Patents

Literature

190results about How to "High slag removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

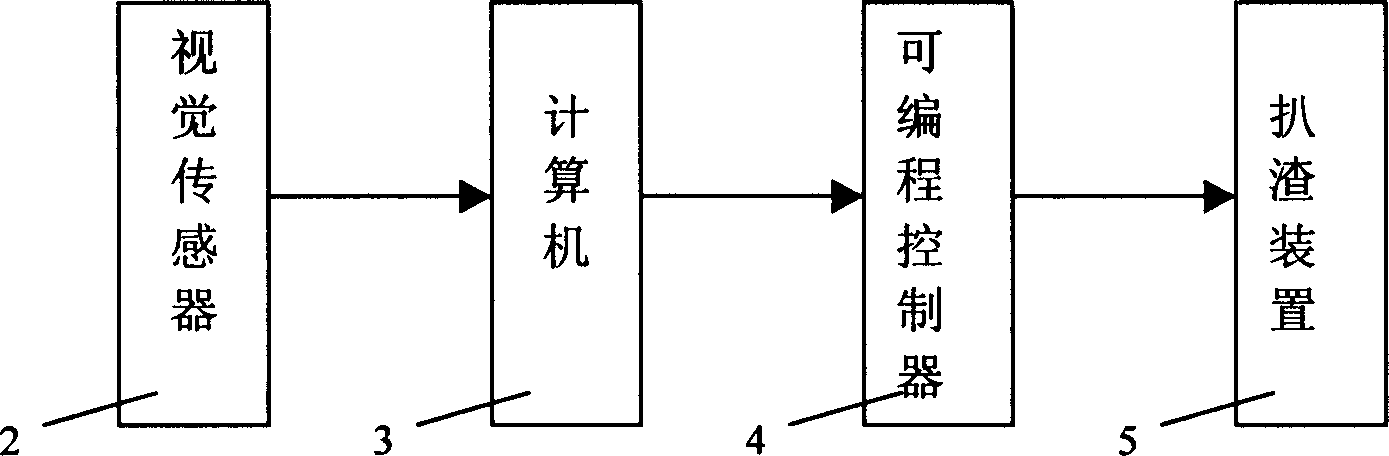

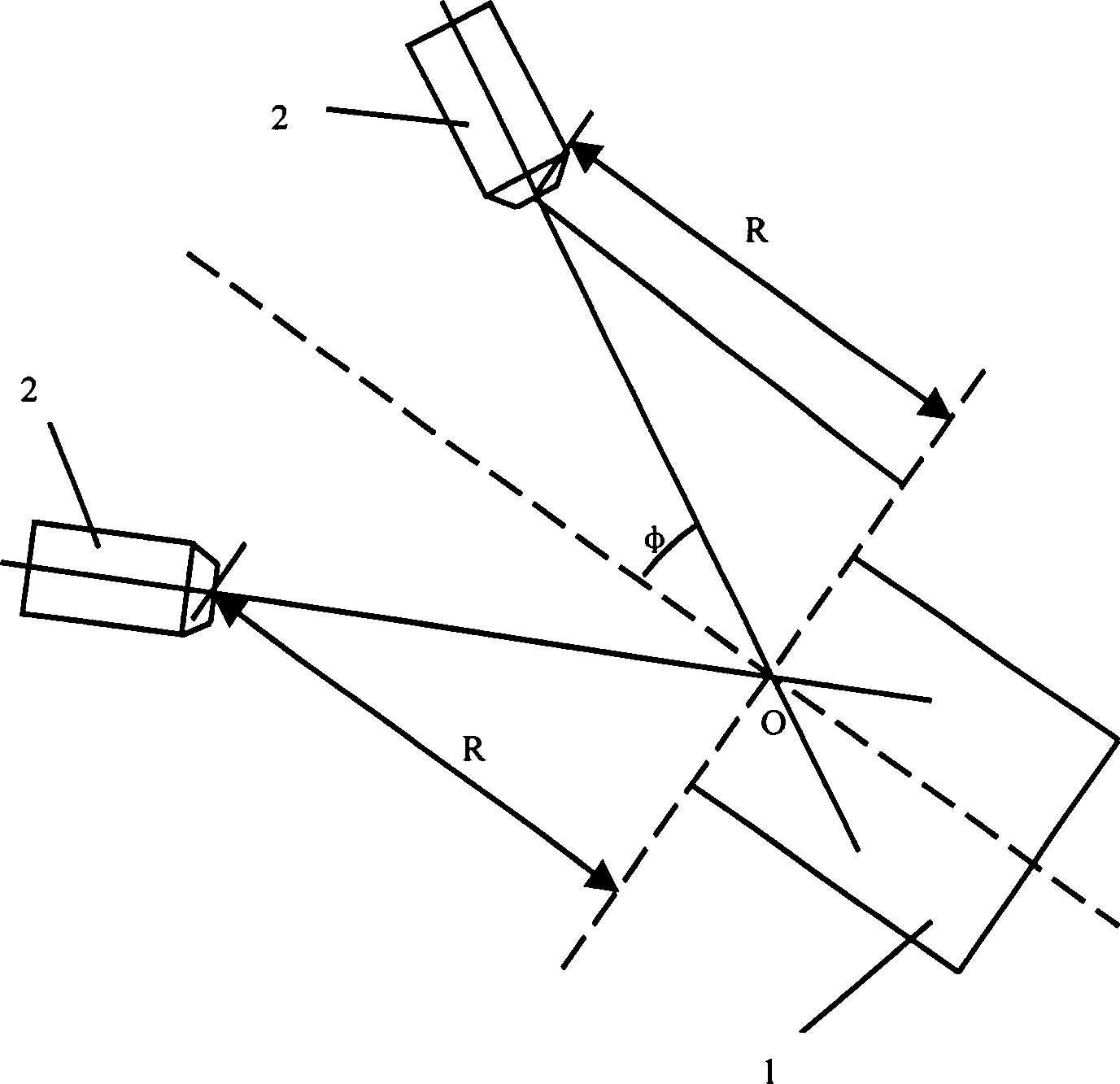

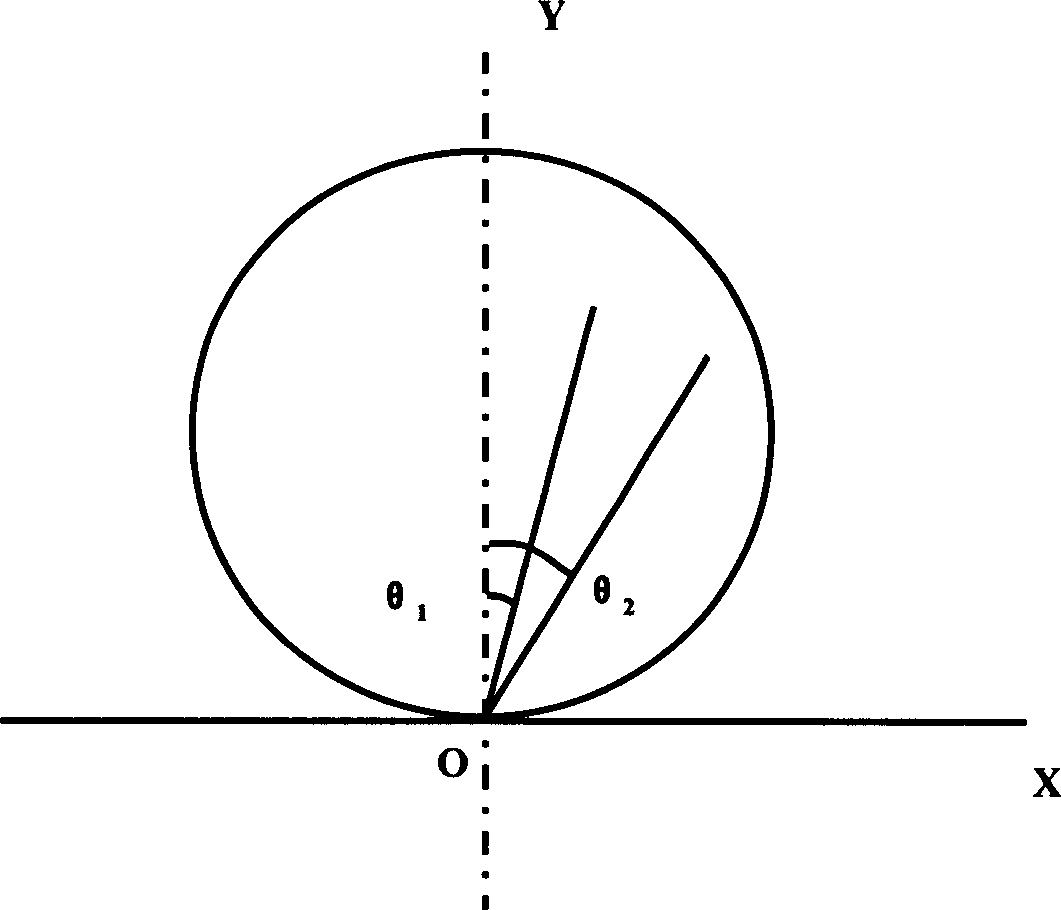

Automatic skimming method and apparatus

The present invention relates to a skimming method for auxiliary equipment in steel-smelting technique and an automatic skimming machine. It is characterized by that a visual sensor is mounted over the ladle, said visual sensor can be used for detecting steel slag on the surface of ladle, then the detected image can be inputted into computer, after having been processed by computer a signal can be outputted by computer and transferred into programmable controlled to control manipulator of skimming machine to implement skimming operation.

Owner:BAOSHAN IRON & STEEL CO LTD

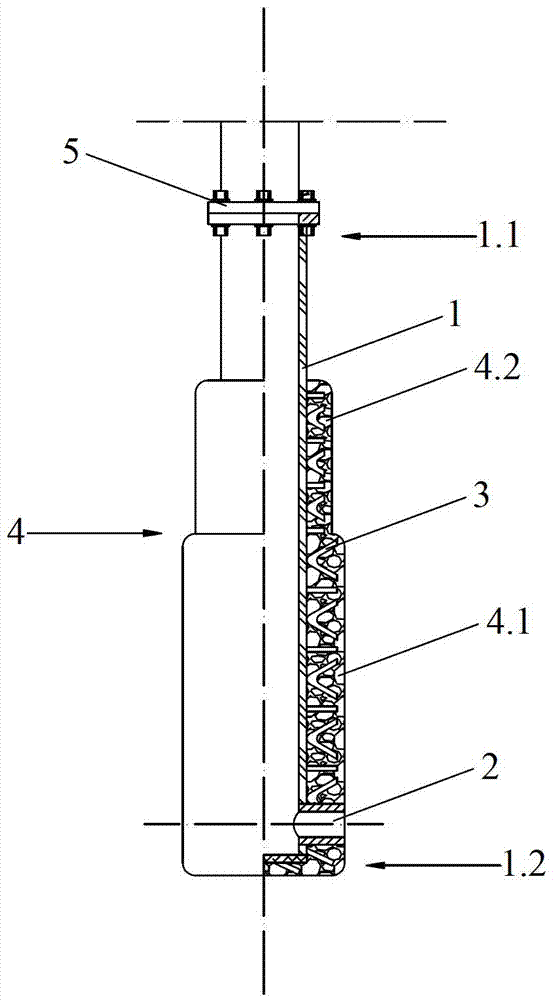

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

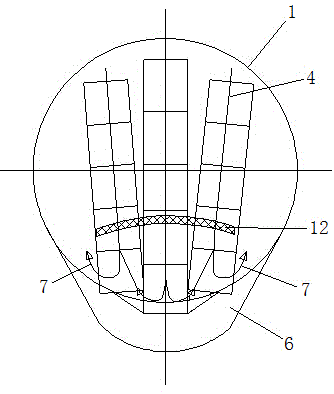

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

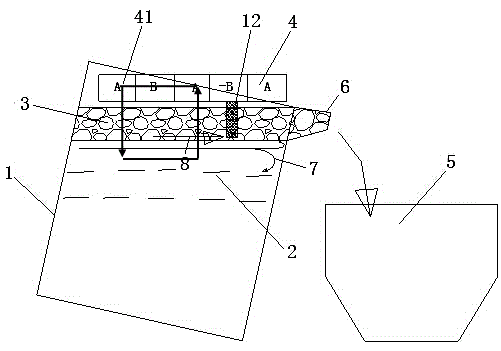

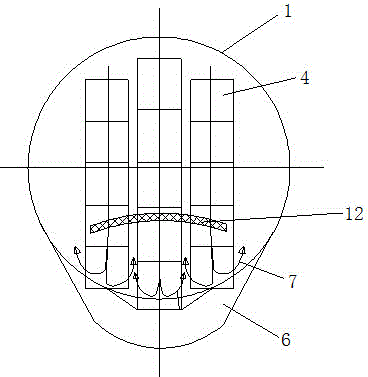

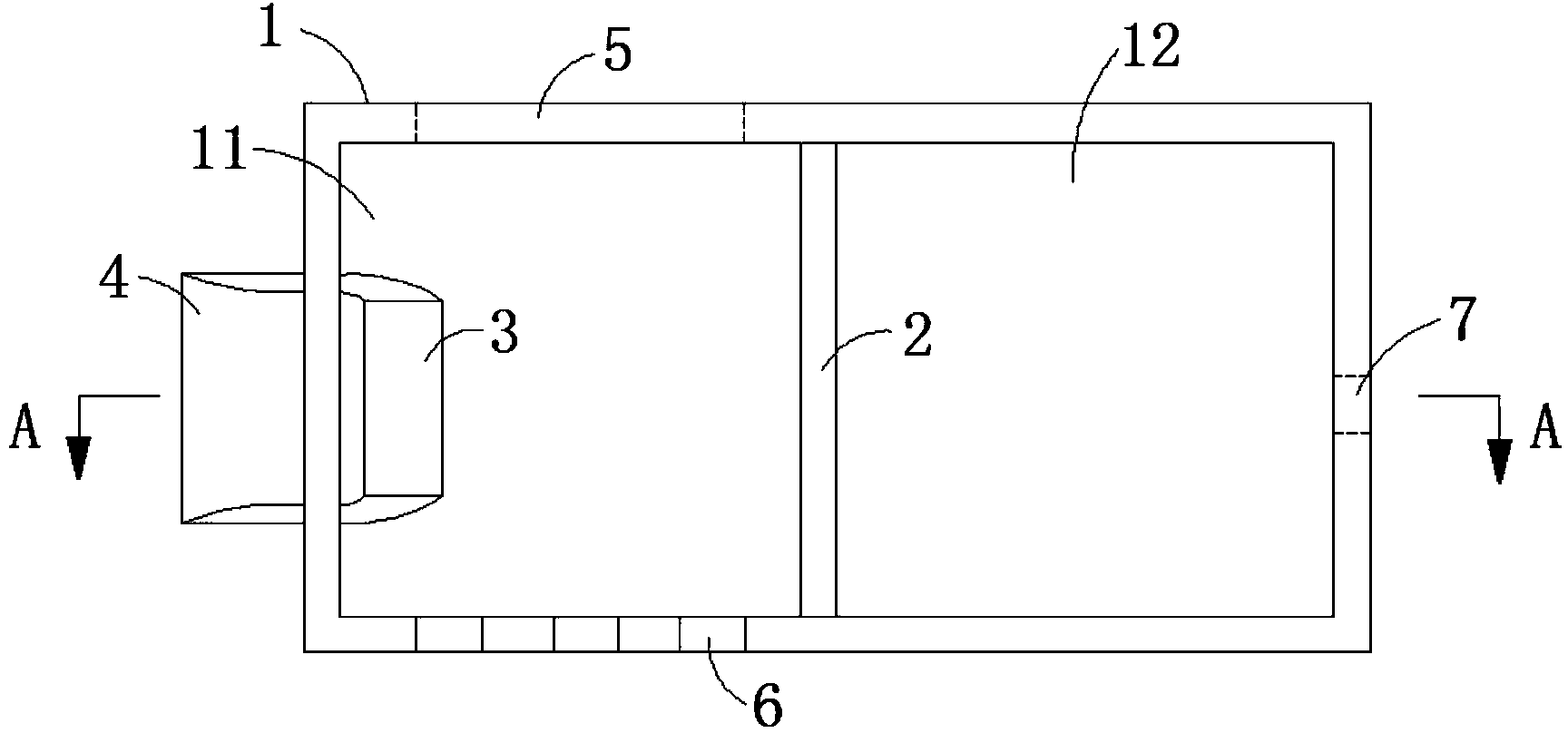

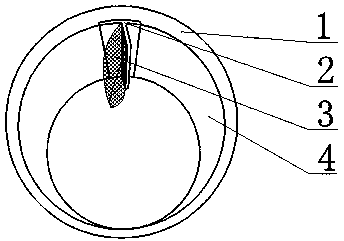

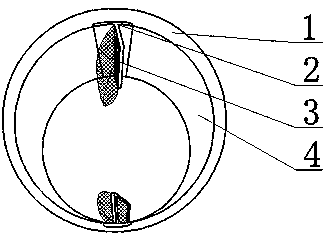

Slag conglomerating and skimming method and device

The invention relates to the field of molten iron pretreatment desulfurization processes, in particular to a slag conglomerating and skimming method and a device. The slag conglomerating and skimming method sets a traveling wave magnetic field; the phase of the magnetic field is controlled to enable the moving direction of molten iron driven by the traveling wave magnetic field to point to a ladle port; the traveling wave magnetic field enables the molten iron to flow to the ladle port under the effect of electromagnetic force, so that molten iron slag is conglomerated in the ladle port; and when the conglomerated molten iron slag is higher than the ladle port, the molten iron slag can overflow a ladle to enter a slag receiving tank so as to realize the ladle slag skimming. The slag conglomerating and skimming device comprises an electromagnetic winding and the slag receiving tank; the electromagnetic winding is arranged above the ladle; the magnetic force line of a magnetic field generated by the electromagnetic winding is pointed to an area of the ladle port; and the slag receiving tank is arranged below the ladle port. The slag conglomerating and skimming process is finished under non-contact conditions without generating the molten iron oscillation phenomenon; the molten iron nearly has no loss; the precise slag conglomerating and skimming operation is realized without polluting the molten iron; and the ton steel energy consumption can be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Scum dredger

InactiveCN102494544AAvoid bodily harmReduce the labor intensity of slag removalIncrustation removal devicesEngineeringMechanical equipment

The invention discloses a scum dredger, which comprises a machine frame, a power system and an execution system, wherein the power system and the execution system are arranged on the machine frame, and the machine frame is used for supporting the power system and the execution system; the execution system comprises a support arm and a scum dredging part for cleaning scum; the support arm is arranged on the machine frame in a mode of swinging up and down, is connected with the scum dredging part and is used for supporting the scum dredging part to drive the scum dredging part to move; the power system comprises an energy device for providing energy and a power device for driving the support arm to swing; the power device is connected with the energy device and the execution system; and the energy device provides energy for the power device, so that the support arm can swing up and down. By the structural design of the scum dredger, the scum can be dredged mechanically, so that the bodily injury of operators due to direct scum dredging is avoided. In addition, the scum is dredged by using the mechanical equipment, so that the labor intensity of the scum dredging of the operators is reduced, and the scum dredging efficiency is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

