Patents

Literature

56results about How to "Tacit cooperation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

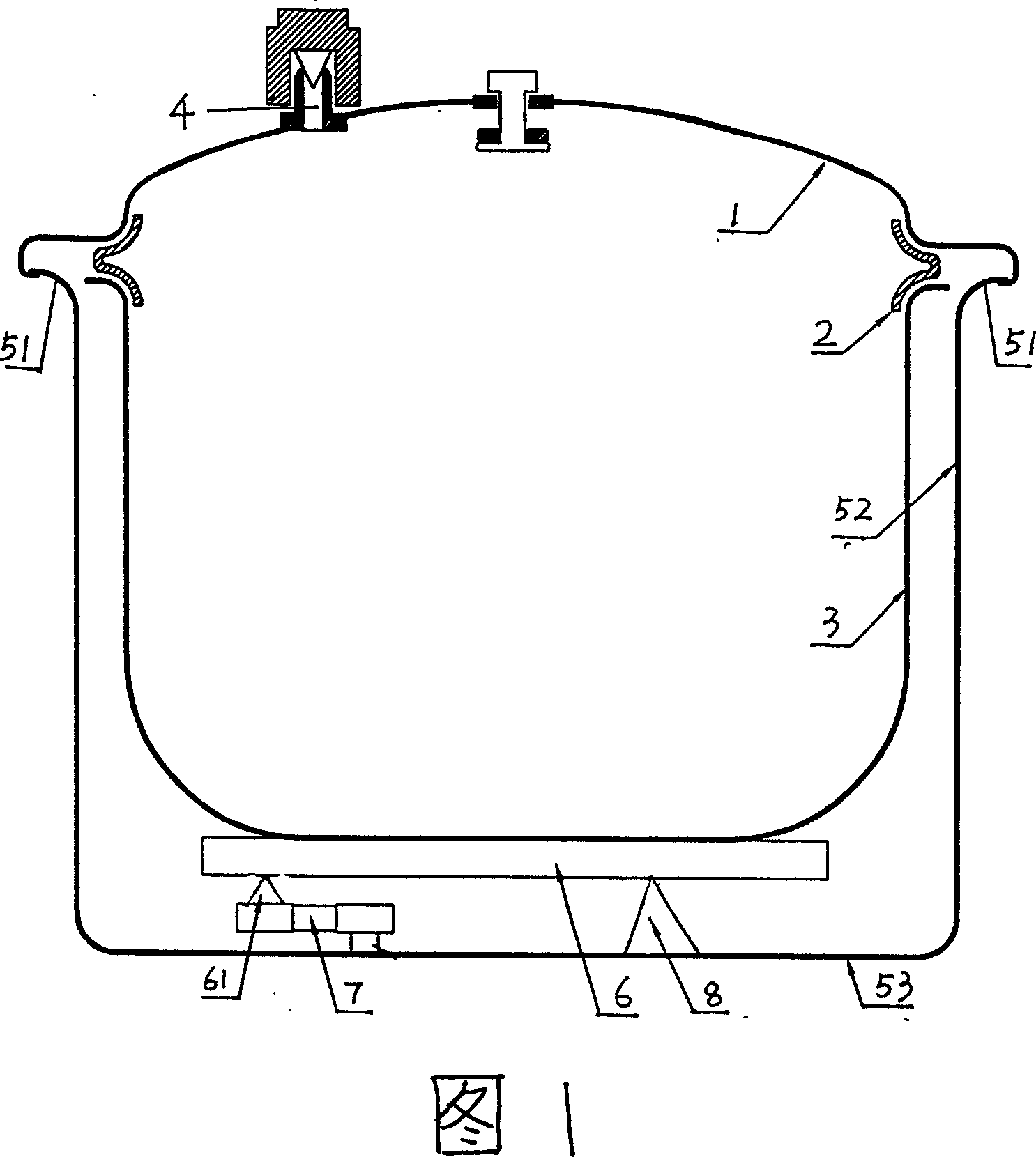

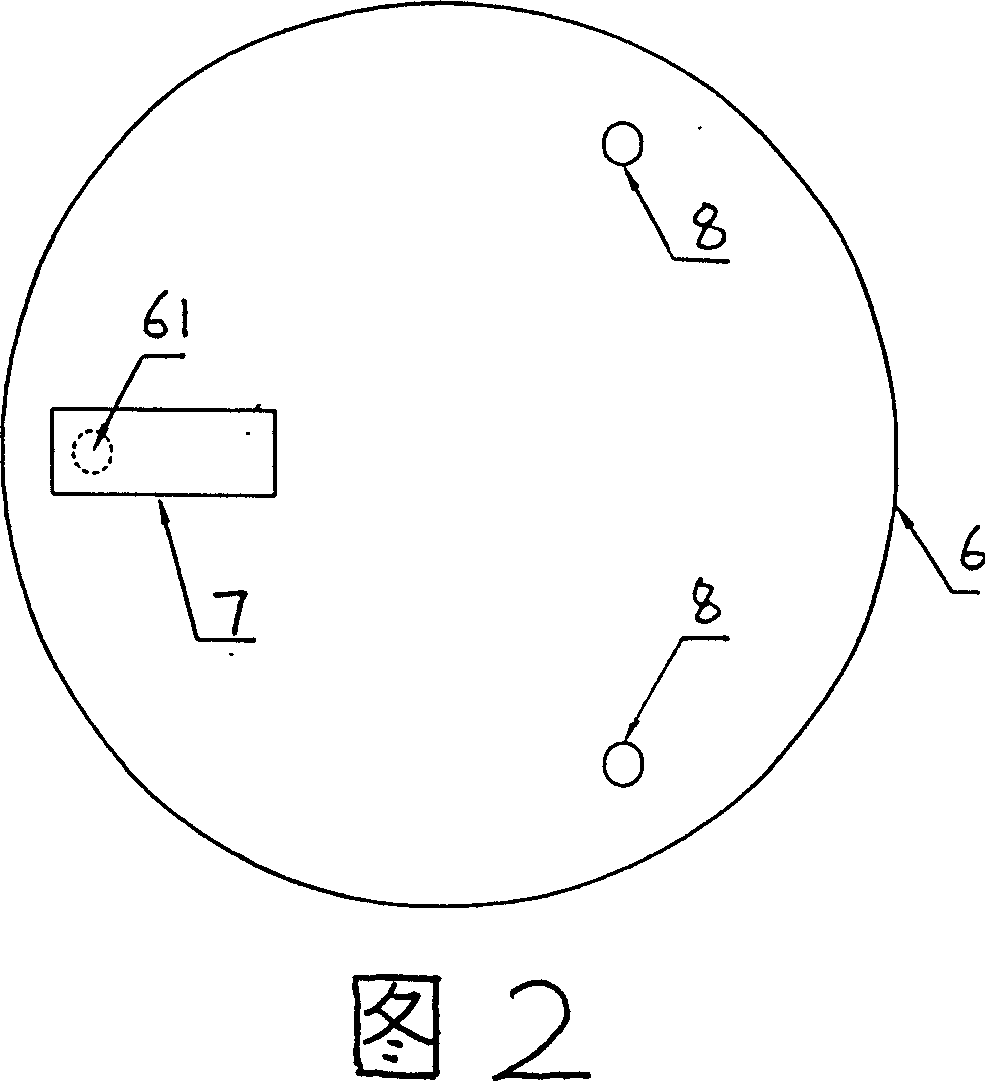

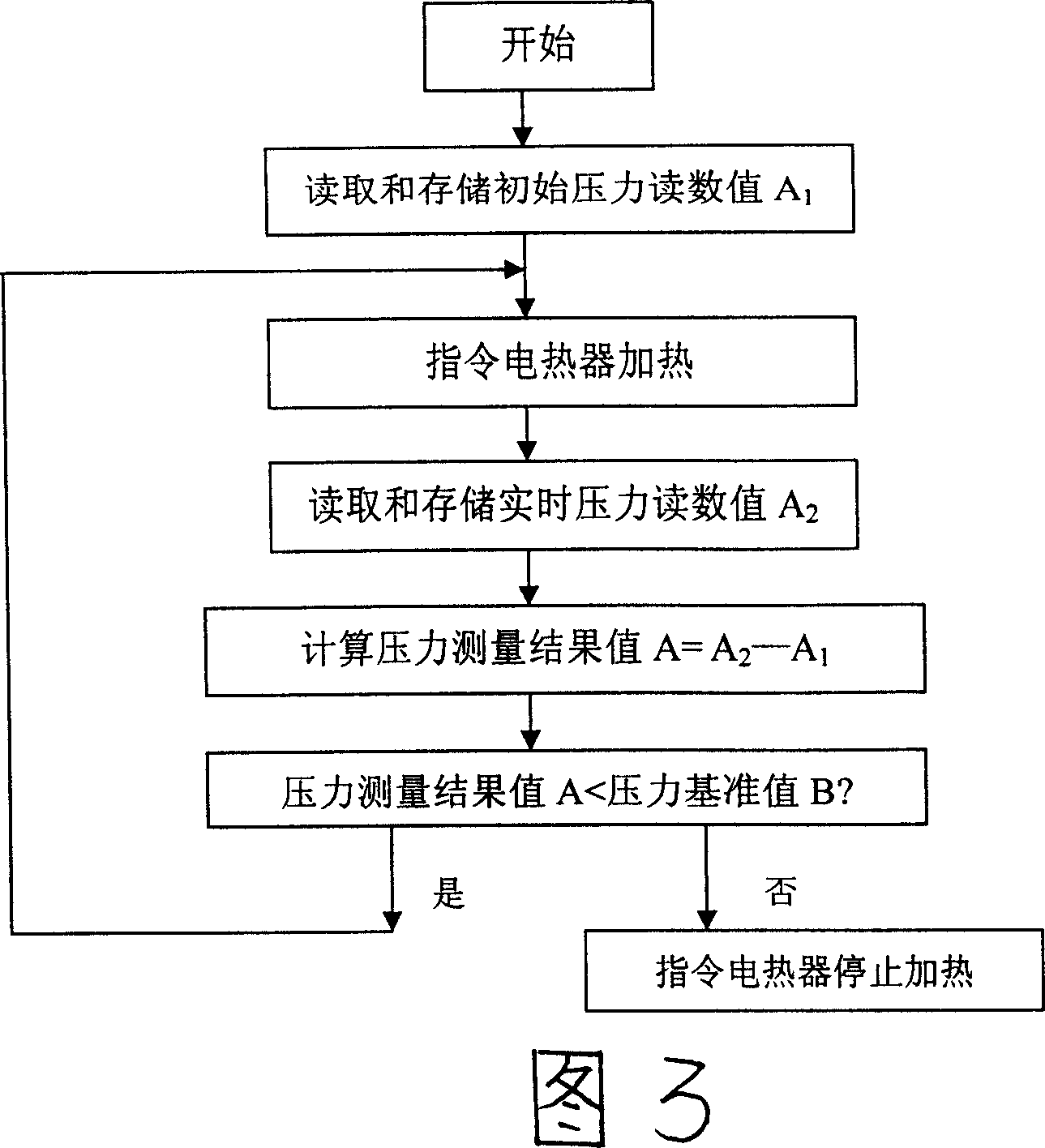

Electric pressure cooker

InactiveCN1919120AFlexible and accurateTacit cooperationPressure-cookersEngineeringAtmospheric pressure

The invention discloses an electric pressure cooker with weighing sensor on the bottom, which comprises the following parts: rigid transverse tray and rigid frame with rigid beam, rigid vertical connecting board and rigid tray, wherein the rigid beam and rigid tray chucks pan-lid, sealing coil, inner pan, heater and weighing sensor together from upwards to downwards, the output end of weighing sensor connects circuit control device, which controls heating condition of heater according to the testing result of weighing sensor.

Owner:汕头市夏野电器有限公司

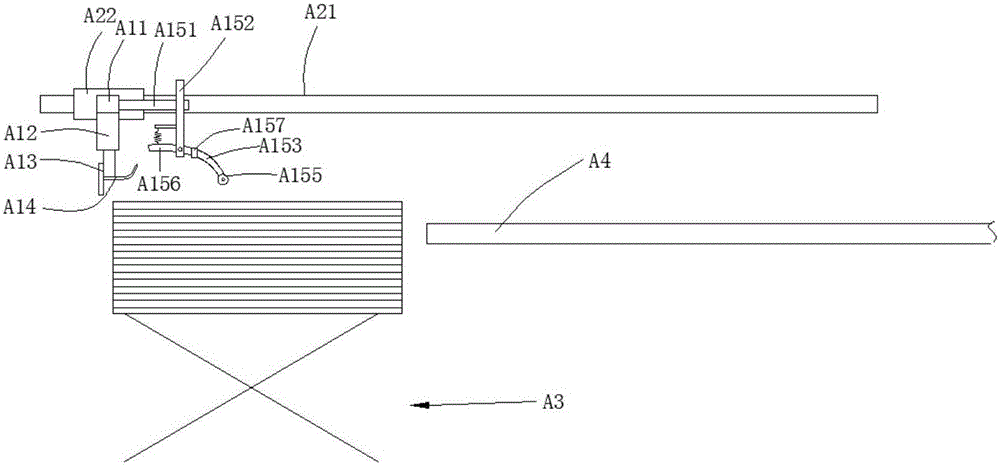

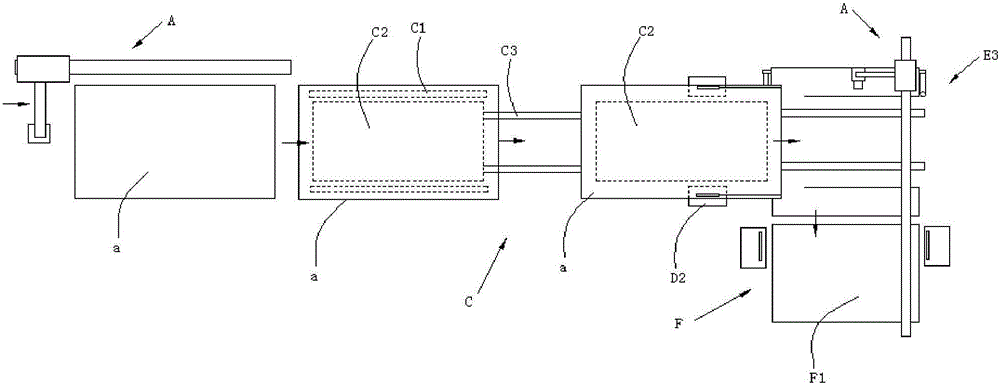

Full-automatic trimming machine

The invention provides a full-automatic trimming machine which comprises a feeding device, a long edge trimming device, a steering device and a short edge trimming device, wherein panels sequentially pass through the feeding device, the long edge trimming device, the steering device and the short edge trimming device; the long edge trimming device and the short edge trimming device are respectively positioned on the two adjacent sides of the steering device; and the horizontal-direction included angle of the long edge trimming device and the short edge trimming device is 90 degrees. Compared with the prior art, the trimming machine provided by the invention has the advantages that the structure is simple, the panel feeding is smooth, all the steps closely cooperate with each other, before the next step is carried out, the next work task is prepared in the precious step, the connection is close, and the working efficiency is high.

