Patents

Literature

31results about How to "Strengthen the internal binding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of in-situ self-assembly in solid wood to prepare polyurethane reinforced wood

ActiveCN103586947AImprove water resistanceExcellent anti-corrosion and mildew resistancePressure impregnationPolymerisation impregnationSolid woodPolymer science

The invention discloses a method of in-situ self-assembly in solid wood to prepare polyurethane reinforced wood. The method comprises the following steps: utilizing a vacuum high-pressure technology to impregnate isocyanate monomers, vacuum dehydrated polyalcohol, a chain extender, a cross-linking agent, a catalyst and other modifiers which are uniformly mixed to inside of the wood; then ageing, homogenizing and taking a polymerization reaction by heating or microwave to allow the isocyanate and the polyalcohol to take the polymerization reaction on the internal surface of the wood pores, so as to forming the polyurethane reinforced wood. The wood prepared with the method is of the excellent performances of wood and polyurethane, can be applied to various fields, and has high additional value and market prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

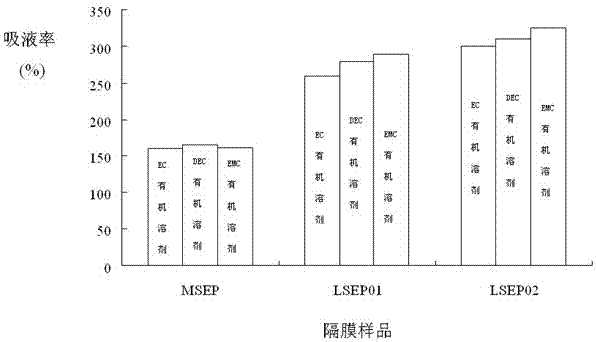

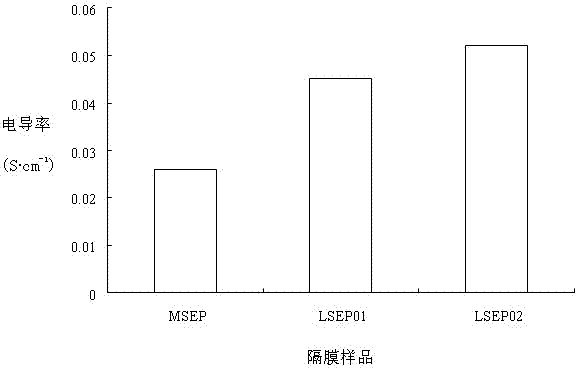

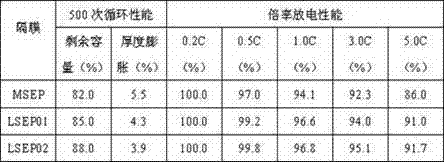

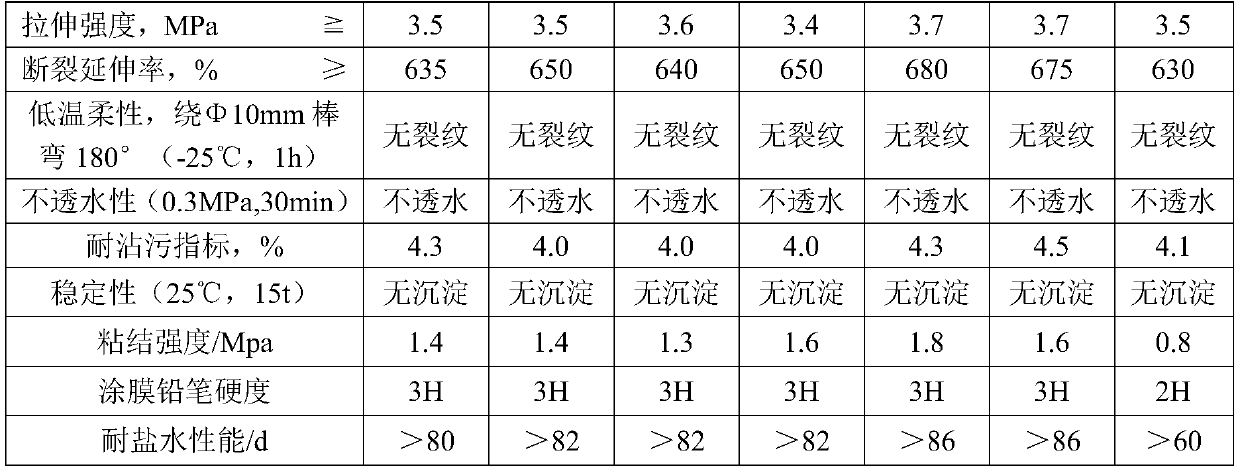

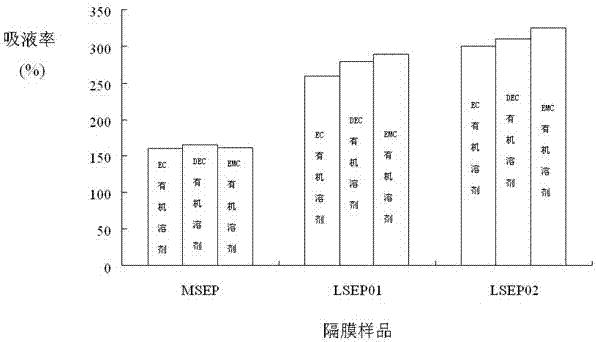

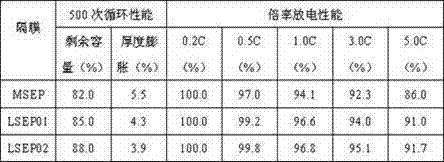

Coating for power lithium battery diaphragm, power lithium battery diaphragm and preparation thereof

ActiveCN102433745AHigh liquid absorptionHigh tensile strengthCell component detailsNatural fibresNano siliconN dimethylformamide

The invention provides a coating for a power lithium battery diaphragm, a power lithium battery diaphragm and preparation thereof. The coating for the power lithium battery diaphragm which takes wet nonwoven cloth as a base material is characterized by comprising 5-20% (wt) chlorinated polyvinylidene fluoride, 10-20% (wt) glycerol, 60-80% (wt) N, N-dimethylformamide, 2.5-5% (wt) sodium hypochlorite and 2.5-5% (wt) nano-silicon carbide whiskers. A method for preparing the coating for the power lithium battery diaphragm which takes the wet nonwoven cloth as the base material is characterized bycomprising the following specific steps of: proportionally dissolving chlorinated polyvinylidene fluoride in the mixed solution of glycerol, sodium hypochlorite and N, N-dimethylformamide to form thick transparent fluid; adding the nano-silicon carbide whiskers to the thick transparent fluid and stirring the same until the whiskers are completely homogenized and dispersed, thereby obtaining the coating for the power lithium battery diaphragm which takes the wet nonwoven cloth as the base material. The coating is capable of obviously improving the absorbency, electrical properties, high temperature shrinkage resistance and tensile strength of the power lithium battery diaphragm.

Owner:CHINA HAISUM ENG

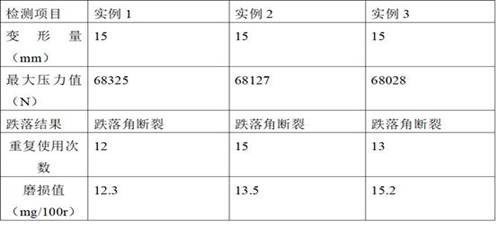

Sintered NdFeB magnet having high integral magnetic performance and preparation method thereof

InactiveCN108320902AImprove adhesionImprove liquiditySolid state diffusion coatingInductances/transformers/magnets manufactureAdhesion forceRare-earth element

The invention relates to a preparation method of a sintered NdFeB magnet having high integral magnetic performance. The preparation method comprises the following steps of (1) pre-processing a surfaceof the magnet; (2) uniformly spraying a layer of homogeneous paste containing a heavy rare-earth element, an adhesion force improvement agent and a plasticizer onto the surface of the magnet; and (3)performing drying, wherein a flexible coating layer with high adhesion force is formed on the surface of the sintered NdFeB magnet, and high-temperature permeation diffusion thermal processing and low-temperature tempering are performed on the magnet uniformly coated with the flexible coating layer. By forming the flexible coating layer on the surface of the sintered NdFeB magnet, the problem ofplating layer falling caused by turnover spraying of the magnet during mass production process is solved, and industrial preparation of the sintered NdFeB magnet having high integral magnetic performance can be achieved.

Owner:ZHEJIANG SHEENSEN MAGNETICS TECH CO LTD

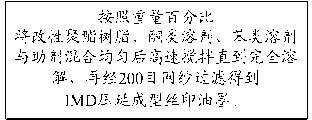

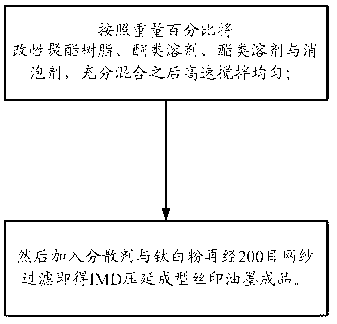

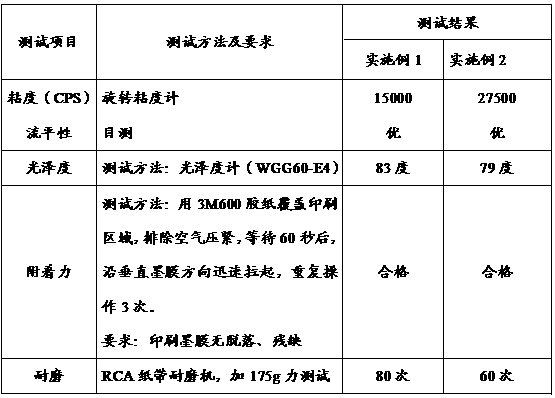

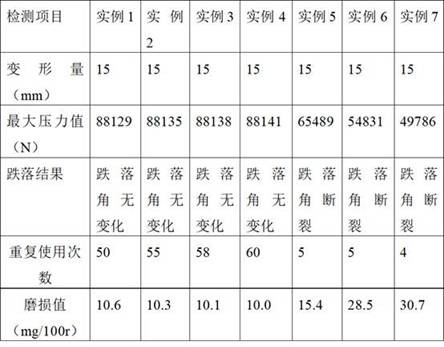

IMD (In-Mold Decoration) calendaring silk-screen printing ink

The invention discloses IMD (In-Mold Decoration) calendaring silk-screen printing ink which comprises the following components in percentage by weight: 40-50% of modified polyester resin, 25-30% of ketone solvent, 20-25% of benzene solvent and 1-5% of assistant. The printing ink solves the problems that existing IMD calendaring is poor in draying effect and the printing process is too fussy. The printing time is reduced, and the extremely strong inner binding force is improved, so that the printing ink has excellent using performance and has the effects of good leveling performance and excellent adhesion force on the printing surfaces of PC (Poly Carbonate) and PET (Polyethylene Terephthalate) materials. The printing oil is bright in color and high-temperature resistance, and the demands of clients on high temperature resistance, high ductility, high adhesive force and high adhesion of products are met.

