Patents

Literature

52results about How to "Change aperture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

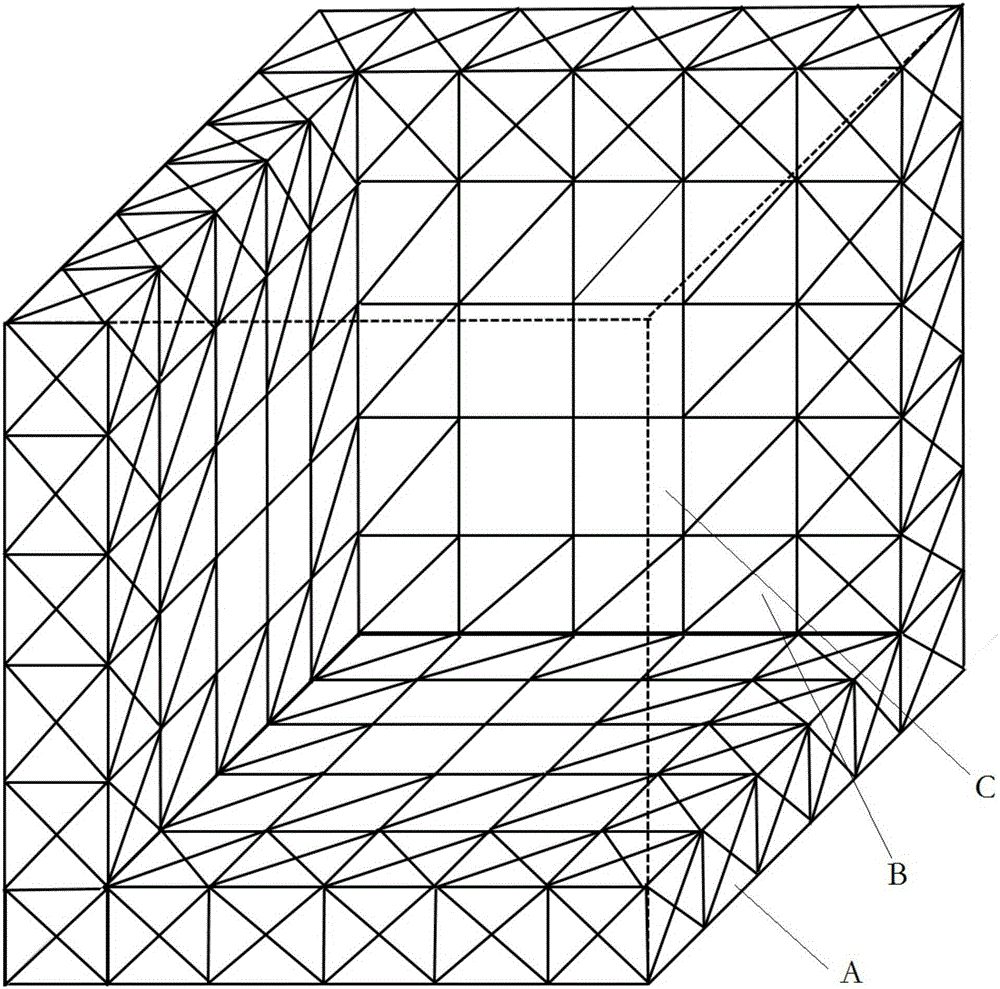

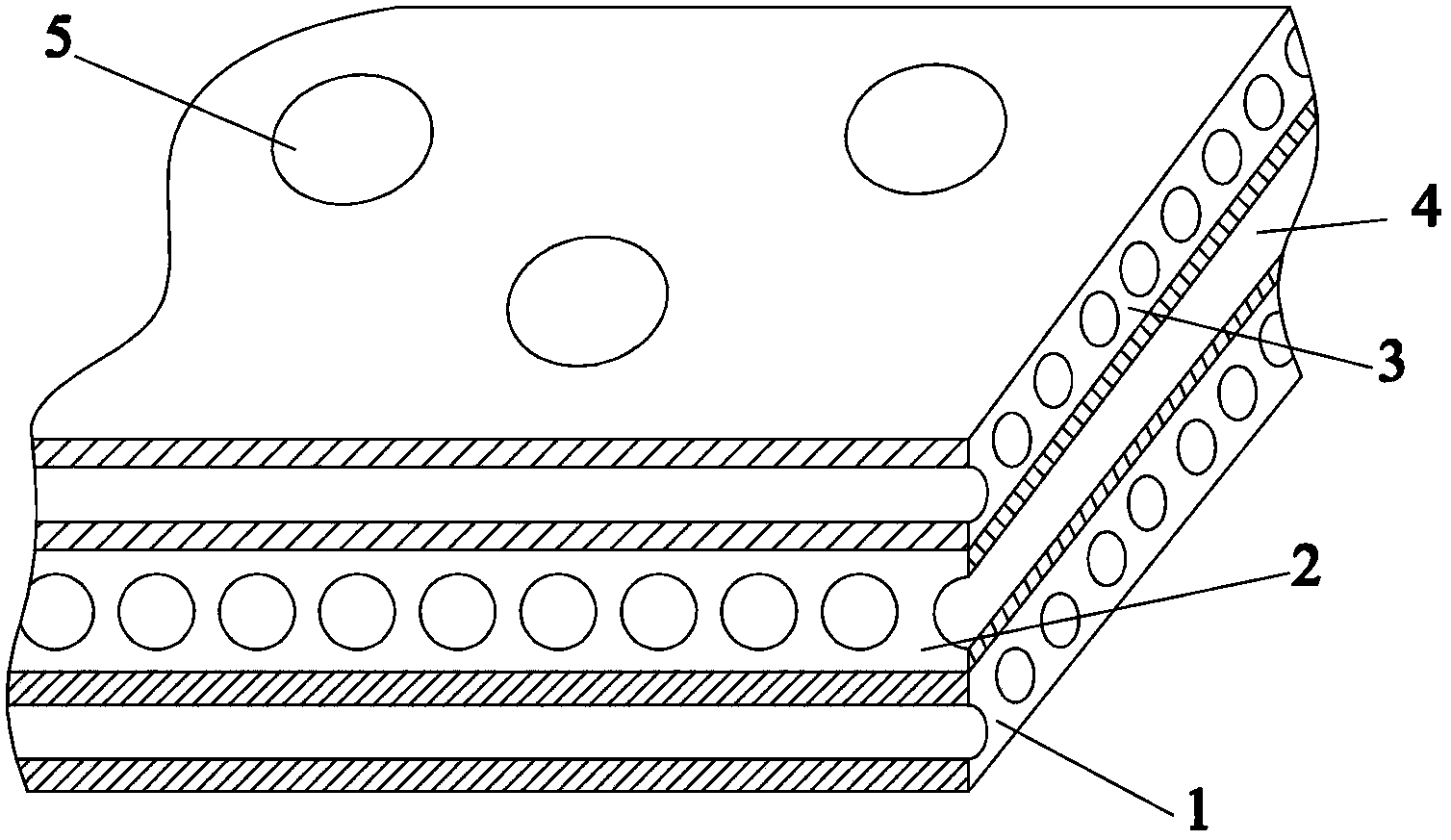

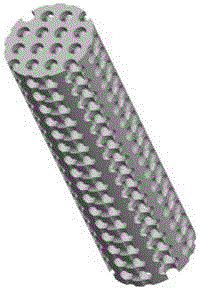

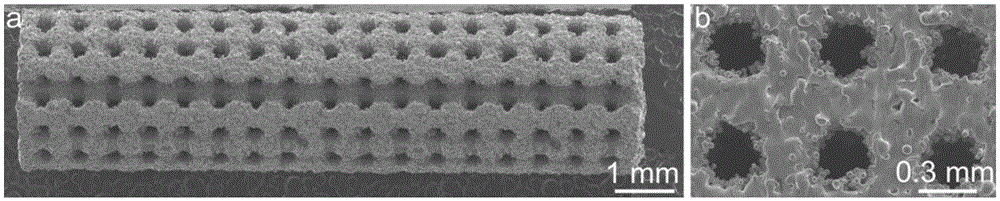

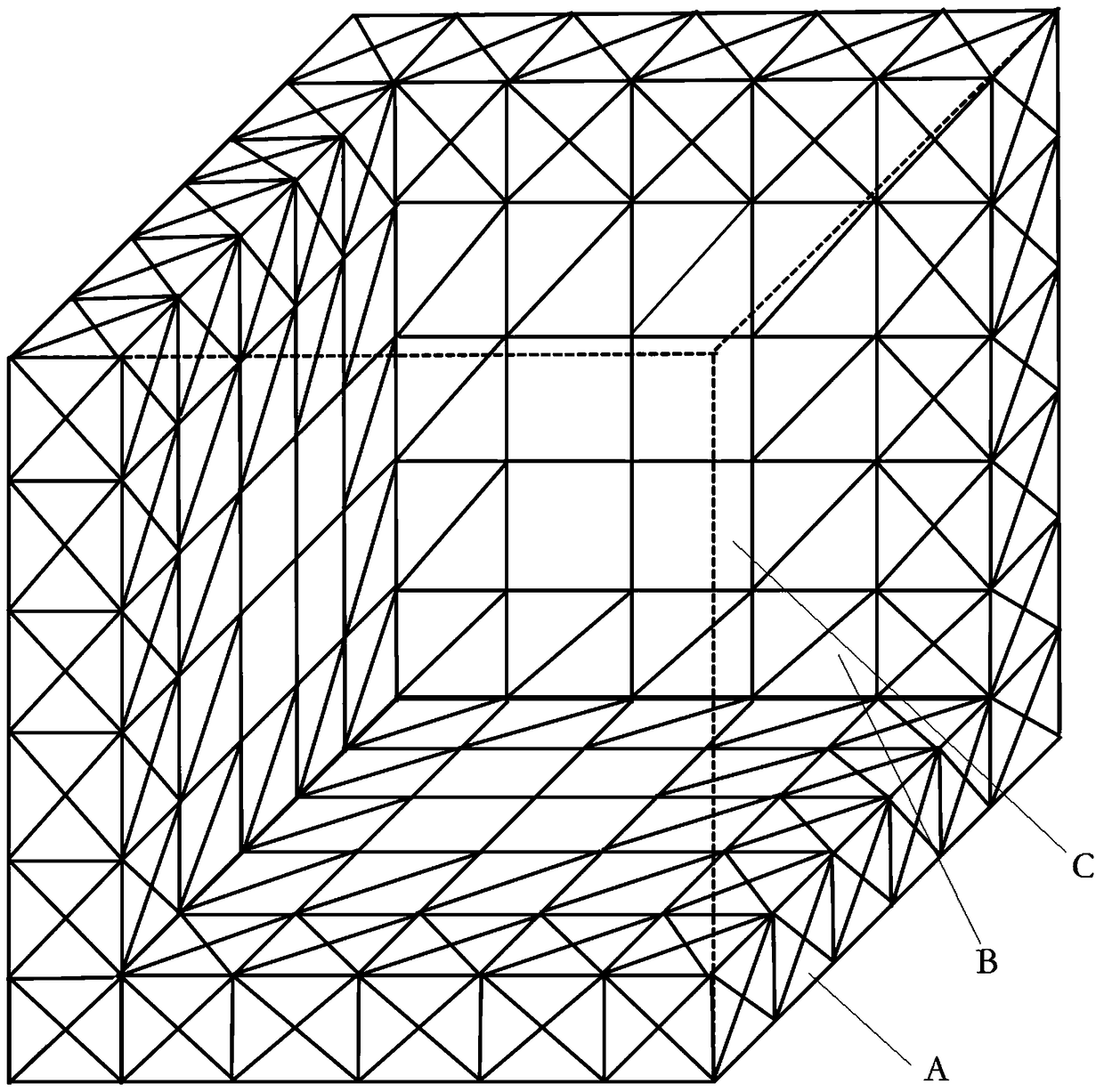

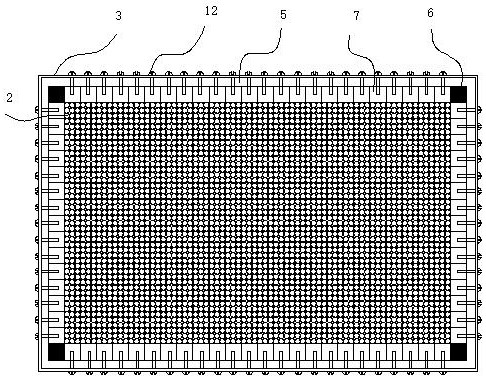

3D-printed gradient-diameter medical porous metal bone tissue scaffold

The invention discloses a 3D-printed gradient-diameter medical porous metal bone tissue scaffold and aims to solve the problems that a single repeated microporous structure in the prior art is adverse to bone tissue ingrowth and a bone tissue implant has difficulty in bony healing with self-bones. The scaffold is in a hexahedron structure as a whole, and comprises components A, components B and components C in tight arrangement, wherein the components A are arrayed on an outermost layer of the hexahedron structure; the components B are arrayed on a secondary outer layer; and the components C are arrayed on the innermost layer; all the components A, B and C are in a hexahedron frame structure; the pore diameter of the components A is greater than that of the components B; and the pore diameter of the components B is greater than that of the components C. Through the reinforcing structural design, the gradient-pore tissue engineering bone scaffold is produced; through regulating the ingrowth of bone tissues, fibroblasts and the like by gradient-change pores, the optimal bone healing can be achieved finally.

Owner:JILIN UNIV

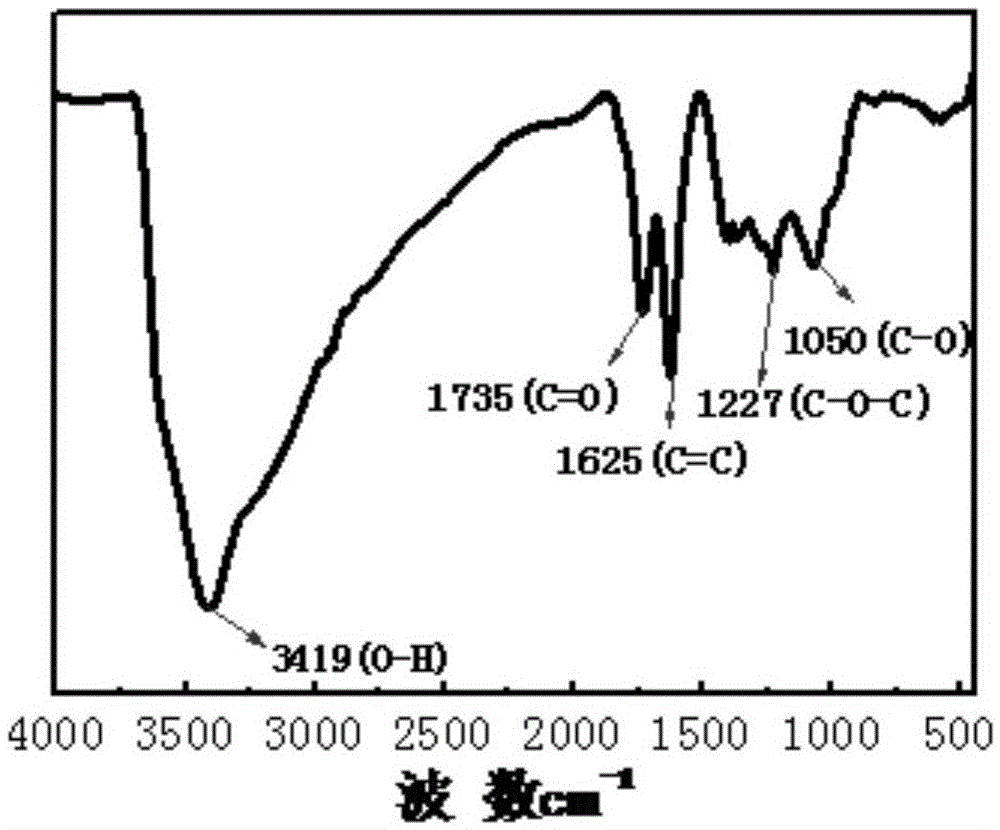

Preparation method of forward osmosis membrane modified with oxidized graphene

InactiveCN105582816AEasy to implementEase of mass industrial productionSemi-permeable membranesGrapheneOrganic solvent

The invention provides a preparation method of a forward osmosis membrane modified with oxidized graphene. The preparation method comprises the following steps: 1, firstly, conducting ultrasonic dispersion on the oxidized graphene in high-polarity organic solvent, so that homogeneous dispersion liquid is obtained; 2, adding organic solvent of raw materials of a produced membrane to the dispersion liquid; 3, sequentially adding additives and the produced membrane to the dispersion liquid obtained in step 2, and stirring the mixture till the mixture is dissolved completely, so that casting membrane liquid is obtained; 4, conducting sufficient defoaming on the casting membrane liquid in a vacuum drying box, then pouring the casting membrane liquid on a glass plate where a support layer is laid, and conducting membrane scraping; 5, after membrane pouring is ended and the casting membrane liquid is volatilized in air, putting the casting membrane liquid in a coagulation bath; 6, separating a membrane piece with the glass plate, and putting the membrane piece into pure water for immersion; 7, conducting natural drying on the membrane which is sufficiently immersed as mentioned above, so that the forward osmosis membrane is obtained. The modified forward osmosis membrane prepared through the preparation method is good in hydrophilicity and water flux and great in antipollution capability, cleaning expense of the membrane is lowered, the service life of the membrane is greatly prolonged, and mechanical properties are improved a lot.