Owner:ANHUI ANSU WORLD HOME CO LTD

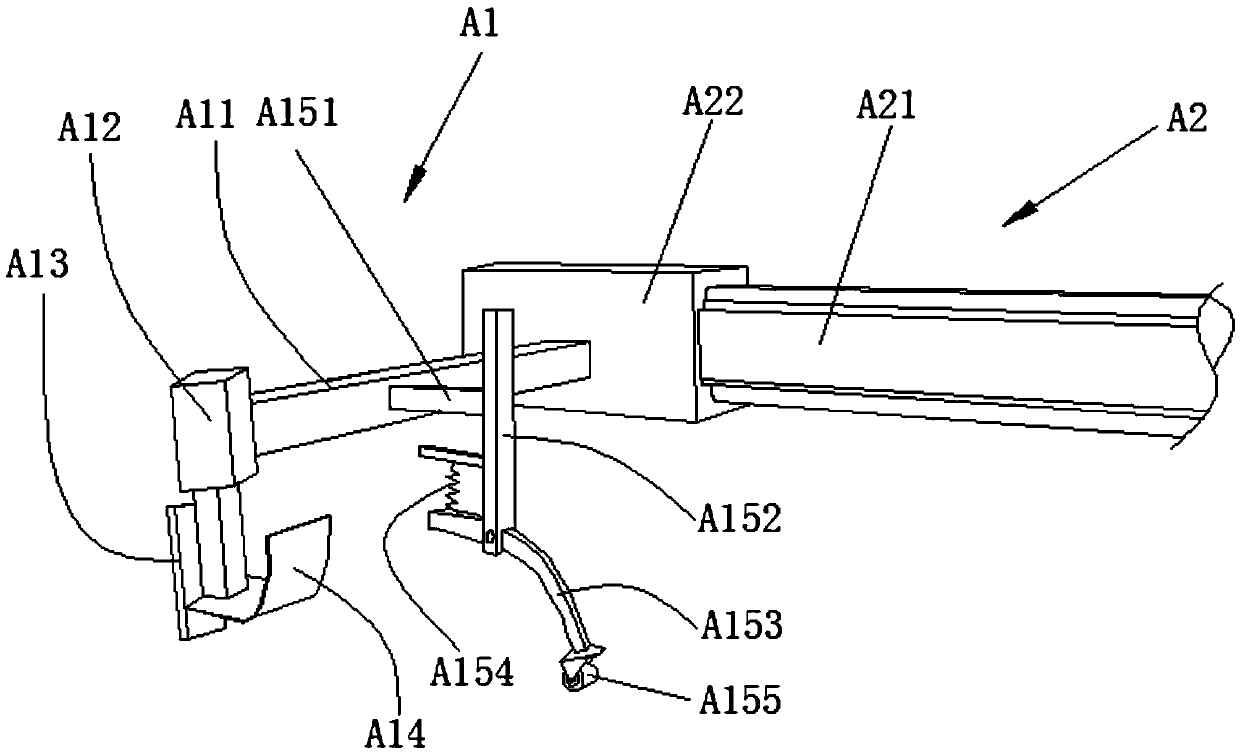

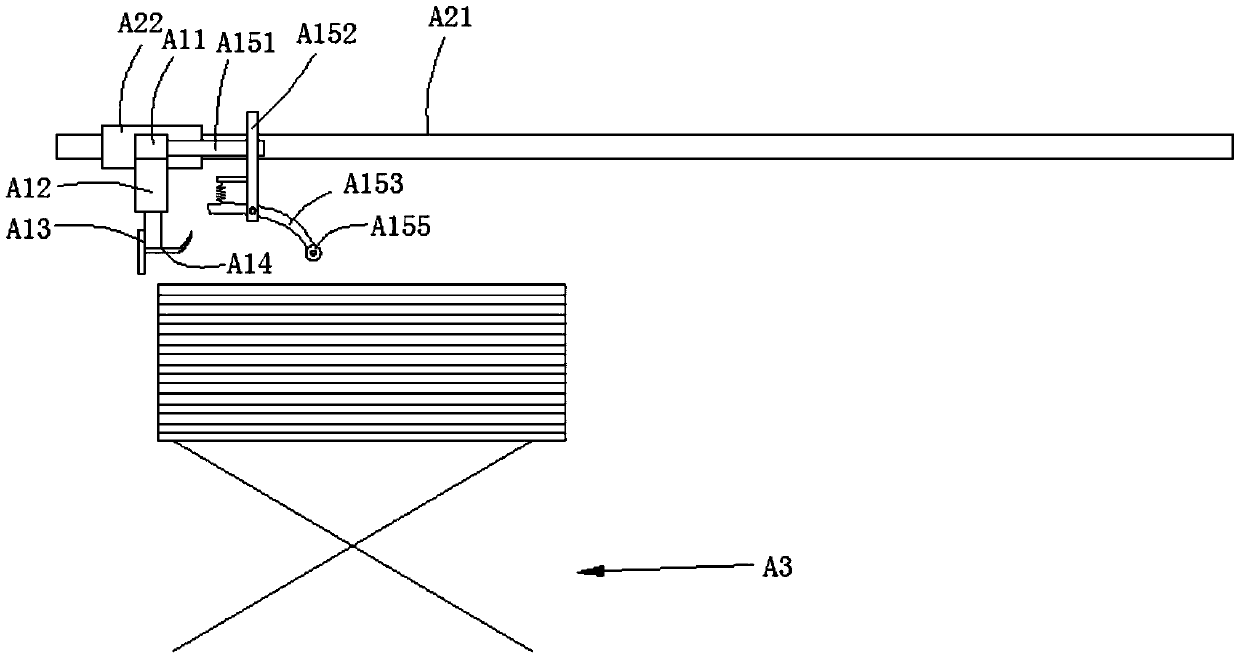

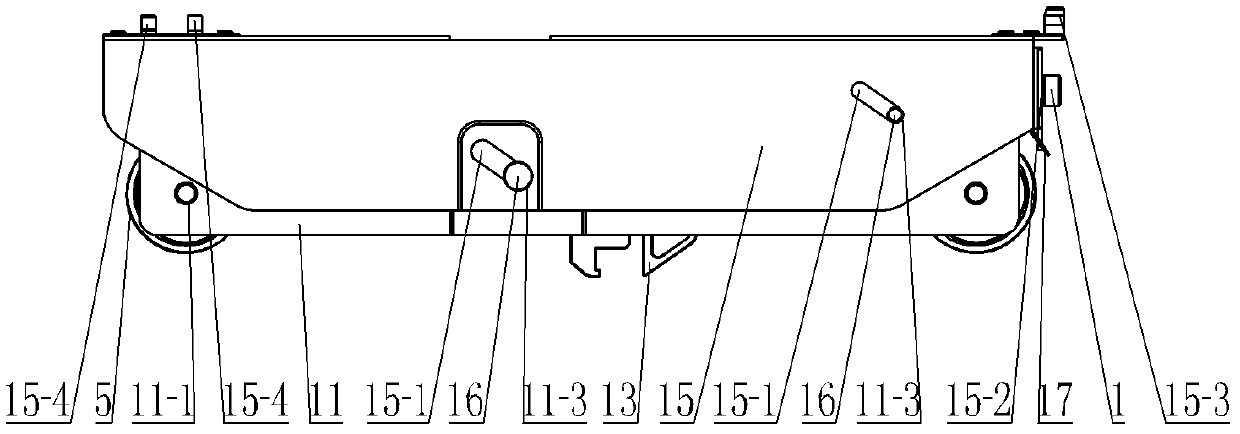

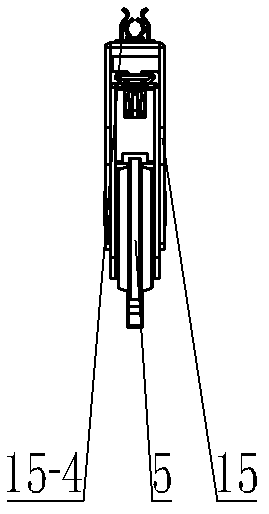

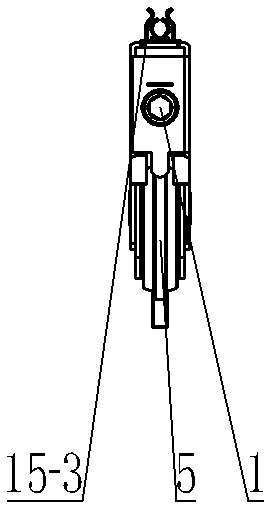

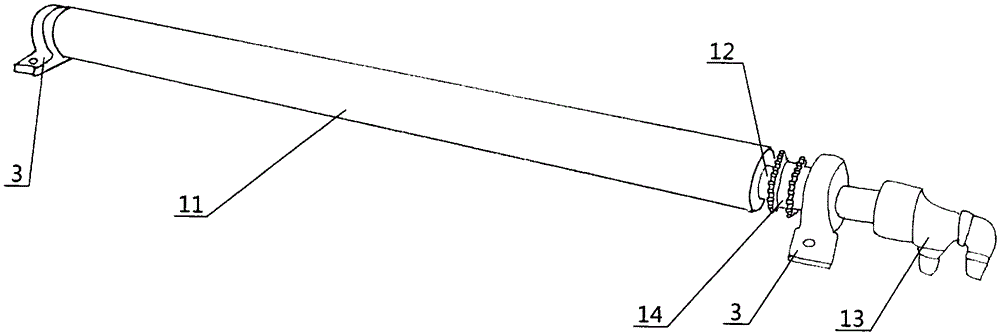

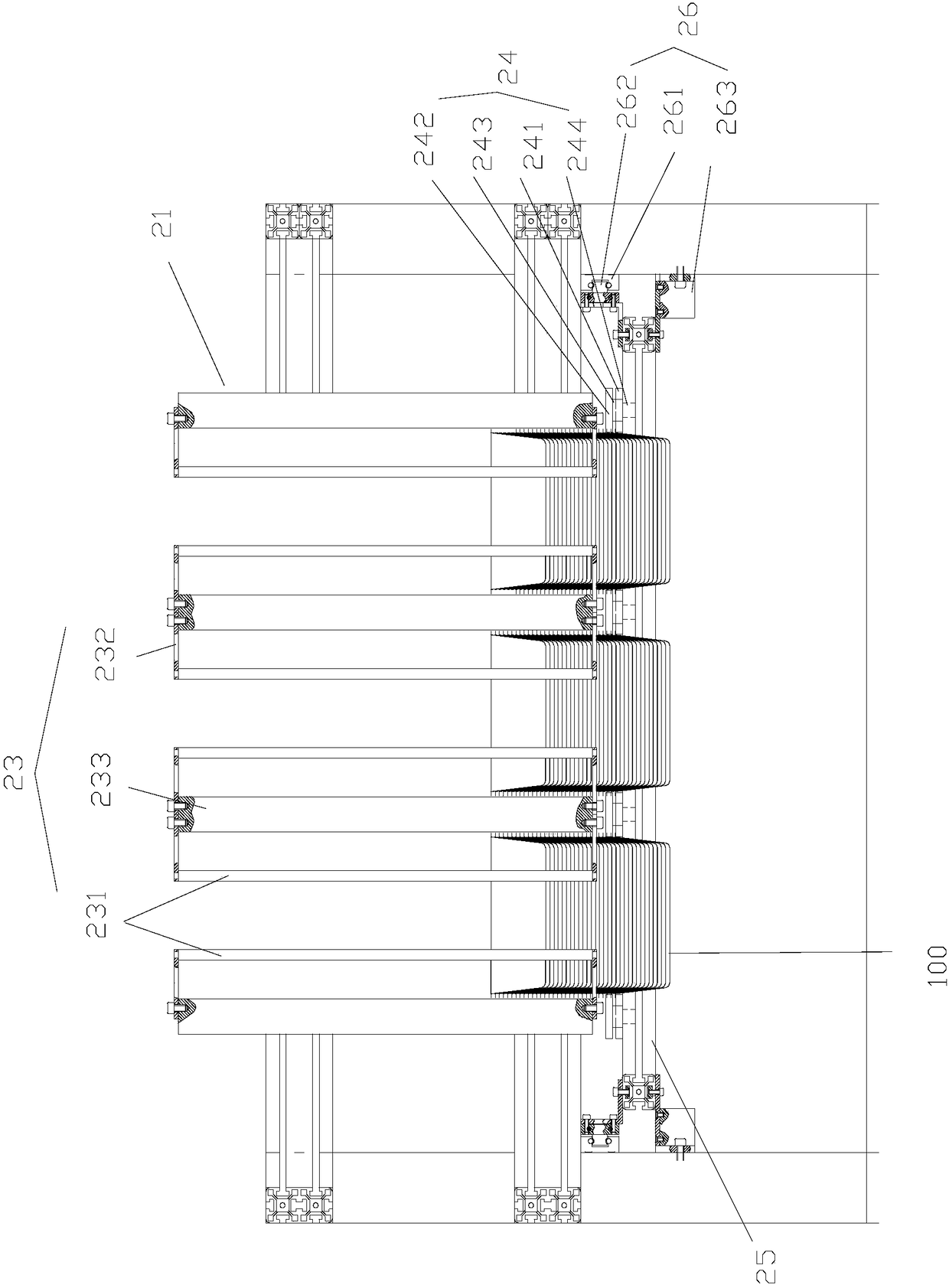

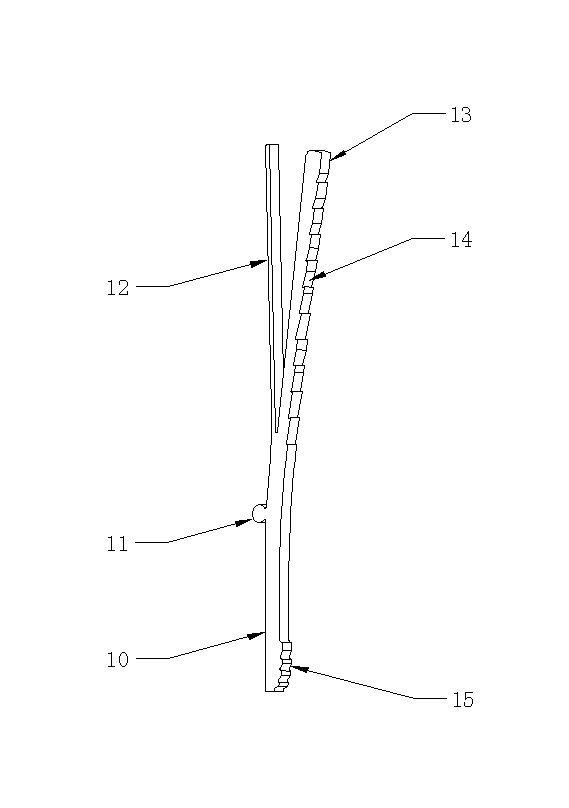

Movable pulley combined unit assembled on upper cross beam and lower cross beam of door leaf of wall cabinet

ActiveCN102536021ACompact assemblyImprove performanceBuilding braking devicesWing suspension devicesManufacturing technologyShock absorber

The invention provides a movable pulley combined unit assembled on an upper cross beam and a lower cross beam of a door leaf of a wall cabinet, and belongs to the manufacturing technology of hardware fittings used in architectural decoration. The movable pulley combined unit assembled on the upper cross beam and the lower cross beam of the door leaf of the wall cabinet adopts the structure that an upper rail is assembled above the door leaf of the wall cabinet; and stop blocks are assembled on the upper rail and a lower rail. When the door leaf departs from a door frame edge, the stirring piece of the damper of the movable pulley combined unit can be hooked in triangular groove tables of the stop blocks and pull the top chord of the damper; and when the door leaf goes back to the door frame edge, the stirring device of the damper can generate a damping action to ensure that the door leaf goes back to the door frame edge slowly and safely without the phenomena of beating and collision. The movable pulley combined unit has the advantages of novel design, reasonable structure, compact components, convenience in mounting and adjusting, and obvious effect. The movable pulley combined unit comprises components such as an adjusting bolt (1) and a movable pulley (2), and is characterized in that the movable pulley combined unit (18) is assembled on a door leaf upper cross beam (2) and a door leaf lower cross beam (3); the upper rail (19) is mounted above the door leaf (6); and the stop blocks (20) are mounted on the upper rail (19) and the lower rail (20).