Owner:深圳市美丽华科技股份有限公司

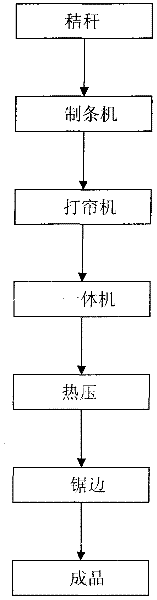

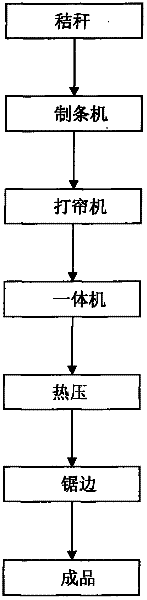

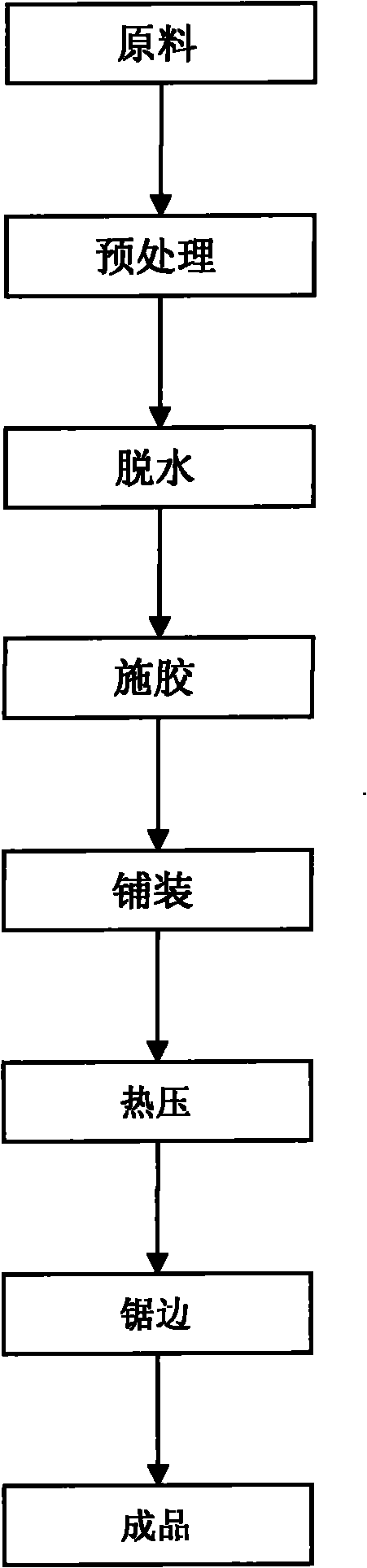

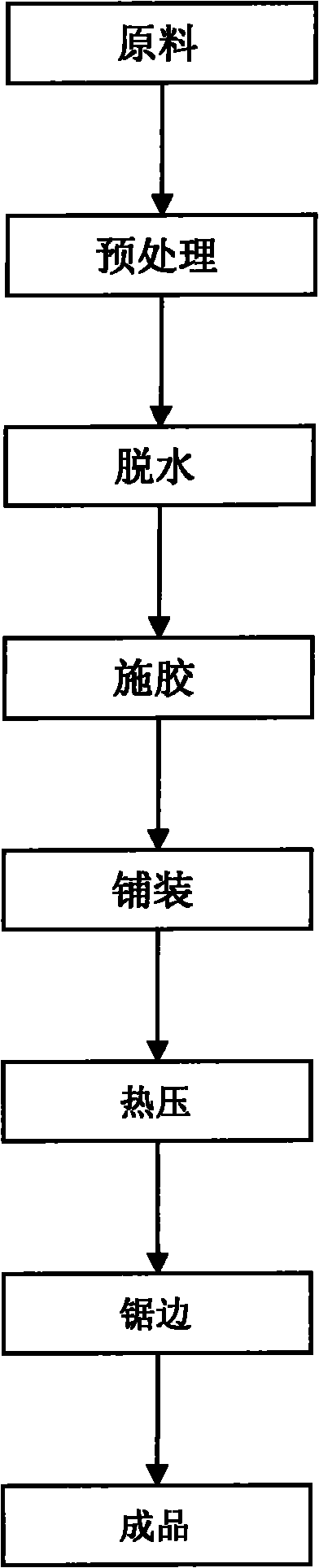

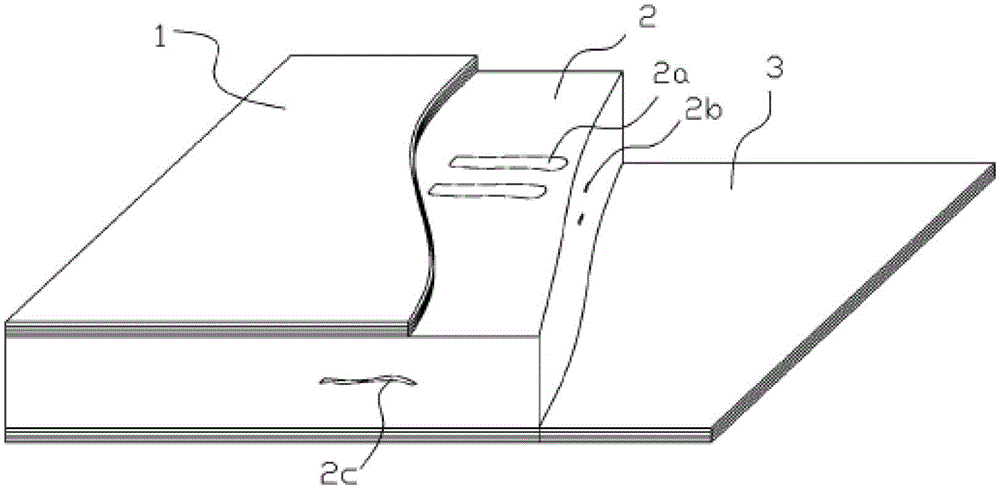

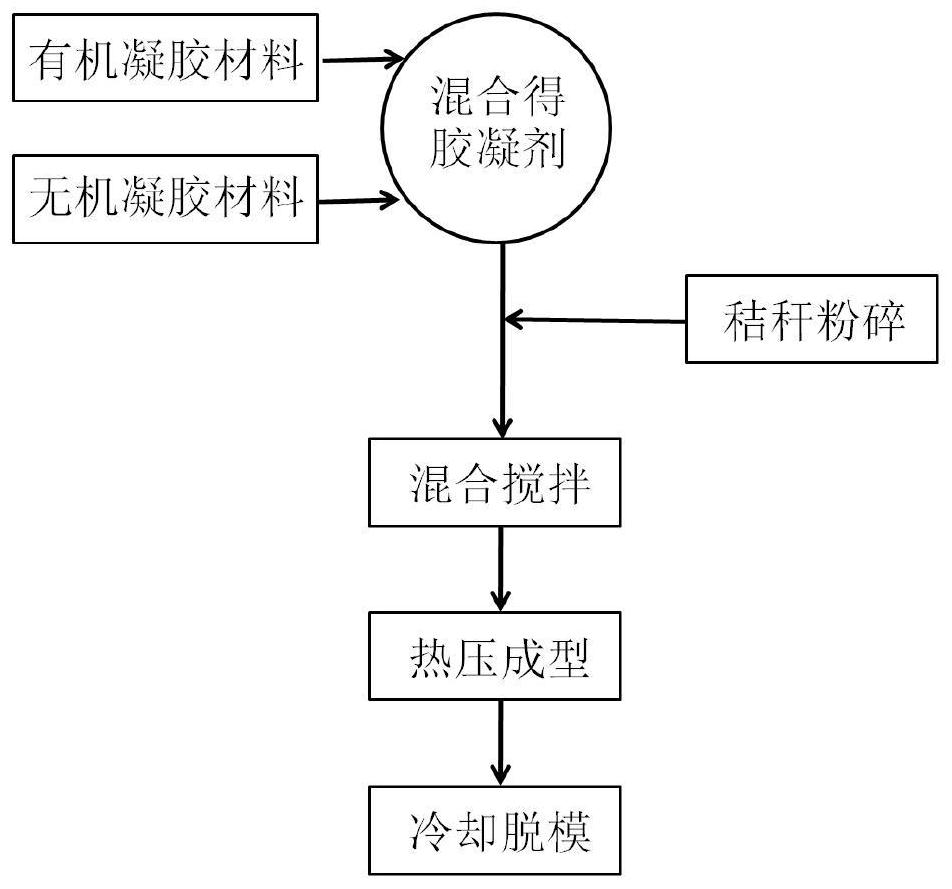

Process for producing straw artificial board

InactiveCN102172933AHigh strengthStrengthen the internal binding forceCane mechanical workingPlant material mechanical workingPerformance indexUltimate tensile strength

The invention discloses a process for producing a straw artificial board, and relates to the artificial board production industry. The process is used for producing the artificial board by substituting wood for crop straws serving as raw materials. A self-made slivering machine, a curtain beating machine and a drying, glue spraying and assembling integrated machine are used in the process; mechanical streamline production of each working procedure of the straw artificial board is realized, the production efficiency is greatly increased, and the production cost is reduced; and the internal structure of the board produced by using the process is scientific and reasonable, the bending strength reaches 52.6MPa, the screw holding force on the board surface reaches 2,140N, various performance indexes are higher than those of the conventional artificial boards and close to those of wood, and the straw artificial board can substitute the wood in many fields and has low manufacturing cost.