Owner:HARBIN ENG UNIV

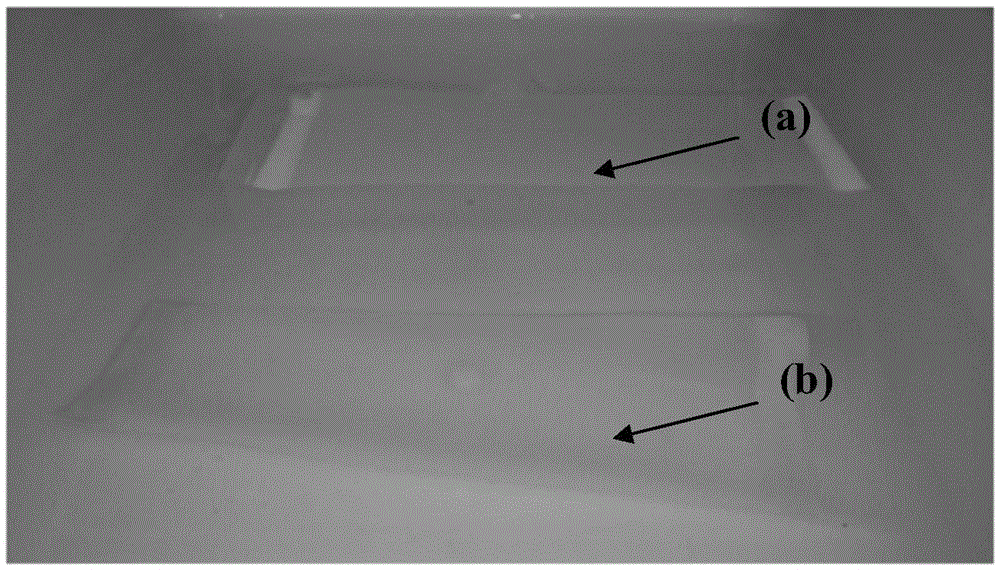

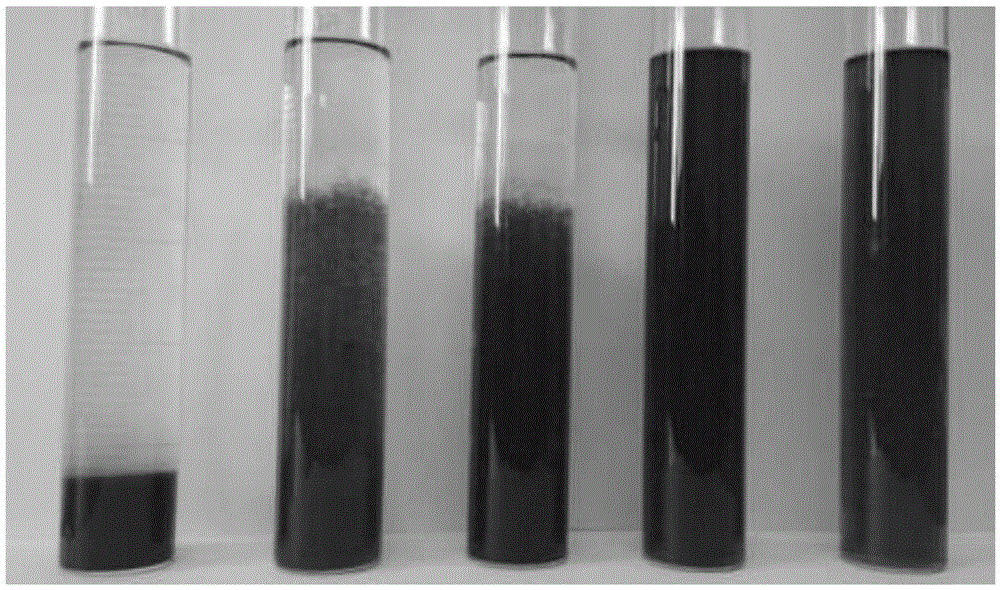

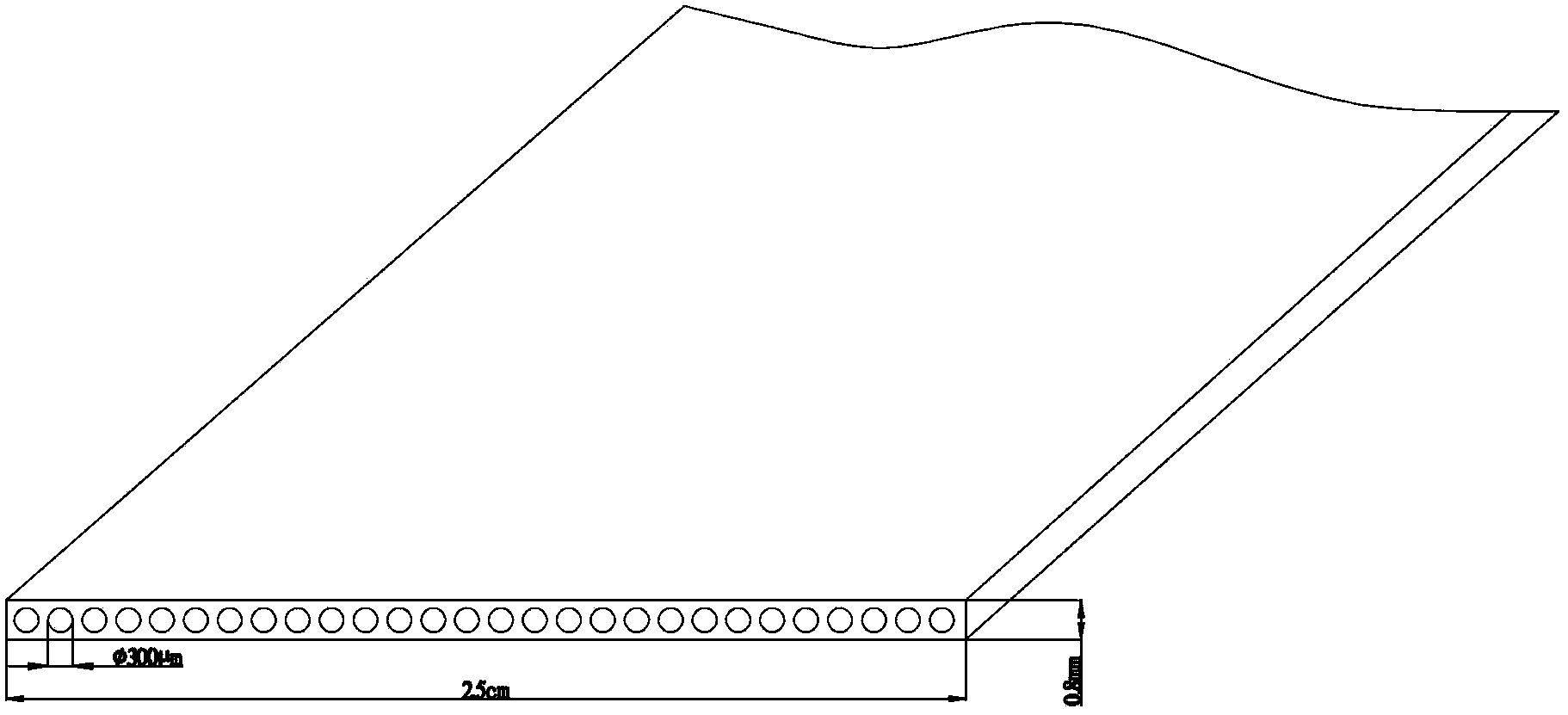

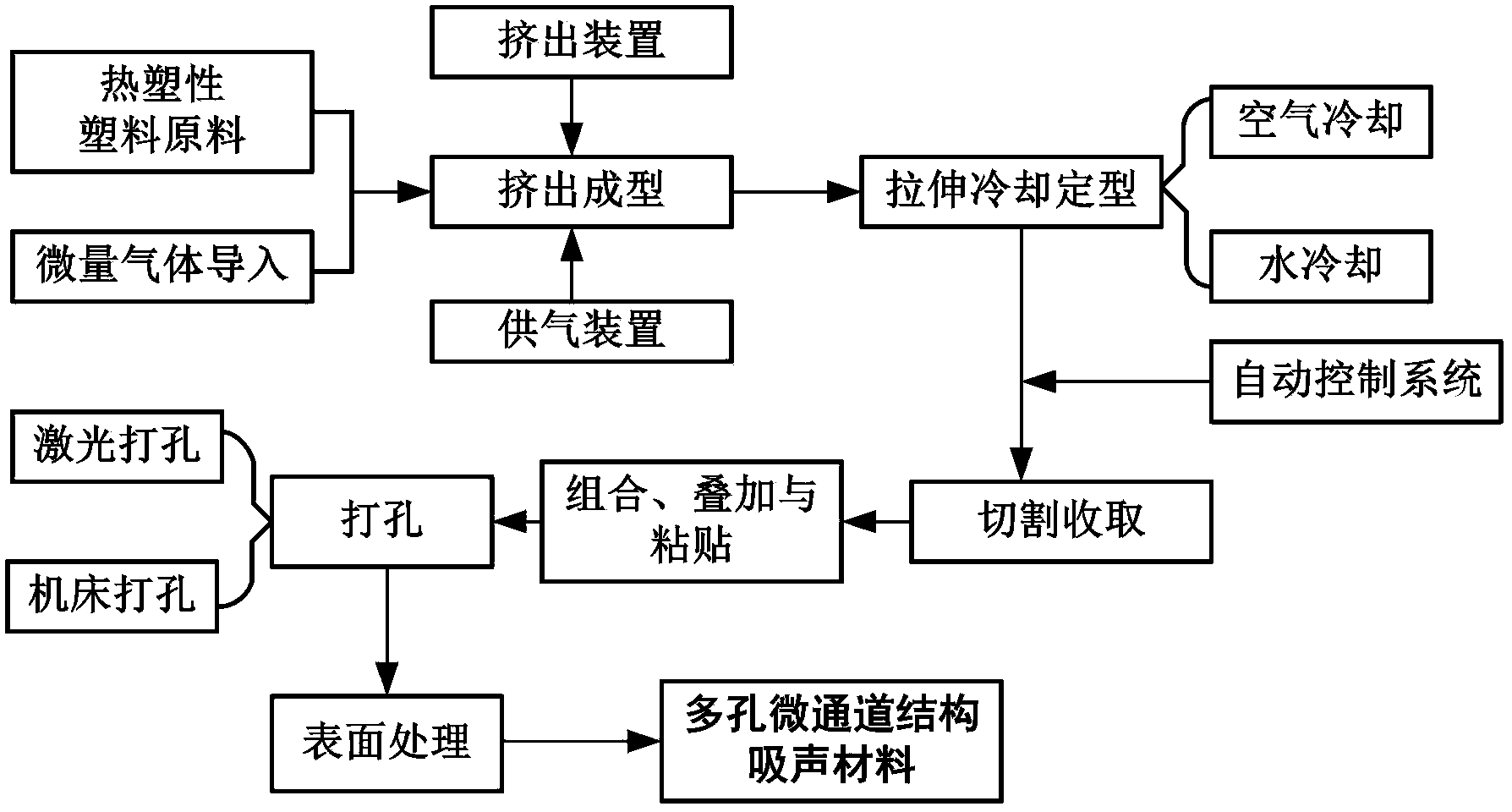

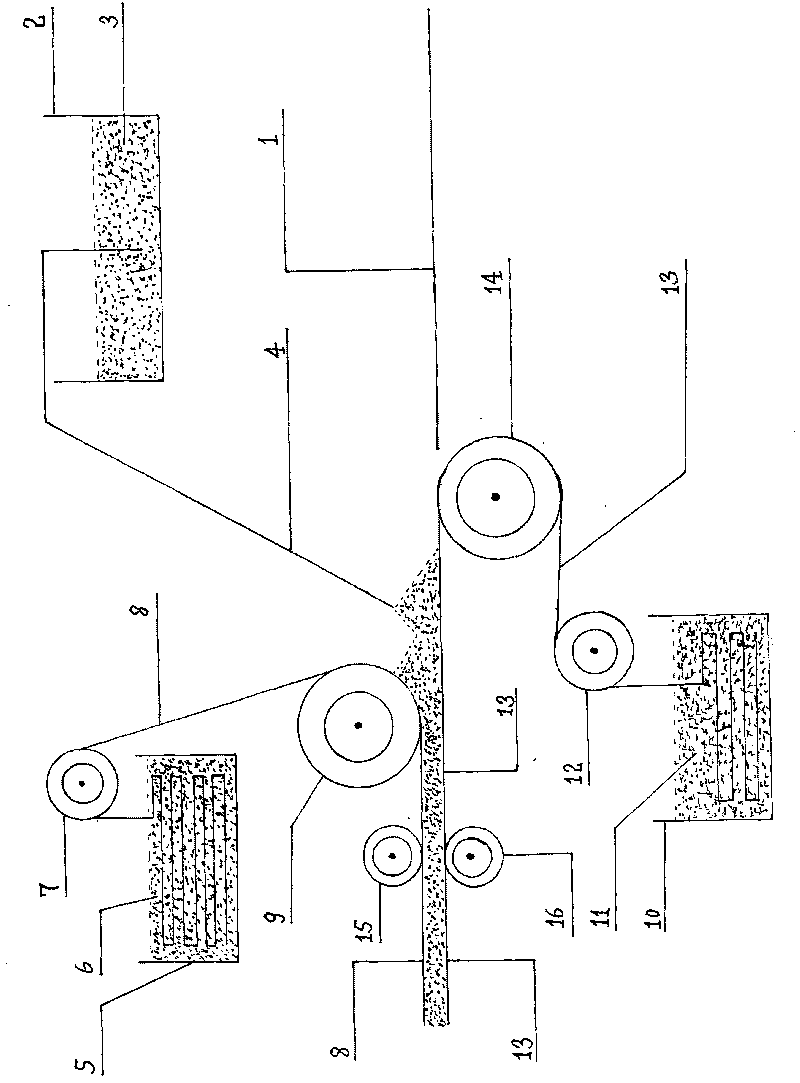

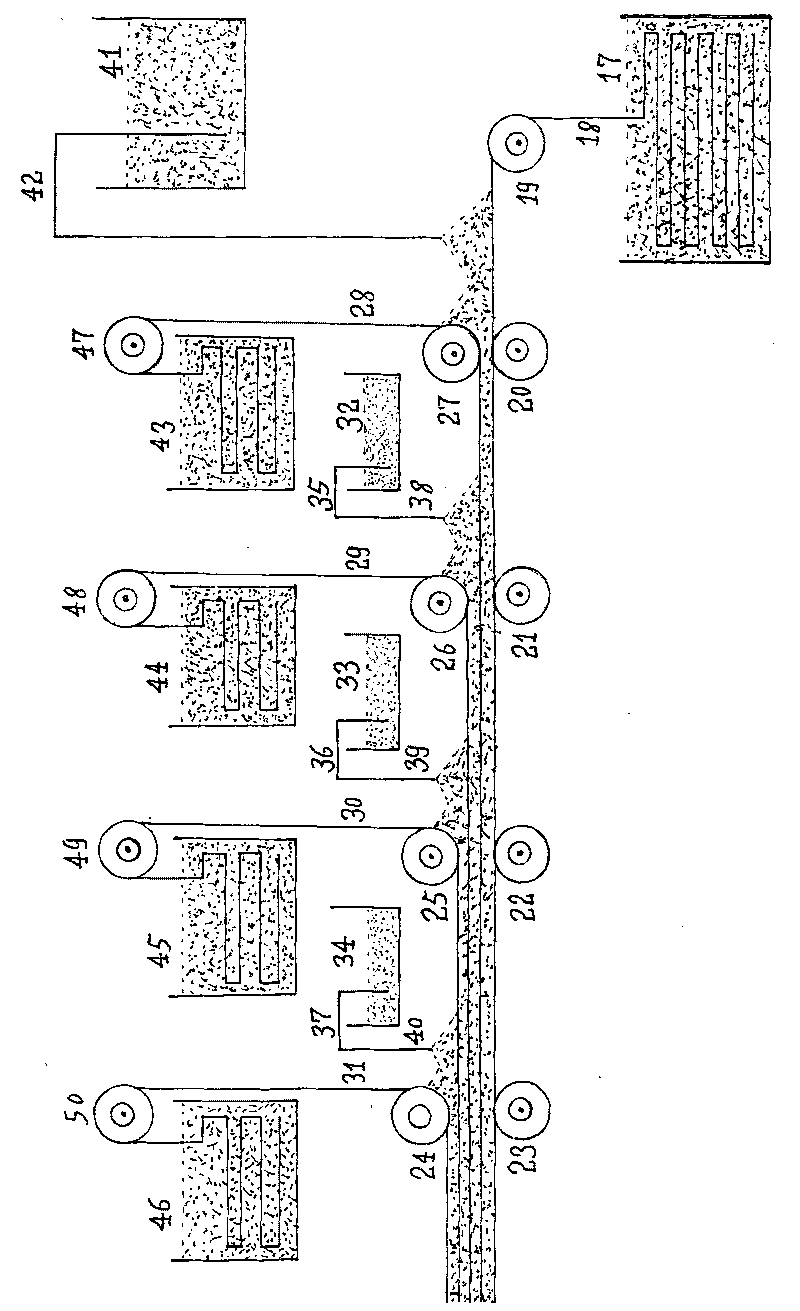

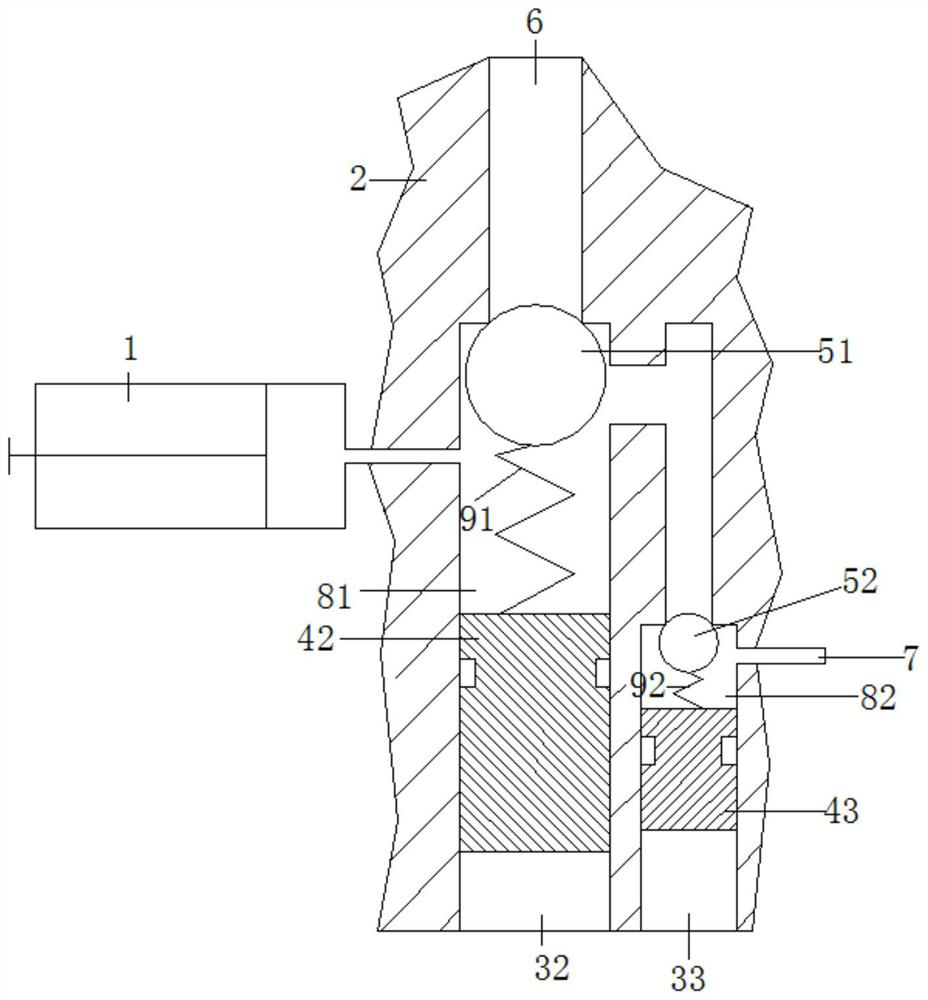

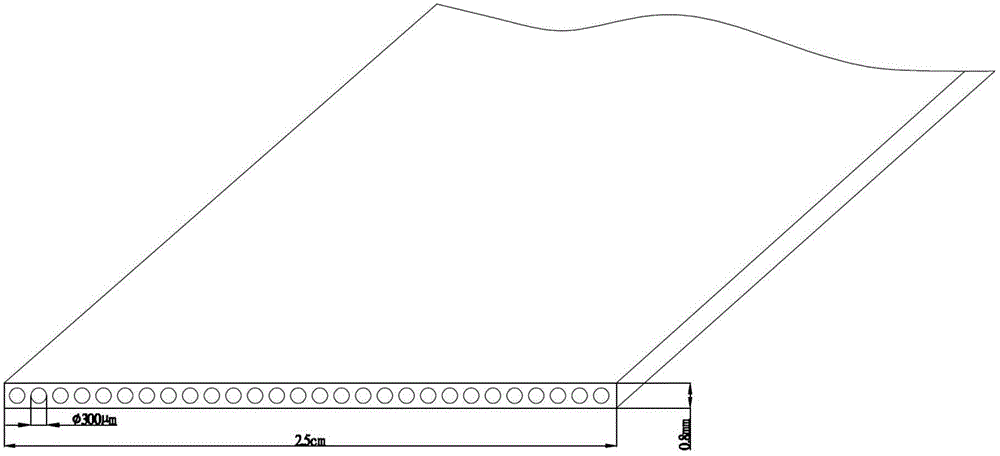

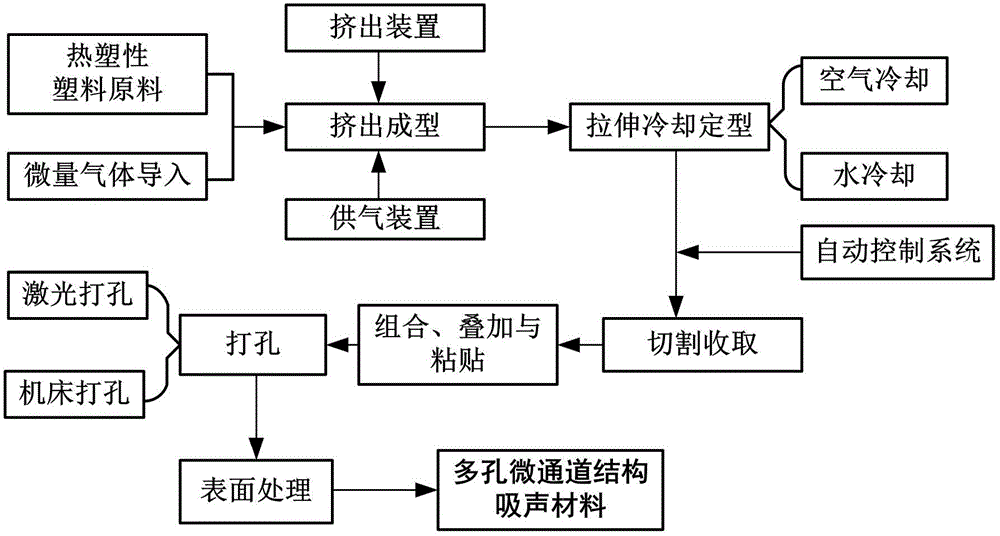

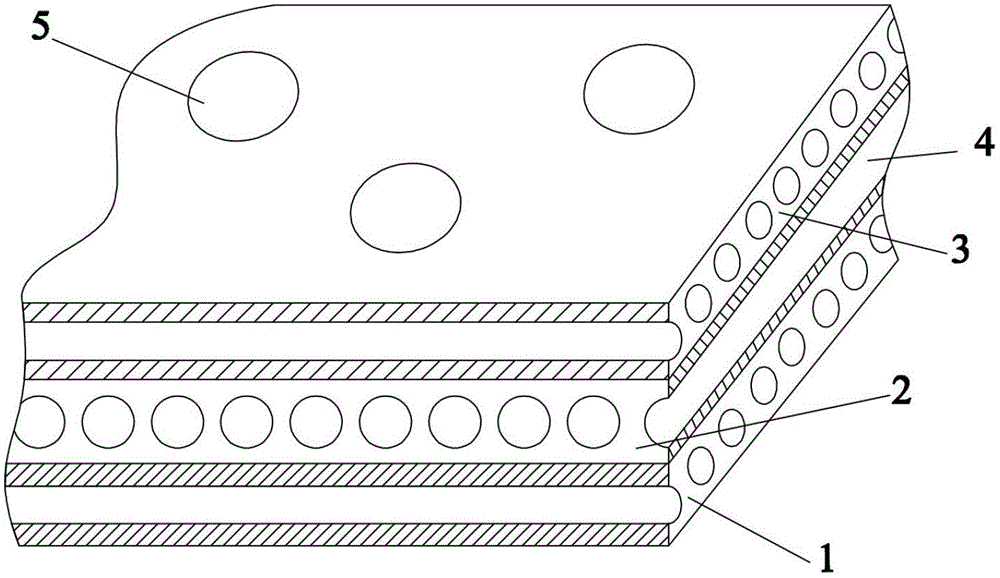

Porous sound absorption material and processing method thereof

ActiveCN104097357AChange the number of layersChange apertureSynthetic resin layered productsResonanceLow frequency

A porous sound absorption material and a processing method thereof. The invention is characterized in that porous sound absorption material is formed by several layers of sheet material with micro channel structure through combination and superposition pasting, a plurality of holes vertical to the superimposed and pasted sheet materials are arranged on the porous sound absorption material, a plurality of parallel micro channels are arranged in each layer of micro channel sheet material, and micro channels between two adjacent layers of micro channel sheets are mutually perpendicular to each other or at different angles. The processing method is as below: using a thermoplastic polymer as a raw material; extruding, stretching and forming the material by an extrusion device with a specially designed headpiece; then setting, rolling and cutting, and choosing an appropriate number of superposition according to the application need; and finally opening holes with different diameters to obtain the porous sound absorption material. The porous sound absorption material provided by the invention has double characteristics of porous foamed material and resonance plate structure, high and low frequency sound absorption function, excellent comprehensive performance; and the processing technology is simple, environment-friendly and low in cost.

Owner:NINGBO HUIBANG NOLY TECH CO LTD +1

Waterproofing agent capable of enhancing waterproofing performance and water impermeability of concrete

The invention discloses a waterproofing agent capable of enhancing waterproofing performance and water impermeability of concrete, which is composed of the following components in percentage by weight: 3% of alum, 11% of copper sulfate, 30% of fly ash, 4% of polycarboxylic acid water reducing agent, 26% of expanding agent, 0.6% of air entraining agent, 0.4% of alkyl sodium sulfonate, 17% of silica fume, 2% of epoxy resin, 1% of 6-dehydroprogesterone and 5% of lineae ablicantes arrowroot leaf powder. The fly ash is first-grade fly ash; the expanding agent is an alunite expanding agent EA-L, U-type cement expanding agent UEA, composite expanding agent CEA or calcium aluminate expanding agent AEA; and the air entraining agent is a non-rosin air entraining agent. The waterproofing agent can reduce the porosity, promote the hydration of the cement, enhance the density of the concrete, reduce the shrinkage of the concrete and improve the comprehensive durability of the concrete.

Owner:张淑芬

Method for preparing bamboo charcoal with controllable aperture

InactiveCN104607145AUniform and dense microstructureRipe evenlyOther chemical processesAlkali metal oxides/hydroxidesNitrogenRoom temperature

The invention relates to a method for preparing bamboo charcoal with a controllable aperture. The method comprises the following steps: cutting bamboo, selecting a middle section of cut bamboo which is more than 1m above the ground for drying treatment, controlling the water content of the bamboo to be less than 20%, placing the bamboo in a high-temperature furnace, feeding high-purity nitrogen or argon into the high-temperature furnace at a flowing rate of more than 5L / min to carry out deoxidization, then, raising the temperature of the high-temperature furnace to 400-1,500 DEG C at a speed of 3-40 DEG C / min, charring at the constant temperature for 1 to 8h, naturally cooling the high-temperature furnace to the room temperature after the thermal decomposition and the charring are finished, taking the product out and grinding, controlling the fineness of the product to be more than 20 meshes, and modifying the pore structure to obtain the bamboo charcoal with the controllable aperture. Compared with the prior art, the method is simple in preparation process, can effectively reduce the production cost by pressure maintaining and charring and effectively improve the adsorption capability of the bamboo charcoal by adopting the pore structure modification; moreover, the prepared bamboo charcoal can be suitable for application scenarios of different adsorbates, and is wide in application range.