Owner:许姜德

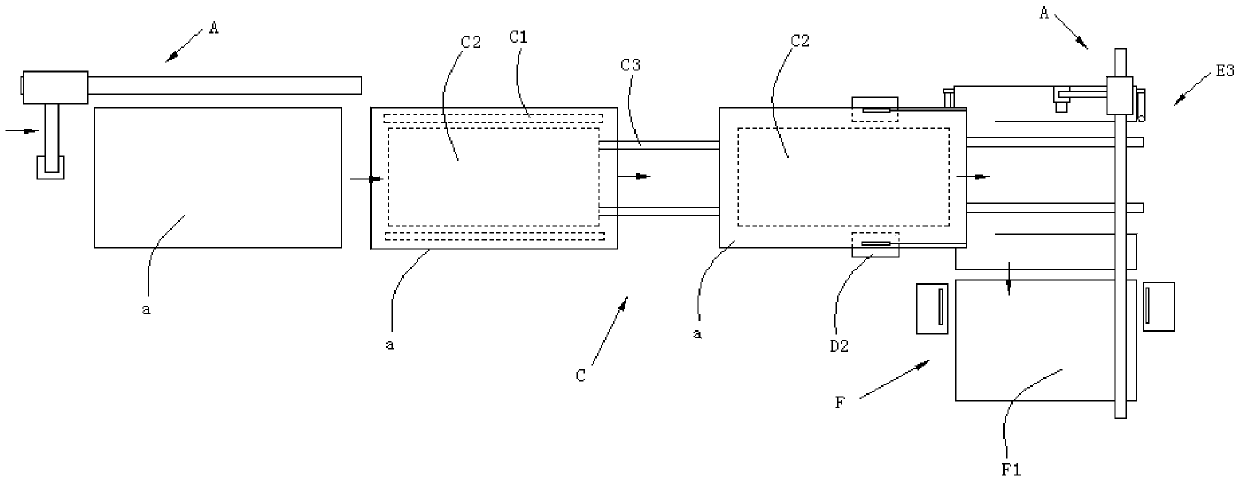

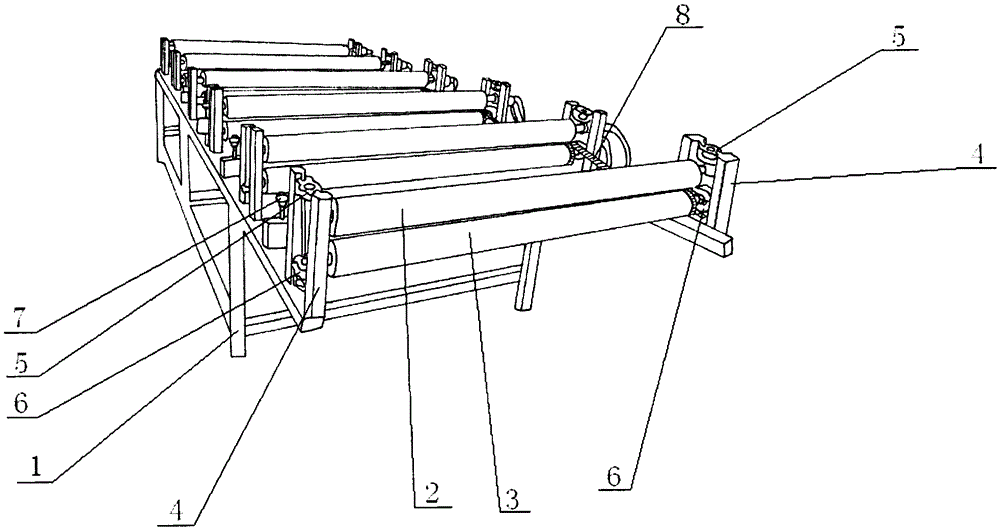

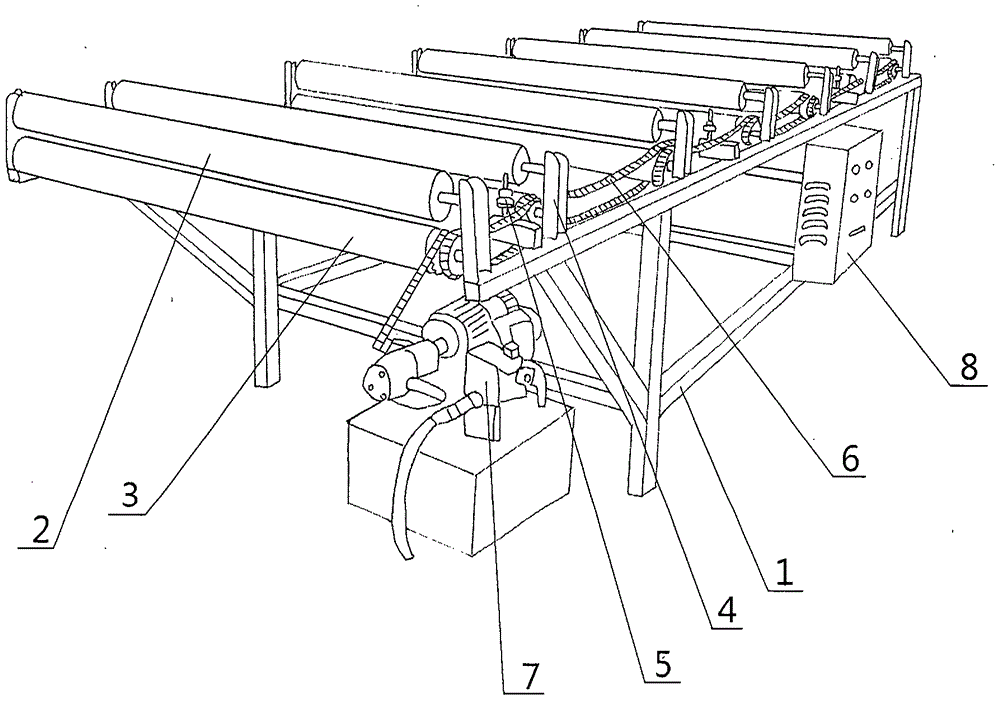

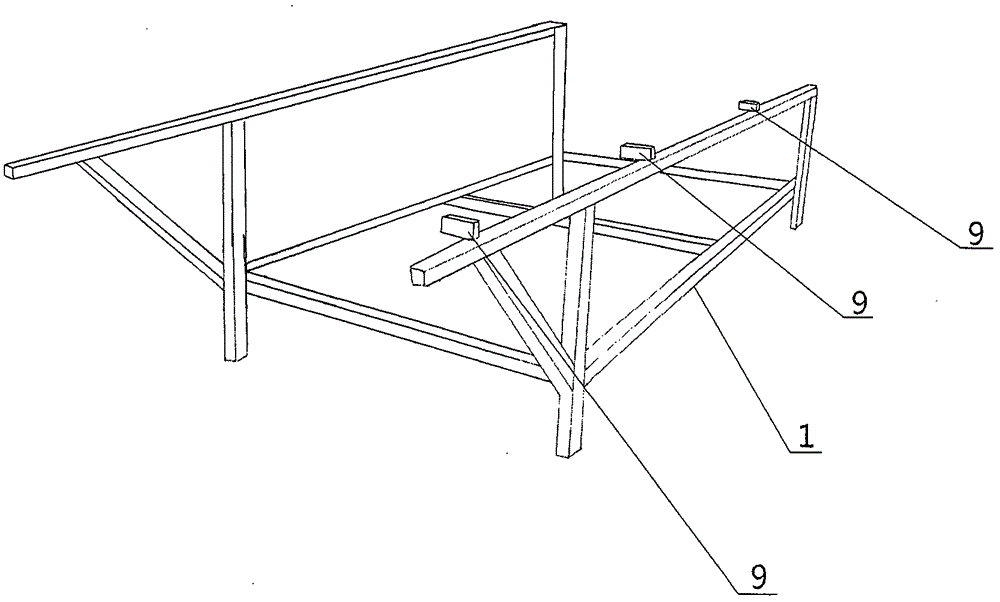

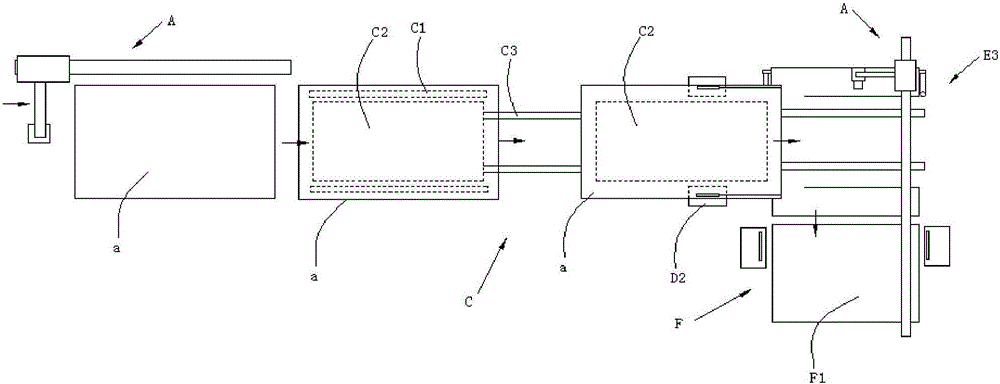

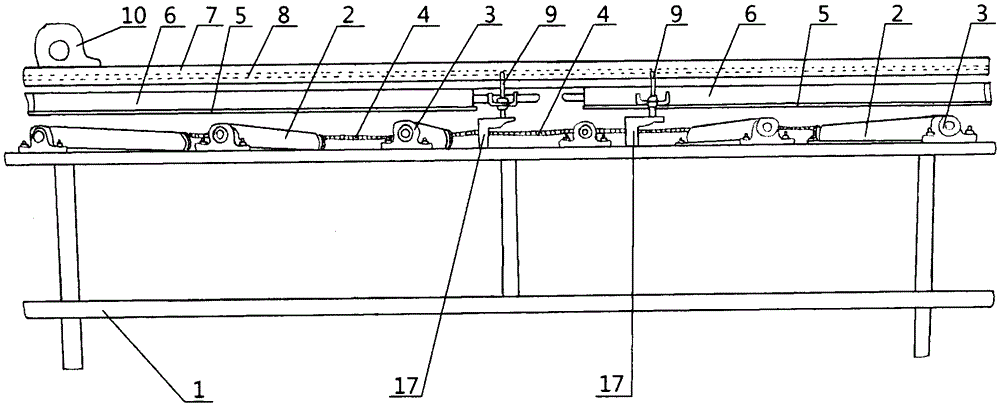

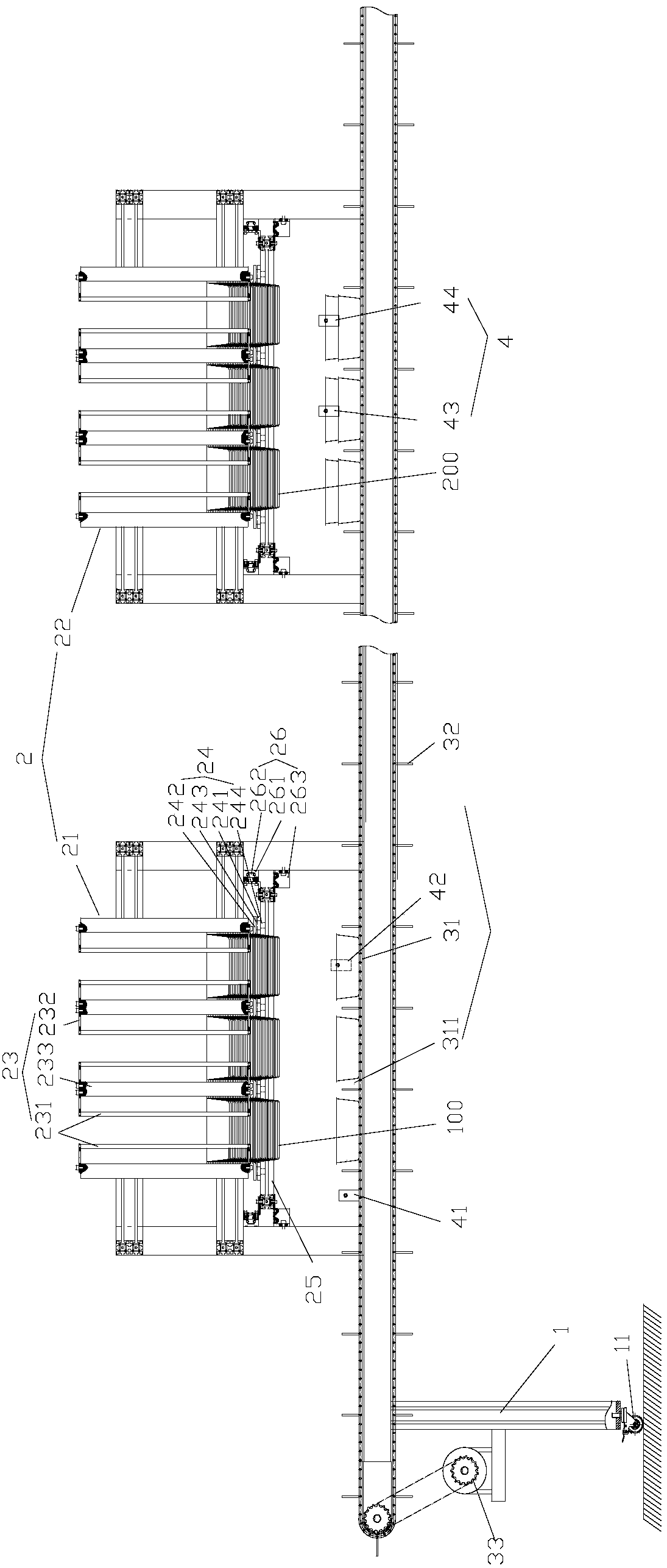

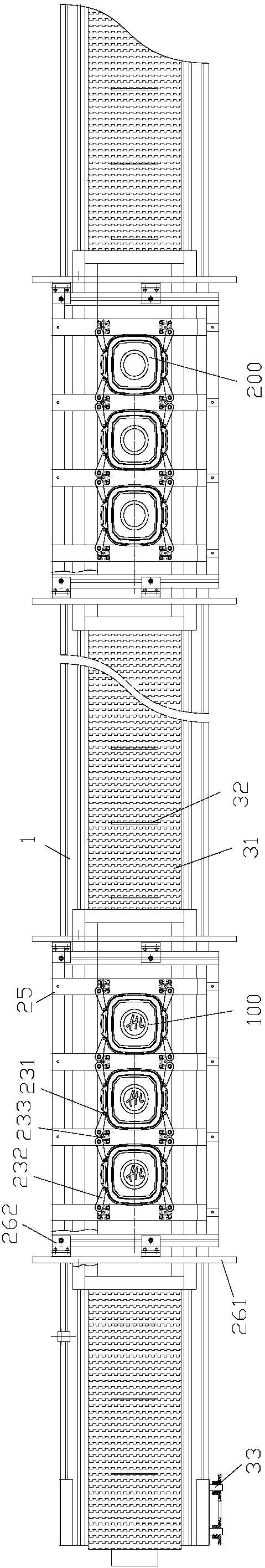

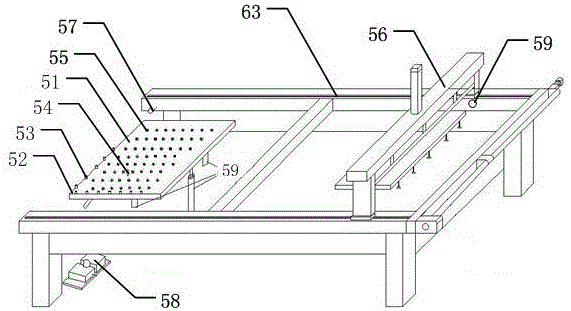

Integrated device capable of achieving rolling, heating, drying, positioning and leveling sizing synchronously during plate conveying

ActiveCN105583920AScientific and reasonable structureObvious effectOther plywood/veneer working apparatusWood veneer joiningEngineeringIntegrated devices

The invention discloses an integrated device capable of achieving rolling, heating, drying, positioning and leveling sizing synchronously during plate conveying. The integrated device is composed of a frame body, heating, pressurizing and leveling rollers, heating and conveying rollers, roller fixing groove frames, sliding bearing bases, fixed bearing bases, plate positioning idler wheels and chains. By means of the integrated device, heated liquid cyclically enters and exits from the heating, pressurizing and leveling rollers and the heating and conveying rollers, so that it is ensured that enough heat energy can be used for heating the two faces of a plate. The heating, pressurizing and leveling rollers can vertically fluctuate freely and automatically, so that it is ensured that the heating, pressurizing and leveling rollers and the heating and conveying rollers are attached to and roll the compound plate all the time, and rolling is even. The operation direction of the integrated plate is maintained in the operation process through the plate positioning idler wheels, so that it is ensured that the integrated plate is operated stably and does not deviate. By means of the integrated device, production can be conducted in dry or moist climate environmental conditions, the plate can be fed, dried and manufactured into a finished product meeting the quality requirement only within 40 minutes or so, the production period is short, and the dryness and humidity of the plate are easy to control.

Owner:GUANGXI NANNING QIAOSHENG WOOD

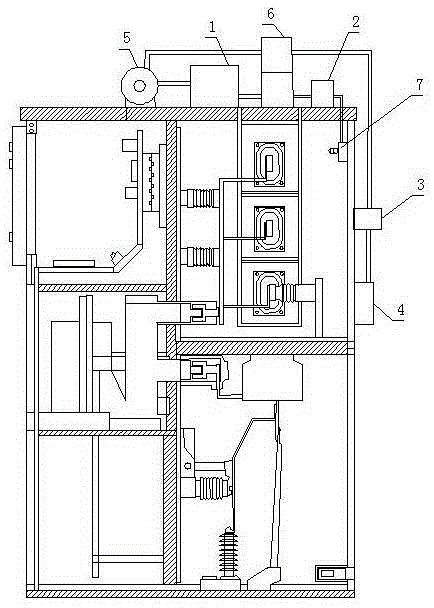

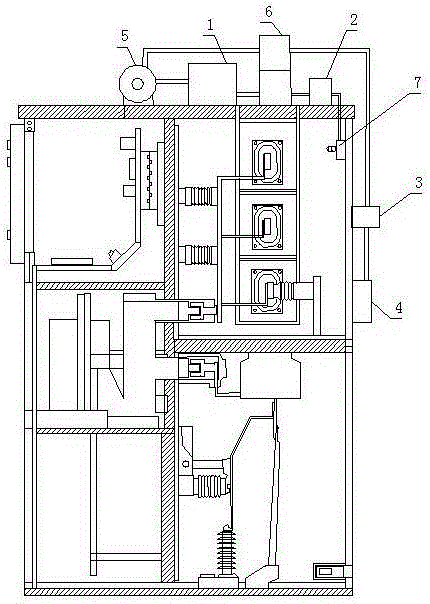

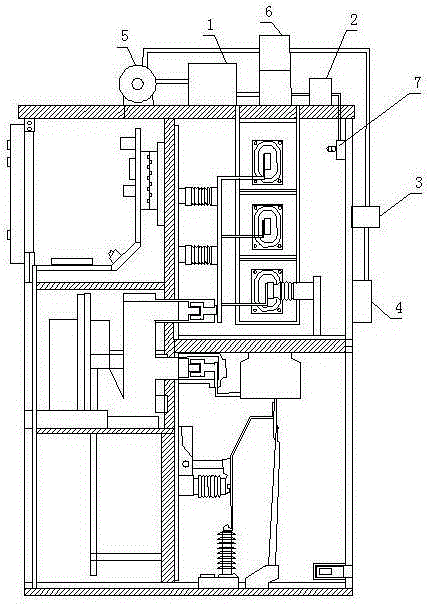

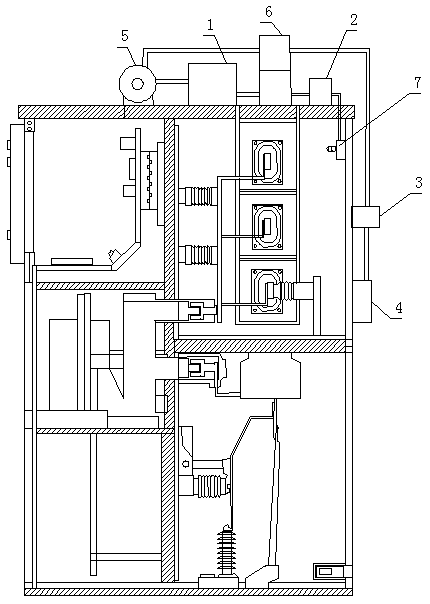

Dedusting 10 kv switch cabinet

ActiveCN105161991ASimple structureEasy to useSubstation/switching arrangement casingsCleaning using gasesControl systemDust control

The invention relates to a dedusting 10 kv switch cabinet. The switch cabinet comprises a cabinet body. The switch cabinet is characterized in that the cabinet body is provided with a dedusting mechanism. The switch cabinet is simple in structure, convenient to use, convenient to popularize, applicable to all cabinet inner cavity structures of various kinds of switch cabinets and good in dedusting effect. A control system of the dedusting mechanism is reasonable in matching, tacit in cooperation, unified in control and capable of uniformly and cooperatively completing dedusting, spraying, cleaning and gas exhausting. Air more suitable for dedusting is provided by a cleaning method, a supercharging method and a spraying method enable dedusting air to form air flows, a better deducting effect is achieved, and dust absorbed to parts is removed. The dedusting mechanism is suitable for live-line dedusting of the cabinet switch, and the switching frequency caused by dedusting is lowered, so that the service lifetime of the switch cabinet is prolonged, and dust is prevented from accumulating in the cabinet and further reducing the insulating property or influencing normal work of elements.

Owner:浙江精鼎电力设备有限公司

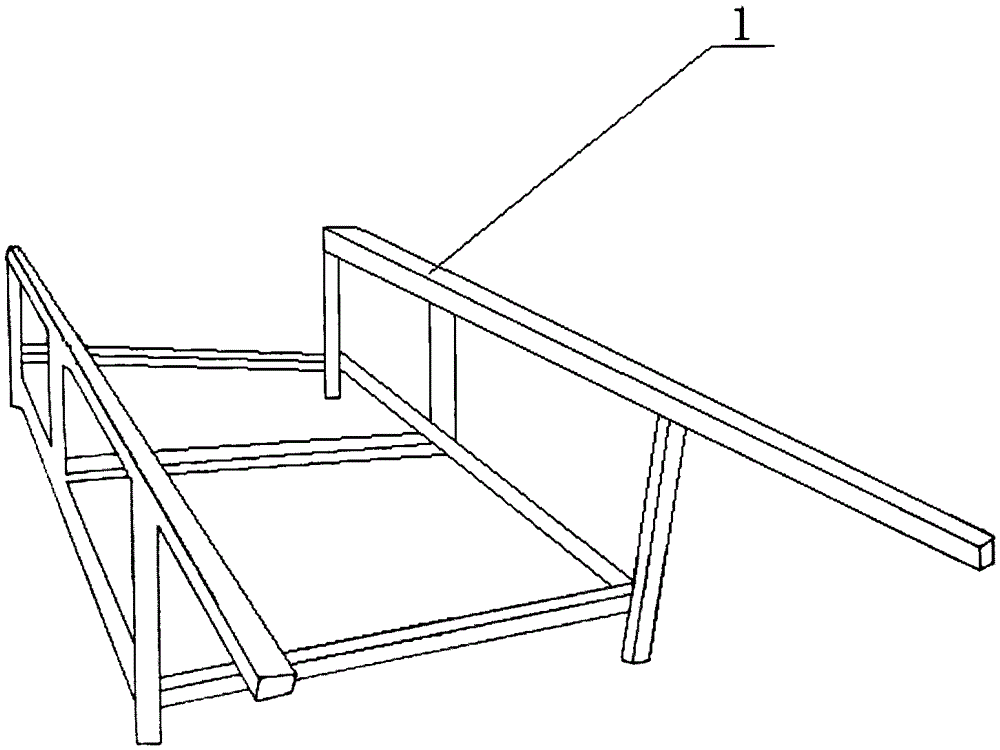

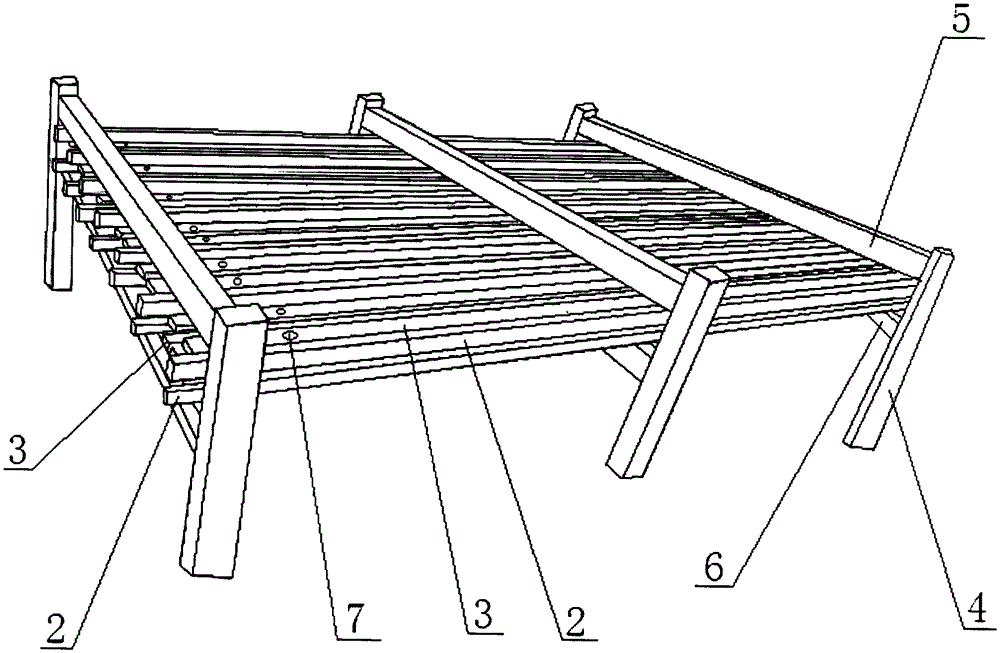

Board conveying and shaping device

InactiveCN105690505ATacit cooperationStructural composition is scientific and reasonableWood veneer joiningEngineeringBinding force

A board conveying and shaping device consists of a rack body, pressure shaping rollers, conveying rollers, roller fixing groove racks, board positioning rollers, chains, a motor group and a power supply box. According to the board conveying and shaping device disclosed by the invention, the pressure shaping rollers can optionally fluctuate vertically to enable the pressure shaping rollers and the conveying rollers to press integrated boards, so that the integrated boards can be evenly rolled; a moving direction of each putty-applied integrated board is maintained by the plate positioning rollers in a moving process so as to enable the integrated board to stably move without deviation; meanwhile, the boards are combined firmly and secondary shaping is performed on the boards, so that quality of the boards is greatly increased, and an internal binding force between the boards is increased; and as the putty-applied integrated boards are dried to be shaped once rather than being aired, not only are time and labor saved but also a production cycle is shortened, and a production spot is saved. The board conveying and shaping device disclosed by the invention is simple in structure but high in automation degree and has a remarkable effect, is capable of greatly increasing working efficiency, replacing manual operation with mechanized operation and reducing working labor, and is very worthy of being popularized widely.

