Patents

Literature

32results about How to "Enhance internal bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

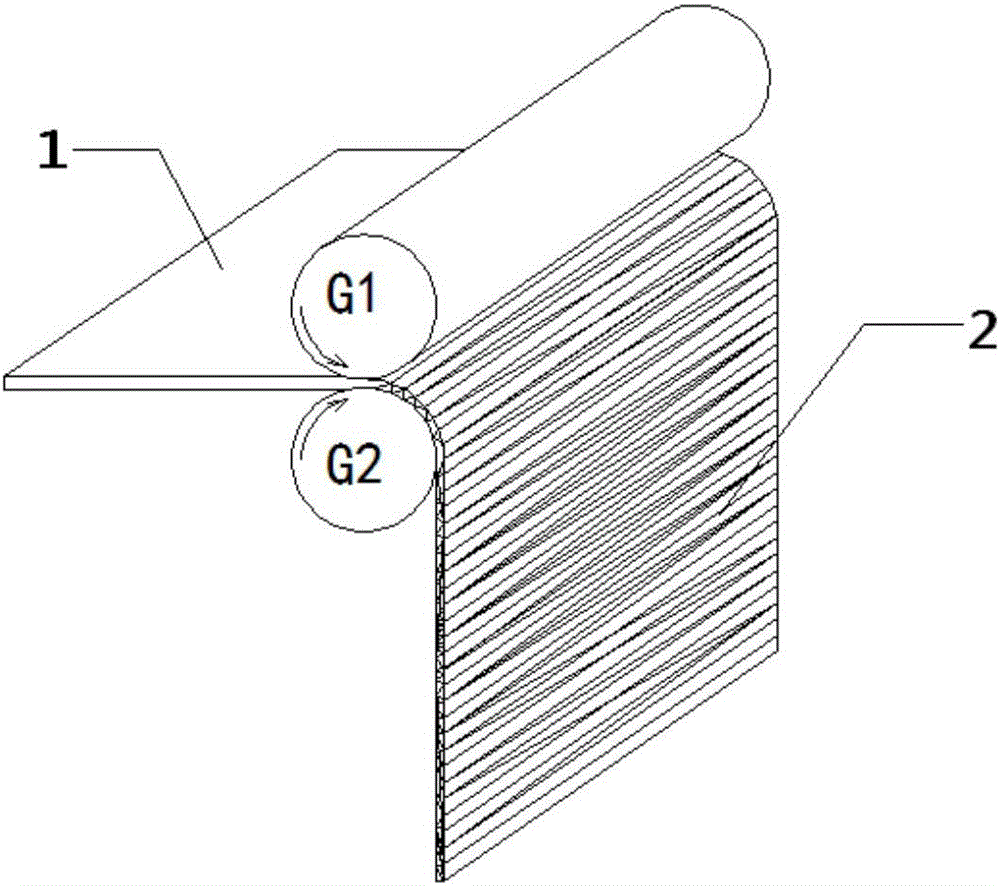

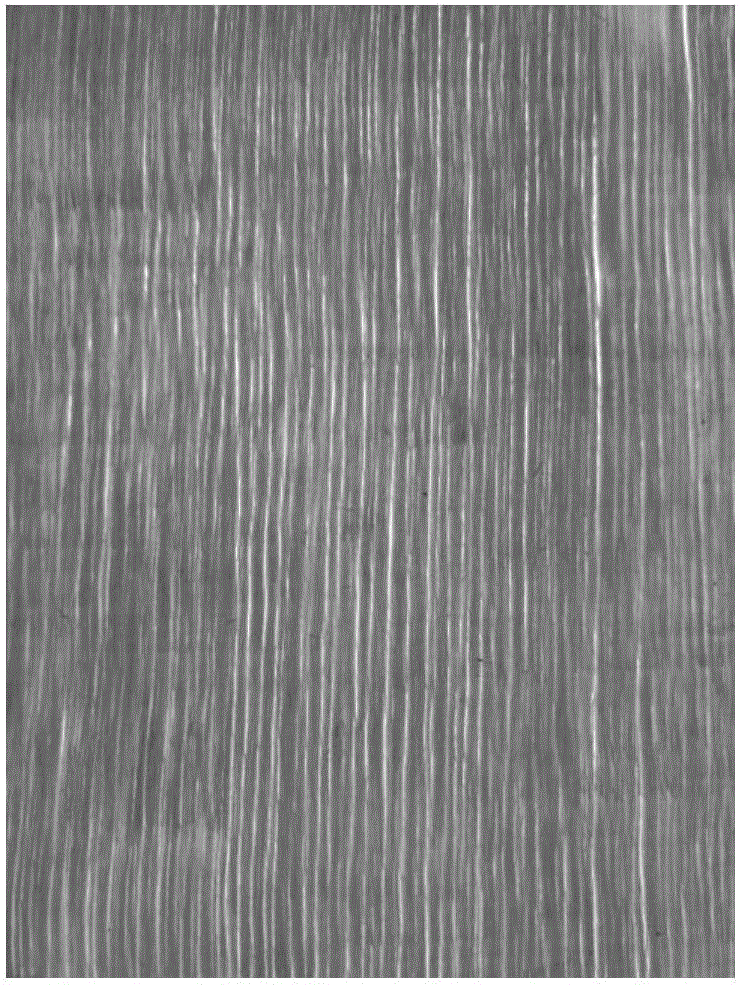

Wood veneer treatment method and reconstituted wood

InactiveCN106426430AReduce rigidityImprove density uniformityOther plywood/veneer working apparatusWood compressionWood veneerFiber

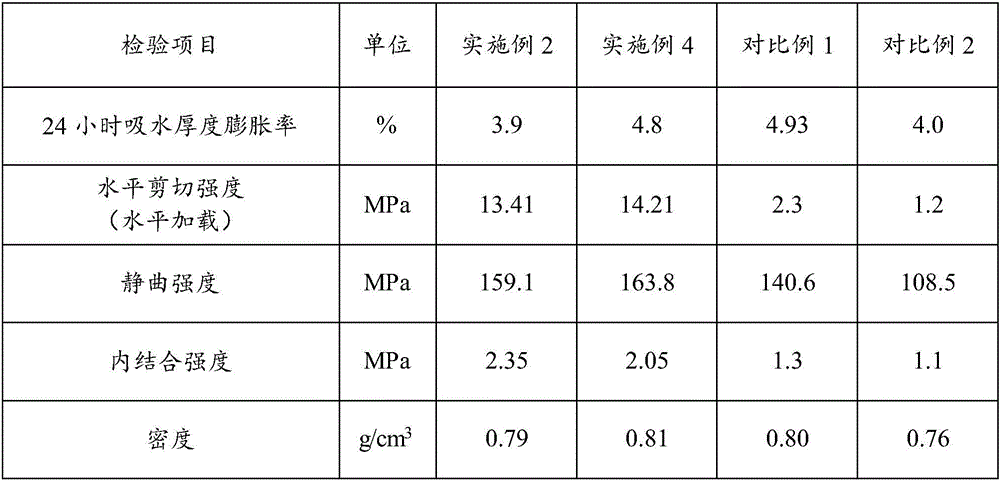

The invention belongs to the field of wood processing, and particularly relates to a wood veneer treatment method and reconstituted wood. The method comprises the step of placing a wood veneer in a rolling machine according to the fibre cross-grain direction thereof, and rolling to obtain a treated veneer, wherein a roll gap of the rolling machine is 10-80% of a thickness of the wood veneer. With the adoption of the method provided by the invention, the wood veneer can be rolled into a broomed-meshy-structure veneer with fibres which are not broken in a longitudinal direction and loose in a transversal direction, a natural texture structure of raw wood is reserved, the rigidity of the veneer is eliminated, and an initial stress and a pressing pressure are reduced, thus the density uniformity of the pressed reconstituted wood is improved, and the warping and deformation of the reconstituted wood are reduced; meanwhile, the surface area of the treated veneer is increased, and glue dipping is more uniform, thus a cracking risk of the prepared reconstituted wood is reduced; and in addition, fine fibres in the treated veneer are mutually interleaved to increase an internal binding force, thus cracking and warping risks caused by the reconstituted wood are further reduced.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