Owner:TONGJI UNIV

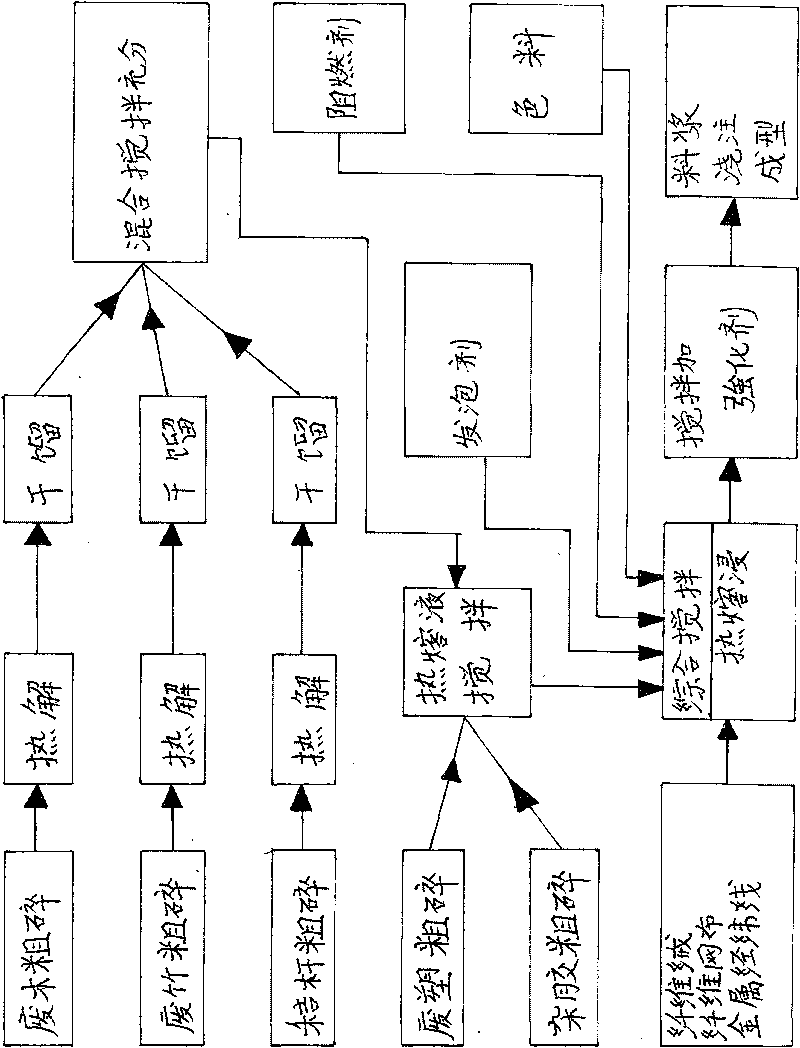

Technology for processing special materials such as waste plastic and wood

InactiveCN101724283AStir well mix well mix wellWell mixedPlastic recyclingVegetable fibersEngineering

The invention discloses a technology for processing special materials such as waste plastic and wood, belonging to utilization of waste. The adopted materials, such as waste plastic, nylon, rubber, chemical fiber, vegetable fiber, asbestos, waste and varied wood, bamboo, crop straw and the like, all belong to utilization of waste. To strengthen the physicochemical properties of the product, heat fusible plastic and the like are subject to heat fusing and processing, wood, bamboo, crop straw and the like are subject to pyrolysis and destructive distillation for removing other fraction or oil or non-fiber matters to change the molecular structure, the apertures among the fiber are enlarged, and comprehensive processing of enhancing the viscosity with heat fused plastic is carried out to obtain the matter; the matter is fully agitated with the heat fused plastic and rubber (under heat preservation for standby use), according to need, keel, namely, metal filaments or non-fusible fiber warp and weft filaments are added, non-fusible fiber filaments (short) are inlaid, and according to actual need, fire retardant, intensifier, foaming agent, pigment and the like can be added. The invention has scientific design and reasonable formula, can be directly poured into a die to be made into a product, and can be manufactured into various section bars of round, square, plate and tube shapes, can be manufactured by planning, sawing, riveting and the like as the same as the traditional modes, and also can be processed into slurry for standby use.

Owner:董四清

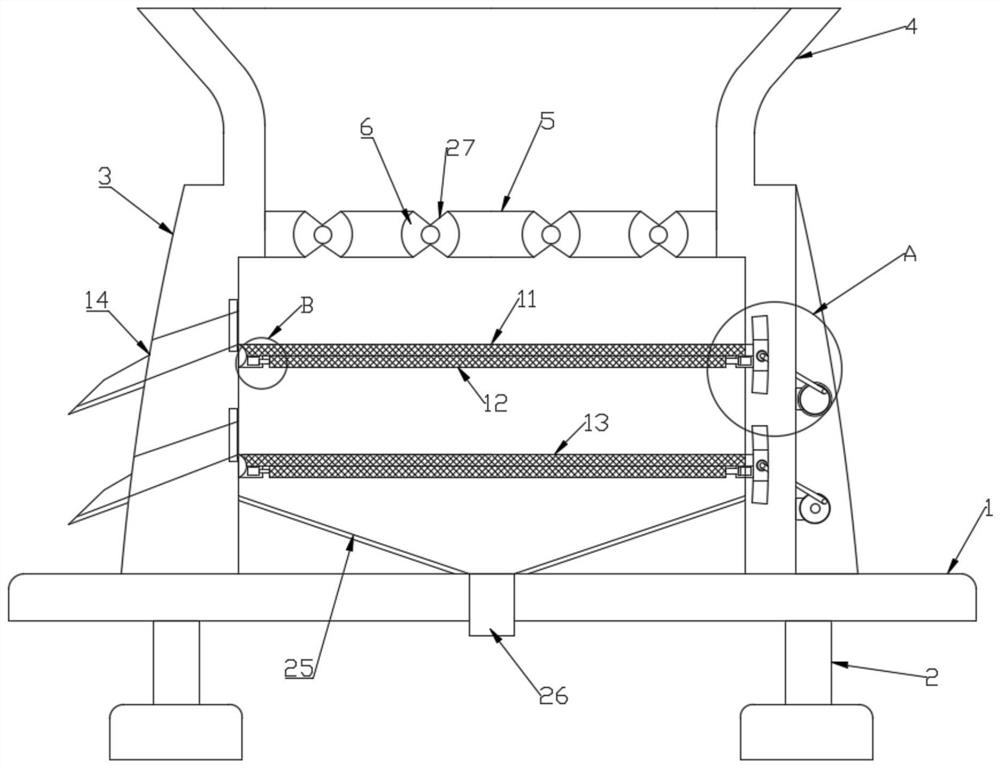

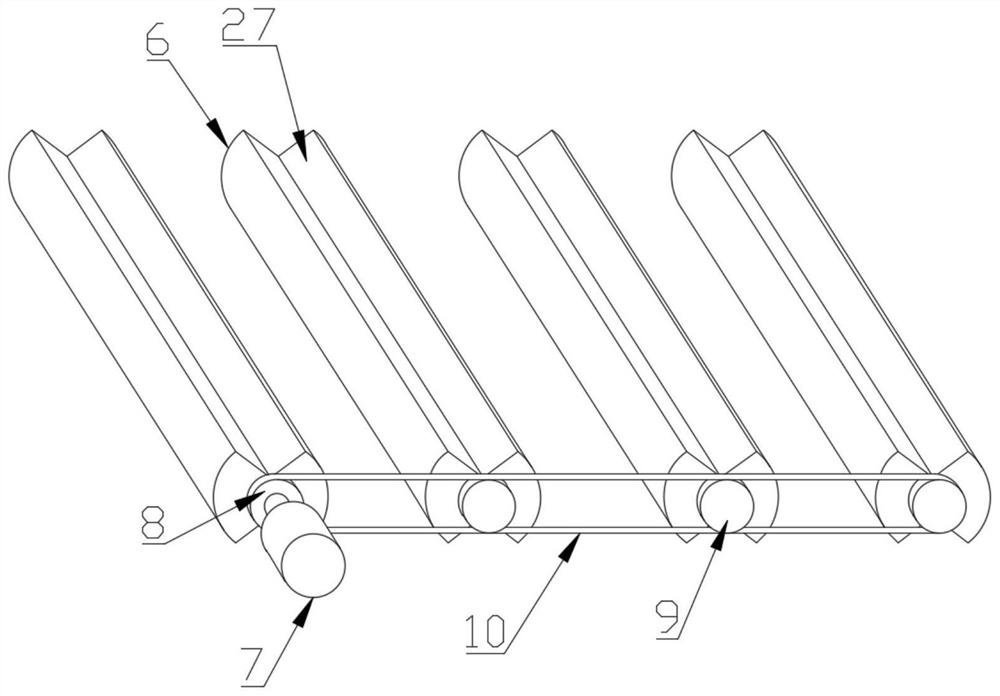

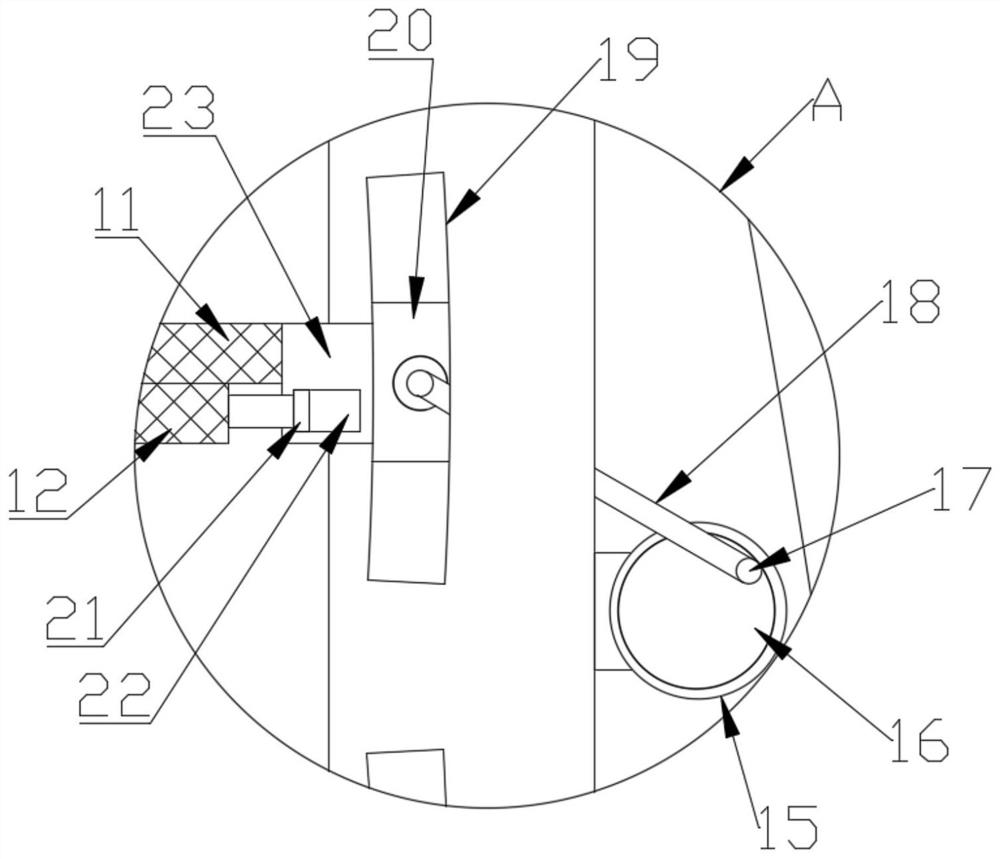

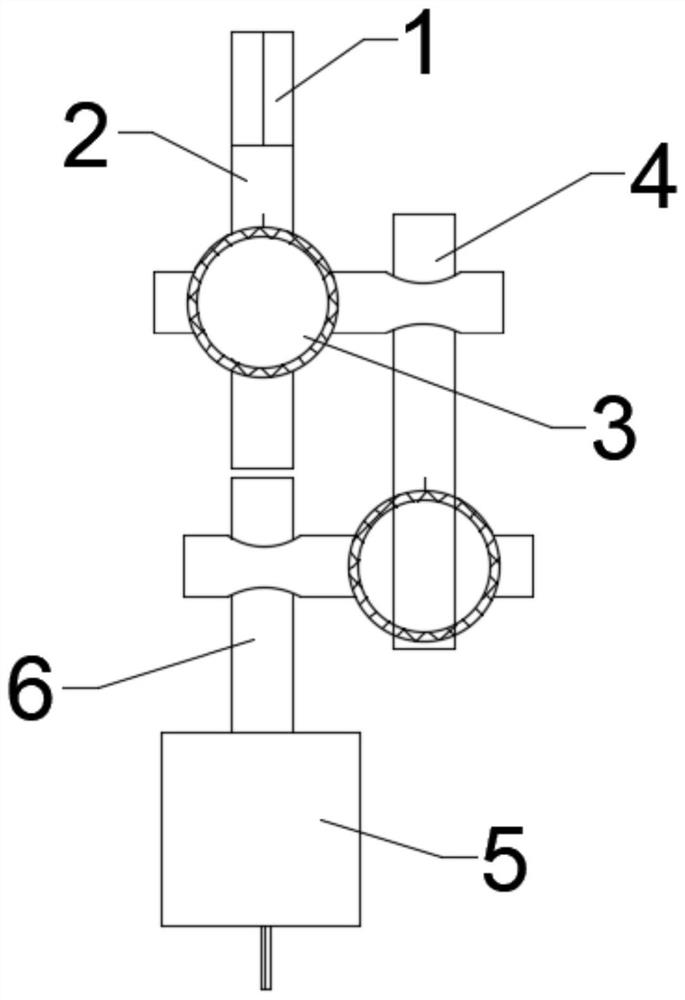

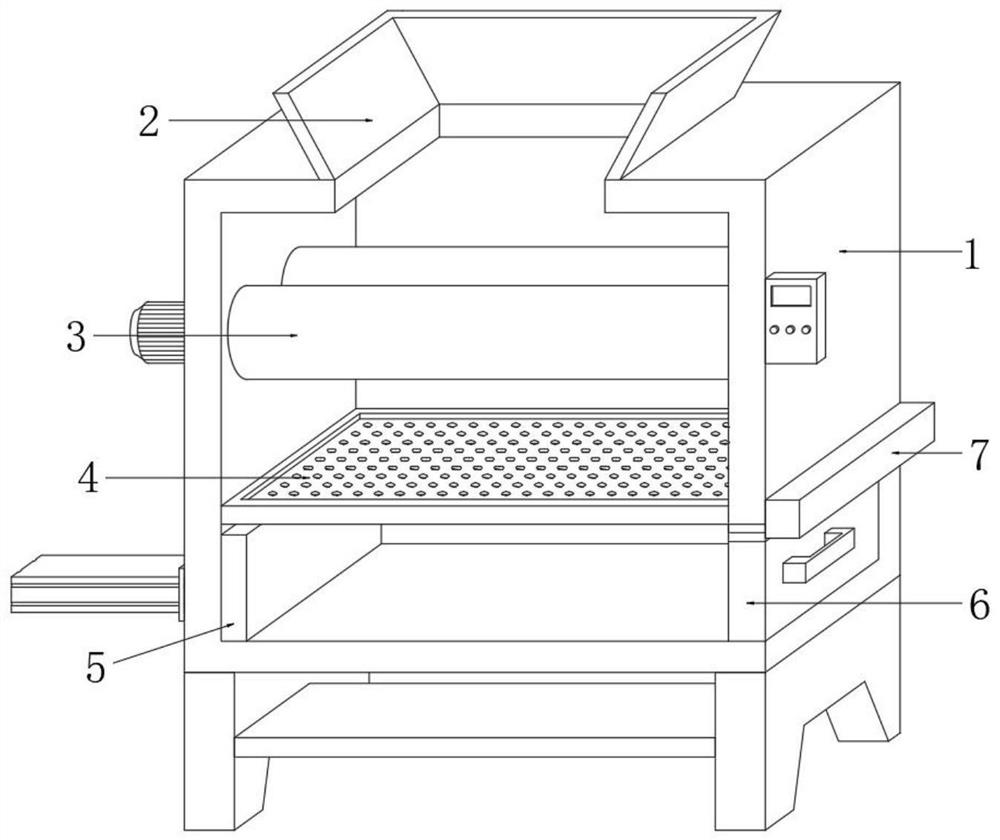

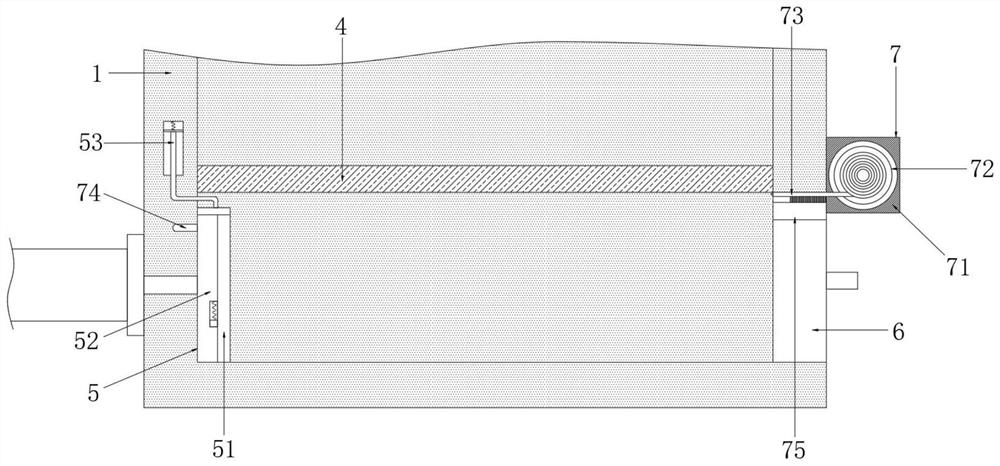

Metal powder screening device for 3D printing

InactiveCN112893107AAperture free controlRealize quantitative additionSievingAdditive manufacturing apparatusStructural engineeringScreens (device)

The invention discloses a metal powder screening device for 3D printing. The metal powder screening device comprises a base, supporting legs and a shell, the supporting legs are fixedly installed at the bottom of the base, the shell is fixedly installed at the upper end of the base, a feeding port is formed in the upper end of the shell, a partition plate is fixedly installed in the shell, and the interior of the shell is divided into two parts by the partition plate; and a quantitative adding mechanism is installed on the partition plate, and a screening mechanism is installed below the partition plate inside the shell. When the metal powder screening device is used, two screening assemblies on the screening mechanism can conduct screening on metal powder twice, due to the fact that the hole diameters of screens on the two screening assemblies are different, the metal powder can be divided into three parts according to different particle sizes, meanwhile, adjusting mechanisms installed on screen frames can adjust the hole diameters of the screens, and therefore the maximum hole diameter of the screened metal powder can be freely controlled according to requirements.

