Technology for processing special materials such as waste plastic and wood

A special material, plastic wood technology, applied in the field of raw materials, can solve problems such as natural pollution and loss of use value of land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

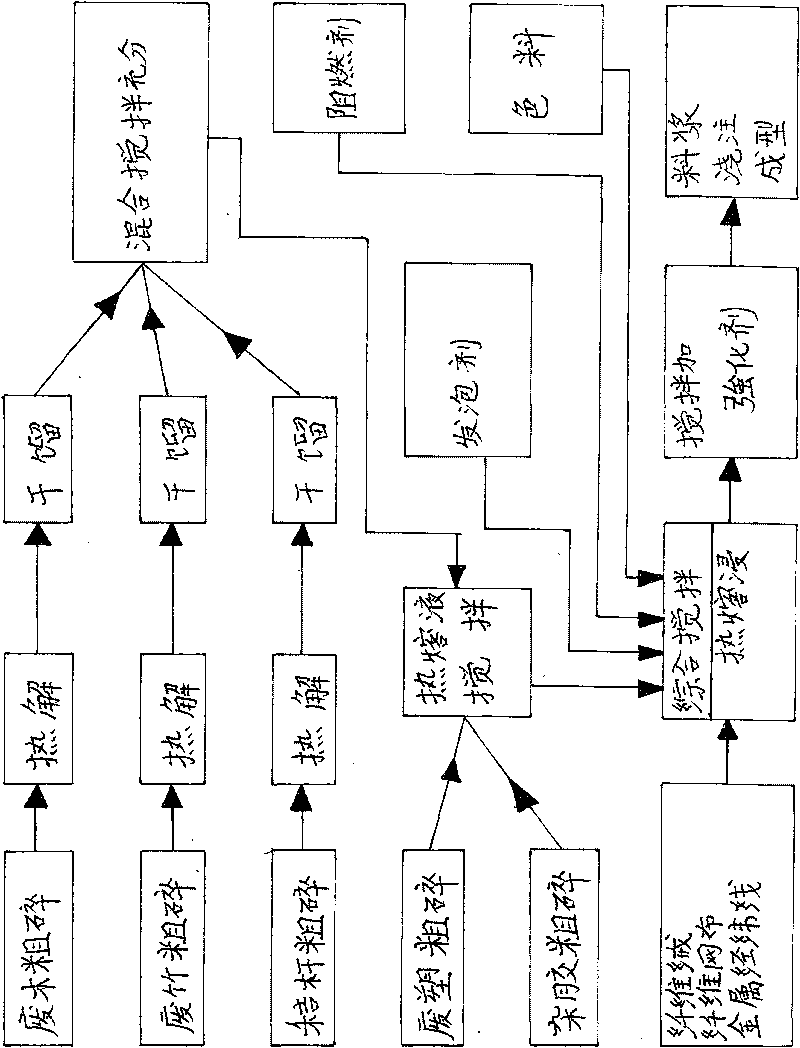

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

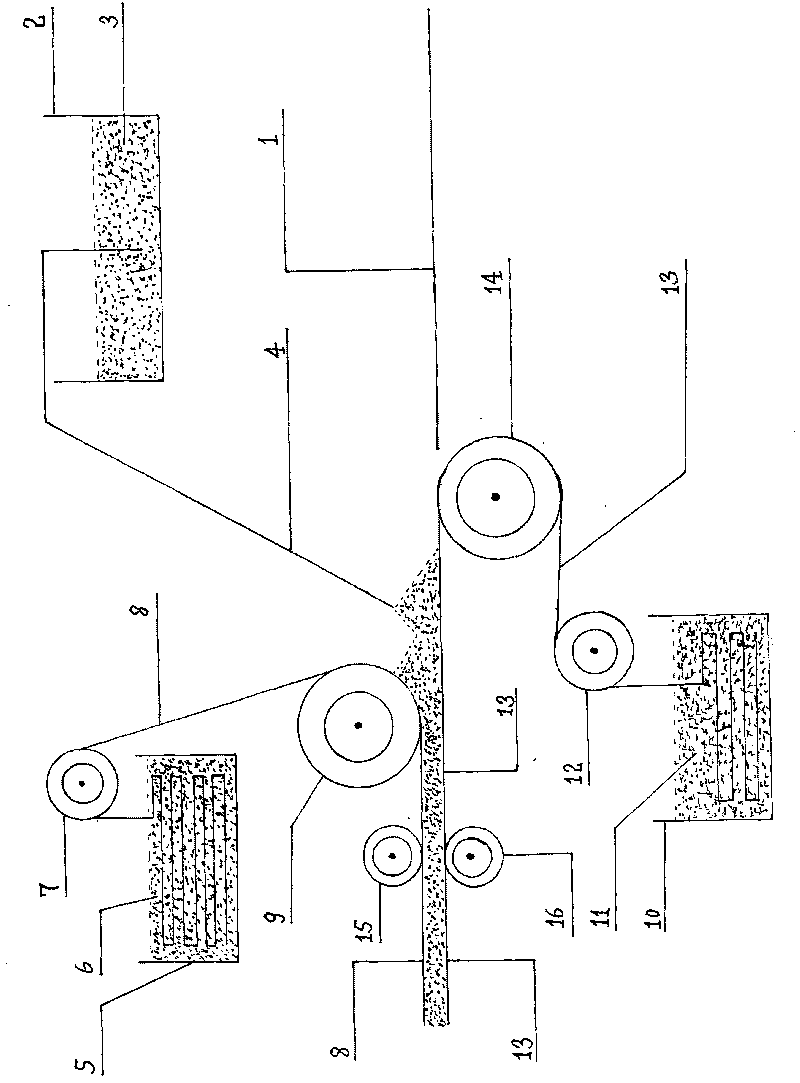

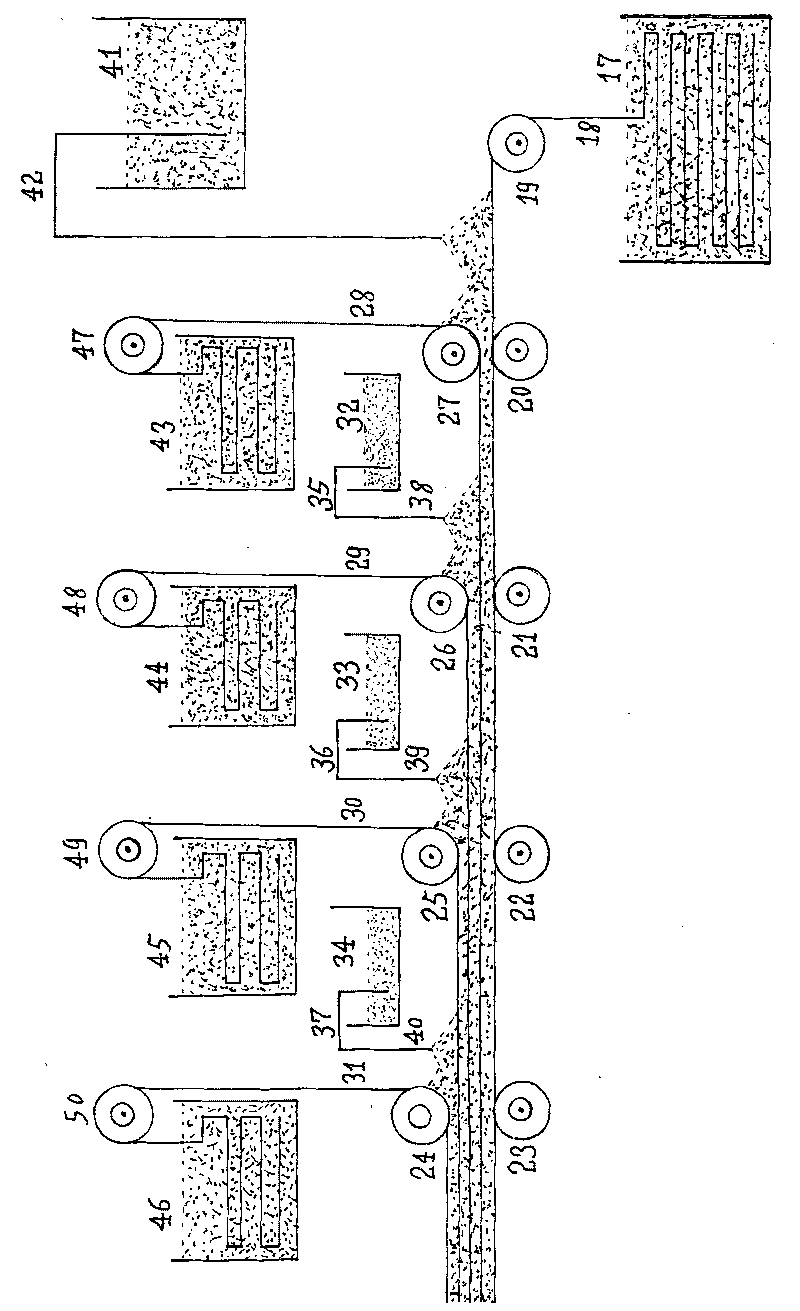

[0010] Figure 4 After rough processing and crushing of waste plastics and waste miscellaneous wood and bamboo stalks after rough processing and crushing and pyrolysis and dry distillation, the two will be respectively added to the hopper 56 or 55 and enter the hot-melt immersion through the funnel tube 57 or 54. The device 58 is fully heated so that the hot-melt plastic liquid is completely immersed in the wood and bamboo stalks, so that the wood and bamboo straws are also completely melted and immersed in the hot-melt plastic liquid, and completely mixed into one. Enter agitator 52 through funnel 59 again, motor 51 rotates at a high speed to make agitator 52 high-speed stirring, and agitation post 60 makes the mixed wood-plastic liquid that enters mix thoroughly and produce a large amount of air bubbles. The homogenized material is then pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com