A vertical unloading device

A vertical and feeding technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve problems such as affecting the work progress, and achieve scientific and reasonable structure, efficient and active operation, and significant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

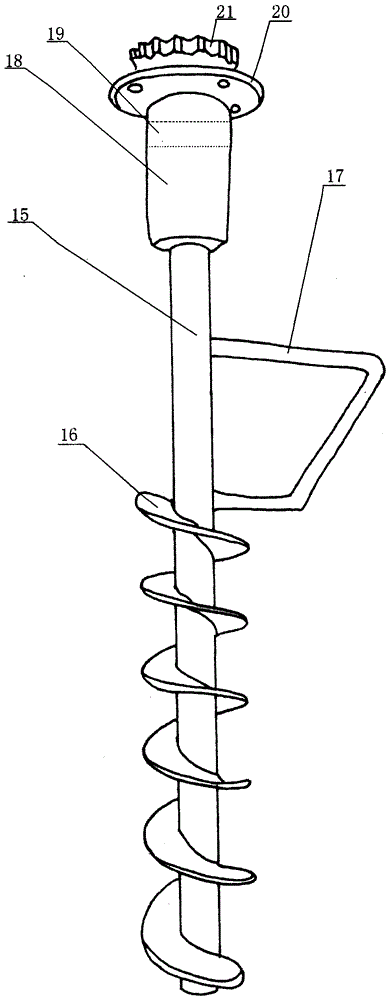

[0040] The invention is composed of a feeder (1), a feeding screw rod (2), a rotating motor (3), a connecting seat (4) and a chain (5).

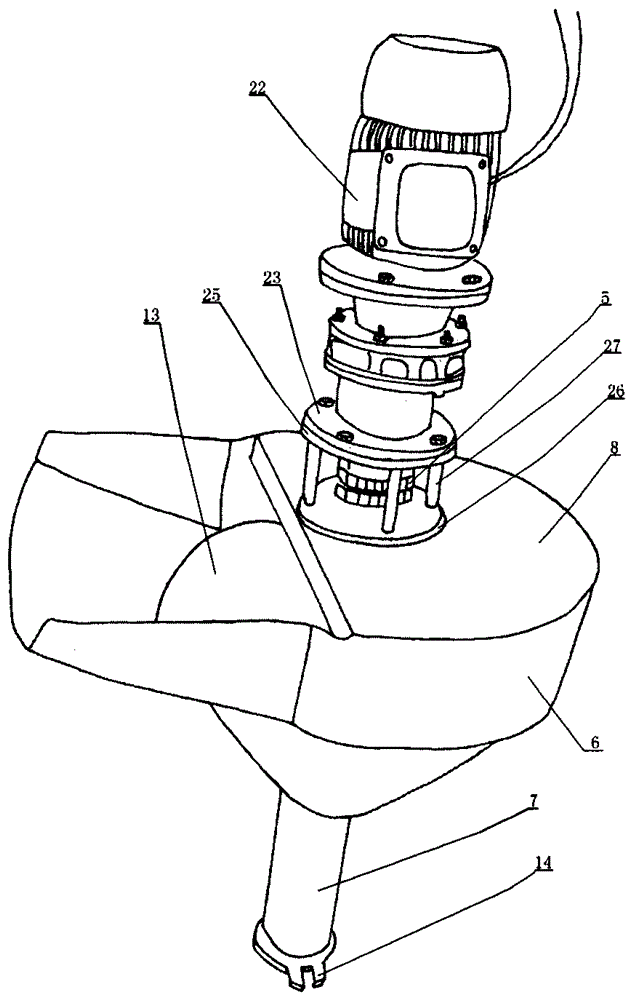

[0041] figure 1 Shown is the structural representation of the present invention. Among them, 5 is a chain (5), 6 is a funnel (6), 7 is a funnel (7), 8 is a baffle (8) provided on the top of the funnel, and 13 is a baffle provided on one side of the baffle. Feed inlet (13), 14 is the locking flange one (14) that is provided with at the bottom of the drain pipe, 22 is the motor (22), 23 is the connecting seat frame (23), and 25 is the flange one (25) , 26 is flange two (26), and 27 is connecting rod (27).

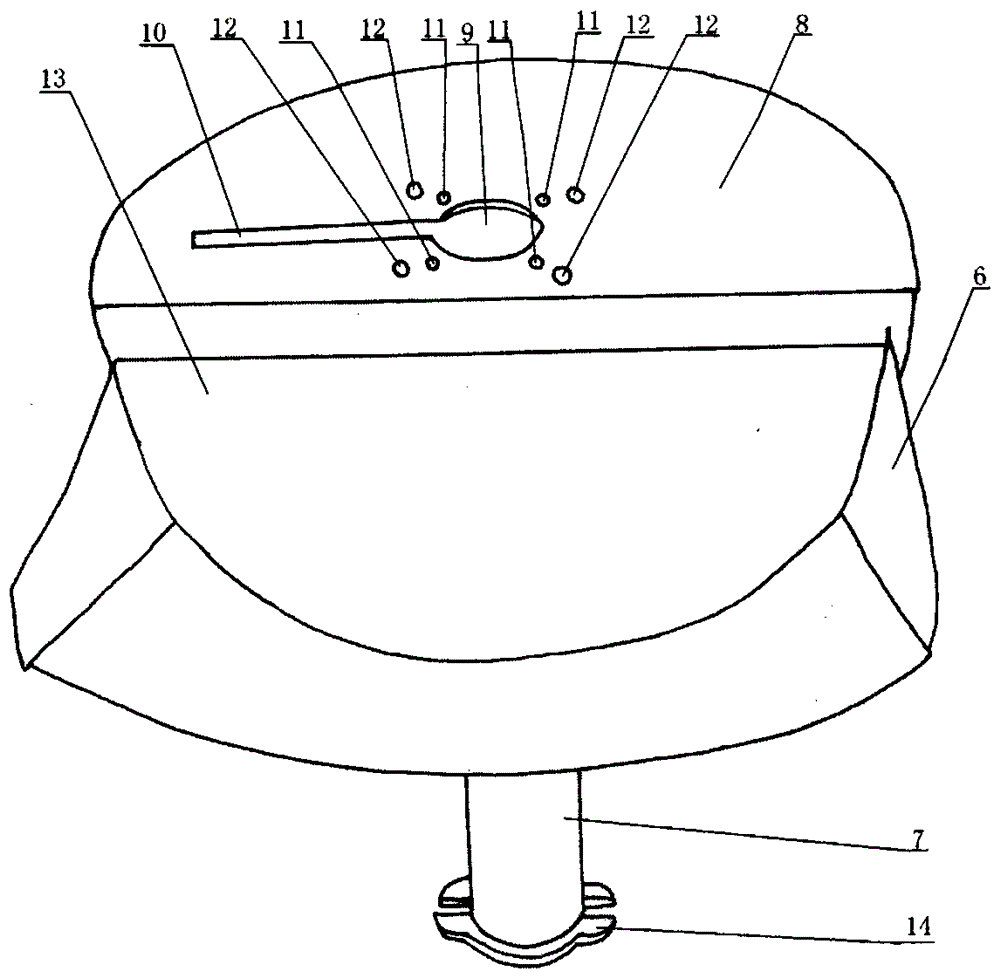

[0042] figure 2 Shown is a schematic structural view of the feeder (1) in the present invention. The feeder (1) is composed of a funnel (6) and a funnel (7), wherein the funnel (6) is installed above the funnel (7), and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com