Owner:JIANGSU VILORY ADVANCED MATERIALS TECH CO LTD

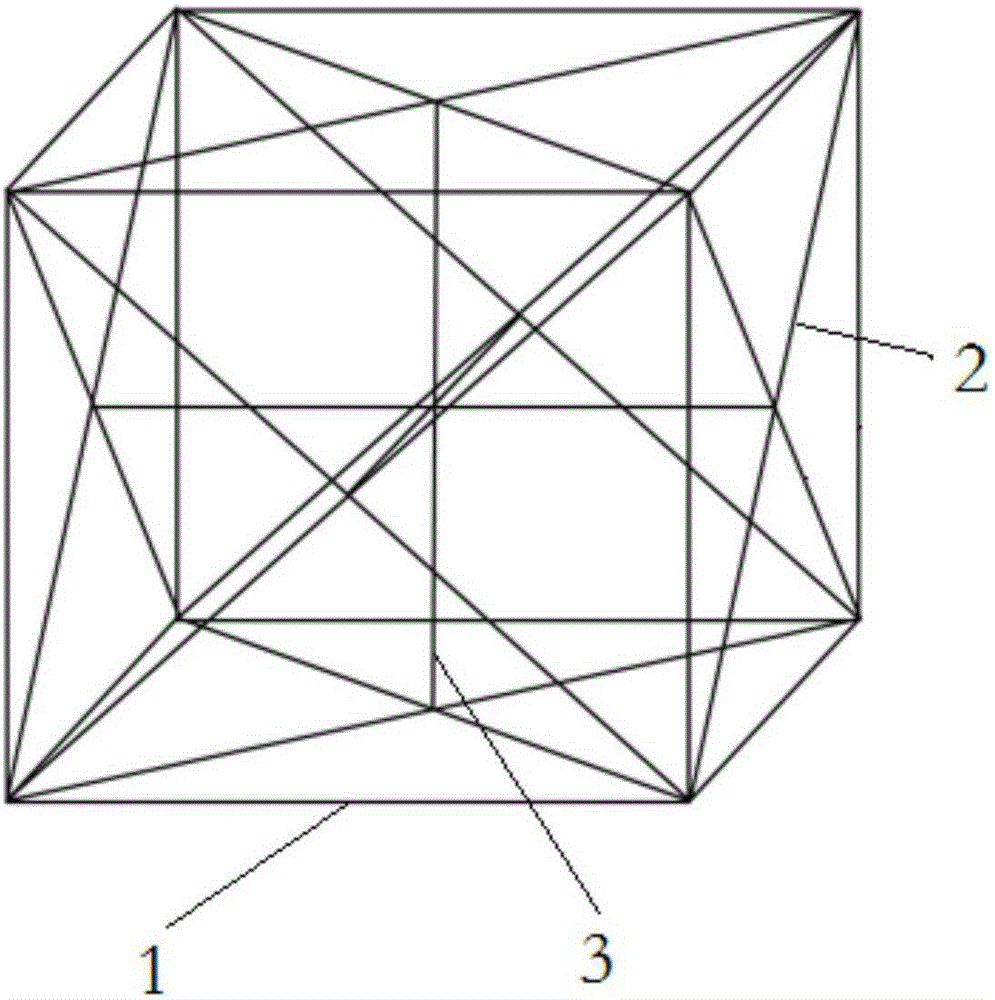

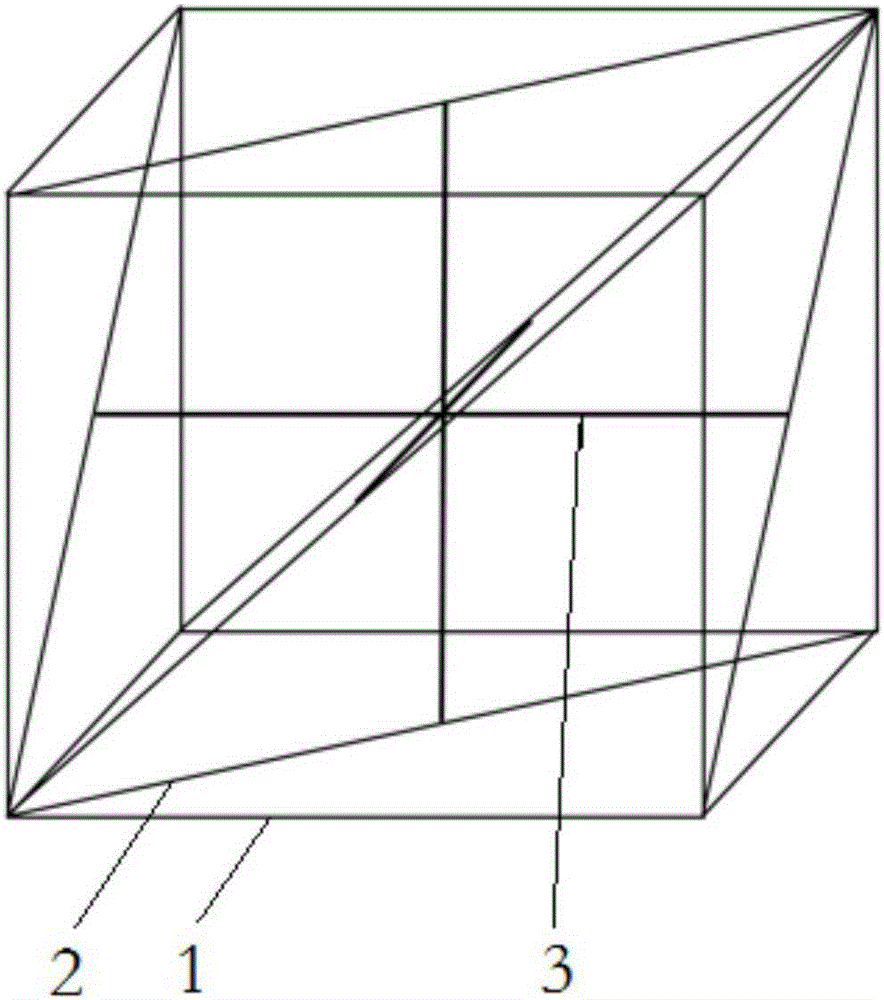

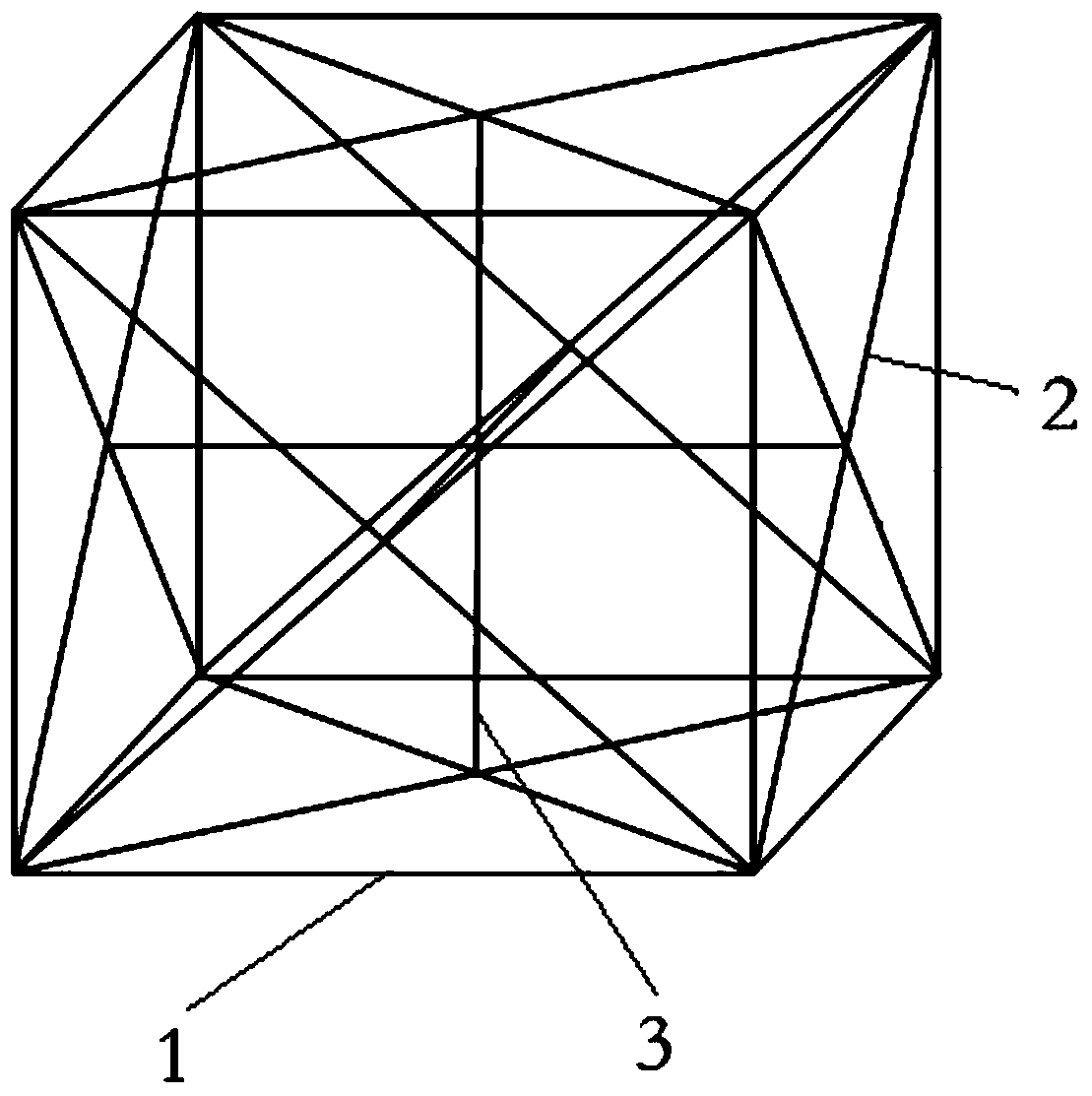

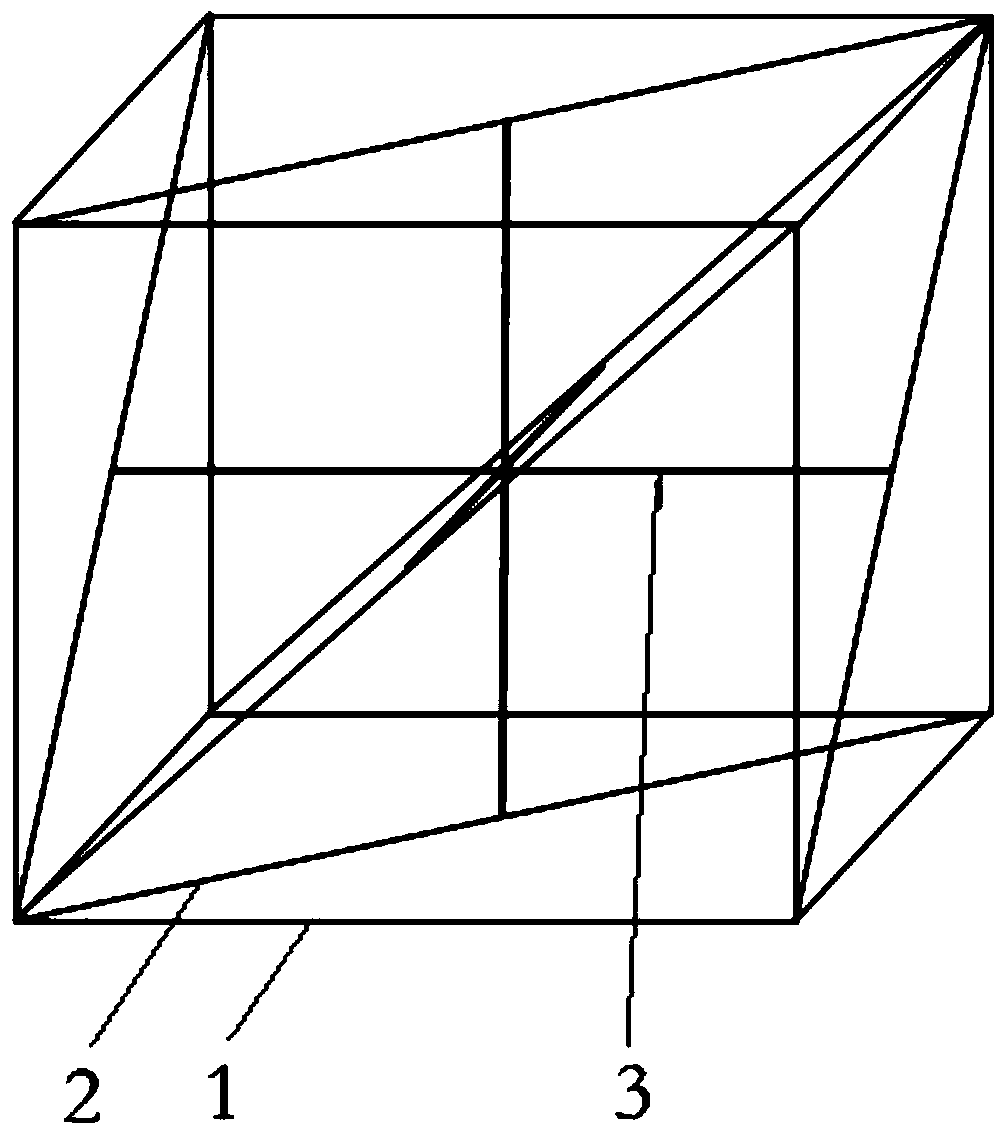

Personalized hard tissue defect restoration body and manufacturing method thereof

InactiveCN105596116ARealize personalized designMechanical property adjustmentBone implantJoint implantsSelective laser meltingTissue defect

The invention provides a personalized hard tissue defect restoration body and a manufacturing method thereof. The personalized hard tissue defect restoration body provided by the invention is porous structure metal with a rough surface, and the appearance and the mechanical property of the personalized hard tissue defect restoration body are accurately matched with a hard tissue defect part of a patient. The manufacturing method comprises the following steps of firstly, designing a restoration body three-dimensional model according to the form and the mechanical property of the hard tissue defect part of the patient; then utilizing a selective laser melting rapid prototyping method to acquire a restoration body entity; carrying out annealing treatment to obtain the restoration body. The method is simple in processing step, short in period, high in material utilization rate, low in cost, and convenient for manufacturing of the hard tissue defect restoration body with a complex structure, and has more efficiency and economic advantages for the personalized design and quick manufacture of the restoration body. The manufactured restoration body is uniform in porosity and adjustable in pore diameter, has mutually penetrated and communicated holes, has the elastic modulus and the compressive strength being very close to those of the hard tissue, and can meet the biomechanical compatibility requirement required by biomedical materials.

Owner:周建宏

Hot fiber stripping pliers

The invention provides hot fiber stripping pliers which include a gland, a pedestal, two clamping cover plates and a blade assembly. The gland and two clamping cover plates are hinged onto the pedestal, the clamping cover plates are positioned in the two sides of the gland respectively, and fiber stripping channels are arranged between the gland and two clamping cover plates and the pedestal; andthe blade assembly comprises upper and lower blades, the upper blade is fixedly connected to the gland, a first V-shaped groove is formed in the upper blade, the lower blade is fixedly connected to the pedestal and positionally corresponds to the upper blade, a second V-shaped groove is formed in the lower blade, and the first V-shaped groove and the upper blade and the second V-shaped groove of the lower blade form a cutting hole matching a fiber core. A fiber is placed in the wire stripping channel of the pliers, the fiber is fixed to the pedestal via the left and right clamping cover plates, the gland is pressed, a coating of the fiber is cut by cooperation of the lower and upper blades, and the fiber core is positioned in the cutting hole, and avoided from damage in the cutting process.

Owner:NANJING JILONG OPTICAL COMM

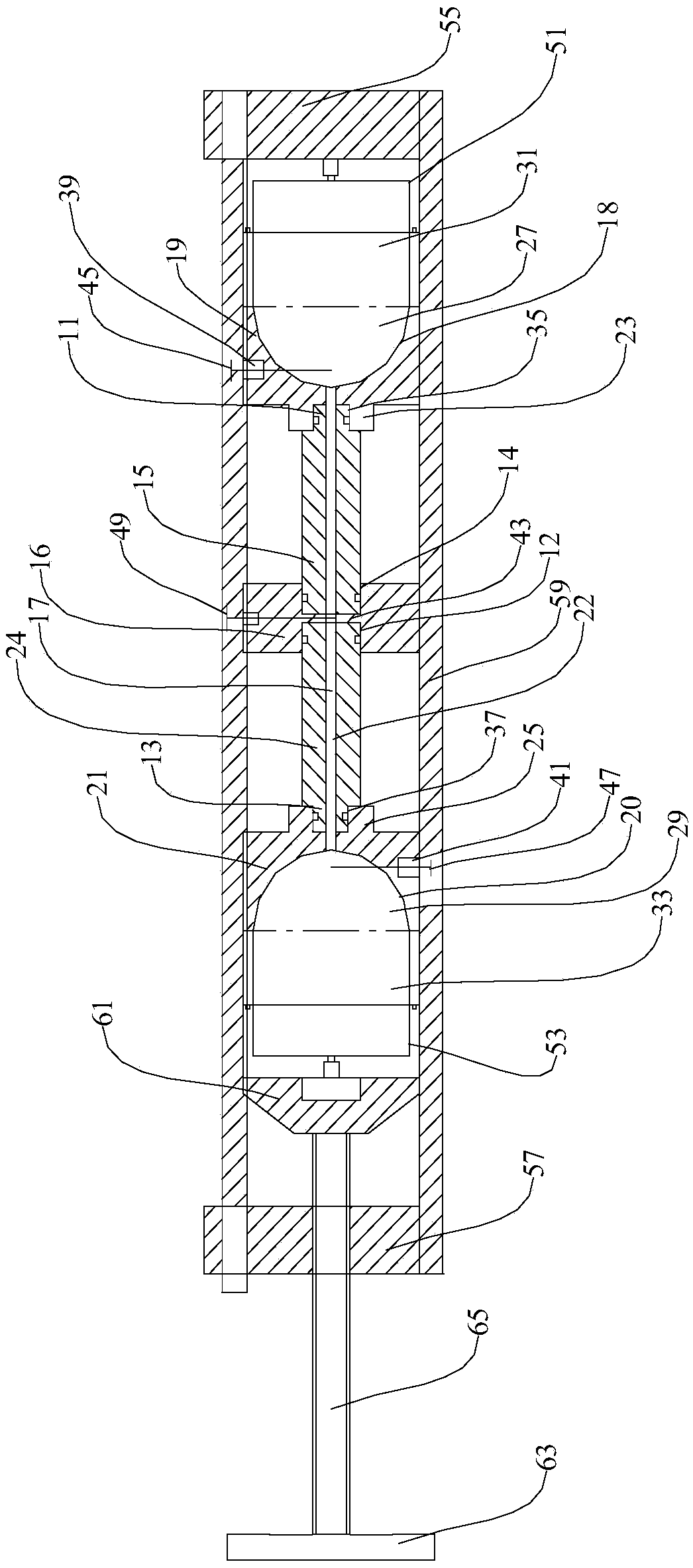

Gas throttling simulator

ActiveCN105545281AStrong throttling and cooling effectChange lengthSurveyLiquid/gas jet drillingAirflowAerospace engineering

The invention provides a gas throttling simulator comprising an airflow roaring path with a first end and a second end arranged in opposite; a passageway penetrating the airflow roaring path from the first end to the second end is arranged in the airflow roaring path; the airflow roaring path comprises a plurality of roaring path units fixed through connectors; each roaring path unit is provided with a channel; when the roaring path units are fixed through connectors, the roaring path channels are connected to form the passageway; the simulator also comprises a throttling room and a detection part; the throttling room is detachably arranged on the first end of the airflow roaring path, and comprises a first chamber connected with the passageway of the airflow roaring path; the first chamber comprises a first portion with a cross section area bigger than that of the passageway of the airflow roaring path; the detection part is used for detecting the gas before and after the throttling; the gas throttling simulator can provide stronger throttling effect.

Owner:PETROCHINA CO LTD

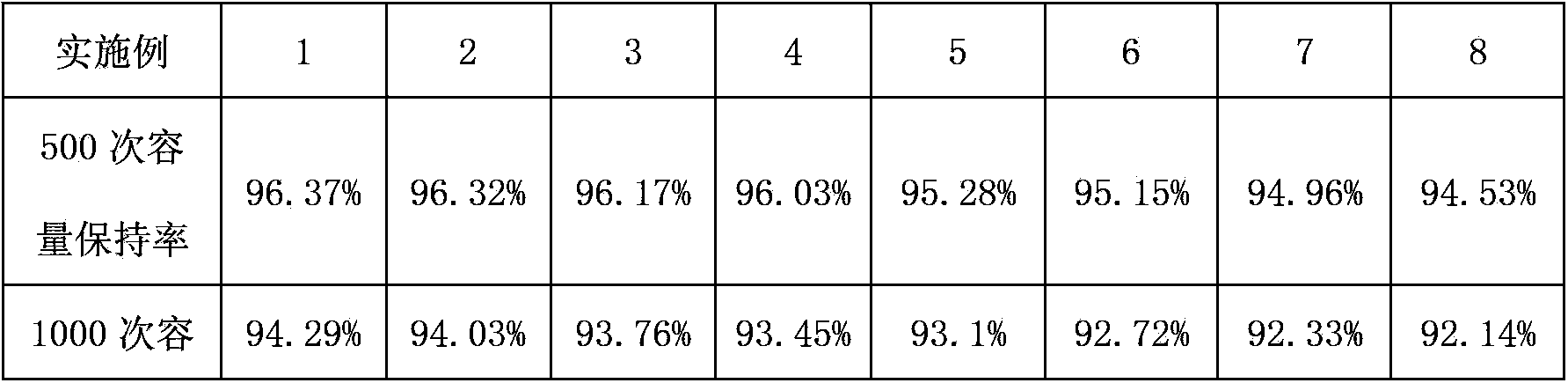

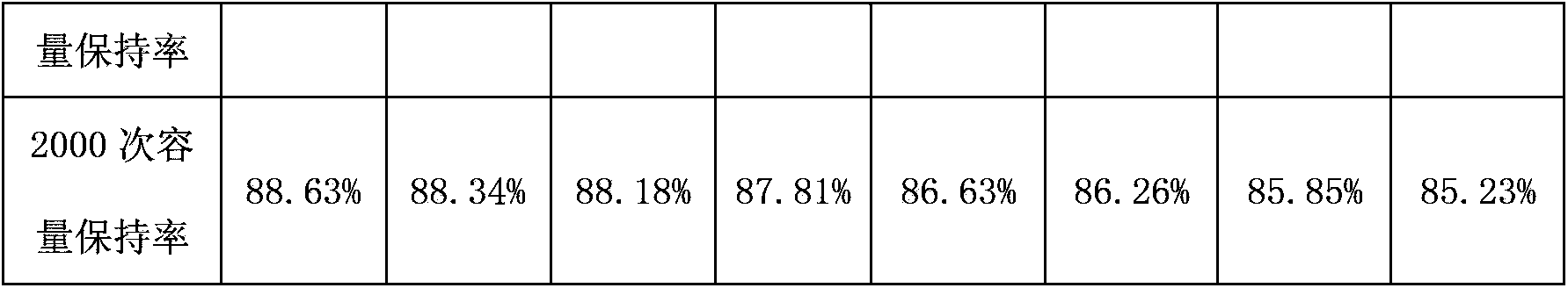

Conductive agent applicable to lithium iron phosphate material and preparation method of conductive agent

The invention relates to a preparation method a lithium ion battery, particularly relates to a conductive agent applicable to a lithium iron phosphate material and a preparation method of the conductive agent, and mainly solves the technical problems in the prior art that the utilization rate of an active material is low, the residual capacity of an electrode is great and the like caused by great inner resistance and not enough discharging depth of the lithium iron phosphate electrode. The method provided by the invention comprises the following steps: under a constant-temperature condition, slowly adding conductive carbon black into a dispersant and a salt solution; heating and agitating to form a rheological phase; putting the rheological phase into a high-temperature furnace and heating; in a heating process, introducing inert gas all the time and cooling the rheological phase to the room temperature along with a furnace; washing with a strong acid and filtering; drying in a vacuum box under a high-temperature condition to prepare the treated conductive carbon black; and mixing a carbon nano tube, the conductive carbon black and conductive graphite according to a mass ratio of (0.1-1) to (0.1-5) to (0.1-1) to prepare the conductive agent.

