Patents

Literature

113 results about "Sodium hexafluoroaluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium aluminium hexafluoride is the inorganic compound with the formula Na₃AlF₆. This white solid, discovered by José Bonifácio de Andrada e Silva, occurs naturally as the mineral cryolite and is used extensively in the industrial production of aluminium metal. The compound consists of the sodium (Na⁺) salt of hexafluoroaluminate (AlF₆³⁻).

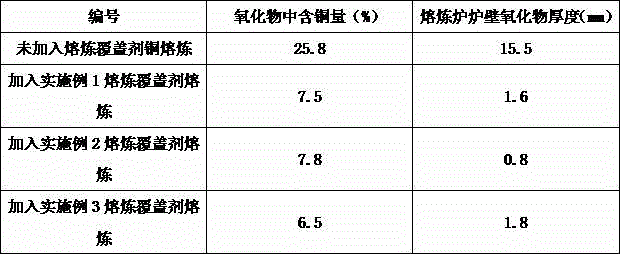

Covering agent for smelting copper alloy

The invention discloses a covering agent for smelting copper alloy, which is prepared by adopting the mixture of calcium chloride, potassium chloride, sodium chloride, sodium fluoaluminate and calcium fluoride; one layer of favourable protective layer with the thickness of 5-80 mm is formed on the surface of smelting furnace solution so as to effectively prevent oxygen in air outside a molten pool from entering and avoid oxidation burning loss of alloy elements in the smelting process, and the covering agent has the action of thermal insulation. The covering agent of the invention can ensure that copper alloy requiring vacuum smelting can be smelted under the atmospheric environment. The covering agent of the invention is suitable for smelting copper alloy, such as copper zirconium, copper chromium, copper magnesium, copper chromium zirconium and the like which contain oxidizable elements, and is suitable for ingot blank casting, vertical continuous casting, horizontal continuous casting, up-drawing continuous casting and the like.

Owner:SHENYANG NONFERROUS METALS PROCESSING CO LTD

Method for preparing foamed glass by using waste fiberglass products

InactiveCN101955319AEfficient use ofImprove structural strengthAntimony trioxideSodium hexafluoroaluminate

The invention relates to a method for preparing foamed glass by using waste fiberglass products, which comprises the following steps of: firstly, airing collected waste fiberglass mats and fiberglass meshes, manually sorting out the impurities of metal, organic matter and the like, cutting into fragments smaller than 20 mm*20 mm, and ball-milling to 200 meshes to form glass powder; loading the glass powder, silicon carbide, diantimony trioxide, sodium sulfate, sodium fluoaluminate, sodium nitrate and cobalt oxide into a ball mill, and ball-milling to form a batch; loading the batch into a heat-resisting mold, and firing into foam glass. In the invention, the waste fiberglass products are used as a main raw material to produce foam glass, and the prepared foam glass has low density, high strength, small heat conductivity and low water absorption rate. The preparation method has simple operation process, low founding temperature and low cost, not only changes wastes into valuables, but also protects the environment, and is applicable to industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

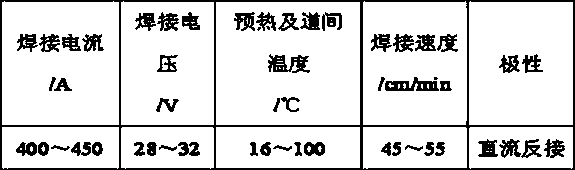

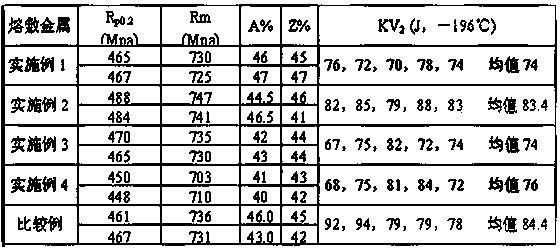

Sintered flux for use in submerged-arc welding of nickel-based alloy and preparation method

InactiveCN103447715ALow impurity contentWelding specifications are stableArc welding apparatusWelding/cutting media/materialsSlagAlloy

The invention discloses a sintered flux for use in submerged-arc welding. The sintered flux comprises a dry powder combination and a bonding agent, wherein the dry powder combination consists of the following components in percentage by weight: 40-52 percent of CaF2, 38-47 percent of Al2O3, 4-8 percent of CaCO3, 0.5-3 percent of metal aluminum powder and 0.5-3 percent of sodium fluoroaluminate, wherein the bonding agent consists of 1:1 potassium sodium water glass; the using amount of the bonding agent is 20-32 percent of the weight of the dry powder in the welded flux. The sintered flux for use in submerged-arc welding is matched with an ERNiCrMo-3 welding wire, has the advantages of standard and stable welding, excellent slag detachability, uniform width of a welding bead, appropriate pile height, smooth transition with parent metal and no defects of gas indentations, crystallization lines, cracks, bonded slag and the like on the surface of a welding line.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-performance wet green sand for steel casting and preparing method thereof

InactiveCN104525841AImprove performanceImprove wet compressive strengthFoundry mouldsFoundry coresBrickTemperature resistance

The invention discloses high-performance wet green sand for a steel casting and a preparing method of the high-performance wet green sand. High-performance wet green sand is composed, by weight, of 40-60 parts of zircon sand, 15-20 parts of sea mud, 10-15 parts of ardealite, 25-35 parts of diopside, 20-30 parts of polyphenyl granule, 5-10 parts of sodium fluoroaluminate, 15-20 parts of coconut shell powder, 10-15 parts of crushed brick powder, 4-8 parts of hydroxypropl xanthan gum, 3-6 parts of sulfonated asphalt powder, 5-10 parts of bitter ling soil, 2-4 parts of calcium sulfite, 3-5 parts of poly aluminum chloride, 4-6 parts of polyoxyethylene, 2.5-4.5 parts of sodium hexametaphosphate, 5-10 parts of modified kaolin and a proper amount of water. The wet green sand is good in comprehensive performance, has the high green compression strength, the high compaction rate and the low thermal expansivity, also has the good high-temperature resistance, ventilating performance and fluidity and can effectively overcome the defects that air holes, scabbing, sand clamping, sand holes and the like can happen on the steel casting, the surface quality of the steel casting is improved, the finished product rate of the steel casting is increased, and the high-performance wet green sand has important economic benefits.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Wear-resistant copper alloy material and casting method thereof

The invention relates to a wear-resistant copper alloy material and a casting method thereof, wherein total seven raw materials, including an aluminum-copper alloy, a nickel plate, pure iron, electrolytic copper, metal manganese, hexachloroethane and cullet, are employed; the CuAl10Ni wear-resistant copper alloy material is obtained through the steps of stove charging, melting, sodium fluoroaluminate doping and sand mold test sample casting, casting molding and the like; and the mechanical properties of the obtained wear-resistant copper alloy material reach the following standards: yield strength B0.2: more than or equal to 270N / mm<2>; tensile strength Bb: more than or equal to 600N / mm<2>; elongation sigma5: more than or equal to 12%; and Brinell hardness HBW: more than or equal to 140; the wear-resistant copper alloy material is specially used for manufacture of the positioning guide sleeve of the air spring of a rail transit vehicle, and has excellent comprehensive mechanical properties, and extremely high abrasive resistance and corrosion resistance; and the service life of the wear-resistant copper alloy material is twice as long as that the service life of the traditional ZCuAl9Mn2(S) material.

Owner:株洲联诚集团铸业有限责任公司

Preparation technology of aluminum intermediate alloy

InactiveCN106987735ASolve the costSolve the problem of energy consumptionPotassiumSodium hexafluoroaluminate

The invention relates to the field of synthesis of aluminum intermediate alloys, in particular to a preparation technology of an aluminum intermediate alloy. According to the preparation technology of the aluminum intermediate alloy, aluminum ingots are fed into an electric induction furnace and molten, and the temperature of the molten aluminum is raised to 660-850 DEG C; then, magnesium fluoride, sodium hexafluoroaluminate, potassium hexafluoroaluminate and potassium chloride are mixed into a mixture, the mixture is fed into the electric induction furnace, and the temperature is raised to 750-1000 DEG C; one or two of scandium oxide and scandium chloride are added into the electric induction furnace to a reaction, and after the reaction is qualified, a slagging former is added to remove remaining fused salt on the surface of the alloy; the temperature of the alloy is kept at 760-900 DEG C, a rotating exhauster is used for feeding argon to conduct refining degassing; and then, the slagging former is added for secondary slagging treatment. By the adoption of the preparation technology of the aluminum intermediate alloy, the electric induction furnace is utilized, the chloride and the fluoride are mixed and then added to high-temperature molten aluminum with the surface covered with fused salt, the aluminum-scandium alloy is directly generated, and the problems that when the aluminum-scandium alloy is prepared through a mix-melting method, cost is high, the energy consumption is high, time is long, efficiency is low, and the quality is not stable are solved.

Owner:山东滨州华创金属有限公司

High-efficiency aluminum alloy refining agent, as well as preparation method and usage method thereof

The invention provides a high-efficiency aluminum alloy refining agent, as well as a preparation method and a usage method thereof. The high-efficiency aluminum alloy refining agent comprises refining agent components including sodium chloride, potassium chloride, potassium fluosilicate, sodium fluoaluminate, light-weight sodium carbonate, calcium fluoride, hexachloroethane, sodium sulfate, potassium fluoaluminate and quartz sand. The preparation method of the high-efficiency aluminum alloy refining agent comprises the following steps: respectively weighing all the components according to the weight percentage of the refining agent components, and fully mixing to obtain the high-efficiency aluminum alloy refining agent. The usage method of the high-efficiency aluminum alloy refining agent comprises the following steps: placing the high-efficiency aluminum alloy refining agent into a refining tank, introducing nitrogen gas or argon gas into the refining tank when the temperature of aluminum alloy liquid achieves 700-740DEG C, and delivering the high-efficiency aluminum alloy refining agent into the aluminum alloy liquid. The high-efficiency aluminum alloy refining agent is strong in degassing and inclusion removal capabilities, high in reaction speed, high in deslagging efficiency and low in usage temperature. The preparation method and usage method of the high-efficiency aluminum alloy refining agent are simple and effective.

Owner:SICHUAN LANDE IND

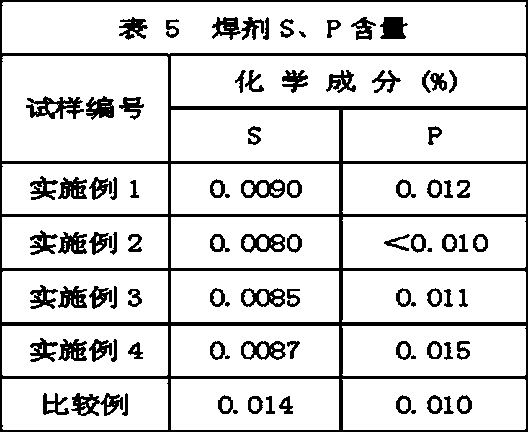

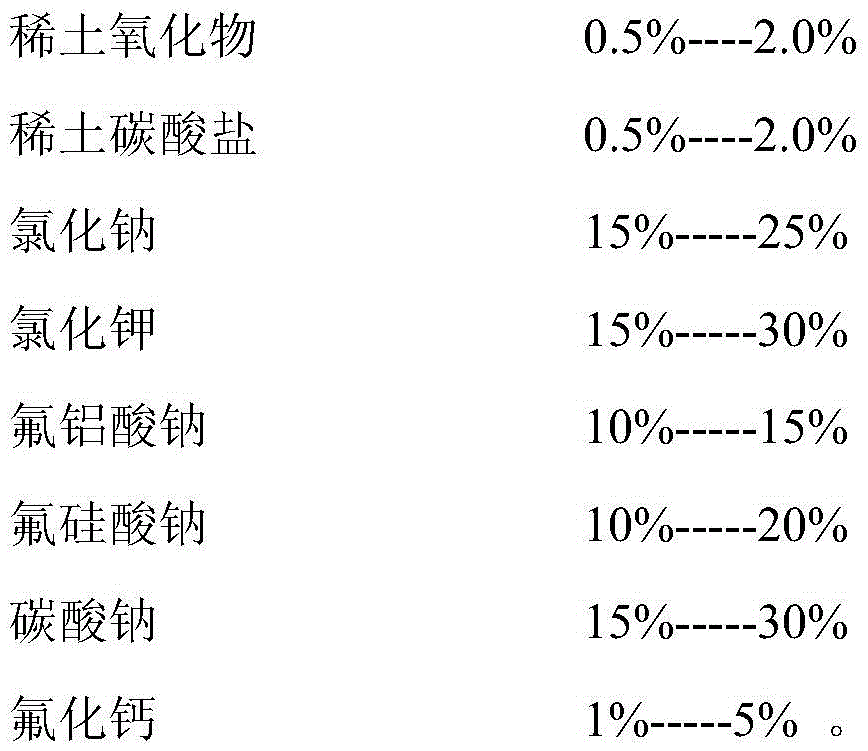

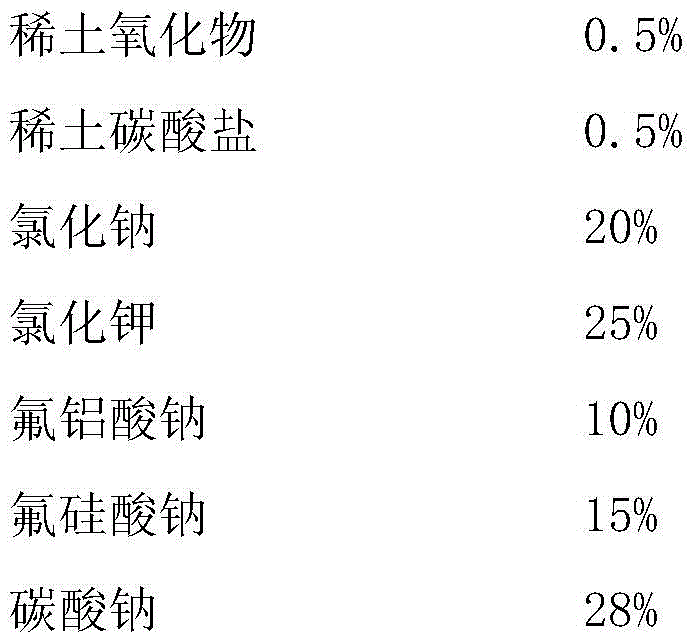

Rare earth contained deslagging and refining flux for smelting of cast aluminium alloy and preparation method of flux

The invention discloses rare earth contained deslagging and refining flux for smelting of a cast aluminium alloy and a preparation method of the flux. The flux is formed by adding finely powdered rare earth oxide and rare earth carbonates to powder mainly containing sodium chloride, potassium chloride, sodium fluoroaluminate, sodium fluosilicate, sodium carbonate and calcium fluoride, and then carrying out mixing, dehydration and curing. Based on the characteristics of metamorphism and inactivation of rare earth on the aluminium alloy, the characteristic of promoting a series of low-melting-point impurities to form infusible compounds, and other characteristics of rare earth, if the flux is used during the smelting, a molten aluminium alloy can be effectively purified, the liquidity and casting property can be improved, the refinement of crystal grains in an aluminium alloy casting structure and dispersed precipitation of a second phase in the crystal grains can be facilitated, thus the strength, hardness, abrasive resistance and corrosion resistance of the aluminium alloy can be improved. With the adoption of the flux, the disadvantage that the conventional aluminium alloy deslagging and refining flux produces a large amount of harmful gas and smoke in a molten aluminium alloy purification treatment process is overcome.

