Lead residue reducing agent and preparation method thereof

A slag reducing agent and formula technology, applied in the field of lead slag reducing agent and its preparation, can solve the problems of low recycling rate, pollution, lead poisoning, etc., achieve the effect of reducing the amount of lead slag and improving the efficiency of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

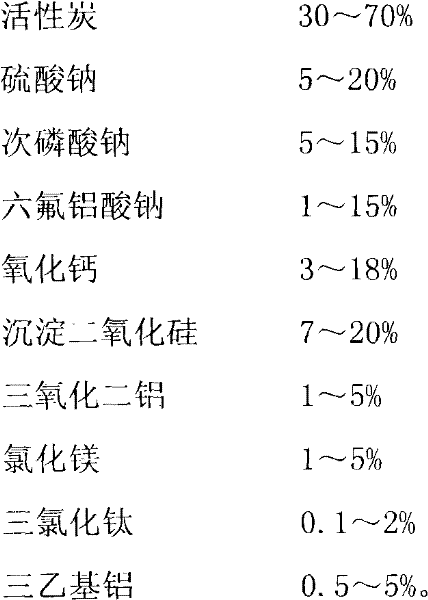

[0020] This embodiment provides a lead slag reducing agent, which is used in the production of lead-calcium-tin-aluminum alloy smelting, battery grid casting, and lead slag regeneration to reduce the amount of lead slag produced and the emission pollution in lead slag regeneration. Slag reducing agent comprises following each raw material (each raw material consumption is by weight percentage):

[0021]

[0022] The above-mentioned multiple compounds are manufactured into a composite compound capable of alkali and less lead slag through chemical and physical methods. The specific preparation method is as follows:

[0023] Get each raw material that prepares lead slag reducing agent according to above-mentioned formula, preparation steps are as follows:

[0024] Prepare a co-initiator for aluminum compounds: use titanium trichloride in the above formula as a main initiator and triethylaluminum as a co-initiator to make a co-initiator for aluminum compounds after reaction;

...

Embodiment 2

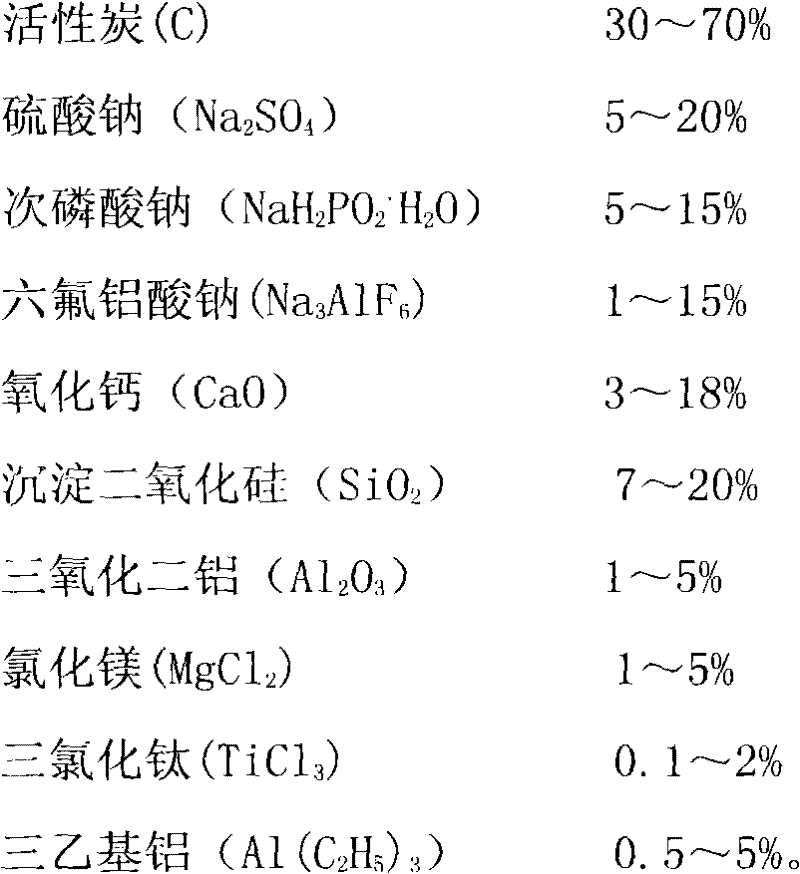

[0033] This embodiment provides a lead slag reducing agent, which is used to reduce the generation of lead slag in the smelting of lead-calcium-tin-aluminum alloy and the production of battery grid casting, and to reduce the emission pollution generated in the production process in the regeneration of lead slag. The slag reducer specifically includes:

[0034]

[0035]

[0036] The preparation process steps are as follows:

[0037] Prepare a co-initiator for aluminum compounds: use titanium trichloride in the above formula as a main initiator and triethylaluminum as a co-initiator to make a co-initiator for aluminum compounds after reaction;

[0038] Prepare the carrier of the co-initiator: the precipitated silica, aluminum oxide and magnesium chloride in the above formula are made into the initiator carrier by the grinding method of physical dispersion, and the co-initiator of the aluminum compound prepared above is uniformly dispersed and loaded to the surface of the ...

Embodiment 3

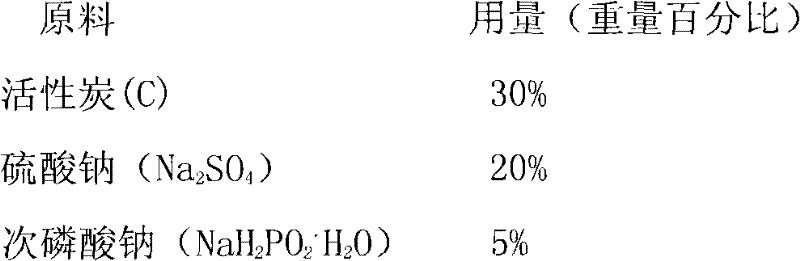

[0042] This embodiment provides a lead slag reducing agent, which is used to reduce the generation of lead slag in the smelting of lead-calcium-tin-aluminum alloy and the production of battery grid casting, and to reduce the emission pollution generated in the production process in the regeneration of lead slag. The slag reducing agent specifically includes the following components by weight:

[0043]

[0044]

[0045] The preparation process of the lead slag reducing agent is the same as in Example 3, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com