Owner:杭州金马新能源科技有限公司

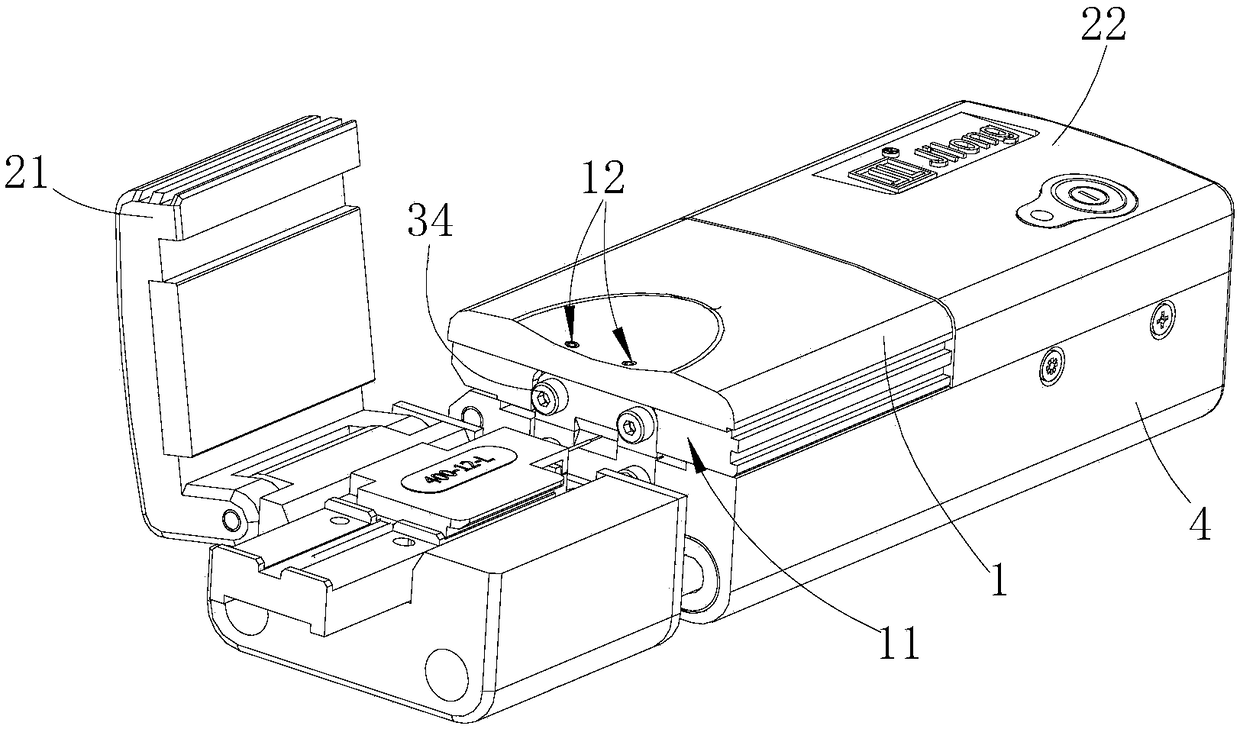

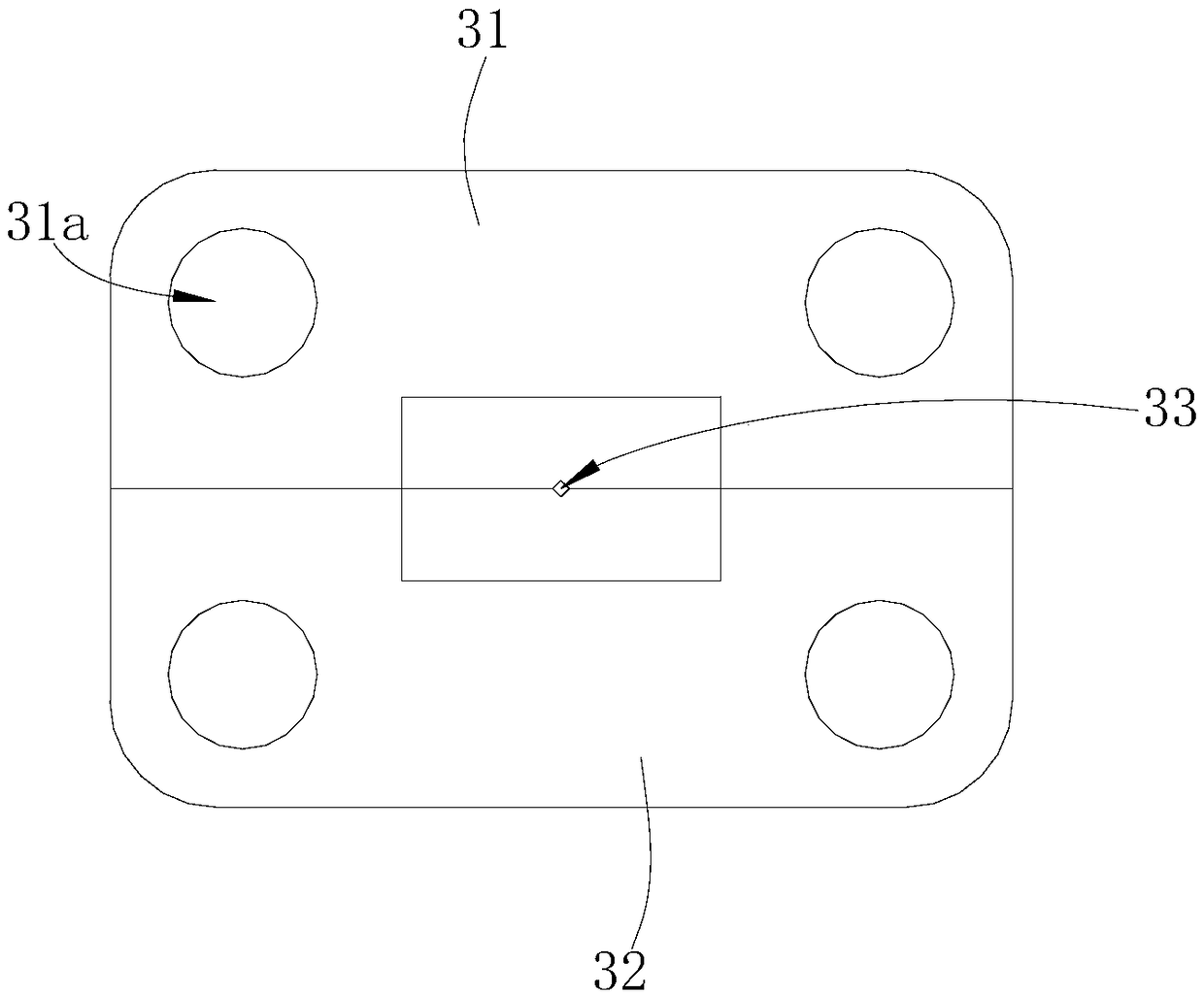

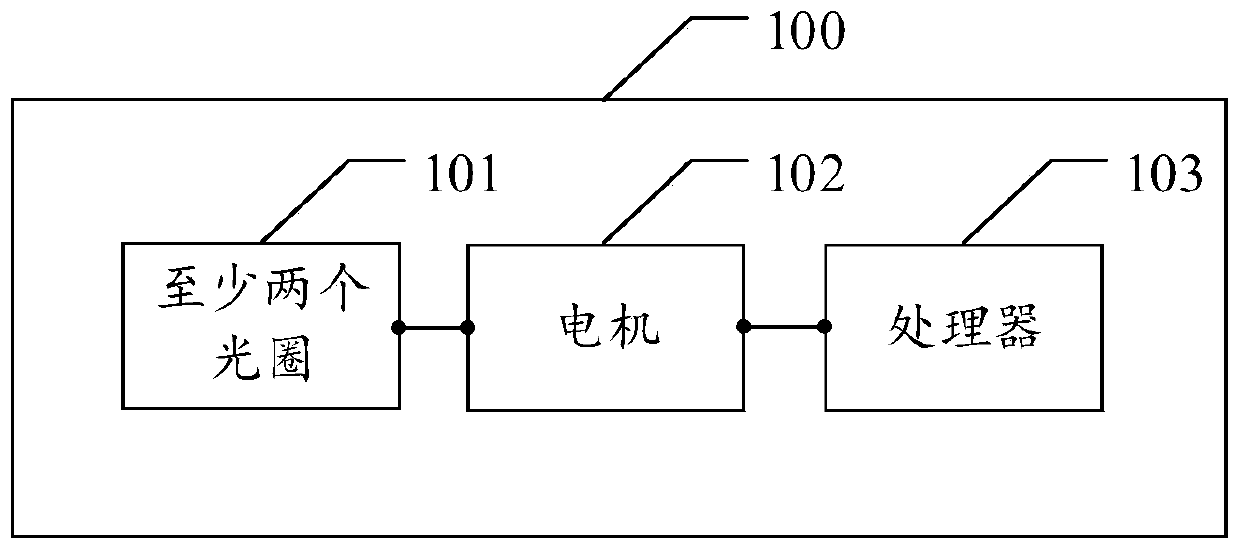

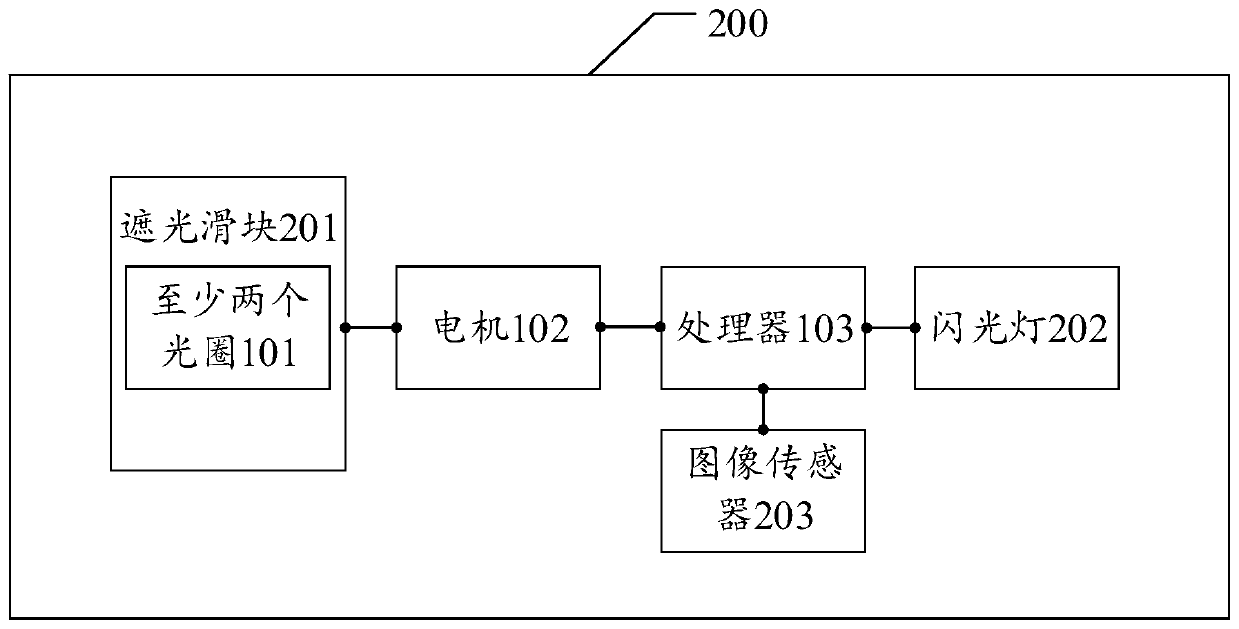

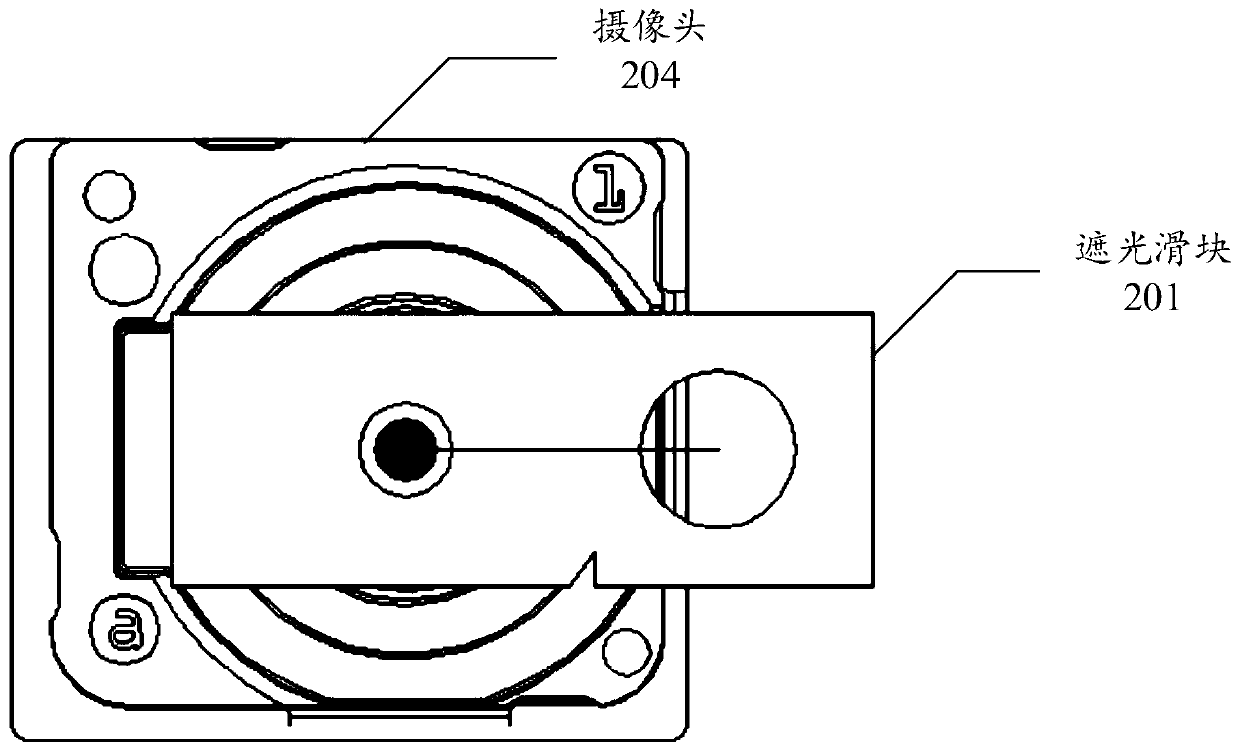

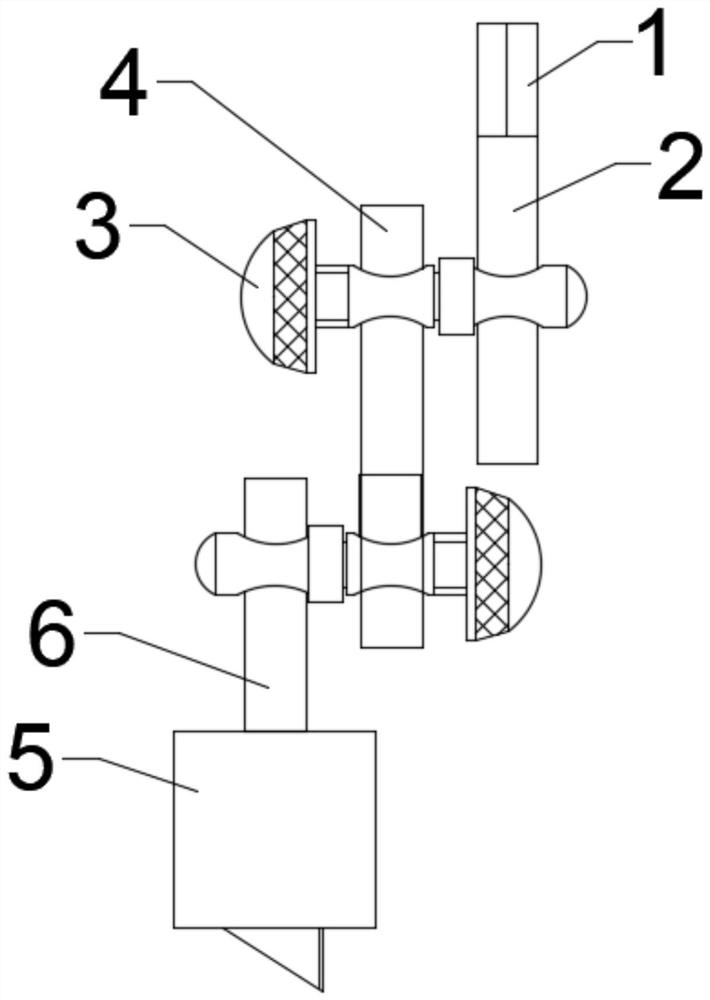

Imaging equipment and aperture control method of imaging equipment

PendingCN111147762AAperture changes accuratelyChange apertureTelevision system detailsColor television detailsSoftware engineeringImaging equipment

The embodiment of the invention discloses imaging equipment and an aperture control method of the imaging equipment. The imaging equipment comprises at least two apertures, a motor and a processor. And the processor selects a target aperture matched with the current ambient light of the imaging equipment from the at least two apertures and sends an aperture switching instruction to the motor, andthe aperture switching instruction is used for instructing the motor to switch the current aperture of the imaging equipment to the target aperture. According to the embodiment of the invention, the aperture of the aperture is accurately changed by switching the aperture.

Owner:SHANGHAI TRANSSION CO LTD

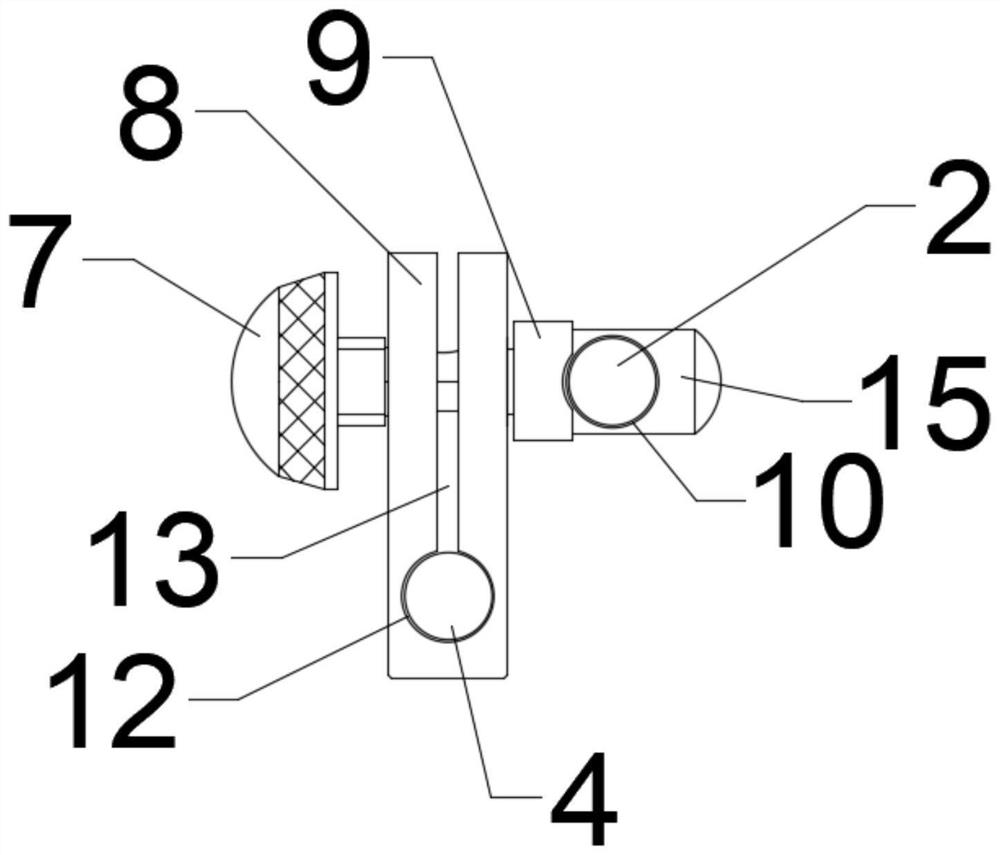

Adjustable electrode chuck

ActiveCN113020726AChange the axial angleEasy to useElectrical-based machining electrodesAviationTurbine blade

The invention relates to an adjustable electrode chuck, and belongs to the technical field of aviation turbine blade machining. The electrode chuck comprises a connecting circular pipe, two adjusting clamps and an installation rod. The two ends of the connecting circular pipe are rotationally connected with the two adjusting clamps correspondingly, and the connecting circular pipe is clamped through the adjusting clamps. The installation rod is used for being connected with a machine tool, one end of the installation rod is detachably connected with one adjusting clamp, and the other adjusting clamp is used for being detachably connected with an electrode. According to the electrode chuck, the machining angle of an electrode can be adjusted very conveniently, and the machining efficiency is greatly improved.

Owner:GUIYANG AVIC POWER PRECISION CASTING

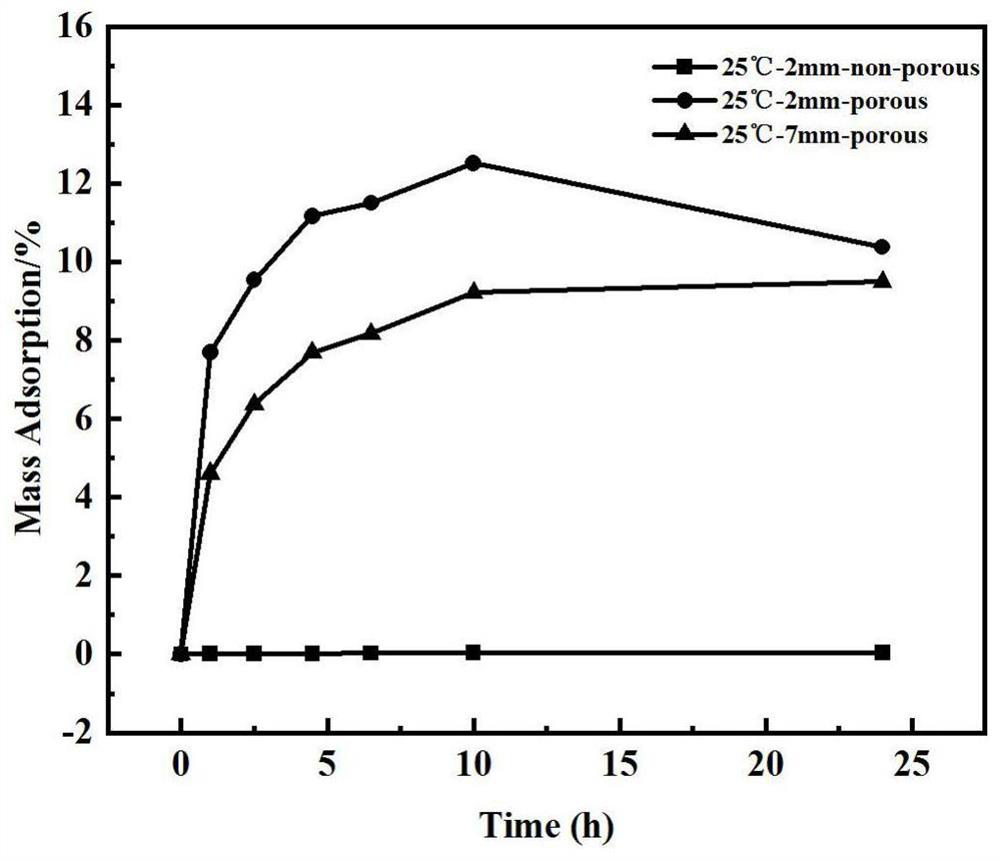

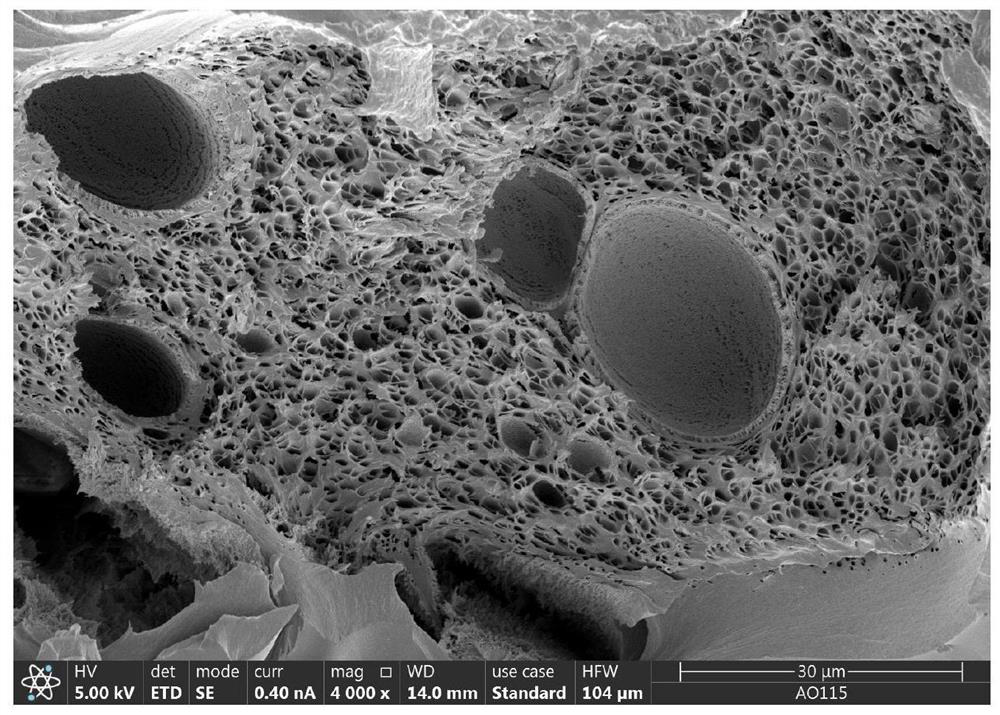

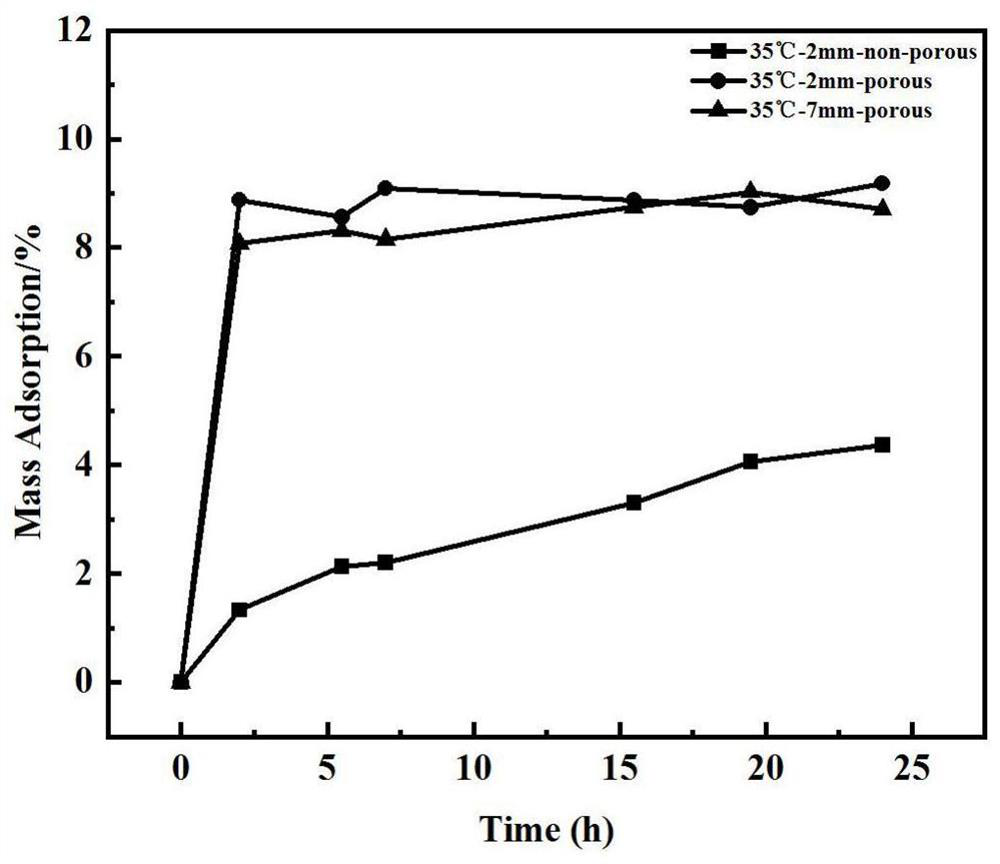

High-molecular polymer foaming material as well as preparation method and application thereof