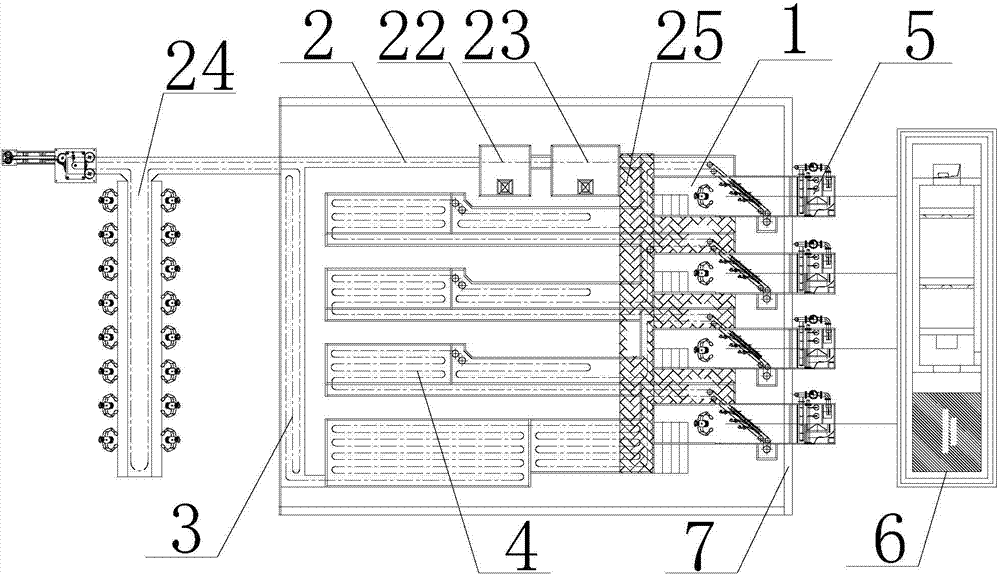

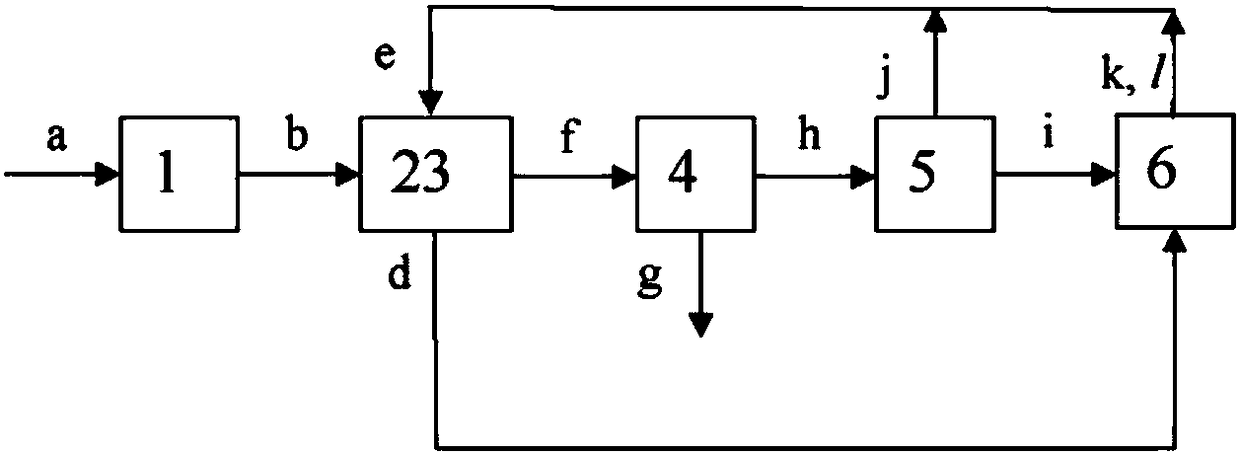

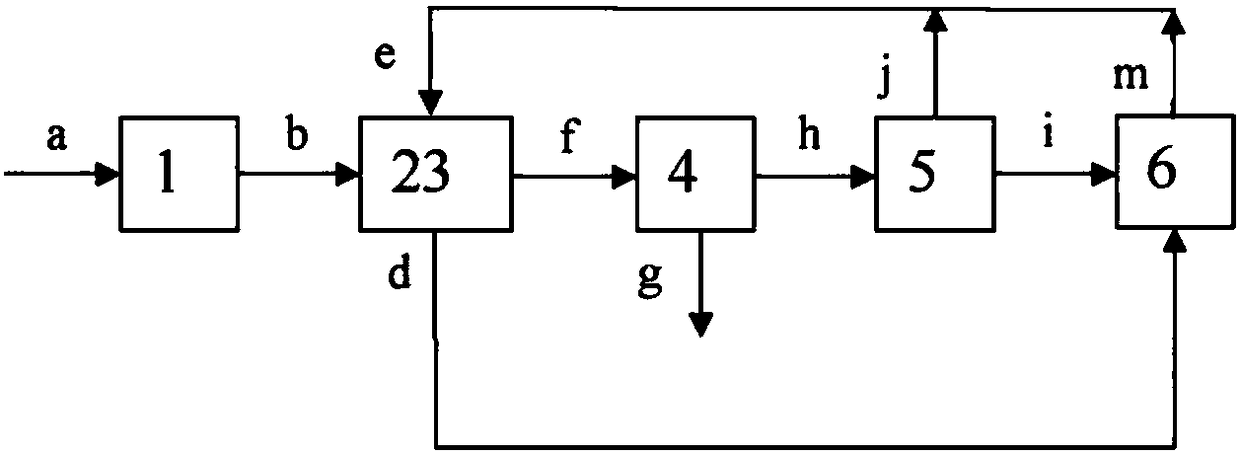

Continuous type coating production line

ActiveCN104492643AEasy to cleanImprove cleanlinessSpraying apparatusPretreated surfacesProduction lineTransmitted power

The invention discloses a continuous type coating production line, which comprises spray rooms, a conveying belt, a cooling section, drying rooms, water and gas supply and exhaust systems, a slag removal system and a human and material flow supply platform, wherein the spray rooms, the conveying belt, the cooling section and the drying rooms are arranged in a room, the water and air supply and exhaust systems and the slag removal system are arranged outside the room, the spray rooms are arranged near a partition, and are connected with the water and air supply and exhaust systems outside the partition, the water and air supply and exhaust systems convey waste water and waste gas to the slag removal system, the spray rooms and the drying rooms arranged in the room are connected in series to form a production line, the drying room at the final section is connected with the cooling section, a to-be-processed workpiece which is conveyed on the conveying belt sequentially passes through each spray room, each drying room and the cooling section, and the human and material flow supply platform is in charge of supplying coating for each spray room. The continuous type coating production line has the advantages that the spraying processing is separated form the slag removal treatment, the spray rooms are separated from the air and water supply and exhaust systems by the partition, the cleanliness and coating quality of the spray rooms are improved, the transmitting power consumption is decreased, and the treatment efficiency is improved.

Owner:SICHUAN LONGXIN TECH PACKING

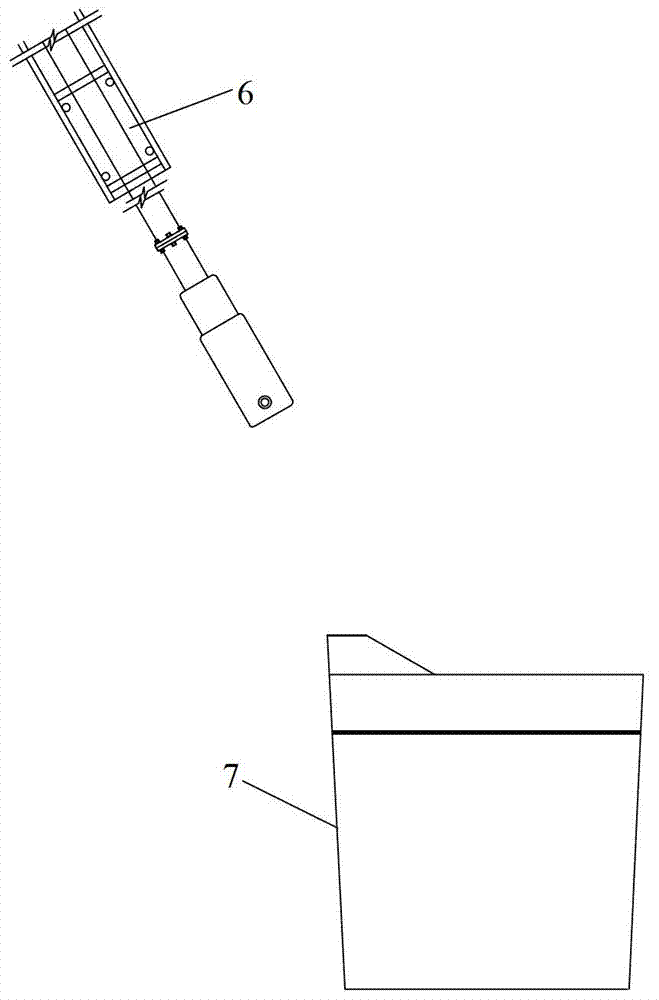

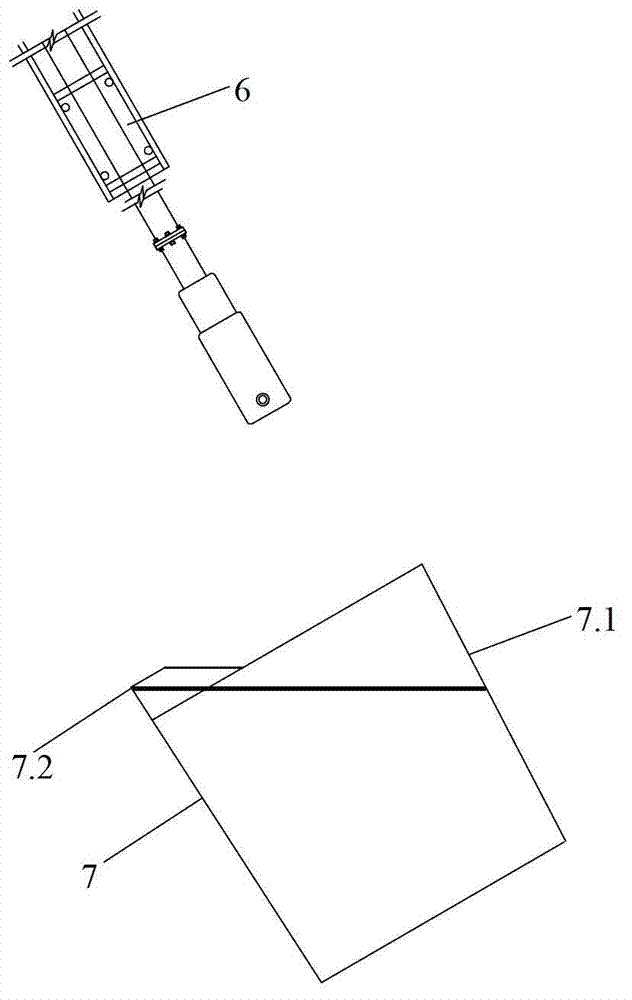

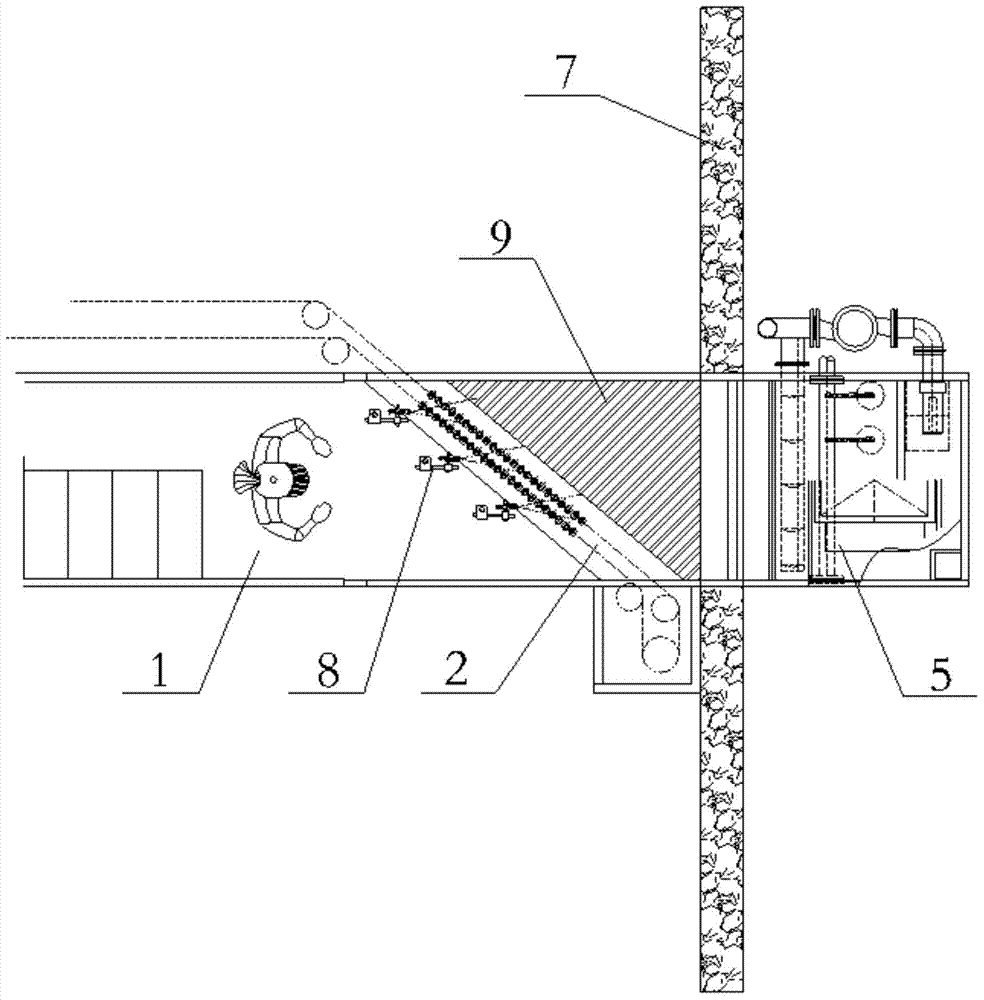

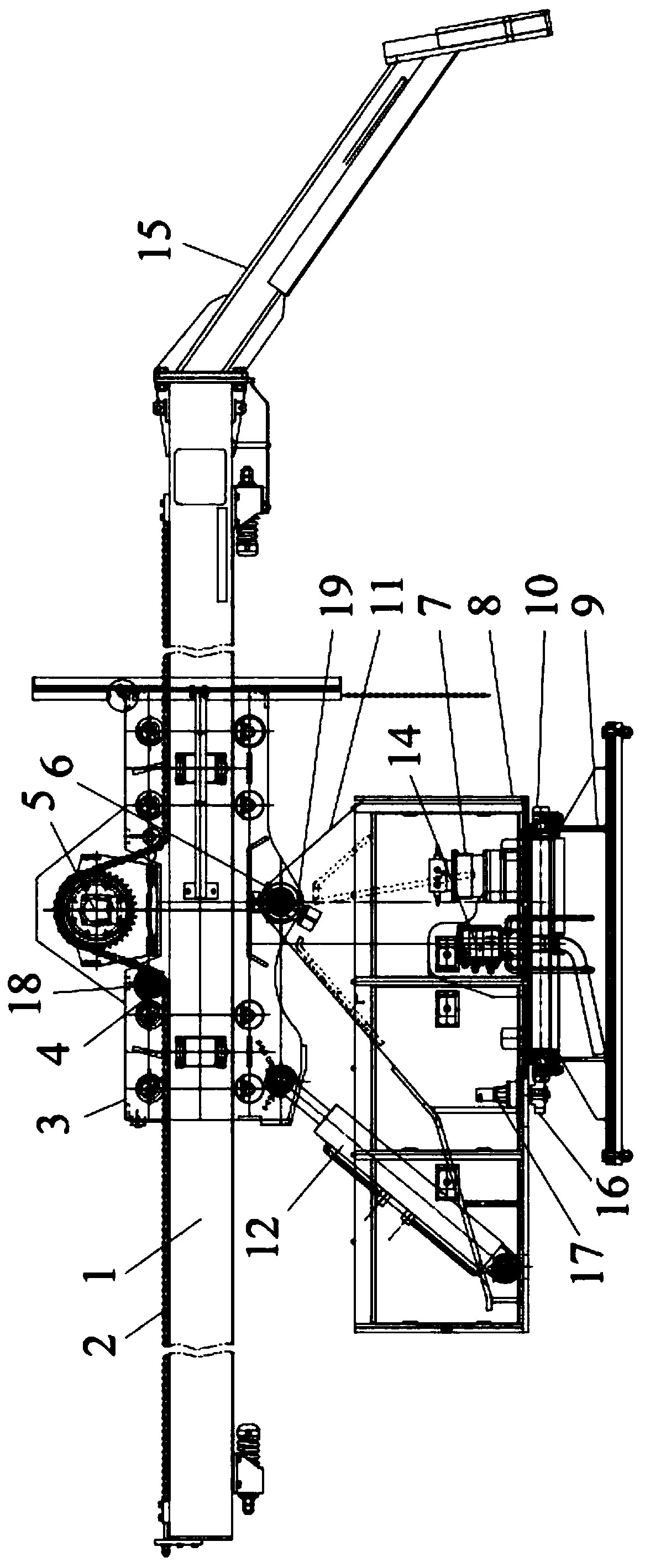

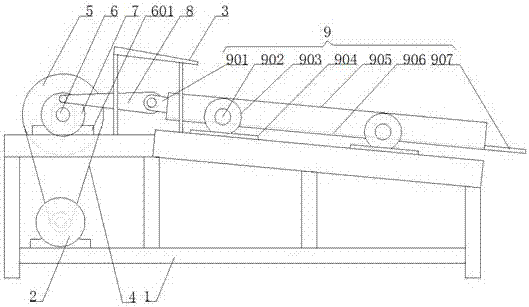

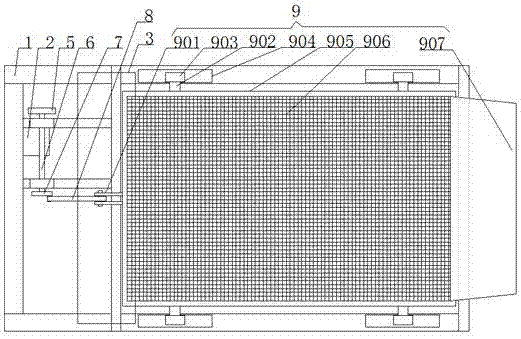

Slag blow-removal mechanism

ActiveCN104831013AAir blowing and slag removal area is largeImprove slag removal efficiencySlagEngineering