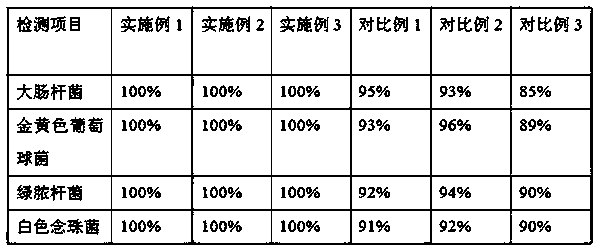

Environment-friendly nano-silver bacteriostatic compound

The invention relates to an environment-friendly nano-silver bacteriostatic compound, and belongs to the technical field of antibacterial agents. Nano-copper powder as a raw material cooperates with epoxy resin to be used as a bacteriostatic carrier, the bacteriostatic effect can be fully played and good biodegradability is achieved; with sodium alginate as a reducing agent and a stabilizing agent, an AgNO3 solution is irradiated by ultraviolet light to prepare the nano-silver and silver compound, so the compound gives full play to a bacteriostatic effect, and has high biodegradability; addedmicrocrystalline paraffin wax can carry nano-silver in the system to float upward to the surface of the system during preparation, a water-inhibiting bacteriostatic layer is formed on the product surface, and the plasticity of the bacteriostatic compound system can be improved; in the subsequent preparation process, plant essential oil can occupy the positions of a part of functional groups in thecross-linking network of a composite matrix and chitosan, reduces the vibration intensity of covalent bonds in the cross-linking network molecules, plays a multi-level bacteriostatic effect, and hasno secondary pollution. The problems that the commonly used bacteriostatic agent can cause secondary pollution and has poor bacteriostatic effect in the use process are solved.

Owner:FOSHAN SENANG BIO TECH CO LTD

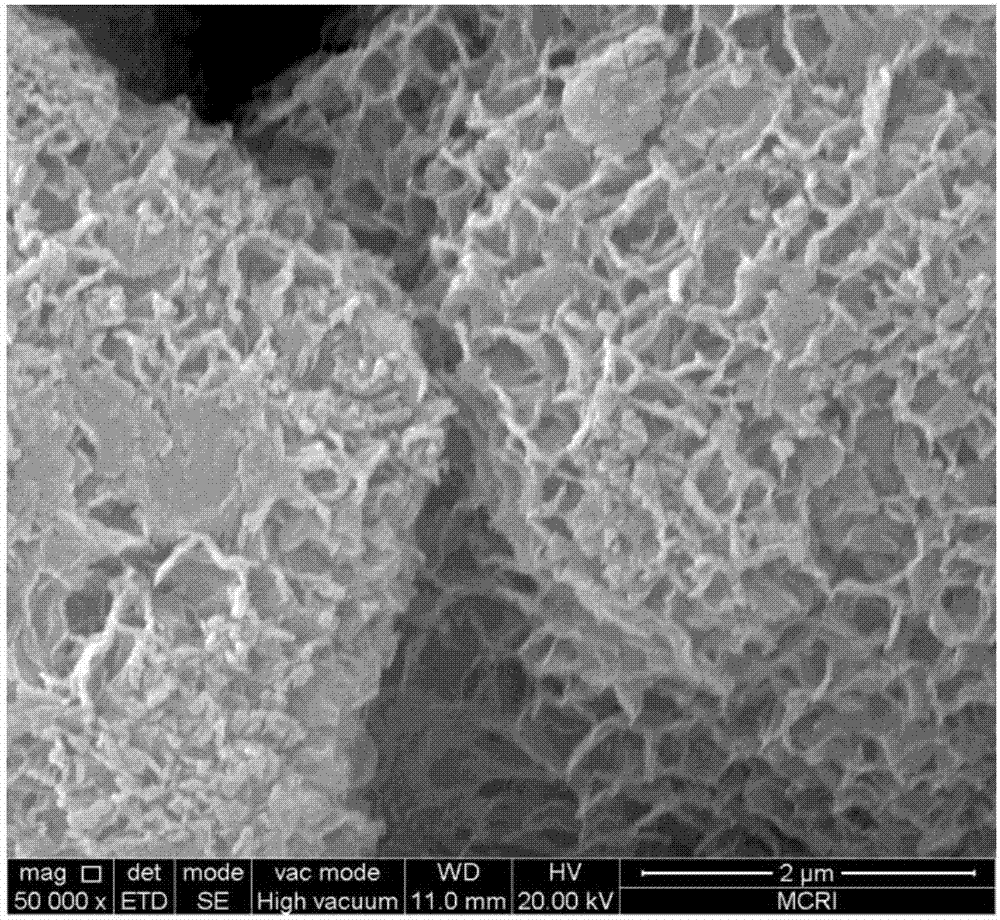

Application of synthetic calcium carbonate as high paper filler and preparation method of high paper filler

InactiveCN107287980AHigh total retentionHigh opacityInorganic compound additionFiberCalcium silicate

The synthetic calcium carbonate, as the application of papermaking filler, belongs to the papermaking technical field. The plant pulp fiber material is as the skeleton, synthetic calcium silicate power is as the filler, and the high paper filler is produced by paper-making technics. The synthetic calcium silicate power is as the hydrated calcium aluminate, and the object composition includes C-S-H polymer gel and tobermorite, and the brightness of synthetic calcium silicate power is greater than or equal to 90%, the specific surface area is greater or equal to 120 square meters per gram, the bulk density is from 0.12 grams per centimeter to 0.30 grams per centimeter, the oil-absorbed value is 120-200 milliliters per milligram, and the average grain diameter is (D50) from 12 microns to 40 microns . Meanwhile, the invention also discloses the preparation method of synthetic calcium carbonate: the synthetic calcium silicate power is the paper filler, then under the premise that paper properties are guaranteed, the usage of plant fiber can be decreased at the greatest extent. Replacing the traditional paper filler by synthetic calcium silicate power can not only reduce the usage of plant filler at the greatest extent, but also increase the retention rate of calcium carbonate, decrease the waste of filler and improve the paper ash content.

