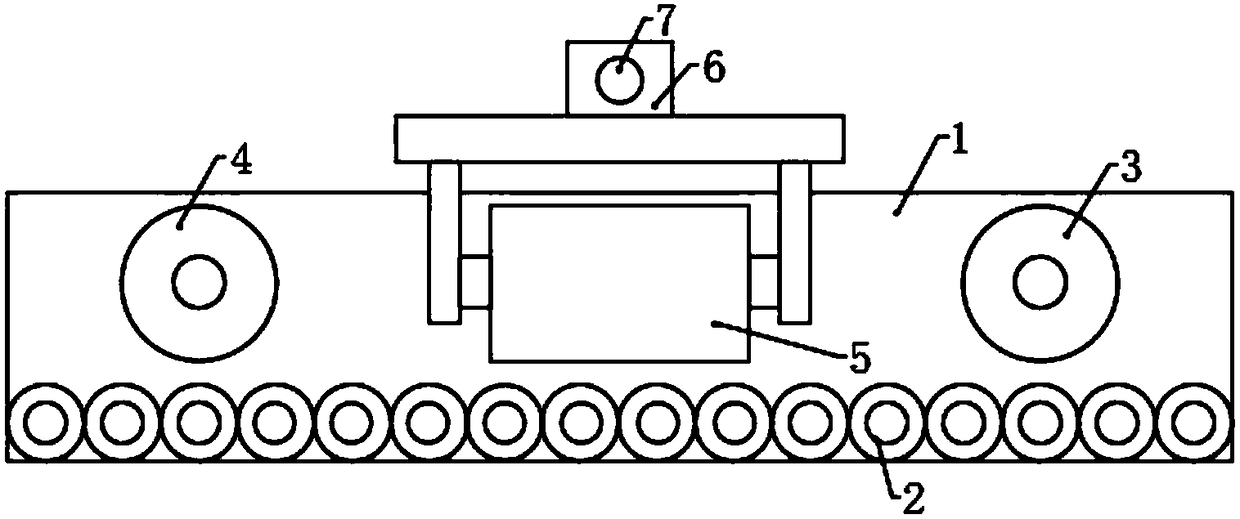

Quick lamination device for shoe production

InactiveCN107660844AImprove pressing efficiencyEven by forceInsolesUpperEngineeringUltimate tensile strength

Owner:晋江诺研机械设计有限公司

Adjustable steel tube joint closing device

InactiveCN104148873AWill not deviate in direction,Those who don't slip outWelding/cutting auxillary devicesAuxillary welding devicesOperation safetySteel tube

The invention provides a novel steel tube machining device, and particularly relates to an adjustable steel tube joint closing device which comprises a base, a press-fitting roller fixing seat, a first press-fitting roller, a second press-fitting roller, a third press-fitting roller and a lifting support. By means of the adjustable steel tube joint closing device, press-fitting adjustment can be carried out from multiple angles, prominent load bearing capacity and press-fitting precision are achieved, the novel press-fitting rollers can be better attached to the surfaces of tubes to be machined, press-fitting force is accurate and uniform, tube joint closing efficiency and quality can be effectively improved, operation is easy, and operation safety risks are effectively lowered.