Owner:吴炳尧

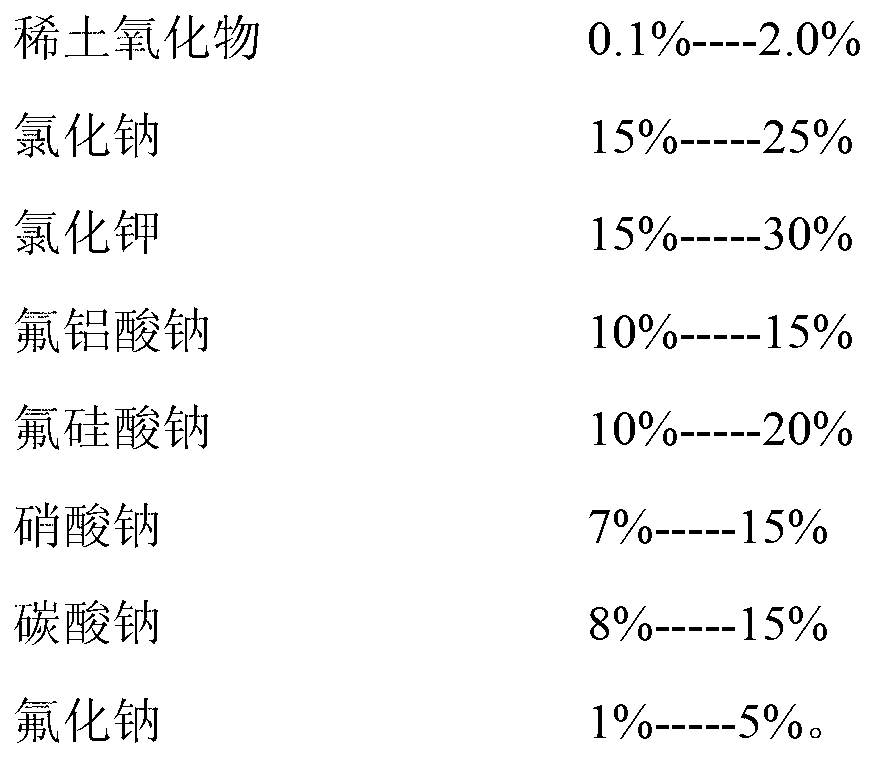

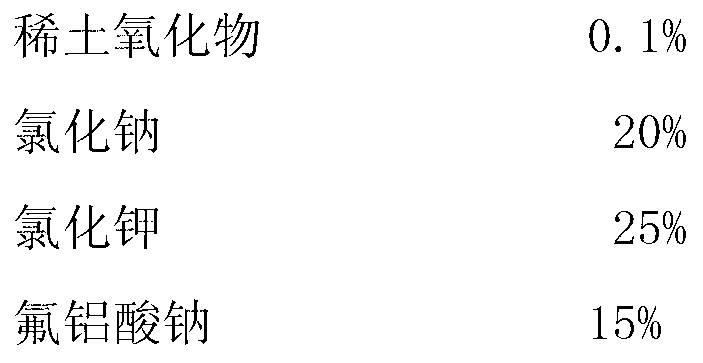

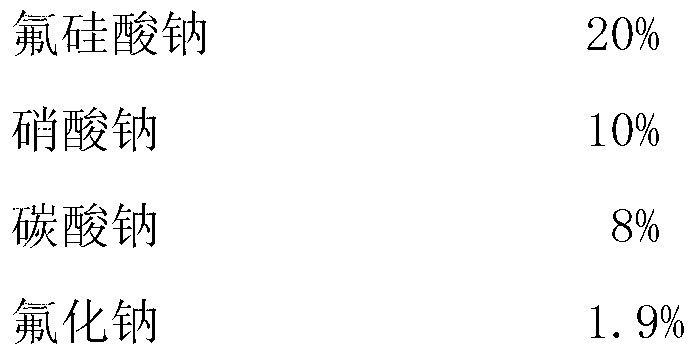

Deslagging smelting flux for smelting casting zinc alloy and preparation method thereof

The invention relates to a deslagging smelting flux for smelting a casting zinc alloy and a preparation method thereof. The flux is prepared by adding ultramicrofine rare earth oxide into powder mainly comprising sodium chloride, potassium chloride, sodium fluoroaluminate, sodium fluosilicate, sodium nitrate, sodium carbonate and sodium fluoride, and stirring, dehydrating and curing the materials. By using the flux, the zinc alloy fluid can be effectively purified, the liquidity and casting property can be improved, grains in a zinc alloy casting structure can be refined, and the second phase can be dispersed and separated out in the crystal, so that the strength, hardness, abrasive resistance and corrosion resistance of the zinc alloy are improved, and the defect that the environment is seriously polluted by a great amount of harmful gas and smoke dust produced by the conventional deslagging smelting flux for smelting zinc alloy is effectively overcome.

Owner:SOUTHEAST UNIV

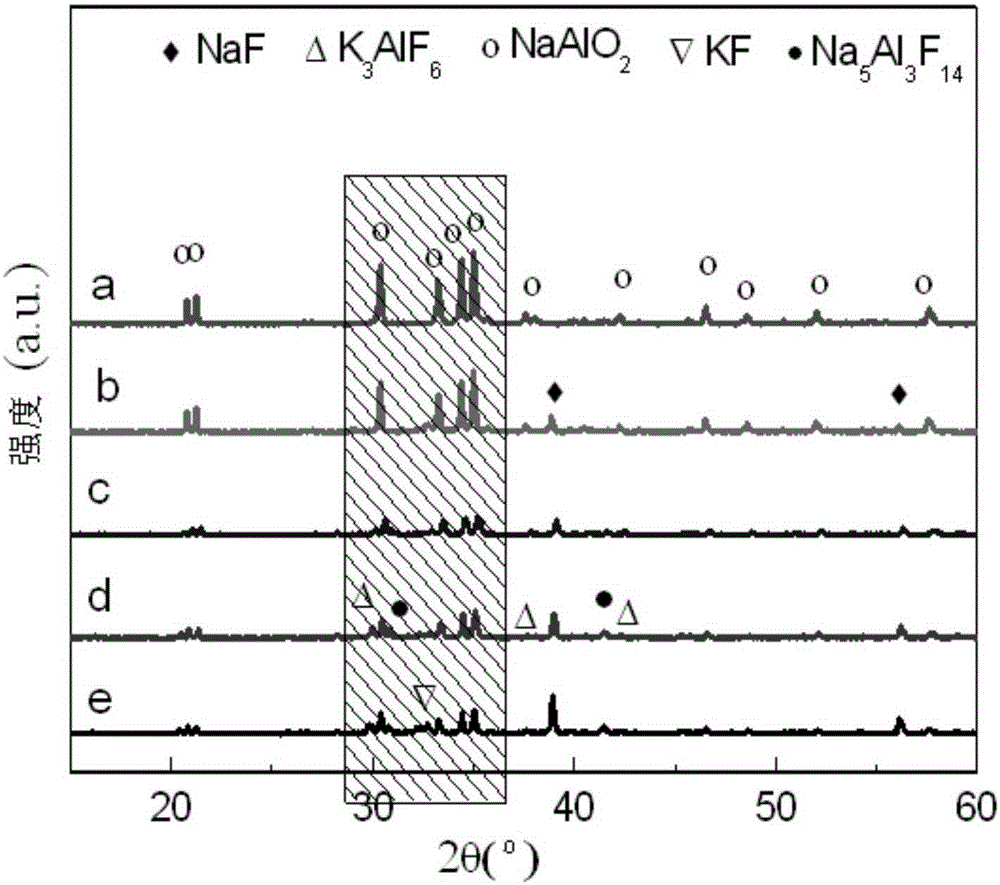

Supported solid base catalyst, preparation method and appliance thereof for compounding novel biological diesel oil

ActiveCN105195181AEvenly dispersedHigh activityPhysical/chemical process catalystsFatty acid esterificationPotassium fluoridePotassium

The invention discloses a supported solid base catalyst, a preparation method and an appliance thereof for compounding novel biological diesel oil, which relate to a solid base catalyst, a perpetration method and a method for catalyzing and preparing novel biological diesel oil, and aim to solve the problems that existing homogeneous base catalysts are not high in reaction activity, can not be recycled, are complex in post-processing process, need to neutralize and wash reaction products, and leads to discharge a lot of waste water and pollute environment. The supported solid base catalyst comprises sodium aluminate, potassium fluoride, sodium fluoride, potassium fluoroaluminate and sodium fluoroaluminate. The preparation method comprises steps: 1 x-KF / NaAlO2 precursors are prepared; and 2 drying and calcining, thereby obtaining the supported solid base catalyst. The method for catalyzing and preparing the novel biological diesel oil is that reaction materials and catalysts are added into a reactor with a reflux condensation device, are stirred and reacted in normal reaction pressure and protection of nitrogen, and then are centrifugally separated, decompressed and distilled. The supported solid base catalyst can be used to catalyze and compound the novel biological diesel oil.

Owner:中德晨晰环保工程有限公司

Electrostatic dry powder spraying ceramic powder composite material

The invention relates to an electrostatic dry powder spraying ceramic powder composite material, which comprises the combination of the following base materials in part by mass: 45 to 60 parts of network former, 2 to 17 parts of network forming and fusing agent, 8 to 13 parts of network modifier and fusing agent, 15 to 20 parts of flux and 5 to 7 parts of nucleating agent, wherein the network former is silicon dioxide; the network forming and fusing agent is diboron trioxide; the network modifier and the fusing agent are alumina, magnesia, calcium oxide, sodium fluoroaluminate and zinc oxide; the flux is sodium oxide, potassium oxide and lithium oxide; and the nucleating agent is titanium dioxide, zirconia and phosphorus pentoxide. A steel structure sprayed by the material in the open air and under atmospheric pollution environment for a long period can effectively prevent rust corrosion; and moreover, the service life of a highway guardrail plate, an upright post and the like can reach over 30 years.

Owner:安阳市三超钢结构工程有限公司

One-time-coating enamel and preparation method

The invention discloses one-time-coating enamel and a preparation method thereof. The one-time-coating enamel comprises the following components in part by weight: 42 to 45 parts of silica, 4 to 6 parts of aluminum oxide, 7 to 9 parts of sodium oxide, 2 to 3 parts of potassium oxide, 2 to 3 parts of lithium oxide, 17 to 19 parts of diboron trioxide, 5 to 6 parts of titanium dioxide, 1 to 2 parts of calcium oxide, 3 to 4 parts of zirconium dioxide, 1 to 2 parts of sodium hexafluoroaluminate, 2 to 3 parts of strontium oxide, 3 to 4 parts of phosphorus pentoxide, 4 to 5 parts of cobalt oxide, 4 to 5 parts of nickel oxide, 4 to 5 parts of ferric oxide, 1 to 3 parts of potassium nitrate, 1 to 3 parts of sodium nitrate, 1 to 3 parts of boric acid, 1 to 3 parts of lithium fluoride and 1 to 3 parts of strontium carbonate. The preparation method comprises the following steps of: weighing all the components respectively; uniformly mixing the cobalt oxide, the nickel oxide and the nitrate; fully stirring all materials till the uniformity is more than or equal to 98 percent; smelting the mixture in a smelting furnace at the temperature of between 1,200 and 1,300 DEG C, taking a thread sample out and discharging the sample, wherein each meter of the sample is divided into 2 to 3 segments; pressing an enamel tablet by a tablet press till the thickness is less than 2mm; and cooling and smashing the obtained product. When the one-time-coating enamel is coated and enameled on the surface of steel sheets and cast irons, the bottom enamel unifying effect can be achieved at one time, so that the technical problem of one-time enameling is solved.