Owner:内蒙古普诺思新材料科技有限公司

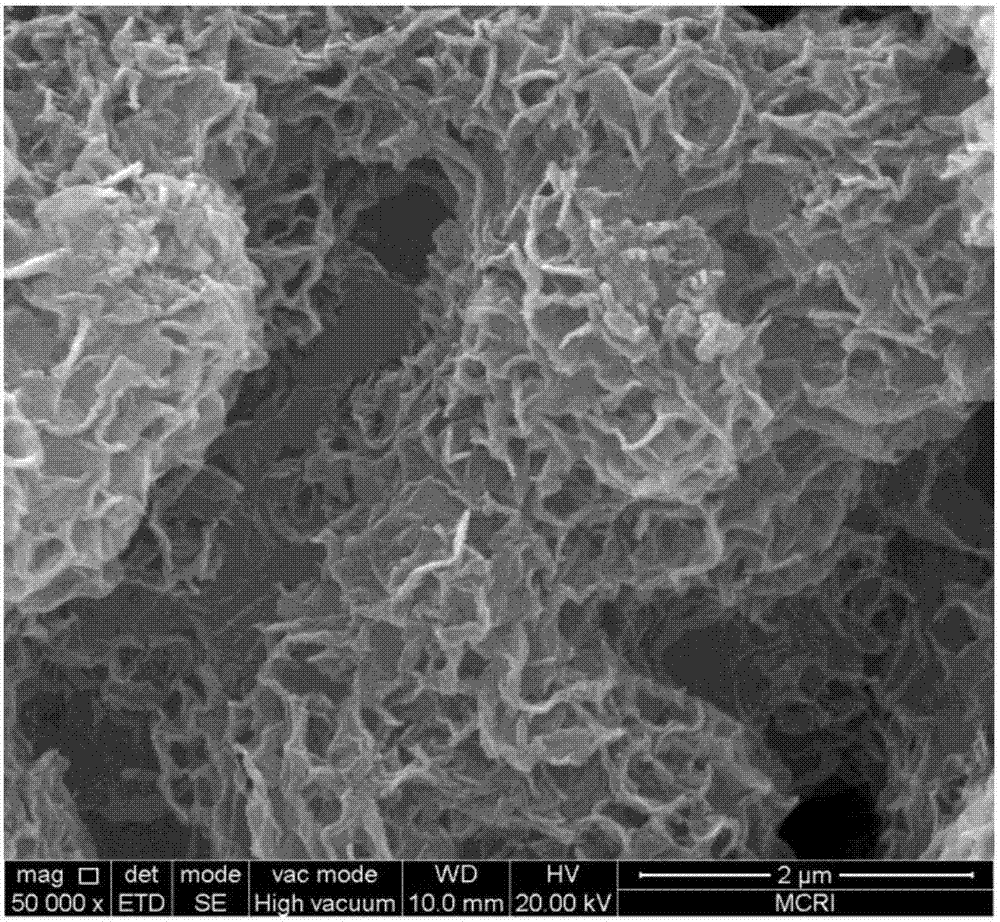

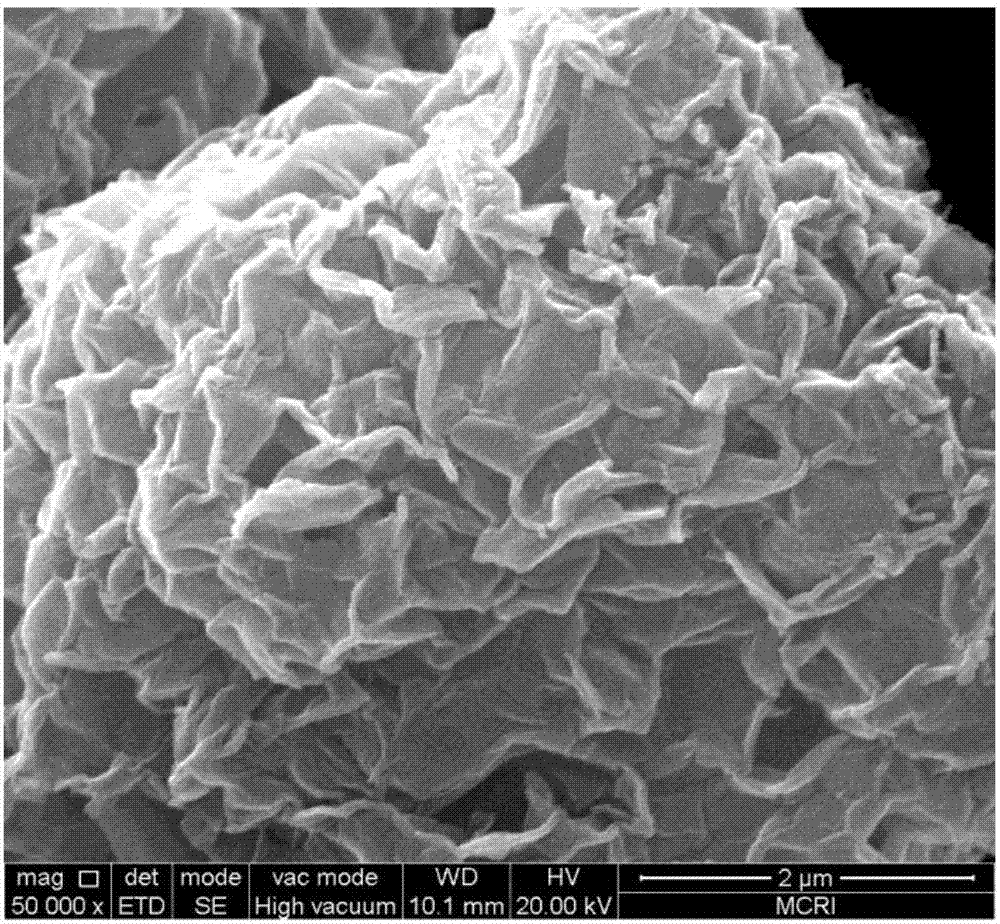

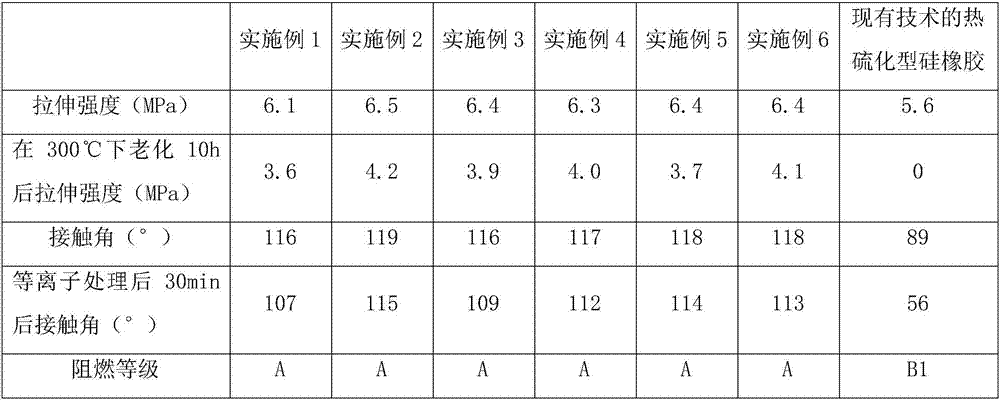

Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

InactiveCN107286671AImprove mechanical propertiesImproved modulus of elasticityCross-linked polyethyleneIon

The invention provides hydrophobicity-enhanced heat-vulcanized silicone rubber and a preparation method thereof. The specific preparation method of the silicone rubber comprises steps as follows: divinyltetramethyldisiloxane is mixed with a mixed solution of concentrated hydrochloric acid, deionized water and ethanol, the mixture is mechanically stirred, ethyl orthosilicate is dropwise added, the mixture is subjected to hydrolytic condensation, methylbenzene is added for extraction and layering, methyl vinyl silicone resin is obtained, crosslinked polyethylene particles are added to the methyl vinyl silicone resin, the mixture is stirred uniformly and subjected to molding curing and vacuum heat treatment, and the polyethylene particle crosslinked methyl vinyl silicone resin is obtained; nano-montmorillonite, amorphous alumina and titanium dioxide are added to a polydimethylsiloxane prepolymer, the mixture is mixed and subjected to crosslinking and curing, and a reinforced material coated with organic silicone rubber is obtained; the polyethylene particle crosslinked methyl vinyl silicone resin, the reinforced material coated with organic silicone rubber, 2,4-dichlorobenzoyl peroxide, diphenyl silanediol and octamethylcyclotetrasiloxane are mixed uniformly, left to stand, subjected to open milling and secondary vulcanization, and the hydrophobicity-enhanced heat-vulcanized silicone rubber is obtained.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