Owner:GUANGXI NANNING QIAOSHENG WOOD

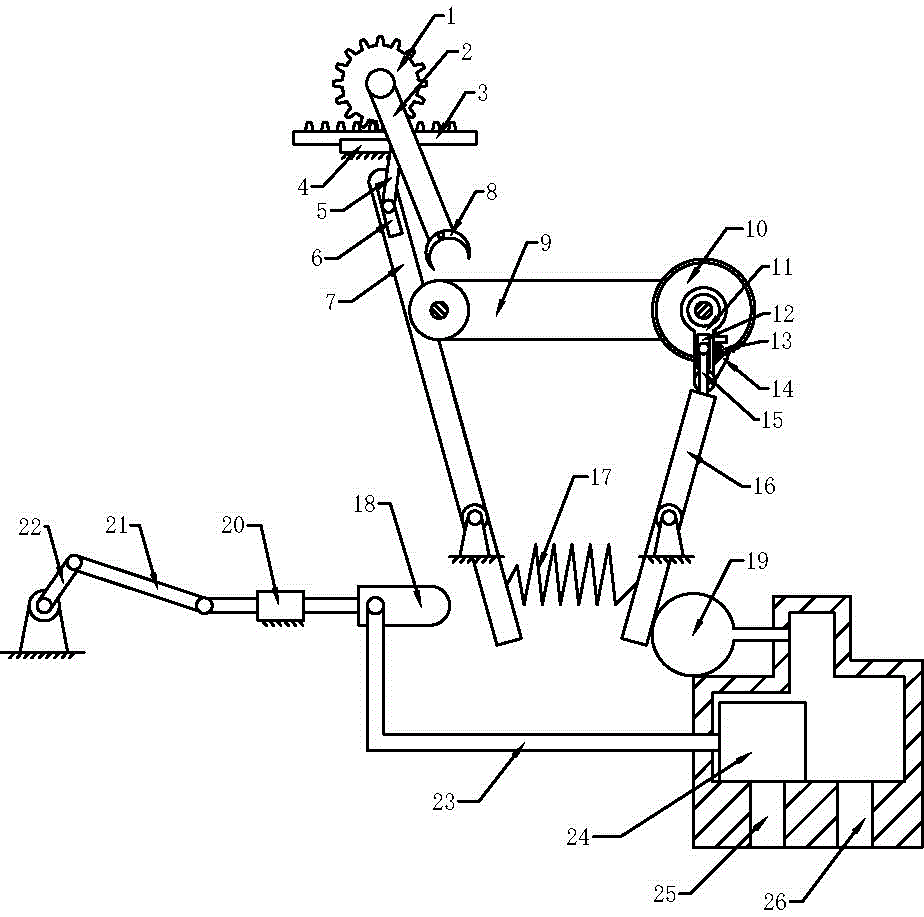

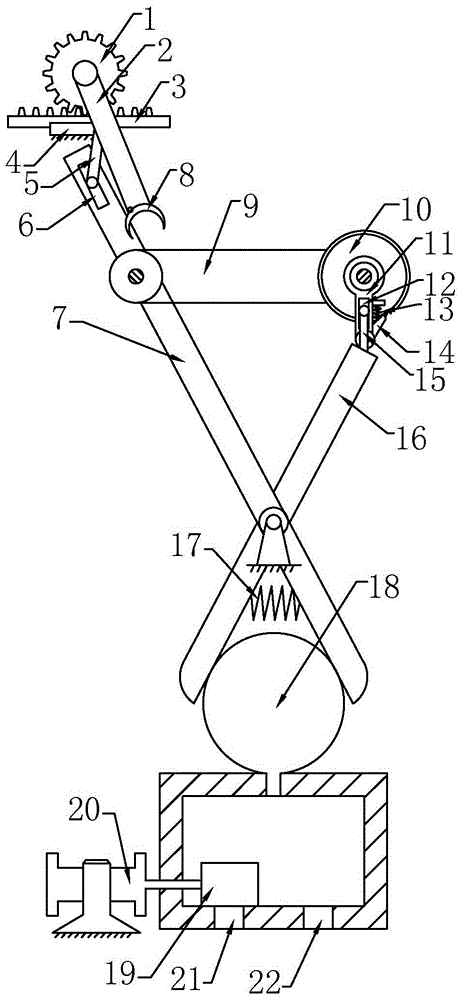

Material-gripping device for paint transportation

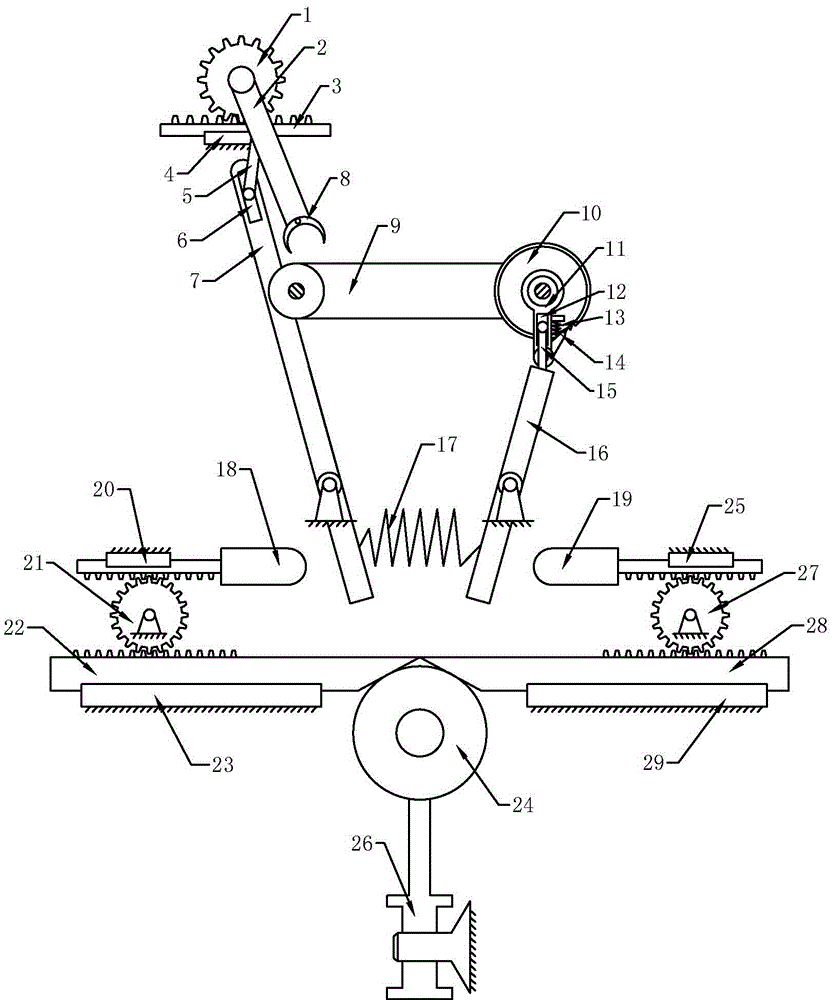

InactiveCN105540248AIncrease or decrease in sizeReduce volumeConveyorsConveyor partsConveyor beltFixed Slide

The invention discloses a material-gripping device for paint transportation. The material-gripping device for paint transportation comprises a conveyor belt and a gripping jaw. A ratchet is connected to the conveyor belt. A first swinging rod is arranged below the ratchet. A rotating rod is arranged on the first swinging rod. The first swinging rod is connected to the rotating rod in a sliding mode. A pawl is hinged to the rotating rod. A first elastic piece is connected to the pawl. A second swinging rod is arranged on the left side of the first swinging rod. A second elastic piece is arranged between the first swinging rod and the second swinging rod. A fixed sliding groove is formed above the second swinging rod and internally provided with a rack. A pulling rod is hinged to the rack and connected to the second swinging rod in a sliding mode. The rack is engaged with a gear. The gripping jaw is connected to the gear. A cavity is formed in the right side of the first swinging rod. The upper portion of the cavity communicates with an air bag. A stopping block is connected to the bottom of the cavity in a sliding mode. A pushing block is arranged on the left side of the second swinging rod. A linkage rod is hinged to the pushing block. A crank is hinged to the linkage rod. A pushing rod is connected to the pushing block and connected with the stopping block. According to the material-gripping device for paint transportation, the structure is simplified due to air cylinder control and the connected structure, so that the matching difficulty is reduced.

Owner:CHONGQING HENGO SCHILLER DECORATION ENG CO LTD

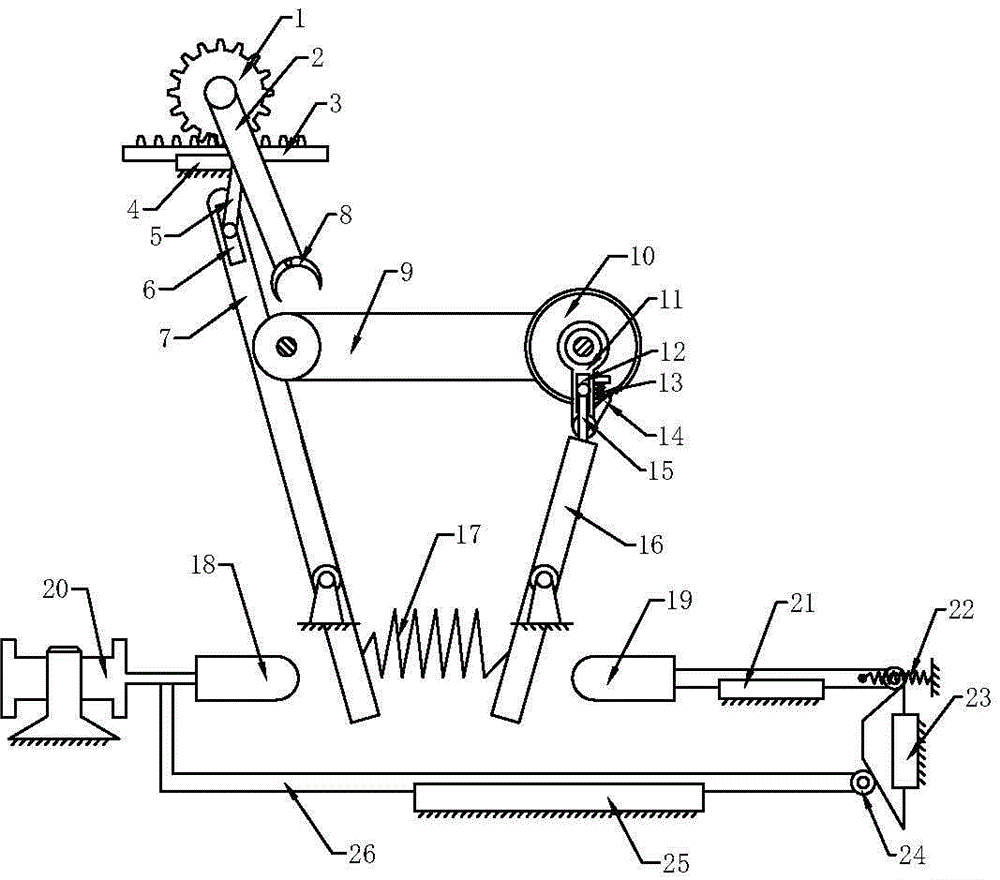

Conveying and grabbing integrated device for paint

PendingCN105417012AEasy to SynchronizeSimple structureConveyorsConveyor partsEngineeringIntegrated devices

The invention discloses a conveying and grabbing integrated device for paint. The conveying and grabbing integrated device comprises a conveying belt and a gripper arm. A ratchet wheel is connected to the conveying belt. A first swing rod is arranged below the ratchet wheel and provided with a rotary rod. The first swing rod is in sliding connection with the rotary rod, and the rotary rod is hinged to a pawl. The pawl is connected with a first elastic piece. A second swing rod is arranged at the left side of the first swing rod, and a second elastic piece is arranged between the two swing rods. A fixed sliding groove is formed above the second swing rod. A rack is arranged in the fixed sliding groove. A pull rod is hinged to the rack. The pull rod is in sliding connection with the second swing rod. The rack is meshed with a gear. The gripper arm is connected to the gear. A first push block is arranged at the right side of the first swing rod. A second push block is arranged at the left side of the second swing rod. The second push block is connected with an air cylinder and a push rod. Rolling wheels are arranged at the right end of the push rod and the right end of the first push block, the two rolling wheels abut against the same wedge block, and the first push block is connected with a third elastic piece. According to the device, by means of air cylinder control and the arrangement of a connected structure, the structure is simplified, and coordinating difficulty is lowered.

Owner:CHONGQING HENGO SCHILLER DECORATION ENG CO LTD

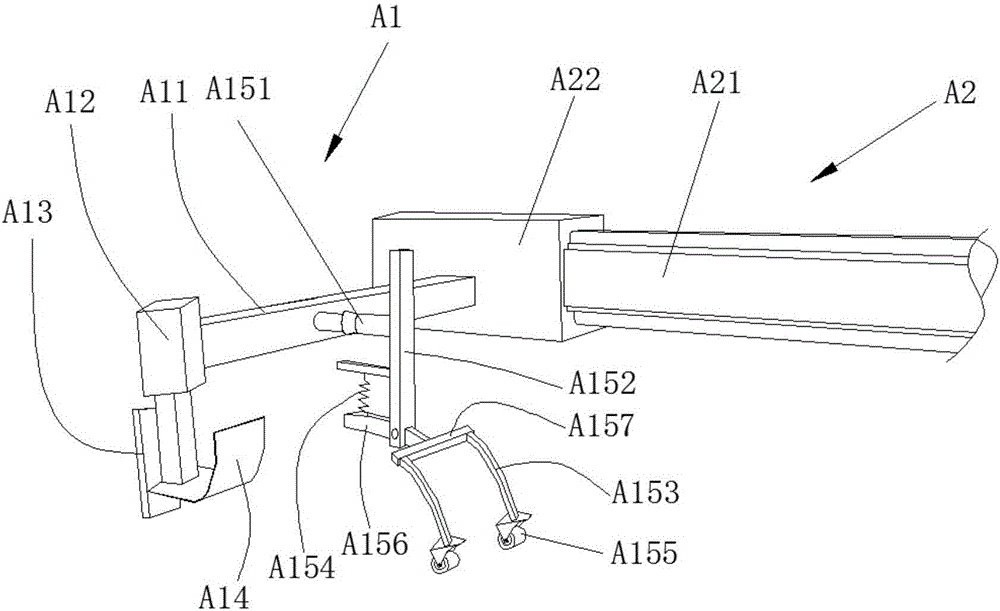

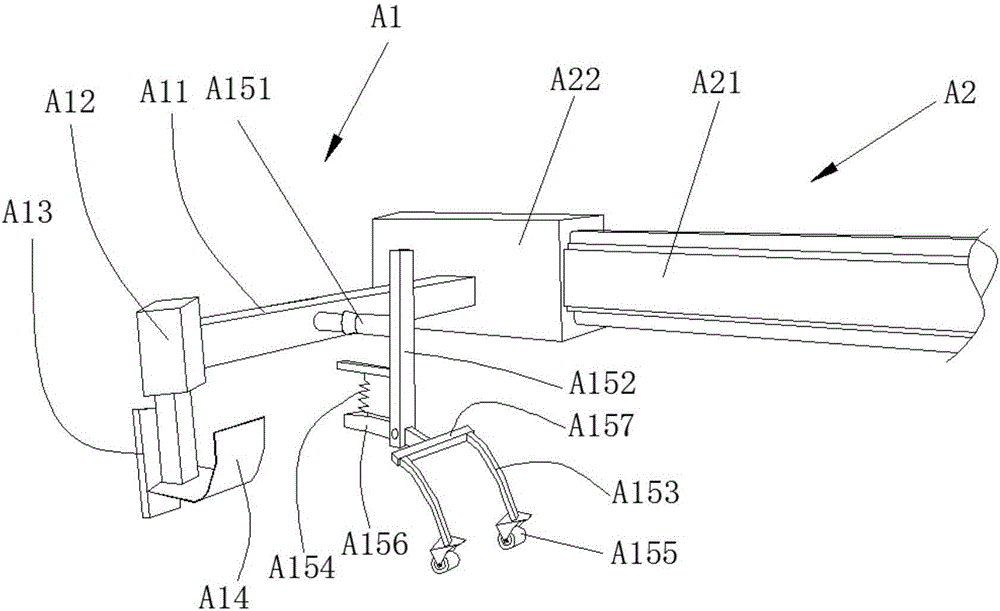

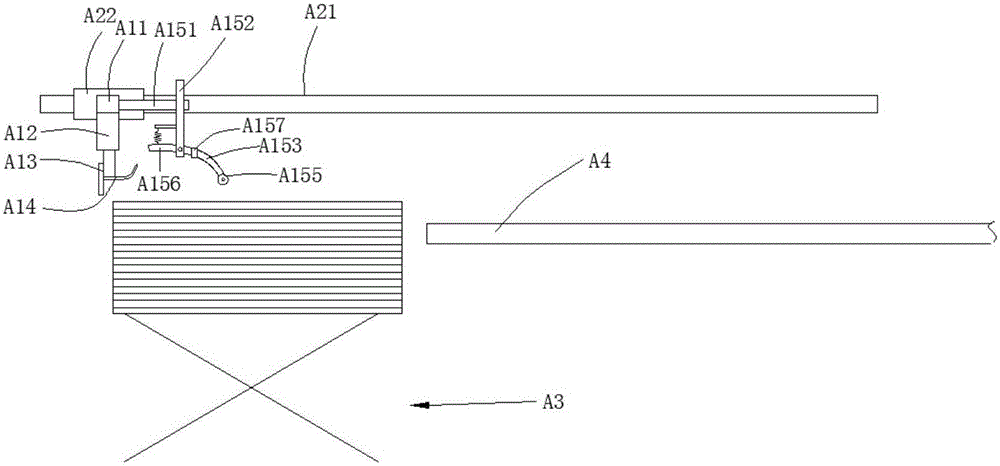

Edge sawing machine capable of conducting automatic feeding and turning

InactiveCN105773376ASimple structureTacit cooperationGrinding drivesGrinding machinesMechanical engineeringEngineering