Owner:江苏振光电力设备制造有限公司

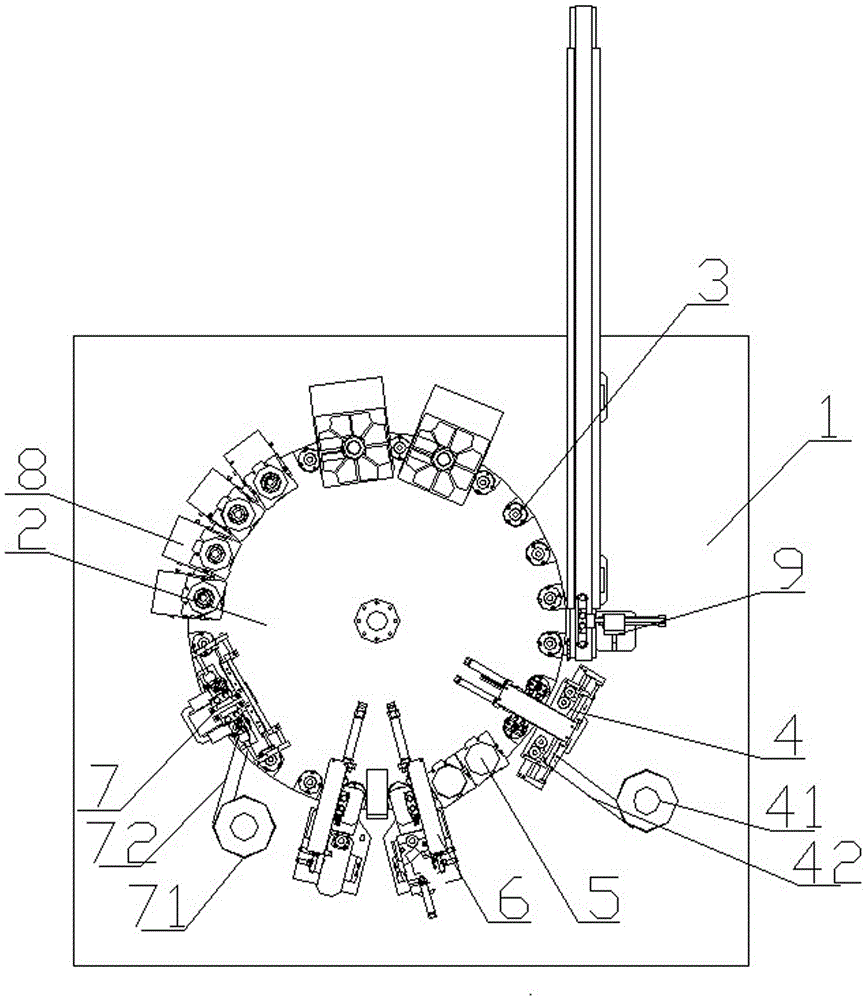

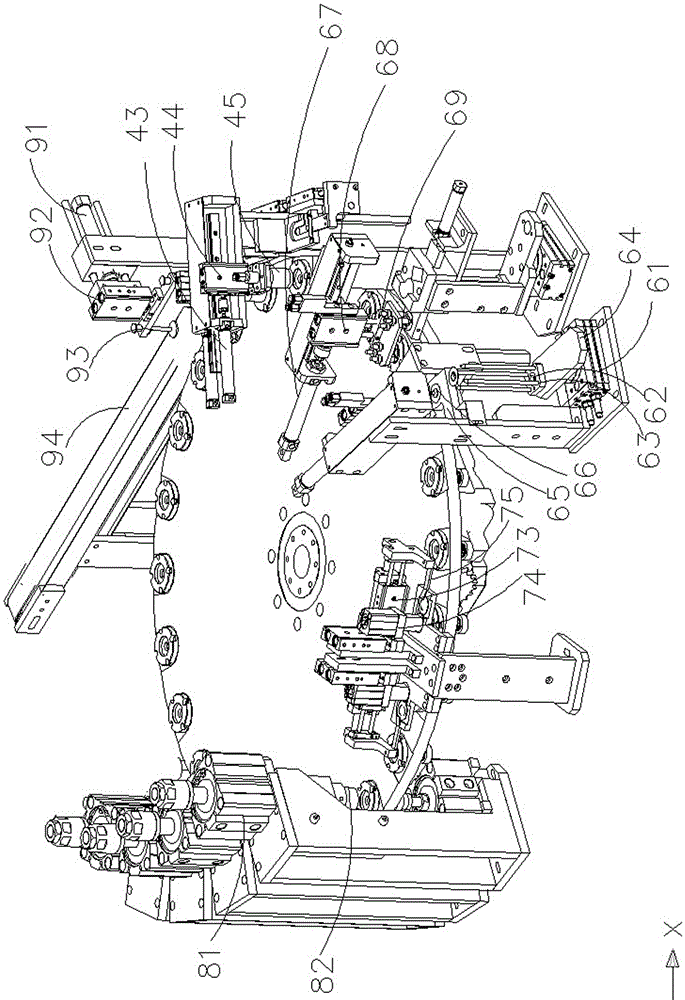

Antenna terminal pressing equipment

ActiveCN105903821ASmooth runningEasy to operateContact member manufacturingMetal-working feeding devicesMan machineEngineering

The invention discloses antenna terminal pressing equipment. The antenna terminal pressing equipment comprises an antenna clamp, a clamping and transferring mechanism, a material pressing mechanism, a man-machine controller, a machine frame, a preparation plate and a discharging plate. The material pressing mechanism is arranged on the upper plane of the machine frame. The horizontal preparation plate and the horizontal discharging plate are installed on a side arm of a main installation frame of the material pressing mechanism. The antenna clamp can be placed on the preparation plate. The clamping and transferring mechanism is installed on the portion, behind the antenna clamp, of the upper plane of the machine frame. The man-machine controller is installed on the portion, at one side of the clamping and transferring mechanism, of the upper plane of the machine frame. The antenna clamp is placed on the upper end face of the main installation frame manually, the clamping and transferring mechanism conveys the antenna clamp into the material pressing mechanism, and a copper sheet in the material pressing mechanism is punched into an antenna of the antenna clamp through a bending head device in the material pressing mechanism. In this way, the antenna terminal pressing equipment is stable in operation, good in pressing effect, convenient to operate and capable of greatly improving the production efficiency and reducing the production cost.

Owner:安徽邦耀电子科技有限公司

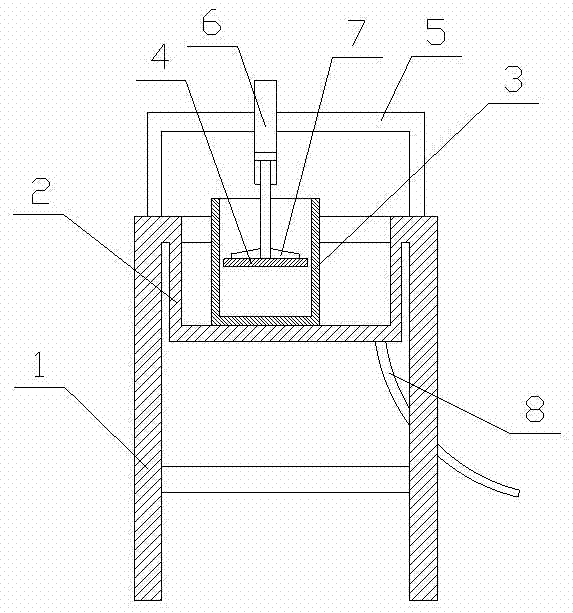

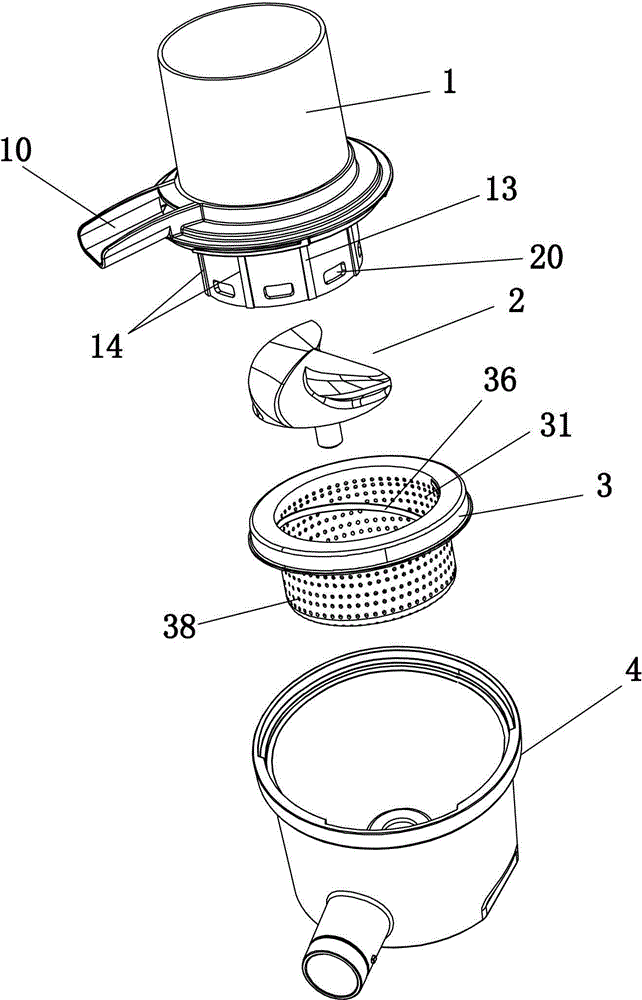

Juice extracting and squeezing machine

The invention provides a juice extracting and squeezing machine which comprises a stander, wherein a water tank is arranged at the upper part of the stander, the water tank is internally provided with a squeezing device, the squeezing device comprises a material storing barrel and a squeezing disc, the material storing barrel is arranged on the bottom surface of the water tank, the press disc is horizontally arranged in the material storing barrel, the top of the stander is provided with a support, the support is vertically provided with an air cylinder, and a piston rod of the air cylinder is connected with the press disc. The juice extracting and squeezing machine is simple in structure, and low in cost; the meat filled in a gauze bag is squeezed by the means that the press disc is pushed by the air cylinder; the juice extracting and squeezing machine is high in work efficiency, time-saving and labor-saving; the juice in the meat can be completely pressed as much as possible, the waste of raw materials can be avoided, and the cost can be saved; the juice can more easily flow out due to sieving holes of the press disc and the material putting barrel; the connecting strength between the press disc and the air cylinder position rod can be improved due to a reinforcing plate arranged on the press disc, so that a greater force can be output by the air cylinder, and the squeezing effect can be improved; and the squeezed juice is convenient to recover due to a liquid outlet pipe arranged at a corner at the bottom of the water tank.