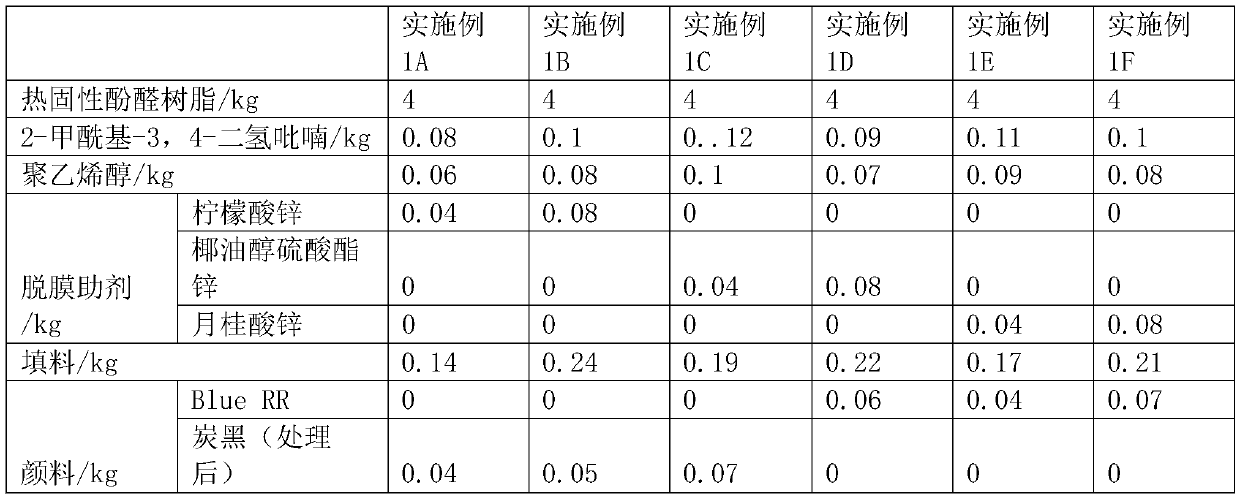

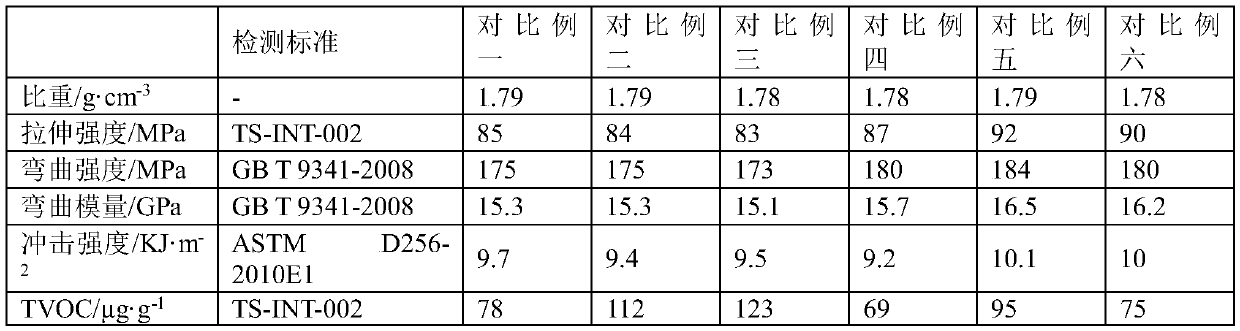

Modified phenolic molding compound with high bending strength and preparation method of modified phenolic molding compound

The invention relates to a phenolic plastic, discloses a modified phenolic molding compound with high bending strength and a preparation method of the modified phenolic molding compound, and solves the problems that properties such as tensile strength and flexural modulus of a phenolic molding compound are reduced when brittleness of the phenolic molding compound is reduced in the prior art. The modified phenolic molding compound with the high bending strength comprises the following raw materials, in parts by mass: 200 parts of thermosetting phenolic resin, 4-6 parts of 2-formyl-3,4-dihydropyran, 3-5 parts of polyvinyl alcohol, 0.2-4 parts of a demolding auxiliary agent, 7-12 parts of a filler, and 2-3.5 parts of a pigment, wherein the thermosetting phenolic resin is liquid thermosettingphenolic resin; and the method comprises the steps of firstly mixing the 2-formyl-3,4-dihydropyran and the thermosetting phenolic resin for a reaction, then adding the polyvinyl alcohol, performing areaction under mixing, adding the demolding auxiliary agent, the filler and the pigment, performing mixing, and performing plastication to obtain the modified phenolic molding compound. According to the method provided by the invention, the rigidity and toughness performance are improved while the brittleness of the modified phenolic molding compound is reduced.

Owner:浙江安瑞电器有限公司

Novel electronic material with high thermal stability and preparation method thereof

ActiveCN109880566ALower surface energyReduce self-aggregationNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxySilicon dioxide

The invention discloses a novel electronic material with high thermal stability and a preparation method thereof and belongs to the field of high molecular materials for electronics. The preparation method comprises the following steps: Firstly, after carrying out chain expanding on nano silicon dioxide through polyacrylic acid, mixing with tetraethylenepentamine and polyethylenimine to prepare aminated nano silicon dioxide; then grafting the nano silicon dioxide with an epoxy group under the action of isocyanate; then grafting a flexible chain section containing hydroxyl on the nano silicon dioxide grafted with the epoxy group under the action of alkaline amine, so as to prepare modified nano silicon dioxide; finally, mixing epoxy resin, filler, a diluting agent, the aminated nano silicondioxide, the modified nano silicon dioxide, epoxidized soybean oil and a catalyst to prepare the novel electronic material with high thermal stability. The novel electronic material with high thermalstability, prepared by the technical scheme, can have very good utilization performance under a high-temperature condition.