Owner:梁梦林

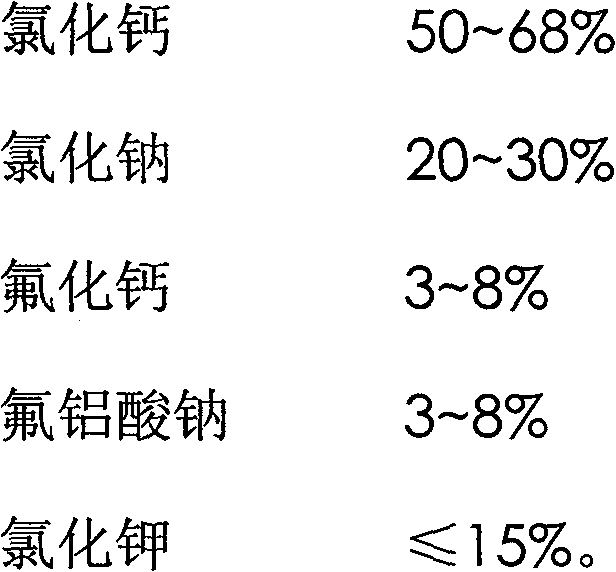

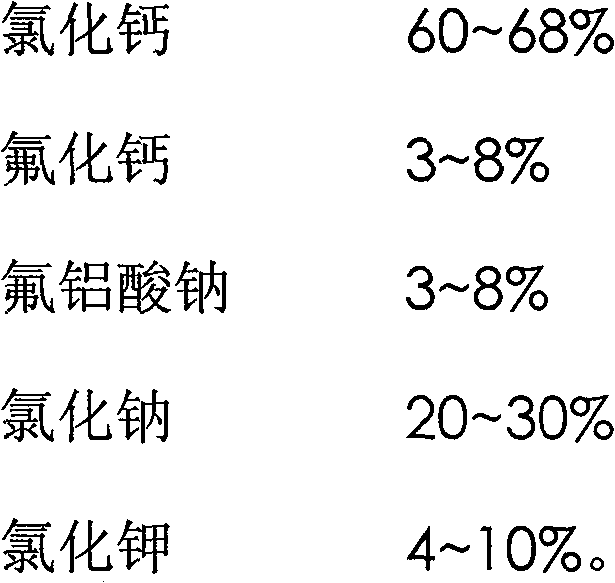

Covering agent for smelting copper alloy

The invention discloses a covering agent for smelting copper alloy, which is prepared by adopting the mixture of calcium chloride, potassium chloride, sodium chloride, sodium fluoaluminate and calcium fluoride; one layer of favourable protective layer with the thickness of 5-80 mm is formed on the surface of smelting furnace solution so as to effectively prevent oxygen in air outside a molten pool from entering and avoid oxidation burning loss of alloy elements in the smelting process, and the covering agent has the action of thermal insulation. The covering agent of the invention can ensure that copper alloy requiring vacuum smelting can be smelted under the atmospheric environment. The covering agent of the invention is suitable for smelting copper alloy, such as copper zirconium, copper chromium, copper magnesium, copper chromium zirconium and the like which contain oxidizable elements, and is suitable for ingot blank casting, vertical continuous casting, horizontal continuous casting, up-drawing continuous casting and the like.

Owner:SHENYANG NONFERROUS METALS PROCESSING CO LTD

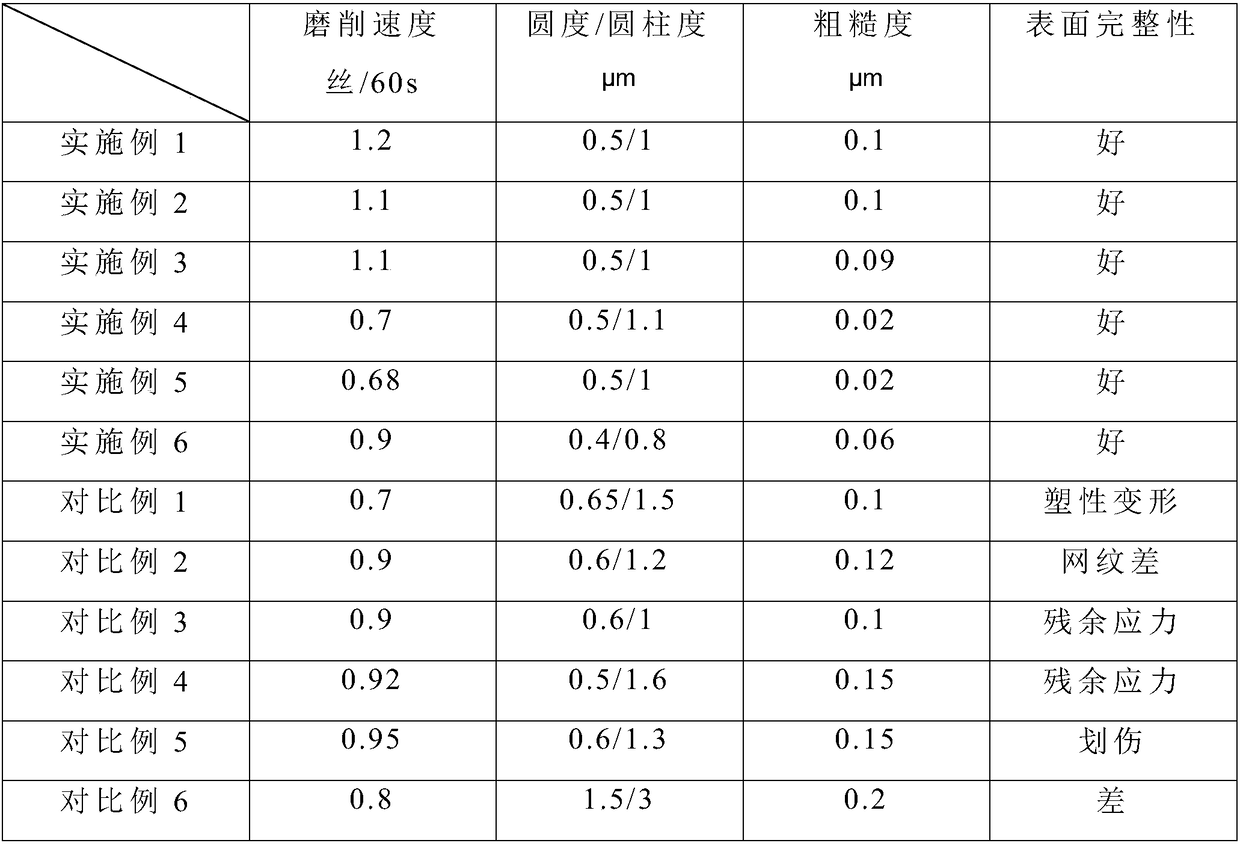

Honing oilstone and preparation method and application thereof

ActiveCN108115546APromote pore formationHigh hardnessAbrasion apparatusGrinding devicesSuperhard materialAlloy

The invention discloses a honing oilstone and a preparation method and application thereof. The honing oilstone comprises copper, tin, zinc, silver and superhard materials, and further comprises antimony, ferrophosphorus alloy, sodium hexafluoroaluminate, bronze, lubricant and wetting agent, wherein the feeding mass ratio of the copper, tin, zinc, silver, antimony, ferrophosphorus alloy, sodium hexafluoroaluminate, bronze, lubricant and wetting agent is 40-80:10-30:1-10:1-5:1:1-3:1-10:1-3:1-3:0.1-1, and the honing oilstoneis formed by mixing and sintering the raw materials. The preparation includes the steps of weighing raw material except the superhard materials according to the formula, mixing each weighed raw material with the superhard materials, sintering the mixture, and obtaining the honing oilstone. The application is the application of the honing oilstone in processing stainless steel materials. When the prepared honing oilstone is used to process materials difficult to process, such as stainless steel, no cutter adhesion, high precision and good processing surface integrity can be achieved, the preparation of the honing oilstone is simple, the cost is low, and the processing efficiency is high.

Owner:SUZHOU XINNENG PRECISE MACHINERY

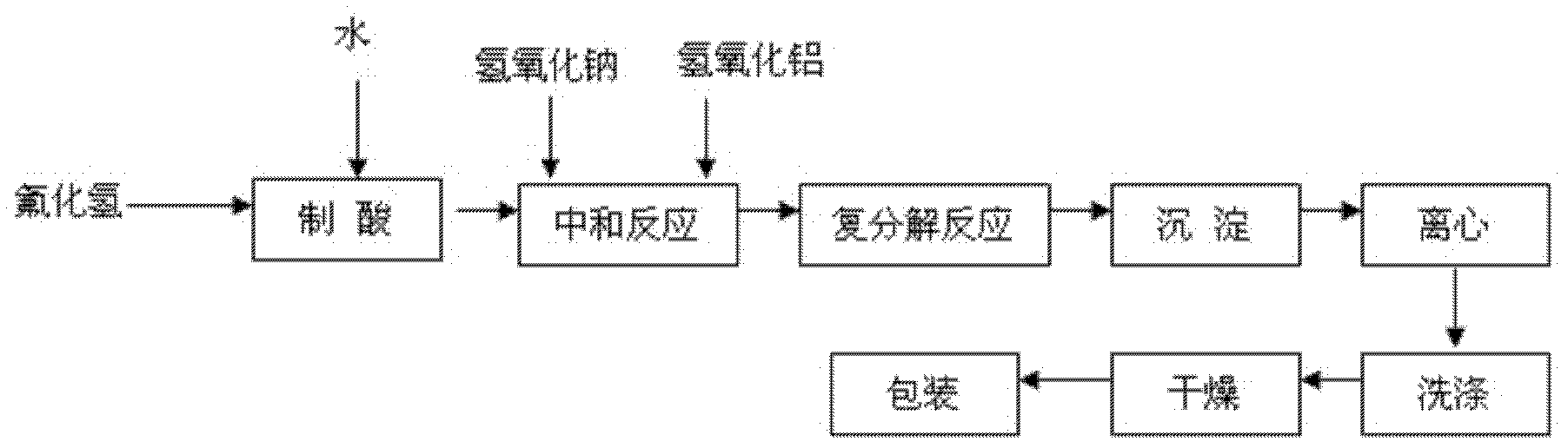

Method for production of sodium aluminum fluoride

The invention discloses a method for the production of sodium aluminum fluoride, comprising the steps of: (1) adding anhydrous hydrofluoric acid to water at room temperature and pressure, for dissolving to produce a hydrofluoric acid solution with a concentration of 40% for use; (2) at room temperature and pressure, adding aluminum hydroxide and sodium hydroxide into a reaction tank according to a ratio to react to produce sodium meta-aluminate with stirring; (3) adding the hydrofluoric acid solution with the concentration of 40% in step (1) into the reaction tank in step (2) to react with sodium meta-aluminate to produce a crude product; and (4) precipitating, centrifuging, separating, washing and drying the obtained crude product to obtain finished sodium aluminum fluoride. The method for the production of sodium aluminum fluoride of the invention has simple process, easily controlled conditions, and a high production rate, and can achieve industrial mass production.

Owner:CHANGSHU XINHUA CHEM

Dispersing agent for aluminum titanium boron production and preparation method thereof

The invention relates to a dispersing agent for Al-Ti-B production and a preparation method thereof. The dispersing agent for Al-Ti-B production comprises (wt%) sodium fluoroaluminate 30-50, potassium chloride 20-30, sodium chloride 15-25, magnesium fluoride 10-20 and cerium chloride 2-5. The inventive preparation method comprises the following steps of: (1) mixing sodium fluoroaluminate, potassium chloride and sodium chloride at a proper proportion, adding into a crucible furnace, heating to melt, and stirring; (2) sequentially adding magnesium fluoride and cerium chloride, and stirring; and (3) pouring the obtained molten liquid into a mould, cooling, crushing, and pulverizing to obtain product. The inventive dispersing agent solves the stacking problem of large and needle-shaped TiAl3 phase and TiB2 phase in Al-Ti-B crystal grains; and can improve non-uniform structural distribution.