Owner:YEBIO BIOENG OF QINGDAO

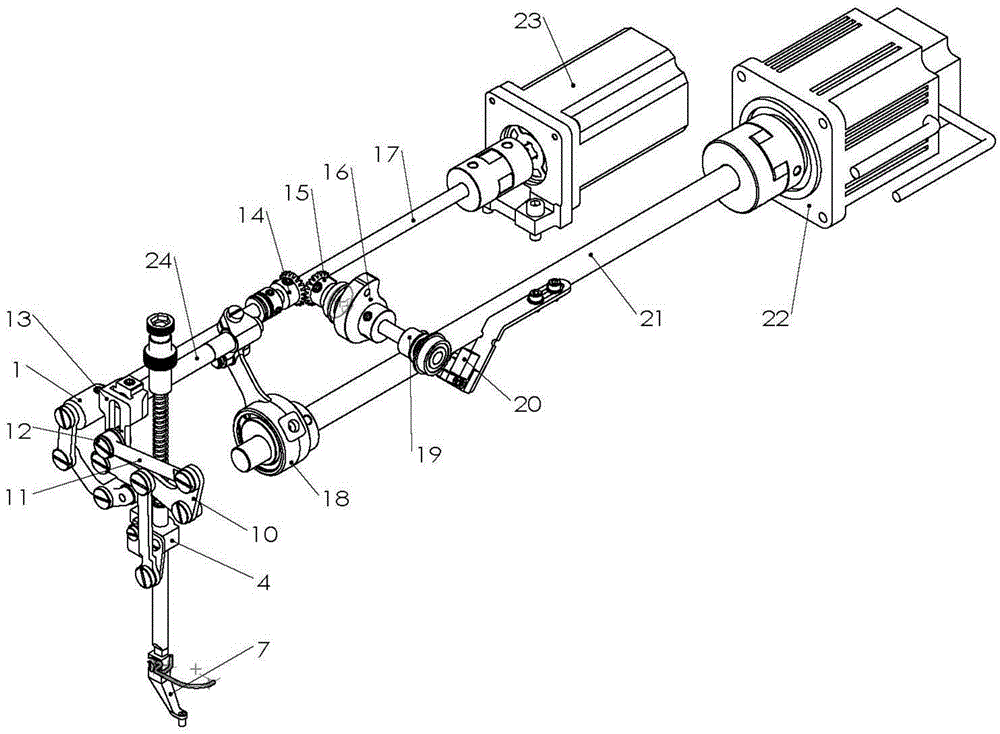

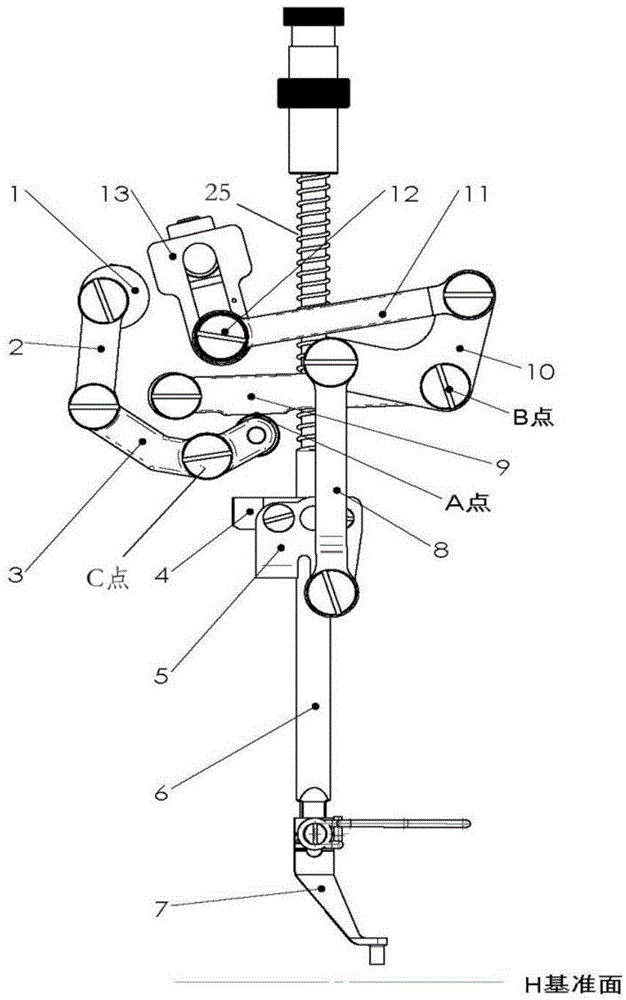

Automatic variable presser foot mechanism of sewing machine

The invention relates to an automatic variable presser foot mechanism of a sewing machine. The automatic variable presser foot mechanism of the sewing machine is characterized by comprising a presser foot height adjusting assembly and a presser foot travel adjusting assembly; the output shaft of a first electromotor of the presser foot height adjusting mechanism is connected with a first transmission shaft, an oscillating bar is a bend rod, and a fixing hinging point is arranged at the bend part of the oscillating bar; a fixing rod is provided with a fixed end and a free end, the fixed end is hinged and fixed to the sewing machine, the free end can rotate around the fixed end, the oscillating bar butts against the lower portion of the fixing rod, and thus the fixing rod is driven to rotate around the fixed end to adjust the up-and-down position of the free end; the output shaft of a second electromotor of the presser foot travel adjusting assembly is connected with a second transmission shaft, the second electromotor rotates, an adjuster is driven through the second transmission shaft and a connecting rod assembly, a connecting plate is driven to do swing movement around the free end of the fixing rod, and the height of a third connecting rod and the height of a presser foot are adjusted; a guide frame and a reset spring are arranged on the upper portion of a presser rod, and the reset spring exerts pressure downwards to keep the presser foot to be free of vertical jumps. The automatic variable presser foot mechanism of the sewing machine is capable of automatically adjusting the height of the presser foot, simple in structure and convenient to adjust.