Owner:SUZHOU YUDESHUI ELECTRIC TECH CO LTD

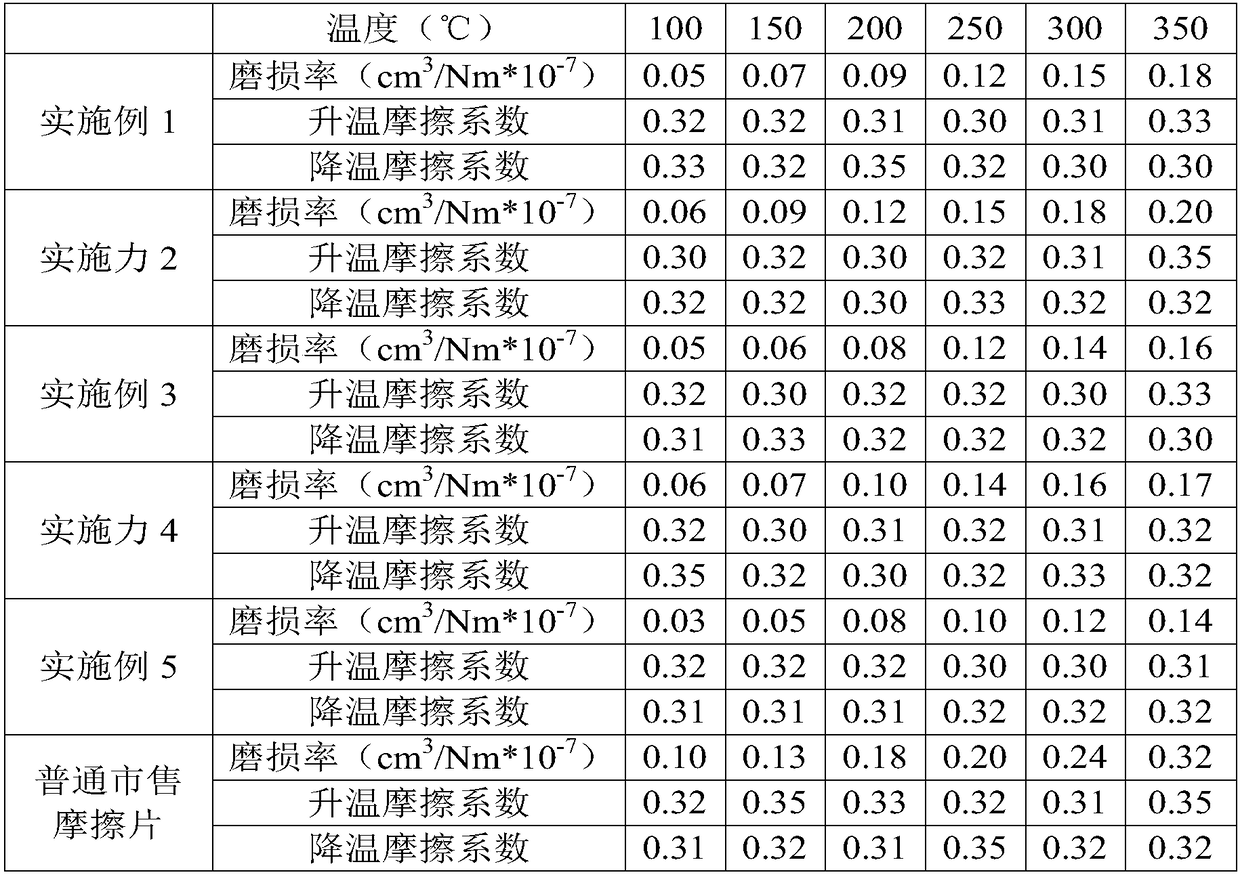

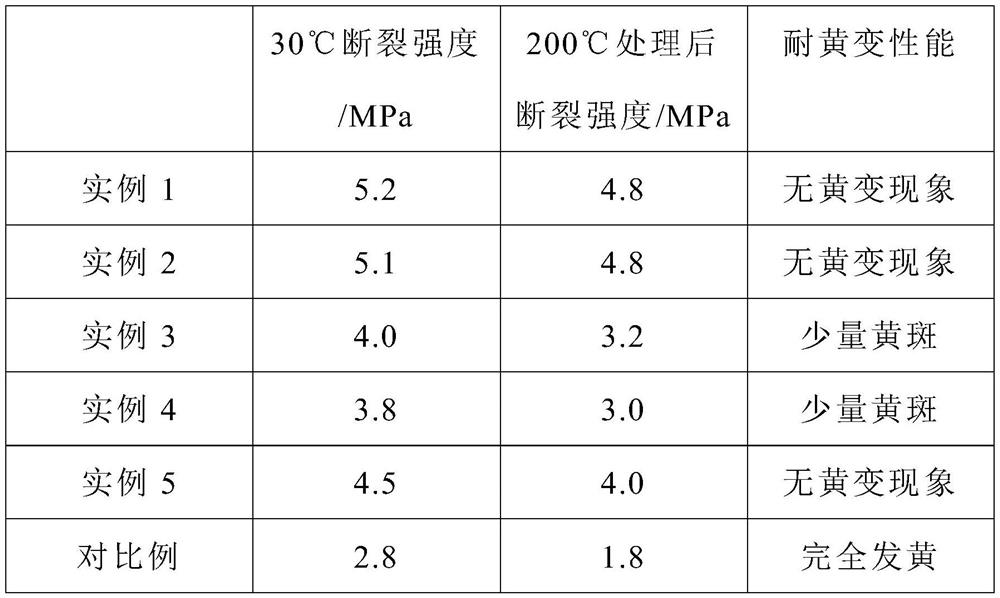

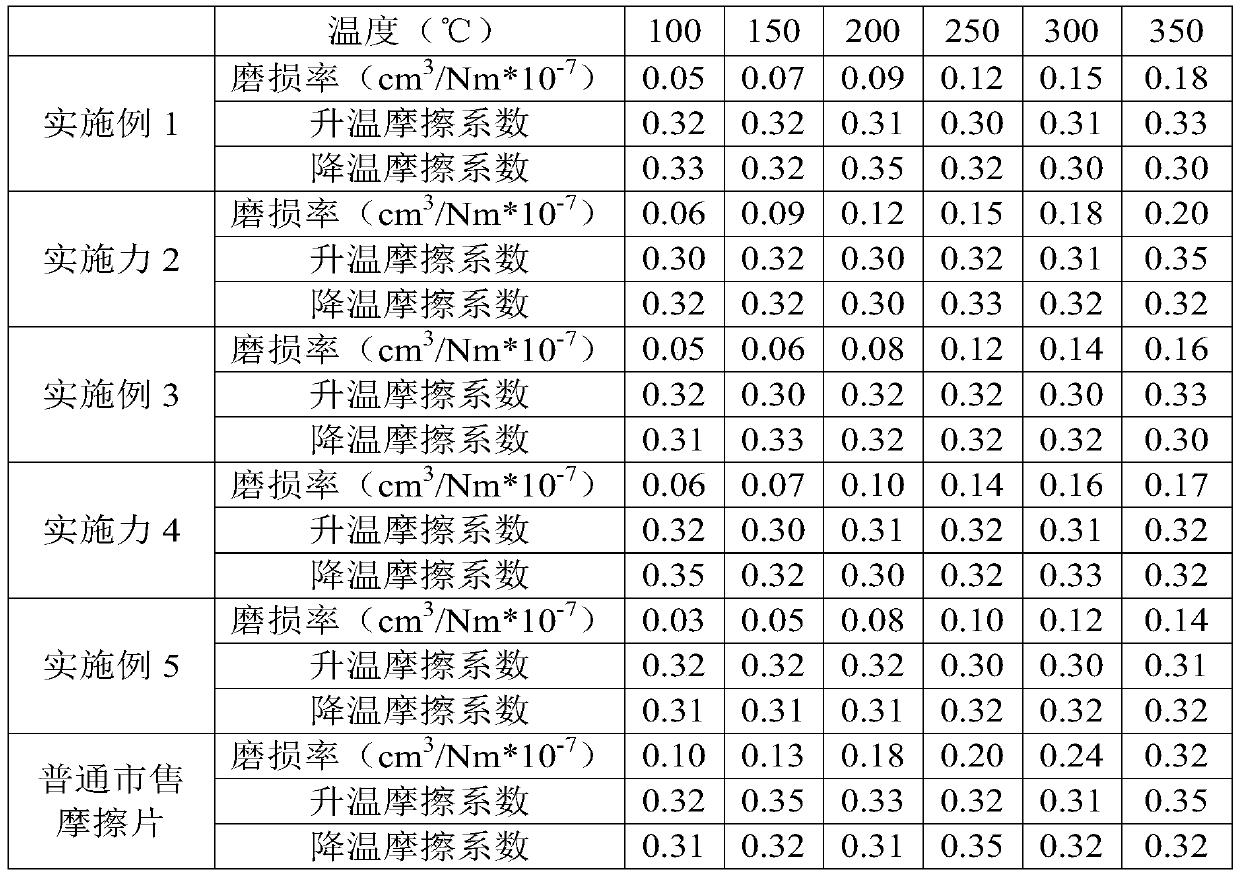

Friction material and preparation method thereof

ActiveCN108468736AIncreased strength and wear resistanceEnhance internal bondingOther chemical processesFriction liningNoise pollutionHydroquinone Compound

The invention belongs to the technical field of friction materials, and particularly relates to a friction material and a preparation method thereof. The friction material is composed of synthetic fibers, magnesium oxide, aluminum oxide, barium sulfate, boron oxide, sodium bicarbonate, tert-butyl hydroquinone, ethanol and a structure enhancer. The raw materials of the friction material are matchedwith each other to prepare the friction material, the defects that the friction material has strength difference, is easy to oxidize and poor in wear resistance are improved, and the problems that the manufacturing process is complex, the consumed time is long, and the production cost is high are solved, the friction material has a special elastic effect, the performance problem of a traditionalfriction material can be changed, the wear resistance of the friction material is improved, the friction material is light in texture, environment-friendly and anti-oxidation, high pressure resistanceand material selection are achieved, and noise pollution caused by friction is effectively avoided.

Owner:HANGZHOU POLYTECHNIC

Preparation method of non-burnt environment-friendly water permeable brick

InactiveCN107188493AImprove water permeabilityHigh porosityCeramicwareSilicate CementForming pressure

The invention relates to the technical field of preparation of building materials, in particular to a preparation method of a non-burnt environment-friendly water permeable brick. According to the preparation method, firstly, the porosity of basalt is modified and increased, and the pore diameter of the basalt is further broadened by utilizing an ice splitting function, so that the basalt has more abundant pore channels so as to be provided for water molecules to pass through, and the water permeation rate of a brick body can be increased by using the basalt as a raw material of the non-burnt environment-friendly water permeable brick; then, silicon hydroxyl groups are added on the particle surface of the basalt, high-bond energy chemical bonding can be generated by utilizing the silicon hydroxyl groups on the surface of the basalt and silicon hydroxyl groups in silicate cement, and the internal bonding strength of the non-burnt environment-friendly water permeable brick is increased, so that the problem that the mechanical performance of a common non-burnt water permeable brick is not ideal is solved; in addition, with the enhancement of the internal bonding strength, required compression molding pressure is reduced while the same molding effect is achieved, so that the porosity of the non-burnt environment-friendly water permeable brick is increased, the water permeability of the non-burnt environment-friendly water permeable brick is further increased, and a wide application prospect is obtained.

Owner:常州蓝森环保设备有限公司

Polyolefin synthetic paper-pulp capable of being used for producing battery separator

InactiveCN101245567AEnhance internal bondingHigh breaking lengthPaper/cardboardPolyolefinPulp and paper industry

The invention relates to the technical field of polyolefine synthetic paper pulp used for manufacturing a battery septum. The polyolefine synthetic paper pulp of the invention that can be used for manufacturing the battery septum includes a polyolefine resin composition. The polyolefine resin composition includes 60 to 100 percent by weight of ethene, the multipolymer of unsaturated carboxylic acid and 10 to 50 percent by weight of polythene resin. The thickness of the battery septum, etc. can be reduced to the greater degree by using the polyolefine synthetic paper pulp of the invention. A second polyolefine synthetic paper pulp of the invention consisting of ethene / a, p-multipolymer of unsaturated carboxylic acid and polythene resin shows stable thermal sealing property and thermal viscosity in a broad thermal sealing temperature range from low temperature to high temperature.

