A tool for crimping wire noses

A tool and nose technology, which is applied in the field of tools for crimping wire noses, can solve the problems of easy slippage, weak crimping of wires, laborious and other problems, and achieve the effect of small size, good versatility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

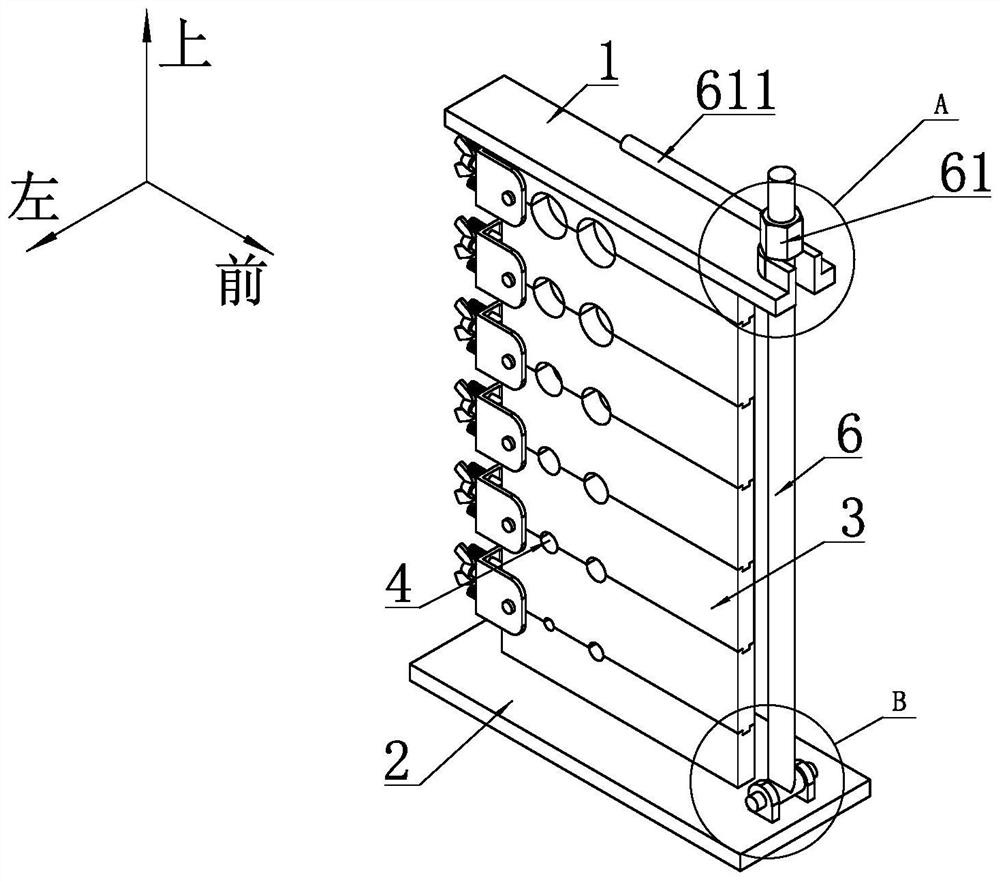

[0049] For the convenience of description, the coordinate system is defined as figure 1 , and the left-right direction is horizontal, the front-back direction is vertical, and the up-down direction is vertical.