Owner:上海富山精密机械科技有限公司

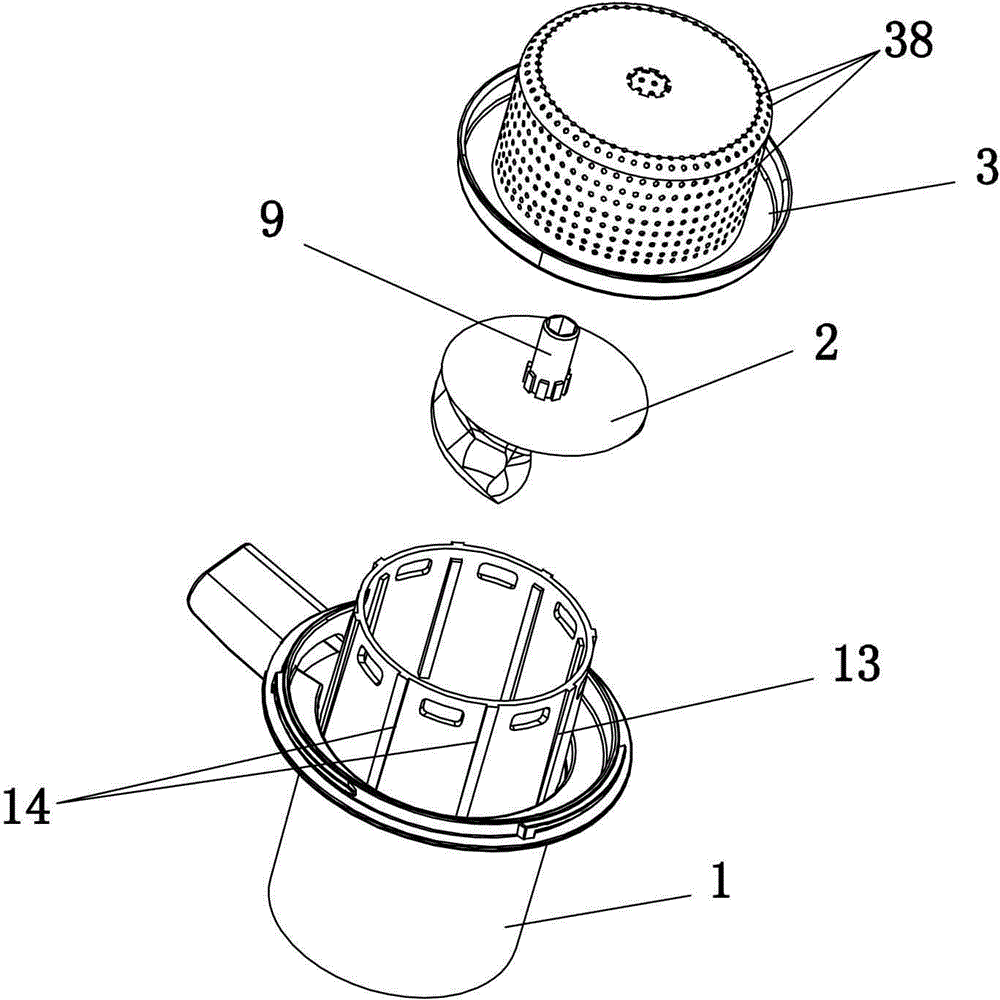

Residue and juice separation device for food processor

The invention discloses a residue and juice separation device for a food processor. The device comprise an inner channel and a food preprocessor and is characterized by further comprising a filter screen outer layer and a juice receiving container, the filter screen outer layer is arranged on the outer side of the inner channel, a gap exists between the filter screen outer layer and the inner channel, the filter screen outer layer and the inner channel are jointly arranged in the juice receiving container, a squeezing channel extending from bottom to top is formed in the gap and provided with at least one inclined segment, an inlet of the squeezing channel is in the lower portion, an outlet of the squeezing channel is in the upper portion, the inlet is communicated with the inner channel, and the outlet serves as a residue discharging opening. The residue and juice separation device for the food processor has the advantages of being simple and reasonable in structure, and capable of guaranteeing that discharged residues are fully and evenly squeezed, the juicing effect is obviously improved, and the situation that residue and juice separation is not thorough is also avoided.