Owner:刘金忠

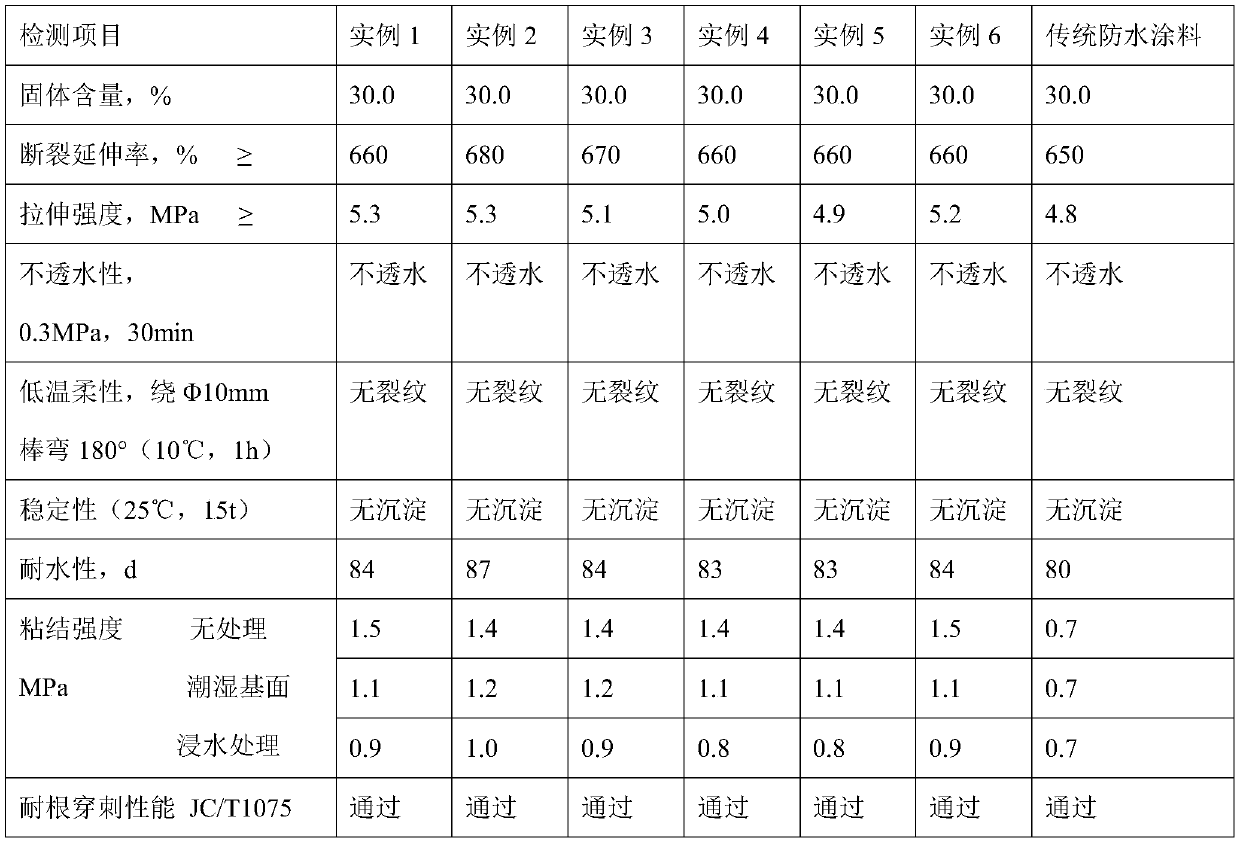

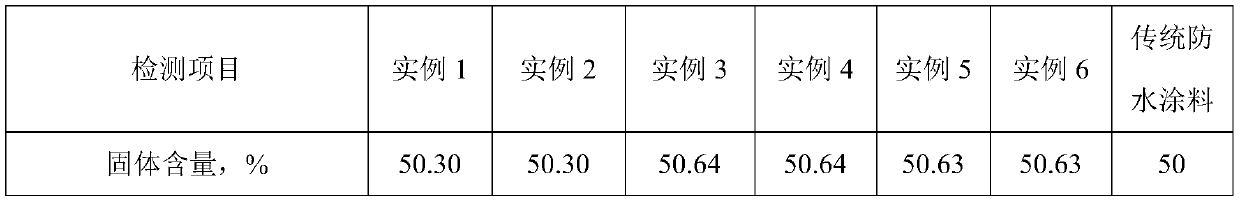

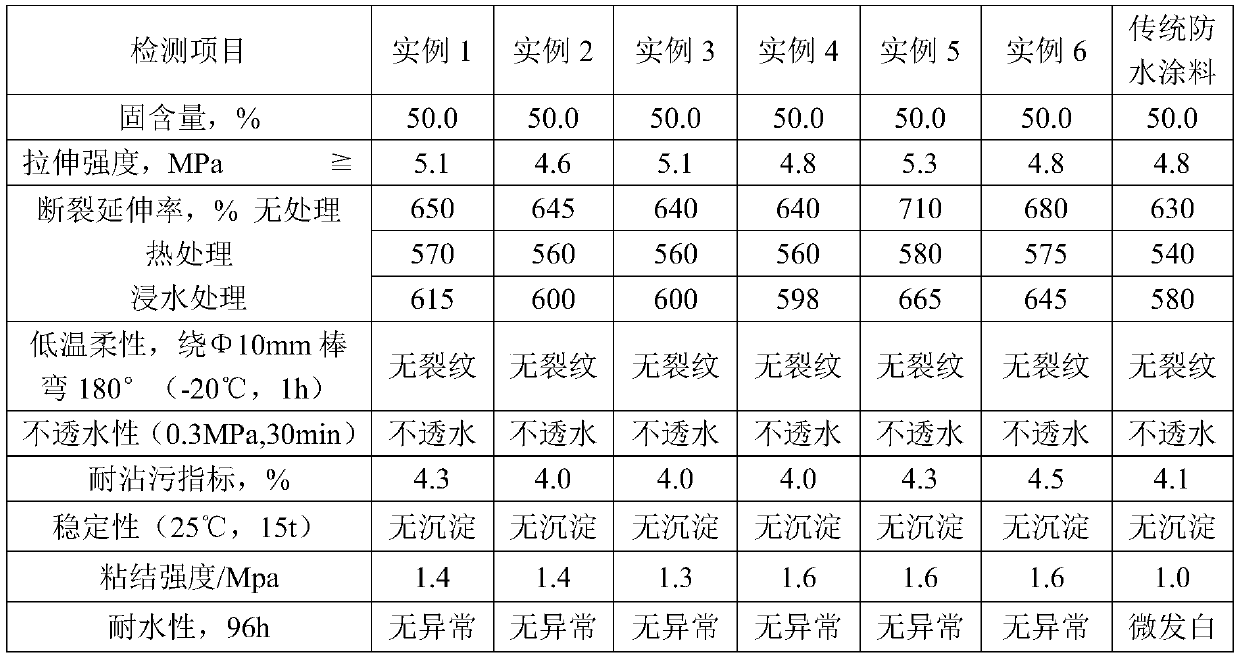

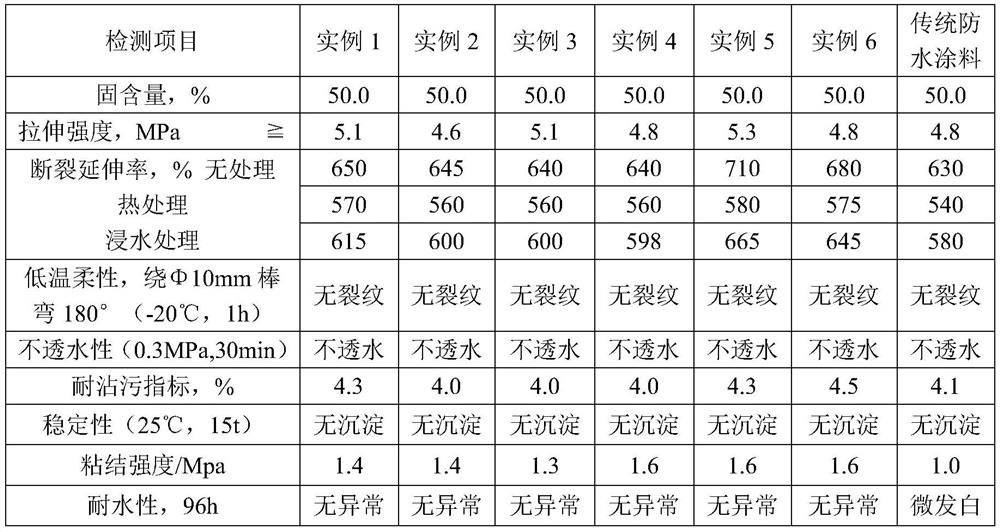

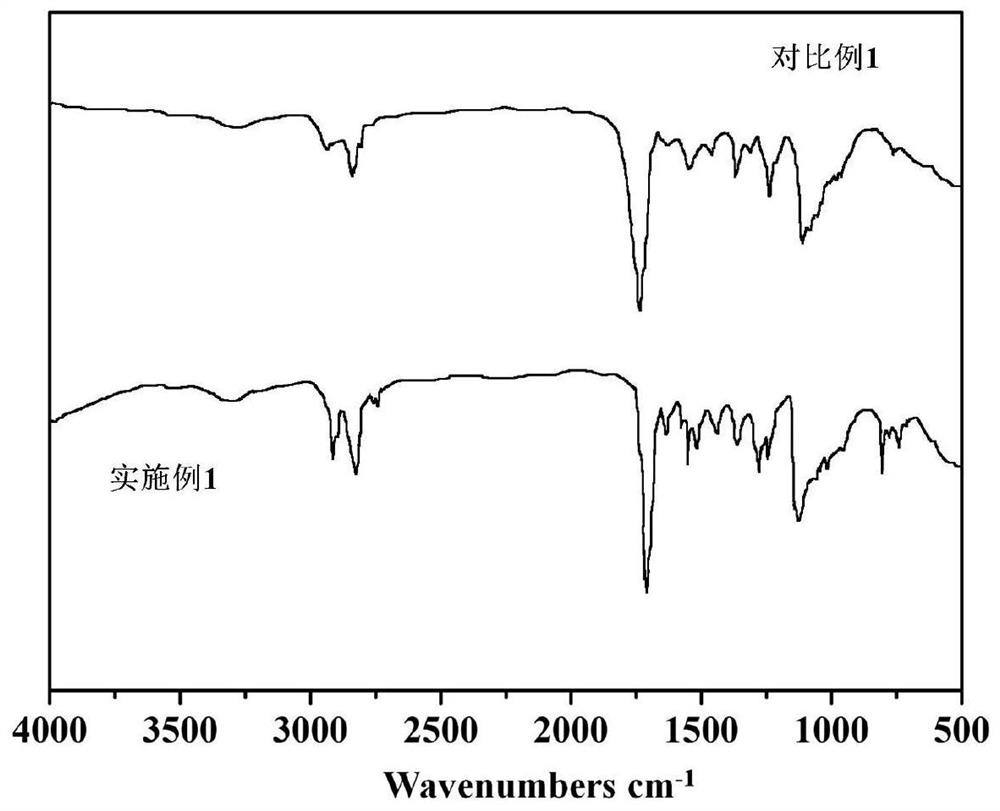

Graphene oxide reinforced waterproof polymer emulsion preparation method

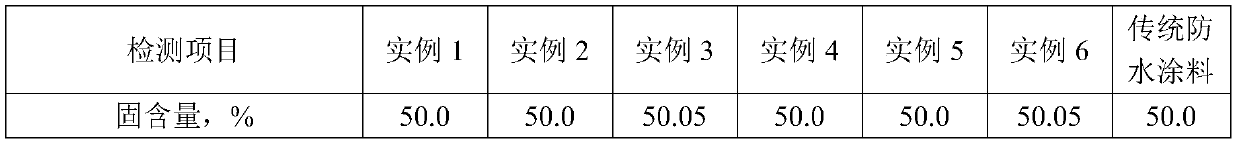

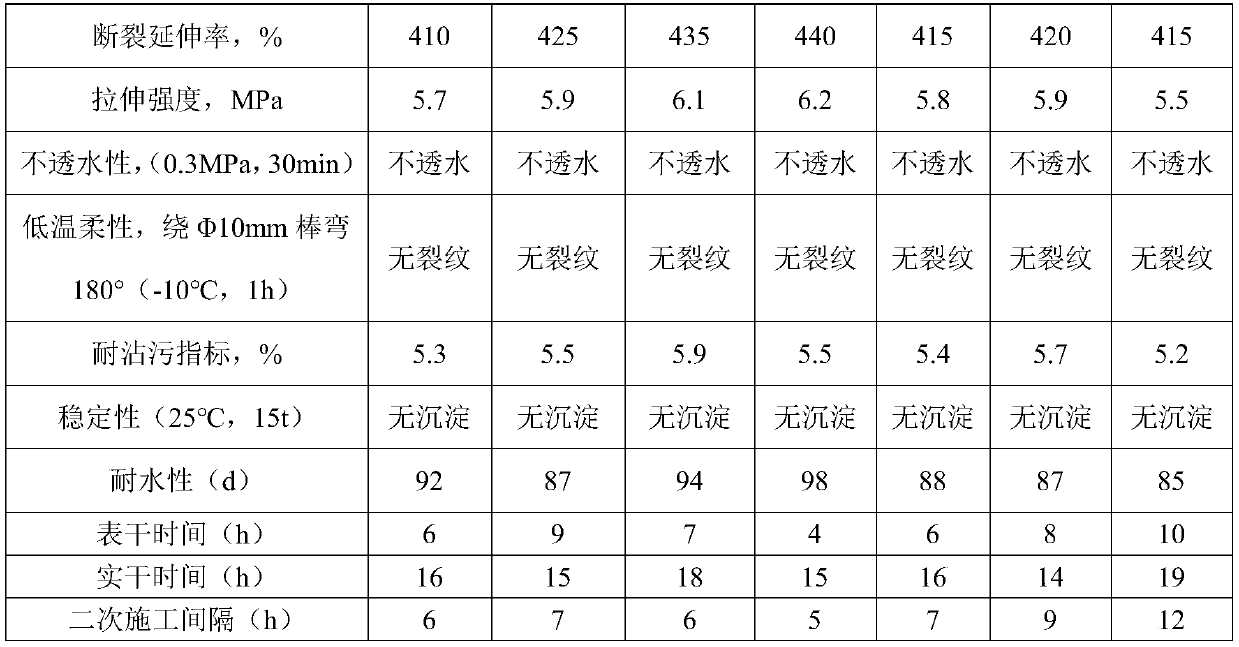

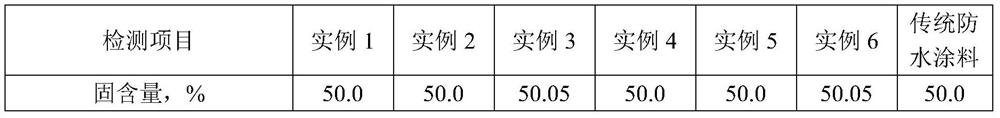

ActiveCN110591009AImprove environmental adaptabilityGood low temperature flexibilityCoatingsHydrophilic monomerFunctional monomer

The invention provides a graphene oxide reinforced waterproof polymer emulsion preparation method, wherein 1000 parts of the graphene oxide reinforced waterproof polymer emulsion comprise the following raw materials: 3.3-5.5 parts of an amide hydrophilic small monomer for emulsification, 6.5-15.0 parts of an alkyl hydrophobic small monomer for emulsification, 0.12-0.35 part of an emulsion initiator a, 0.24-0.56 part of a chain transfer agent, 8.3-13.5 parts of an amide hydrophilic small monomer, 35-46 parts of a flexible small monomer, 23-32 parts of an ether polymer, 2.5-6.0 parts of an initiator b, 200-280 parts of an alkyl hydrophobic small monomer, 100-160 parts of an acrylate-based hard monomer, 2.6-7.5 parts of a cross-linking agent, 1.2-2.6 parts of a neutralizer, 2.3-4.0 parts of apH regulator, 0.64-1.35 parts of a functional monomer, and the balance of deionized water. According to the invention, the polymer emulsion with advantages of good stability, strong adhesion, excellent tensile strength, excellent wear resistance and excellent water resistance is synthesized by using the amide-based strong hydrophilic monomer and the long alkyl chain hydrophobic monomer as the rawmaterials through