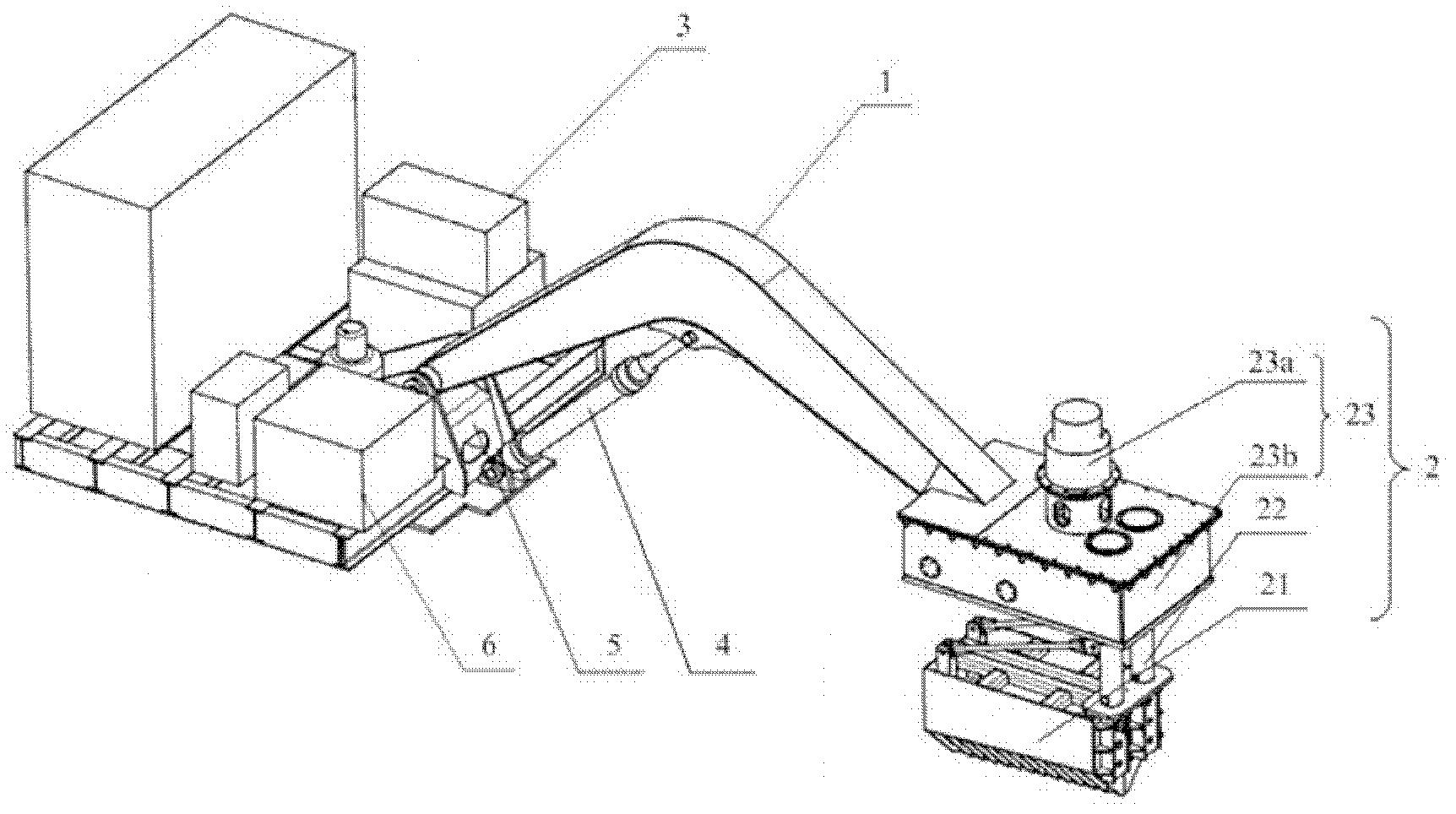

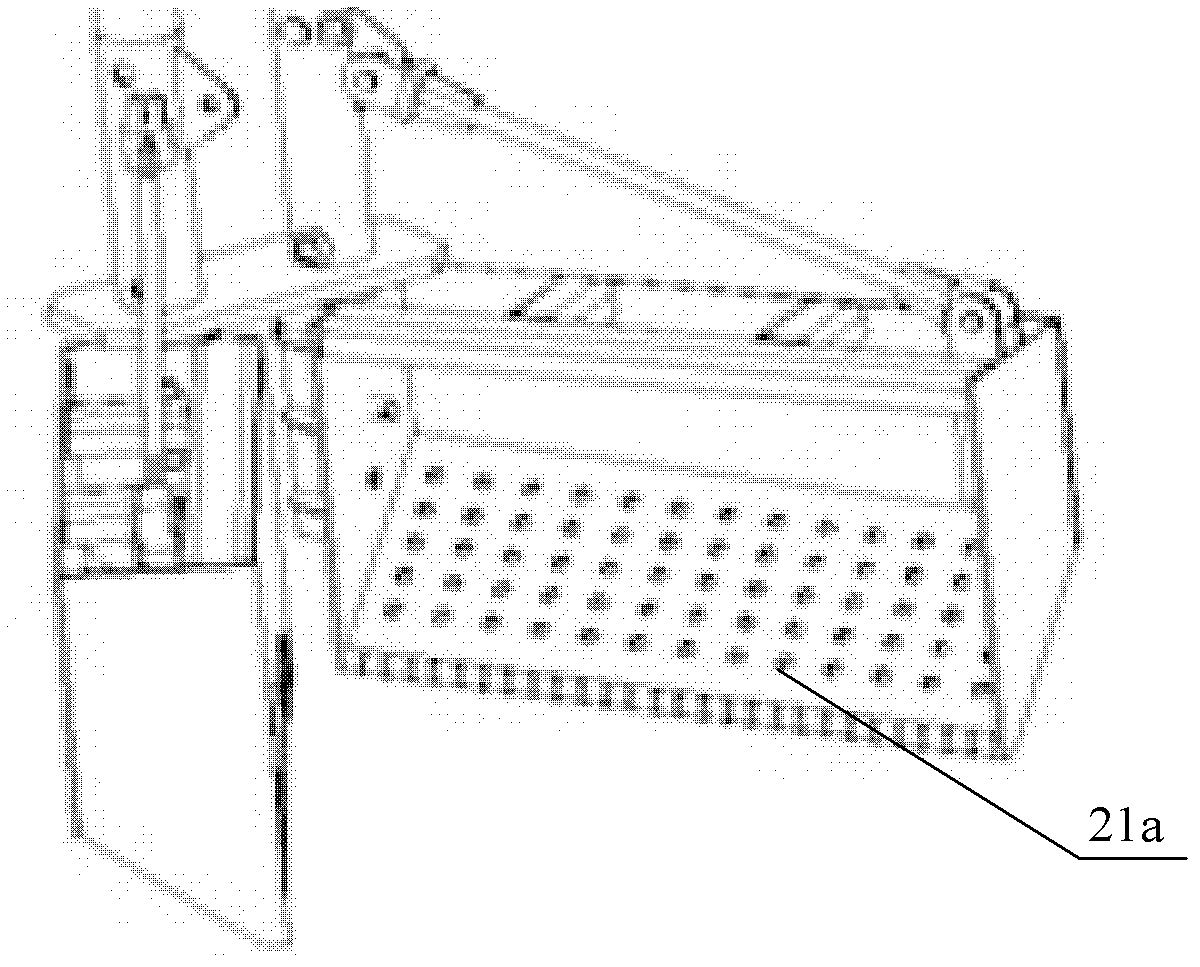

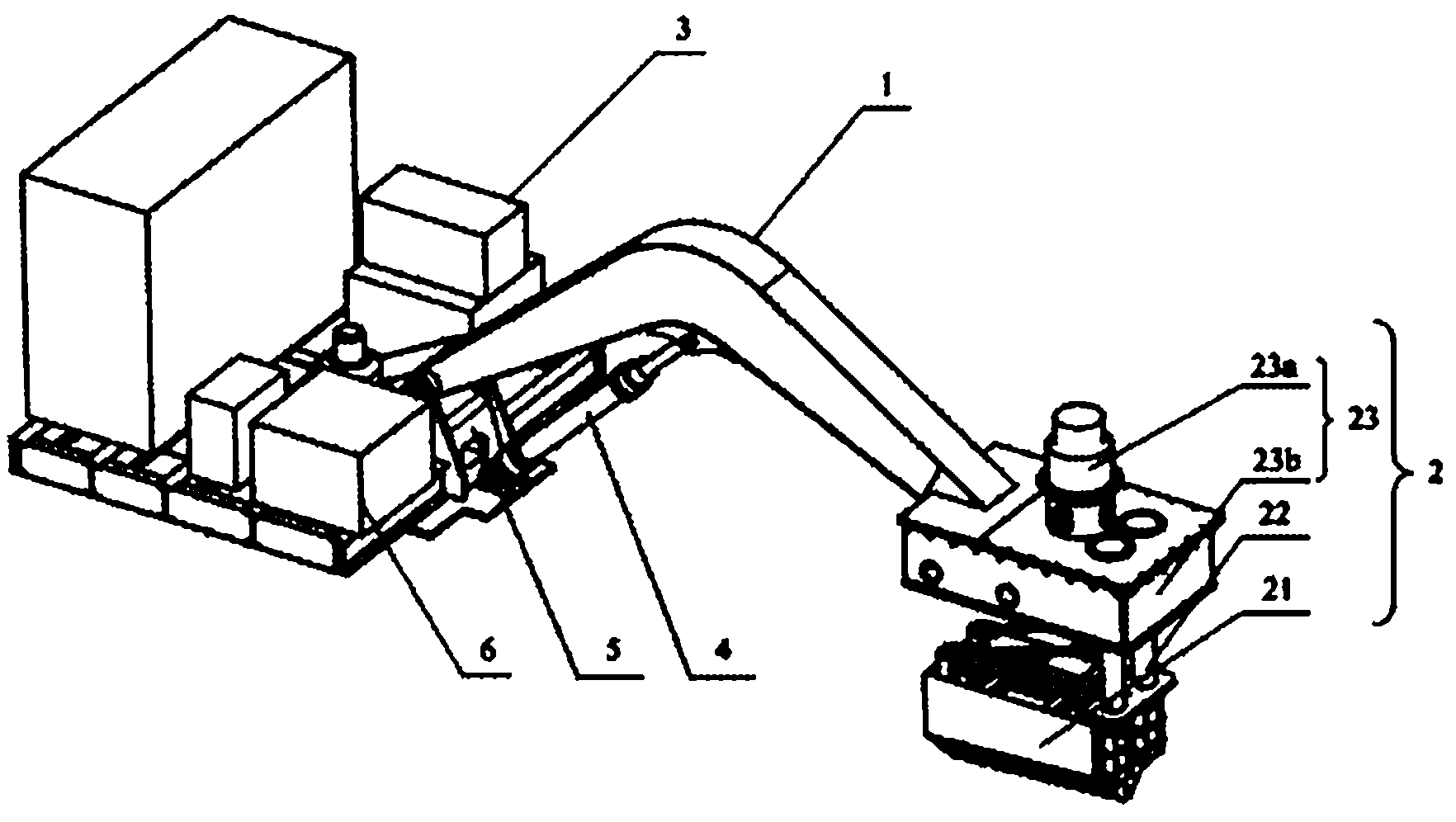

The invention provides a slag blow-removal mechanism comprising a guide rail frame, a lifting trolley, a slag blow-removal spray gun, a lifting transmission device, a tilting device and a hinging mechanism. The guide rail frame is obliquely arranged on the hinging mechanism; under the action of the tilting device, the guide rail frame can rock around a hinge pin of the hinging mechanism; the lifting trolley is slidably connected to the guide rail frame; the slag blow-removal spray gun is fixed to the lifting trolley, and the head of the slag blow-removal spray gun is located above the level of molten iron; the head of the slag blow-removal spray gun is a multi-nozzle arc pipe which is provided with a plurality of blow branch pipes arranged in an arc form; the lifting transmission device is disposed at the top of the guide rail frame and is used for driving the lifting trolley to slide up and down along the guide rail frame. The slag blow-removal mechanism has the advantages such that the mechanism is suitable for removing the slag under different heights of the molten iron and different tilting angles, the area of slag removal in same periods is large, the slag removal area is small, the efficiency is high, the operating time is short, many furnaces can be operated, the structure is simple, and maintenance is convenient.

Owner:CISDI ENG CO LTD

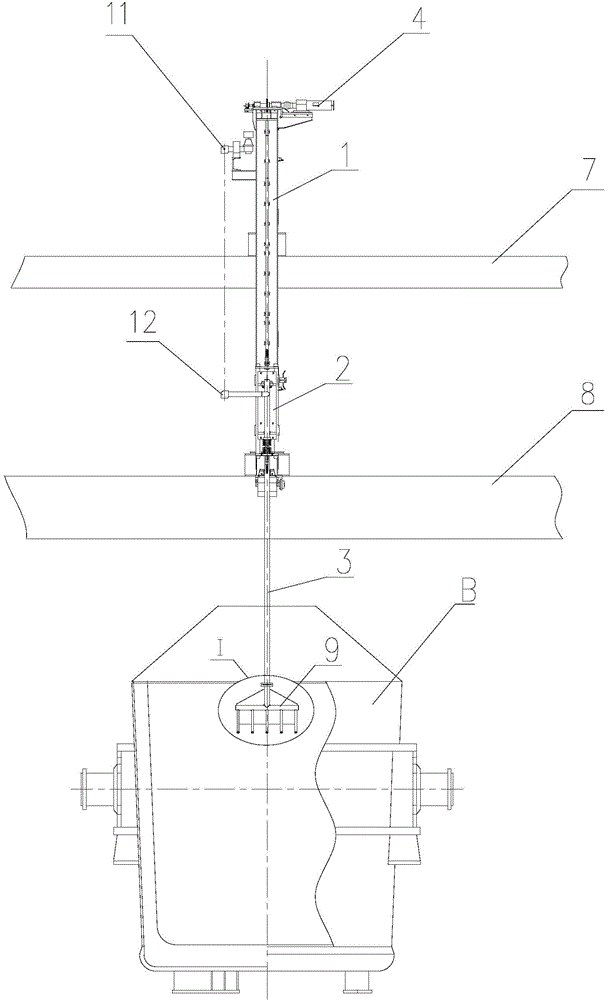

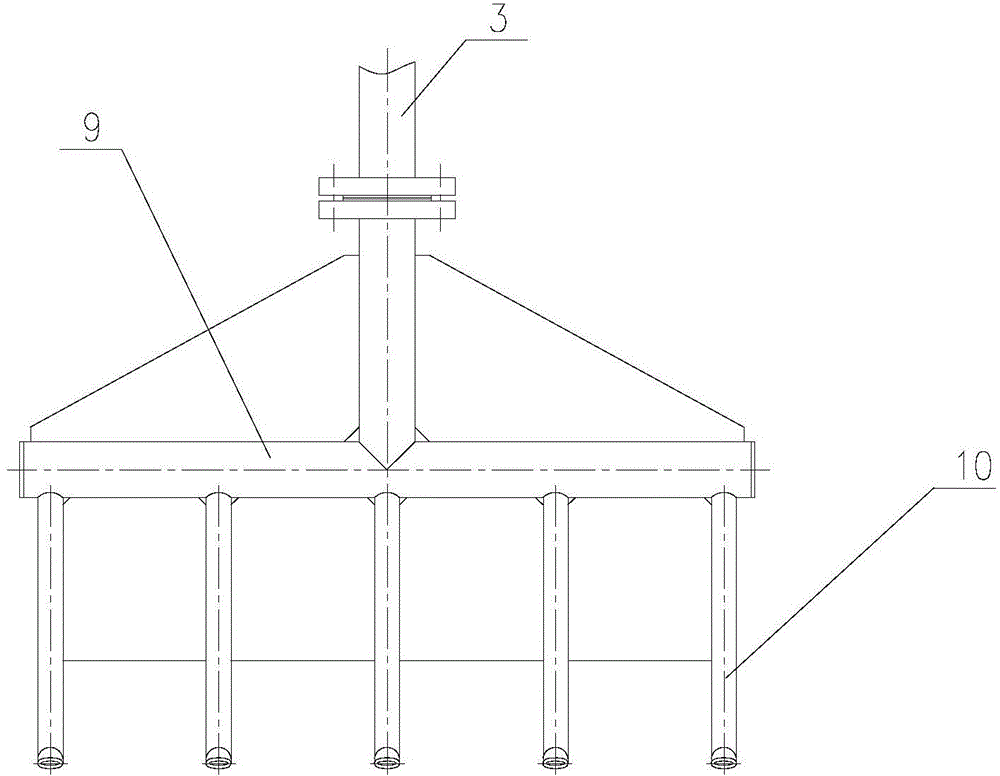

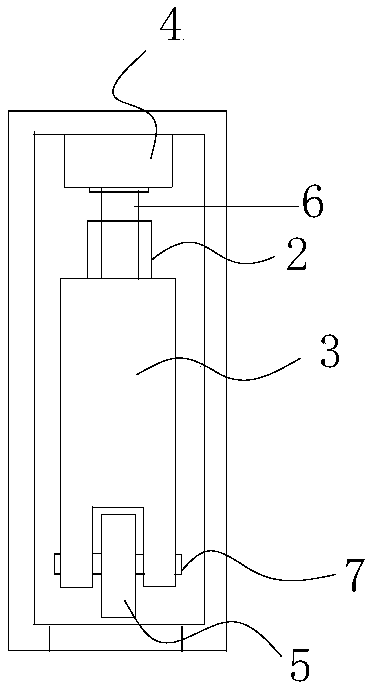

Liquid ironslag extractor

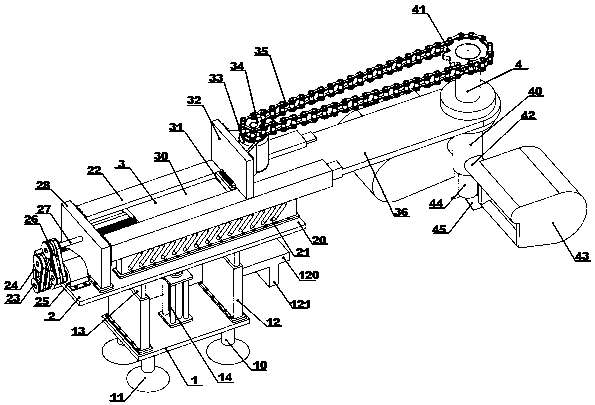

InactiveCN108085457ARealize automatic entry and exitFast and efficient automatic slag removal workCasting cleaning apparatusSlagLiquid iron

The invention belongs to the technical field of steel metallurgy, and provides a liquid iron slag extractor. The liquid iron slag extractor comprises a workbench, the workbench is provided with a movable base, and the movable base comprises a screw rod sleeve, a base body, a screw rod motor and a pulley; the liquid iron slag extractor further comprises a first motor fixed to a supporting base, a first conveying mechanism connected between the first motor and a turntable and a slide block base which is arranged on a slide rail and can slide along the slide rail; the liquid iron slag extractor further comprises a slag extracting arm, a slag extracting mechanism is arranged at the front end of a fishing arm, a horizontal rotary shaft arranged at the tail end of the fishing arm is rotatably connected with the slide block base, the slag extracting mechanism comprises a hanging frame, a slag extracting claw is connected to the lower portion of the hanging frame, the hanging frame is providedwith a hydraulic driving device driving the slag extracting claw to move, a second motor is fixed to the slide block base, and a second conveying mechanism is connected between the second motor and the rotary shaft. The liquid iron slag extractor is simple in structure, can effectively improve the slag extracting efficiency and achieve automated slag extracting.

Owner:柳州市金升汽车配件有限公司

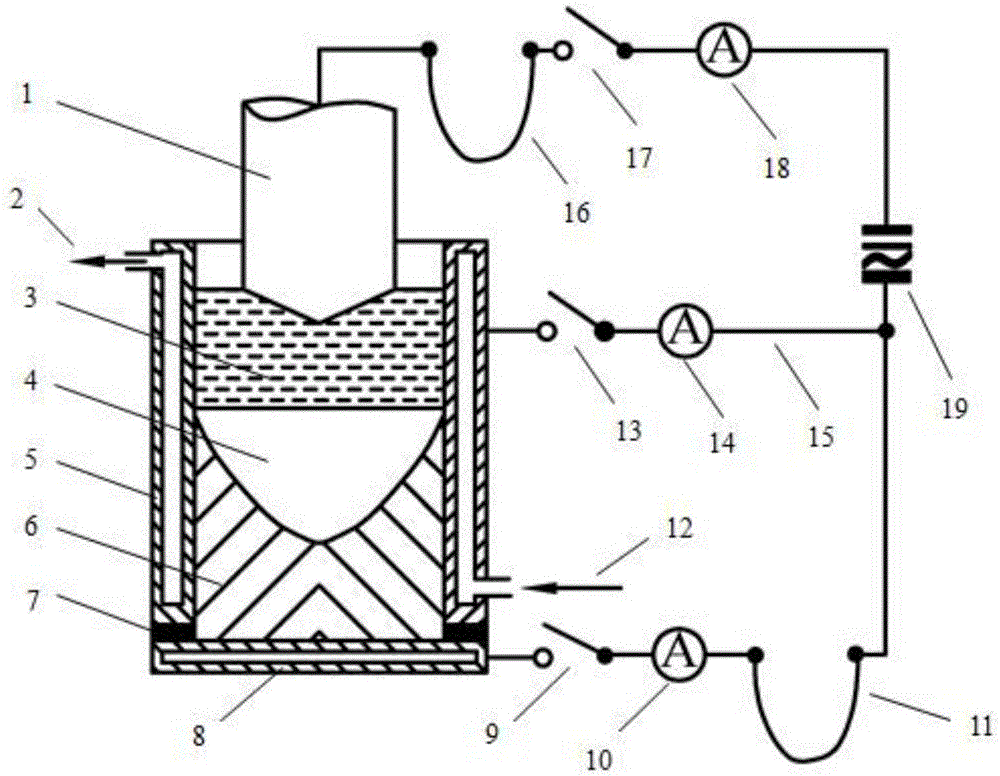

Method for controlling direction of solidification structure of cast ingot through electricity conductive crystallizer electroslag remelting

The invention discloses a method for controlling the direction of a solidification structure of a cast ingot through electricity conductive crystallizer electroslag remelting and belongs to the technical field of metallurgy. The method comprises the steps that (1) a slag material with the high conductivity is prepared and then baked; (2) the filling rate and the insertion depth of an electrode are determined, and a base wad, an arc striking agent and an electricity conductive crystallizer are right placed; and (3) a path of an electric current flowing through a power source, the consumable electrode, the slag material, a bottom water tank and the power source is selected, and arc striking, material charging and slag melting are conducted; after the slag material is melted down, a remelting electric current and the remelting voltage are set; the path of the electric current is set through closing of a switch in the electroslag remelting process, the distribution ratio of electric currents flowing through the crystallizer and the bottom water tank is controlled, the shape and the depth of a metallic molten pool are changed, and the direction of the solidification structure is controlled; and in the later period of remelting, electricity is cut off after electroslag remelting feeding operation, cooling is conducted, and the remelted cast ingot is obtained. According to the method for controlling the direction of the solidification structure of the cast ingot through electricity conductive crystallizer electroslag remelting, a slag system with the high conductivity distribution ratio is adopted, and the tendency of axial crystallization of the solidification structure of the cast ingot is improved; and the crystallization direction of the solidification structure of the cast ingot is controlled in the remelting process, and the prepared cast ingot has good surface quality.

