Local fine-adjustment air rectification device for purification equipment and adjustment method of local fine-adjustment air rectification device

A purification equipment and micro-adjustment technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of not being able to adjust individually, not having too much, etc., to achieve better air outlet effect, uniform wind speed, and optimized uniformity. The effect of the wind straightening device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

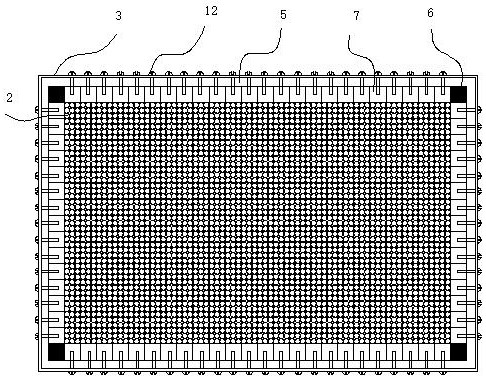

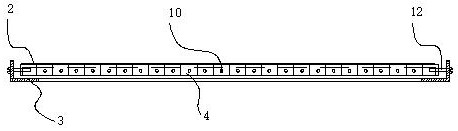

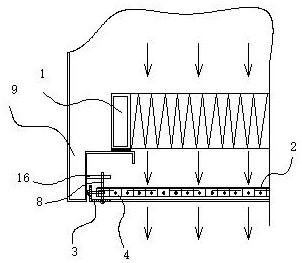

[0038] Embodiment one: see Figure 1-11 As shown, a local fine-tuning device for purification equipment includes a high-efficiency air filter 1 and a uniform flow device arranged on the air outlet of the high-efficiency air filter 1. The uniform flow device includes a porous membrane 2 and a fixed A uniform flow frame of a porous membrane, the uniform flow frame includes an outer frame 3 and an inner frame 4, and an activity space 5 is provided between the two frames, and the inner frame 4 includes several fixed blocks 6 and several moving blocks 7, so The fixed block 6 is fixed with the cabinet 9 of the purification equipment by the fixing screw 8, and is respectively located at the inside of the four corners of the outer frame 3, and is fixed with the cabinet from the outside to the inside; the moving block 7 is arranged in sequence along the edge of the outer frame 3, Each moving block 7 is provided with a screw hole 10 corresponding to the side of the outer frame 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com