The invention relates to the technical field of foaming materials, and provides a high-molecular polymer foaming material as well as a preparation method and application thereof. The preparation method comprises the following steps: introducing pores into a polymer, then carrying out supercritical CO2 foaming on the obtained porous polymer, and increasing the diffusion rate of CO2 and accelerating the time from gas dissolution to the saturation of the polymer by utilizing the high specific surface area of the porous polymer. The method provided by the invention is not only suitable for thin film foaming, but also suitable for sheet polymer foaming, is also suitable for various different types of polymers, and is wide in application range. The interior of the prepared polymer foam material is in a hierarchical pore shape, the polymer foam material has the advantages of being high in environment and interior interconnection, low in surface energy, large in specific surface area, high in mass transfer efficiency and the like, hierarchical pore polyetherimide can be applied to the field of friction lubrication, and the oil content and the oil retention rate at a high rotating speed can be remarkably improved due to the existence of hierarchical pores.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A 3D printed medical porous metal bone tissue scaffold with gradient pore size

The invention discloses a 3D printing gradient aperture medical porous metal bone tissue scaffold, which aims to overcome the disadvantages of the prior art that the single and repeated microporous structure is not conducive to the growth of bone tissue, and the bone tissue implant is difficult to achieve bone healing with its own bone. The problem is that it is a hexahedral structure as a whole, which is composed of components A, B and C closely arranged, component A is arrayed on the outermost layer of the hexahedral structure, component B is arrayed on the second outer layer, and component C is arrayed on the innermost layer; components A, Both component B and component C have a hexahedral frame structure, and the aperture of component A is larger than that of component B, and the aperture of component B is larger than that of component C. The present invention manufactures tissue engineering bone scaffolds with gradually changing pores by strengthening the structural design, regulates the ingrowth of bone tissue and fibroblasts through the gradually changing pores, and finally achieves the best bone healing.

Owner:JILIN UNIV

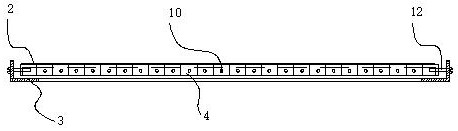

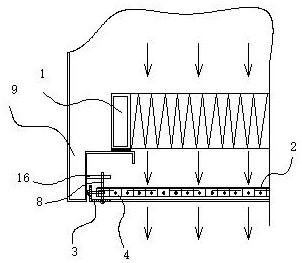

Local fine-adjustment air rectification device for purification equipment and adjustment method of local fine-adjustment air rectification device

ActiveCN113398675AUniform wind speedMeet laminar airflow requirementsDispersed particle filtrationAir velocityAir filter

The invention discloses a local fine-tuning rectification device for purification equipment and an adjusting method of the local fine-adjustment air rectification device. The local fine-tuning rectification device comprises a high-efficiency air filter and a flow uniformizing device, and is characterized in that the flow uniformizing device comprises a porous membrane and a flow uniformizing frame, the flow uniformizing frame comprises an outer frame and an inner frame, a movable space is arranged between the outer frame and the inner frame, the inner frame comprises a plurality of fixed blocks and a plurality of movable blocks, the fixed blocks are fixed to a machine box of the purification equipment through fixing screws, the movable blocks are sequentially arranged along the edge of the outer frame, a screw hole is formed in the side, corresponding to the outer frame, of each movable block, a transition hole corresponding to the screw hole is formed in the outer frame, and an adjusting screw is connected with the screw hole in the moving block from the transition hole in the outer frame. Through relative movement of the moving blocks, the porous membrane attached to the moving blocks is stretched or shrunk, and the aperture of the porous membrane is changed, so that the air outlet speed at an adjusting point position is changed, flexible adjustment of different positions of points, rows and surfaces is achieved, and laminar airflow is output.