Owner:NORTHEASTERN UNIV

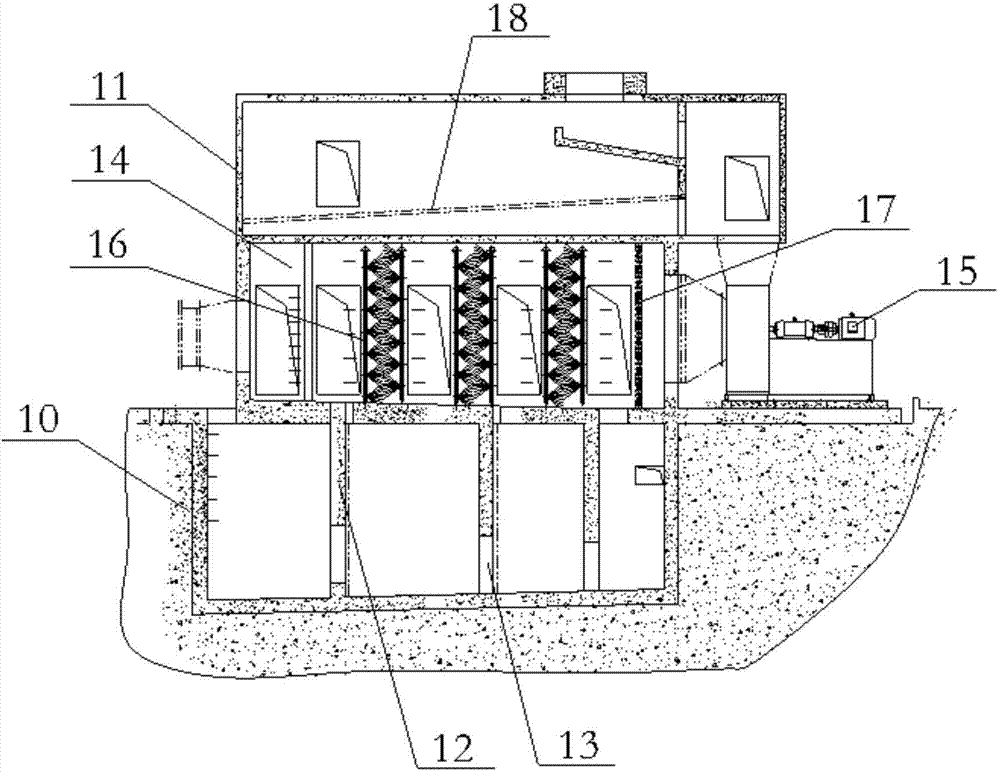

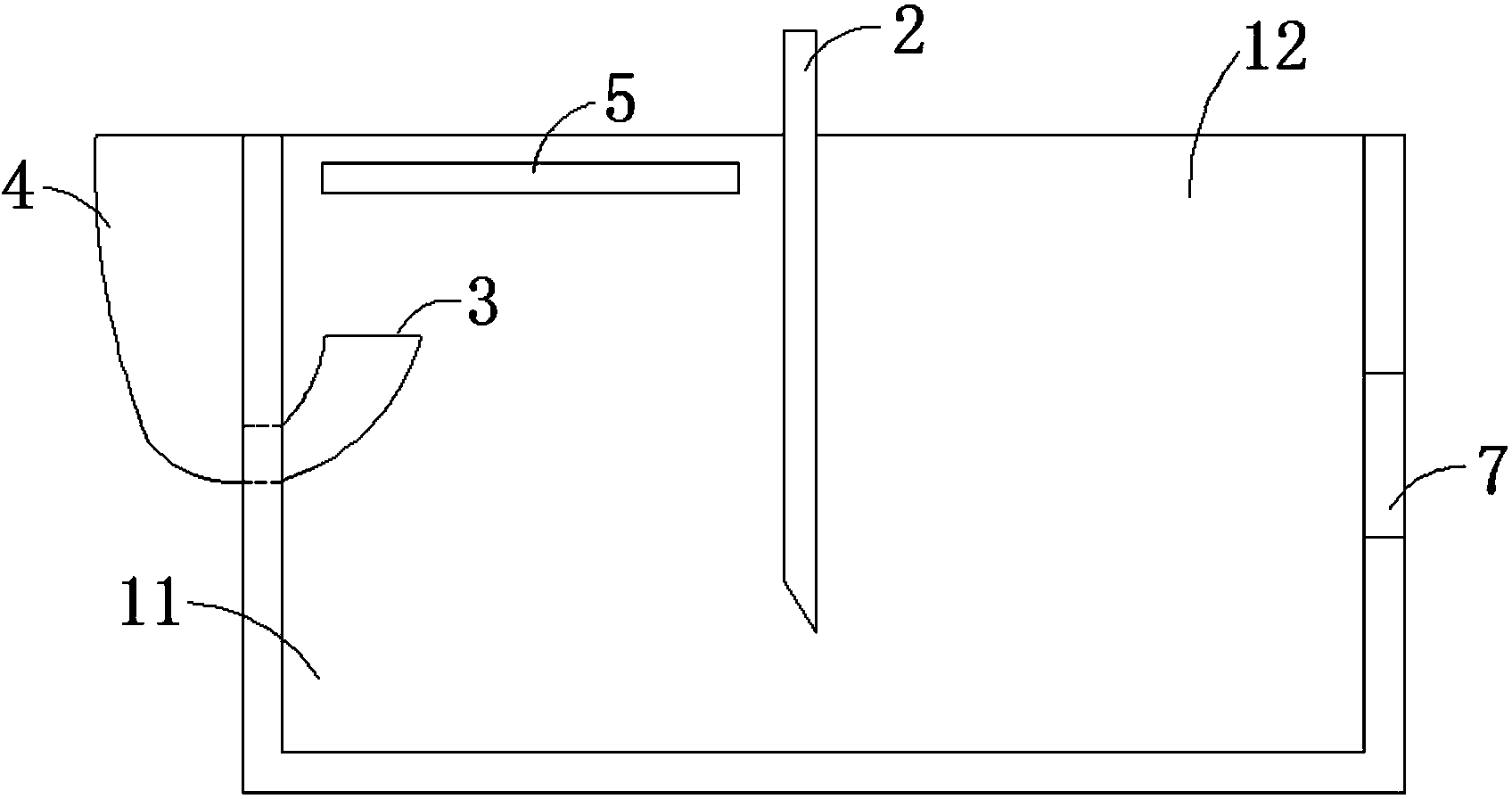

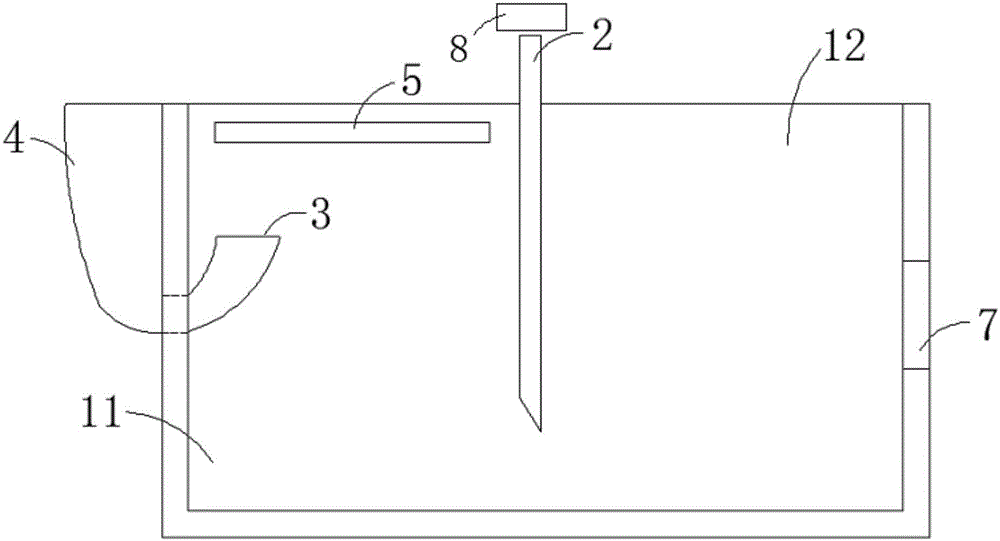

Smelting water receiving and residue filtering tank

ActiveCN104390467ASpeed up the outflowImprove outflow efficiencyCharge manipulationContinuous operationWaste management

The invention relates to a smelting water receiving and residue filtering tank. The smelting water receiving and residue filtering tank comprises a tank body, wherein the tank body is made of a refractory material and comprises a first branch tank and a second branch tank; a partition plate which can move in the vertical direction is arranged between the first branch tank and the second branch tank; a water inlet is formed in an inner side face of a side part of the first branch tank, and an opening of the water inlet faces upwards; a water receiving opening, corresponding to the water inlet, is formed in an outer side face of the side part of the first branch tank; the water receiving opening is communicated with the water inlet; a residue discharging opening is formed in one side part adjacent to the side part of the water receiving opening; at least one fan is arranged at the upper end of the other side part adjacent to the side part of the water receiving opening; a water drainage opening is formed in a side part of the second branch tank. Compared with the prior art, the smelting water receiving and residue filtering tank has the advantages that dross floats quickly, the residue removing efficiency is high and continuous operation can be realized.

Owner:XINGHUA GUANGFU METAL PROD

Device capable of removing surface material residues on surface of new material panel

InactiveCN109909205AGuaranteed slag removal effectMeet processing needsCleaning using toolsBiochemical engineeringNew materials

A device capable of removing surface material residues on the surface of a new material panel comprises a bottom plate, a clamping device located above the bottom plate, a lifting plate device arranged on the clamping device, an electric cylinder device arranged on the bottom plate, a drive device arranged on the clamping device, a first scraping device arranged on the drive device, a piston device arranged on the first scraping device, and a second scraping device arranged on the clamping device. By means of the device, efficient scraping treatment can be conducted on impurities on the uppersurface and the lower surface of the new material panel at the same time, the residue removal efficiency is high, operation is simple, usage is convenient, meanwhile, the automation degree is high, the labor intensity of manual work is low, and usage is convenient; and meanwhile, in the residue removal process, the new material panel can be stably fixed, accordingly, the new material panel residueremoval effect can be guaranteed, and the new material panel machining requirement is met.

Owner:深圳市中科智诚科技有限公司

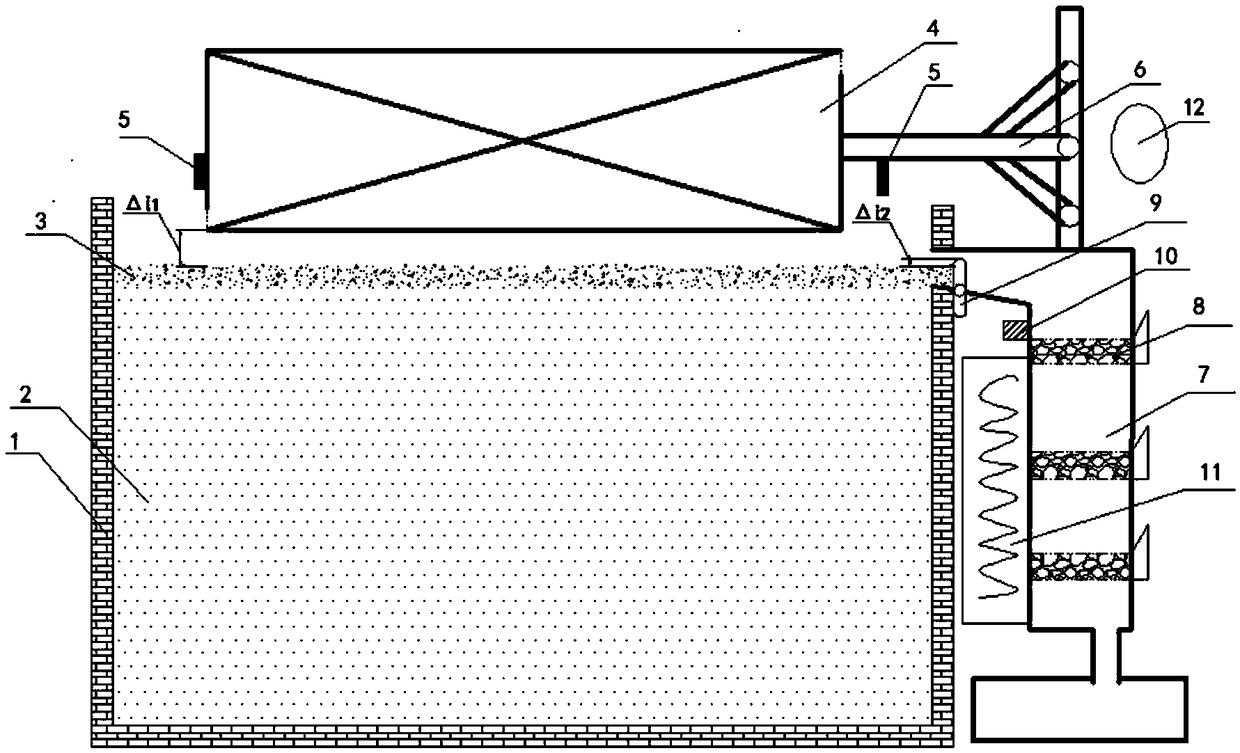

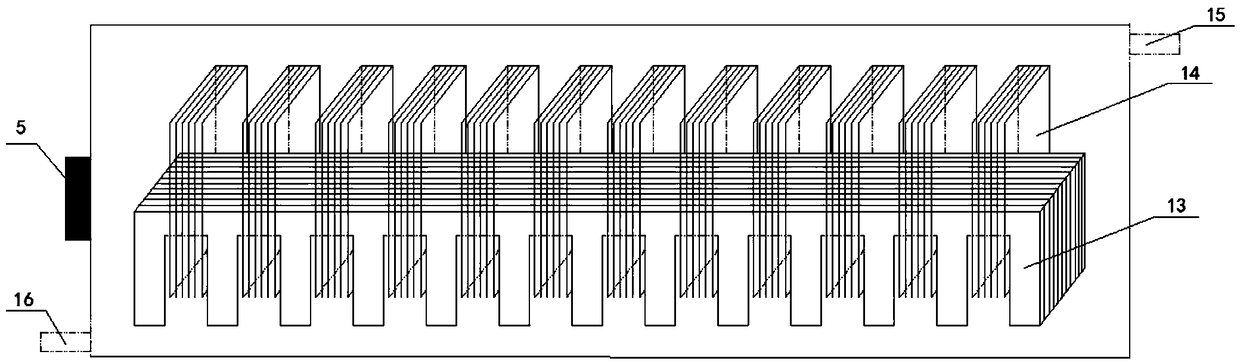

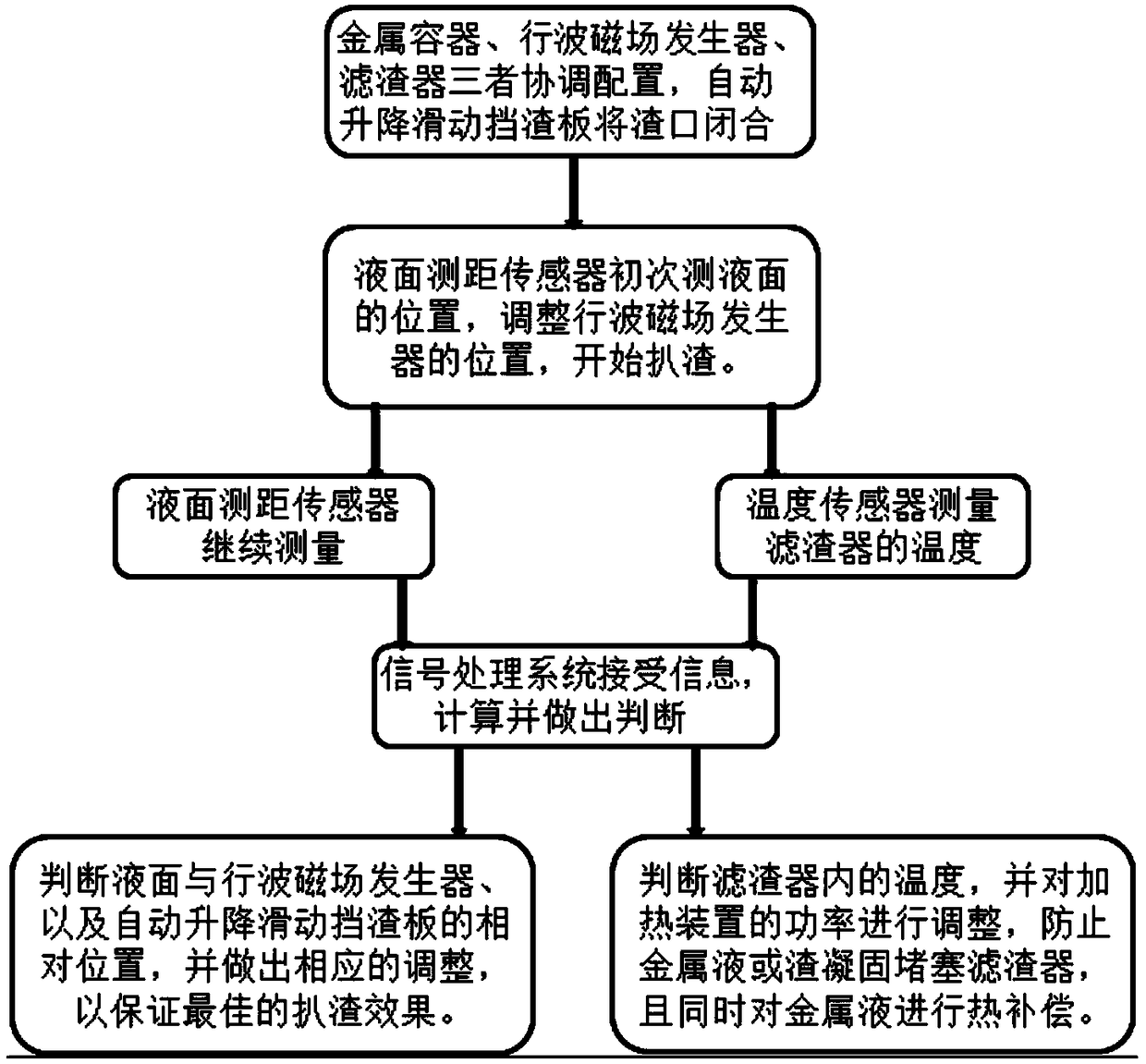

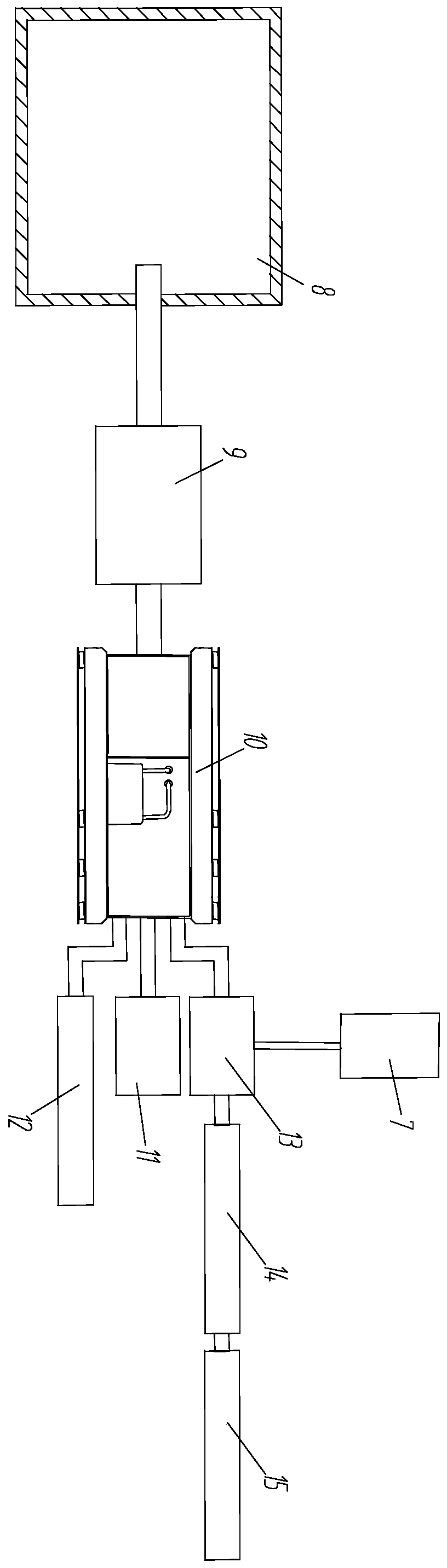

Non-contact metal liquid surface slag layer electromagnetic automatic treatment device and method