Owner:佛山市顺德区毅鸣佳塑料有限公司

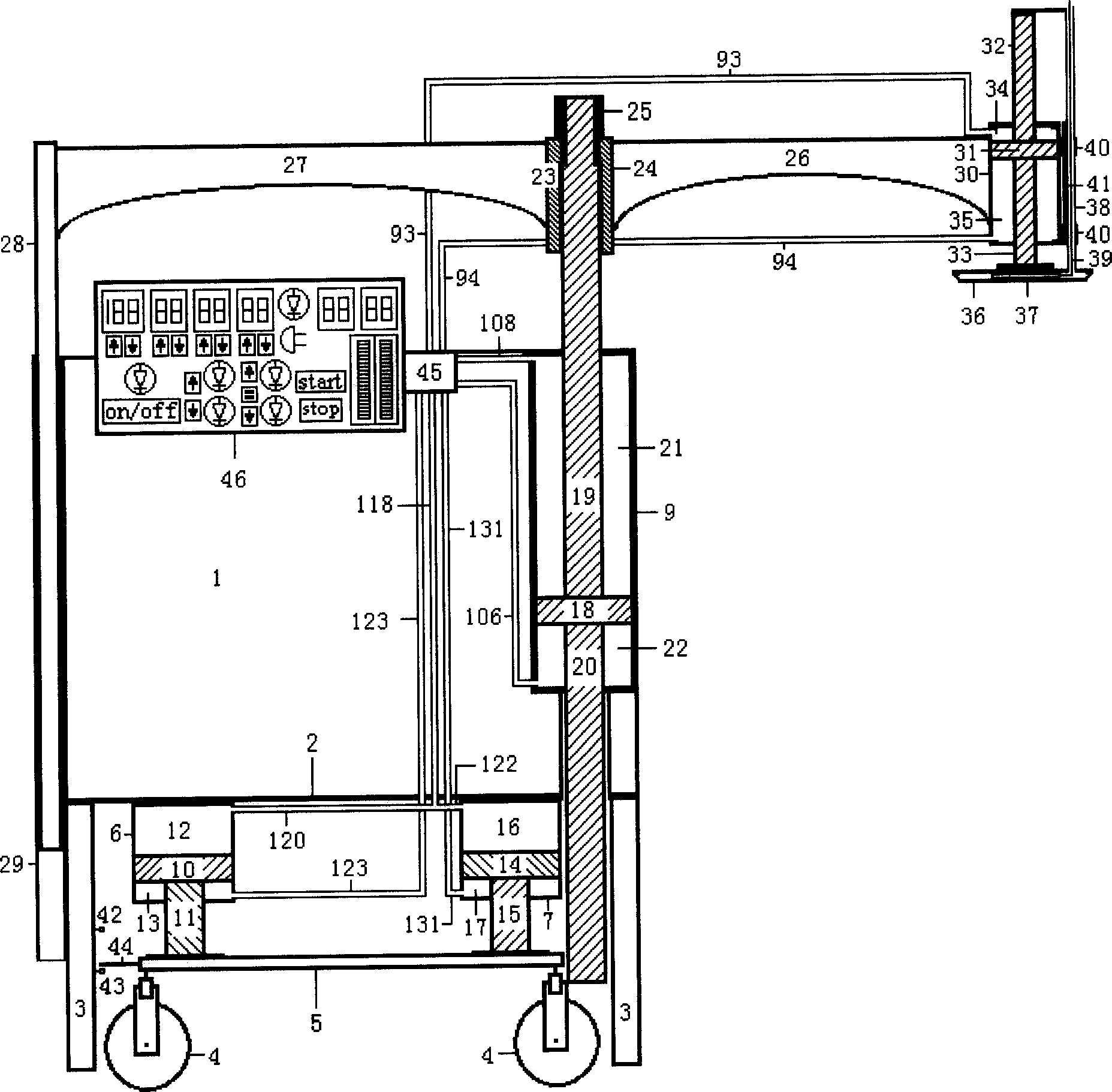

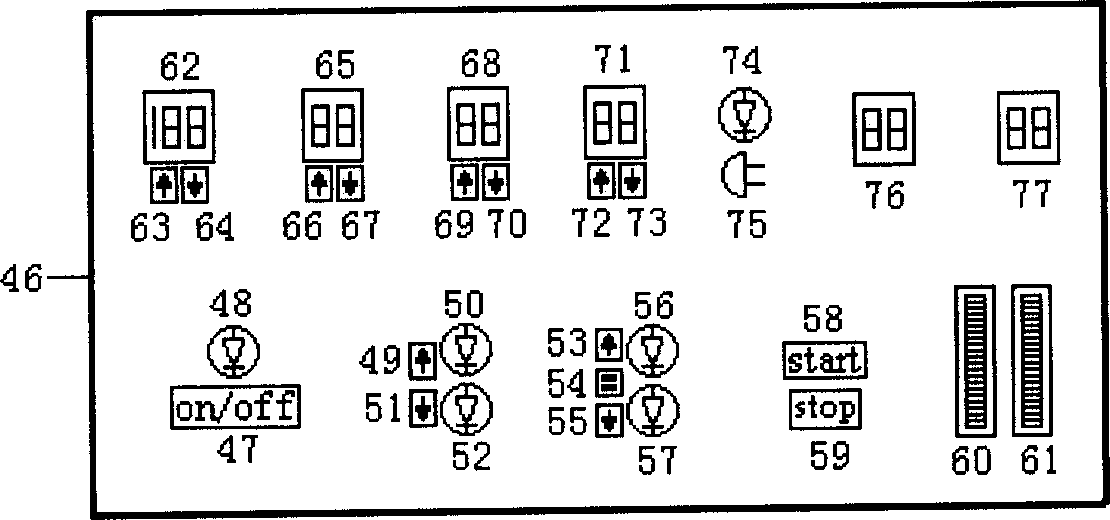

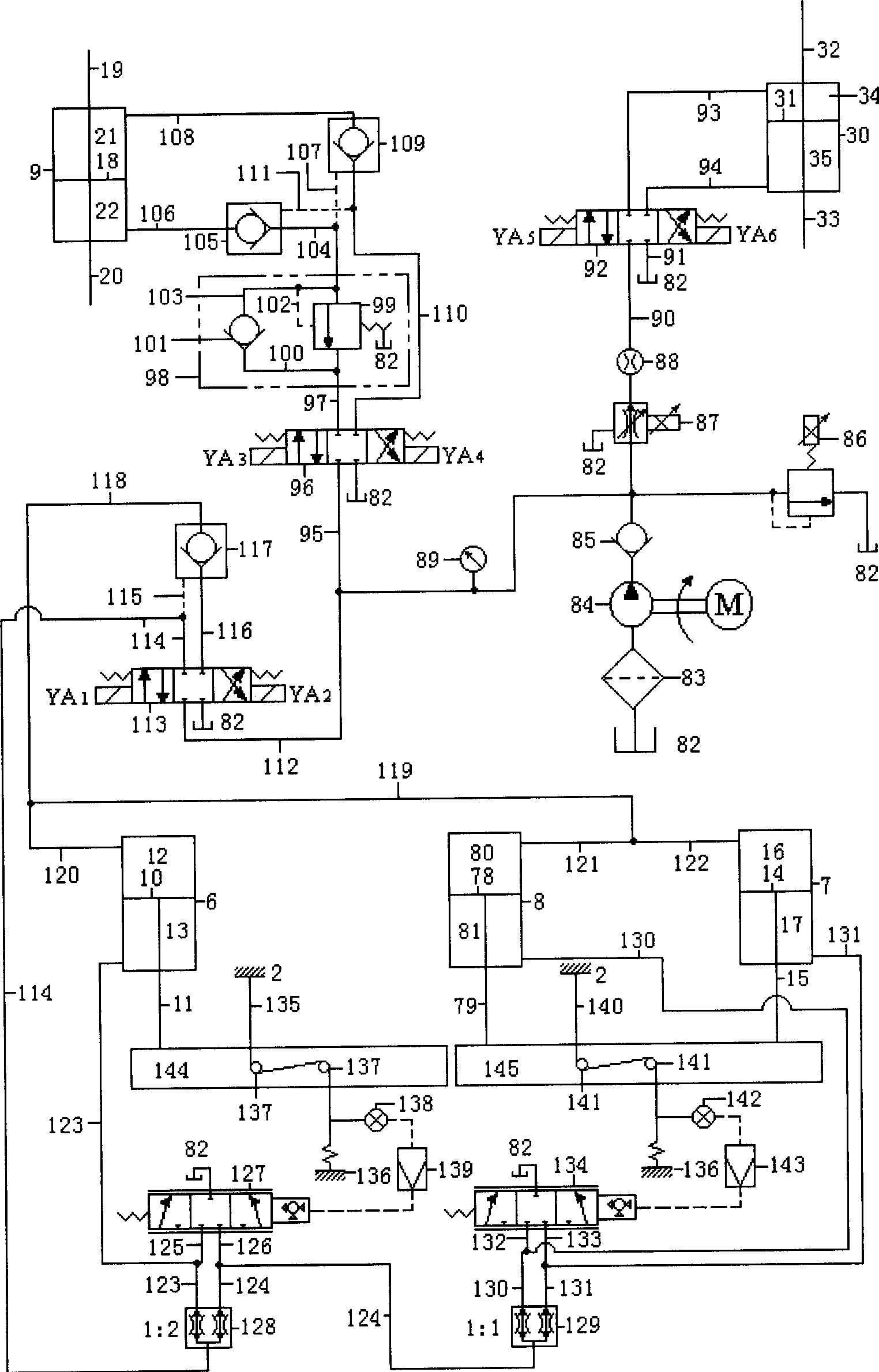

Mobile type numerically controlled hydraulic external heart pressing apparatus

InactiveCN1513432APress down at a constant speedThe process of pressing down is stableElectrotherapyHeart stimulationMicrocontrollerDisplay device

A numerally controlled movable external hydraulic heart pressing machine features that three cylinders for respectively controlling the universal wheel, pressing frame and pressing head are driven by an oil pump, the motor of oil pump, commutating electromagnetic valve, the reverse valve of step motor, proportional electromagnetic pressure valve, flow valve and hydraulic system are controlled by the sensed different signals and predefined program, and after the machine is turned on, the heart is automatically and periodically pressed according to default parameters.