Owner:苏州安泰空气技术有限公司

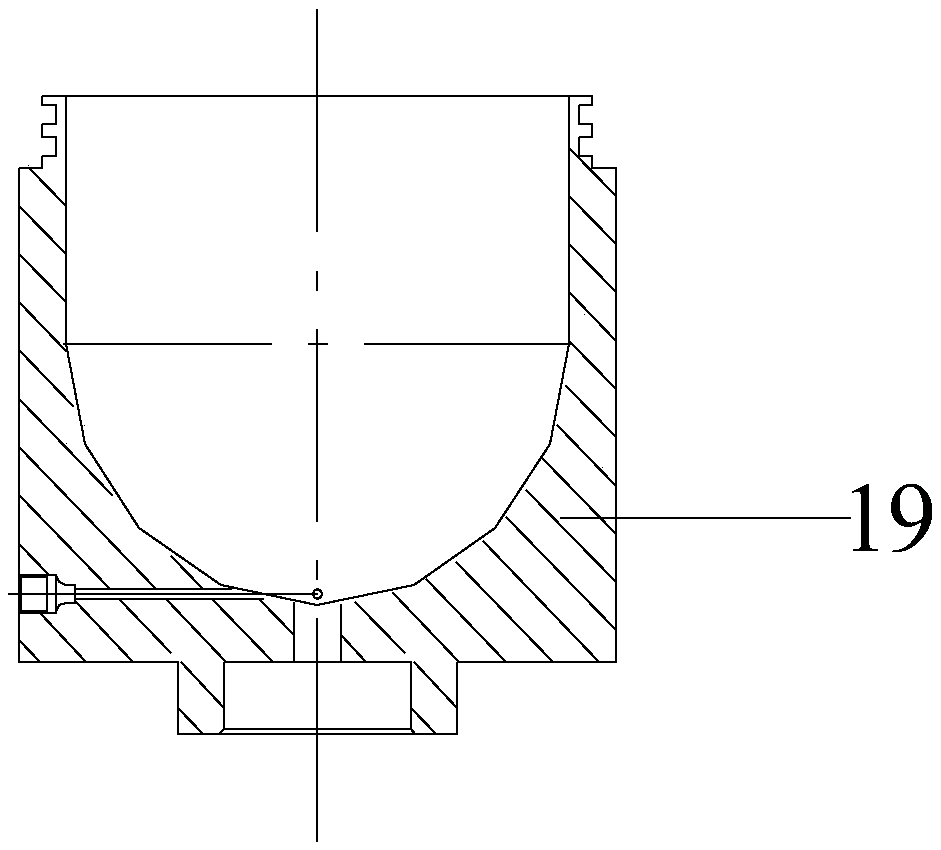

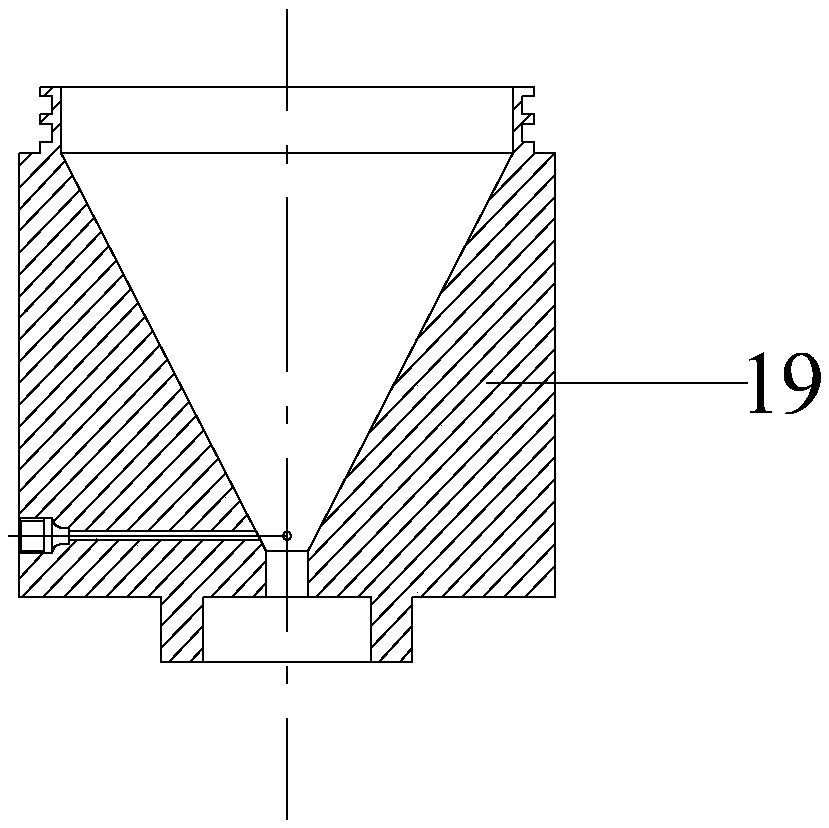

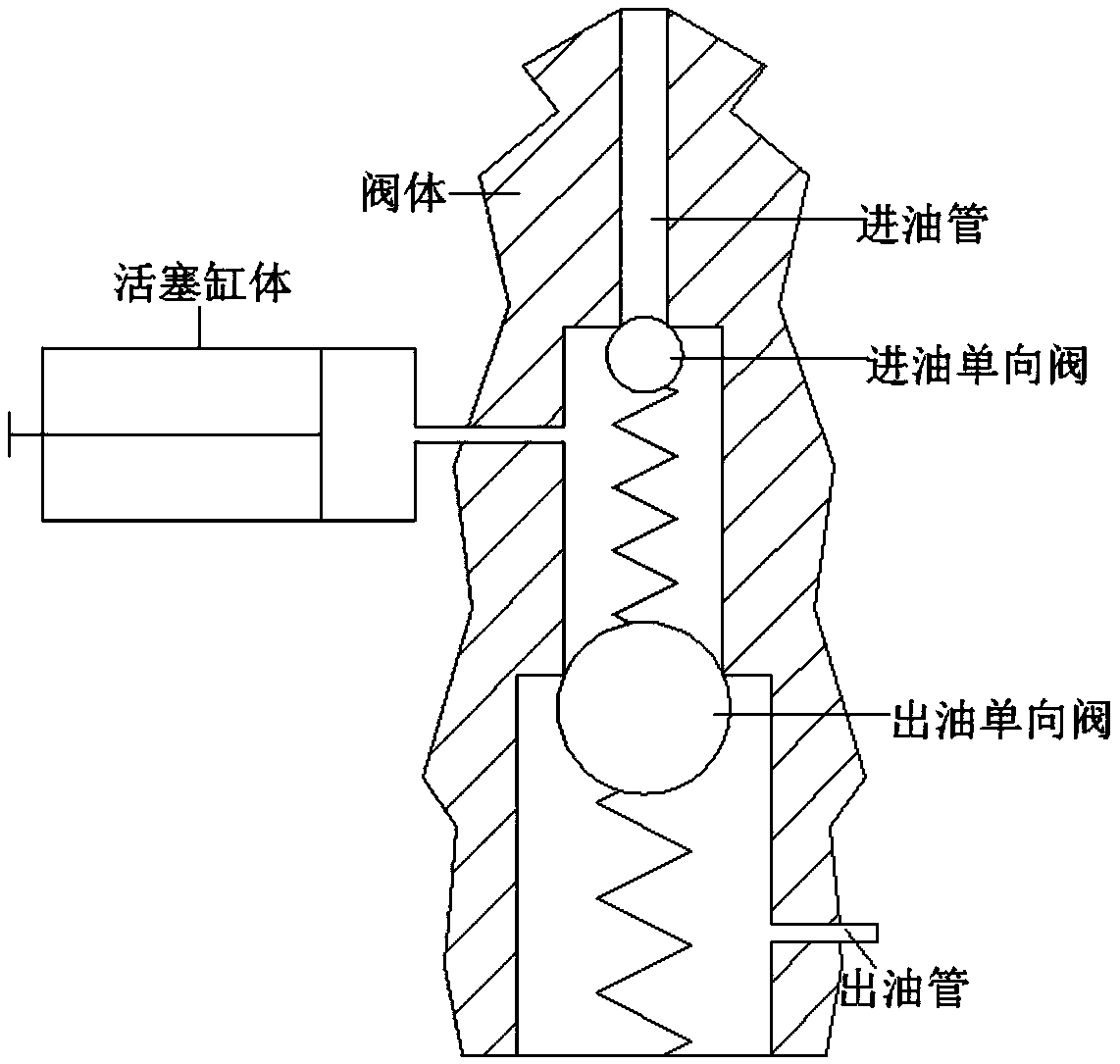

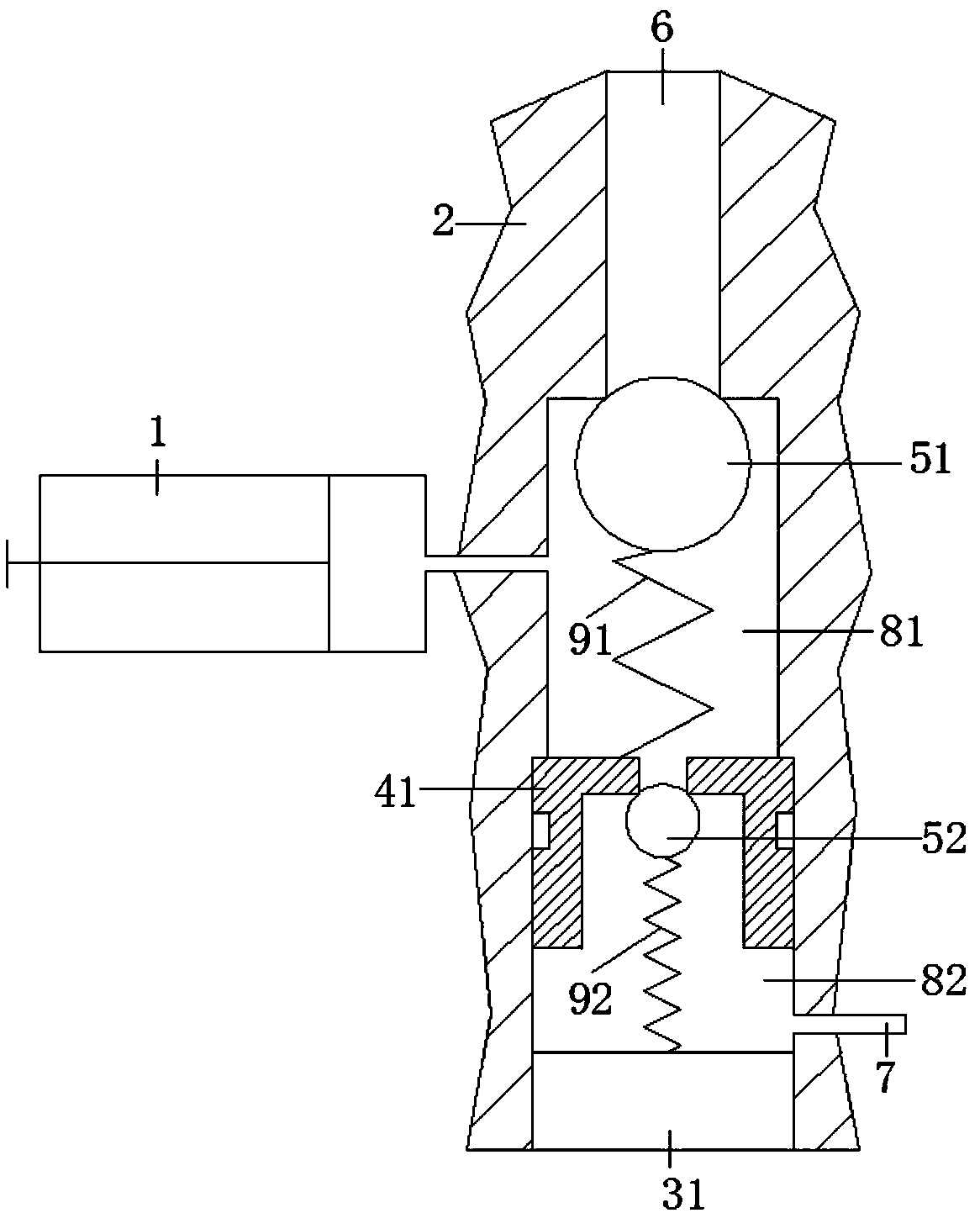

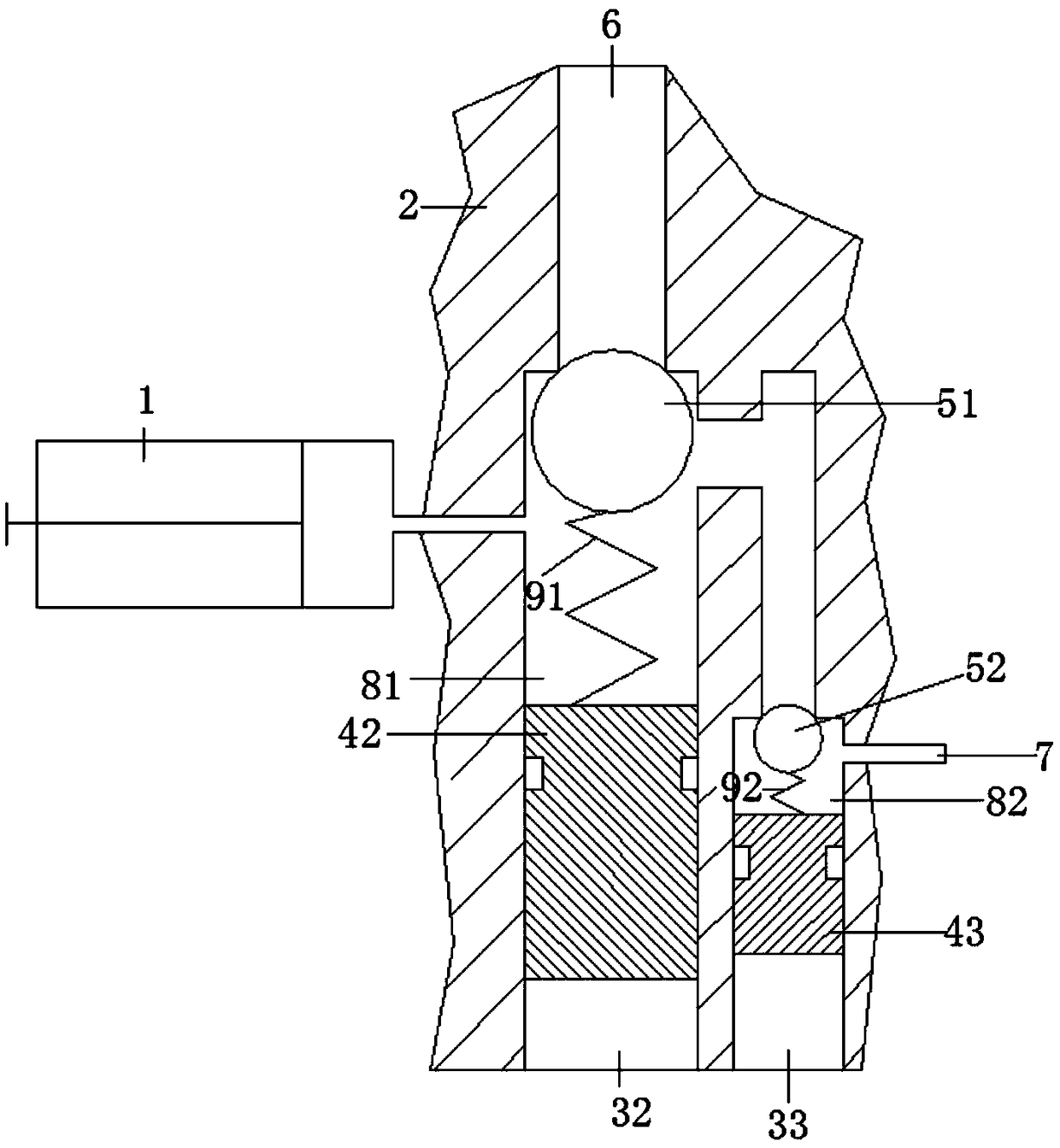

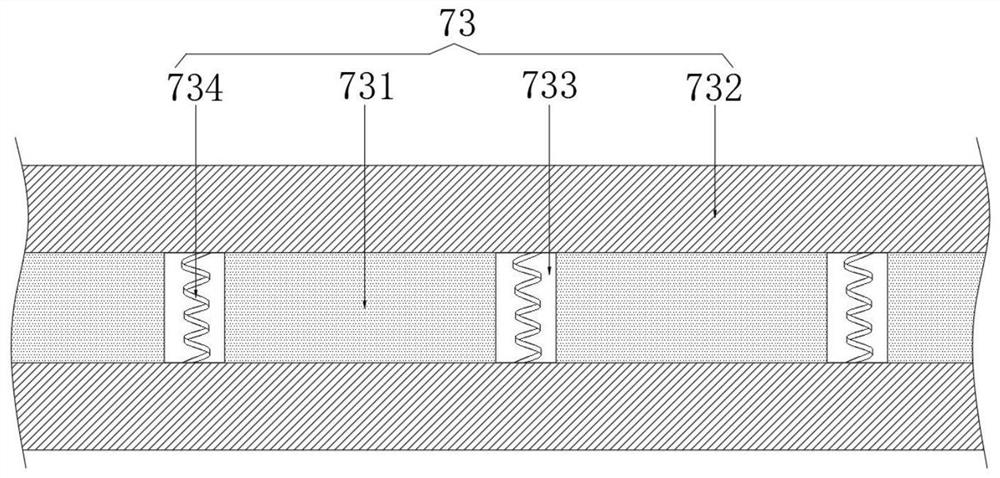

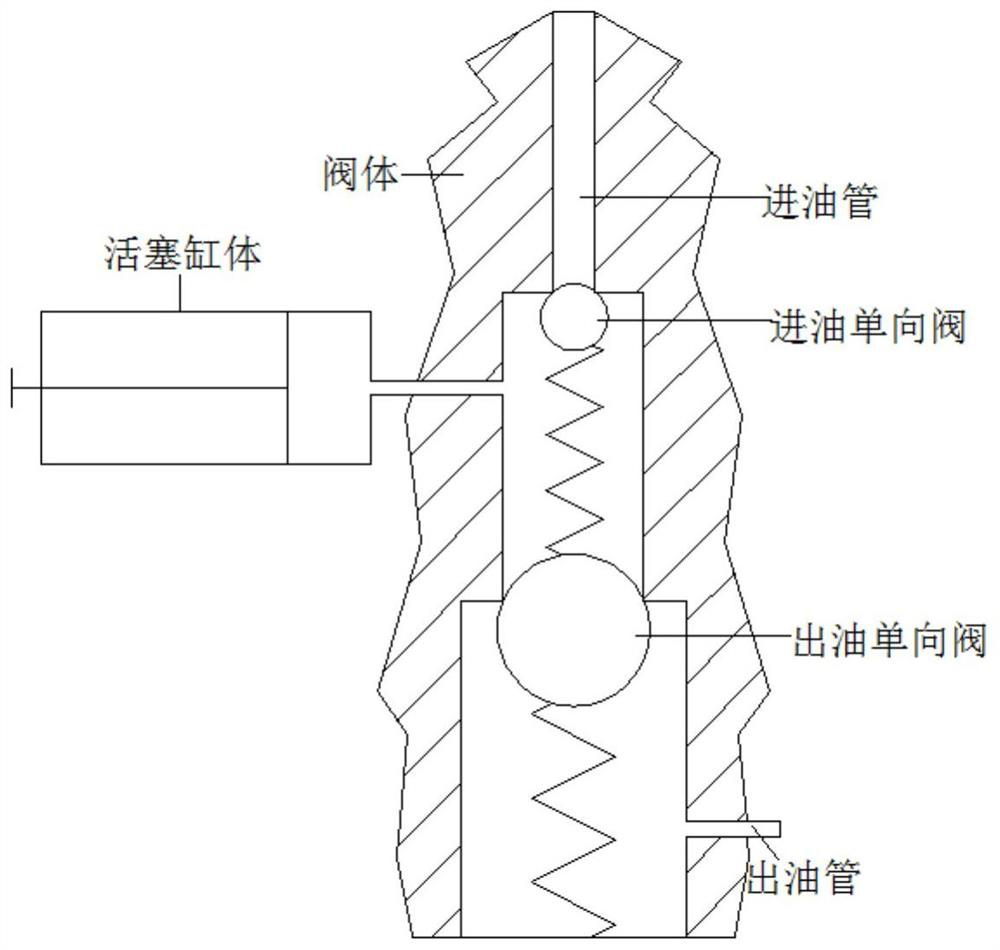

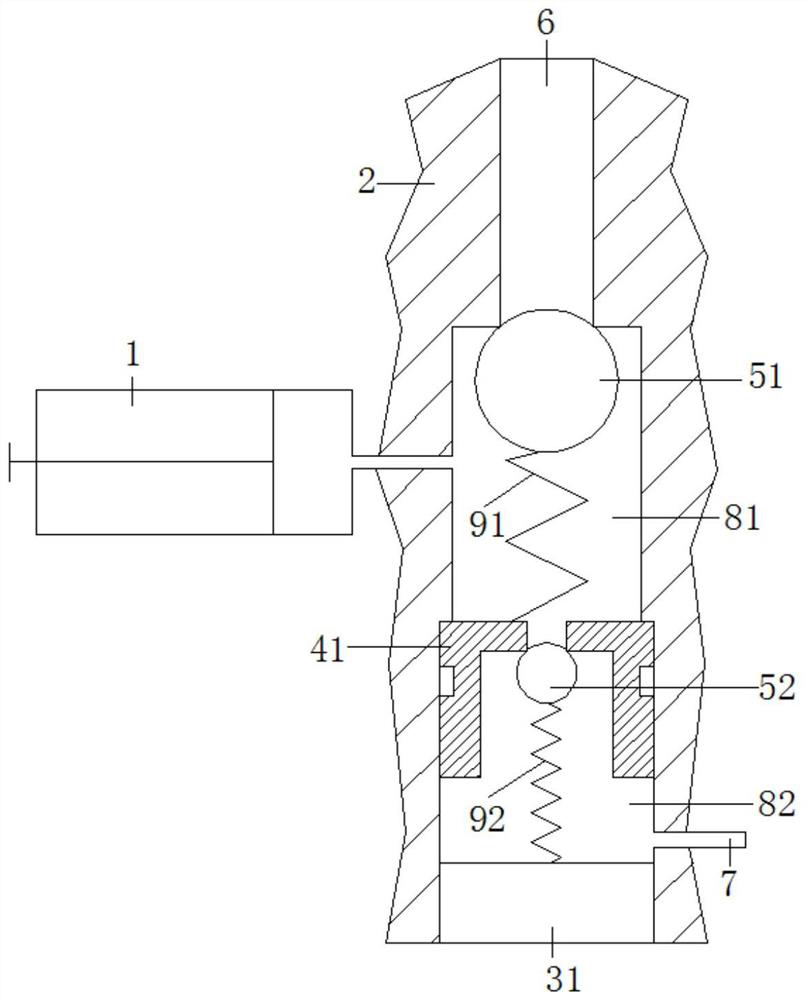

Man-powered hydraulic pump with high-reliability

ActiveCN109488552AImproved pressure retentionChange aperturePositive displacement pump componentsPiston pumpsHydraulic pumpCylinder block

The invention belongs to the technical field of hydraulic pumps and discloses a man-powered hydraulic pump with a high-reliability. The man-powered hydraulic pump comprises a cylinder body, a valve body, an oil inlet hole, an oil suction valve chamber, an oil outlet valve chamber and an oil outlet hole, wherein the oil inlet, the oil suction valve chamber, the oil outlet valve chamber and the oiloutlet hole are communicated in sequence and are arranged in the valve body; an oil suction sealing ball is arranged on an oil inlet of the oil suction valve chamber; the oil suction sealing ball is sealed and plugged in the oil inlet of the oil suction valve chamber through a first elastic assembly arranged in the oil suction valve chamber; compared with the prior art, the oil conveying speed ofthe man-powered hydraulic pump is improved by multiple times, the pressure maintaining performance is obviously improved, and the device can be designed to be portable.

Owner:湖北超星液压自动化有限公司

Forging and heat treatment process of free forge piece

ActiveCN110423924AHigh strengthHigh tensile strengthMetal-working apparatusSlagSodium hexafluoroaluminate

The invention discloses a forging and heat treatment process of a free forge piece. The forging and heat treatment process comprises the following raw materials including, by weight percent, 0.5%-1.0%of Cr, 5.0%-7.5% of Mg, 0.05%-0.10% of Zn, 0.03%-0.05% of Ti, 1.5%-2.0% of Cu, 0.10%-0.15% of Fe, 3.5%-5.0% of a slag removal agent, and the balance Al. The slag remover can remove hydrogen and floating oxidation slag inclusion in the aluminum alloy liquid, so that the alloy liquid is purer, the strong adsorption performance of the alloy liquid is used for adsorbing the slag inclusion, the purityof the aluminum alloy is improved, the added sodium hexafluoroaluminate chemical structure is similar to alumina, and can be mutually dissolved at high temperature, and on the other hand, the surfacetension during making contact with an aluminum melt can be improved, and then aluminum oxide in the aluminum alloy liquid is removed, the metal on the interface between the aluminum oxide and the aluminum can be corroded by adding the sodium fluoride, so that the oxide film falls off and falls into the flux, and then the aluminum alloy is purified.

Owner:江苏裕隆特种金属材料科技有限公司

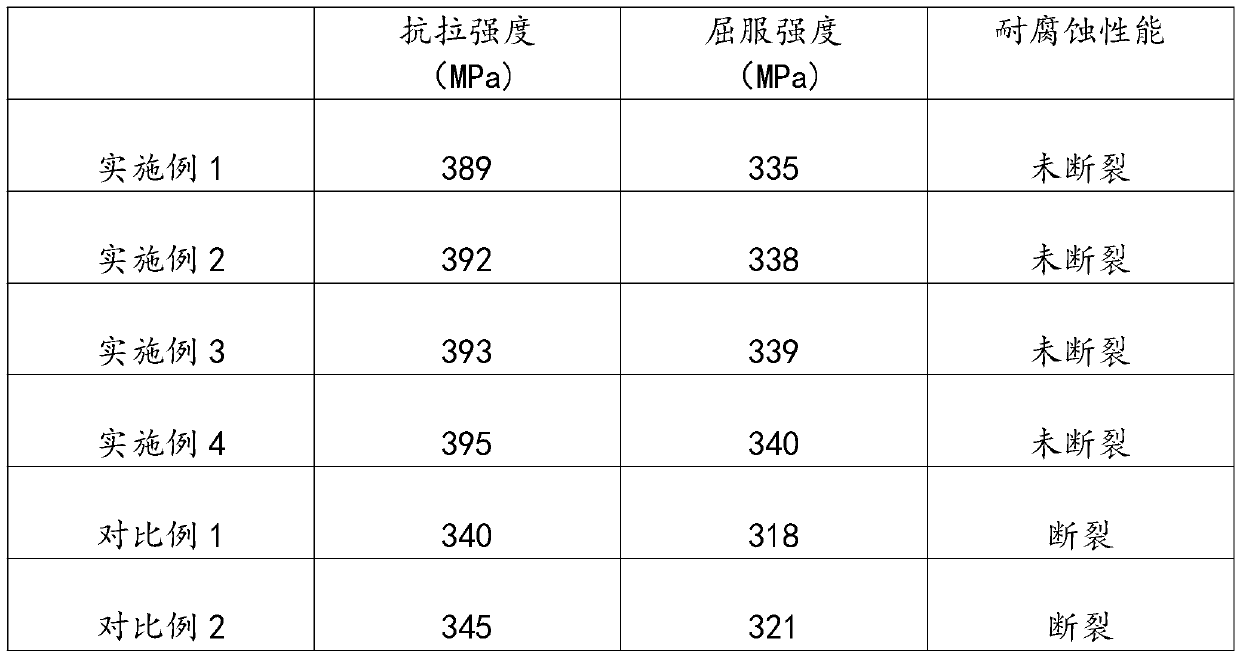

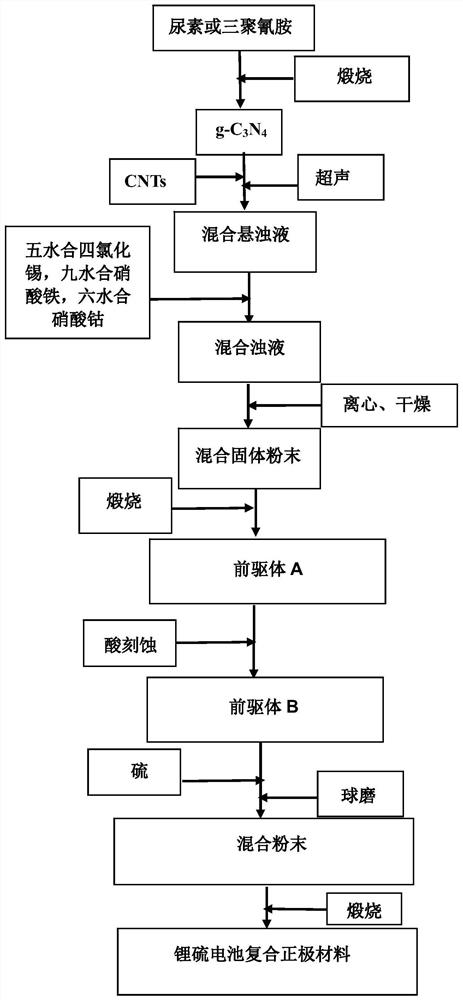

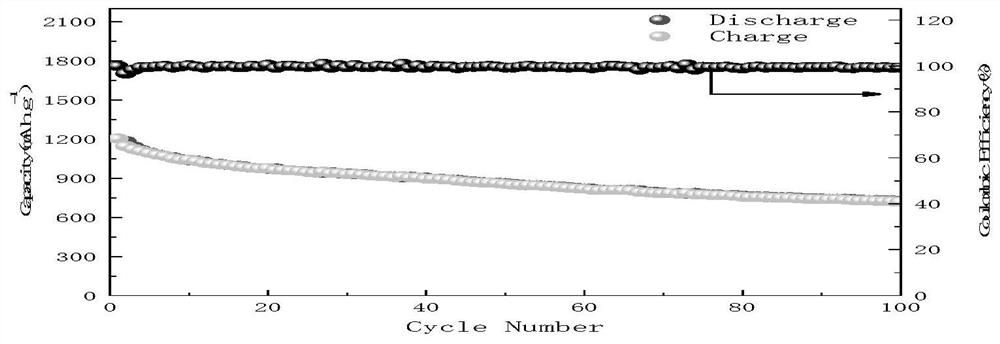

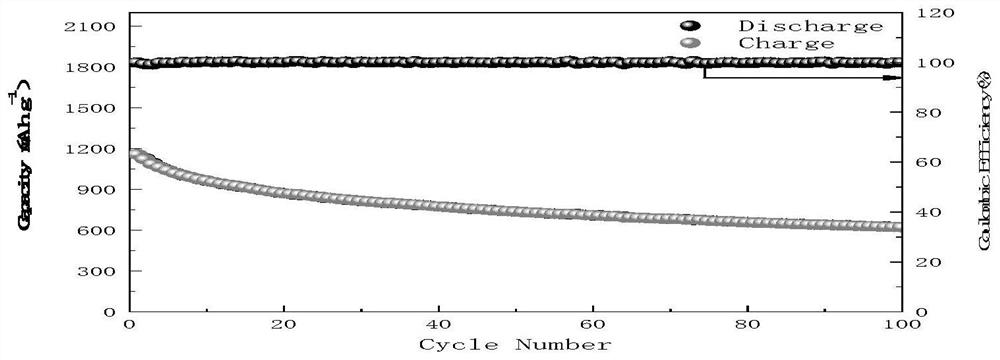

Preparation method of lithium-sulfur battery composite positive electrode material

ActiveCN113471421APrevent oxidationImprove protectionPositive electrodesLi-accumulatorsAcid etchingElectrical battery

The invention belongs to the technical field of lithium-sulfur battery preparation, and particularly relates to a preparation method of a lithium-sulfur battery composite positive electrode material. The preparation method comprises the following steps: dispersing g-C3N4 and carbon nanotubes in deionized water to obtain a mixed suspension; dissolving tin tetrachloride pentahydrate, ferric nitrate nonahydrate and cobalt nitrate hexahydrate in deionized water to obtain a mixed solution; stirring, mixing and reacting the mixed solution and the mixed turbid liquid to obtain a precipitate; drying and calcining the precipitate to obtain a precursor A; performing acid etching on the precursor A to obtain a precursor B; mixing the precursor B with sulfur, and carrying out ball milling to obtain mixed powder; and calcining the mixed powder to obtain the lithium-sulfur battery composite positive electrode material. Based on the defect of electrochemical performance of a single doped material of the lithium-sulfur battery, the SnO2 template and the g-C3N4 frame are creatively doped with the raw material of the lithium-sulfur battery at the same time, so that the battery performance is greatly improved.

Owner:SHANDONG UNIV OF TECH

Garden garbage recycling device and method

ActiveCN113926528AAvoid changing the pore sizeGuaranteed accuracySolid waste disposalTransportation and packagingRefuse DisposalsMechanical engineering

The invention discloses a garden garbage recycling device and belongs to the technical field of garbage treatment equipment. The device comprises a garbage treatment box, a hydraulic cylinder is fixedly mounted on the outer wall of the bottom of the left side of the garbage treatment box, and a hydraulic rod at the right side of the hydraulic cylinder extends into an inner cavity of the garbage treatment box and is fixedly connected with a pressing plate; a shielding device is arranged on the outer wall of the right side of the garbage treatment box, a shielding plate is driven by a connecting rope to move leftwards in the device, so that garbage and a filter screen are separated by the shielding plate, the garbage is not in contact with the filter screen in the garbage extruding process of a pressing plate, the filter screen is prevented from being extruded and deformed, and the filter screen is protected; and the aperture of the filter screen is prevented from being changed, the use precision of garbage treatment equipment is guaranteed, the filter screen is separated from the garbage through the shielding plate, the garbage cannot enter the left side of the pressing plate in the rightward moving process of the pressing plate, residual garbage in the garbage treatment box is avoided, and the use performance of the garbage treatment equipment is improved.

Owner:厦门市艺述集团有限公司

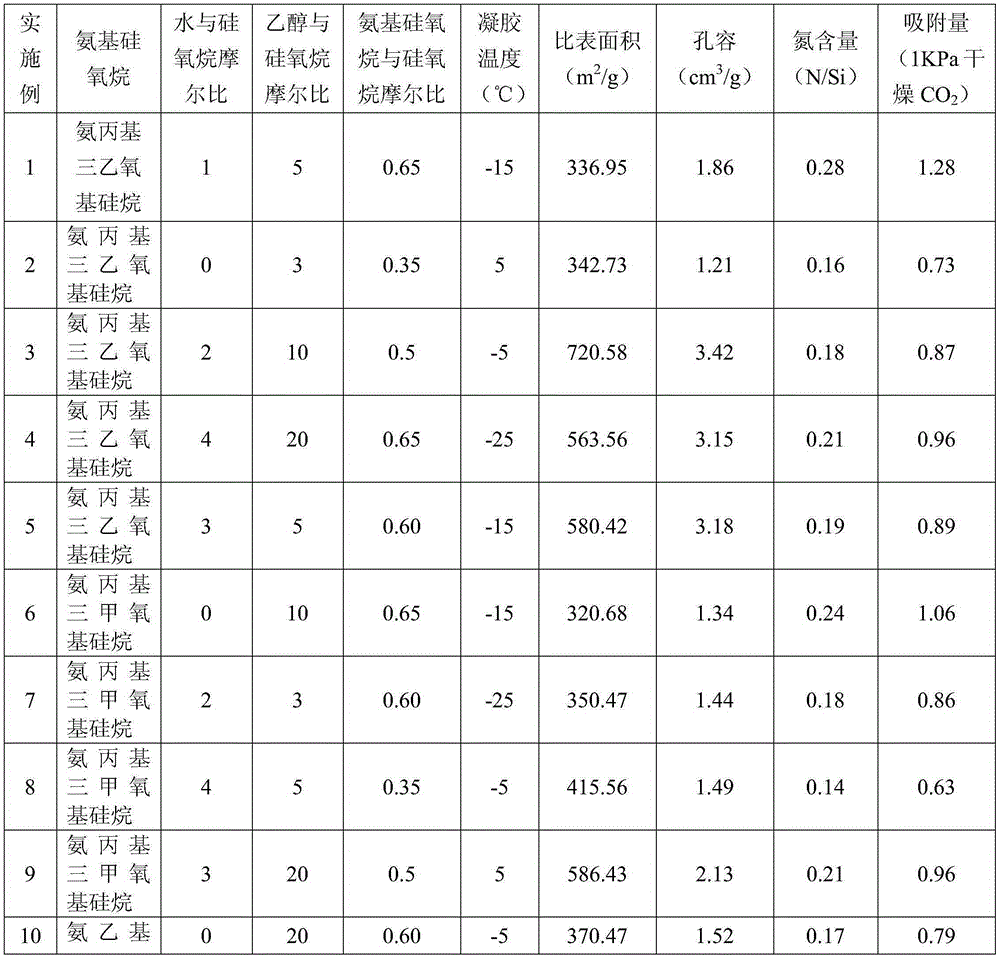

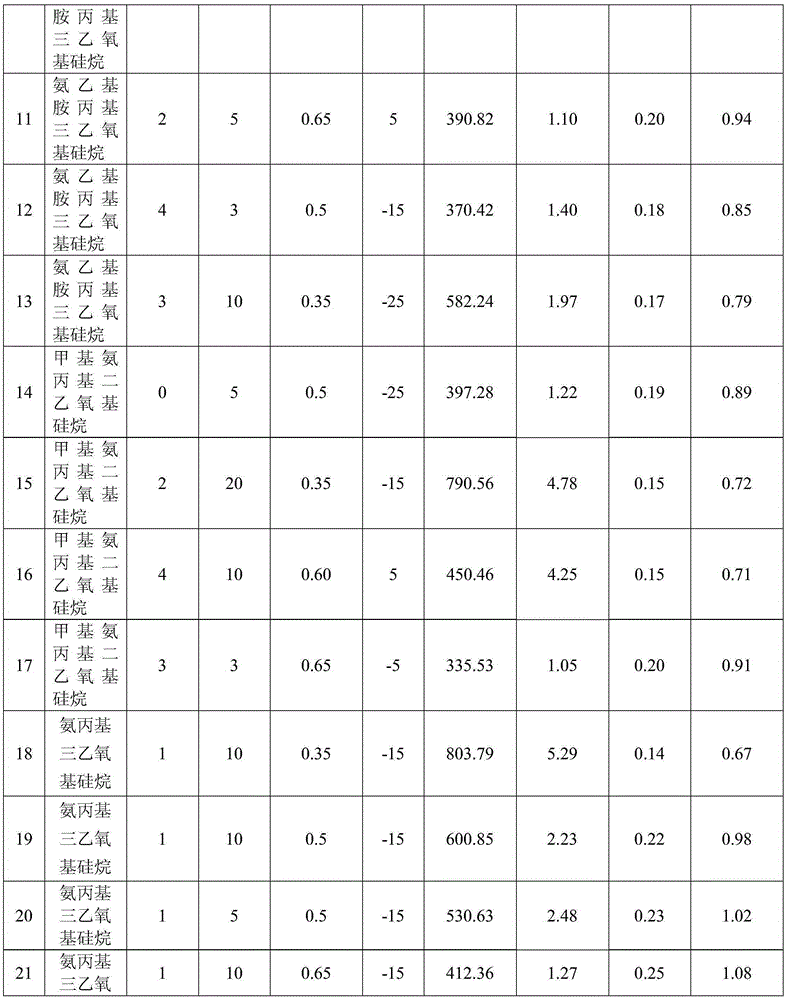

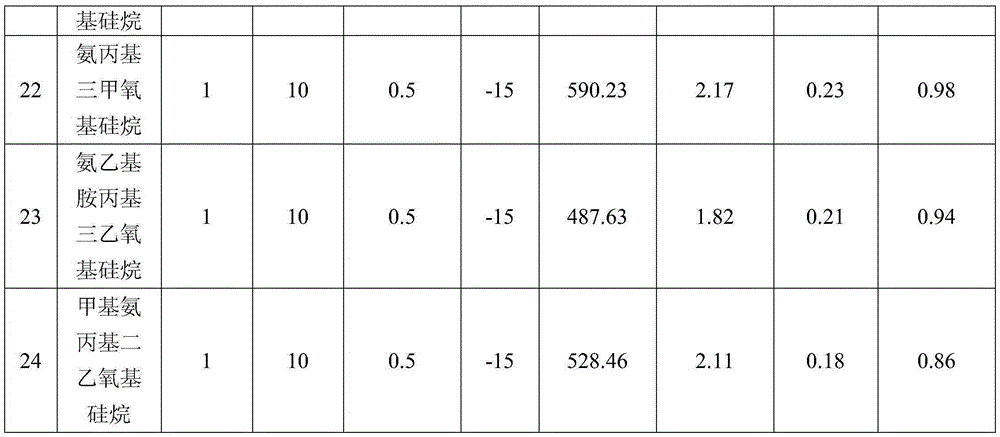

A kind of preparation method of renewable low-concentration CO2 high-efficiency adsorption material