Owner:山东云信铝业科技有限公司

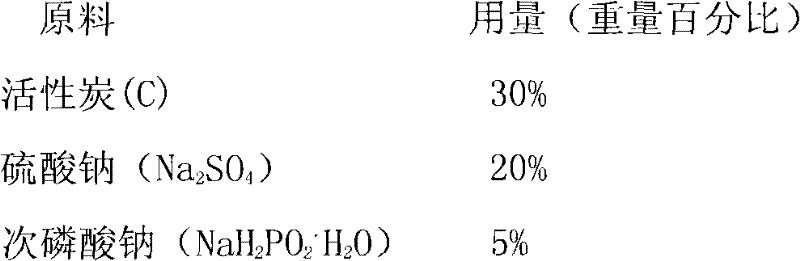

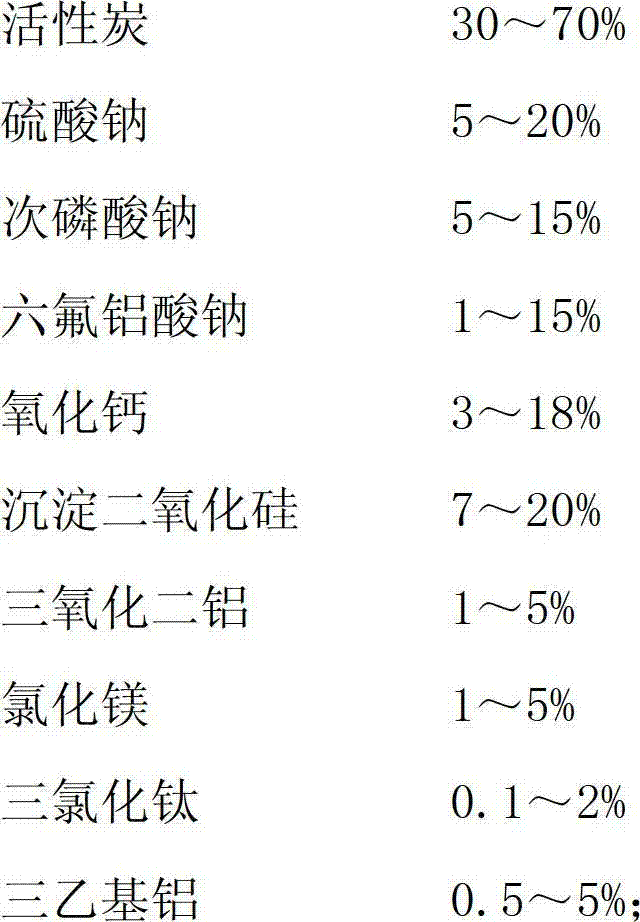

Lead residue reducing agent and preparation method thereof

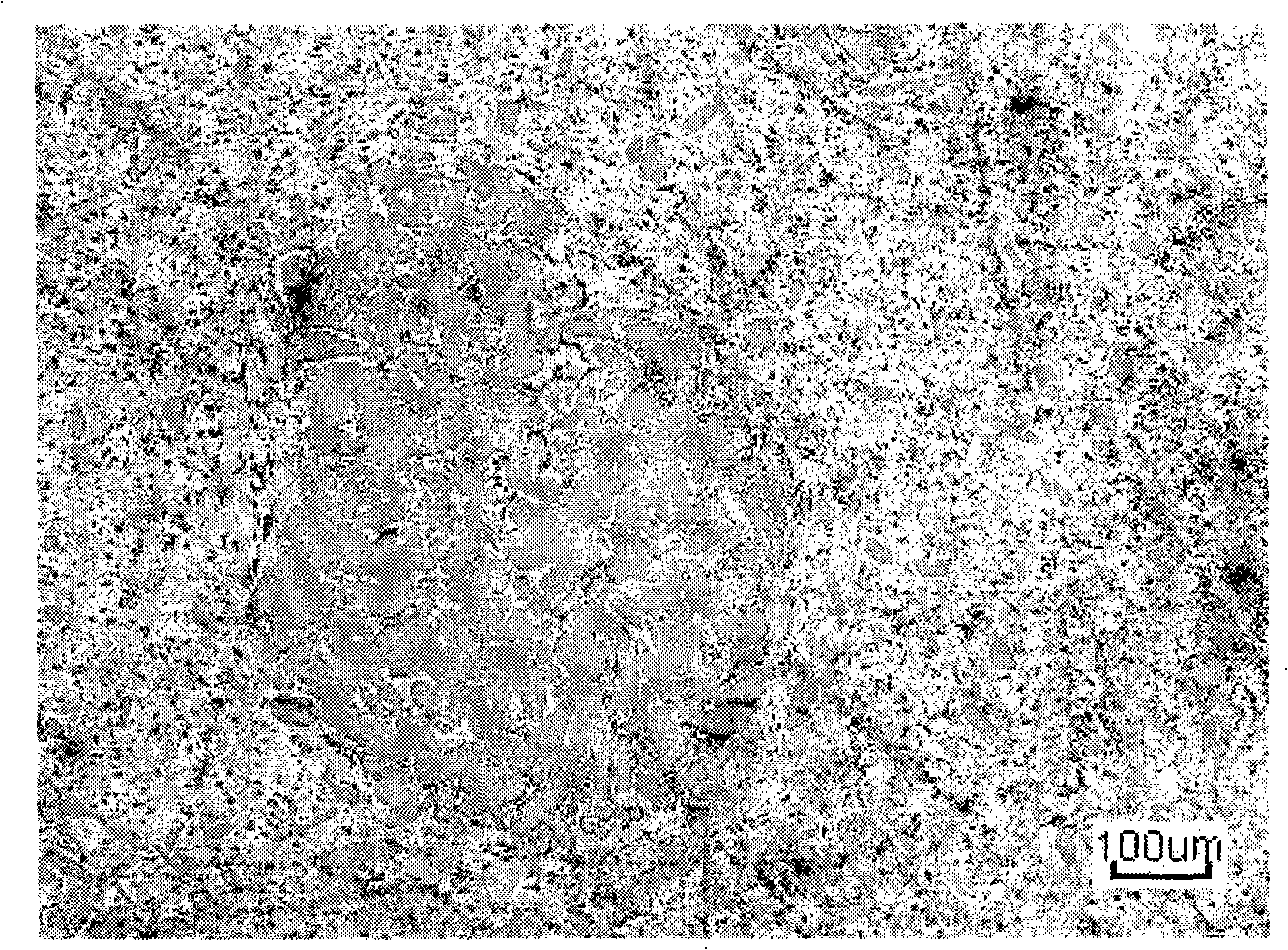

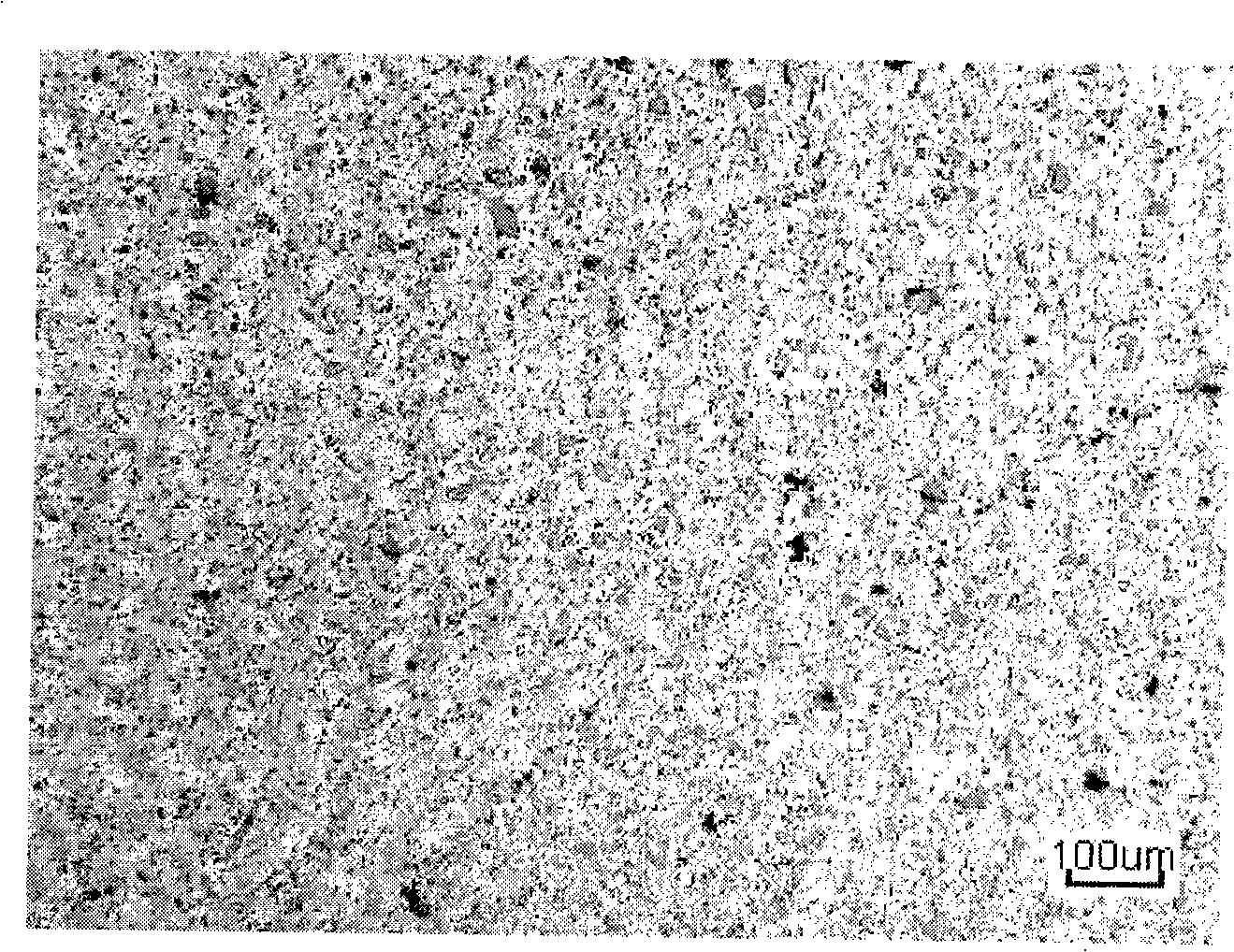

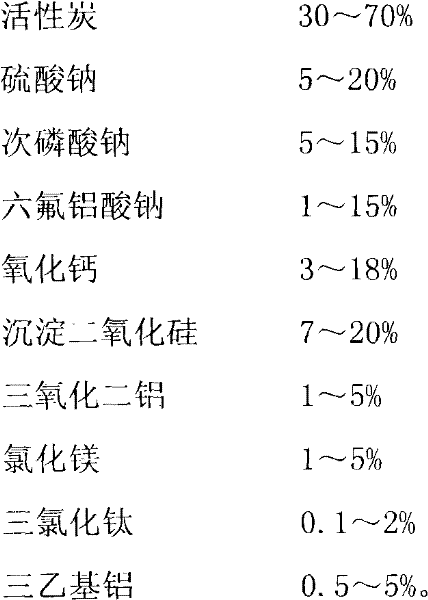

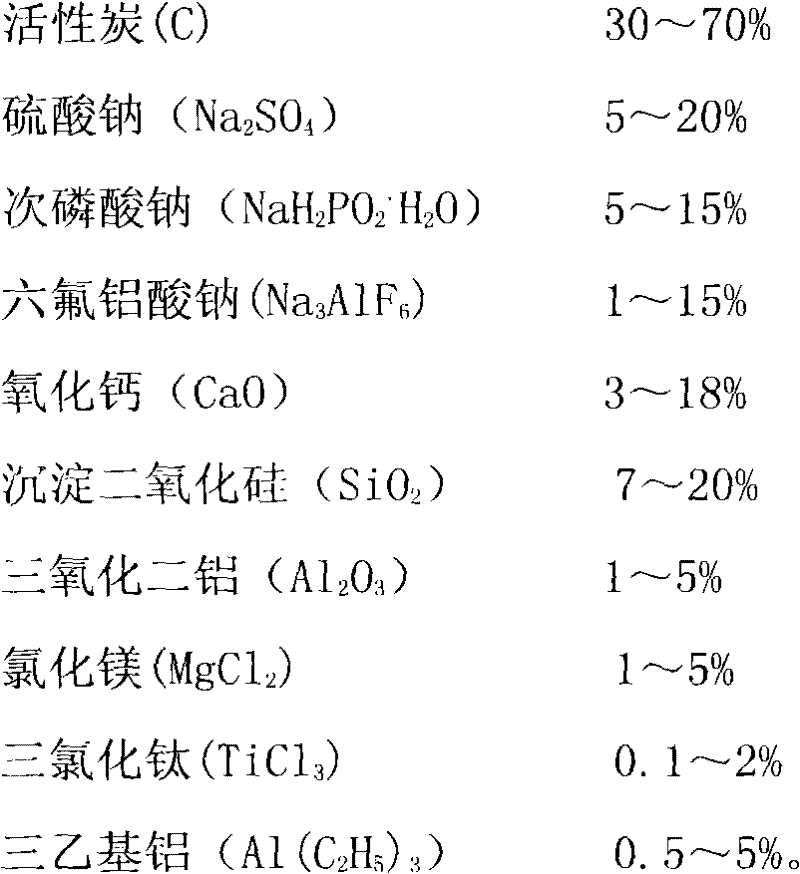

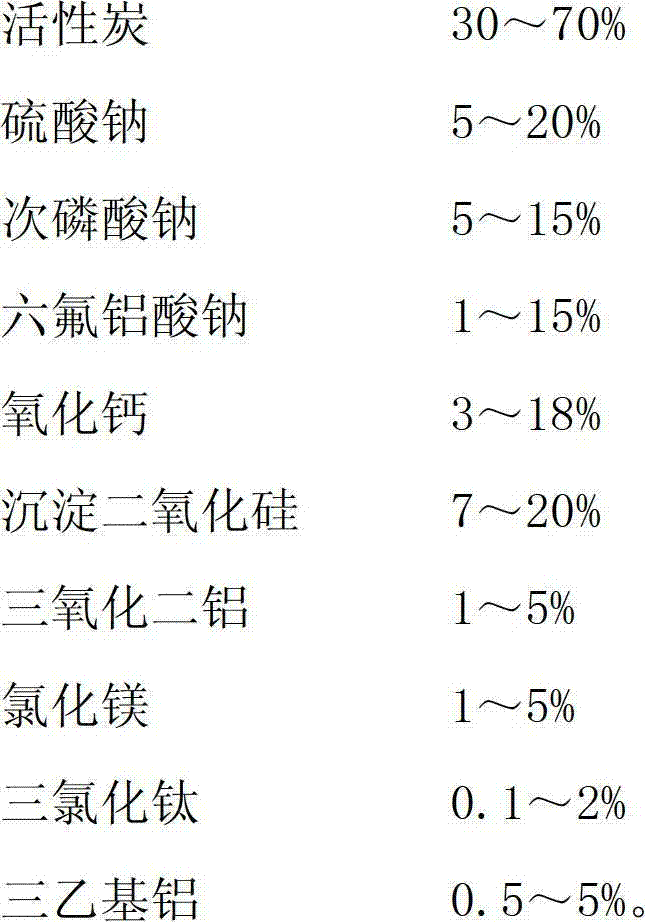

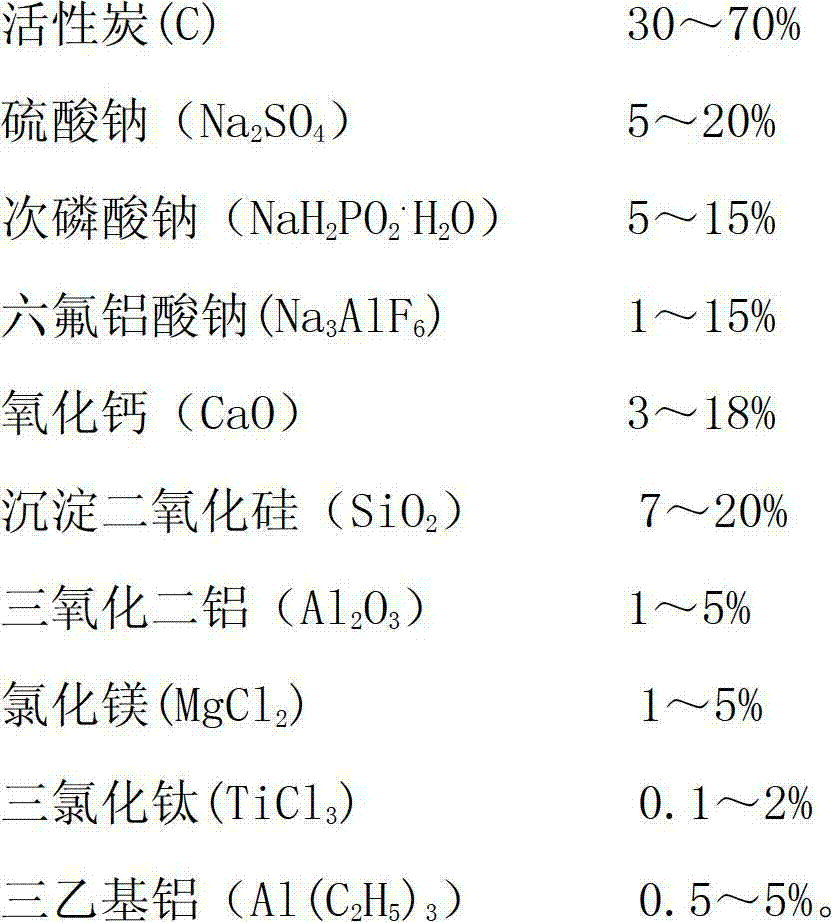

The invention discloses a lead residue reducing agent and a preparation method thereof and belongs to the technical field of chemical industry. The lead residue reducing agent comprises the following components in percentage by weight: 30 to 70 percent of active carbon, 5 to 20 percent of sodium sulfate, 5 to 15 percent of sodium hypophosphite, 1 to 15 percent of sodium hexafluoroaluminate, 3 to 18 percent of calcium oxide, 7 to 20 percent of precipitated silica, 1 to 5 percent of aluminium oxide, 1 to 5 percent of magnesium chloride, 0.1 to 2 percent of titanium trichloride and 0.5 to 5 percent of triethyl aluminum. The lead residue reducing agent can directly reduce oxide-state scum produced during alloy preparation of lead, calcium, tin and aluminum alloys and casting of grids of storage batteries into metal-state residue, so the residue amount of the lead, calcium, tin and aluminum alloys is reduced obviously. When the agent is used, the lead residue produced during the preparation of the lead, calcium, tin and aluminum alloys and the casting of grids can be directly reduced into molten metals of lead, calcium, tin and aluminum to flow back to an alloy pot, so the lead residueis reduced while the lead, calcium, tin and aluminum in the designated alloys are hardly lost; and thus, the effective ingredients of the grid alloys of the storage batteries are ensured.

Owner:XIANGXIANGSHI YOUHAO METALLURGICAL MATERIAL

Plating auxiliary for plating alloy coating with high aluminum content on steel by using solvent method

ActiveCN104032248AImprove wettabilityImprove and overcome easilyHot-dipping/immersion processesPotassium borohydrideLithium chloride

The invention discloses a plating auxiliary for plating an alloy coating with high aluminum content on steel by using a solvent method. According to a formula, the plating auxiliary comprises the concrete components according to the content (g / L): 20-60g / L of potassium borohydride, 1-10g / L sodium hydroxide, 20-40g / L of calcium chloride, 10-40g / L of potassium fluoride, 3-20g / L of lithium chloride, 2-12g / L of sodium fluoroaluminate, 5-30g / L of potassium fluotitanate, 1-10g / L of nonionic surfactant and the balance of water. The plating auxiliary disclosed by the invention is simple in production process and capable of forming a uniform salt film on a piece to be plated. During hot plating, the plating auxiliary is not reacted with aluminum in a zinc solution, and sodium fluoroaluminate in the plating auxiliary can be used for cleaning an alumina film on the surface of the zinc solution, so that the plating leakage phenomenon is avoided, and the surface of a coating is bright.

Owner:STATE GRID CORP OF CHINA +2

Aluminium alloy manganese additive containing boride

The invention discloses a boride-containing aluminum alloy Mn-additive, belonging to the field of metal material technology. The compositions and the mass percentages thereof are as follows: 10%-25% sodium chloride, 10%-25% potassium chloride, 1%-10% sodium fluoaluminate, 1%-10% sodium borate, and 30%-75% manganese chloride. The Mn-additive can quickly react in an aluminum melt to reduce Mn, the actual yield is high, and the reaction is an exothermic reaction which causes no furnace temperature reduction. In addition, the Mn-additive produces primary iron rich phases more quickly and more easily than conventional Mn-additive, at the same time, the addition proportion of Mn is lessened, the Mn residual is reduced. The Mn-additive is convenient for use, low-cost, and is easy to operate.

Owner:江西金达通新材料科技有限公司

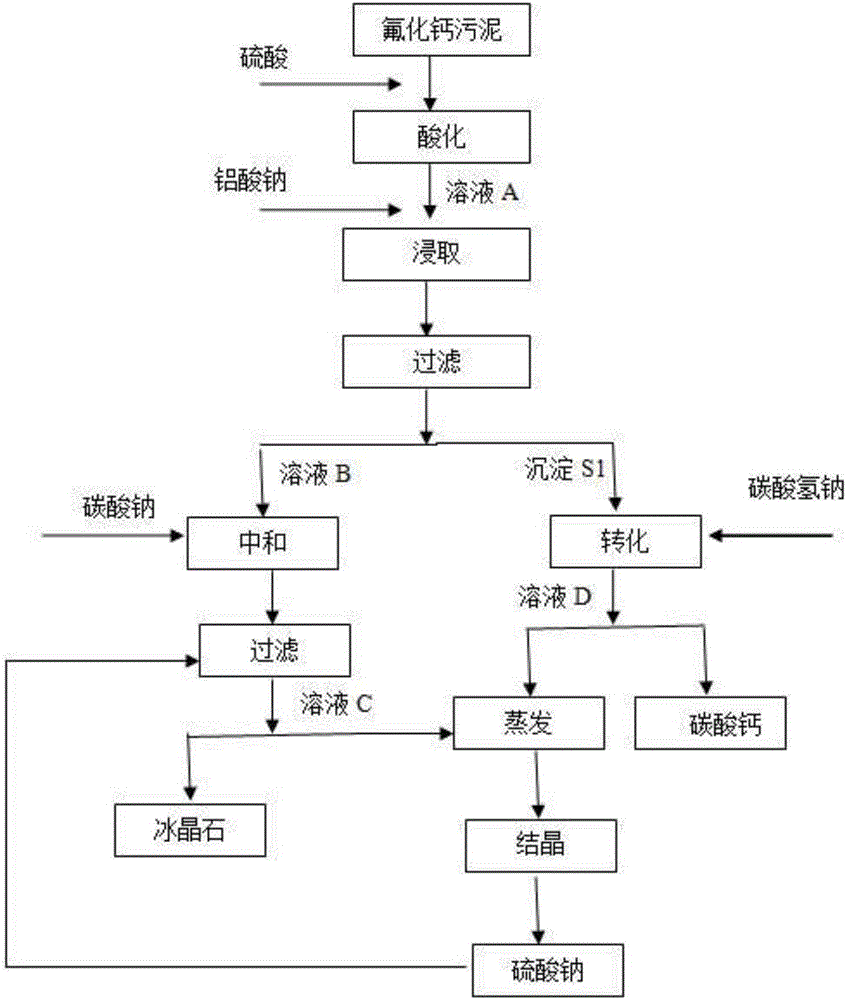

Method for recycling cryolite, calcium carbonate and sodium sulfate from calcium fluoride sludge resources

