Heat supply transmission roller

A technology of driving rollers and rollers, which is applied in the field of supporting equipment for the production of man-made panels, achieves the effect of significant effect, easy control of dry and humidity, and reduction of work and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

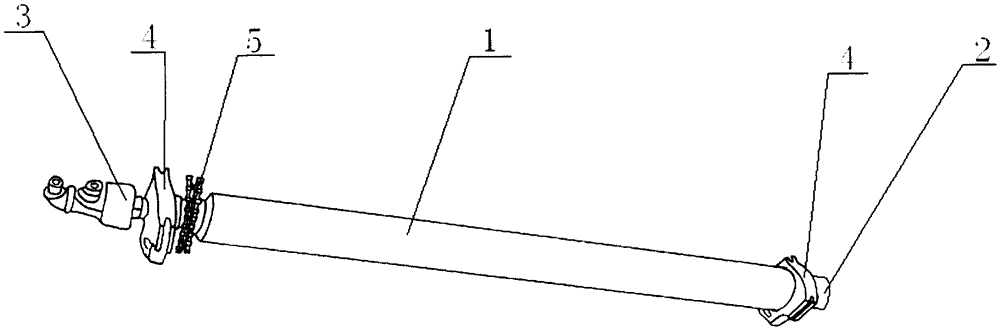

[0040] The invention is composed of a roller body (1), a liquid-guiding and steam-guiding roller shaft (2), a liquid gas input and output circulation pipe (3), a fixed bearing seat (4), and a gear set (5).

[0041] figure 1 Shown is the structural representation of the present invention. Among them, 1 is a roller body, 2 is a liquid-guiding and steam-conducting roller shaft, 3 is a liquid gas input and export circulation pipe, 4 is a fixed bearing seat, and 5 is a gear set.

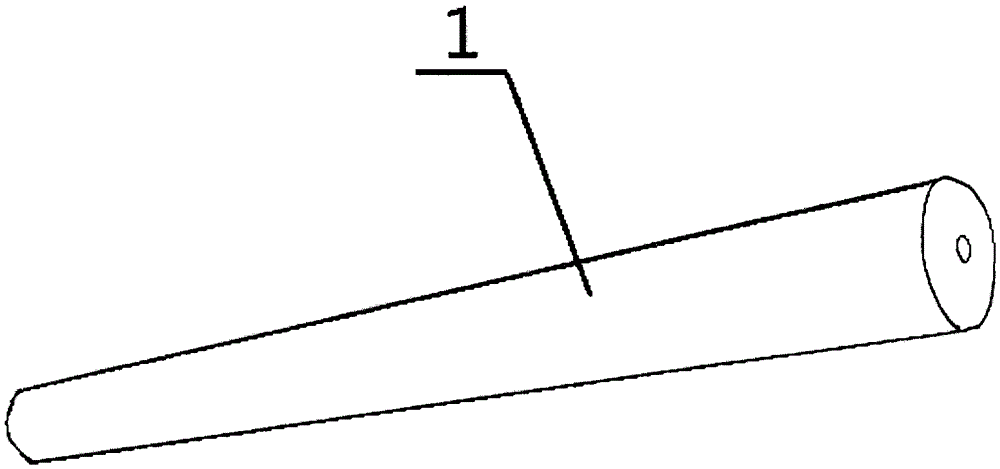

[0042] figure 2 Shown is a structural schematic diagram of the roller body (1) in the present invention. The roller body (1) is a cylindrical hollow body.

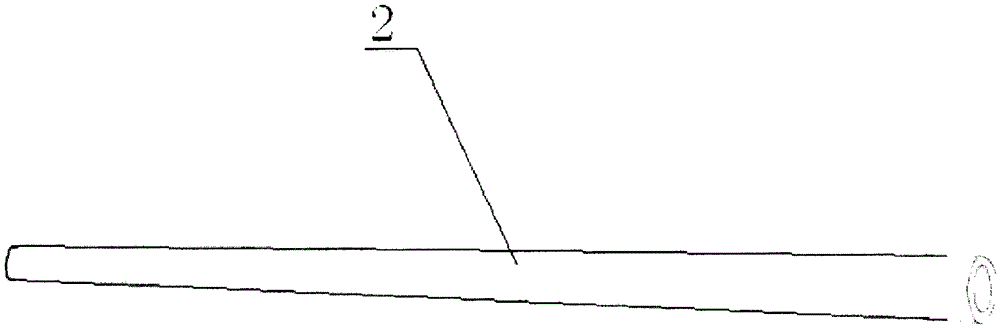

[0043] image 3 Shown is the structural schematic diagram of the liquid-guiding and steam-guiding roller shaft (2) in the present invention. The liquid-guiding and steam-guiding roller shaft (2) is a cylindrical inner hollow pipe. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com