The invention provides an edge sawing machine capable of conducting automatic feeding and turning. The edge sawing machine comprises a feeding device and a turning device. A panel sequentially passes through the feeding device and the turning device. The feeding device comprises a panel pushing mechanism and a guide mechanism. The panel pushing mechanism is fixed to the guide mechanism and can advance and retreat along the guide mechanism. The turning mechanism comprises a conveying device and a panel pushing device. The conveying device receives the panel conveyed in the long edge direction of the panel. The panel pushing device pushes the panel to the next procedure in the width direction of the panel. The panel pushing device is located above the conveying device. An included angle of 90 degrees exists between the running paths of the conveying device and the panel pushing device. Compared with the prior art, the edge sawing machine is simple in structure and smooth in panel feeding, all links are in close fit, the previous link starts to prepare the next working task when the next link works, connection is tight, and the work efficiency is high.

Owner:ANHUI ANSU WORLD HOME CO LTD

Oil paint material grabbing and conveying integrated device

InactiveCN105417154AEasy to SynchronizeSimple structureConveyorsConveyor partsIntegrated devicesFixed Slide

The invention discloses an oil paint material grabbing and conveying integrated device which comprises a conveyor belt and a gripper arm. A ratchet wheel is connected to the conveyor belt. A first swing rod is arranged below the ratchet wheel and provided with a rotating rod. The first swing rod is connected to the rotating rod in a sliding manner. A pawl is hinged to the rotating rod and connected with a first elastic piece. A second swing rod is arranged on the left side of the first swing rod. A second elastic piece is arranged between the two swing rods. A fixed slide groove is formed above the second swing rod and internally provided with a rack. A pull rod is hinged to the rack and connected to the second swing rod in a sliding manner. The rack is meshed with a gear. The gripper arm is connected to the gear. A first push block is arranged on the right side of the first swing rod. A second push block is arranged on the left side of the second swing rod. An air cylinder and the push rod are connected to the second push block. A linkage gear is meshed with the push rod and is meshed with the first push block. By means of control of the air cylinder and the arrangement of the connected structure, the structure is simplified, and the matching difficulty is lowered.

Owner:CHONGQING HENGO SCHILLER DECORATION ENG CO LTD

System capable of conducting heating and drying simultaneously during board conveying

ActiveCN105627712ATacit cooperationScientific and reasonable structureDrying gas arrangementsDrying machines with progressive movementsEngineeringAir blower

The invention discloses a system capable of conducting heating and drying simultaneously during board conveying. The system is composed of a frame body, conveying and heating double-function rollers, bearing seats, chains, board circulating guide plates, radiators, a heat-insulating wind resistant hood, a wind resisting and gas uniformizing row-hole metal net, fasteners and an air blower. By using the system, heat-carrying liquid circulates in the conveying and heating double-function rollers, the radiators are continuously provided with hot gas through a heating device, so that both sides of a laminated board can be evenly heated, the board drying speed is high, and plaster smeared on the board face does no adhere to equipment after being heated. Production can be conducted under a dry or humid climatic environment condition, and the process that the board is fed and dried and a finished product with the humidity meeting the quality requirement is obtained only takes about 40 minutes, so that the production cycle is short, the humidity of the board is easy to control, and the board quality is good. By the adoption of the system, the board is dried and formed at a time without airing, so that time and effort are saved, the production cycle is shortened, and a small production spot is occupied.

Owner:GUANGXI NANNING QIAOSHENG WOOD

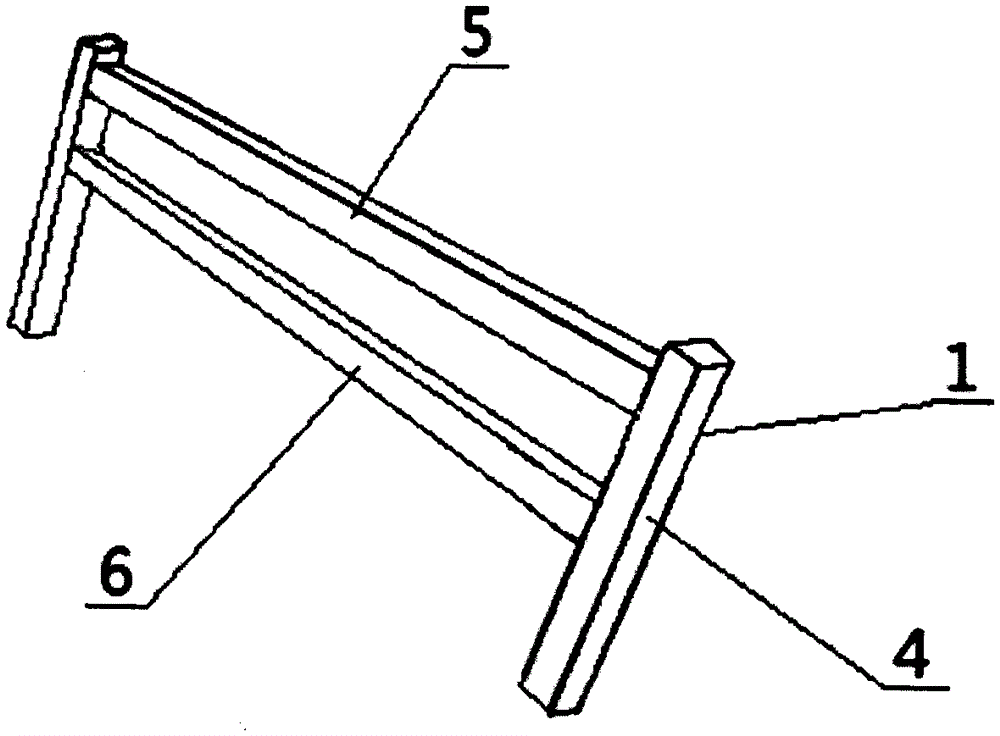

Splicing and drying integration device for integrated boards

InactiveCN105397878AScientific and reasonable structureObvious effectWood veneer joiningHeating arrangementFixed frameMachining process

A splicing and drying integration device for integrated boards is composed of frame bodies, board limiting pipe frames and heat supply pipelines. The board limiting pipe frames are fixed to upper fixing frames and lower fixing frames of the three frame bodies correspondingly, the heat supply pipelines are arranged among the upper fixing frames of the frame bodies, the lower fixing frames of the frame bodies and the board limiting pipe frames correspondingly, and therefore the whole device is formed. According to the device, the process of drying the boards or square timber and then splicing the boards or the square timber is eliminated, and drying and splicing are directly and synchronously realized on a machine; the board limiting pipe frames do not serve as heat supply pipelines of heat conduction carriers, and the movable heat supply pipelines without the limiting and forming effect are used for heating, drying and forming the boards side by side; when the board splicing machine splices the boards and carries out feeding, because the board limiting pipe frames are insusceptible to heat expansion and cold shrinkage and do not deform, the boards are insusceptible to the board limiting pipe frames and do not warp or deform accordingly; the number of the subsequent machining processes of the prepared boards is small, loss is reduced, and the quality is more stable.

Owner:GUANGXI NANNING QIAOSHENG WOOD

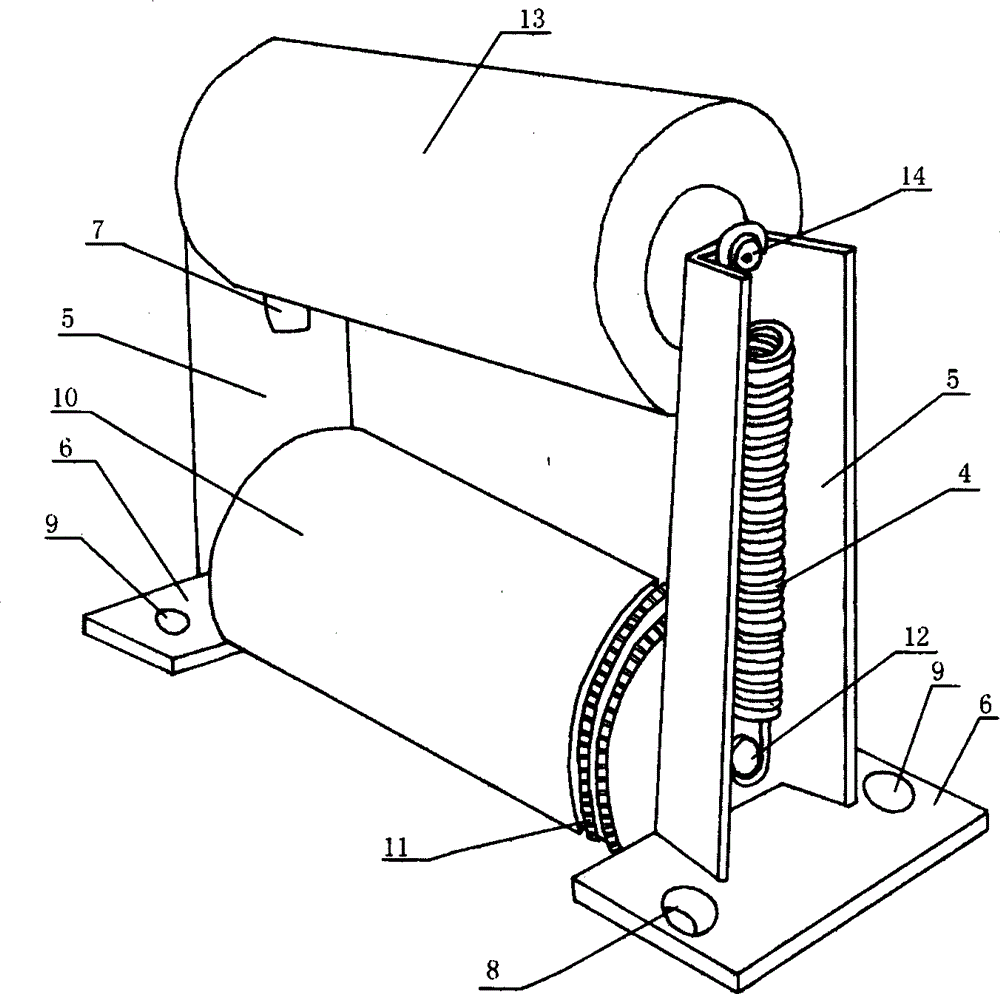

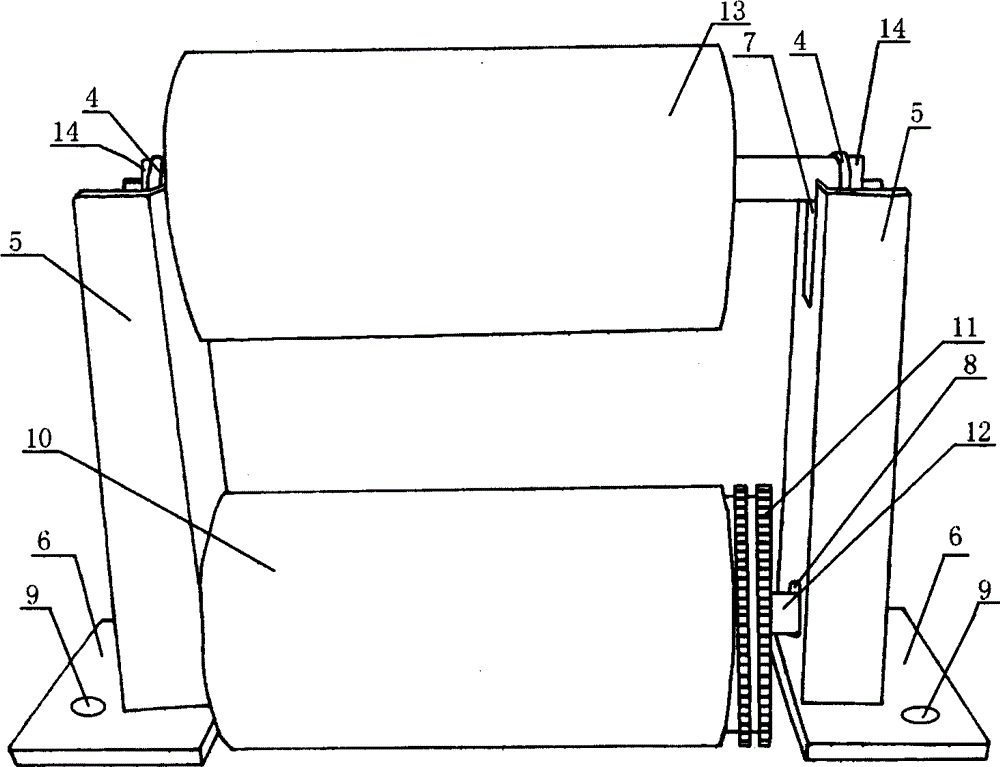

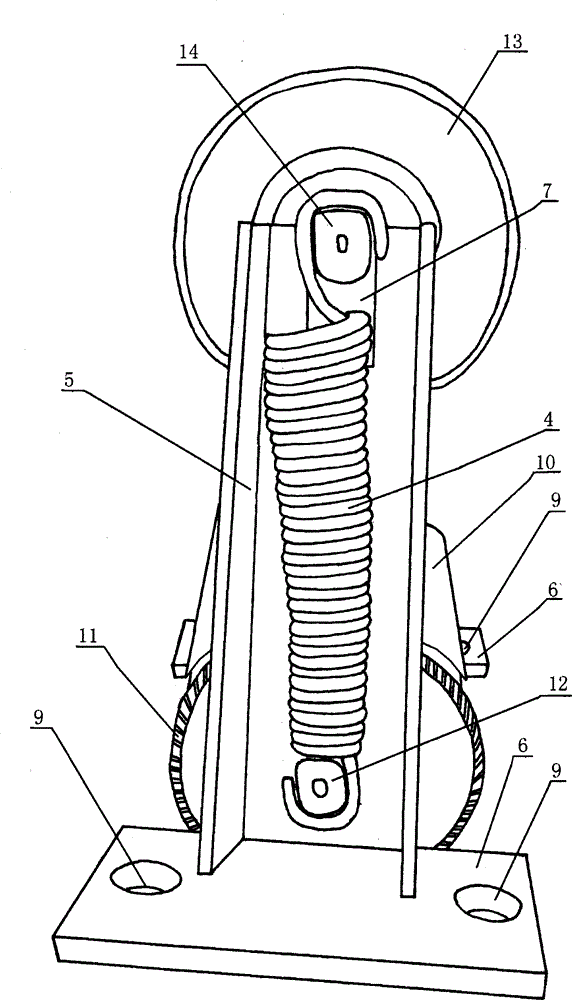

Plate setting roller press

The invention discloses a plate setting roller press, which specifically comprises machine body racks, a primary movable compression roller, a secondary movable compression roller and a spring, wherein the two machine body racks are correspondingly put and fixed on the ground; rotating shafts on two sides of the primary movable compression roller are put into through holes which are formed in the lower parts of rack bodies of the two machine body racks; the rotating shafts on two sides of the secondary movable compression roller are respectively put into elevating shaft passages which are formed in the upper parts of the rack bodies of the two machine body racks; and the spring is used for simultaneously hooking the rotating shafts on two sides of the primary movable compression roller and the secondary movable compression roller respectively above and below the rack bodies, thereby forming an overall plate setting roller press. By virtue of the plate setting roller press, firm combination of cement and plates and secondary setting of the plates are simultaneously realized; the flatness of the plate is improved; and meanwhile, the quality of the plates is greatly improved. The plates do not need to be aired, and are dried and molded once, so that time and labor are saved; the production cycle is shortened; and the production site is saved.

Owner:GUANGXI NANNING QIAOSHENG WOOD

Self-heating hot-pot noodle packaging system

ActiveCN108190140AGuaranteed success rateAdjustable speedPackaging automatic controlEngineeringInductor

The invention provides a self-heating hot-pot noodle packaging system which comprises a rack, two bowl falling machines, a conveying device, four photoelectricity inductors and a controller. The conveying device comprises a conveying belt, and bowl falling parts are arranged on the conveying belt. The two bowl falling machines are arranged on the rack in a spaced mode in the conveying direction ofthe conveying device, the two bowl falling machines are each provided with three discharging openings, and all the discharging openings are located above the bowl falling parts correspondingly. The distance between every two adjacent bowl falling parts is the same as that between every two adjacent discharging openings in the same bowl falling machine. The distance between the two bowl falling machines is an integral multiple of the sum of the distances between the three bowl falling parts. The four photoelectricity inductors are used for detecting the passing number of the bowl falling partsand whether bowl falling exists or not correspondingly to control the bowl falling machines to execute the bowl falling action. The self-heating hot-pot noodle packaging system is ingenious in structural design, tacit in operating cooperation, stable and reliable, the worker deployment is greatly reduced, and the production efficiency is further improved.