Owner:毛宝伦

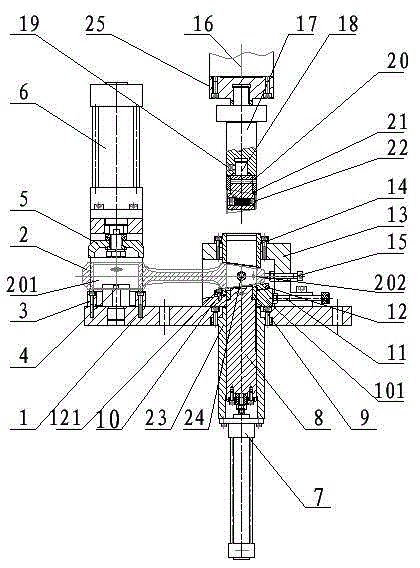

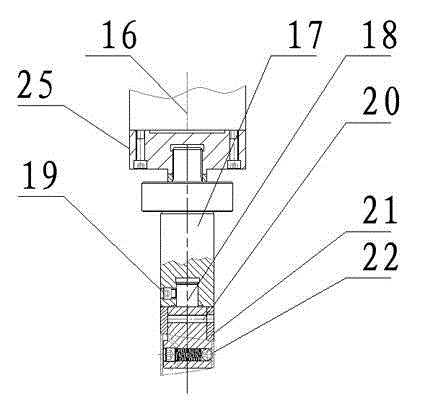

Three-in-one lithium battery cap assembly device

InactiveCN105489922ASave loading timeGuaranteed continuityAssembling battery machinesFinal product manufactureElectrical and Electronics engineeringLithium battery

The invention relates to a three-in-one lithium battery cap assembly device. The three-in-one lithium battery cap assembly device comprises a base, wherein a rotary disc is arranged on the base and driven by a stepping motor, a circle of internally-sunken round stations which are uniformly arranged are arranged on the rotary disc, and an anti-explosion sheet feeding station, a gasket feeding station, an upper cover feeding station, a press sealing station and a discharge station are sequentially arranged along the external circumference of the rotary disc; the gasket feeding station adopts multiple clips to sequentially feed; when a gasket in a clip is finished, a support rod retracts, a rotary air cylinder rotates, another clip fully loaded with gaskets is transferred to the part above the support rod for continuously feeding, the feeding time is saved, and the production continuity is maintained; and anti-explosion sheet is in press fit with an upper cover, and one-time forming is prevented to cause deformation of the anti-explosion sheet. According to the technical scheme, lamination is gradually carried out by three times, and the lamination effect is good; a hole expansion station is additionally arranged behind the anti-explosion sheet station, the mouth of the anti-explosion sheet is expanded, the gasket and the upper cover are conveniently loaded into the anti-explosion sheet in subsequent stations, the efficiency and the yield are effectively improved, and the loss is reduced.

Owner:TAIXING ZHENGXING ELECTRON

Press-fitting and locating mechanism and press-fitting method of wedge-shaped connecting rod bush

ActiveCN102744592AGuaranteed positioning accuracyImprove the pressing effectWork holdersMetal working apparatusSurface phaseSet screw

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

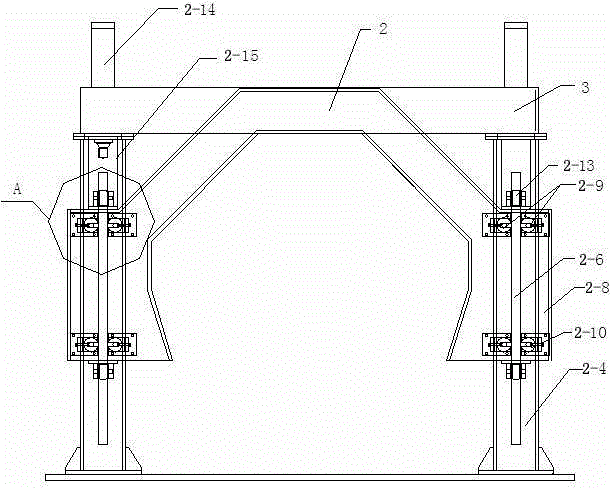

Adjustable external chest compression device

InactiveCN107811840AAdjust the motion strokeAdjust pressureElectrotherapyHeart stimulationCompression deviceEngineering

The invention discloses an adjustable external chest compression device. The adjustable external chest compression device comprises a mounting plate, a compression hemisphere, a screw rod, a first motor, a movable block, a mounting box, a first rotating shaft, a first electronic push rod, a movable rod, a compression hemisphere, a second rotating shaft, a second electronic push rod, a first gear,a second gear, a third gear and a fourth gear. By virtue of the cooperation of the second motor, the second electronic push rod, the second rotating shaft, the third gear, the fourth gear, the secondgear, the first gear, the first rotating shaft, the first electronic push rod, the movable rod, a spring and the compression hemispheres, and the compression hemispheres are driven to move up and downso as to automatically and repeatedly compress the chest of a patient, so that the compression effect is good, the time and the labor are saved, and the efficiency is high; and meanwhile, by adjusting the motion strokes of the compression hemispheres, the compression force can be adjusted, and a telescopic rod of the second electronic push rod is controlled, so that the up-down motion frequency of the compression hemispheres can be adjusted by changing a transmission ratio.

