A 10kv Switchgear with Efficient Dust Removal

A switchgear, high-efficiency technology, applied in the direction of using gas flow cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. problem, to achieve good dust removal effect, improve service life, and facilitate the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

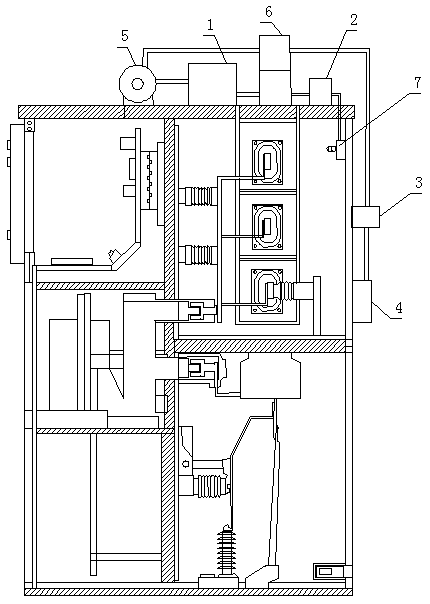

[0037] like figure 1 , a high-efficiency dust removal 10kv switch cabinet of the present invention includes a cabinet body, and a dust removal mechanism is arranged on the cabinet body. The dust removal mechanism includes a gas storage tank 1, a purification mechanism 3, a decompression mechanism 2, a booster mechanism 5, and a heat exchanger 6. The air injection mechanism 7, the exhaust mechanism 4, the gas storage tank 1 is connected to the air injection mechanism 7 in the cabinet through the heat exchanger 6 and the decompression mechanism 2 in turn, and the cabinet is provided with an exhaust mechanism 4 to exhaust the air. The mechanism 4 is connected back to the gas storage tank 1 through the purification mechanism 3, the heat exchanger 6, and the pressurization mechanism 5 in turn, and the gas storage tank 1 is filled with inert gas.

[0038] The purification mechanism 3 includes a vacuum cleaner, a humidity controller, and an electroparticle adsorber connected in seque...

specific Embodiment 2

[0045] According to the control system of the switchgear of embodiment 1, comprise:

[0046] (1), control unit;

[0047] (2) The purification unit includes a vacuum cleaner, a humidity controller, and an electric particle adsorber. The dust suction net in the vacuum cleaner filters the airflow; the filtered airflow enters the humidity controller, and the humidity controller includes a sponge net and an extruded plate. The sponge net has a number of curved through holes with a diameter not greater than 3cm and a length greater than 10cm. Activated carbon with a particle size of less than 5 mesh is arranged on the inner wall of the through hole. The sponge net absorbs the moisture in the airflow and filters the airflow again; Embosses are arranged horizontally on the pressing plate, the height of the embossing is 3-5mm, and the spacing of the embossing is 5-8mm. The extruding plate is connected with an extruder, and the extruder controls the extruding plate to extrude the sponge...

specific Embodiment 3

[0055] Injection method according to the control system of embodiment 2:

[0056] (1) The control unit controls the rotation of the motor installed on the spray seat, and the spray head rotates around the spray seat at an average speed of 20r / min. The spray head rotates non-uniformly, and the spray head rotates at a speed of 16r when it is down. / min, the rotation speed of the spray head is 24r / min when it is upward;

[0057] (2) The control unit controls the reciprocating movement of the injection seat on the spiral slide rail. The control unit controls the movement speed of the injection seat. When the injection seat is above the center point of the slide rail, its moving line speed is 1-2m / min. The moving line speed is 2-3m / min when it is lower than the center point of the slide rail;

[0058] (3) When the control unit controls the wind pressure at the spray head to be lower than 1kpa, the moving speed of the spray seat on the slide rail is 0m / min, and the average rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com