Adjustable electrode chuck

An electrode chuck, adjustable technology, applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of low processing efficiency, inconvenient adjustment of electrode chuck, narrow adjustment angle and adaptable range, etc., to achieve The effect of changing the axial angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

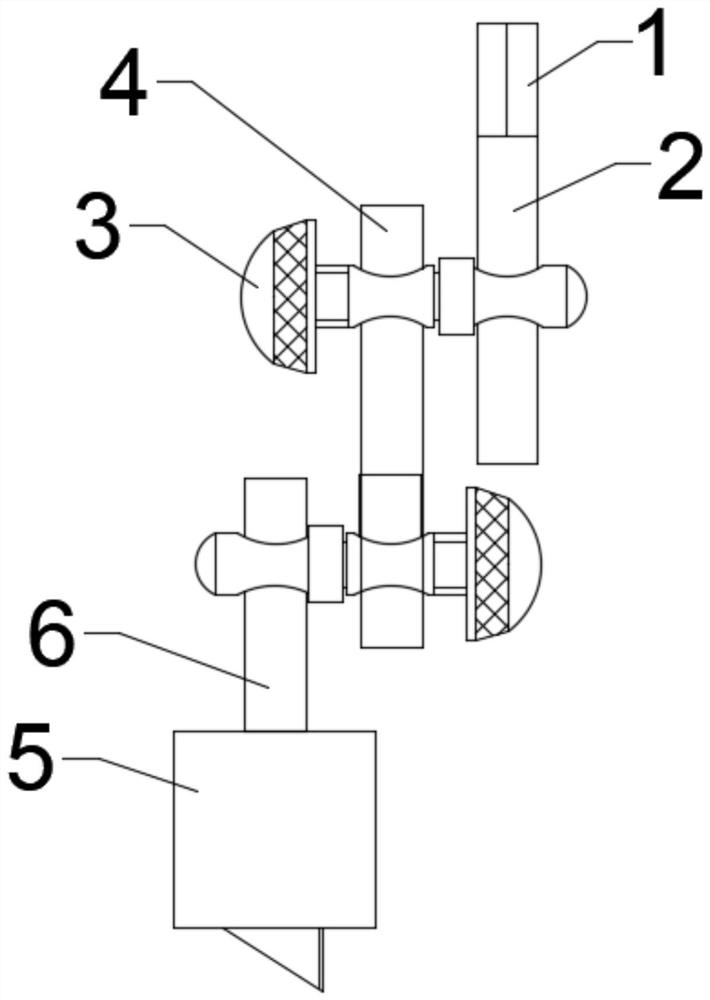

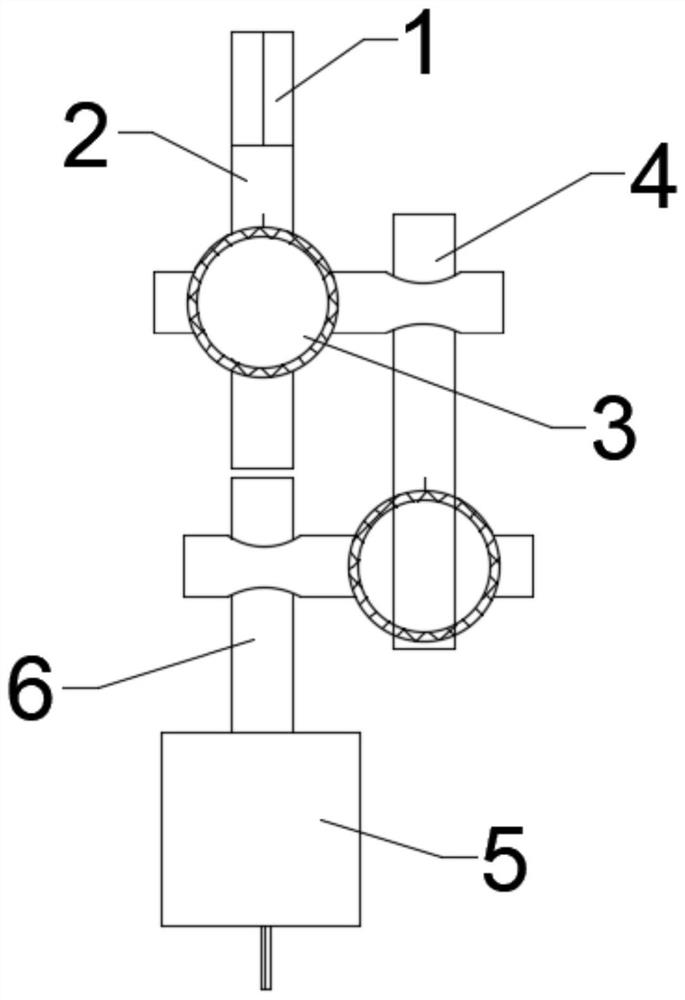

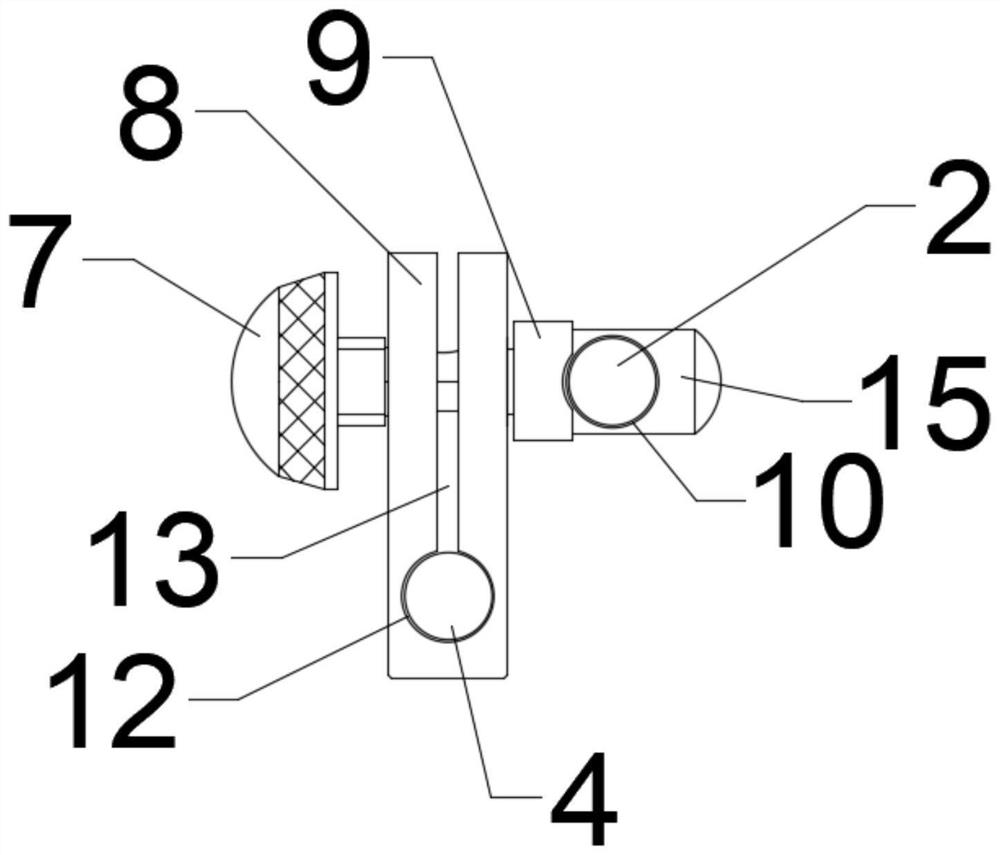

[0038] like Figure 1-Figure 4 As shown, this embodiment provides an adjustable electrode clamp, including: a connecting tube 4 , a mounting rod 2 and two adjusting clips 3 .

[0039] The two ends of the connecting round pipe 4 are respectively rotatably connected with two adjusting clips 3 , and the connecting round pipe 4 is clamped by the adjusting clips 3 . The installation rod 2 is used for connecting with the machine tool, one end of the installation rod 2 is detachably connected with an adjustment clip 3 , and the other adjustment clip 3 is used for detachable connection with the electrode 5 .

[0040] Wherein, after an adjusting clip 3 is connected with the installation rod 2, the installation rod 2 is connected with the external machine tool, and the connecting round pipe 4 is connected with the rotation of an adjusting clip 3, so that the installation rod 2 rotates on the axis of the connecting round pipe 4 , to achieve angle adjustment. Wherein, the connection bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com