ActiveCN109440038AHigh slag removal efficiencyProcessing can be timelyHot-dipping/immersion processesProcess efficiency improvementPower flowSlag

The invention provides a non-contact metal liquid surface slag layer electromagnetic automatic treatment device and method. A traveling wave magnetic field generator is placed above a metal liquid surface slag layer, does not make contact with the metal liquid surface slag layer, and generates a traveling wave magnetic field by introducing an alternating current to interact with metal liquid to generate electromagnetic force, the electromagnetic force pushes the metal liquid to move towards a slag opening, the flowing metal liquid drives the slag layer through the effect of shearing force to enter a slag filter through an automatic lifting sliding baffle at the slag opening, floating slag with the small amount of metal liquid flows through a slag filtering layer to be filtered out, the metal liquid flows to the lower part of the slag filter for recycle. According to the non-contact metal liquid surface slag layer electromagnetic automatic treatment method, the positions of the traveling wave magnetic field generator and an automatic lifting slag baffle are adjusted in real time so as to achieve the optimal slagging-off effect, the power of a heating device is adjusted in real timeto heat the slag filter, thus the metal liquid or the slag are prevented from being solidified to plug the slag filter, and liquid metal in a container is subjected to heat compensation. The non-contact metal liquid surface slag layer electromagnetic automatic treatment device is high in slagging-off efficiency, can treat the slag in real time and recycle the metal liquid in time, and a process iseasy to operate and easy to popularize.

Owner:SHANGHAI UNIV +1

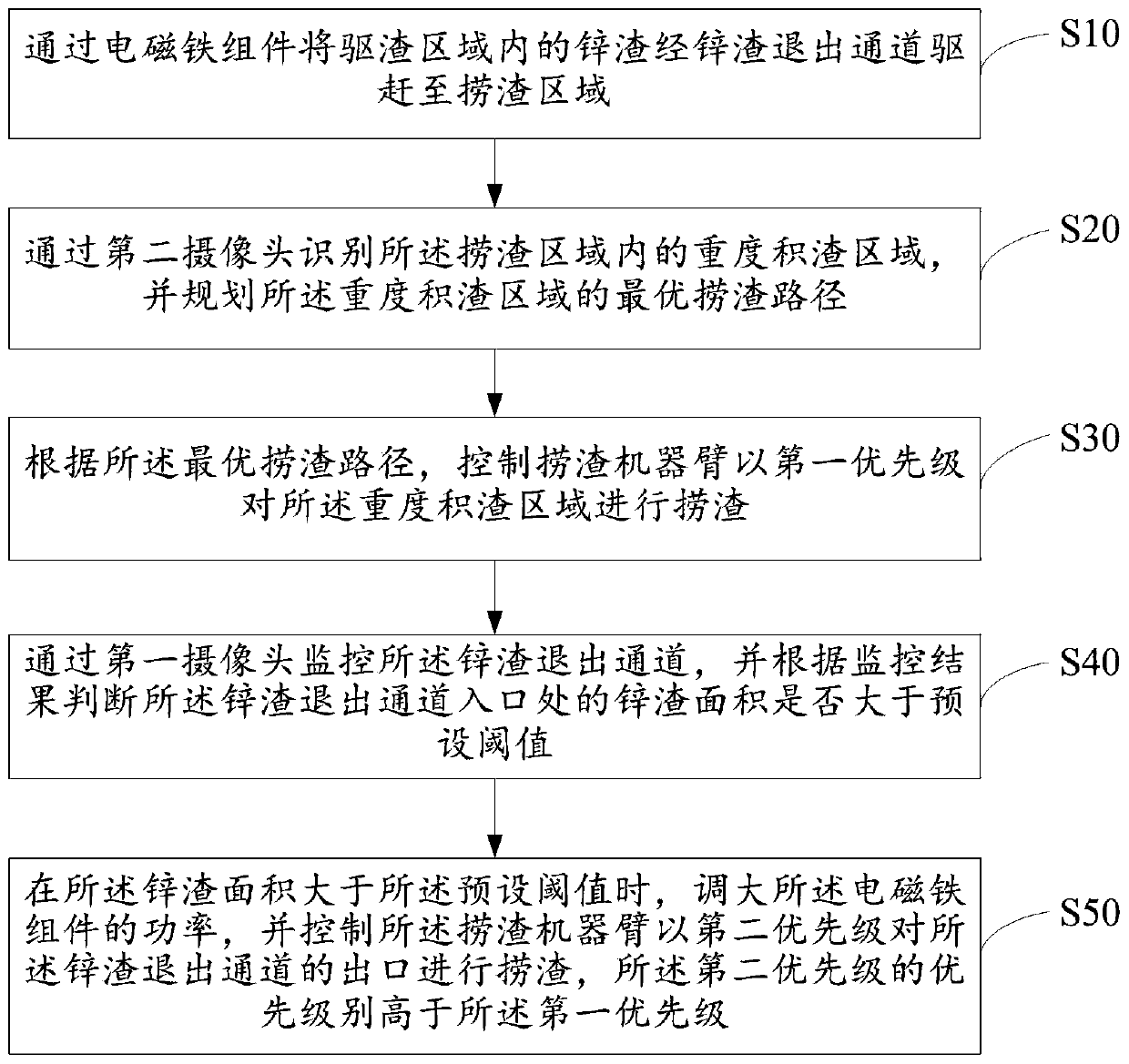

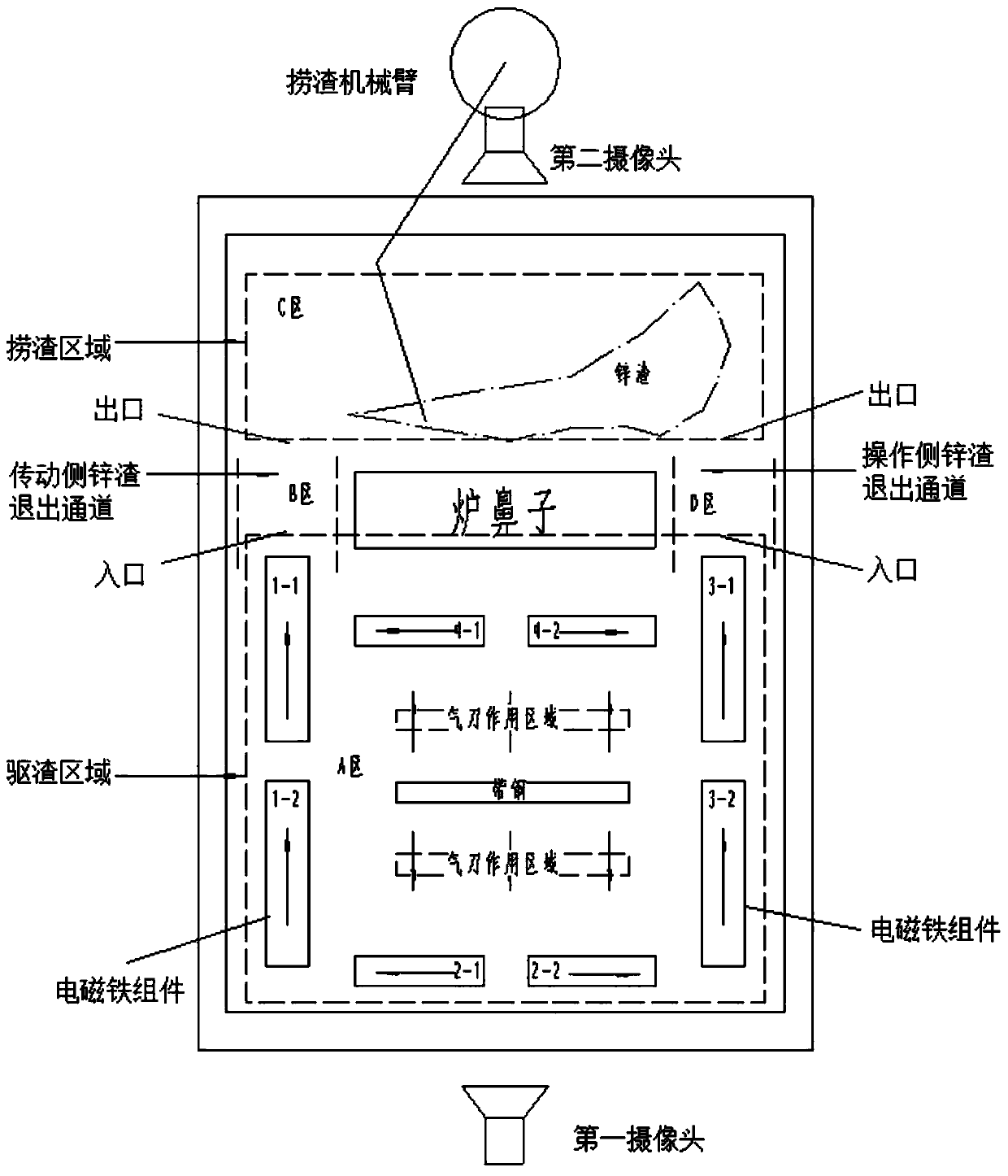

Intelligent collaborative deslagging method and system for zinc pot

ActiveCN111394671AAvoid cloggingImprove surface qualityHot-dipping/immersion processesMetallurgySlag

The invention relates to the technical field of hot galvanizing, in particular to an intelligent collaborative deslagging method and system for a zinc pot. The method comprises the following steps ofdriving zinc slag in a slag driving area to a slag salvaging area through a zinc slag exiting channel through an electromagnet assembly; controlling a slag salvaging mechanical arm to salvage slag ina severe slag accumulation area in the slag salvaging area according to the optimal slag salvaging path; and when the inlet of the zinc slag exiting channel is likely to be blocked, increasing the power of the electromagnet assembly, and controlling the slag salvaging mechanical arm to salvage slag at the outlet of the zinc slag exiting channel. The method has the beneficial effect that when the inlet of the zinc slag exit channel is likely to be blocked, a slag removal system and a slag salvaging system are cooperated, and on the basis that the inlet of the zinc slag exit channel is dredged through increasing the power of the electromagnet assembly, the outlet of the zinc slag exiting channel is cleaned with a higher second priority in combination with the slag salvaging mechanical arm, so that the cooperativity between the slag removal and salvaging systems is improved, the slag removing efficiency is improved, and the zinc slag exiting channel is prevented from being blocked.

Owner:武汉钢铁有限公司

Kitchen waste treatment device and treatment method

InactiveCN110303029AQuality improvementProcessing speedSolid waste disposalWater filterWater storage tank

The invention discloses a kitchen waste treatment device and a treatment method. The treatment device comprises a discharging bin, a water filtering screw or a water filtering auger, a belt conveyor,a slag remover, a feeding screw, a pulverizer, a dehydrator, a water storage tank, a water pump, a sedimentation centrifuge, an oil tank, a sewage treatment line, a fermentation tank, an organic fertilizer production line and a quantitative packaging system. On the same time, the invention provides a kitchen waste treatment method. The treatment method comprises the following steps including discharging; conveying and water filtering; sorting; slag removing; pulverizing; dehydrating; degerming; sewage treatment; fermentation; organic fertilizer production; and packaging. Compared with the prior art, the kitchen waste treatment device and the treatment method have the beneficial effects that the kitchen waste treatment speed is increased, and the organic fertilizer yield is increased.

Owner:陕西天仁雪农业科技有限公司

Zinc alloy and manufacturing method thereof

The invention discloses a zinc alloy and a manufacturing method thereof. The zinc alloy comprises the following elements: 4-7% of Al, 0.5-1.5% of Cu, 0.4-0.7% of Ti, 0.07-0.1% of B, 0.02-0.025% of Mg,0.1-1% of others, and the balance Zn. The method comprises the following steps: (1) pure aluminum is heated to a molten state, and is sprayed on the inner surface of a crucible; and a filter structure is fixed on the side surface of the inner surface; (2) zinc alloy raw materials are put in the crucible, and are vacuumized and heated until the raw materials are totally molten to obtain a molten pool; (3) a graphite stirring device is started; and a refining agent is continuously added to obtain a purified molten pool; (4) the purified molten pool is modified, and is cast and molded by a cooling extrusion process to obtain a zinc alloy ingot to be treated; and (5) the zinc alloy ingot to be treated is subjected to spheroidizing annealing to obtain the needed zinc alloy. The zinc alloy is high in purity, low in large-size dendritic segregation, uniform in overall grain size refining and low in primary structure multiple eutectic dendritic crystals.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

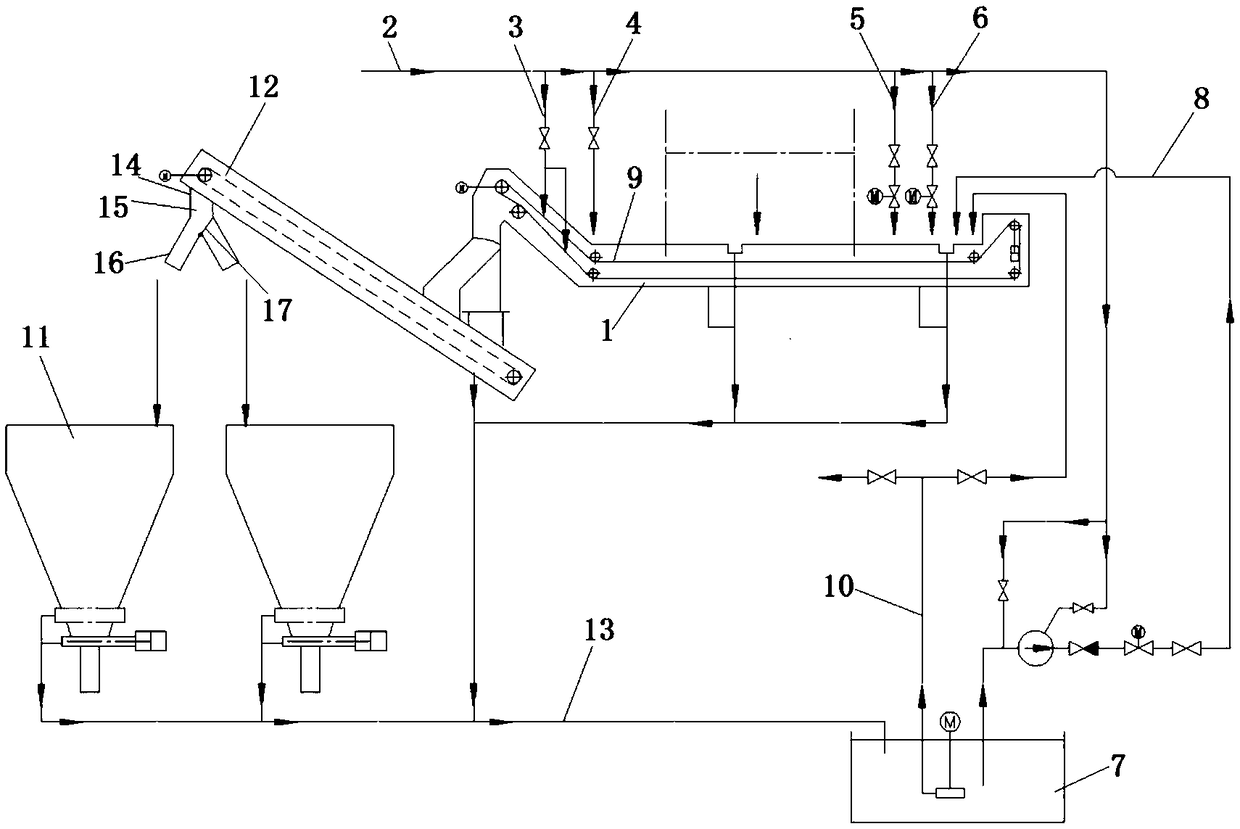

Slag dredging machine

ActiveCN108954356AImprove precipitation effectGuaranteed uptimeLighting and heating apparatusSlagSewage

The invention relates to the field of slag dredging machines, and discloses a slag dredging machine. The slag dredging machine comprises a slag dredging pool (1), a main water supply pipeline (2) provided with a chain flushing water pipeline (3), a manual door continuous water supply pipeline (4), an electric door water supply pipeline (5) and an electric door emergency water supply pipeline (6),a water collecting pool (7), and a slag dredging machine emergency water supply pipeline (8); and along with lowering of the liquid level of the slag dredging pool (1), the electric door water supplypipeline (5), the electric door emergency water supply pipeline (6) and the slag dredging machine emergency water supply pipeline (8) are opened in sequence. In the slag dredging machine, a concentrator, a concentrator sewage pump, a dedusting water pump and a slag water medicine charging system are canceled; the slag dredging pool is basically not disturbed by the external, so that the precipitation effect is better; and the water collecting pool only receives less water without easily generating blockage, so that the slag dredging machine is reliably operated, and the slag dredging efficiency is improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

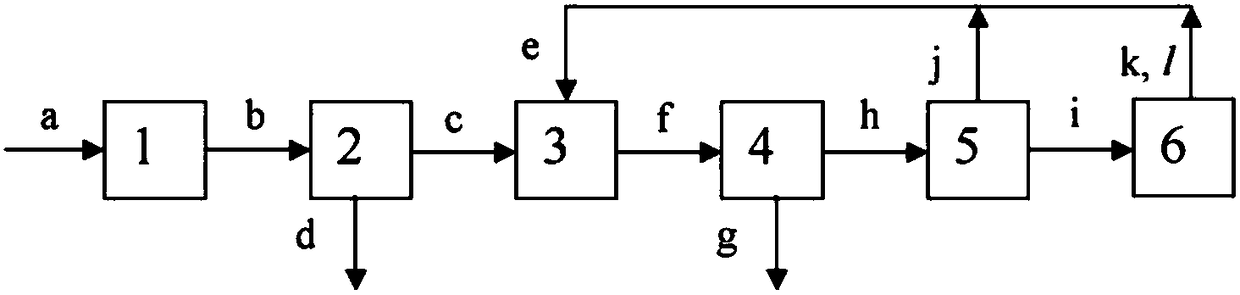

Method and system for treating slag-containing coal tar

ActiveCN108342212AEfficient removalIncrease profitCoke ovensTar working-up by distillationSlagPhenol