dispersion pre-emulsification, constant-temperature polymerization, variable-speed stirring, pH adjustment and a series of processes, wherein the amide molecules can enhance the adhesion of the polymer, and the tensile strength, the water resistance and the wear resistance of the film formed by the emulsion are remarkably enhanced by graphene oxide.

Owner:HUBEI UNIV OF TECH

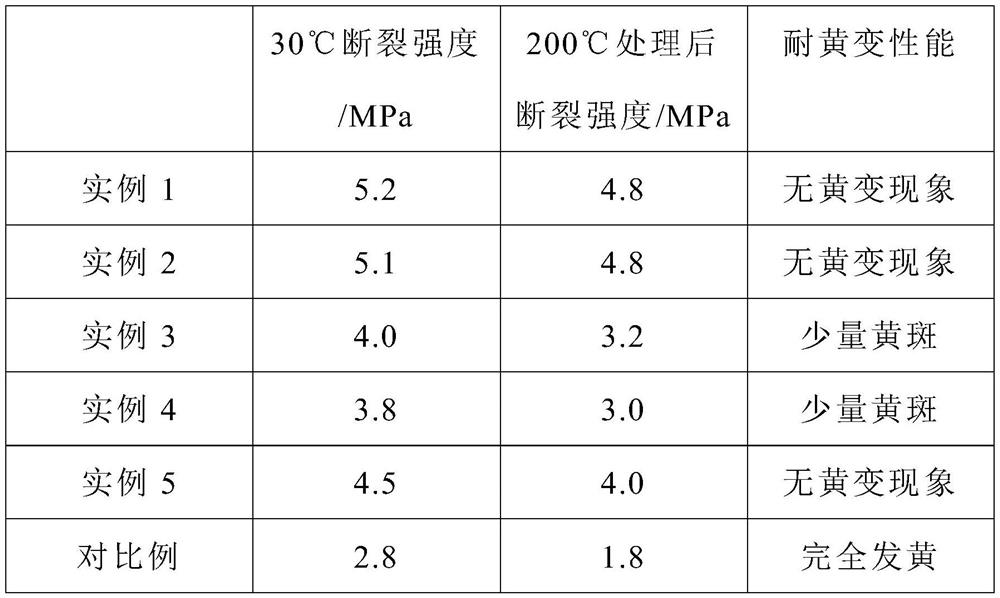

Novel electronic material with high thermal stability and preparation method thereof

ActiveCN109880566ALower surface energyReduce self-aggregationNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxySilicon dioxide

The invention discloses a novel electronic material with high thermal stability and a preparation method thereof and belongs to the field of high molecular materials for electronics. The preparation method comprises the following steps: Firstly, after carrying out chain expanding on nano silicon dioxide through polyacrylic acid, mixing with tetraethylenepentamine and polyethylenimine to prepare aminated nano silicon dioxide; then grafting the nano silicon dioxide with an epoxy group under the action of isocyanate; then grafting a flexible chain section containing hydroxyl on the nano silicon dioxide grafted with the epoxy group under the action of alkaline amine, so as to prepare modified nano silicon dioxide; finally, mixing epoxy resin, filler, a diluting agent, the aminated nano silicondioxide, the modified nano silicon dioxide, epoxidized soybean oil and a catalyst to prepare the novel electronic material with high thermal stability. The novel electronic material with high thermalstability, prepared by the technical scheme, can have very good utilization performance under a high-temperature condition.

