Heating and adhering-preventing integrated conveying roller assembly

A conveying roller and assembly technology, which is applied in the field of man-made board production equipment, can solve the problem of ash glue easily sticking to the roller, etc., and achieve the effect of ensuring the stable operation of the machine, the obvious effect and the novel structure concept.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

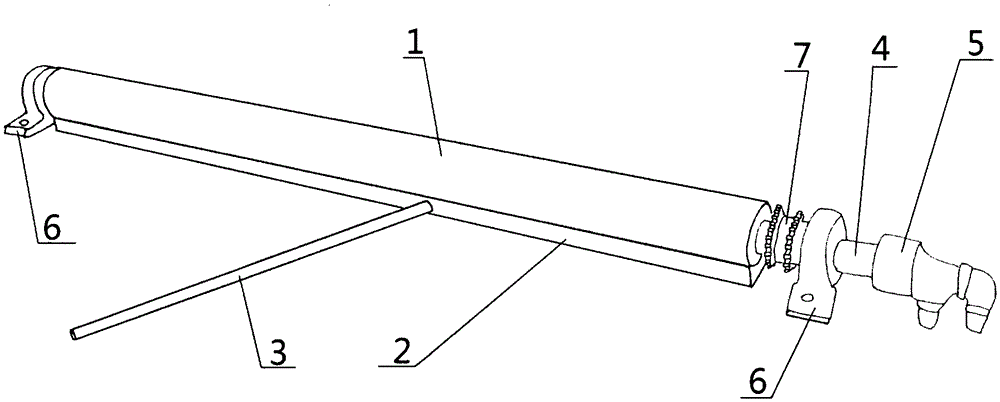

[0046] The present invention is composed of a roller body (1), an oil storage tank (2), a liquid and gas delivery pipeline (3), a liquid and gas guide roller shaft (4), a liquid gas input and output circulation pipeline (5), a bearing sleeve (6), Gear set (7) is formed.

[0047] figure 1 Shown is the structural representation of the present invention. Among them, 1 is the roller body, 2 is the oil storage tank, 3 is the infusion gas pipeline, 4 is the liquid guide and gas guide roller shaft, 5 is the liquid gas input and export circulation pipeline, 6 is the bearing sleeve, and 7 is the gear set.

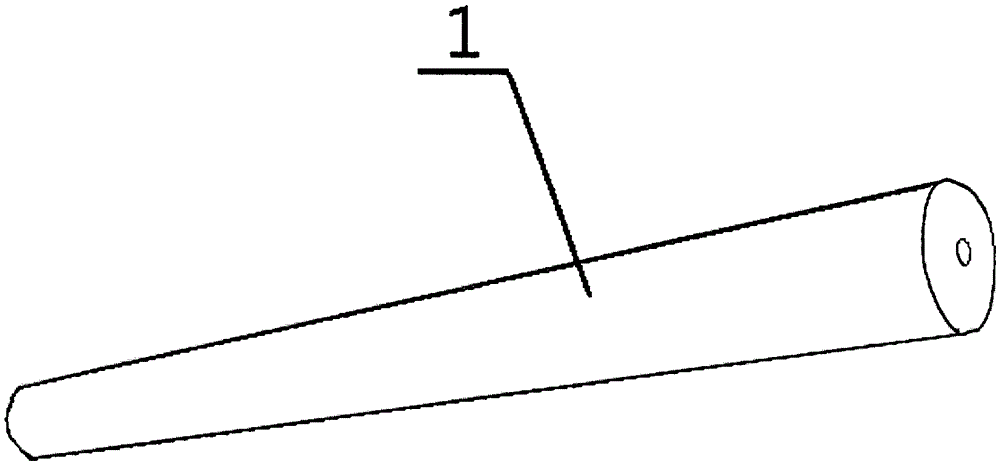

[0048] figure 2 Shown is a structural schematic diagram of the roller body (1) in the present invention. The roller body (1) is a cylindrical hollow body.

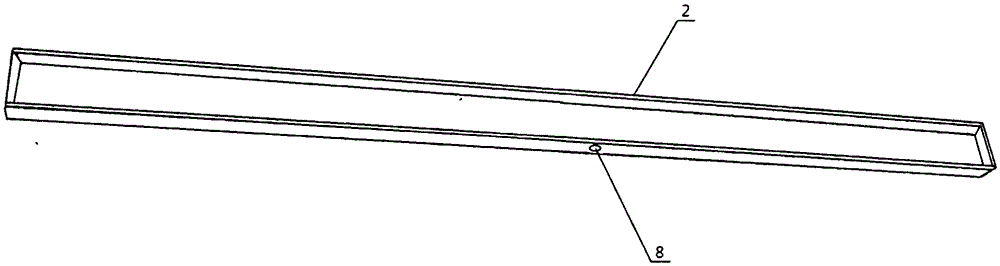

[0049] image 3 Shown is the structural representation of the oil storage tank (2) in the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com