Owner:黄莉

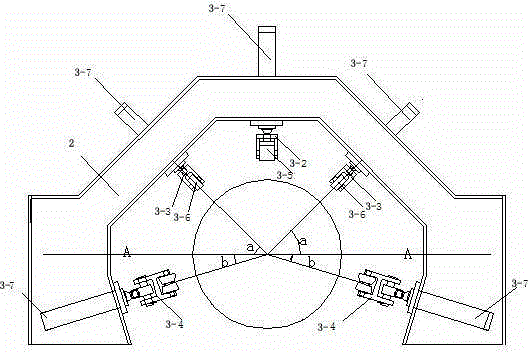

Timing gear locating device and timing gear assembling equipment comprising same

PendingCN107627088APrecise positioningGood pressing effectMetal working apparatusGear wheelControl theory

The invention provides a timing gear locating device and timing gear assembling equipment comprising the same, and relates to the field of timing gear assembling equipment. The timing gear locating device comprises a timing gear, a supporting mechanism, a gear angular locating mechanism and a straight tooth locating mechanism, wherein the timing gear is placed on the supporting mechanism; the timing gear comprises a first end face and a second end face which are opposite; a timing hole is formed in the first end face; the gear angular locating mechanism comprises a locating pin; the locating pin is selectively matched with the timing hole; the straight tooth locating mechanism is provided with a first imitation block and a straight tooth locating cylinder used for driving the first imitation block to perform movement; the first imitation block is provided with a tooth groove; and the tooth groove is selectively meshed with the straight teeth of the timing gear. According to the timinggear locating device and the timing gear assembling equipment comprising the same, the timing gear can be located accurately, so that the subsequent assembling process is facilitated, and the productquality of assembly parts is improved; besides, the timing gear assembling equipment comprising the timing gear locating device can effectively solve the problem of unsatisfactory quality caused during the assembling process.

