A kind of electronic material with high thermal stability and preparation method thereof

A technology of high thermal stability and electronic materials, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of affecting the service life of LEDs, cracking of epoxy packaging materials, thermal stability Poor performance and other problems, to achieve the effect of improving crack resistance, reducing self-aggregation, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

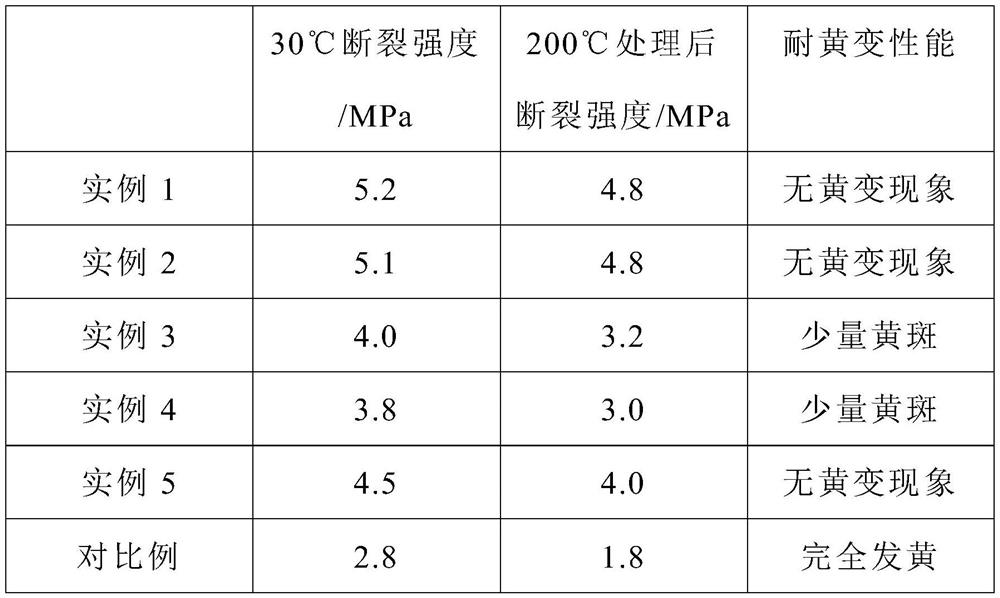

Examples

example 1

[0042] An electronic material with high thermal stability, in parts by weight, mainly comprising: 65 parts of epoxy resin E-44, 10 parts of diglycidyl ether, 15 parts of aluminum powder, 8 parts of curing agent, 18 parts of additives, 24 parts of Modified titanium dioxide, 5 parts zinc chloride, 10 parts epoxidized soybean oil.

[0043] A preparation method of an electronic material with high thermal stability, the preparation method of an electronic material with high thermal stability mainly comprises the following preparation steps:

[0044] (1) Mix nano-silica and polyacrylic acid in a beaker at a mass ratio of 1:2, and add N,N-dimethylformamide with a mass of 300 times the mass of nano-silica into the beaker, at a temperature of 90°C , under the condition of rotating speed of 360r / min, stirring and mixing for 80min to obtain nano-silica mixed dispersion, mix nano-silica mixed dispersion with 4-dimethylaminopyridine in a mass ratio of 200:1, and add 4- N,N'-dicyclohexylca...

example 2

[0054] An electronic material with high thermal stability, in parts by weight, mainly comprising: 65 parts of epoxy resin E-51, 10 parts of diglycidyl ether, 15 parts of aluminum powder, 8 parts of curing agent, 18 parts of additives, 24 parts of Modified titanium dioxide, 5 parts zinc chloride, 10 parts epoxidized soybean oil.

[0055] A preparation method of an electronic material with high thermal stability, the preparation method of an electronic material with high thermal stability mainly comprises the following preparation steps:

[0056] (1) Mix nano-silica and polyacrylic acid in a beaker at a mass ratio of 1:2, and add N,N-dimethylformamide with a mass of 300 times the mass of nano-silica into the beaker, at a temperature of 90°C , under the condition of rotating speed of 360r / min, stirring and mixing for 80min to obtain nano-silica mixed dispersion, mix nano-silica mixed dispersion with 4-dimethylaminopyridine in a mass ratio of 200:1, and add 4- N,N'-dicyclohexylca...

example 3

[0066] An electronic material with high thermal stability, in parts by weight, mainly comprising: 65 parts of epoxy resin E-44, 10 parts of diglycidyl ether, 15 parts of aluminum powder, 8 parts of tetraethylene pentamine, 18 parts of additives, 24 parts of modified titanium dioxide, 5 parts of zinc chloride, 10 parts of epoxidized soybean oil.

[0067] A preparation method of an electronic material with high thermal stability, the preparation method of an electronic material with high thermal stability mainly comprises the following preparation steps:

[0068] (1) Mix nano-titanium dioxide and diisocyanate in a mass ratio of 1:1, and add anhydrous acetone with a mass of 30 times the mass of nano-titanium dioxide and an epoxy resin solution with a mass of 5 times the mass of nano-titanium dioxide, under a nitrogen atmosphere, at a temperature of 150 ℃, under the condition of rotating speed of 320r / min, after stirring and reacting for 24h, filter and dry at the temperature of 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com