The present invention provides a method and a system for treating slag-containing coal tar. The method and the system relate to destructive distillation pyrolysis, oil and gas cooling, detergent dilution, centrifugation, reduced pressure flash evaporation, delayed coking, and preferably also relate to phenol oil extraction, water soluble fertilizer production, hydrogen production, and / or diesel hydrogenation. The method and the system can efficiently remove mechanical impurities in the coal tar, improve the quality of delayed coking products, fully utilize by-products, greatly reduce the costand improve the utilization rate of the coal tar.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

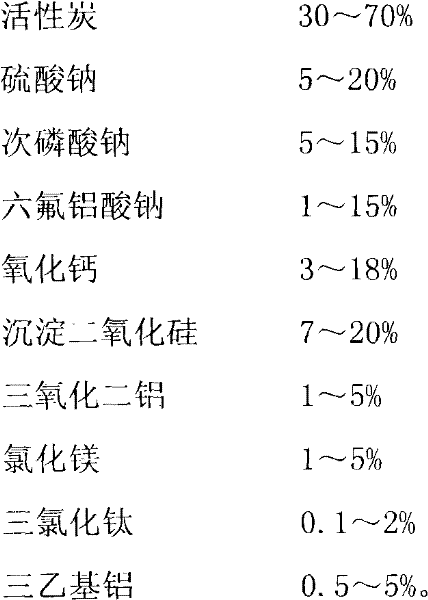

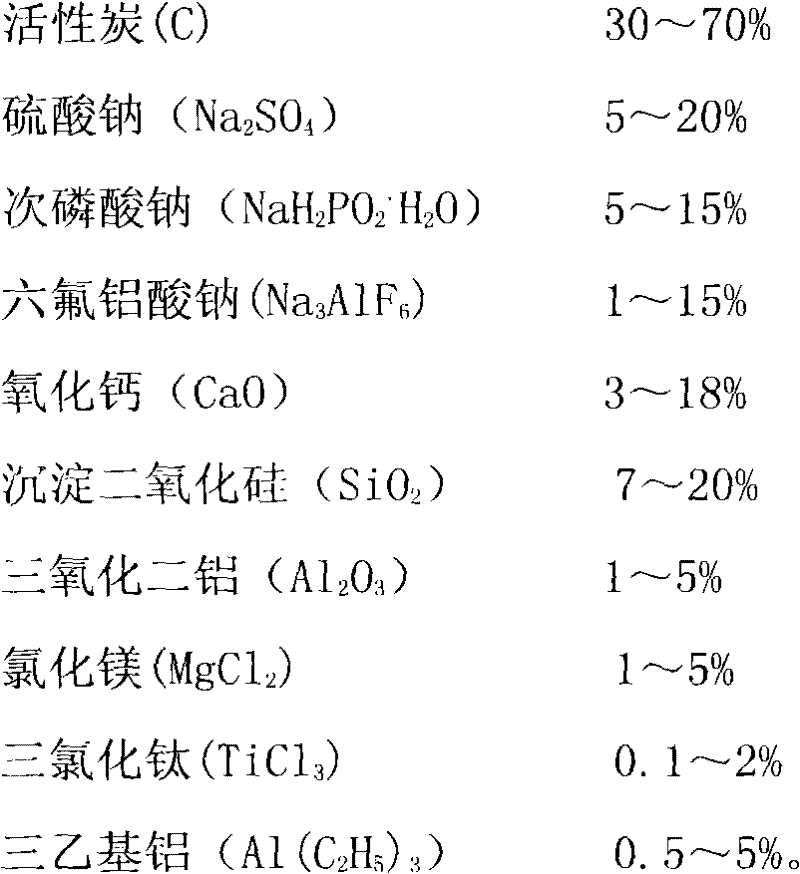

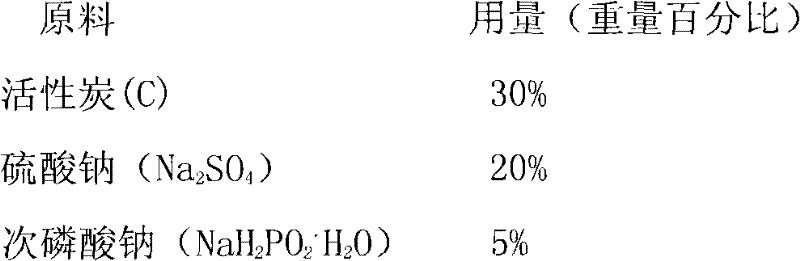

Lead residue reducing agent and preparation method thereof

The invention discloses a lead residue reducing agent and a preparation method thereof and belongs to the technical field of chemical industry. The lead residue reducing agent comprises the following components in percentage by weight: 30 to 70 percent of active carbon, 5 to 20 percent of sodium sulfate, 5 to 15 percent of sodium hypophosphite, 1 to 15 percent of sodium hexafluoroaluminate, 3 to 18 percent of calcium oxide, 7 to 20 percent of precipitated silica, 1 to 5 percent of aluminium oxide, 1 to 5 percent of magnesium chloride, 0.1 to 2 percent of titanium trichloride and 0.5 to 5 percent of triethyl aluminum. The lead residue reducing agent can directly reduce oxide-state scum produced during alloy preparation of lead, calcium, tin and aluminum alloys and casting of grids of storage batteries into metal-state residue, so the residue amount of the lead, calcium, tin and aluminum alloys is reduced obviously. When the agent is used, the lead residue produced during the preparation of the lead, calcium, tin and aluminum alloys and the casting of grids can be directly reduced into molten metals of lead, calcium, tin and aluminum to flow back to an alloy pot, so the lead residueis reduced while the lead, calcium, tin and aluminum in the designated alloys are hardly lost; and thus, the effective ingredients of the grid alloys of the storage batteries are ensured.

Owner:XIANGXIANGSHI YOUHAO METALLURGICAL MATERIAL

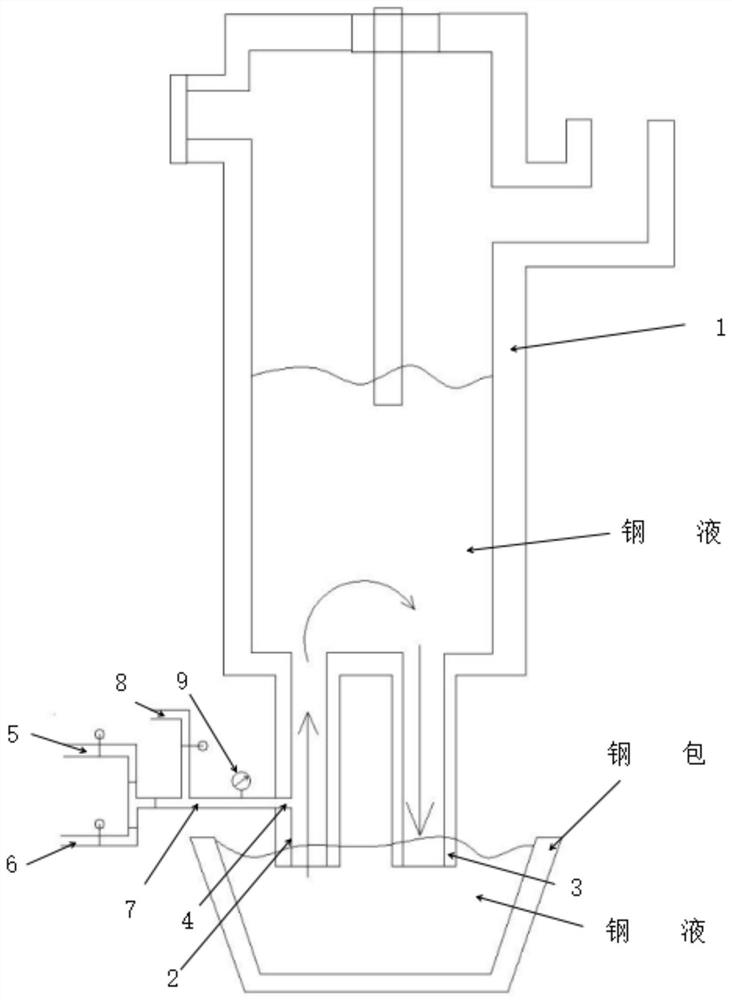

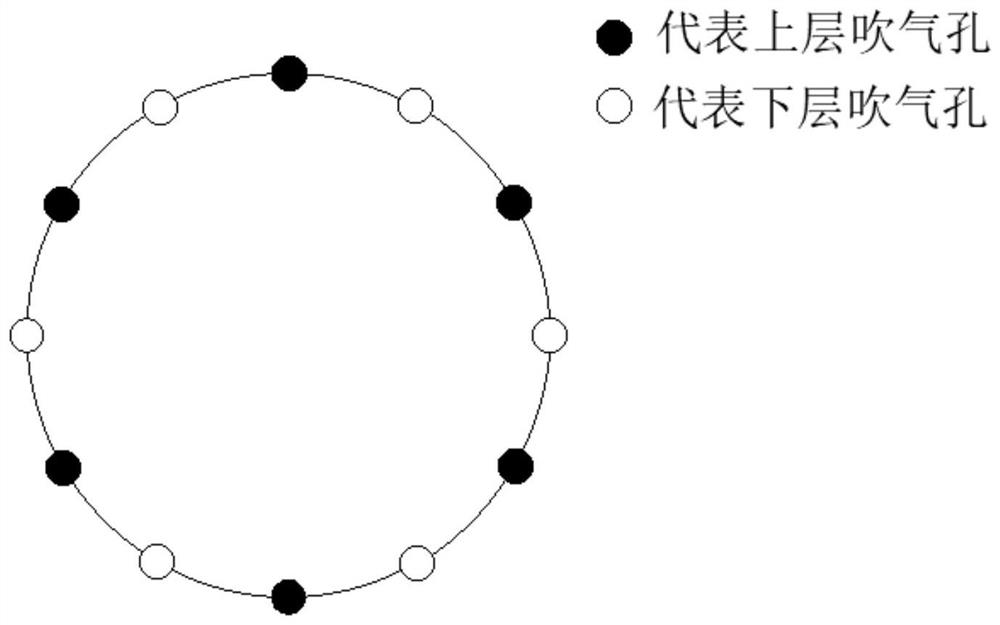

Anti-blocking device for blow hole of dip tube of RH furnace and method for removing steel slag from blow hole

PendingCN112877507AExtended service lifeEnsure circulation efficiencyProcess efficiency improvementFerrous metallurgyEngineering

The invention belongs to the field of ferrous metallurgy steelmaking, and particularly relates to an anti-blocking device for a blow hole of a dip tube of a RH furnace and a method for removing steel slag from the blow hole. By arranging an oxygen branch pipeline and a flow meter on a blow pipeline, when the blow hole in an ascending tube of the dip tube becomes smaller or is completely blocked, oxygen gas is introduced when a vacuum tank is not treated, and oxygen gas and the steel slag in the blow hole of the ascending tube of the dip pipe are subjected to oxidation reaction, so that the blocked steel slat at the blow hole of the ascending tube of the dip tube is melted, and the steel slag or molten steel is blown out of the blow hole by virtue of oxygen gas at a certain flow speed. The cleaning process is safe and efficient, is more efficient than additional reactants, is short in treatment time and lower in cost, and particularly can be used for effectively removing steel slag which is deeply blocked in the blow hole. The anti-blocking device can effectively reduce a condition that flow of the blow hole is reduced or the blow hole is completely blocked, so that the circulation effect in the service life of the dip tube is ensured, and the dip tube is prevented from being off line due to blockage.

Owner:SHANDONG IRON & STEEL CO LTD

Automatic smelting, water-containing and residue-filtering slot

InactiveCN106338207ASpeed up the outflowImprove outflow efficiencyCharge manipulationWater dischargeEngineering

The invention relates to an automatic smelting, water-containing and residue-filtering slot which comprises a slot body; the slot body is made of a refractory material; the slot body comprises a first sub slot and a second sub slot; a partition plate capable of moving in the vertical direction is arranged between the first sub slot and the second sub slot; a water inlet is formed in the inner side surface of the first sub slot; the opening of the water inlet faces upwards; a water containing hole is formed in the outer side surface, which corresponds to the side wall, of the water inlet; the water containing hole communicates with the water inlet; a residue discharge hole is formed in one side wall, which is adjacent to the side wall where the water containing hole is located; at least one fan is arranged at the upper end of the other side wall, which is adjacent to the side wall where the water containing hole is located; a water discharge hole is formed in the side wall of the second sub slot; the upper end of the partitioning plate is equipped with an air cylinder; the output shaft of the air cylinder is fixedly connected with the partition plate; and the output shaft of the air cylinder drives the partition plate to vertically move in a telescopic manner. Compared with the prior art, floating residues float quickly, residue removal efficiency is high, continuous operation can be realized, and degree of automation is high.