ActiveCN104117343BWell mixedAvoid inhomogeneityOther chemical processesDispersed particle separationSupercritical dryingAminosilochrome

Owner:NAT UNIV OF DEFENSE TECH

A method for preparing rice husk-based negative electrode material

ActiveCN110429264BImprove Coulombic efficiencyChange apertureSecondary cellsNegative electrodesChemical industrySilicon dioxide

Owner:JILIN UNIV

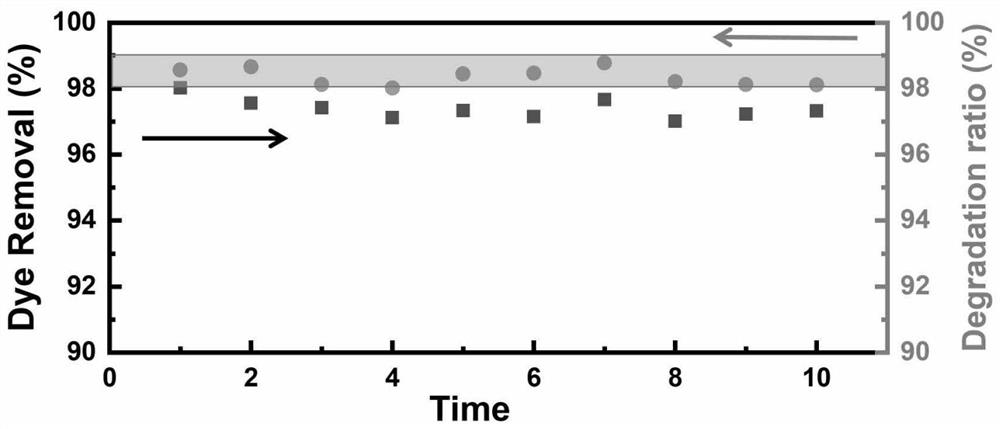

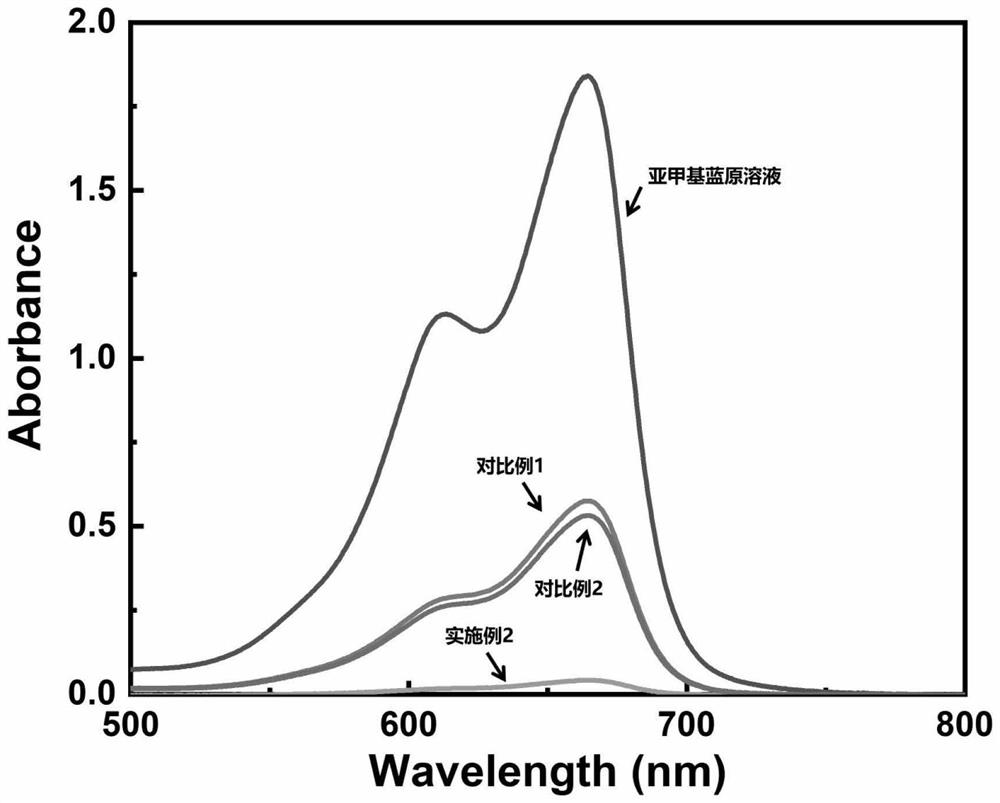

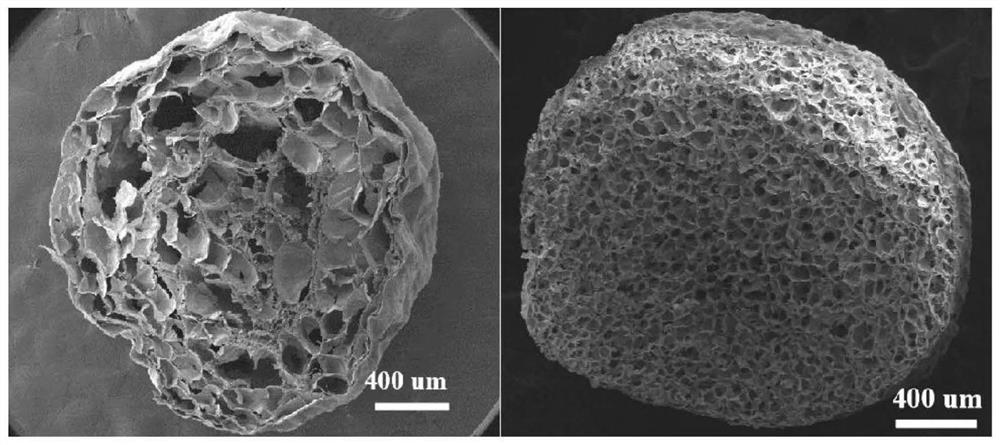

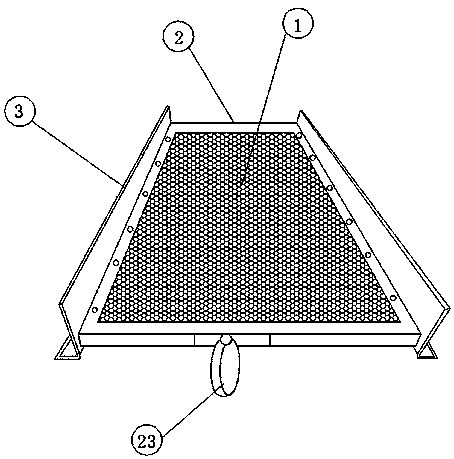

Biomass nanomaterial porous microsphere and preparation method thereof

PendingCN113368830ALarge specific surface areaImprove adsorption efficiencyOther chemical processesCombustible gas purificationPhysical chemistryManganese oxide

The invention provides a biomass nanomaterial porous microsphere and a preparation method thereof. The biomass nanomaterial porous microsphere mainly comprises a biomass nanomaterial, nano manganese dioxide, nano titanium dioxide and sodium alginate, has a rich pore structure, and has the pore diameter of 10-600 microns. The microsphere has super-strong capability of adsorbing and degrading cationic dyes, can be regenerated through short-time ultraviolet irradiation, and has the characteristic of reusability.

Owner:QINGDAO UNIV OF SCI & TECH

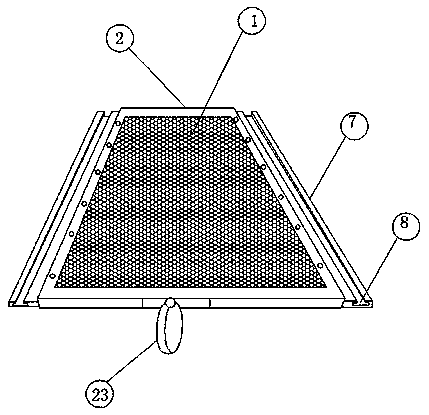

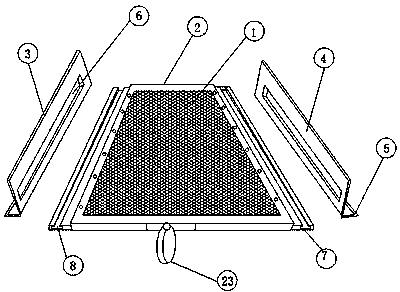

Frame screen plate with screens convenient to replace

Owner:安徽屹翔滤材有限公司

A kind of high reliability manpower hydraulic pump

ActiveCN109488552BImproved pressure retentionChange aperturePositive displacement pump componentsPiston pumpsHydraulic pumpCylinder block

The invention belongs to the technical field of hydraulic pumps, and discloses a high-reliability manual hydraulic pump, which includes a cylinder body, a valve body, and an oil inlet hole, an oil suction valve chamber, an oil outlet valve chamber and an oil outlet hole connected in sequence. The oil inlet hole, the oil suction valve chamber, the oil outlet valve chamber and the oil outlet hole are all arranged in the valve body, and an oil suction sealing ball is arranged on the oil inlet of the oil suction valve chamber, and by being arranged in the The first elastic member in the oil suction valve chamber seals the oil suction sealing ball on the oil inlet of the oil suction valve chamber; compared with the prior art, the oil delivery speed of the manual hydraulic pump of the present invention is doubled , The pressure holding performance has also been significantly improved, and it can be designed to be portable.

Owner:湖北超星液压自动化有限公司

A porous sound-absorbing material and its processing method

ActiveCN104097357BChange the number of layersChange apertureSynthetic resin layered productsResonanceMaterials science

Owner:NINGBO HUIBANG NOLY TECH CO LTD +1

A method for regulating the pore structure of a nanofiber membrane

ActiveCN113481659BRealize regulationChange apertureFilament/thread formingConjugated cellulose/protein artificial filamentsPolymer scienceSpinning

Owner:NANTONG UNIVERSITY

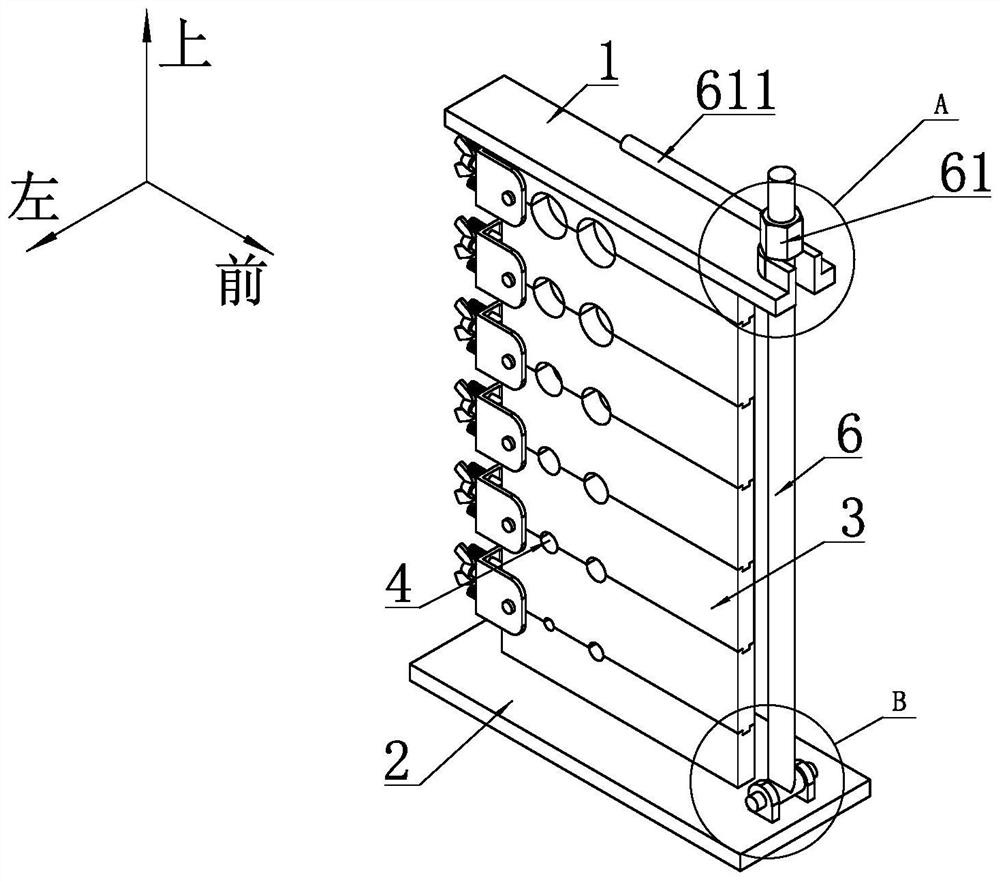

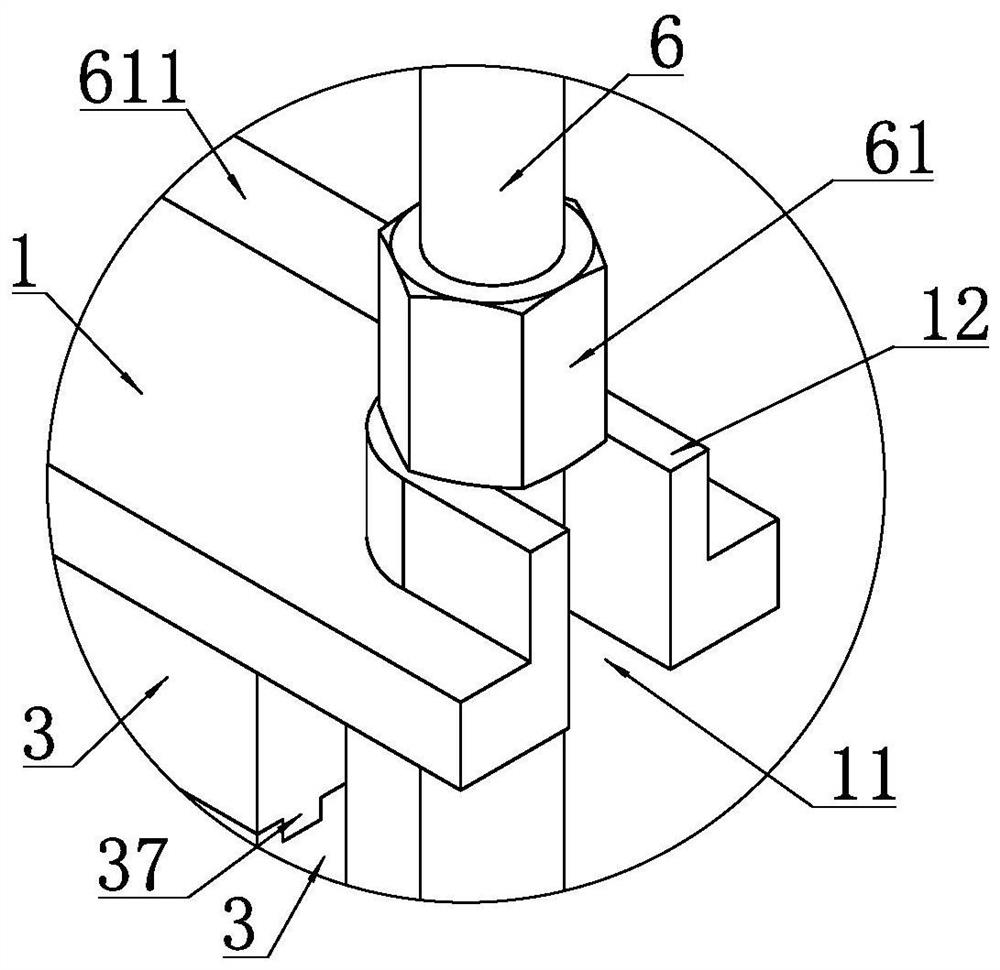

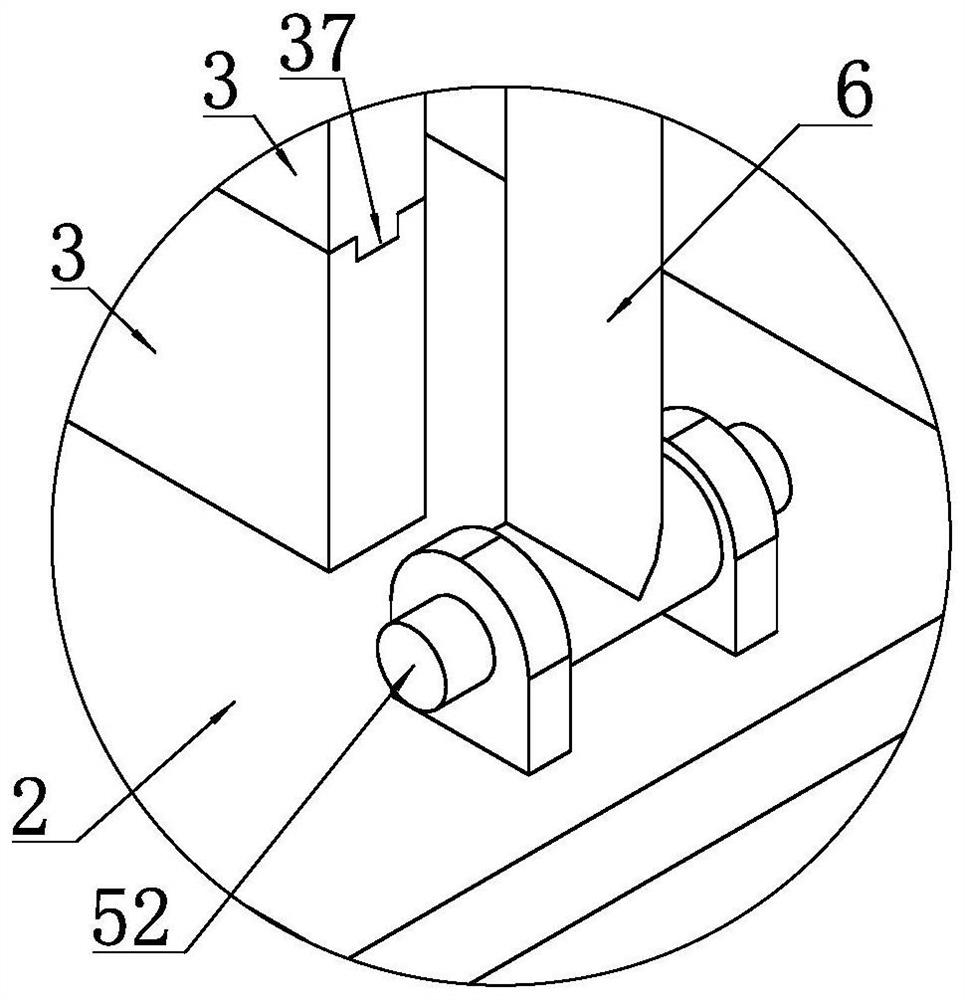

A tool for crimping wire noses

ActiveCN112164954BEven by forceFirmly connectedLine/current collector detailsClassical mechanicsStructural engineering

The invention discloses a tool for crimping wire lugs and relates to the technical field of electric construction equipment. The tool comprises an upper clamping plate and a lower clamping plate, and a plurality of pressing plates are stacked vertically between the upper clamping plate and the lower clamping plate. The two adjacent pressing plates are hinged by the first hinge shaft, and the pressing plates are provided with grooves. When the two adjacent pressing plates are in the closed state, the grooves on the adjacent two pressing plates jointly form a complete crimp holes. Between the upper clamping plate and the lower clamping plate, a tension rod is arranged on the front side of the pressure plate, the lower end of the tension rod is hinged to the lower clamping plate, and the upper clamping The front end of the plate is provided with a U-shaped notch for accommodating the tension rod, and the tension rod is provided with a locking nut. This tool not only saves labor, but also can ensure the uniformity of pressing, so that the wire and the wire lug are fastened together, and it is not easy to slip off.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

A kind of sintered synthetic slag and its preparation method

ActiveCN111850241BPermanent negative chargeChange apertureProcess efficiency improvementSlagMolten steel

The invention discloses a sintered synthetic slag, which comprises the following raw materials in weight percentage: 10-15% of high-adsorption filler, 25-35% of CaO, and 10-20% of SiO 2 , 8‑10% MgO, 6‑10% FeO, 1‑2.5% CaF 2 , 0.01-0.03% of P, 5-8% of water, 3-5% of aluminum iron balls, and the balance is impurities; the invention also discloses a preparation method of sintered synthetic slag; CaO and SiO 2 Grind into powder, then add water, MgO, FeO, CaF in sequence 2 , P, high-adsorption filler, mixed uniformly and made into a spherical shape, the particle size is controlled to be 50-60mm, and then mixed with aluminum-iron balls and then transferred to a high-temperature furnace for firing. The temperature of the high-temperature furnace is controlled at 1200-1300°C, The sintering synthetic slag was prepared in 3 hours; the high-adsorption filler can remove the hydrogen and floating oxidized slag inside the molten steel to make the molten steel more pure, and its own strong adsorption performance can absorb the slag. And quickly escape from the melt to improve the purity of molten steel.

Owner:芜湖县天海耐火炉料有限公司

A conductive agent suitable for lithium iron phosphate material and preparation method thereof

ActiveCN103456965BHigh degree of graphitizationChange apertureCell electrodesInternal resistanceMass ratio

The invention relates to a preparation method a lithium ion battery, particularly relates to a conductive agent applicable to a lithium iron phosphate material and a preparation method of the conductive agent, and mainly solves the technical problems in the prior art that the utilization rate of an active material is low, the residual capacity of an electrode is great and the like caused by great inner resistance and not enough discharging depth of the lithium iron phosphate electrode. The method provided by the invention comprises the following steps: under a constant-temperature condition, slowly adding conductive carbon black into a dispersant and a salt solution; heating and agitating to form a rheological phase; putting the rheological phase into a high-temperature furnace and heating; in a heating process, introducing inert gas all the time and cooling the rheological phase to the room temperature along with a furnace; washing with a strong acid and filtering; drying in a vacuum box under a high-temperature condition to prepare the treated conductive carbon black; and mixing a carbon nano tube, the conductive carbon black and conductive graphite according to a mass ratio of (0.1-1) to (0.1-5) to (0.1-1) to prepare the conductive agent.

Owner:杭州金马新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com