Bias gear speed changing shaft

A technology of shifting shafts and gears, applied in gear transmissions, belts/chains/gears, components with teeth, etc., can solve the problems of single function and poor adaptability, and achieve long service life, simple manufacturing, and debugging. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

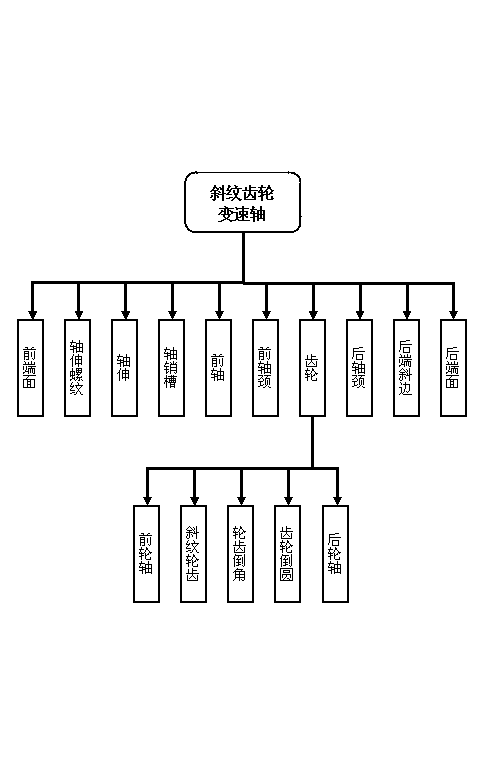

[0029] As a technical solution for product manufacturing, the present invention can make the solution concretely implemented through the organic combination of corresponding components. The product organization structure of an embodiment of the present invention is as follows: figure 1 shown.

[0030] figure 1 Among them, the embodiment product is formed by the combination of ten components: front end face, shaft extension thread, shaft extension, shaft pin groove, front axle, front journal, gear, rear journal, rear end hypotenuse, and rear end face, among which the gear The component also includes five small components of the front axle, twill gear teeth, gear tooth chamfer, gear rounding, and rear axle.

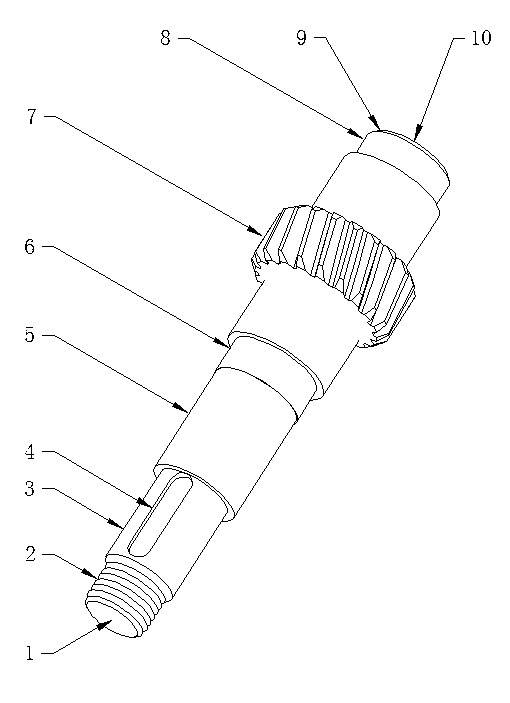

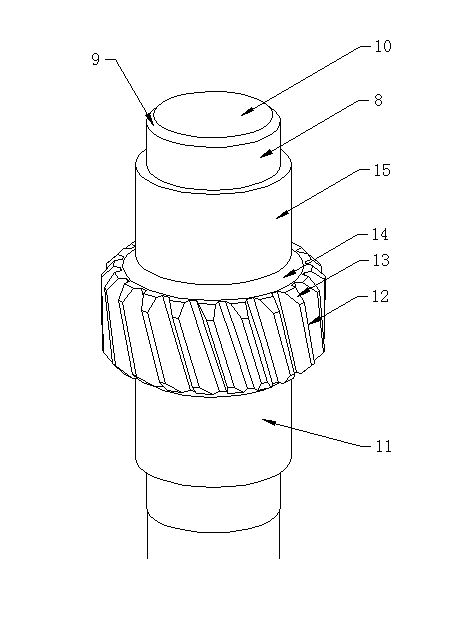

[0031] In the embodiment, the structural shape of the product entity and the mutual positional relationship between its various components, such as figure 2 shown.

[0032] figure 2 Among them, the structure of the product includes front end face (1), shaft exten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com