Owner:桂林百坚汽车附件有限公司

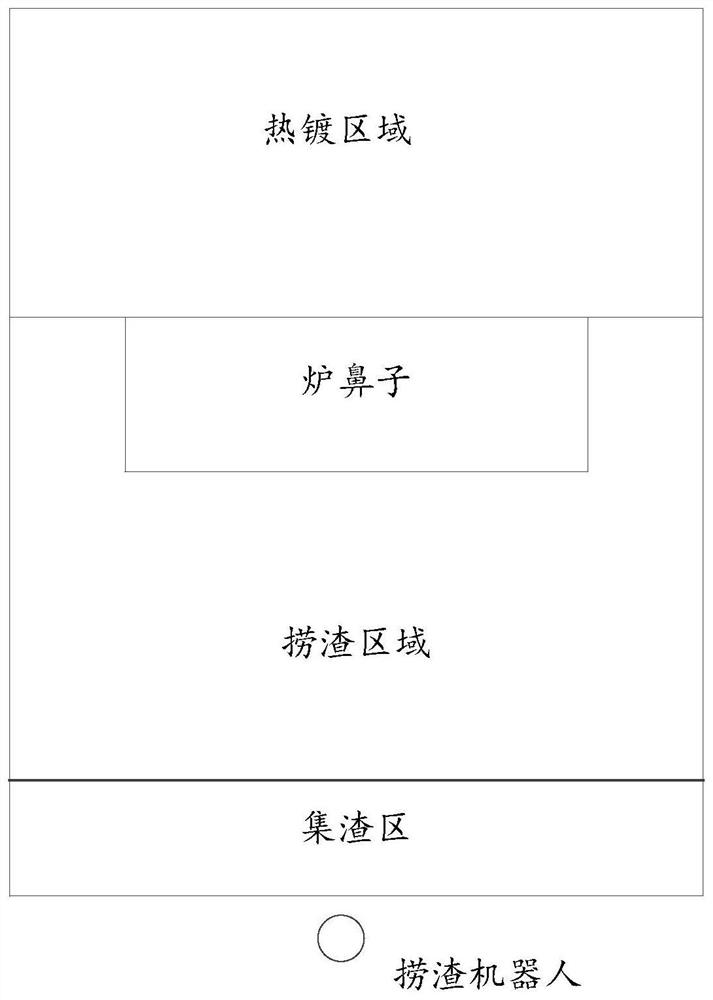

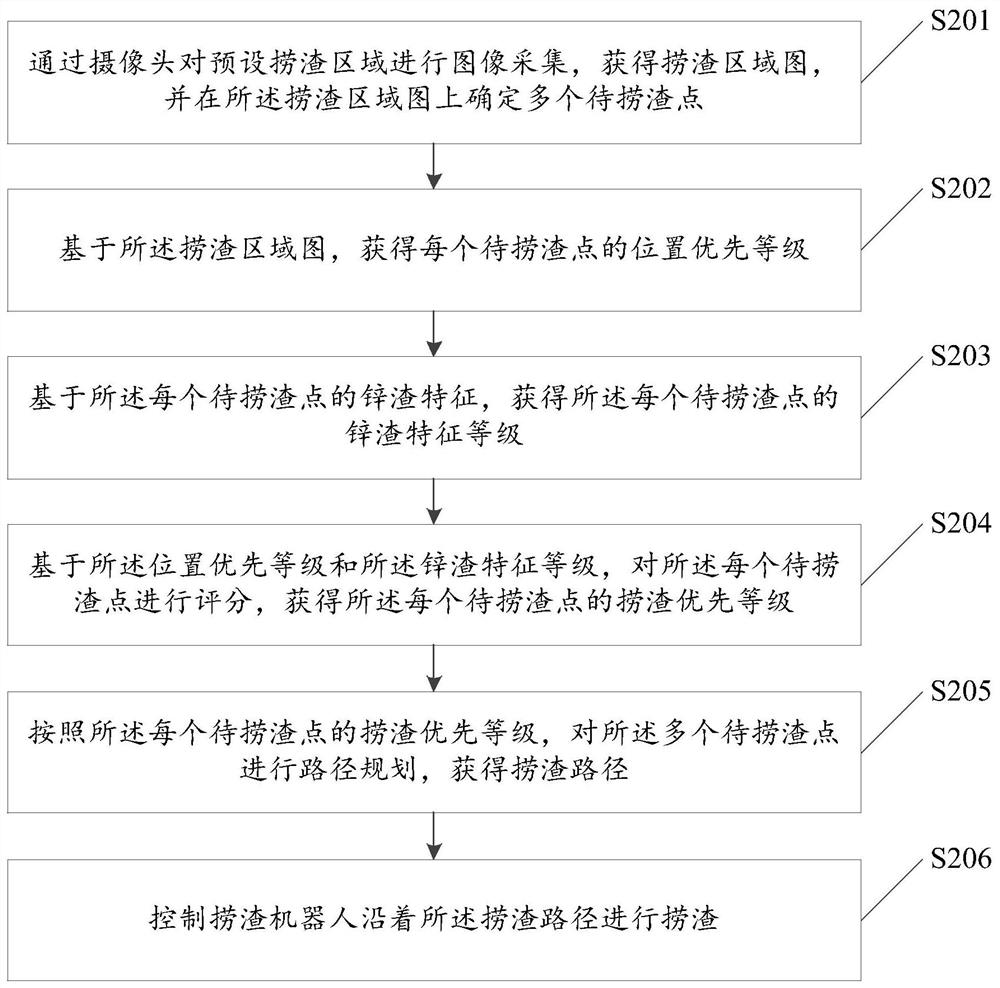

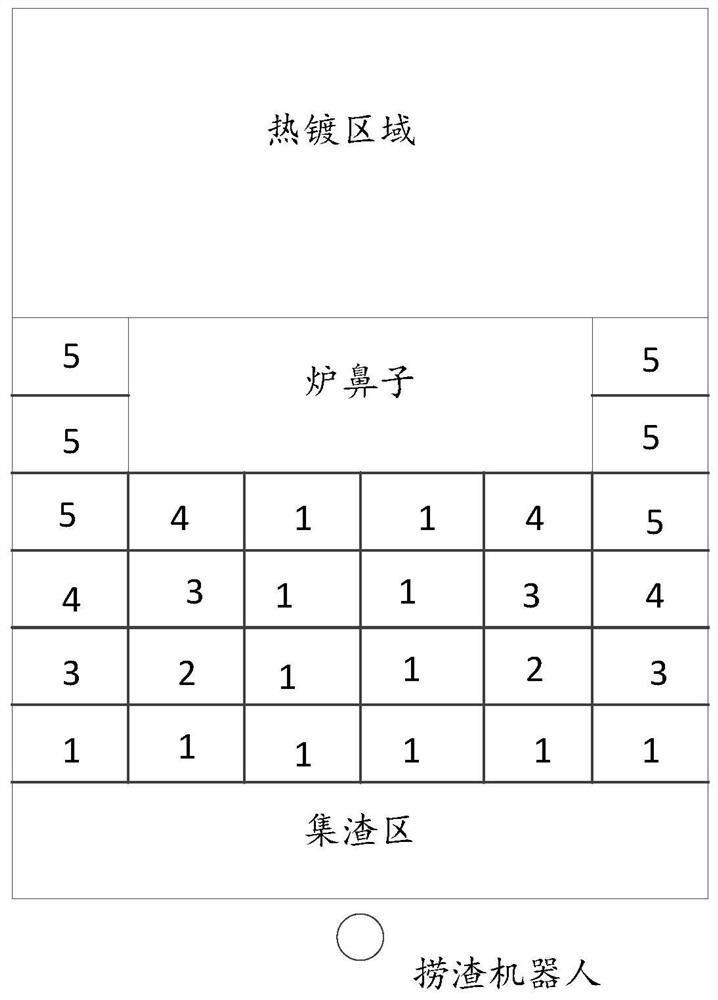

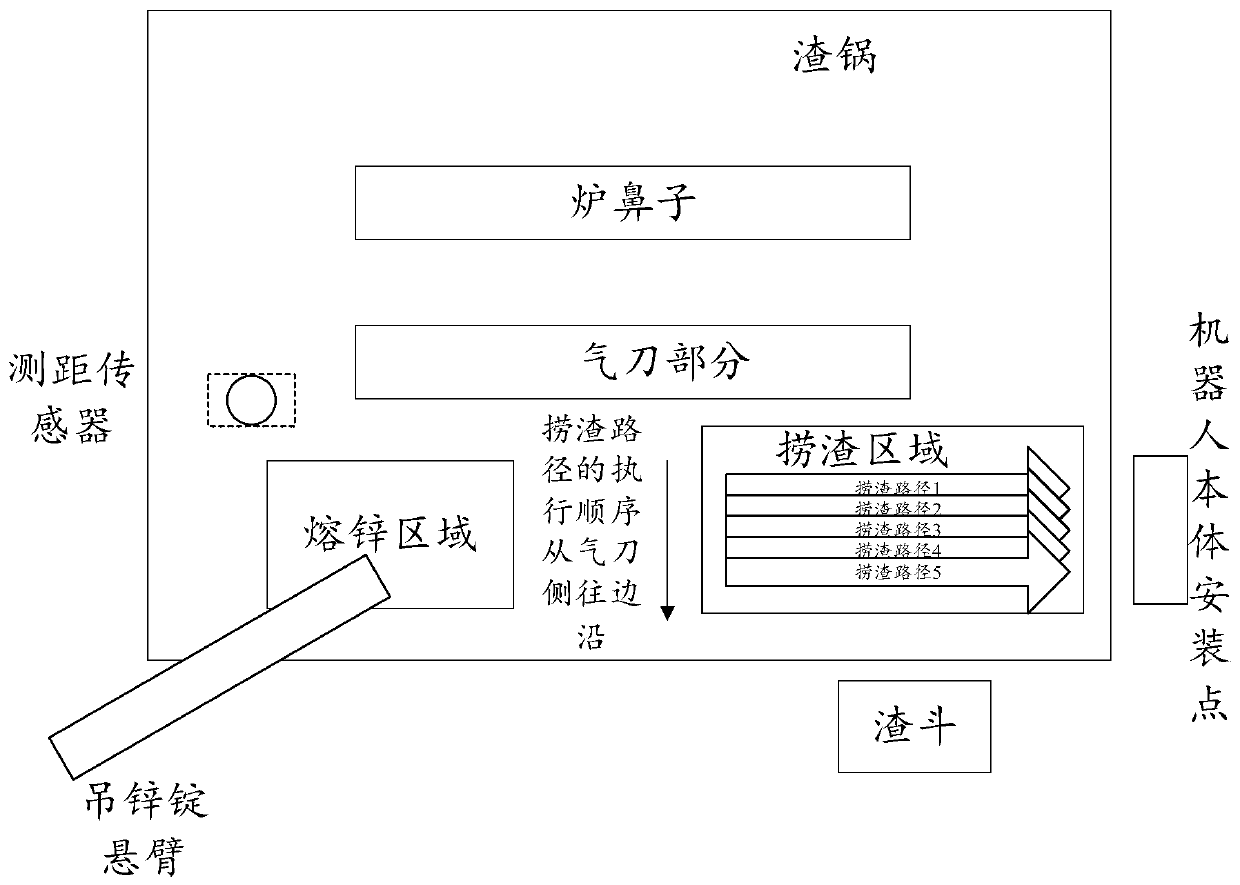

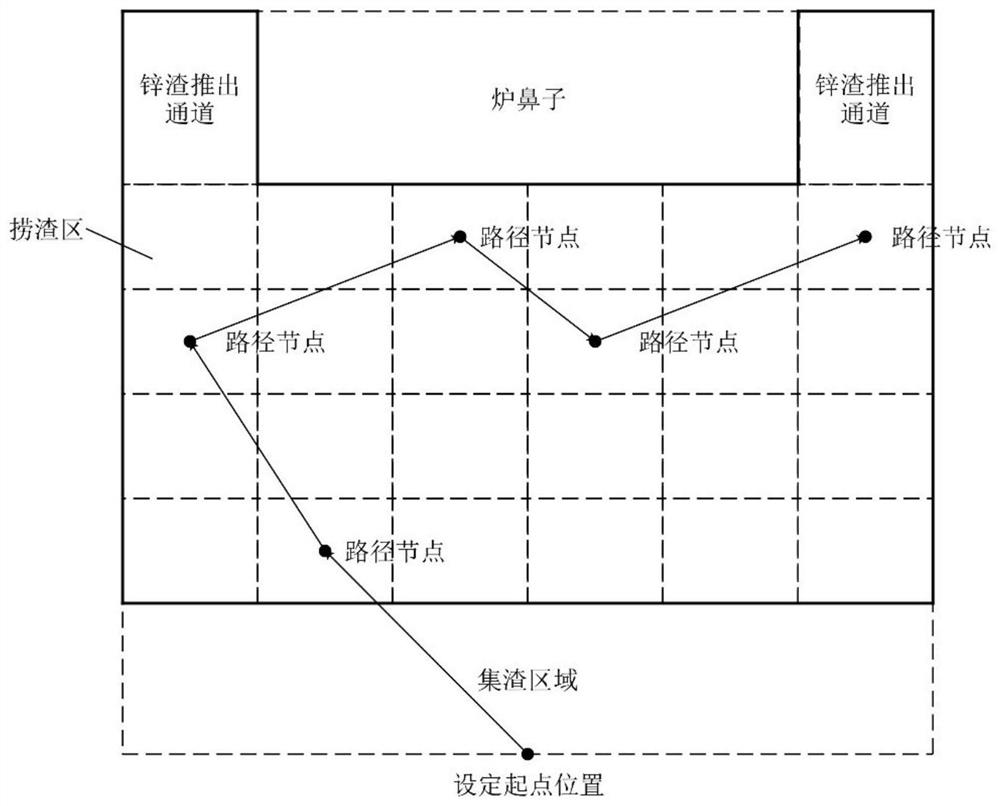

Method and device for optimizing slag bailing

ActiveCN111705283AShorten the timeHigh slag removal efficiencyHot-dipping/immersion processesImage enhancementSlagRoboty

The invention relates to the technical field of continuous hot-dip galvanizing of strip steel, in particular to a method and device for optimizing slag bailing. The method comprises the steps that image acquisition of a preset slag bailing area is conducted by a camera to obtain a slag bailing area map, and a plurality of to-be-slag-bailed points are determined on the slag bailing area map; basedon the slag bailing area map, the position priority of each to-be-slag-bailed point is obtained; based on the zinc slag characteristics of each to-be-slag-bailed point, the zinc slag characteristic grade of each to-be-slag-bailed point is obtained; based on the position priority and the zinc slag characteristic grade of each to-be-slag-bailed point, the slag bailing priority of each to-be-slag-bailed point is scored, and the slag bailing priority of each to-be-slag-bailed point is obtained; according to the slag bailing priority of each to-be-slag-bailed point, path planning of the multiple to-be-slag-bailed points is conducted to obtain a slag bailing path; and a slag bailing robot is controlled to conduct slag bailing along the slag bailing path, and thus the slag bailing efficiency is improved.

Owner:武汉钢铁有限公司

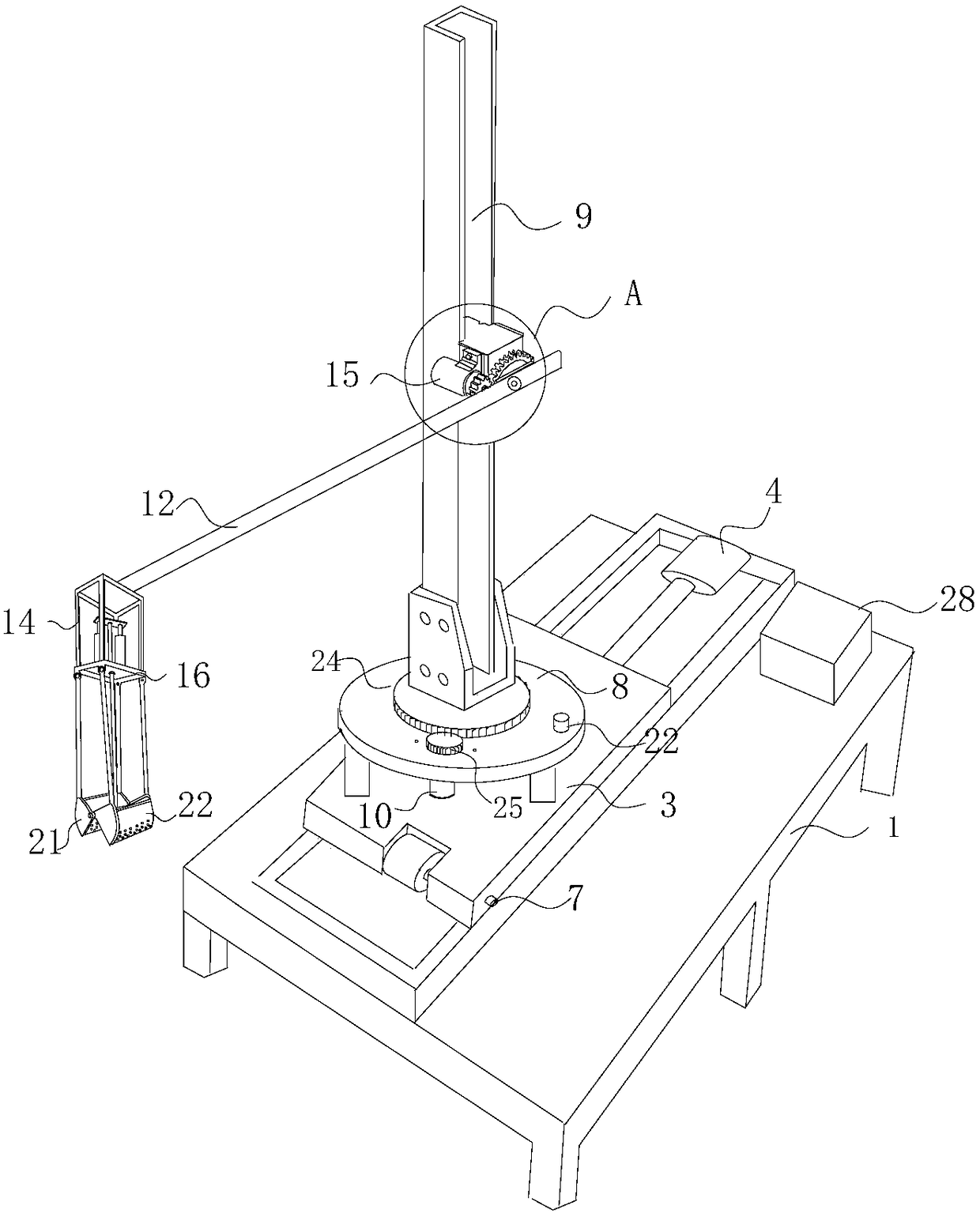

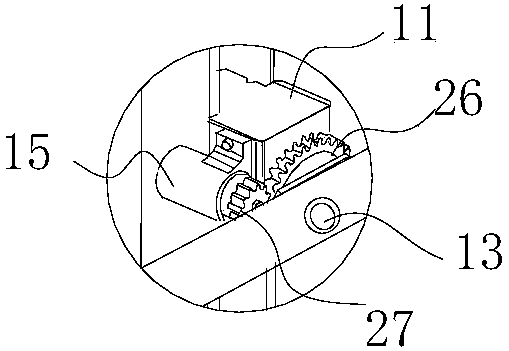

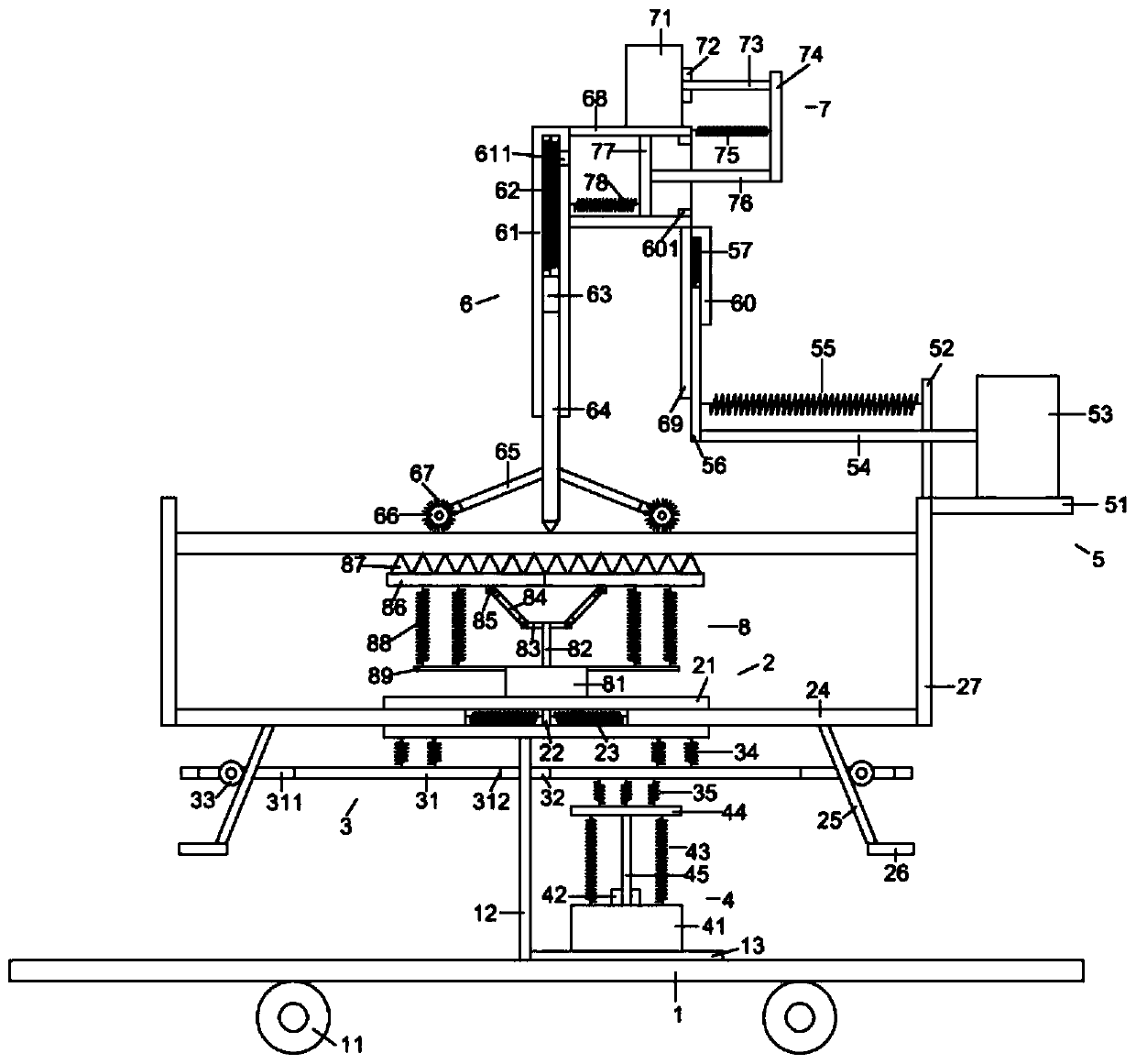

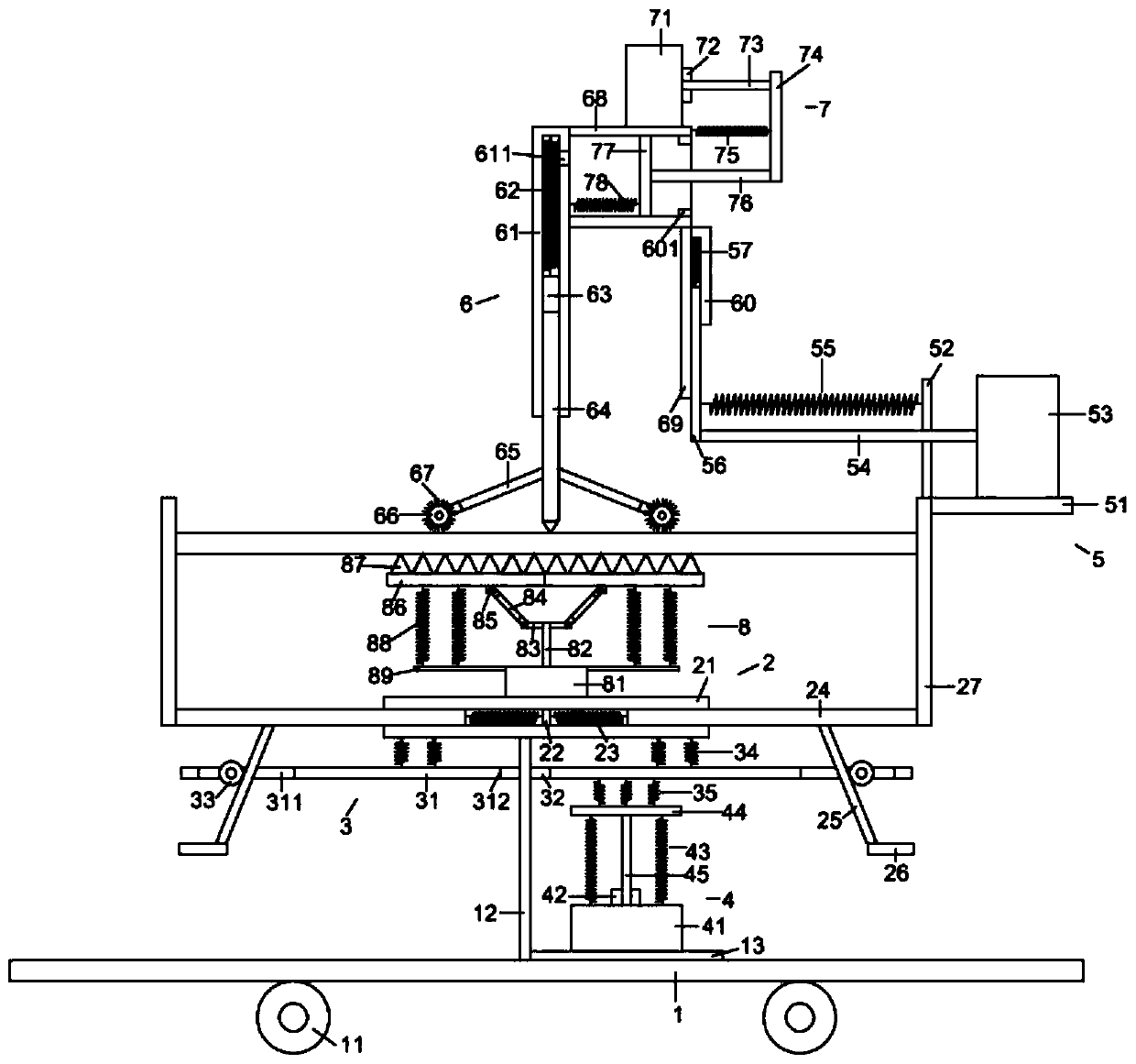

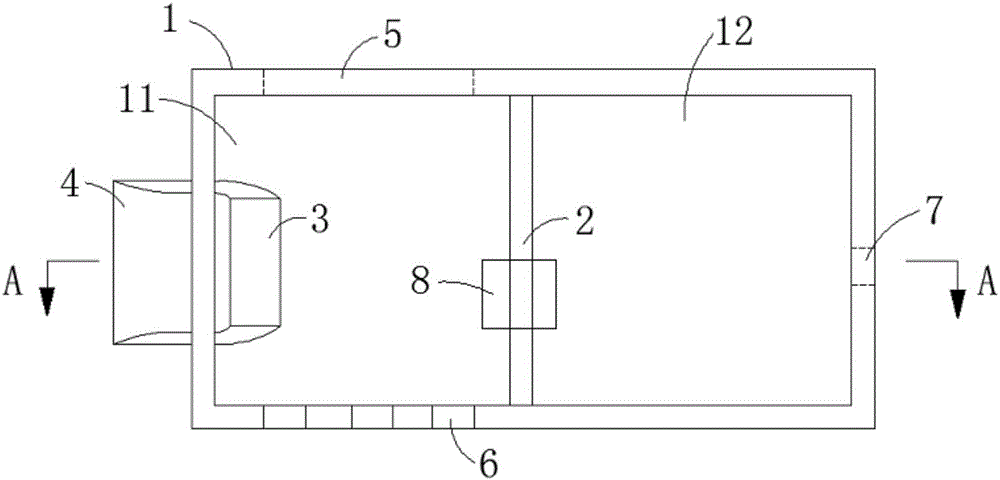

Stirring slag scraping machine used for molten aluminum mixing furnace

The invention discloses a stirring slag scraping machine used for a molten aluminum mixing furnace. The stirring slag scraping machine used for the molten aluminum mixing furnace comprises a base, a movable platform, a forward stretching mechanism and a stirring slag scraping mechanism; the movable platform is arranged on the base; the forward stretching mechanism is arranged on the movable platform; and the stirring slag scraping mechanism is arranged at one end of the forward stretching mechanism. The stirring slag scraping machine used for the molten aluminum mixing furnace is simple in structure, the slag scraping efficiency of the slag scraping machine is greatly improved, and shaking of the slag scraping machine in the slag scraping process is reduced to the maximum extent; and by means of stirring, dispersed slag in the molten aluminum mixing furnace is precipitated out, and high practicability is achieved.