Owner:北京东方卓成科技有限公司

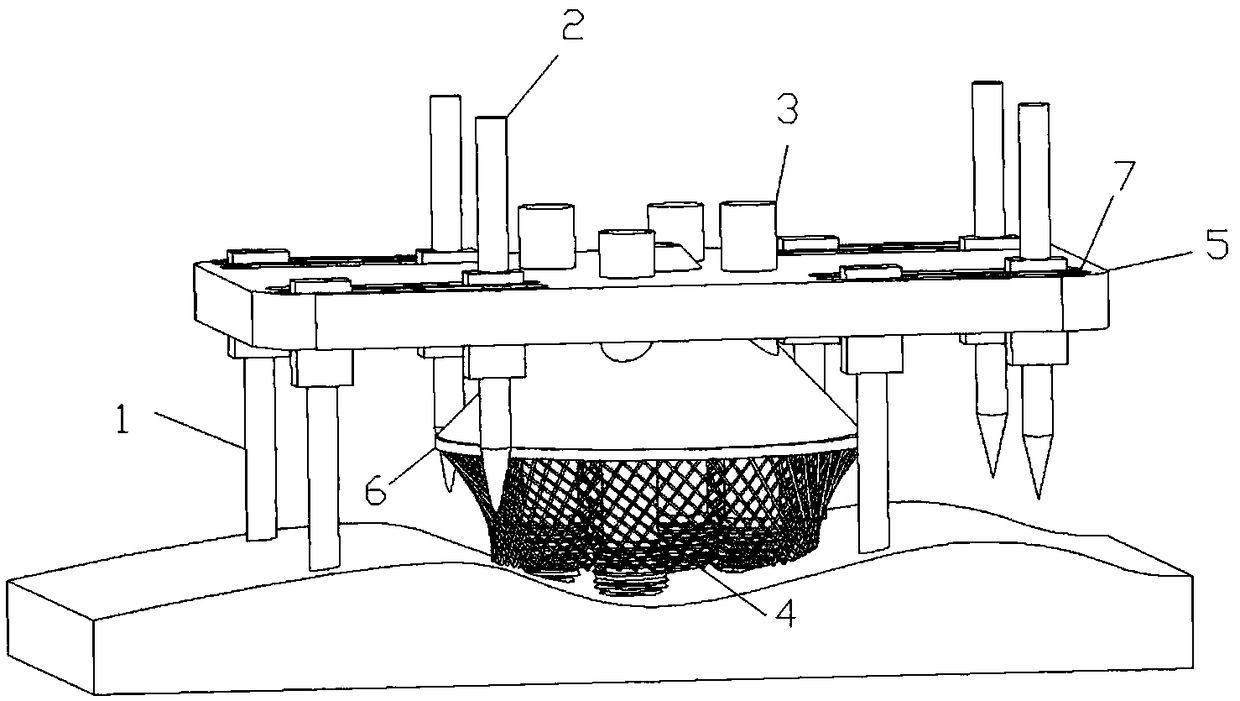

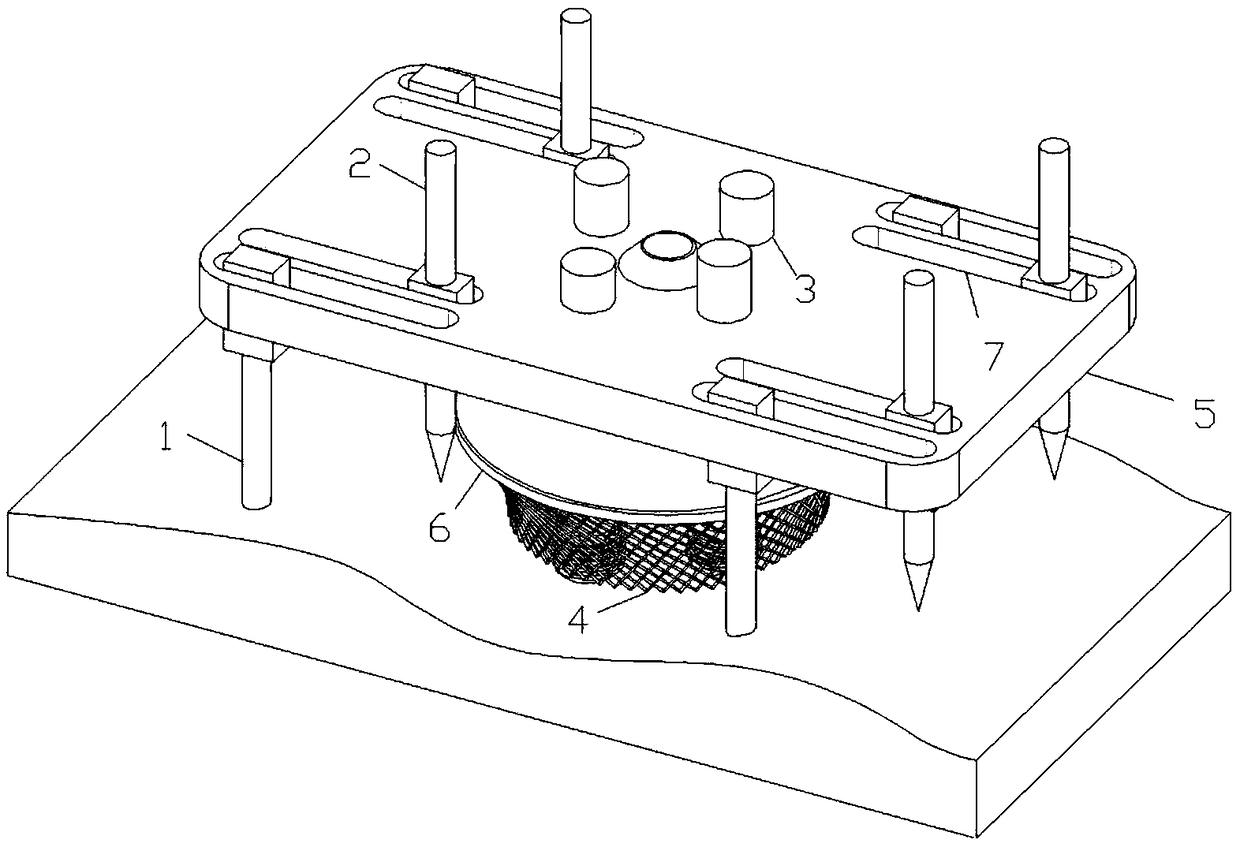

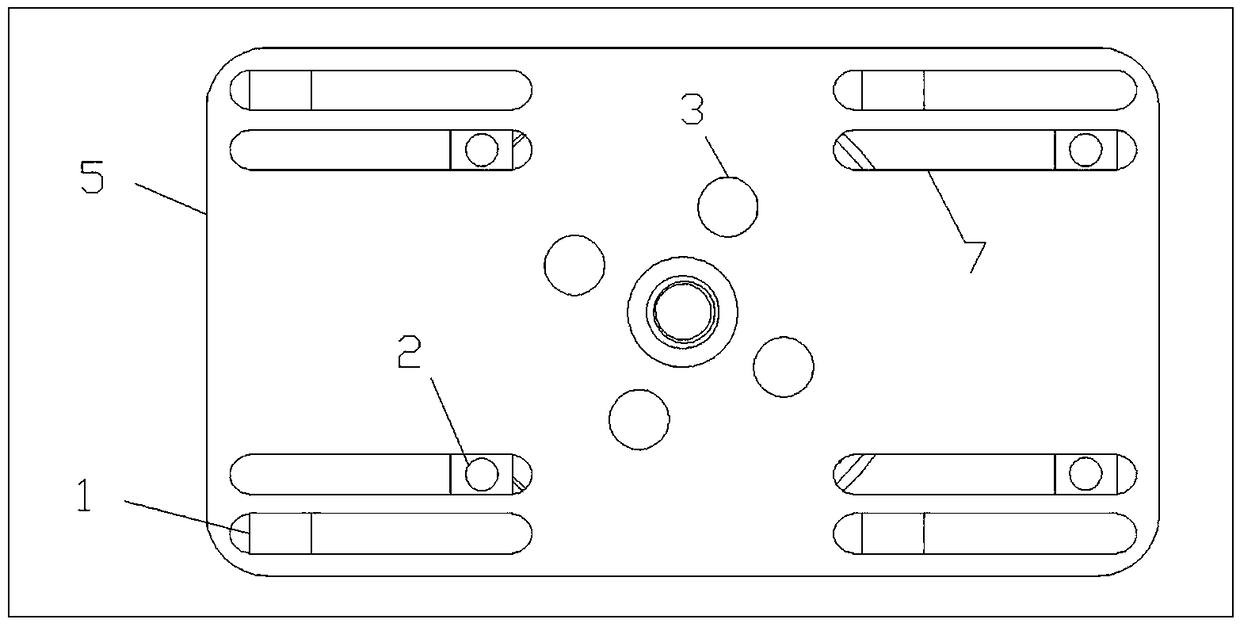

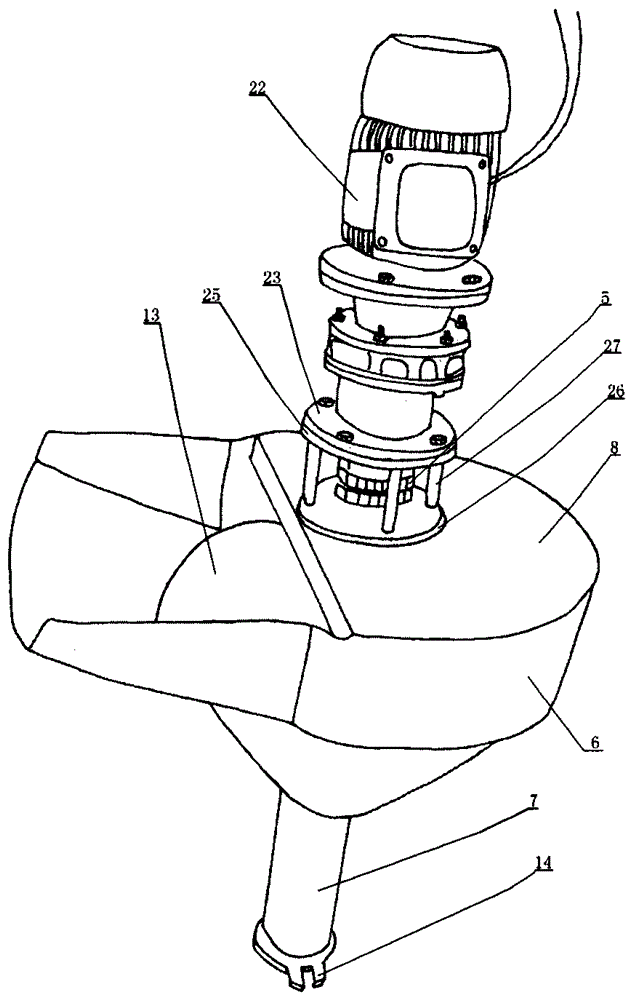

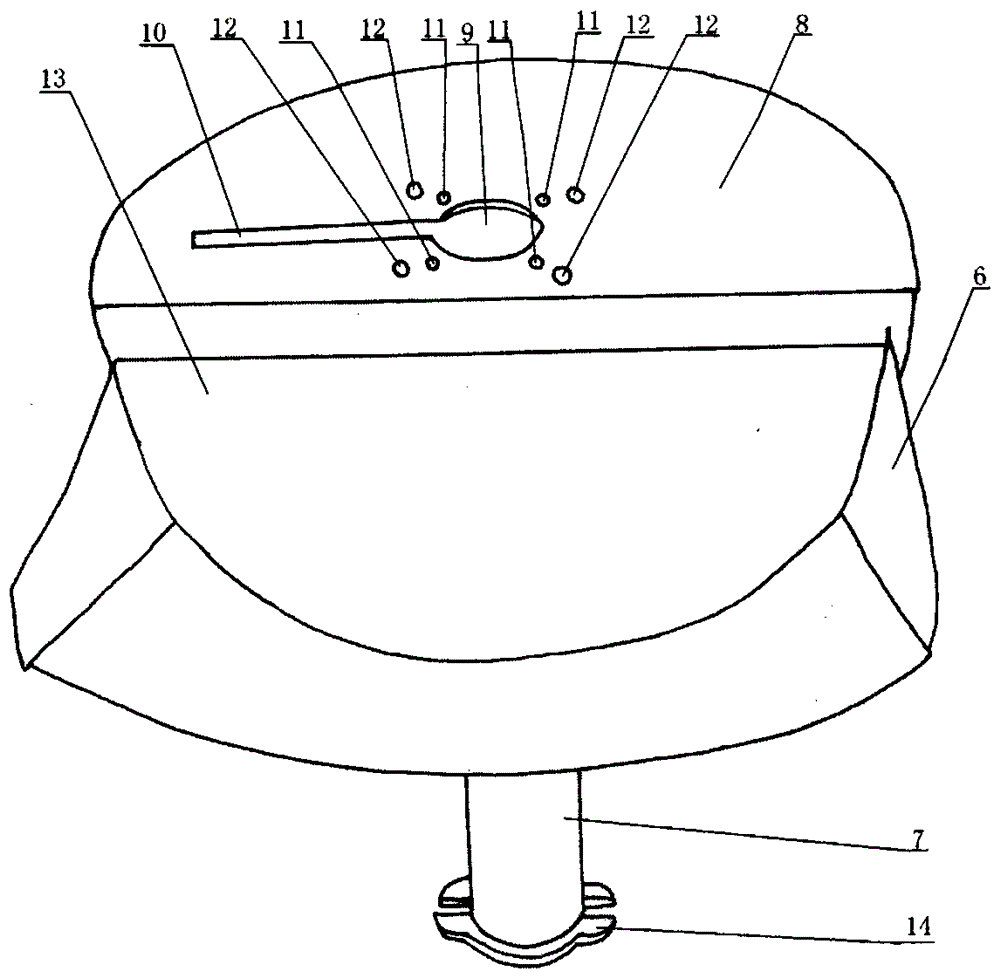

Sampling and cutting seabed intelligent mining vehicle

ActiveCN105863644BSmooth connectionTacit cooperationWithdrawing sample devicesMineral miningOcean bottomEngineering

The invention provides a submarine intelligent mining vehicle for sampling and cutting. The submarine intelligent mining vehicle comprises a mining vehicle working platform provided with a small hole formed in the center, groove-shaped openings formed in four top corners of the mining vehicle working platform, pestle-shaped cutting machines, pile drivers, an annular ore sucking cover downwards inlaid in the small hole, rotatable annular water jet nozzles arranged in the annular edge of the lower end of the ore sucking cover, columnar lifters penetrating through the mining vehicle working platform and the annular ore sucking cover to be inserted into the submarine ground and an ore pulp pump placed in the annular ore sucking cover, wherein the pestle-shaped cutting machines and the pile drivers are placed in the groove-shaped openings, perform longitudinal extension and perform horizontal linear sliding in the groove-shaped openings. The submarine intelligent mining vehicle for sampling and cutting is driven by an undersea high-voltage motor, integrates sampling, cutting, ore collection and other functions and has a series of advantages of being smooth in work matching, safe, reliable, accurate in positioning, intelligent, efficient, capable of saving energy, environmentally friendly and the like.

Owner:SHANGHAI JIAOTONG UNIV

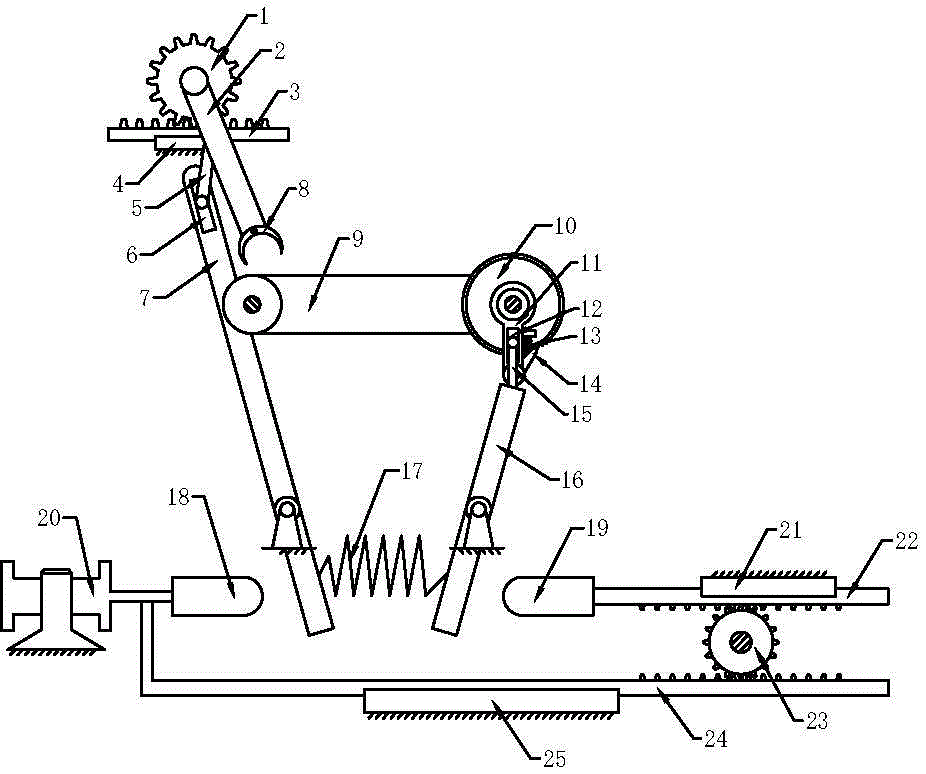

Swing rod crossed type transporting and material grabbing integrated machine

The invention discloses a swing rod crossed type transporting and material grabbing integrated machine which comprises a conveyor belt and a gripper arm. A ratchet wheel is connected to the conveyor belt. A first swing rod and a second swing rod with the bottoms hinged in a crossed manner are arranged below the ratchet wheel. A rotating rod is arranged on the first swing rod. The first swing rod is connected into the rotating rod in a sliding manner. A pawl is hinged to the rotating rod. A first elastic piece is connected to the pawl. A second elastic piece is arranged between the two swing rods. A fixed slide groove is formed above the second swing rod. A rack is arranged in the fixed slide groove. A pull rod is hinged to the rack and connected into the second swing rod in a sliding manner. The rack is meshed with a gear. The gripper arm is connected to the gear. A gas bag is arranged below the portion between the first swing rod and the second swing rod and communicated with a cavity. A gas inlet and a gas outlet are formed in the bottom of the cavity. A stop piece is connected to the bottom of the cavity in a sliding manner. An air cylinder is arranged on the left side of the cavity. The output end of the air cylinder penetrates the wall of the cavity to be connected with the stop piece. By means of control of the air cylinder and the arrangement of the connected structure, the structure is simplified, and the matching difficulty is lowered.