ActiveCN106277005AAchieve separate extractionEase of mass productionCalcium/strontium/barium carbonatesSulfate/bisulfate preparationSodium bicarbonateSludge

The invention provides a method for recycling cryolite, calcium carbonate and sodium sulfate from calcium fluoride sludge resources. The method includes the following specific steps that 1, sulfuric acid is added into calcium fluoride sludge, the pH is adjusted to range from 1 to 3, calcium, existing in the form of calcium hydroxide and calcium carbonate, in the sludge is converted into calcium sulfate, and a solution A is obtained; 2, sodium aluminate solids are added into the solution A, stirring and leaching are carried out, and calcium fluoride is converted into fluoaluminic acid, calcium sulfate precipitates S1 and a solution B; 3, sodium carbonate is added into the solution B, the pH ranges from 0.1 to 2, sodium sulfate is replenished, the calcium sulfate is promoted to be completely precipitated, and cryolite and a solution C are obtained; 4, a sodium bicarbonate solution is added into the precipitates S1 for treatment, and calcium carbonate and a solution D are obtained through filtering; 5, the solution C and the solution D are mixed and subjected to evaporative crystallization to obtain sodium sulfate. The method has the advantages that process conditions are easy to control, and large-scale production is easy, and calcium fluoride sludge recycling can be achieved.

Owner:盛隆资源再生(无锡)有限公司

Copper alloy pipe fusion covering agent

The invention relates to a copper alloy pipe fusion covering agent. The copper alloy pipe fusion covering agent comprises the following components in parts by weight: 8-16 parts of aluminum sulfate, 5-10 parts of silica sand, 12-25 parts of calcium fluoride, 12-20 parts of medical stone, 15-26 parts of sodium fluoroaluminate, 10-30 parts of bentonite and 8-20 parts of fluorite. The fusion covering agent integrates the functions of deoxidizing, degassing and impurity-eliminating and has a strong absorbing, dissolving and combined slagging ability, and is capable of deoxidizing the oxide inclusion in the copper alloy melting solution and eliminating the hydrogen, oxide and metal oxide absorbed on the oxide inclusion. Because the surface tension between the copper alloy tube fusion covering agent and the fuse element is high, the slag can be promoted to float and flow, and the slag is preferably separated from the copper solution, and then the effects of refining and impurity-eliminating and fuse element purifying can be obtained. The copper alloy tube fusion covering agent is strong in chemical stability and heat stability without corrosive effect on the copper solution and the furnace lining so that the original components and the performances of the alloy can be kept, besides, the copper alloy tube fusion covering agent is pollution-free, safe, environmentally friendly, convenient to use and cheap in price.

Owner:浙江同诚合金铜管有限公司

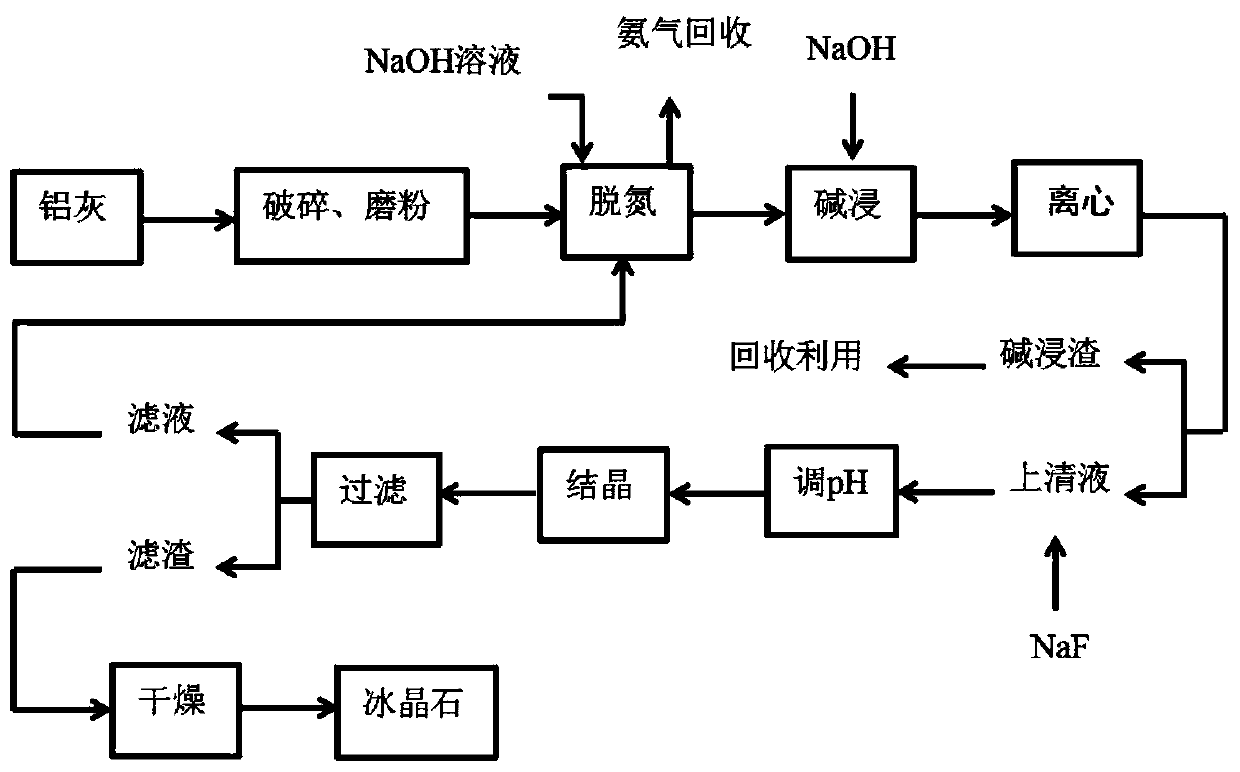

Preparation method of sodium hexafluoroaluminate

ActiveCN111348669AHigh puritySimple and fast operationAluminium fluoridesProcess engineeringSodium hexafluoroaluminate

The invention provides a preparation method of sodium hexafluoroaluminate, and belongs to the technical field of preparation of sodium hexafluoroaluminate. The preparation method provided by the invention comprises the following steps: mixing denitrified aluminum ash with sodium hydroxide, carrying out alkaline leaching reaction, and separating to obtain a supernatant solution; and crystallizing the supernatant solution to obtain the sodium hexafluoroaluminate. According to the method, the denitrified aluminum ash is used as a raw material, and the F element in the aluminum ash is fixed whilethe Al element in the aluminum ash is finely taken through alkaline leaching reaction, so that aluminum and aluminum oxide in the aluminum ash can be utilized at the same time, and the aluminum ash can be harmlessly treated; and the sodium hexafluoroaluminate is prepared through crystallization, and the purity of the sodium hexafluoroaluminate is high.