Owner:SUZHOU YUDESHUI ELECTRIC TECH CO LTD

Coating for power lithium battery diaphragm, power lithium battery diaphragm and preparation thereof

ActiveCN102433745BHigh liquid absorptionHigh tensile strengthCell component detailsNatural fibresNano siliconN dimethylformamide

Owner:CHINA HAISUM ENG

High-strength wear-resistant wood-plastic composite material and preparation method thereof

The invention relates to a high-strength wear-resistant wood-plastic composite material and a preparation method thereof, and belongs to the technical field of polymer composite material preparation. According to the wood-plastic composite material disclosed by the invention, the treated wood chips, the self-made wear-resistant particles and the corresponding plastic wear-resistant reinforcing material are added into the wood-plastic composite material, so that the wear resistance and the mechanical property of the wood-plastic composite material are greatly improved, the application range of the wood-plastic composite material is widened, and the wood-plastic composite material has a wide application prospect.

Owner:王诗英

CCK release paper and preparation method thereof

PendingCN112878090AImprove water and oil repellencyImprove high temperature resistanceWater-repelling agents additionPulp beating methodsChemical pulpPaper sheet

The invention provides a preparation method of CCK release paper. The method comprises the following process steps: respectively subjecting coniferous wood chemical pulp and broadleaf wood chemical pulp to pulping, pulp mixing, auxiliary material adding, wet paper making with pulp, pre-drying, coating in a machine, post-drying, calendaring, finishing and the like so as to obtain the CCK release paper. According to the invention, the raw paper is subjected to in-machine coating treatment, so that the waterproof and oil-proof performance and the high-temperature resistance of the CCK release paper are effectively improved, and the tensile strength, the surface smoothness, the covering property and the heat insulation property of the paper are further improved after the coating. The product prepared by the method provided by the invention has the characteristics of good barrier property, high smoothness, high internal binding force, stable peel strength, environmental friendliness and the like, is directly coated with silicon and does not need to be coated in release processing, has the characteristics of cost reduction and environmental protection, and is a typical product replacing plastic. The invention also provides the CCK release paper.

Owner:YUEYANG FOREST & PAPER CO LTD

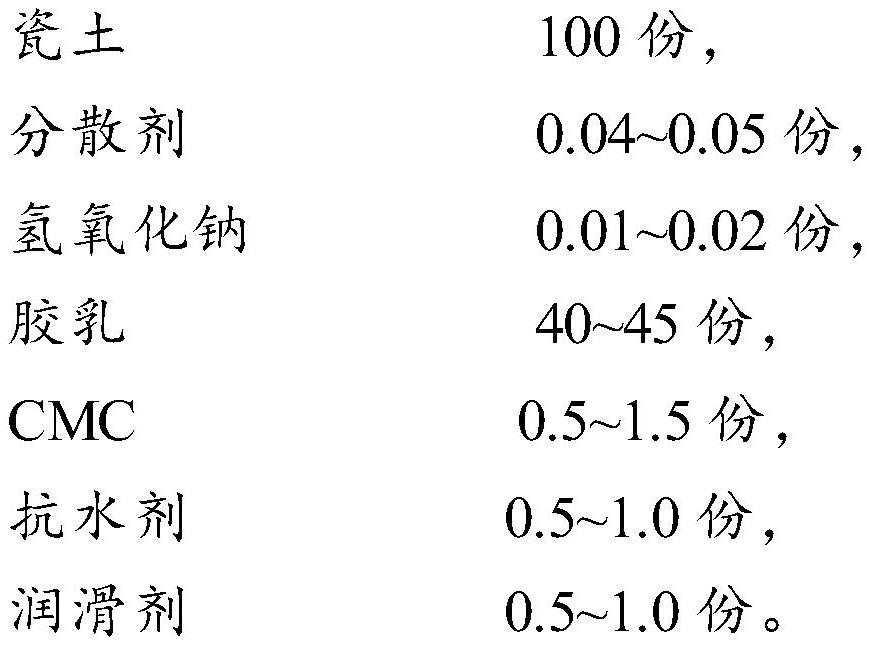

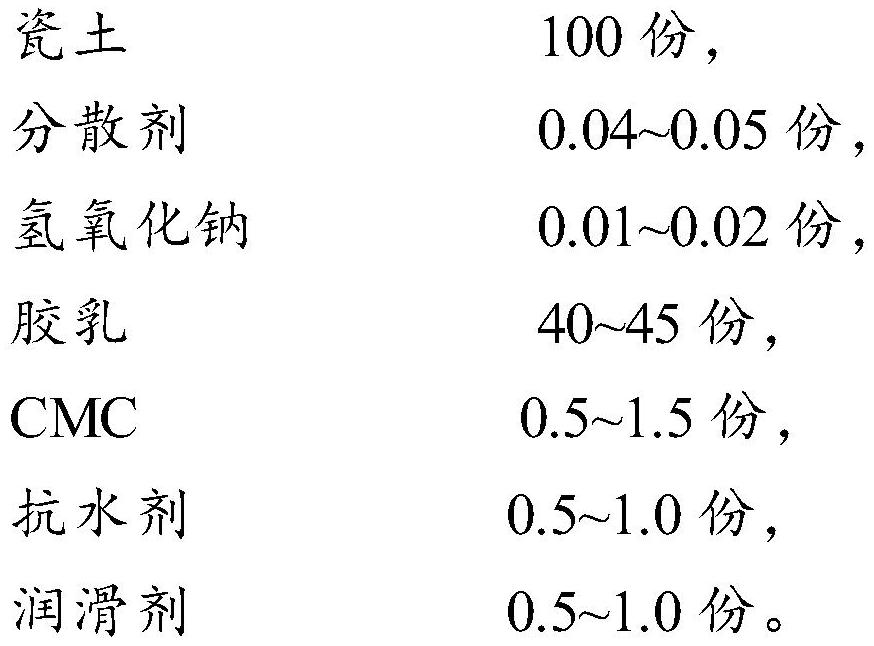

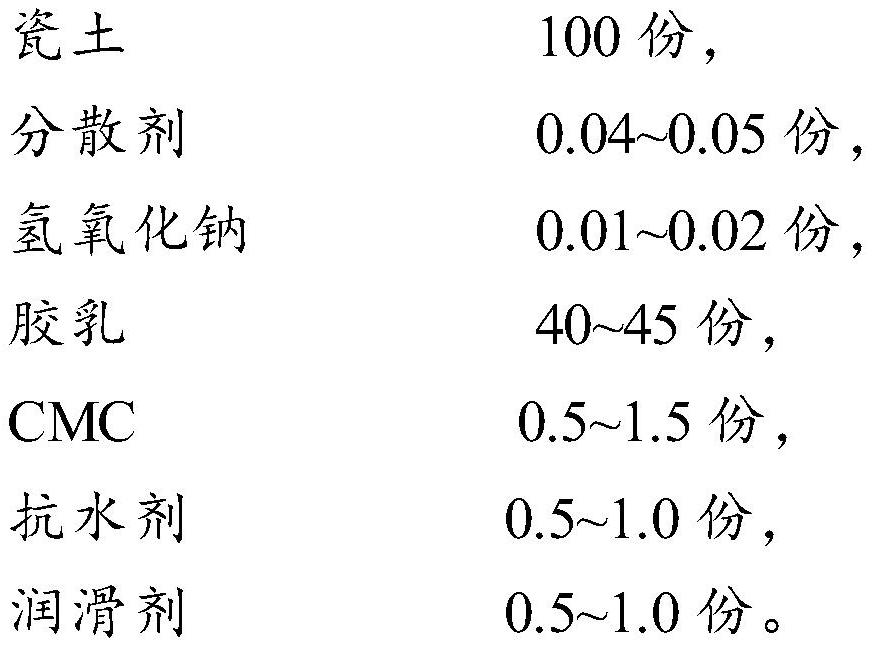

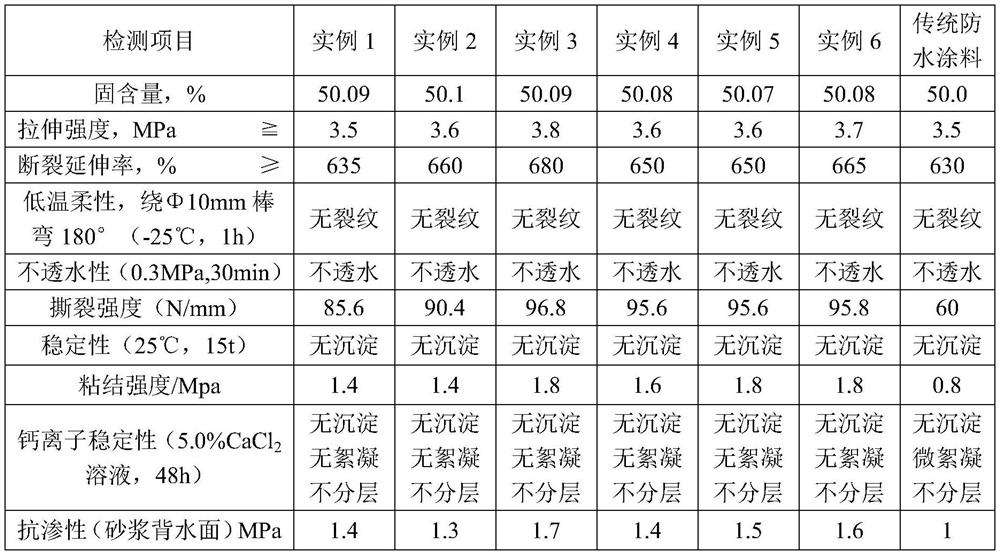

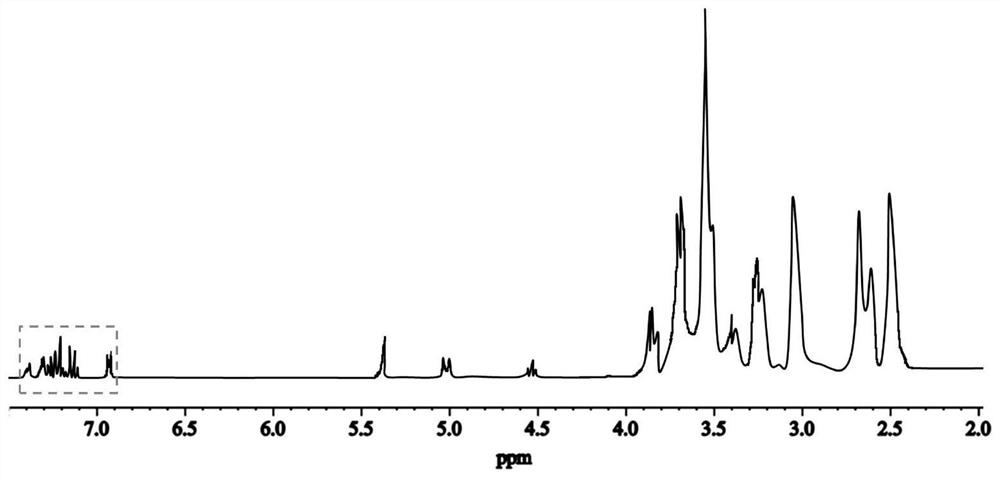

Preparation method of fluorine functional monomer modified soap-free emulsion polymer for polymer cement