Owner:CHONGQING HENGO SCHILLER DECORATION ENG CO LTD

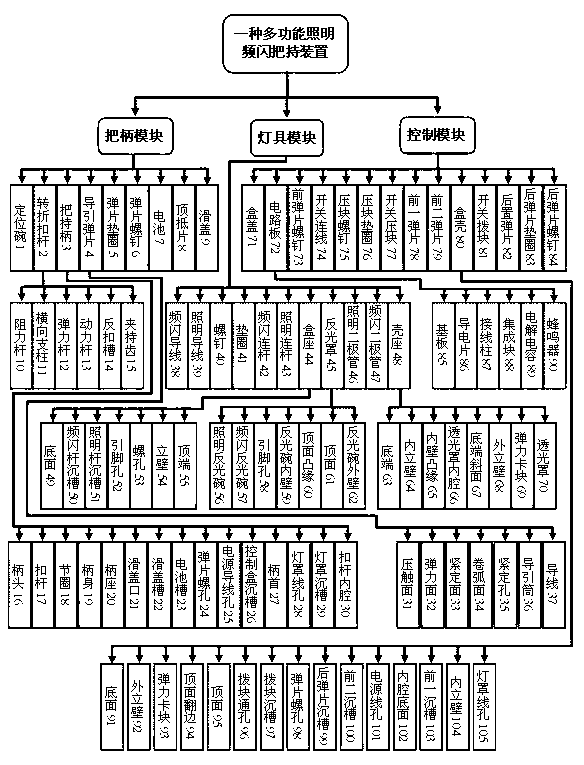

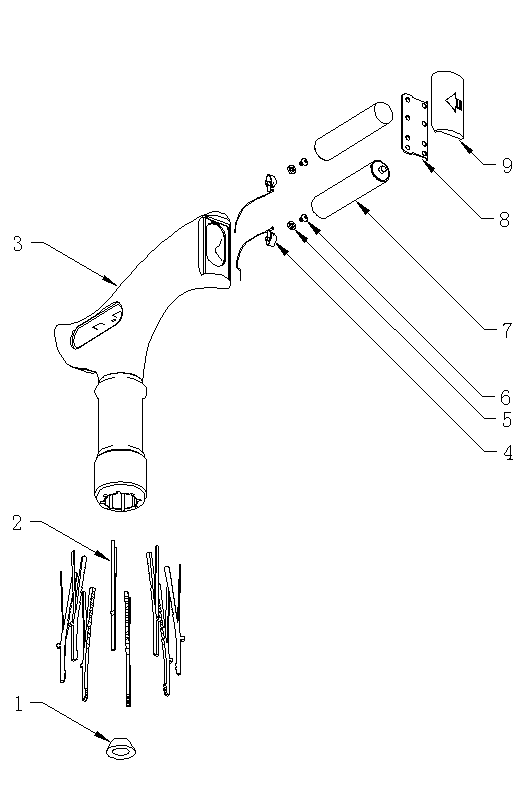

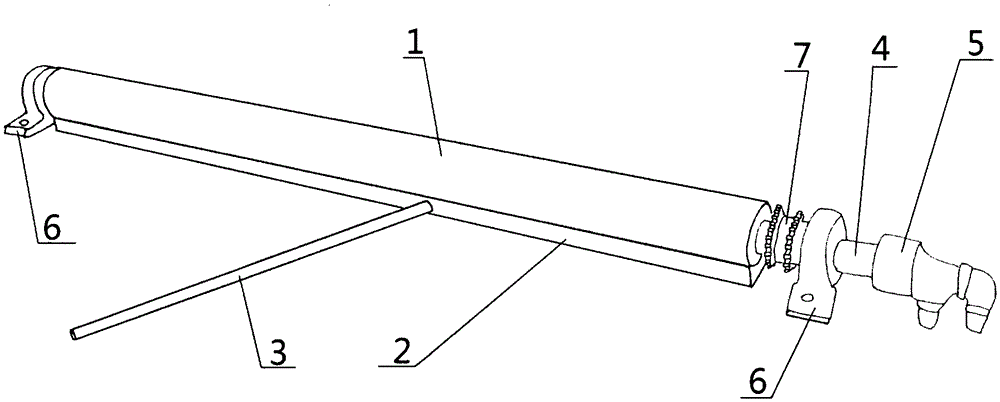

Multifunctional lighting stroboscopic holding device

InactiveCN102840564AEasy to implementEasy to manufactureLighting support devicesElectric circuit arrangementsEffect lightEngineering

The invention relates to a handholding device, in particular to a multifunctional lighting stroboscopic holding device which is suitable for connecting rods of various specifications and has the functions of lighting and calling. The multifunctional lighting stroboscopic holding device consists of three modules which are respectively a handle, a light and a control module. The multifunctional lighting stroboscopic holding device comprises thirty-four parts such as a positioning bowel, a turning buckling rod, a holding handle, a guide spring sheet, a spring sheet gasket, a propping cushion sheet, a sliding cover, a stroboscopic lead, a stroboscopic connecting rod, a lighting connecting rod, a box seat, a reflecting cover, a housing seat, a lighting diode, a stroboscopic diode, a box cover,a press block bolt, a press block gasket, a switch press block, a first front spring sheet, a second front spring sheet, a box housing, a switch shifting block, a rear spring sheet, a rear spring sheet gasket, a rear spring sheet bolt and a circuit board. The holding device has the characteristics that the holding device is convenient to install, is suitable for various proximate matters and various apertures, has the functions of lighting and calling, is convenience to use, and is firm and durable; therefore, the holding device has a wide market space, and relatively high social application value and economic additional value.

Owner:钟婕

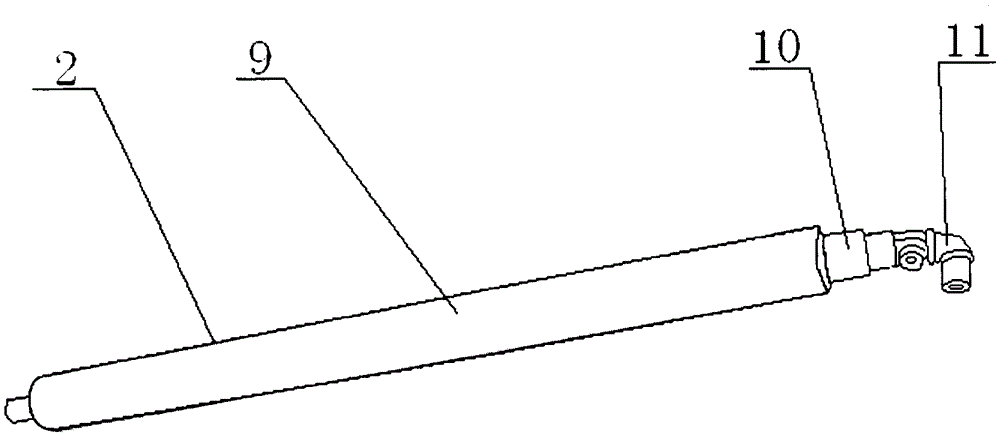

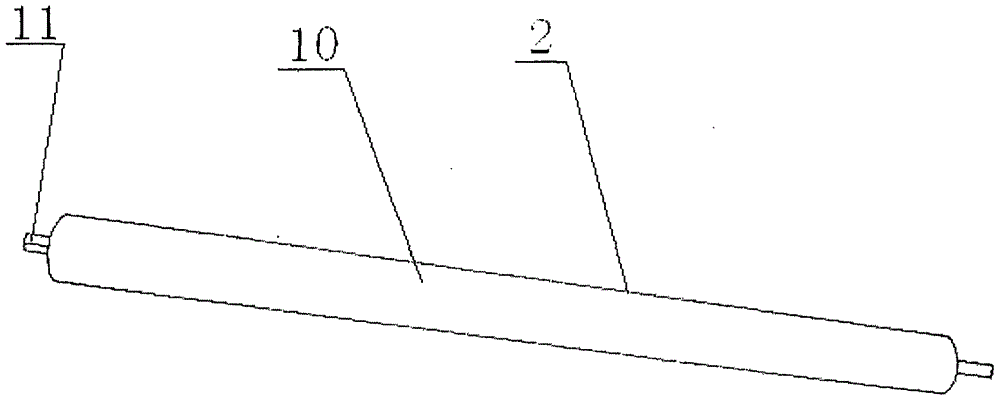

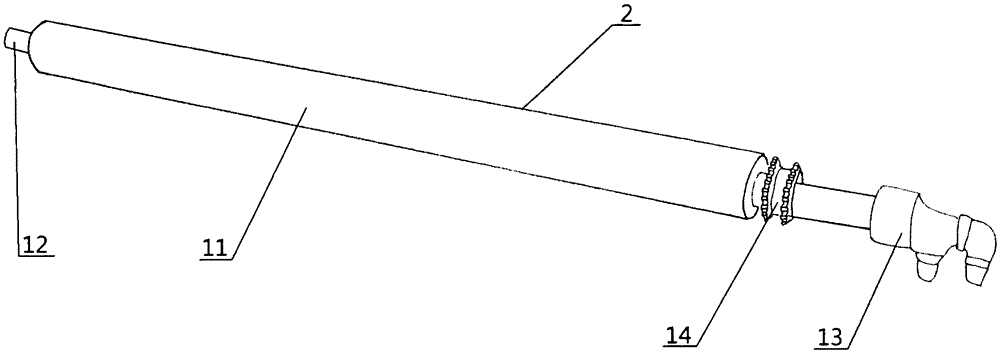

Heat supply transmission roller

InactiveCN105564927ATacit cooperationNovel structure conceptRollersHeating arrangementThermal energyFixed bearing

A heat supply transmission roller specifically comprises a roller body, a liquid guide roll shaft, a liquid input and output circulating pipeline, a fixed bearing pedestal and a gear set. By utilizing the heat supply transmission roller, during the running process of a puttied integrated board, a heat source is conveyed to the roller body through the liquid and gas input and output circulating pipeline and heats the board surface of the puttied integrated board; the heat source can cyclically go in and out of the liquid and gas input and output circulating pipeline to guarantee that there is sufficient heat to heat the board. The heat supply transmission roller can carry out production in dry or humid climate environment conditions, and it only takes about 40 minutes to feed and dry the board until the humidity of a finished product meets the quality requirement. The production cycle is short, and the humidity of the board is easy to control. By utilizing the heat supply transmission roller, the integrated board can be combined firmly and be subjected to secondary setting simultaneously, the quality of the board is substantially improved, and the internal bonding force of the board is enhanced.

Owner:GUANGXI NANNING QIAOSHENG WOOD

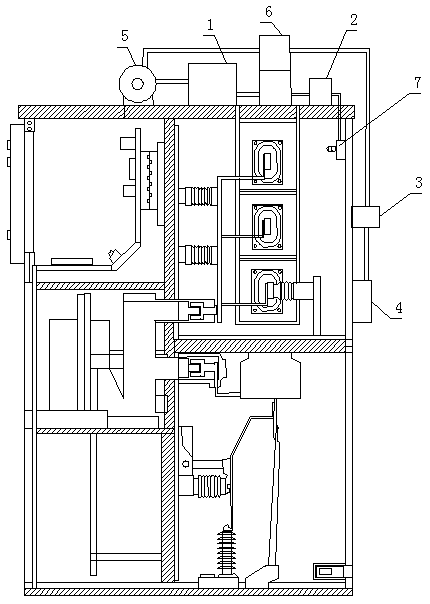

10 kv switch cabinet realizing live-line dedusting

ActiveCN105161993ASimple structureEasy to useSubstation/switching arrangement casingsControl systemDust control

The invention relates to a 10 kv switch cabinet realizing live-line dedusting. The switch cabinet comprises a cabinet body. The cabinet body is provided with a dedusting mechanism. The switch cabinet is simple in structure, convenient to use, convenient to popularize, applicable to all cabinet inner cavity structures of various kinds of switch cabinets and good in dedusting effect. A control system of the dedusting mechanism is reasonable in matching, tacit in cooperation, unified in control and capable of uniformly and cooperatively completing dedusting, spraying, cleaning and gas exhausting. Air more suitable for dedusting is provided by a cleaning method, a supercharging method and a spraying method enable dedusting air to form air flows, a better deducting effect is achieved, and dust absorbed on parts is removed. The dedusting mechanism is suitable for live-line dedusting of the cabinet switch, and the switching frequency caused by dedusting is lowered, so that the service lifetime of the switch cabinet is prolonged, and dust is prevented from accumulating in the cabinet and further reducing the insulating property or influencing normal work of elements.

Owner:GUANGDONG ZHONGXING ELECTRIC SWITCH

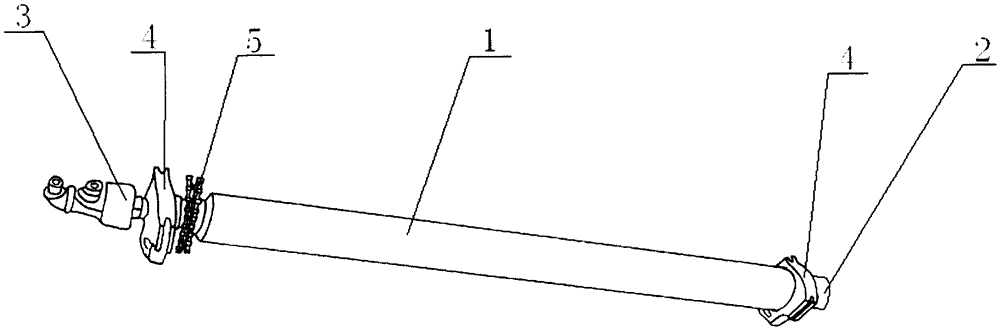

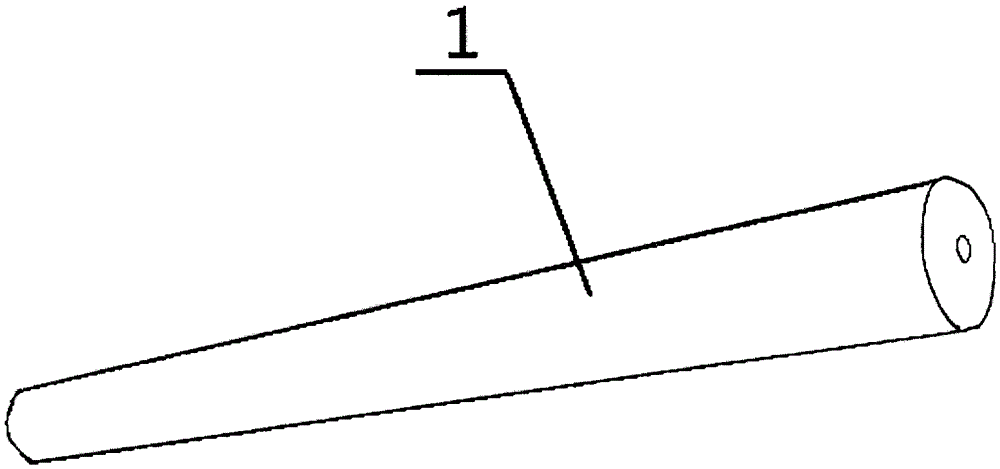

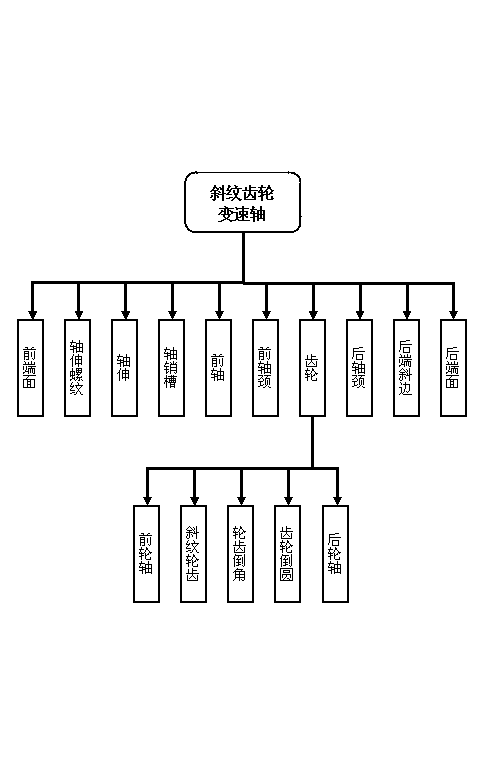

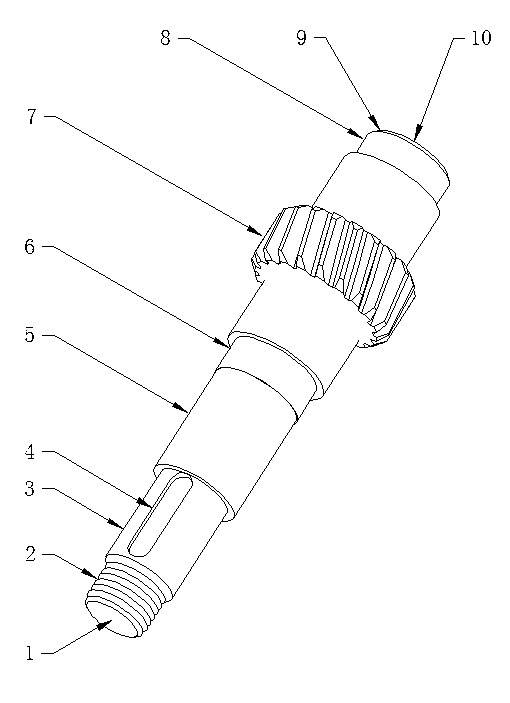

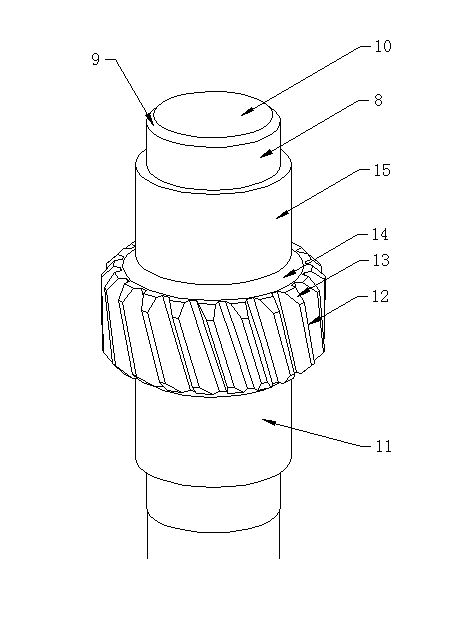

Bias gear speed changing shaft

InactiveCN103195907ACompact structureExtended service lifeToothed gearingsPortable liftingGear wheelEngineering

The invention relates to a gear shaft, in particular to a bias gear speed changing shaft which can be not only used independently and but also used in a group array. Ten components including a front end surface, a shaft extension thread, a shaft extension, a shaft pin groove, a front shaft, a front shaft neck, a gear, a back shaft neck, a back end bevel edge and a back end surface are combined to form the bias gear speed changing shaft. The gear comprises five small components including a front wheel spindle, bias gear teeth, gear teeth chamfers, a gear rounding and a back wheel spindle. Besides the same advantages of the common gear speed changing shafts, the bias gear speed changing shaft further has the advantages of accurate match, long service life, convenience in debugging, adaptability and the like as compared with common gear speed changing shafts; and the bias gear speed changing shaft is easy and convenient to produce, and has a solid and durable structure, wide marketing space, certain social application value and economical additional value.

