Personalized hard tissue defect restoration body and manufacturing method thereof

A manufacturing method and hard tissue technology, applied in prostheses, medical science, bone implants, etc., can solve the problems of difficult to control pore structure, high cost, environmental pollution, etc., and achieve simple process steps, short cycle, and type of raw materials. Choose from a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Collect CT image data of the patient's hard tissue defect, use Mimics7.0 software for three-dimensional reconstruction, and generate a computer-aided design (CAD) model in a standard data format;

[0030] 2) Utilize Surfacer 10.7 software to construct a solid model of the hard tissue defect on the computer-aided design model obtained in step 1);

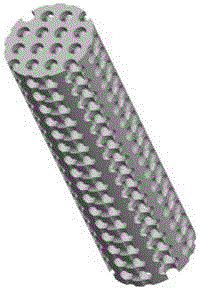

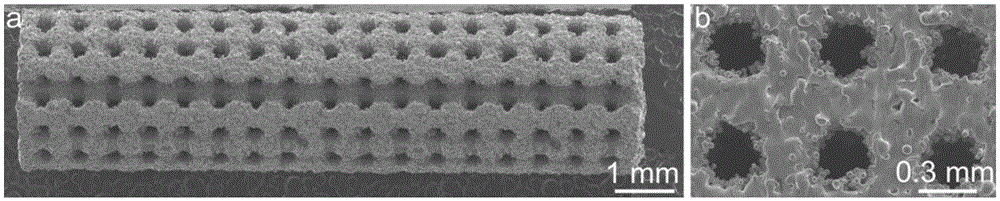

[0031] 3) Using CAD software, combined with the mechanical properties of the patient's hard tissue defect, construct a porous structure on the surface and inside of the solid model of the hard tissue defect obtained in step 2), and obtain a three-dimensional model of the restoration of the hard tissue defect (such as figure 1 As shown, it is in the shape of a porous cylinder as a whole, with a diameter of 3 mm, a length of 11 mm, a porosity of 50%, a circular hole, a diameter of 300 μm, and a wall thickness of 350 μm);

[0032] 4) According to the three-dimensional model of the prosthetic body of the hard tissue defect obta...

Embodiment 2

[0035] 1) Collect CT image data of the patient's hard tissue defect, use Mimics7.0 software for three-dimensional reconstruction, and generate a computer-aided design (CAD) model in a standard data format;

[0036] 2) Utilize Surfacer 10.7 software to construct a solid model of the hard tissue defect on the computer-aided design model obtained in step 1);

[0037] 3) Using CAD software, combined with the mechanical properties of the patient's hard tissue defect, construct a porous structure on the surface and inside of the solid model of the hard tissue defect obtained in step 2), and obtain a three-dimensional model of the restoration of the hard tissue defect (its overall It is porous cylindrical, with a diameter of 2 mm, a length of 10 mm, a porosity of 55%, a circular hole, a diameter of 400 μm, and a wall thickness of 200 μm);

[0038] 4) According to the three-dimensional model of the prosthetic body of the hard tissue defect obtained in step 3), the spherical titanium p...

Embodiment 3

[0041] 1) Collect CT image data of the patient's hard tissue defect, use Mimics7.0 software for three-dimensional reconstruction, and generate a computer-aided design (CAD) model in a standard data format;

[0042] 2) Utilize Surfacer 10.7 software to construct a solid model of the hard tissue defect on the computer-aided design model obtained in step 1);

[0043] 3) Using CAD software, combined with the mechanical properties of the patient's hard tissue defect, construct a porous structure on the surface and inside of the solid model of the hard tissue defect obtained in step 2), and obtain a three-dimensional model of the restoration of the hard tissue defect (its overall It is a porous cube with a length of 10 mm, a porosity of 50%, a circular hole, a diameter of 500 μm, and a wall thickness of 200 μm);

[0044] 4) According to the three-dimensional model of the prosthetic body of the hard tissue defect obtained in step 3), the spherical titanium powder with a particle size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com