The invention discloses a preparation method of a fluorine functional monomer modified soap-free emulsion polymer for polymer cement. Hydroxyl monomers and ester monomers are used as raw materials; asoap-free emulsion polymerization method is adopted, meanwhile, a pH regulator is used for controlling the pH value of the reaction environment to be 8 to 8.5; the soap-free hydroxyl hydrophilic monomers, soap-free ester-based hydrophobic monomers and an initiator a are subjected to reaction to synthesize a soap-free polymer; the soap-free polymer reacts with other raw materials to synthesize a polymer waterproof coating. The preparation method has the advantages of high polymerization speed, fewer reaction steps, small environmental pollution and mild reaction conditions, and the synthesizedproduct has quite good adhesion force, tensile elasticity and durability with a basal plane due to the proper pH value in the polymerization process.

Owner:HUBEI UNIV OF TECH

High-strength waterborne wood coating and manufacturing method thereof

InactiveCN109456669AHigh strengthHigh modulusAntifouling/underwater paintsPaints with biocidesFiberMaterials science

The invention discloses a high-strength waterborne wood coating and a manufacturing method thereof. The high-strength waterborne wood coating is prepared by taking polyurethane acrylate grafted acrylate, starch grafted sodium acrylate, water-soluble alkali, aluminum borate whisker, silicon carbide powder, CF (carbon fiber), tackifier extracted from cornu gorais powder, blocked isocyanate, polyether-siloxane copolymer, and aqueous adhesion promoter as raw materials and deionized water as medium for sufficient reaction at 70-85 DEG C, wherein the tackifier is prepared through the steps of moisturizing, pelletizing, boiling, purifying and concentrating; the waterborne adhesion promoter is prepared through the steps of soaking, microorganism fragmentation, collagen releasing and activating, and concentrating. The high-strength waterborne wood coating has the technical advantages of being applicable to wood surface, waterborne, free from damage to wood, high in strength and wearing resistance, lubricant in surface and good in texture.

Owner:JIANGSU HIMONIA TECH

Waterproof antibacterial coating for exterior walls of buildings applied in mycotic environment and manufacturing method thereof

InactiveCN109135382AGood water solubilityImprove brittlenessAntifouling/underwater paintsPaints with biocidesFiberPollution

The invention discloses a waterproof antibacterial coating for exterior walls of buildings applied in a mycotic environment and a manufacturing method thereof. The waterproof antibacterial coating comprises three parts of a component A, a component B and a component C, wherein the component A is a viscous solution involving the steps that under the combined action of ligninase and diluted hydrochloric acid, an aqueous solution composed of acid-modified polysaccharides and trace useless water-soluble organic matters and water is acquired from schizonepeta stem and houttuynia cordata root, and after heating concentration is carried out, the viscous solution is obtained; the component B is a mixed liquid involving the steps that activated carbon micro powder, chitosan antibacterial gel and Bossini nano-latex paint are mixed in absolute ethyl alcohol and then react with sodium hydroxide, after heating steaming from ethyl alcohol is carried out at 60-70 DEG C, the mixed liquid of a hydroxylated organic matter and activated carbon powder is obtained; the component C is a mixed dry fiber involving the steps that the schizonepeta stem and the houttuynia cordata root are subjected to complete dehydration and then physical mixing, and the mixed dry fiber is obtained. The waterproof antibacterial coating for the exterior walls of the buildings applied in the mycotic environment and the manufacturing method thereof have the advantages that the manufacturing process is detailed and easy to implement, the antibacterial effect is good, the effect is lasting, and the waterproof antibacterial coating is green, environmentally friendly and pollution-free, has no pungent smell, is resistant to water, and has a self-cleaning function.

Owner:山东天汇防水股份有限公司

Method for preparing modified hydroxyl ester-based polymer emulsion

The invention discloses a method for preparing a modified hydroxyl ester polymer emulsion. Required raw materials comprise the following components in parts by mass: 1.0-4.2 parts of a hydrophilic small monomer for emulsification, 1.7-4.5 parts of a hydrophobic small monomer for emulsification, 18-51 parts of a hydroxyl small monomer, 0.05-0.26 part of an emulsion initiator, 2.2-5.4 parts of an initiator a, 3.5-6.6 parts of an initiator b, 380-450 parts of an ester small monomer, 6.2-9.3 parts of a crosslinking agent, 0.06-0.28 part of a chain transfer agent, 0.5-1.0 part of graphene oxide, 15-40 parts of polyether, 5-10 parts of a neutralizer, 5-10 parts of a pH regulator, 2.0-6.5 parts of an emulsifier promoter, 0.4-1.3 parts of a liquid film enhancer and the balance of water, wherein the total parts by mass are 1000, and the solid content is 50%. The waterproof coating disclosed by the invention is suitable for cement mixing; due to a large number of hydroxyl groups, calcium ions can be stably complexed, calcium ion hydrolysis can be effectively inhibited, the cement strength can be increased, and the waterproof effect can be improved; due to hydrogen bonds in molecules of the hydroxyl groups, the internal binding force of the polymer can be improved, and the adhesion of the polymer with a matrix can be improved through a good hydrophilic effect; due to addition of the graphene oxide, the tensile strength of a polymer emulsion in film formation can be remarkably improved; and the water resistance can be also improved to a certain extent.

Owner:HUBEI UNIV OF TECH

Technical method for manufacturing artificial boards with peanut shells and sunflower stalks by pressing

InactiveCN102380902AConvenient secondary processingHigh strengthWood working apparatusFlat articlesNational standardEngineering

A technical method for manufacturing artificial boards with peanut shells and sunflower stalks by pressing belongs to the non-timber artificial board manufacturing industry, and is a technical method for manufacturing artificial boards with agricultural waste such as stalks and shells serving as raw materials by pressing. All indexes of the artificial boards manufactured by the method reach the national standards of flakeboards and shaving boards, so that the artificial boards can be widely applied to packaging and home decoration industries, and are lower in manufacturing cost, free of environmental pollution and suitable for large-scale industrial production.

Owner:刘金忠

Strength-toughness waterproof coating applied in indoor decoration and manufacturing method thereof

InactiveCN109207027AWide variety of sourcesManufacturing process detailsEpoxy resin coatingsChitinKetone

The invention discloses a strength-toughness waterproof coating applied in indoor decoration and a manufacturing method thereof. The waterproof coating comprises two parts, one part is a viscous suspension obtained from heating concentration of a suspension composed of acidified modified methacryloxy light curing resin, chitin micro-powder, lignin decomposed polysaccharide, trace useless organic matters and minerals and water, wherein the acidified modified methacryloxy light curing resin is obtained from lobster shells, methacryloxy light curing resin and sawdust under the combined action oflysase, ligninase and dilute hydrochloric acid; the other part is a hydroxylated bisphenol A epoxy acrylate and hydroxylated 2-hydroxyl-1,2-diphenyl ethyl ketone aqueous solution obtained by dissolving bisphenol A epoxy acrylate and 2-hydroxy-1,2-diphenyl acetone in absolute ethyl alcohol, then undergoing a reaction with sodium hydroxide and then carrying out heating evaporation to remove ethyl alcohol. The strong-tough waterproof coating has the advantages of wide source, detailed and easily realized manufacturing process, quick effect, lasting effect, green and environmental protection, no pollution, high strength, good toughness and self-hydrophobicity.

Owner:山东天汇防水股份有限公司

A production process of digital printing base paper

ActiveCN110485204BHigh base strengthDirectional controllableSpecial paperCane mechanical workingFiberPolyester

The invention discloses a production process of digital printing base paper. The digital printing base paper uses 80-100 parts of peeled alpine bamboo yellow, 20-25 parts of polyester fiber, and 28-32 parts of phosphogypsum whiskers as raw materials ; Xylanase water, sodium hydroxide aqueous solution, MJB-NS bamboo silk softener as auxiliary materials, peeled alpine bamboo yellow is first boiled with water, modified, purified and bleached by a compound softener for two times of enzymatic decomposition, and three times of lightening. After carbonization compound activation treatment, it is hot-melted with other raw materials in a protective atmosphere. The invention has the advantages of high uniformity of fiber arrangement, good stiffness, high whiteness, water loss resistance, moderate electrical performance and smooth surface.

Owner:浙江夏王纸业有限公司

A kind of electronic material with high thermal stability and preparation method thereof

ActiveCN109880566BLower surface energyReduce self-aggregationNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPtru catalyst

The invention discloses an electronic material with high thermal stability and a preparation method thereof, belonging to the field of polymer materials for electronics. In the present invention, nano-silica is firstly chain-extended by polyacrylic acid, and mixed with tetraethylenepentamine and polyethyleneimine to prepare aminated nano-silica, and then nano-titanium dioxide is grafted with rings under the action of isocyanate. Oxygen groups, then grafted epoxy group nano-titanium dioxide and then grafted hydroxyl-containing flexible segments under the action of basic amines to prepare modified nano-titanium dioxide, and finally epoxy resin, fillers, diluents, amination Silicon dioxide, modified titanium dioxide, epoxy soybean oil and catalyst are mixed to prepare electronic material with high thermal stability. The electronic material with high thermal stability prepared by the technical solution of the present invention can have very good performance under high temperature conditions.