Owner:SHENZHEN SENIOR TECH MATERIAL

Anti-stretch rubber seal ring material and preparation method thereof

The invention discloses an anti-stretch rubber seal ring material and a preparation method thereof. The anti-stretch rubber seal ring material is composed of the following raw materials: high impact polystyrene, nano white carbon black, anti-aging agent RD, insoluble sulfur, 3-aminopropyl trimethoxy silane, zinc dialkyl dithiophosphate, modified zinc oxide, diisobutyl phthalate and coco fatty acid diethanol amide. According to the invention, high impact polystyrene is used as the main material and has cheap price, excellent impact resistance and excellent anti-stretch performance, moreover, modified zinc oxide is also added in the raw material, thus, internal binding force of the rubber seal ring can be enhanced, and the properties of the rubber seal ring, such as stretch resistance, high temperature resistance, metal cohesive property and mechanical property, are improved effectively.

Owner:ANHUI SHARPVISION OPTOELECTRONICS TECH

Heat-resistant and ozone-resistant rubber sealing ring material and preparation method thereof

ActiveCN103408852AEnhance internal bondingImprove tensile propertiesPolymer scienceTemperature resistance

The invention discloses a heat-resistant and ozone-resistant rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is prepared from the following raw materials: chlorinated butyl rubber CBK-139, white carbon black obtained by a precipitation method, an anti-aging agent ODA (bis(4-octylphenyl)amine), an accelerant M, methyl triethoxysilane, hydroquinone, modified bentonite, chlorcosane and a dispersing agent NNO. The chlorinated butyl rubber CBK-139 used as a main material is low in price and good in heat resistance and flexing resistance; the modified bentonite is added into the raw materials, so that the inner bonding force of a rubber sealing ring is enhanced. As a result, the tensile resistance, high-temperature resistance, metal bonding property, mechanical property and the like of the rubber sealing ring are effectively improved.

Owner:ANHUI FANGXING IND GRP

Elastic O-shaped rubber sealing ring and preparation method thereof

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

Insulating heat-conducting gasket and preparation method thereof

PendingCN113337121AEnhance internal bondingTightly boundHeat-exchange elementsModifications by conduction heat transferCarbide siliconPolymer science

The invention relates to an insulating heat-conducting gasket which comprises an insulating heat-conducting material, a high-molecular polymer and a binder. The insulating heat-conducting material is of a two-dimensional sheet-shaped structure, the two-dimensional sheet-shaped structure is oriented in the thickness direction of the insulating heat-conducting gasket, the high-molecular polymer is filamentous to connect the two-dimensional sheet-shaped structure, and finally penetrates through the interior of the insulating heat-conducting gasket; a two-dimensional heat-conducting filler is selected from at least one of boron nitride, aluminum nitride and silicon carbide.

Owner:CHANGZHOU FUXI TECH CO LTD

Motor anti-corrosion coating and motor anti-corrosion method

InactiveCN105419436AHigh implementabilityFast formingPretreated surfacesAnti-corrosive paintsEpoxyXylylene

The invention discloses a motor anti-corrosion coating, the anti-corrosion coating is applied on a motor stator and end caps mounted at both sides of the motor stator. The anti-corrosion coating comprises a basic layer and a surface layer from the inside to outside, the basic layer is directly sprayed on the motor stator and the end caps, and the surface layer is sprayed on the basic layer; the basic layer is prepared from the following components (in parts by weight): 40 to 50 parts of acrylic acid / epoxy resin primer; 5 to 8 parts of nano-sized TiO2 particles, 5 to 8 parts of zinc oxide nano particles, 5 to 15 parts of aluminosilicate-based glass beads; 1 to 5 parts of xylene; the surface layer is prepared from the following components (in parts by weight): 90 to 95 parts of silicone polyurethane resin paint / vinyl perchloride anticorrosion varnish; 5 to 10 parts of acrylic acid / epoxy resin primer; 1 to 6 parts of silica sol; 1 to 3 parts of cobalt nitrate; 1 to 3 parts of cerous nitrate.

Owner:安徽皖南新维电机有限公司

A method for preparing rice husk-based negative electrode material

ActiveCN110429264BImprove Coulombic efficiencyChange apertureSecondary cellsNegative electrodesChemical industrySilicon dioxide

Owner:JILIN UNIV

Preparation method of hydrothermal carbon modified asphalt

ActiveCN114686011AImprove road performanceLess sticking to discsBuilding insulationsPhysical chemistryAsphalt

The invention discloses a preparation method of hydrothermal carbon modified asphalt, relates to a preparation method of modified asphalt, and aims to solve the technical problems of poor dispersity and poor modification effect of a hydrothermal carbon material in asphalt in the conventional method for modifying asphalt by utilizing the hydrothermal carbon material. The method comprises the following steps: by taking waste biomass as a carbon source, carbonizing by adopting a hydrothermal carbon method to obtain bulk and granular hydrothermal carbon; the hydrothermal carbon is immersed in liquid nitrogen for soaking treatment and then ground until the particle size reaches 1-100 m, and hydrothermal carbon powder is obtained; adding the hydrothermal carbon powder into the asphalt, and shearing and stirring by adopting a high-speed shearing stirrer; and naturally cooling to obtain the hydrothermal carbon modified asphalt. The hydrothermal carbon modified asphalt has good high-temperature rutting resistance and medium-temperature fatigue resistance, the fatigue life of the hydrothermal carbon modified asphalt is respectively prolonged by 212.6% and 271.8% compared with that of matrix asphalt at 19 DEG C and 25 DEG C, and the hydrothermal carbon modified asphalt can be used in high-temperature and high-load areas.

Owner:CHINA RAILWAY 16TH BUREAU GRP ROAD & BRIDGE ENG CO LTD +3

A kind of electronic material with high thermal stability and preparation method thereof

ActiveCN109880566BLower surface energyReduce self-aggregationNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPtru catalyst

The invention discloses an electronic material with high thermal stability and a preparation method thereof, belonging to the field of polymer materials for electronics. In the present invention, nano-silica is firstly chain-extended by polyacrylic acid, and mixed with tetraethylenepentamine and polyethyleneimine to prepare aminated nano-silica, and then nano-titanium dioxide is grafted with rings under the action of isocyanate. Oxygen groups, then grafted epoxy group nano-titanium dioxide and then grafted hydroxyl-containing flexible segments under the action of basic amines to prepare modified nano-titanium dioxide, and finally epoxy resin, fillers, diluents, amination Silicon dioxide, modified titanium dioxide, epoxy soybean oil and catalyst are mixed to prepare electronic material with high thermal stability. The electronic material with high thermal stability prepared by the technical solution of the present invention can have very good performance under high temperature conditions.

Owner:SUZHOU YUDESHUI ELECTRIC TECH CO LTD

Wood floor wax

InactiveCN108570286AReduce hydrophilicityNot easy to reunitePolishing compositionsParaffin waxMolecular materials

The invention discloses a wood floor wax and belongs to the technical field of high molecular materials. The wood floor wax is prepared through the following steps: weighing the following components in parts by weight in sequence: 15 to 25 parts of paraffin wax, 10 to 15 parts of silicone oil, 10 to 15 parts of vegetable wax, 15 to 20 parts of white oil, 10 to 20 parts of modifying additive and 4to 7 parts of silane coupling agent; mixing the paraffin wax and the vegetable wax in a stirring machine; adding the silicone oil, the white oil, the silane coupling agent and the modifying additive into the stirring machine; stirring and mixing for 30 to 50 minutes under the condition that the temperature is 45 to 60 DEG C and the rotary speed is 200 to 400 r / min, so as to obtain the wood floor wax.

Owner:裴文韬

A heat-resistant and ozone-resistant rubber sealing ring material and its preparation method

ActiveCN103408852BEnhance internal bondingImprove tensile propertiesPolymer scienceTemperature resistance

The invention discloses a heat-resistant and ozone-resistant rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is prepared from the following raw materials: chlorinated butyl rubber CBK-139, white carbon black obtained by a precipitation method, an anti-aging agent ODA (bis(4-octylphenyl)amine), an accelerant M, methyl triethoxysilane, hydroquinone, modified bentonite, chlorcosane and a dispersing agent NNO. The chlorinated butyl rubber CBK-139 used as a main material is low in price and good in heat resistance and flexing resistance; the modified bentonite is added into the raw materials, so that the inner bonding force of a rubber sealing ring is enhanced. As a result, the tensile resistance, high-temperature resistance, metal bonding property, mechanical property and the like of the rubber sealing ring are effectively improved.