Owner:郑州轻大产业技术研究院有限公司 +1

Steel-core aluminum deoxidizing agent blocks and method for producing the same

The invention relates to a steel core aluminum deoxidizer block and a preparation method thereof, and effectively solves the problems that the preparation of the steel core aluminum deoxidizer block is complex, the aluminum content is unstable and the appearance is rough. The technical proposal is as follows: an external layer is coated outside an internal layer, no slit exists between the internal layer and the external layer, the external layer is composed of a lower layer, a transition layer and an upper layer, the transition layer is positioned at the upper end of the lower layer, and the upper layer is positioned at the upper end of the transition layer. The preparation method thereof comprises the following steps: melting pure aluminum ingot to prepare aluminum liquid, adding 0.1-0.3% of sodium fluoroaluminate to 200kg of the aluminum liquid to be taken as a deslagging agent for deslagging, purifying molten aluminum, molding by 35%-65% of the purified molten aluminum and 35%-65% of steel core based on the weight percentages, taking out the purified molten aluminum of the weight percentages to be injected into a die, casting the purified molten aluminum to the top end of the lower layer of the die, stopping casting, vertically placing the weighed steel core of the weight percentages into the purified molten aluminum in the die, naturally cooling, and obtaining the steel core aluminum deoxidizer block by demolding. The method can help realize once casting molding and stable aluminum content, and is an innovation in the steelmaking field.

Owner:郑州万隆冶金炉料有限公司

Low-temperature refining fluxing medium for aluminum alloy smelting and preparation method for low-temperature refining fluxing medium

The invention discloses a low-temperature refining fluxing medium for aluminum alloy smelting and a preparation method for the low-temperature refining fluxing medium. And the low-temperature refining fluxing medium is characterized in that the low-temperature refining fluxing medium comprises, by weight, (1) 15-25 parts of sodium chloride, (2) 15-25 parts of potassium chloride, (3) 8-12 parts of sodium fluosilicate, (4) 3-8 parts of sodium fluoroaluminate, (5) 2-8 parts of light sodium carbonate, (6) 8-13 parts of calcium fluoride, (7) 18-30 parts of sodium nitrate, and (8) 3-5 parts of charcoal powder. The preparation method for the low-temperature refining fluxing medium comprises the following steps of A, adding the first six raw materials into a heating blender according to the weight ratio, stirring for 60 min at the temperature of 105-115 DEG C and the normal pressure, stopping heating and stirring, and obtaining a first mixture; B, adding the sodium nitrate and the charcoal powder into the first mixture according to the weight ratio, stirring for 10 min without heating, and obtaining a second mixture; and C, discharging the second mixture into the material containing plate, cooling the second mixture down to the indoor temperature naturally, and packaging the cooled down second mixture into finished products with 2 kg of the cooled down second mixture in a bag and 20 kg of the cooled down second mixture in a case. The preparation method is mainly used for the low-temperature refining fluxing medium for aluminum alloy smelting.