Owner:SUZHOU YUDESHUI ELECTRIC TECH CO LTD

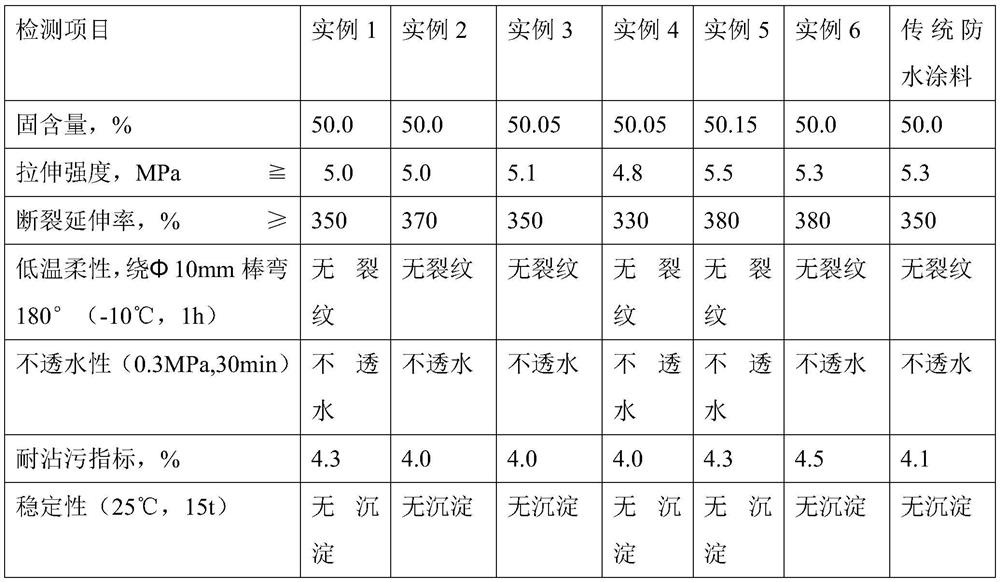

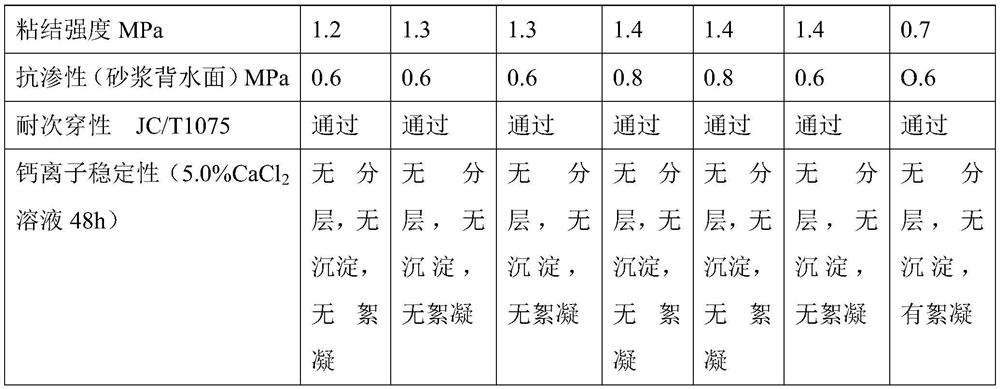

A kind of preparation method of ether modified hydroxy alkyl polymer emulsion

ActiveCN110615874BHigh glass transition temperatureSuitable glass transition temperatureCoatingsHydrophilic monomerPolymer science

The invention discloses a preparation method of ether modified hydroxy alkyl polymer emulsion. Raw materials required for preparation: 3.2-5.5 parts of hydroxyl-based hydrophilic small monomers for emulsification, 6.8-15.0 parts of alkyl-based hydrophobic small monomers for emulsification, 0.15-0.35 parts of emulsion initiator a, 0.35-0.56 parts of chain transfer agent, 8.6-15.5 parts of hydroxyl-based hydrophilic small monomers, 35-46 parts of flexible small monomers, 18-28 parts of ether polymers, 3.5-6.8 parts of initiator b, 230-280 parts of alkyl-based hydrophobic small monomers, 120-160 parts of acrylate hard monomer, 1.2-3.5 parts of cross-linking agent, 1.2-2.6 parts of neutralizer, 2.3-4.5 parts of pH regulator, 0.23-0.46 parts of functional monomer, supplemented with deionized water to 1000 parts . The present invention uses hydroxyl strong hydrophilic monomers and long alkyl chain hydrophobic monomers as raw materials, and synthesizes a product with good stability, strong adhesion and excellent waterproof effect through processes such as dispersion pre-emulsification, constant temperature polymerization, variable speed stirring, and pH adjustment. Durable polymer coating, the polar effect of hydroxyl group can greatly strengthen the stability of polymer emulsion, strong hydrophilic effect strengthens the adhesion, and the cross-linking agent network can significantly improve the mechanical properties.

Owner:HUBEI UNIV OF TECH

A kind of preparation method of benzene ring type core-shell emulsion polymer for cement

ActiveCN110606918BSmall particle sizeControl relative molecular weightCoatingsHydrophilic monomerBenzene

Owner:HUBEI UNIV OF TECH

Formaldehyde-removing, self-cleaning, environment-friendly and waterproof interior coating, and manufacturing method thereof

InactiveCN108997897AReduce air concentrationFacilitate emissions removalAntifouling/underwater paintsPaints with biocidesMicrocrystalline waxDecomposition

The invention discloses a formaldehyde-removing, self-cleaning, environment-friendly and waterproof interior coating, and a manufacturing method thereof. The waterproof interior coating comprises three parts, i.e., a component A, a component B and a component C, wherein the component A is a viscous solution obtained through heating concentration of a mixture of acid-modified methacryloxy light-cured resin, which is obtained through treatment of methacryloxy light-cured resin and sawdust, polysaccharide, which is obtained through lignin decomposition, and water; the component B is a water solution of hydroxylated bisphenol A epoxy acrylate and hydroxylated 2-hydroxy-1,2-phenylacetophenone that is obtained through heating of a reaction product of bisphenol A epoxy acrylate, 2-hydroxy-1,2-phenylacetophenone and sodium hydroxide; and the component C is mixed solid powder obtained through physical mixing of aluminum oxide ceramic powder, microcrystalline wax powder and soybean cake powder,in which micrococcus tetragenus is cultivated, according to parts by weight. The coating and the manufacturing method thereof provided by the invention have the advantages that the manufacturing process is detailed and easy to implement; and the coating achieves quick solidification, long-lasting effects, environmental friendliness, zero pollution, high surface abrasion resistance, high hydrophobicity, and the self-cleaning function.

Owner:山东天汇防水股份有限公司

Building internal wall waterproof formaldehyde-removing coating applied to indoor environment as well as manufacturing method thereof

InactiveCN109233637AImprove wear resistanceImprove breathabilityLignin material coatingsPectinaseBacillus thuringiensis

The invention discloses a building internal wall waterproof formaldehyde-removing coating applied to an indoor environment as well as a manufacturing method thereof. The waterproof formaldehyde-removing coating comprises three parts, namely a component A, a component B and a component C, wherein the component A is prepared by putting sawdust and green straws under the comprehensive action of cellulase, pectinase and diluted hydrochloric acid to obtain a viscous solution, performing high-temperature sterilization, performing neutralizing treatment by using alkali in an amount which is smaller than that of acid and finally implanting bacillus thuringiensis to cultivate; the component B is obtained by suspending an activated carbon micropowder, a 1000-mesh ash calcium powder and a 1000-mesh triple superphosphate powder into absolute ethanol; and the component C is formed by performing enzymolysis and alcohol washing on the sawdust and the green straws and dehydrating the remaining by using the cellulose taking lignin as a main material. The building internal wall waterproof formaldehyde-removing coating has a spontaneous respiration like property, a durable formaldehyde-removing effect and high removing depth, is green, pollution-free and water-resistant, and can consume water.

Owner:山东天汇防水股份有限公司

A wood-plastic composite floor for shopping malls and its manufacturing method

ActiveCN110259046BPreserve structural propertiesHigh strengthWood treatment detailsFlat articlesBenzoic acidCellulose

The invention discloses a wood-plastic composite floor for shopping malls and a manufacturing method thereof. The wood-plastic composite floor is composed of four components, which are respectively used as a base body, using pine trunks with bark as raw materials to be softened by boiling, mechanically Lignocellulose grid structure obtained after pressing and removal of water-soluble substances, poly-3,4-ethylenedioxythiophene / graphene composite material with internal fascia and antistatic function, as adhesive and structure adjustment material Plastic body composed of chopped glass fibers and unsaturated resin isophthalic resin, polysiloxane crystals as surface wear-resistant coating. The surface of the invention is wear-resistant, tear-resistant, high-strength, water-resistant, acid-resistant, and oxidation-resistant.

