Integrated device capable of achieving rolling, heating, drying, positioning and leveling sizing synchronously during plate conveying

A board and drying technology, which is applied in the direction of wood processing equipment, the joining of wooden veneers, other plywood/plywood appliances, etc., can solve the problems of inability to achieve continuous production operations, increase the amount of sanding, and difficulty in controlling dry humidity, etc. To achieve the effect of machine-substituting operation, stable operation without deviation, and easy control of dry humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Now in conjunction with accompanying drawing, the present invention is described in detail:

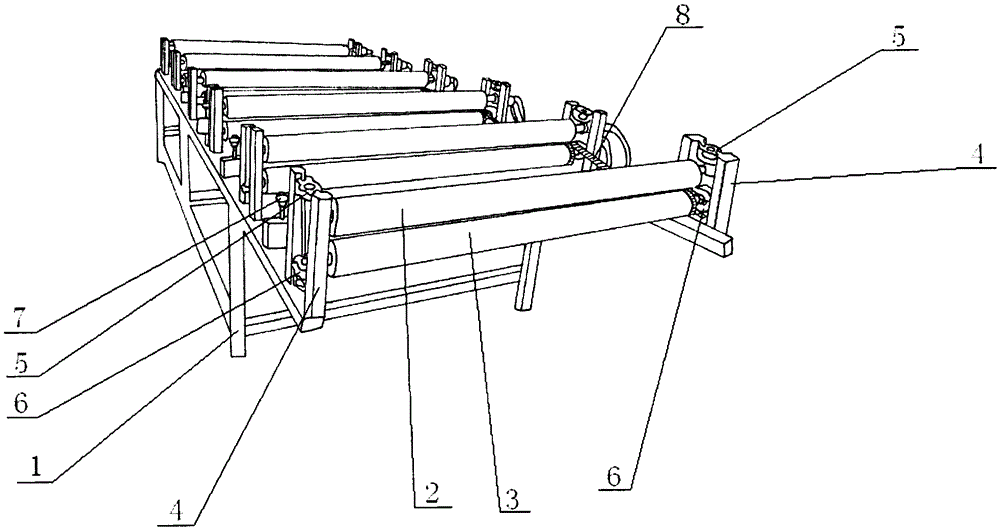

[0047] The present invention has frame body (1), heating and pressing leveling roller (2), heating conveying roller (3), roller fixed groove frame (4), sliding bearing seat (5), fixed bearing seat (6) ), sheet positioning rollers (7), chains (8).

[0048] figure 1 Shown is the structural representation of the present invention. Among them, 1 is the frame body, 2 is the heating and pressure leveling roller, 3 is the heating and conveying roller, 4 is the roller fixing groove frame, 5 is the sliding bearing seat, 6 is the fixed bearing seat, 7 is the plate positioning roller, 8 is a chain.

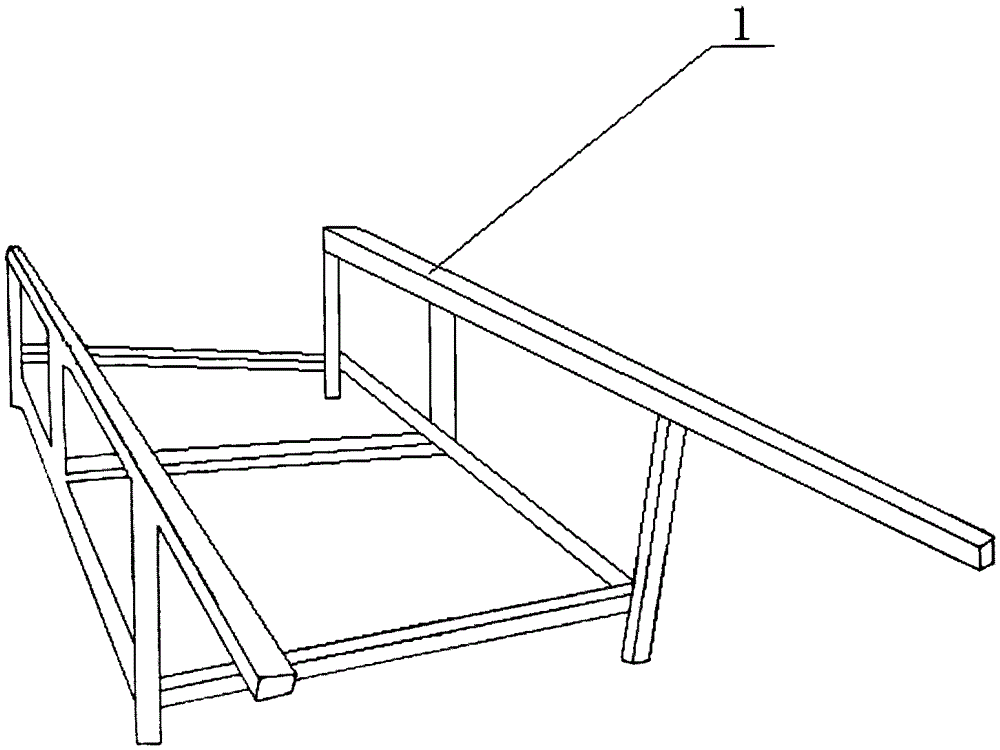

[0049] figure 2 Shown is a schematic structural view of the frame (1) in the present invention. The frame body (1) is a square three-dimensional frame.

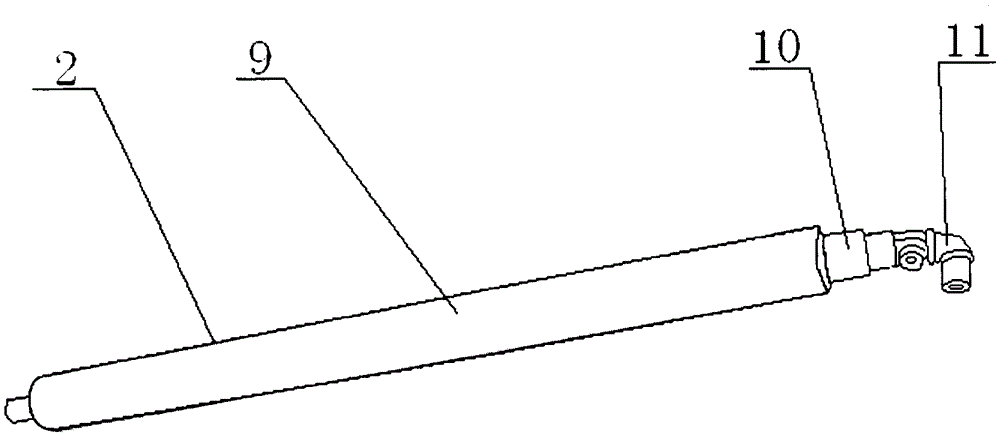

[0050] image 3 Shown is a schematic structural view of the heating and pressing leveling roller (2) in the present invention. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com