Owner:ANHUI FANGXING IND GRP

a paper news medium

InactiveCN105421136BReduce dosageHigh whitenessWater-repelling agents additionReinforcing agents additionChemical pulpChemistry

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

A kind of friction material and preparation method thereof

ActiveCN108468736BHigh strengthImprove wear resistanceOther chemical processesFriction liningSodium bicarbonateHigh pressure

The invention belongs to the technical field of friction materials, and particularly relates to a friction material and a preparation method thereof. The friction material is composed of synthetic fibers, magnesium oxide, aluminum oxide, barium sulfate, boron oxide, sodium bicarbonate, tert-butyl hydroquinone, ethanol and a structure enhancer. The raw materials of the friction material are matchedwith each other to prepare the friction material, the defects that the friction material has strength difference, is easy to oxidize and poor in wear resistance are improved, and the problems that the manufacturing process is complex, the consumed time is long, and the production cost is high are solved, the friction material has a special elastic effect, the performance problem of a traditionalfriction material can be changed, the wear resistance of the friction material is improved, the friction material is light in texture, environment-friendly and anti-oxidation, high pressure resistanceand material selection are achieved, and noise pollution caused by friction is effectively avoided.

Owner:HANGZHOU POLYTECHNIC

Modified alum-containing rubber seal ring material and preparation method thereof

The invention discloses a modified alum-containing rubber seal ring material and a preparation method thereof. The material is prepared from the following raw materials: chloroprene rubber CR322, carbon black N339, accelerant CZ, alumina, crosslinking agent TAIC, antioxidant 1010, modified alum, tributyl citrate and sodium laurylsulfate. The material is prepared by adopting choroprene rubber CR322 as a main material, is low in price, has good performances of heat resistance, oil resistance and flame retardance; the modified alum is added in the raw materials, so that the internal binding force of the rubber seal ring can be enhanced, and the tensile strength, aging resistance, wear resistance, heat resistance, metal binding property, mechanical performance of the rubber seal ring can be effectively improved.

Owner:ANHUI SHARPVISION OPTOELECTRONICS TECH

Paper news media

InactiveCN105421136AReduce dosageHigh whitenessWater-repelling agents additionReinforcing agents additionUltimate tensile strengthChemical pulp

The invention discloses paper news media. The paper news media is prepared from, by weight, 60 parts of deinking chemical pulp, 18 parts of bamboo alkaline hydrogen peroxide mechanical pulp, 7 parts of bamboo chemical hot grinding mechanical pulp, 15 parts of aspen alkaline hydrogen peroxide hot grinding mechanical pulp, 0.03-0.08 part of brightener, 8-15 parts of filler, 0.5-1.5 parts of enhancer, 0.3-1 part of retention and drainage aid and 0.1-0.3 part of sizing agent. The prepared paper news media is high in brightness, opaqueness and strength and excellent in comprehensive performance.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

High-strength fiber cement composite board and preparation method thereof

PendingCN111943582AHigh water solubilityHigh activityConstruction materialFloorsGlass fiberCement composites

The invention provides a high-strength fiber cement composite board and a preparation method thereof. The method comprises the following steps: implanting quantum energy into natural water so as to change a water molecular structure and form quantum-state micro-molecular water; adding the cement and the water implanted with the quantum energy into a stirring tank, and uniformly stirring to mix into cement paste; adding plant fibers into a stirring mill, spraying the cement paste to the plant fibers in the stirring mill which is started at the same time according to a ratio, and performing grinding and stirring to form slurry; paving the stirred and ground slurry into a board blank with the upper part and the lower part clamped in glass fiber cloth, rolling and forming, and curing to obtainthe fiber cement composite board. According to the method, the strength of the fiber cement composite board is improved by changing the phase structure, specifically, under the condition that raw materials are not increased, the internal binding force is enhanced by changing the phase structure of the board, and the strength of the magnesium fiber cement composite board is improved.

Owner:北京水木华宸科技发展有限公司 +1

Tower pressure type wood fiber plywood process

InactiveCN110871479AReduce sheddingImprove distribution uniformityWood treatment detailsThermal wood treatmentWood fibreAdhesive

The invention discloses a tower pressure type wood fiber plywood process which comprises the following steps: a, crushing wood to obtain a wood chip A; b, pre-cooking the wood chip A to obtain a woodchip B; c, pressurizing and cooking the wood chip B to obtain a wood chip C; d, hot grinding the wood chips C to obtain wet wood fibers; e, drying the wet wood fibers to obtain dry wood fibers; f, mixing the dry wood fibers with an adhesive to obtain a soft intermediate material; g, pre-pressing and trimming the soft intermediate material to obtain a front blank plate; h, hot pressing the front blank plate to obtain a rear blank plate; and i, cooling and standing the rear blank plate to obtain a finished plate. The process has the characteristic of improving the internal bonding strength of the fiberboard, so that the mechanical property of the board produced by the process is better, and the nail holding force is also improved.

Owner:ZHEJIANG LIXIANG WOOD IND CO LTD

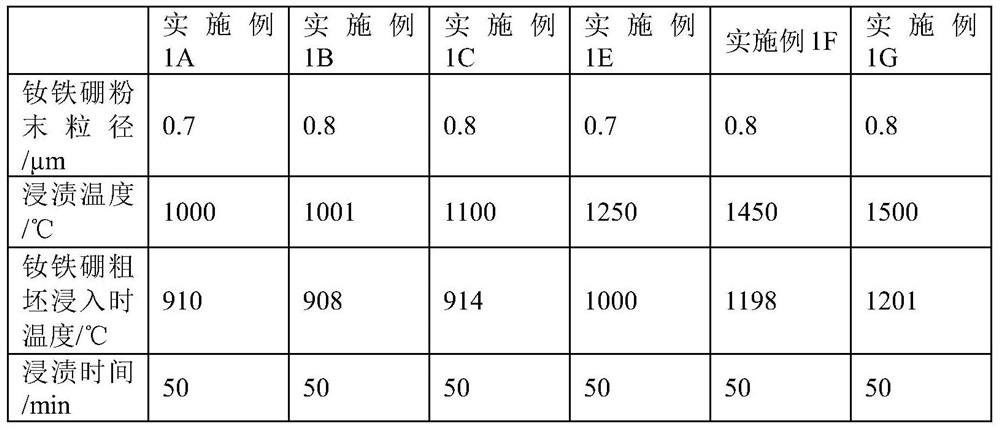

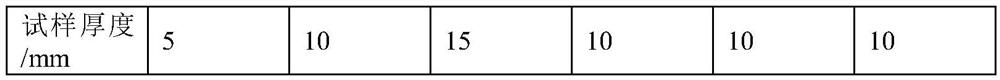

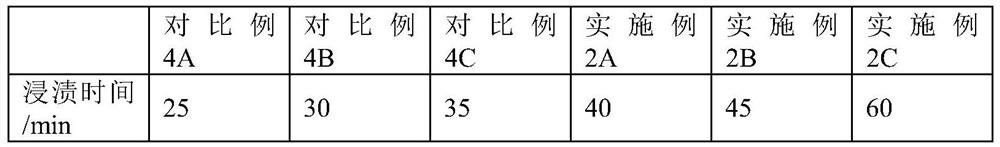

Preparation method of grain boundary diffused heavy rare earth NdFeB magnet and NdFeB magnet

ActiveCN109935462BFill in the gapsImprove grain boundary diffusion efficiencyInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementSolid solution

The invention relates to an NdFeB magnet, and discloses a preparation method of a grain boundary diffused heavy rare earth NdFeB magnet and the NdFeB magnet. The preparation method involves pressing NdFeB powder into a NdFeB rough billet and then immersing it in a heavy rare earth source for melting. solid solution and infiltration between the heavy rare earth source melt and the NdFeB rough billet, filling the gaps and defects in the NdFeB rough billet, and at the same time The heavy rare earth element diffuses in the grain boundary of the NdFeB rough blank, which improves the grain boundary diffusion efficiency of the heavy rare earth element, making it feasible for the grain boundary diffusion heavy rare earth element process to strengthen the coercive force of the thicker NdFeB magnet, and obtains A neodymium-iron-boron magnet with a thickness greater than 5mm and a coercivity enhancement effect higher than the existing process of grain boundary diffusion of heavy rare earth elements.