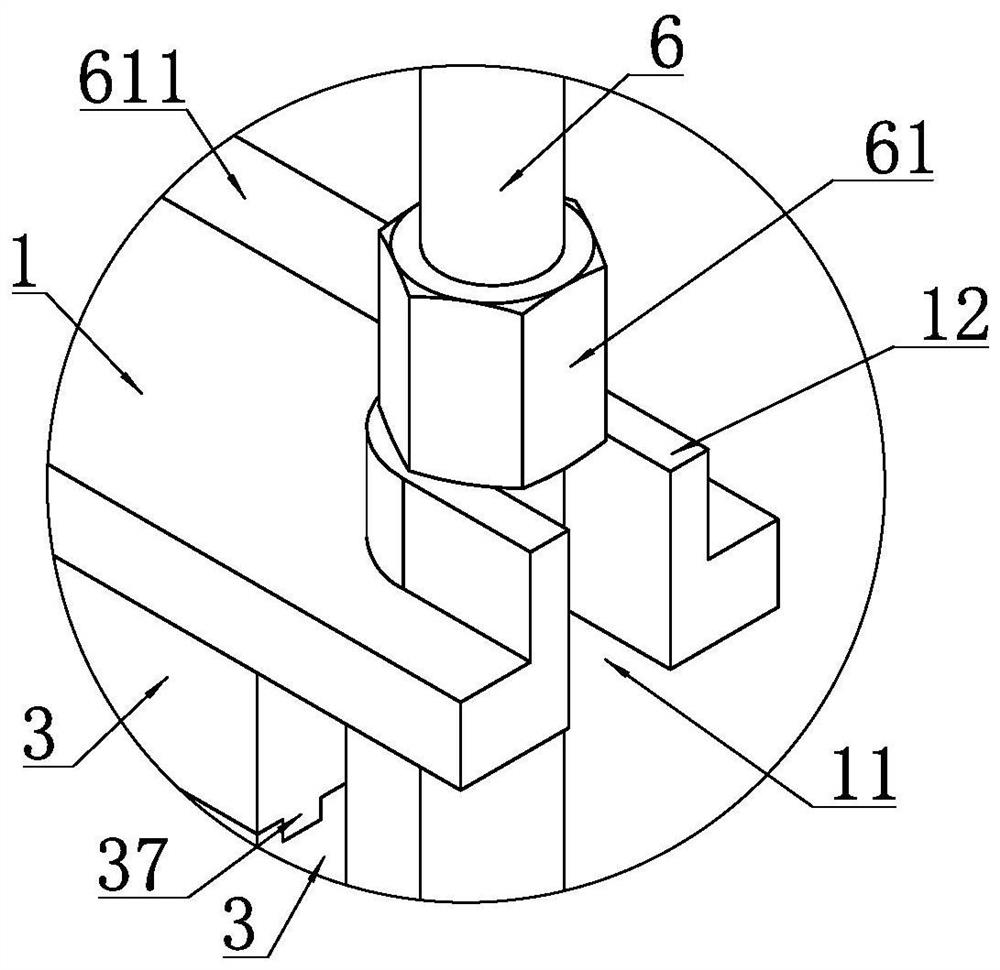

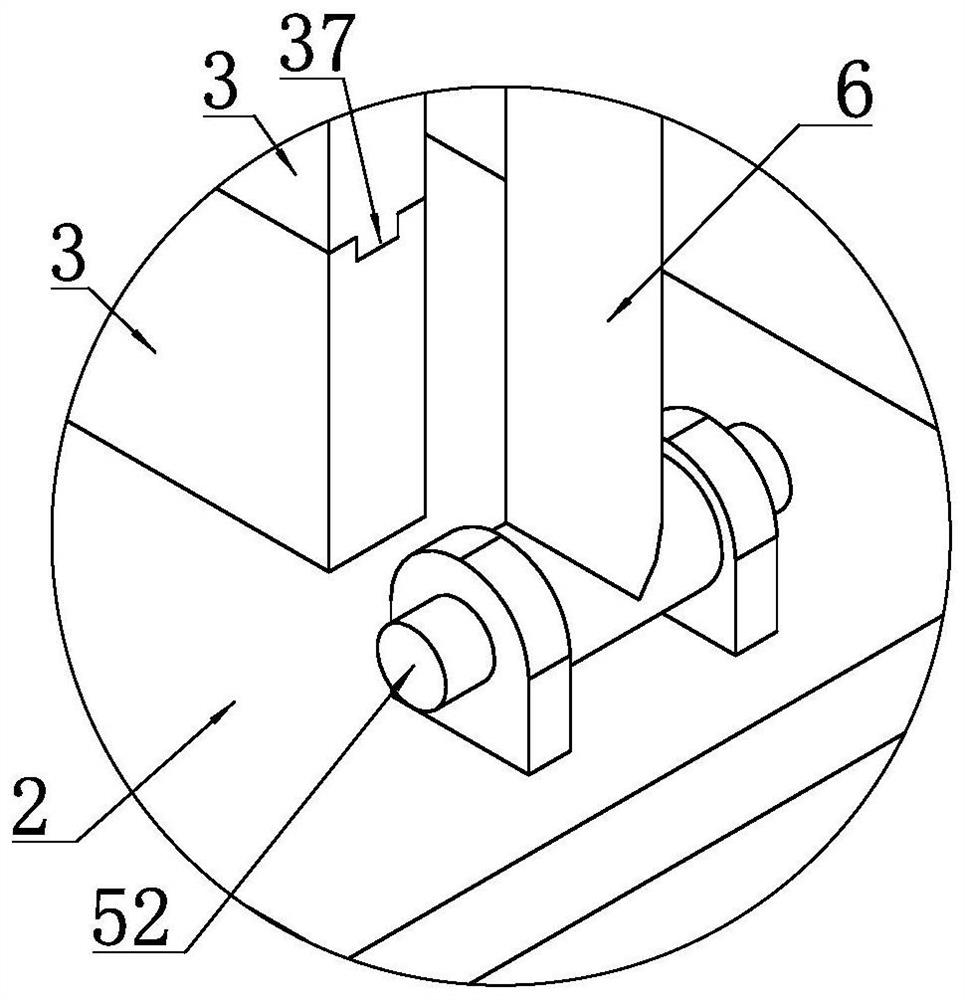

[0050] Such as figure 1 , Figure 4 with Image 6 As shown, a tool for crimping wire lugs includes an upper clamping plate 1 and a lower clamping plate 2 arranged in parallel. As a specific embodiment, the upper clamping plate 1 and the lower clamping plate described in this embodiment 2 are rectangular, and the projections of the geometric centers of the upper clamping plate 1 and the lower clamping plate 2 in the horizontal plane are coincident, and the sides along the length direction of the upper clamping plate 1 and the lower clamping plate The sides along the length direction of 2 are parallel.

[0051] Between the upper clamping plate 1 and the lower clamping plate 2, a plurality of rectangular pressing plates 3 are arranged in the vertical direction, and t...

Embodiment 2

[0067] Such as Figure 17 As shown, the limiting mechanism includes a U-shaped bar 8 arranged between two adjacent pressing plates 3, and the front side of the pressing plate 3 is provided with an insertion hole matched with the U-shaped bar 8 . Preferably, two adjacent wing bars of two adjacent U-shaped bars 8 correspond to different sockets respectively, that is, two sockets are arranged on the front side of the pressing plate 3 located in the middle part, and the socket on the upper side is connected to the socket on the upper side. The lower side wing bar of the U-shaped bar 8 on the side is matched, and the socket positioned at the lower side is matched with the upper side wing bar of the U-shaped bar 8 positioned at the lower side.

[0068] All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com