Owner:ZHUZHOU CHUANGLIN ALLOY

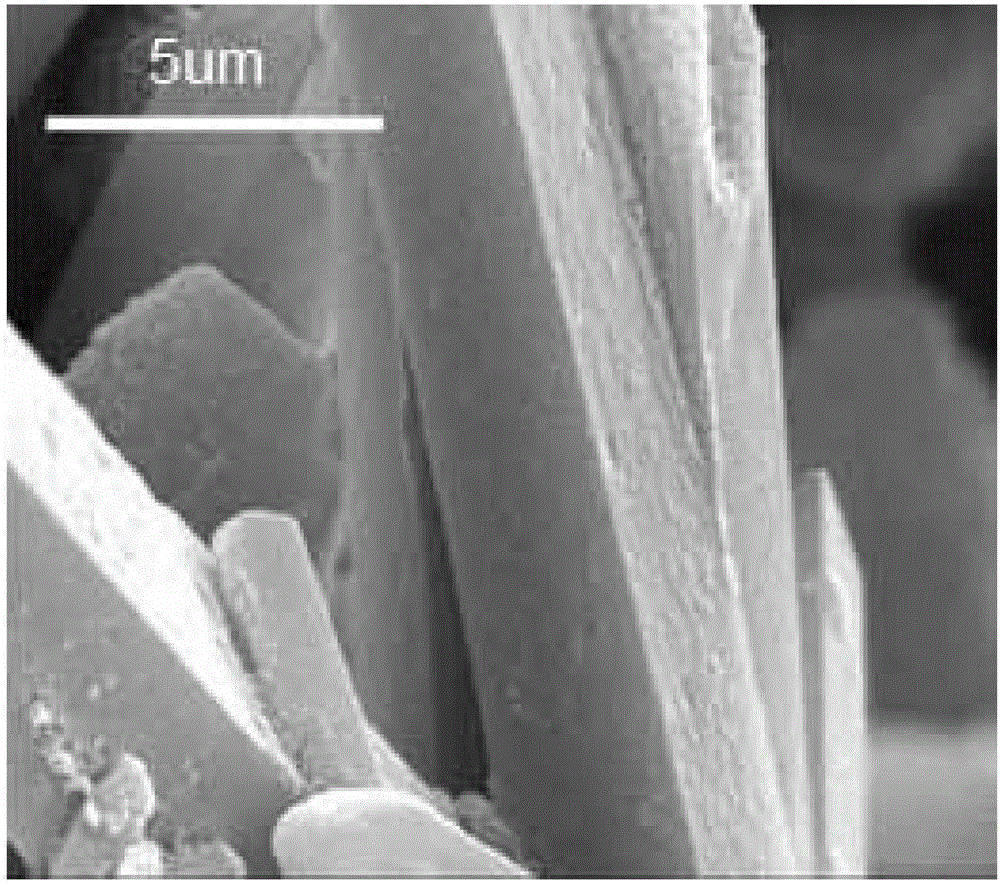

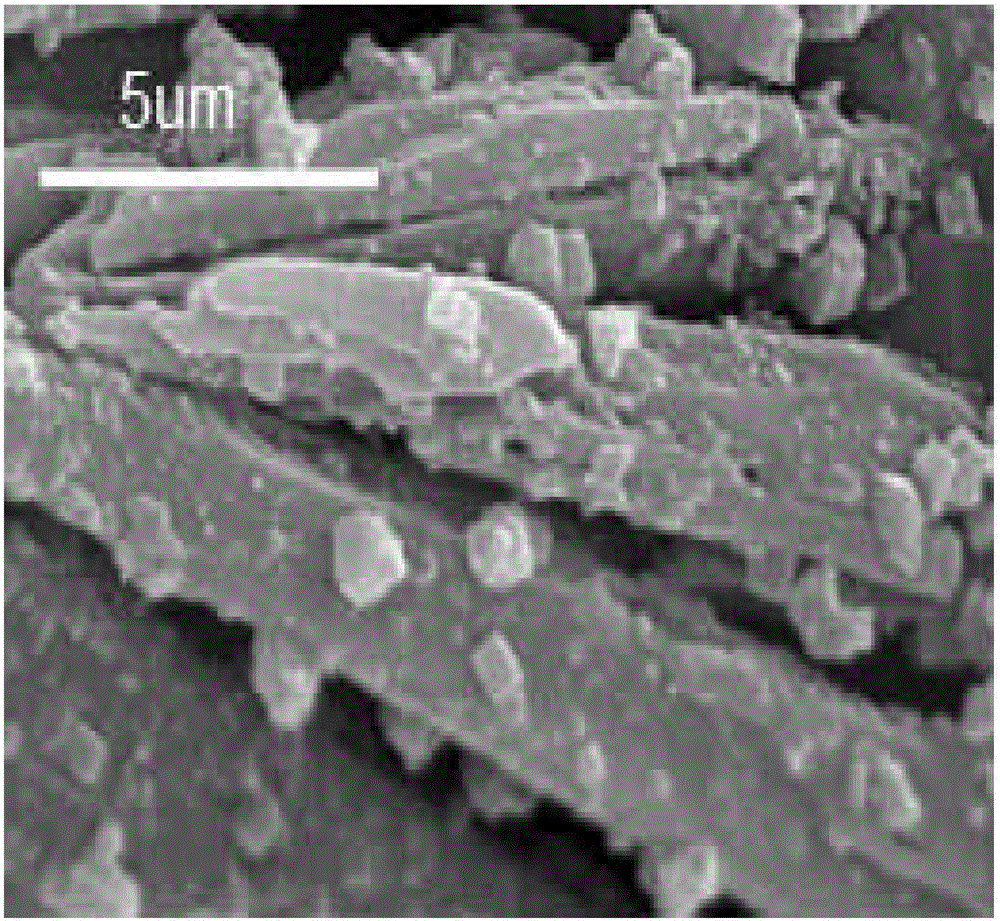

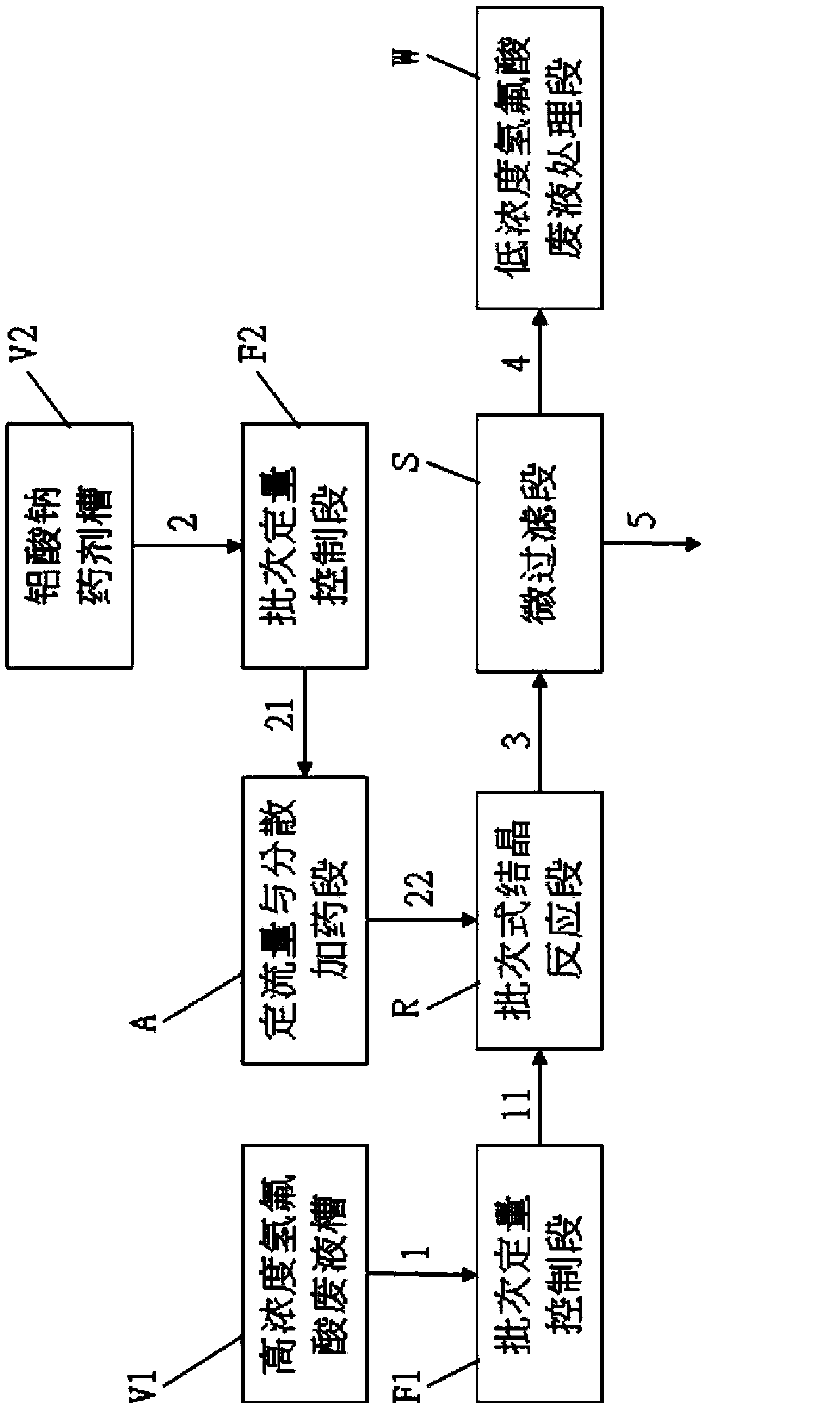

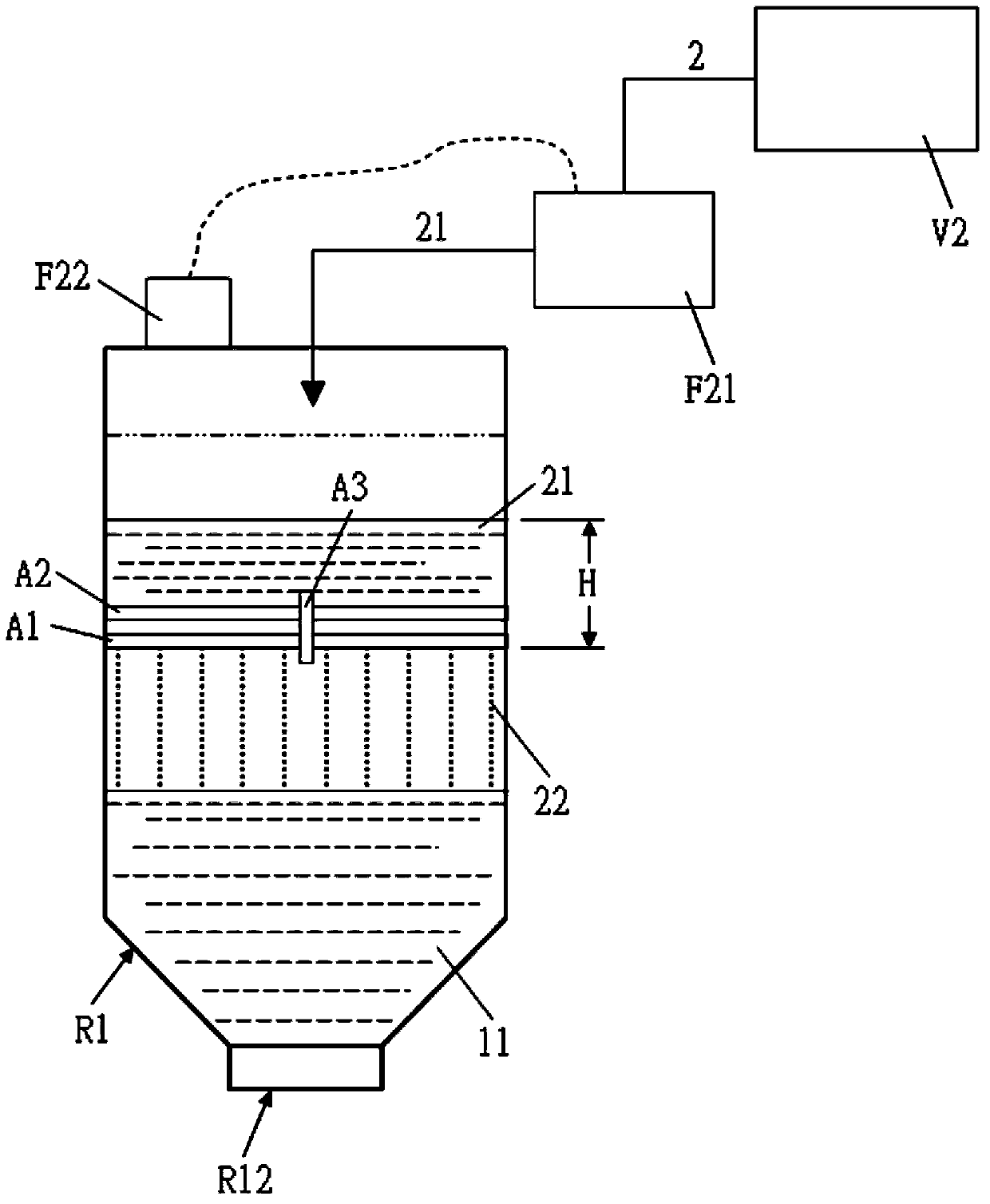

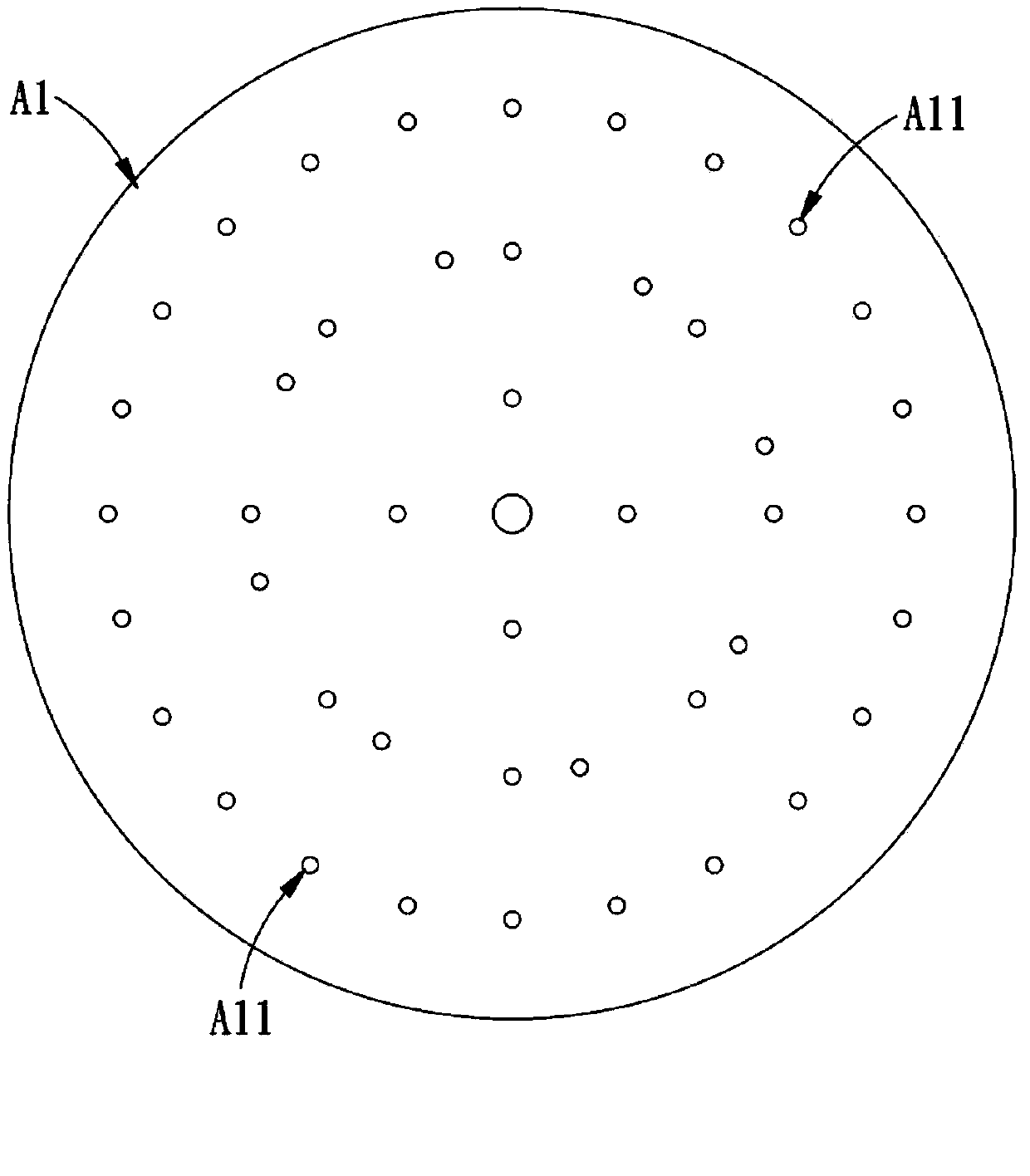

Crystallization system and crystallization method for generating sodium fluoroaluminate crystals by utilizing hydrofluoric acid waste liquid

ActiveCN103663522AReduce volumeHigh purityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHydrofluoric acidSludge

The invention discloses a crystallization system and a crystallization method for generating sodium fluoroaluminate (Na3AlF6) crystals by utilizing a hydrofluoric acid waste liquid. The crystallization system is characterized in that a given-flow-rate and uniformly-dispersed medication section is arranged in a notch of a reaction trough, so that chemicals can be quantitatively controlled in different batches and uniformly dispersed into the hydrofluoric acid waste liquid to be reacted, and the crystallization method which is matched with the crystallization system comprises the steps: feeding the hydrofluoric acid waste liquid, charging sodium aluminate, crystallizing, precipitating the sodium fluoroaluminate crystals, filtering and discharging the water, the hydrofluoric acid waste liquid is purified by adopting a crystallization operation mode to substitute the well-known chemical coagulation operation mode, the reaction efficiency of the hydrofluoric acid waste liquid and the chemicals and the crystallization purity can be improved, and the purposes for effectively recycling the fluoride, reducing the size of chemical sludge and generating the high-economic-benefit sodium fluoroaluminate crystals can be realized.

Owner:RETECH ENVIRONMENTAL SOLUTIONS

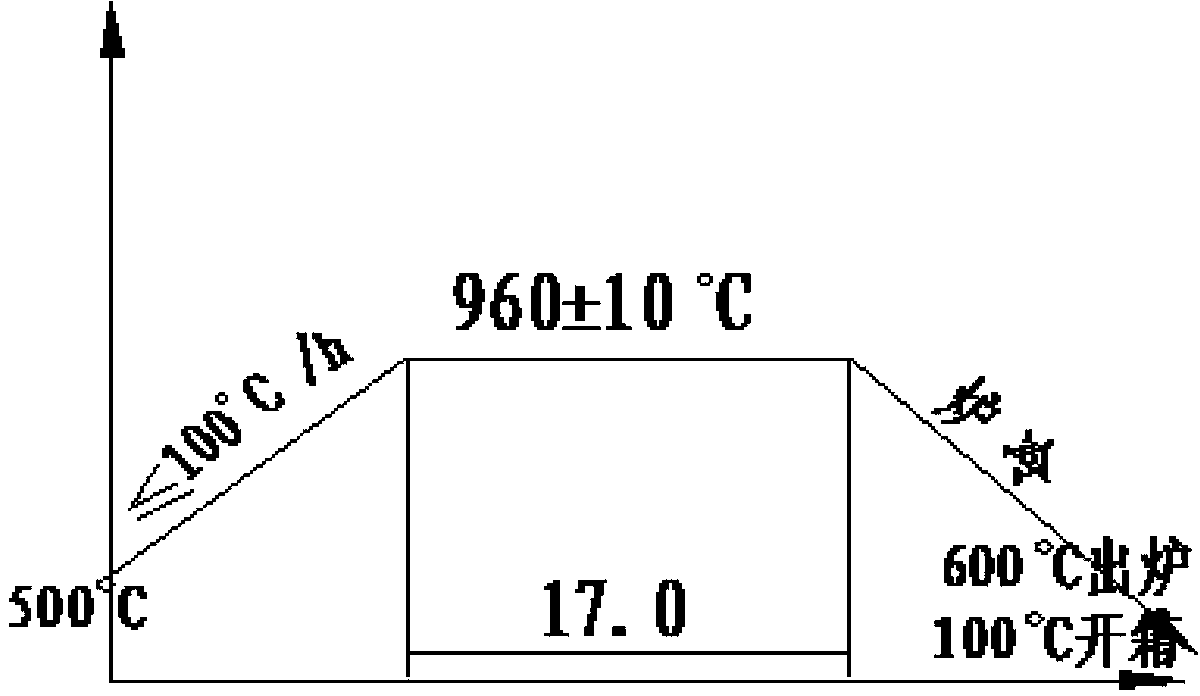

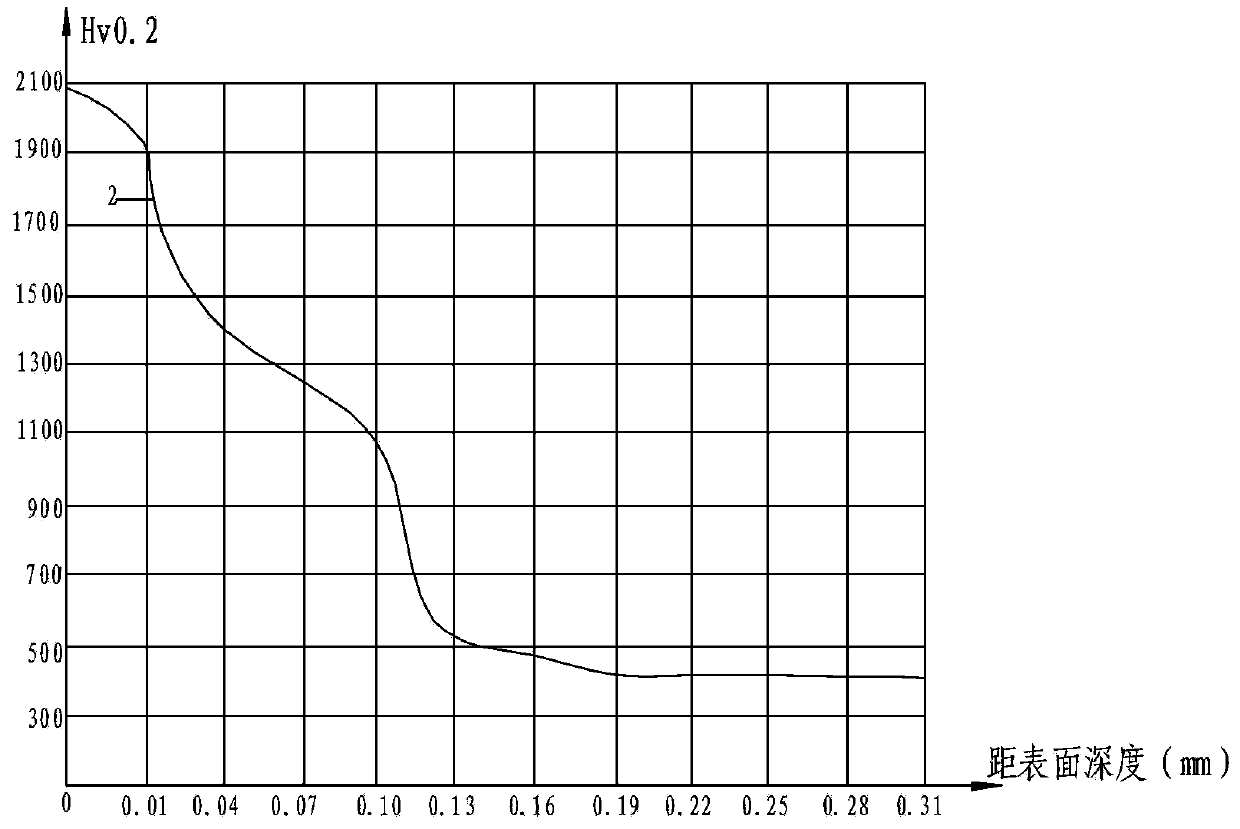

Ni-based high-temperature alloy surface boronizing agent and use method thereof

ActiveCN103966544AHigh hardnessBoronizing effect is goodSolid state diffusion coatingHardnessSuperalloy