Owner:安徽爱瑞德新材料有限公司

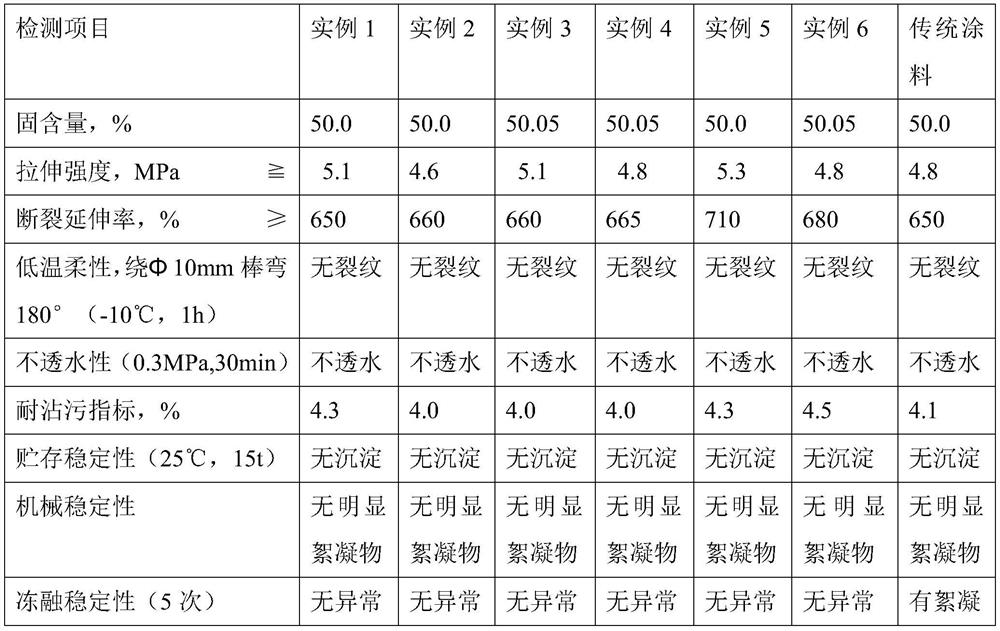

A kind of preparation method of core-shell type carboxyl benzene ring type emulsion polymer for coating

ActiveCN110698603BStrengthen the internal binding forceImprove mechanical propertiesCoatingsHydrophilic monomerPolymer science

Owner:HUBEI UNIV OF TECH

A method of in-situ self-assembly in solid wood to prepare polyurethane-reinforced wood

ActiveCN103586947BImprove water resistanceExcellent anti-corrosion and mildew resistancePressure impregnationPolymerisation impregnationCross-linkSolid wood

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

A kind of preparation method of graphene oxide reinforced waterproof polymer emulsion

ActiveCN110591009BImprove environmental adaptabilityGood low temperature flexibilityCoatingsHydrophilic monomerPolymer science

The invention provides a preparation method of graphene oxide reinforced waterproof polymer emulsion. Required raw materials: 3.3-5.5 parts of amide-based hydrophilic small monomers for emulsification, 6.5-15.0 parts of alkyl-based hydrophobic small monomers for emulsification, 0.12-0.35 parts of emulsion initiator a, 0.24-0.56 parts of chain transfer agent, amides 8.3-13.5 parts of hydrophilic small monomers, 35-46 parts of flexible small monomers, 23-32 parts of ether polymers, 2.5-6.0 parts of initiator b, 200-280 parts of alkyl hydrophobic small monomers, acrylic acid 100-160 parts of hard ester monomer, 2.6-7.5 parts of cross-linking agent, 1.2-2.6 parts of neutralizing agent, 2.3-4.0 parts of pH regulator, 0.64-1.35 parts of functional monomer, and 1000 parts of deionized water. The present invention uses amide-based strong hydrophilic monomers and long alkyl chain hydrophobic monomers as raw materials, and synthesizes a product with good stability, strong adhesion, and Polymer emulsion with excellent tensile, wear-resistant, and waterproof properties, in which amide-based molecules strengthen the adhesion of the polymer, and graphene oxide significantly enhances the tensile strength, water resistance, and abrasion resistance of the emulsion film.

Owner:HUBEI UNIV OF TECH

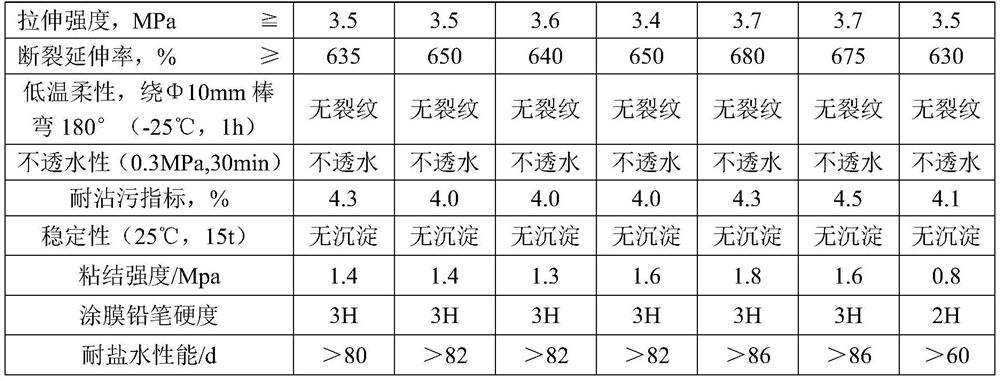

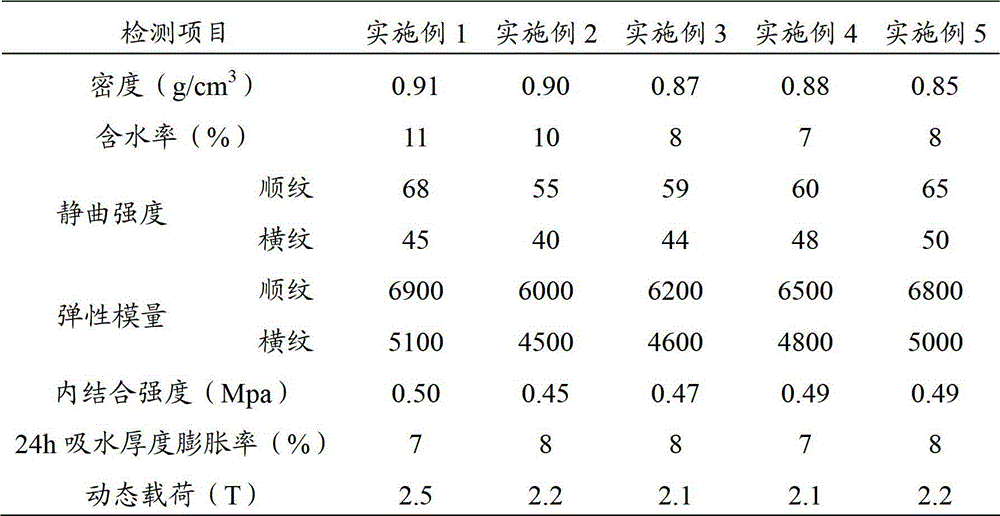

Directional shaving board and manufacturing method thereof

InactiveCN102909772AEasy to shapeImprove mechanical propertiesLaminationWood working apparatusWood shavingsSoft materials

The invention provides a directional shaving board, which comprises a panel, a core board and a bottom board. The directional shaving board is characterized in that wood shavings in the core board comprise soft wood shavings and hard wood shavings; a soft material is wood with the air-dry density of less than 0.5g / cm<3>; and a hard material is wood with the air-dry density of more than or equal to 0.5g / cm<3>. By adopting the mixture of the two shavings, the obtained directional shaving board is high in static bending intensity and elastic modulus, and the internal binding force of the directional shaving board is improved so as to be beneficial to the application of the directional shaving board. Experimental results prove that the static bending intensity along the grain of the directional shaving board is more than or equal to 50MPa, and the static bending intensity across the grain of the directional shaving board is more than or equal to 30MPa; the modulus of elasticity along the grain of the directional shaving board is more than or equal to 5,000MPa, and the modulus of elasticity across the grain of the directional shaving board is more than or equal to 3,000MPa; the internal bonding strength of the directional shaving board is more than or equal to 0.45MPa; and the directional shaving board can bear dynamic load of more than or equal to 2.0T.

Owner:江苏快乐木业集团有限公司

Preparation method of carboxyl alkyl type emulsion polymer

ActiveCN110835390AEffective control of particle size distributionReasonable control of particle size distributionCoatingsHydrophilic monomerPolymer science

A preparation method of a carboxyl alkyl type emulsion polymer is disclosed. A carboxyl strong-hydrophilic monomer and a long alkyl chain hydrophobic monomer are adopted as raw materials in the method. Polymer waterproof coating is prepared by a series of processes including dispersion pre-emulsification, constant-temperature polymerization, variable-speed stirring, and pH adjustment. Hydrogen bonds in carboxyl molecules can strengthen the internal binding force of the polymer, strong hydrophilic effect strengthens the adhesion with a matrix, the network-like binding effect of the cross-linking agent can significantly improve the mechanical properties between the polymers, and the polymer waterproof coating which is good in stability, high in adhesive force, and excellent and durable in waterproof effect can be produced.

Owner:HUBEI UNIV OF TECH

A kind of preparation method of carboxyl alkyl emulsion polymer

ActiveCN110835390BHigh molecular weightImprove hydrophobicityCoatingsHydrophilic monomerPolymer science

The invention discloses a preparation method of a carboxyalkyl emulsion polymer. This method uses carboxyl strong hydrophilic monomers and long alkyl chain hydrophobic monomers as raw materials, and synthesizes a polymer waterproof coating through a series of processes such as dispersion pre-emulsification, constant temperature polymerization, variable speed stirring, and pH adjustment. Hydrogen bonds can strengthen the internal binding force of the polymer, and the strong hydrophilic effect can strengthen the adhesion between the matrix and the crosslinking agent. Large, long-lasting polymer waterproof coating with excellent waterproof effect.

Owner:HUBEI UNIV OF TECH

Environment-friendly MDI glue and fireproof formaldehyde-free plate containing same and used for furniture

PendingCN113667096AExcellent water resistance bonding strengthExcellent combustion resistanceWood working apparatusDomestic articlesPolymer scienceEngineering

The invention discloses environment-friendly MDI glue and a fireproof formaldehyde-free board containing the same and used for furniture, and relates to the technical field of artificial boards. The content of a hard chain segment in the environment-friendly MDI glue structure is 24.2-30.5 wt%; the material of the hard chain segment comprises MDI or H12MDI; a soft chain segment material in the polyurethane structure comprises polytetrahydrofuran; and a chain extender in the polyurethane structure comprises BPO and 3-isomangostin. The prepared environment-friendly MDI glue has better and excellent mechanical properties and gluing effect, is applied to a plywood preparation process, remarkably improves the internal binding force, static bending intensity, nail-holding power and other properties of a board, has a better fireproof effect of the board, does not generate formaldehyde in the use process, and is safe and environment-friendly.

Owner:湖南省玛芸家居科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com