Wedged connecting rod bushing press fitting positioning mechanism

A positioning mechanism, connecting rod bushing technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the outer circle of the bushing and the surface of the inner hole of the connecting rod cannot meet the design requirements, and the bushing rotates And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

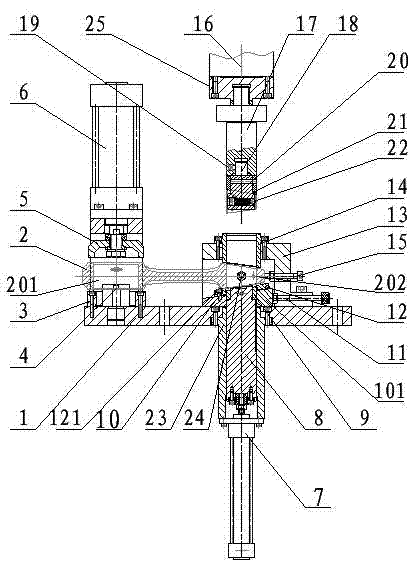

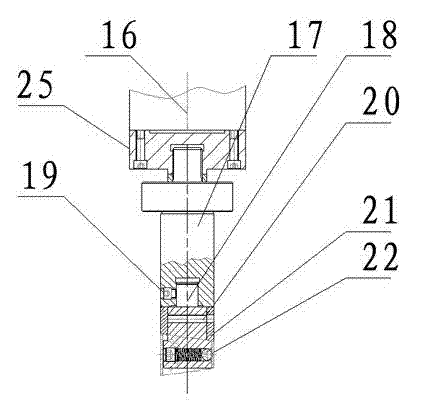

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] figure 1 , 2 As shown, a wedge-shaped connecting rod bushing press-fit positioning mechanism includes a working table 1, a connecting rod 2, a big head hole 201, a small head hole 202, a big head gasket 3, a diamond-shaped positioning pin 4, a pressure plate 5, a first cylinder 6, Second cylinder 7, small head positioning mandrel 8, compression retaining sleeve 9, fixed wedge-shaped positioning seat 10, movable wedge-shaped positioning seat 101, knurled screw 11, small head gasket 12, small head pre-positioning gasket 121, guide Seat 13, guide sleeve 14, pre-positioning screw 15, pre-positioning screw 24, intelligent press machine main shaft 16, pressure post 17, mandrel 18, compression screw 19, set screw 20, pressure sleeve 21, wedge bushing 22. The upper end of the work surface 1 is provided with a big head gasket 3 supporting the lower end of the big head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com