The invention belongs to the field of material surface modification and relates to a Ni-based high-temperature alloy surface boronizing agent and a use method thereof. The Ni-based high-temperature alloy surface boronizing agent comprises amorphous boron powder, activators and a filler according to a certain ratio, wherein the activators comprise sodium fluoroaluminate and cerium oxide and the filler is silicon carbide. Through use of a high-temperature boronizing technology and the Ni-based high-temperature alloy surface boronizing agent, Ni-based high-temperature alloy surface boronizing layer depth, hardness and uniformity are improved and brittleness is reduced. The boronizing layer has depth more than 0.1mm and hardness more than Hv1900 and is uniform and firm.

Owner:SHENYANG BLOWER GRP GEAR COMPRESSOR

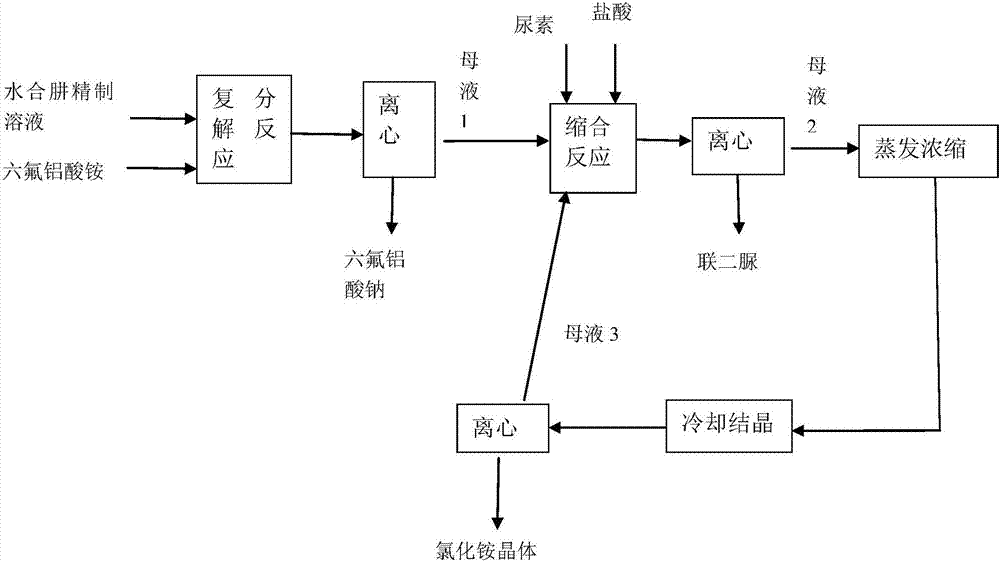

Method for co-producing sodium hexafluoroaluminate and biurea

InactiveCN107055581ANo emissionsFully producedOrganic chemistryAluminium fluoridesAmmonium hexafluoroaluminateBiurea

The invention discloses a method for co-producing sodium hexafluoroaluminate and biurea. The method comprises the following steps: (1) adding ammonium hexafluoaluminate into a sodium carbonate-removed refined hydrazine hydrate solution wherein sodium chloride in the refined hydrazine hydrate solution performs double decomposition reaction with the ammonium hexafluoaluminate, thus generating the sodium hexafluoroaluminate and ammonium chloride, and separating the sodium fluoroaluminate, thus obtaining a mother solution 1; (2) adding urea and hydrochloric acid into the mother solution 1 where hydrazine hydrate and urea in the mother solution 1 performs condensation reaction with the hydrochloric acid, thus generating the biurea and ammonium chloride, and separating the biurea, thus obtaining a mother liquid 2. According to the method, the sodium hexafluoroaluminate, the biurea and the ammonium chloride which are high in yield and high in purity can be respectively produced; the yield of the sodium hexafluoroaluminate is up to 99.3 percent or above, and the contents of fluorine and aluminum in the sodium hexafluoroaluminate can meet the requirement of the national standard; the yield of the biurea is up to 97 percent or above, and the purity is 98 percent or above; the yield of the ammonium chloride is 98 percent or above, and the purity can meet the industrial standard.

Owner:衡阳市锦轩化工有限公司

Lead residue reducing agent and preparation method thereof

The invention discloses a lead residue reducing agent and a preparation method thereof and belongs to the technical field of chemical industry. The lead residue reducing agent comprises the following components in percentage by weight: 30 to 70 percent of active carbon, 5 to 20 percent of sodium sulfate, 5 to 15 percent of sodium hypophosphite, 1 to 15 percent of sodium hexafluoroaluminate, 3 to 18 percent of calcium oxide, 7 to 20 percent of precipitated silica, 1 to 5 percent of aluminium oxide, 1 to 5 percent of magnesium chloride, 0.1 to 2 percent of titanium trichloride and 0.5 to 5 percent of triethyl aluminum. The lead residue reducing agent can directly reduce oxide-state scum produced during alloy preparation of lead, calcium, tin and aluminum alloys and casting of grids of storage batteries into metal-state residue, so the residue amount of the lead, calcium, tin and aluminum alloys is reduced obviously. When the agent is used, the lead residue produced during the preparation of the lead, calcium, tin and aluminum alloys and the casting of grids can be directly reduced into molten metals of lead, calcium, tin and aluminum to flow back to an alloy pot, so the lead residue is reduced while the lead, calcium, tin and aluminum in the designated alloys are hardly lost; and thus, the effective ingredients of the grid alloys of the storage batteries are ensured.

Owner:XIANGXIANGSHI YOUHAO METALLURGICAL MATERIAL

Refining agent for production of aluminum alloy sacrificial anodes, and preparation method thereof

The invention provides a refining agent for production of aluminum alloy sacrificial anodes, and a preparation method thereof. The refining agent for production of aluminum alloy sacrificial anodes comprises 30-40wt% of sodium chloride, 45-55wt% of potassium chloride, 3-5wt% of calcium fluoride, and the balance of sodium hexafluoroaluminate. The preparation method comprises the following steps: 1, carrying out drying dehydration on sodium chloride, potassium chloride, calcium fluoride and sodium hexafluoroaluminate, and weighing the above raw materials according to above weight percentages; and 2, mechanically stirring the weighed raw materials for uniform mixing, heating to 750-850DEG to prepare a melt, condensing the melt, crushing the condensed melt, and screening to obtain powder which is the finished refining agent. The refining agent has the advantages of simple and reasonable design of components, good slag removal effect, degassing and covering effects, low use temperature and ideal effect.

Owner:CHINA NAT OFFSHORE OIL CORP +3

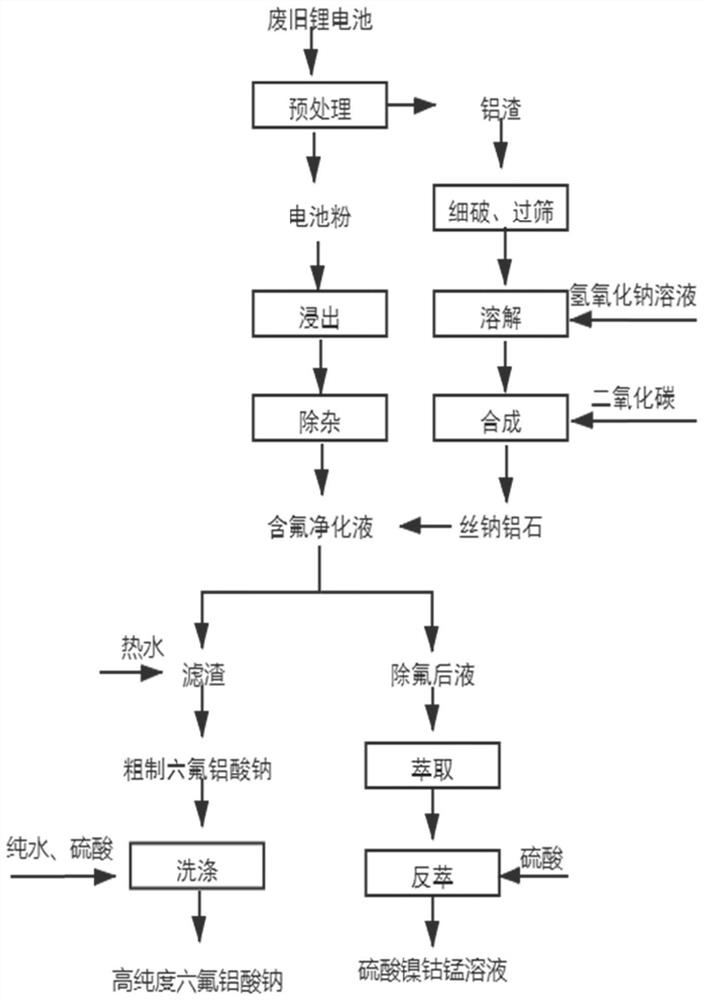

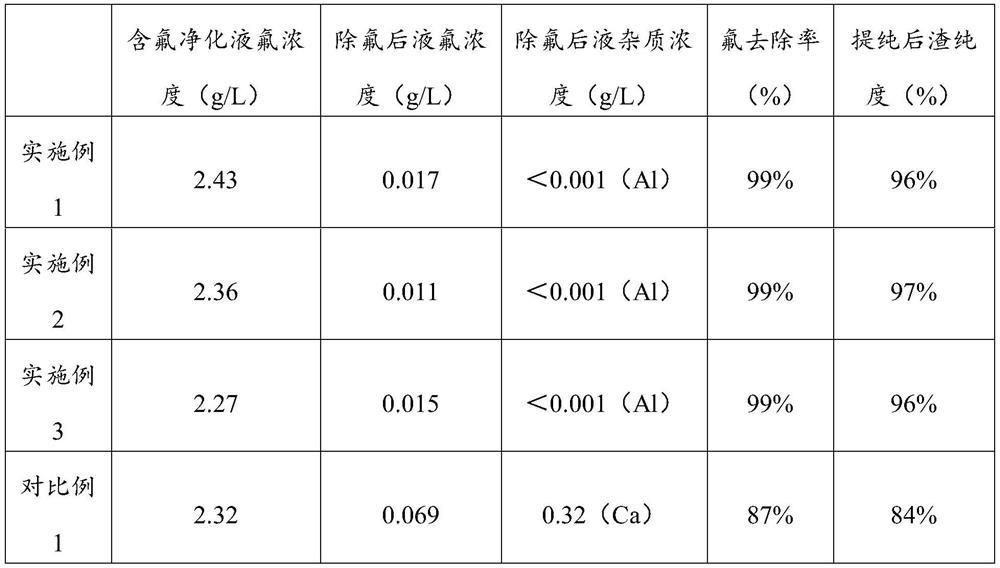

Method for removing fluorine in lithium battery positive electrode lixivium

ActiveCN114214517AGood choiceSelective reachWaste accumulators reclaimingAluminium fluoridesPregnant leach solutionLithium metal

The method comprises the following steps: adding acid and an oxidizing agent into battery powder for leaching, removing impurities from the obtained leaching solution to obtain a fluorine-containing solution, adding dawsonite into the fluorine-containing solution, simultaneously adding sulfuric acid, carrying out stirring reaction at a certain temperature, and carrying out solid-liquid separation to obtain a fluorine-removed solution and filter residues, and washing filter residues to obtain crude sodium hexafluoroaluminate. According to the method disclosed by the invention, the dawsonite is used for removing fluorine from the waste lithium battery, is good in selectivity, does not react with nickel, cobalt, manganese, lithium and the like in the solution, and only reacts with fluorine ions in the solution, so that the purpose of selectively removing fluorine is achieved, and the loss of nickel, cobalt, manganese and lithium metals in the solution is avoided; according to the fluorine removal reaction equation, one mole of aluminum can be combined with six moles of fluorine, the fluorine removal capacity is large, sodium ions in the solution are consumed during fluorine removal, the concentration of the sodium ions in the solution is reduced, and the quality of the nickel cobalt manganese sulfate solution product is improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com