Owner:钟婕

10kV switchgear cabinet capable of being dedusted highly efficiently

ActiveCN105186312ASimple structureEasy to useSubstation/switching arrangement casingsCleaning using gasesDust controlSwitchgear

The invention relates to a 10kV switchgear cabinet capable of being dedusted highly efficiently. The 10kV switchgear cabinet comprises a cabinet body and is characterized in that the cabinet is provided with a dedusting mechanism. The 10kV switchgear cabinet has beneficial effects of being simple in structure, convenient to use, easy to popularize, and suitable for the inner chamber structures of various types of switchgear cabinets, and having a good dedusting effect. Each part in the switchgear cabinet can be blown omnibearingly in order to reduce dedusting dead angles and enhance the dedusting of the top surface and the side surface of each element. The 10kV switchgear cabinet achieves an ideal dedusting way, may centralize much dedusting power consumption on the top surface and the side surface, with much dust, of each element, and reduces energy consumption.

Owner:平顶山三和高压开关有限公司

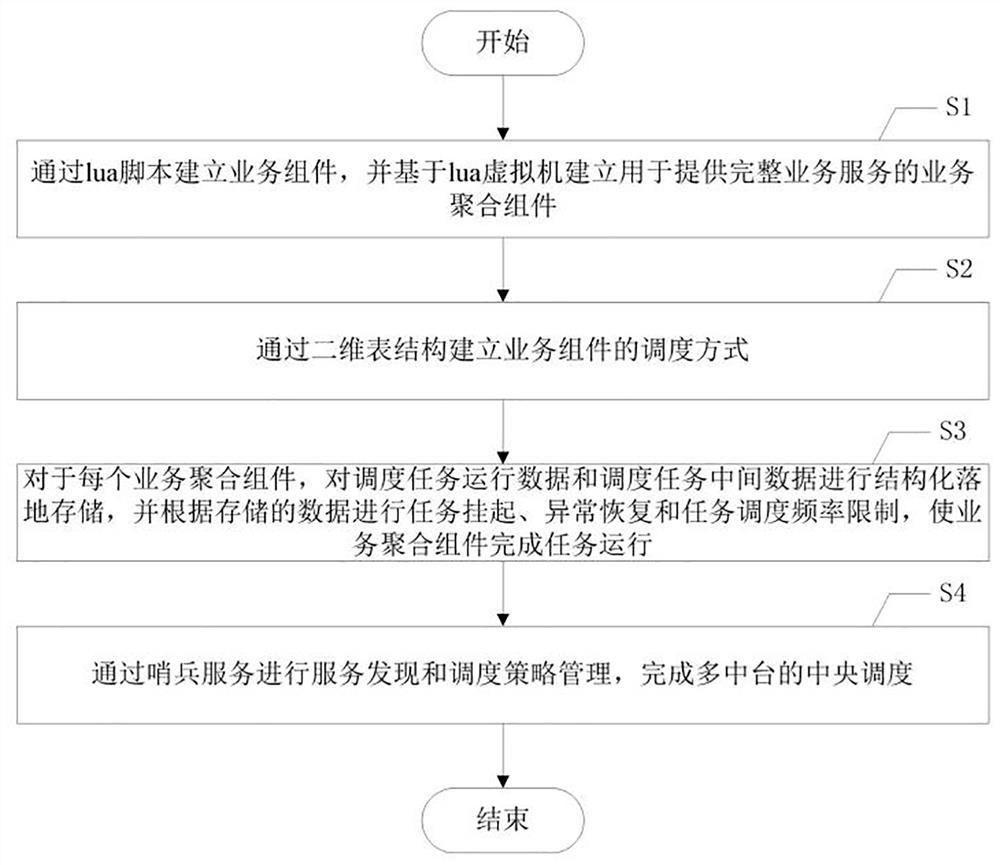

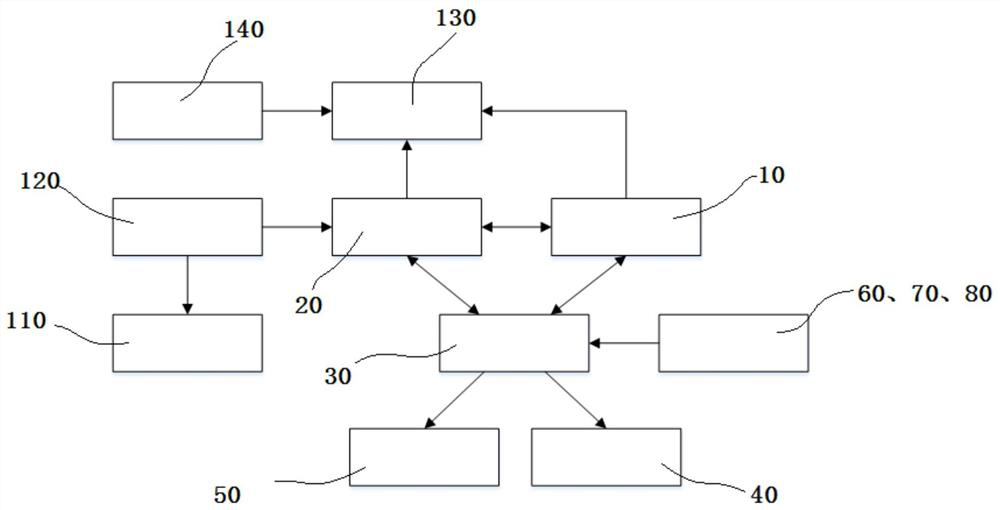

Multi-middle-station central scheduling method and system

ActiveCN111736977ARealize arbitrary schedulingUnification of basic capabilitiesProgram initiation/switchingInterprogram communicationStationThe Internet

The invention discloses a multi-middle-station central scheduling method and system, and belongs to the field of Internet data processing, and the method comprises the following steps: S1, building abusiness assembly through a lua script, and building a business aggregation assembly for providing complete business services based on a lua virtual machine; S2, establishing a scheduling mode of theservice components through a two-dimensional table structure; S3, for each service aggregation component, performing structured storage on the scheduling task running data and the scheduling task intermediate data, and performing task suspension, exception recovery and task scheduling frequency control according to the stored data to enable the service aggregation component to complete task running; and S4, carrying out service discovery and scheduling strategy management through sentry service, and completing central scheduling of multiple middle stations. According to the invention, objectives of unified basic capability, service and bottom layer separation, unified service rule configuration mode and the like can be realized, and thus random scheduling of multiple middle stations is realized.

Owner:成都新希望金融信息有限公司

Full-automatic plate trimming machine

InactiveCN105729275ATacit cooperationCompact structureGrinding machinesGrinding feedersWork taskEngineering

The invention provides a full-automatic edge sawing machine for edge trimming of plates. The edge sawing machine includes a feeding device, a long edge sawing device, and a steering device; the plate passes through the feeding device, the long edge sawing device, and the steering device; the long-side sawing device and the short-side sawing device are respectively located on the two sides adjacent to the steering device, and the horizontal direction of the long-side sawing device and the short-side sawing device The angle is 90°. Compared with the prior art, the edge sawing machine provided by the present invention has a simple structure, smooth plate feeding, and each link cooperates closely. When the next link is working, the previous link starts to prepare for the next task, the connection is tight, and the work efficient.

Owner:ANHUI ANSU WORLD HOME CO LTD

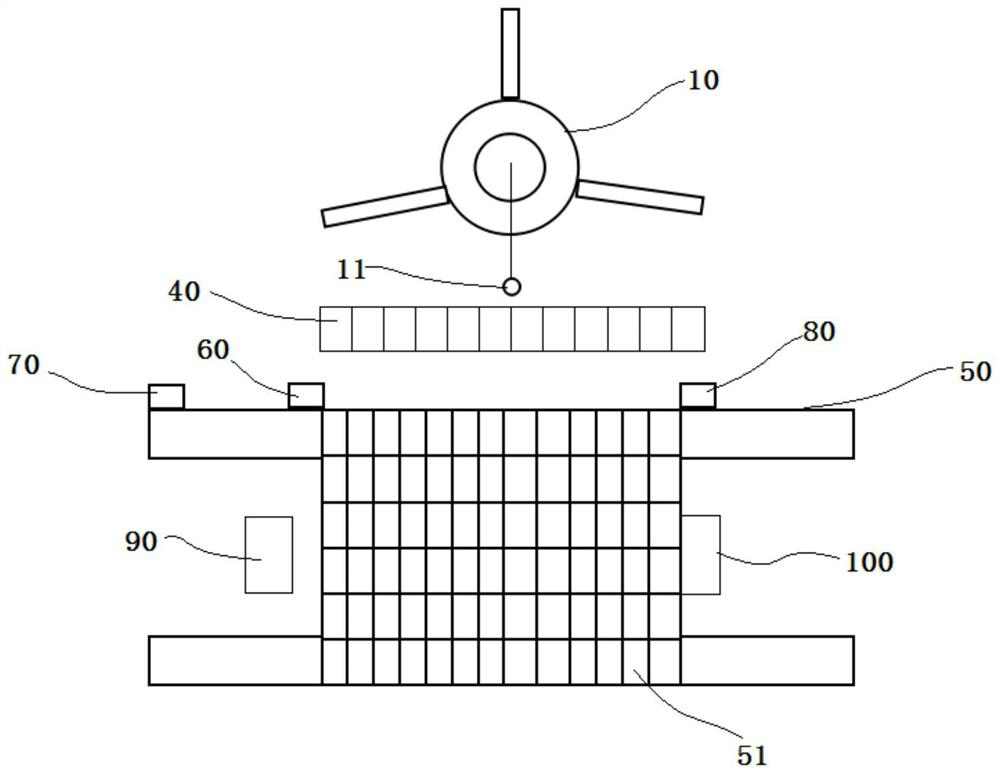

A robot intelligent fast handling device and its handling method based on machine vision

ActiveCN108263856BImprove work efficiencyHigh degree of automationProgramme-controlled manipulatorConveyorsMachine visionEngineering

The invention provides an intelligent fast robot carrying device based on machine vision. The intelligent fast robot carrying device comprises an industrial robot used for grabbing workpieces, an intelligent camera, an assembly line platform and a PLC used for controlling the whole device. A suction cup is arranged at the arm tail end of the industrial robot. The intelligent camera is used for photographing the workpieces and further recording coordinates of the workpieces. The intelligent camera is arranged beside the suction cup. The assembly line platform comprises a carrying line and an assembly line. The assembly line is provided with workpiece trays, and the workpiece trays are composed of left workpiece trays and right workpiece trays. The assembly line platform is arranged below the intelligent camera. The carrying line and the assembly line are arranged in parallel. A first photoelectric sensor and a second photoelectric sensor are sequentially arranged at the left sides of the left workpiece trays in an outward mode. A third photoelectric sensor is arranged at the right sides of the right workpiece trays. A first air cylinder is movably arranged below the left sides of the left workpiece trays, and a second air cylinder is movably arranged below the right sides of the right workpiece trays. The intelligent fast robot carrying device is used for carrying the workpieces, cost and manual work are reduced, the degree of automation is high, the error rate is low, used time is short and efficiency is high.

Owner:上海鉴泉自动化科技有限公司

A 10kv switchgear system with dust removal

ActiveCN105305244BSimple structureEasy to useCombination devicesSubstation/switching arrangement casingsEngineeringSwitchgear

The invention relates to a 10kv switch cabinet system with a dedusting function. The 10kv switch cabinet system comprises a control unit which comprises a control box that is arranged on the cabinet body. The control unit is connected with a purifying unit, a pressurizing unit, a spraying unit, a storing unit and an air discharging unit. The 10kv switch cabinet system is advantageous in that the 10kv switch cabinet system is applied in a dedusting mechanism of the 10kv switch cabinet and is used for realizing blocked control of each unit and facilitating operation and cooperation among the units, thereby realizing a better dedusting effect, facilitating energy saving of the dedusting mechanism, realizing normal operation of each unit, acquiring operation parameters of the units for performing unified control and realizing preset values, and facilitating convenient control for the dedusting mechanism.

Owner:浙江国正安全技术有限公司

Integrated device for paint storage

The invention discloses an integrated device for paint storage. The integrated device comprises a conveying belt and a gripper arm. The conveying belt is connected with a ratchet wheel. A first swing rod is arranged below the ratchet wheel and provided with a rotary rod. The first swing rod is in sliding connection with the rotary rod. A pawl is hinged to the rotary rod and connected with a first elastic piece. A second swing rod is arranged at the left side of the first swing rod. A second elastic piece is arranged between the two swing rods. A fixed sliding groove is formed above the second swing rod. A rack is arranged in the fixed sliding groove. A pull rod is hinged to the rack and is in sliding connection with the second swing rod. The rack is in meshed with a gear. The gripper arm is connected to the gear. Push blocks are arranged on the two opposite sides of the two swing rods. The two push blocks are both meshed with linkage gears. The two linkage gears are meshed with push rods. The two opposite faces of the two push rods are wedge faces, and a rotary disc is arranged below the two wedge faces. The rotary disc abuts against the two wedge faces, and the rotary disc is connected with an air cylinder. According to the integrated device, by means of air cylinder control and the arrangement of a connected structure, the structure is simplified, and coordinating difficulty is lowered.

Owner:CHONGQING HENGO SCHILLER DECORATION ENG CO LTD

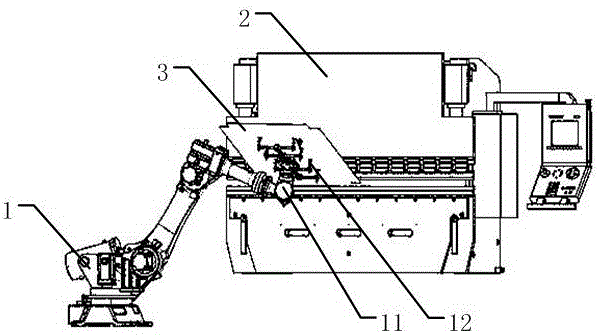

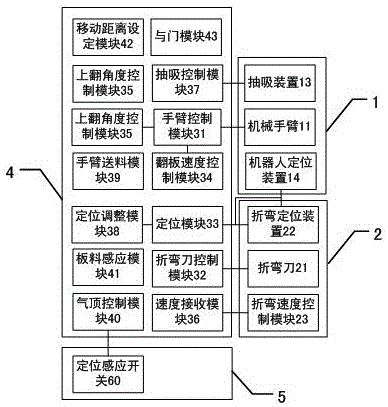

A bending system and method with integrated positioning, feeding and bending

ActiveCN105215096BAvoid stray creasesTacit cooperationMetal-working feeding devicesPositioning devicesArthrobotrysPetroleum engineering

The invention discloses a positioning, conveying and bending combined bending system. After a positioning device positions a plate, a joint robot conveys the plate to the bending device, the joint robot can be in cooperation with the bending device according to the bending process and highly precisely follows the bending device in the bending process, and it is avoided that deviation creases are generated on the plate in the bending process, so that the joint robot can be in good cooperation with the bending device. In the bending process, the joint robot can assist in supporting the plate, the plate is kept stable in the bending process, manual operation is reduced, and bending working efficiency is improved. In the whole bending process, operation staff only need to input related parameters of bending, and the joint robot is in cooperation with the bending device for completing the bending work.

Owner:SHANDONG PROVINCE BOXING COUNTY SINO AUTOMATION EQUIP CO LTD

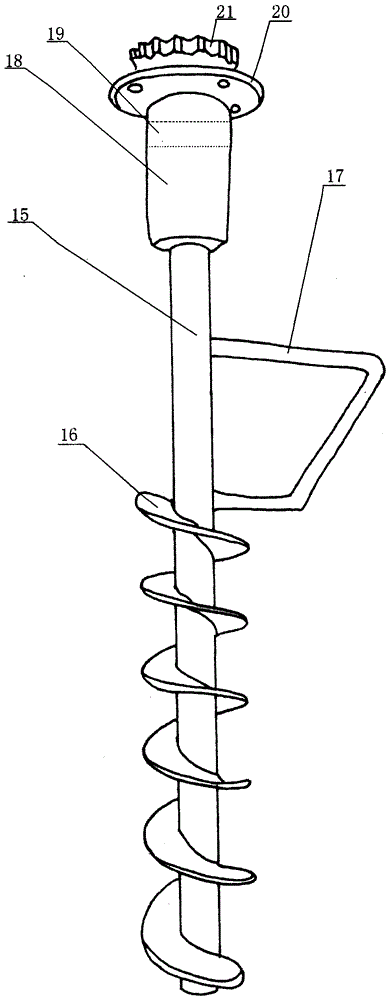

A vertical unloading device

ActiveCN104773529BTacit cooperationThe composition structure is scientific and reasonableLoading/unloadingWhole bodySpiral blade

Owner:GUANGXI NANNING QIAOSHENG WOOD

Heating and adhering-preventing integrated conveying roller assembly

InactiveCN105621052ATacit cooperationNovel structure conceptCleaningPackagingPulp and paper industryHeating energy

The invention discloses a heating and adhering-preventing integrated conveying roller assembly. The heating and adhering-preventing integrated conveying roller assembly is composed of a roller body, an oil storage trough, a liquid and gas conveying pipeline, a liquid and gas guide roll shaft, a liquid and gas import and export circulating pipeline, bearing housings and a gear set. By using the heating and adhering-preventing integrated conveying roller assembly, a heat source is conveyed to the roller body through the liquid and gas import and export circulating pipeline and heats the board face of a laminated board during operation, and the heat source can be imported into and exported out of the liquid and gas import and export circulating pipeline, so that the effect that the board is heated through sufficient heat energy is ensured. The roller body can be lubricated at any time through oil in the oil storage trough, plaster on the board face does not adhere to the roller body when the roller body makes contact with the plaster, and the plaster can be dried rapidly and firmly bonded with the board. Even though a small part of the plaster adheres to the roller body, the oil storage trough can scrape off the plaster adhering to the roller body when the roller body rotates, and machine operation stability is guaranteed.

Owner:GUANGXI NANNING QIAOSHENG WOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com