Owner:银川合宜科技有限公司

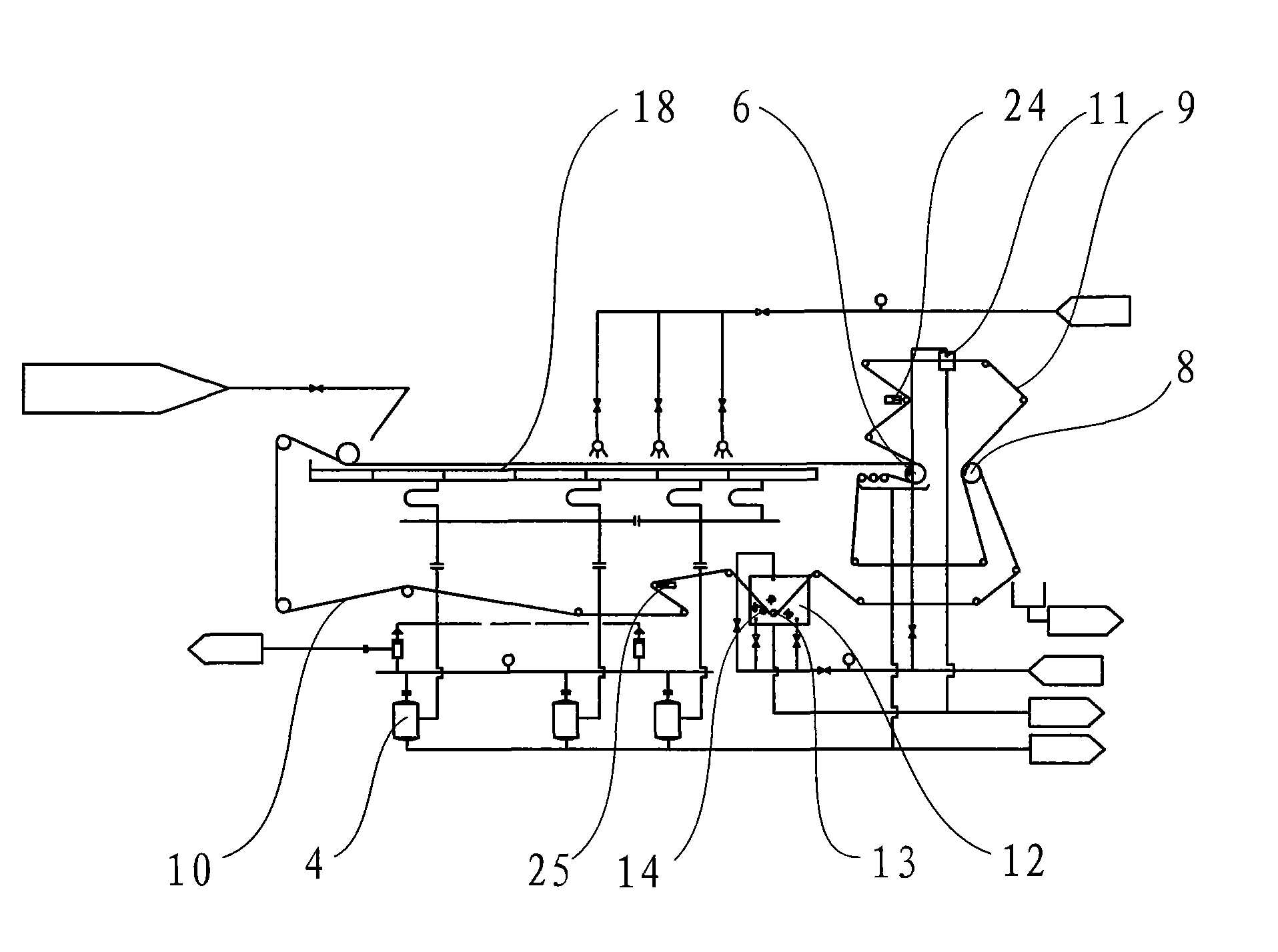

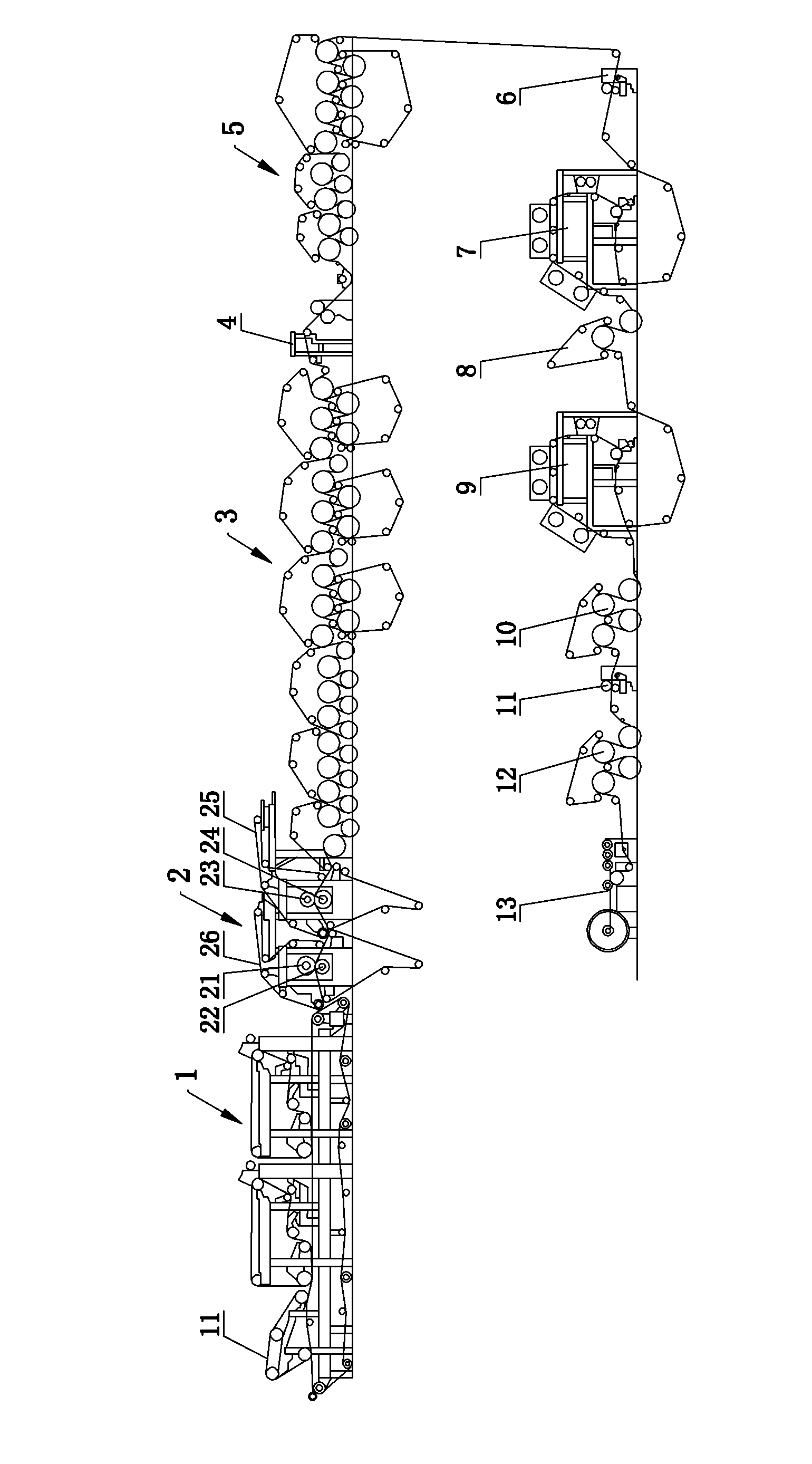

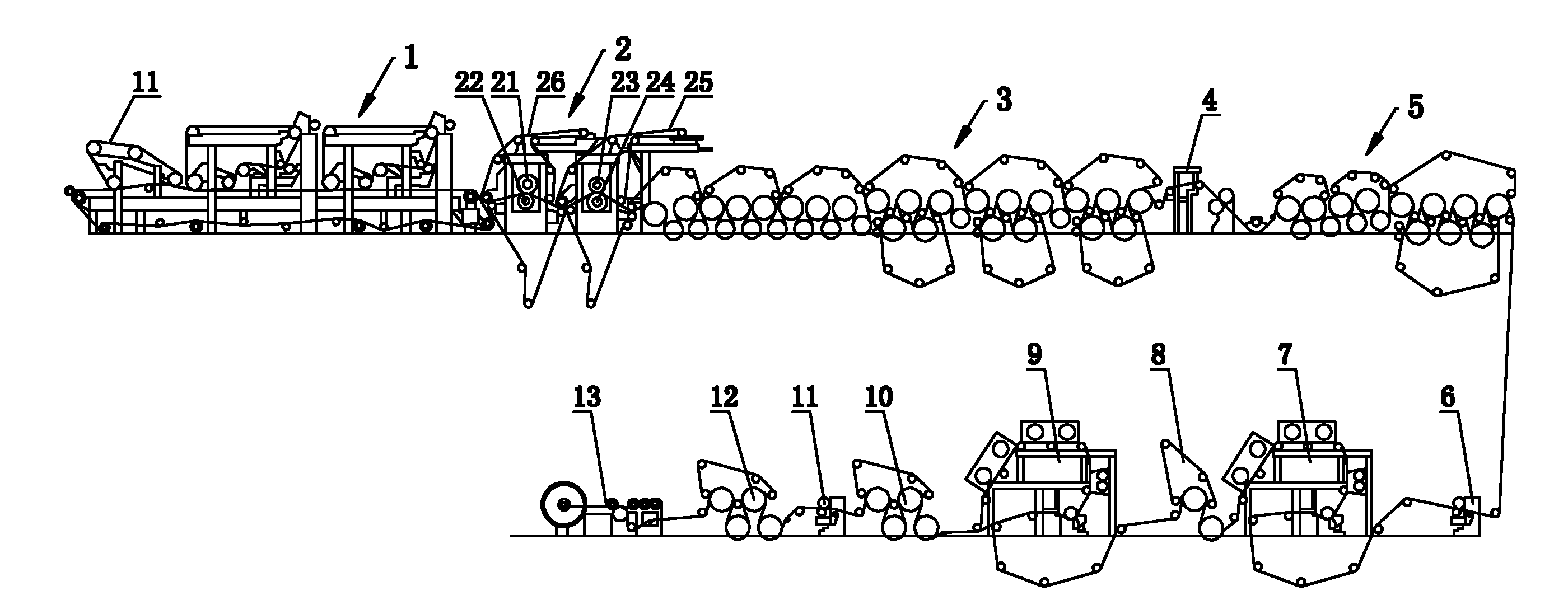

Light-coated kraft production equipment and method

ActiveCN102182098AMeeting the demands of high printing performanceImprove stiffnessSpecial paperPaper/cardboardCardboardSurface layer

The invention discloses light-coated kraft production equipment and a method. The production equipment comprises a triple net forming device, a squeezing device, a front drying device, a film transfer sizing machine, a rear drying device, a hard calendering device, a first scraper coating machine, a first scraper rear drying device, a second scraper coating machine, a second scraper rear drying device, a soft calendering device, a cooling device and a coiling forming device which are sequentially mounted on a rack. In the production of light-coated kraft by adopting the equipment, after the two sides of the original paperboard are sized by the film transfer sizing machine, the ink absorption uniformity of the kraft is improved; and through twice scraper coating, a good coating effect can be obtained at low coating quantity, and the requirement on high printing performance of the kraft can be met; and moreover, the bottom layer, lining layer and surface layer adopt different raw materials as well as proper proportions of raw materials respectively, and the produced light-coated kraft has low ration and high strength.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP +1

Method of treating wool fabric using transglutaminase

The invention is a method for using glutamine transaminage to process wool textile. The glutamine transaminage is dissolved in water to produce the enzyme processing liquid, then the wool textile is put into the liquid to be processed, the invention enhances the association effect of wool protein fiber, realizes the effect of easy nursing. At the same time, the invention uses MTG enzyme process, the invention accords with the demands of environment protection, it has no contamination.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com