Owner:宁波雄海稀土速凝技术有限公司

A kind of oil-resistant rubber sealing ring material and preparation method thereof

The invention discloses an oil-resistant rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is prepared from the following raw materials: chloroprene rubber CR2442, lightweight carbon black AB770, an anti-aging agent MB, dicumyl peroxide, phenyltriethoxysilane, an antioxidant 1035, modified iron ore tailings, propanediol sebacate polyester and perogol. The chloroprene rubber CR2442 as a main material is low in price and good in oil resistance, heat resistance and ozone resistance; the modified iron ore tailings are added into the raw materials, so that the inner bonding force of a rubber sealing ring is enhanced. As a result, the tensile resistance, oil resistance, heat resistance, metal bonding property, mechanical property and the like of the rubber sealing ring are effectively improved.

Owner:ANHUI FANGXING IND GRP

A kind of high temperature resistant rubber sealing ring material and preparation method thereof

ActiveCN103408815BImprove high temperature resistanceEnhance internal bondingPolymer scienceTemperature resistance

The invention discloses a high-temperature-resistant rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is prepared from the following raw materials: butadiene styrene rubber, white carbon black with high abrasion resistance, 2-thiol benzimidazole, an accelerant DTDM (di(morpholin-4-yl) disulphide), aminopropyltriethoxysilane, resorcinol, modified clay, epoxidized soybean oil and sodium lignin sulfonate. The butadiene styrene rubber used as a main material is low in price and good in heat resistance and aging resistance; the modified clay is added into the raw materials, so that the inner bonding force of a rubber sealing ring is enhanced. Thus, the tensile resistance, high-temperature resistance, metal bonding property, mechanical property and the like of the rubber sealing ring are effectively improved.

Owner:ANHUI FANGXING IND GRP

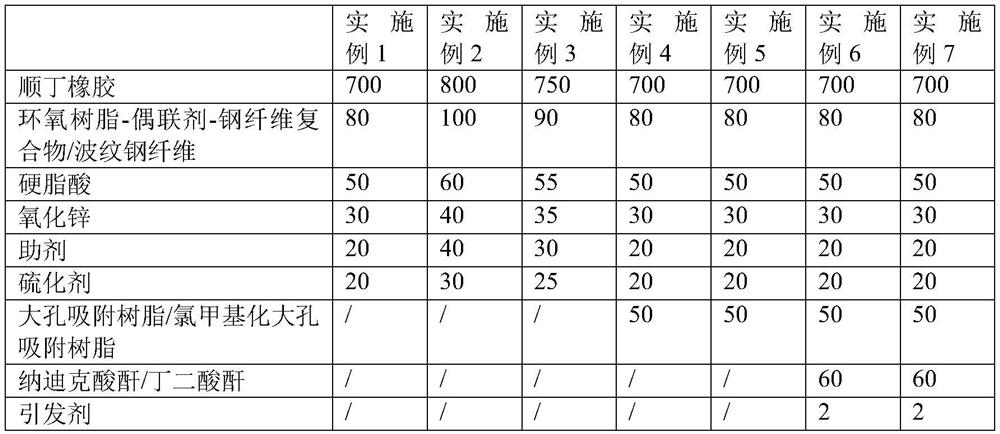

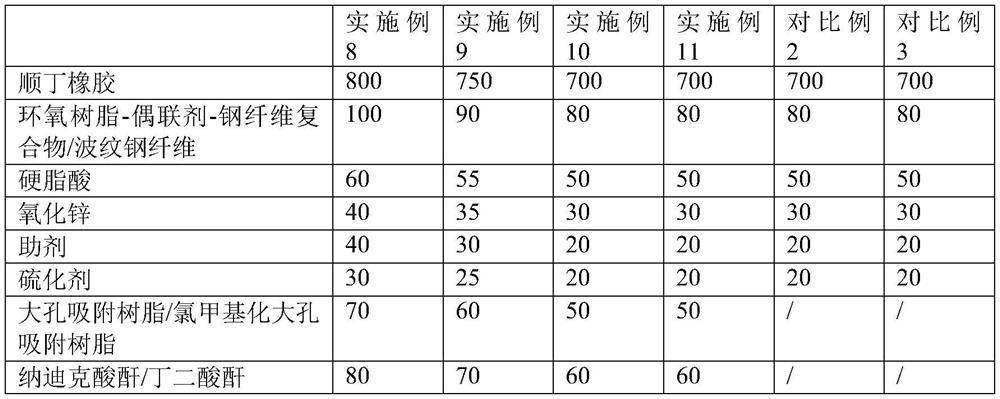

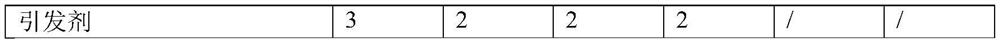

Wear-resistant high-strength shoe material and preparation method thereof

The invention relates to the field of wear-resistant shoe materials, and particularly discloses a wear-resistant high-strength shoe material and a preparation method thereof. The wear-resistant high-strength shoe material comprises the following raw materials: butadiene rubber, an epoxy resin-coupling agent-steel fiber compound, stearic acid, zinc oxide, an auxiliary agent and a vulcanizing agent. The preparation method comprises the following steps: mixing butadiene rubber, an epoxy resin-coupling agent-steel fiber compound, zinc oxide, stearic acid and an auxiliary agent, adding a vulcanizing agent for vulcanization, and cooling to room temperature to obtain the shoe material. The epoxy resin-coupling agent-steel fiber compound is added into the shoe material, so that the overall strength and wear resistance of the shoe material are improved, and the epoxy resin-coupling agent-steel fiber compound is promoted to be uniformly dispersed in butadiene rubber through a core-shell structure formed by the epoxy resin-coupling agent-steel fiber compound, so that the wear resistance of the shoe material is improved. The interface bonding between the epoxy resin-coupling agent-steel fiber compound and the butadiene rubber is improved, the stability of the overall structure of the shoe material is improved, and the wear resistance of the shoe material is indirectly improved.

Owner:浙江三益鞋业有限公司

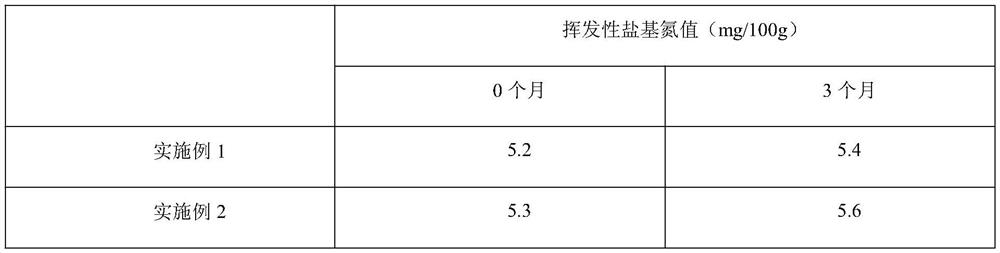

Processing method of dried fish meat slices

InactiveCN112772872AMake up for the lack of market gapRich flavorFood ingredient as antioxidantYeast food ingredientsBiotechnologyDried fish

The invention provides a processing method of dried fish meat slices. The processing method comprises the following steps of firstly, removing heads, tails and internal organs of fresh caught hairtail, cleaning, and cutting into sections to obtain hairtail sections; then soaking the hairtail sections in a compound bacteria solution I, performing primary fermentation, taking out the hairtail sections, washing the hairtail sections, draining the hairtail sections to obtain pre-fermented hairtail sections, and then pickling the pre-fermented hairtail sections with a pickling solution to obtain pickled hairtail sections; and performing supercritical carbon dioxide fluid extraction treatment on the pickled hairtail sections, soaking the hairtail sections in compound bacteria liquid II containing camellia seed superfine powder, performing secondary fermentation, taking out the hairtail sections, draining water to obtain fermented hairtail sections, and performing baking, vacuum packaging and sterilization to obtain the dried fish meat slices. The dried fish meat slice product makes up the market blank of lacking of dried fish meat slice products, is not easy to break, free of fishy smell and rich in flavor, and has a relatively high market popularization value.

Owner:汪华衡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com