Owner:阿坝铝厂

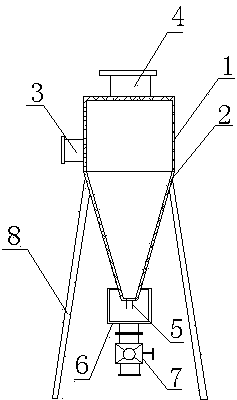

Desander

The invention discloses a cyclone desander including a cylindrical drum (1), a conical drum (2) and a bracket (8), wherein the side wall of the cylindrical drum (1) is provided with a water inlet (3), the top of the cylindrical drum (1) is provided with an overflow water outlet (4), the bottom of the conical drum (2) is provided with a sewage discharge port (5), a sewage storage tank (6) is fixedly arranged on the conical drum (2), the sewage storage tank (6) and the sewage discharge port (5) are communicated, and the sewage storage tank (6) is in fixed connection with a stop valve (7). The beneficial effects of the cyclone desander are that: the stop valve is turned on only when large particle impurities gather in the sewage storage tank (6) and need to be intensively discharged, the number of times of sand discharge can be reduced, labor intensity can be reduced, water loss can be avoided, economic losses can be reduced; in addition, the spiral structural inner wall design enables the suspension in the water to gather more easily, and at the same time also enables water to spirally flow downward, so that wear is minimized, and slag removal efficiency is improved.

Owner:成都市龙泉驿区齐盛机械厂

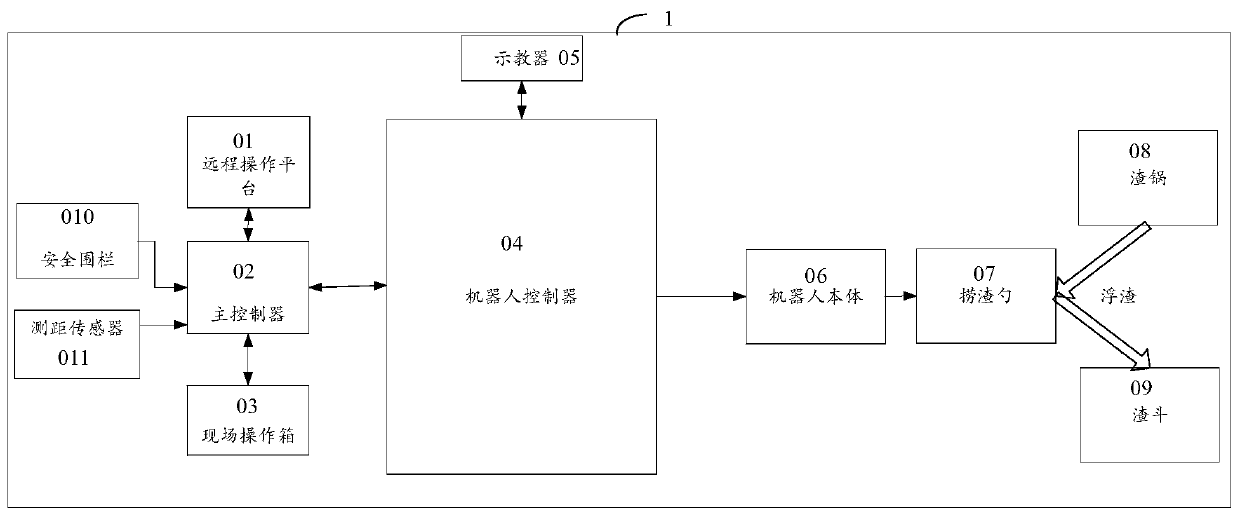

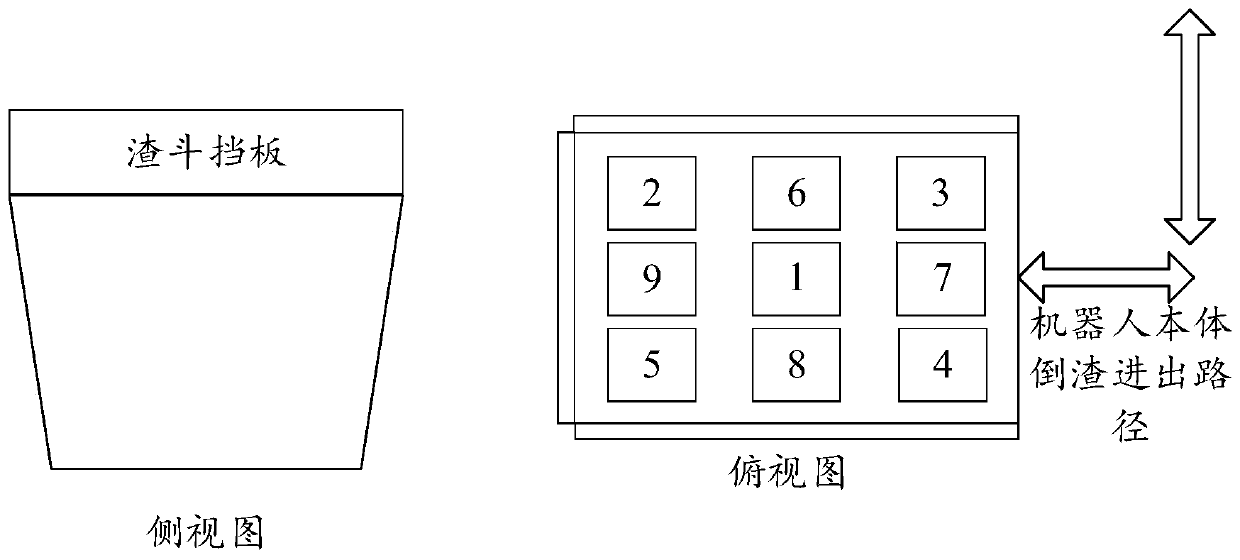

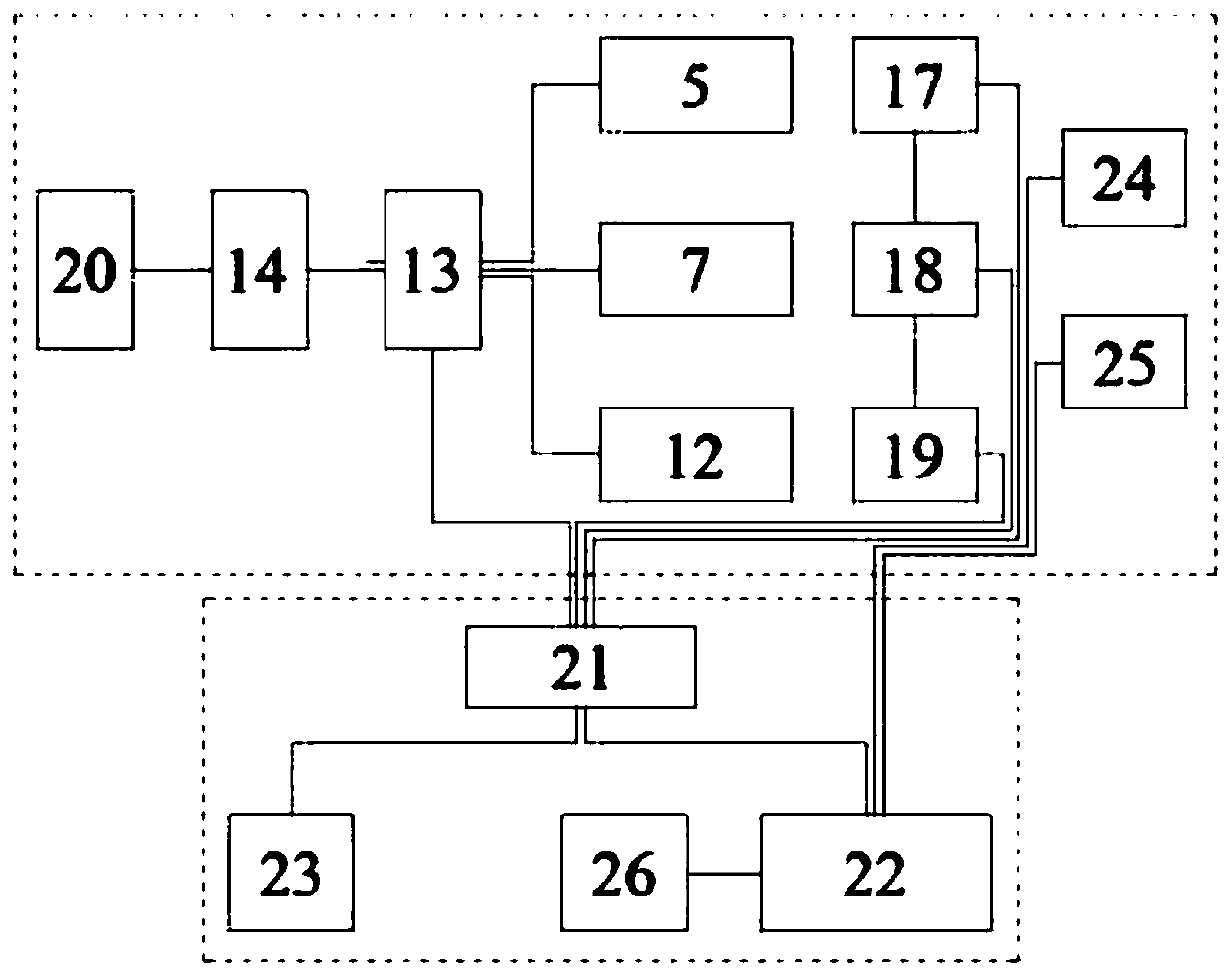

Robot slag-dredging system

PendingCN110670006AHigh slag removal efficiencyHot-dipping/immersion processesSlagControl engineering

The invention provides a robot slag-dredging system. The robot slag-dredging system comprises a main controller, a robot controller, a robot body, a slag pot, a slag hopper and a distance-measuring sensor. A slag-dredging scoop is installed on the robot body. The main controller is connected with the robot controller. The main controller is connected with the distance-measuring sensor. The robot body is driven to dredge floating slag in the slag pot according to the slag-dredging route in the slag-dredging period by the robot controller under control of the main controller and pour the floating slag into the slag hopper. The distance-measuring sensor is used for measuring the liquid level height in the slag pot before the slag-dredging period and generating liquid level signals and sendingthe liquid level signals to the main controller. The liquid level height value is calculated according to the liquid level signals by the main controller and sent to the robot controller. The slag-dredging route is calculated according to the liquid level height value and the preset teaching route by the robot controller. By means of the technical scheme of the robot slag-dredging system, the slag-dredging effect can be kept at the optimal state, slag-dredging efficiency is improved, and manual slag dredging can be replaced.

Owner:湖南华菱涟钢特种新材料有限公司 +1

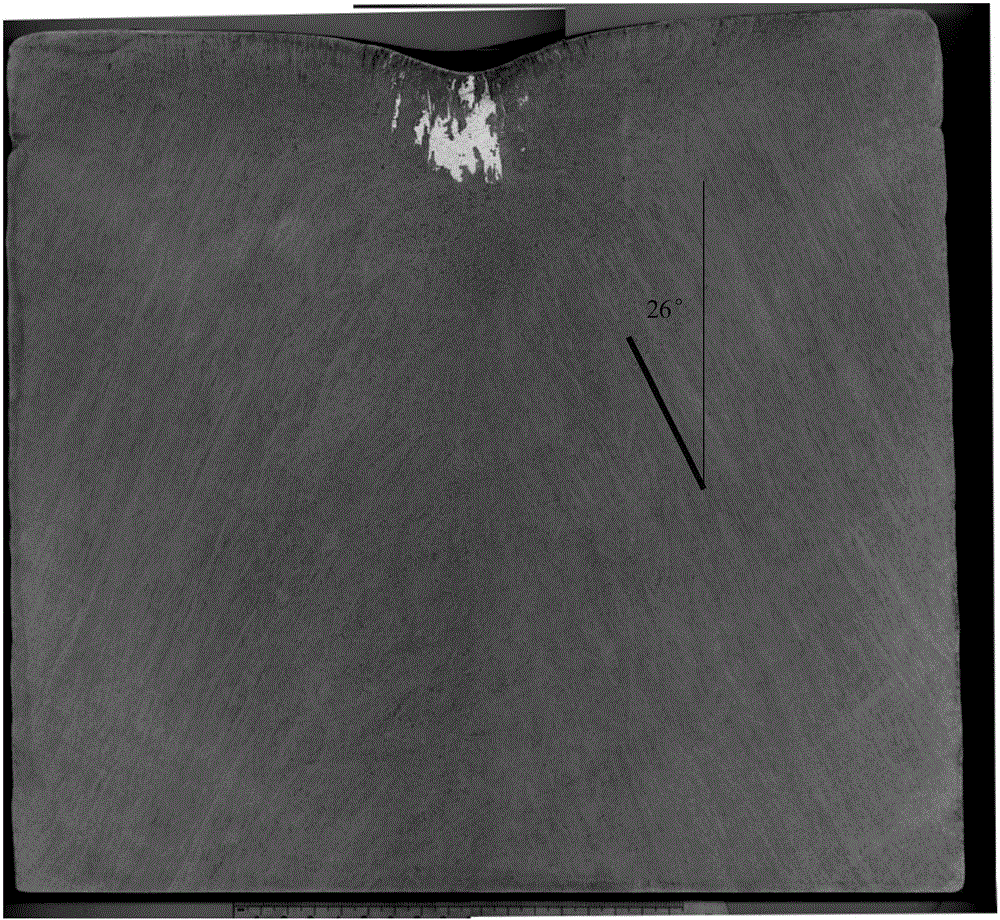

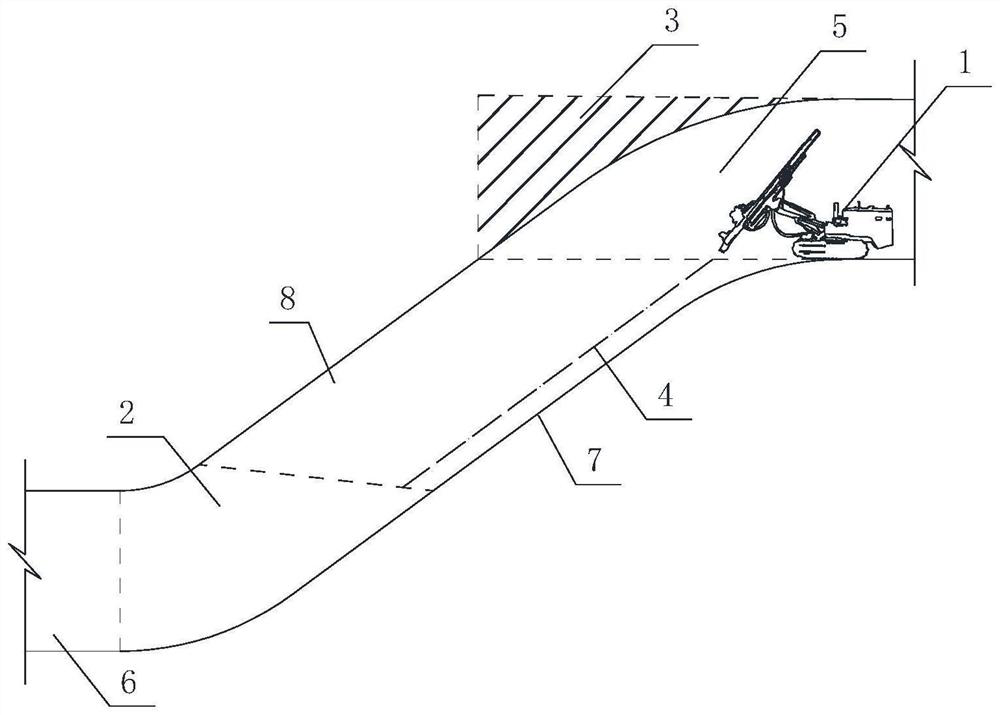

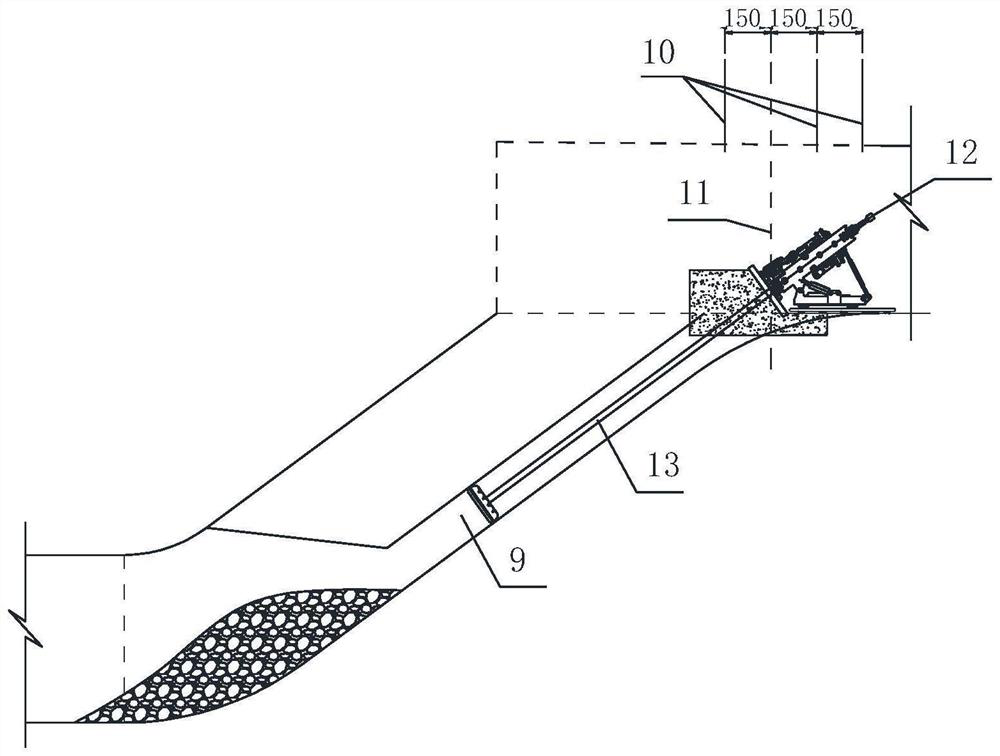

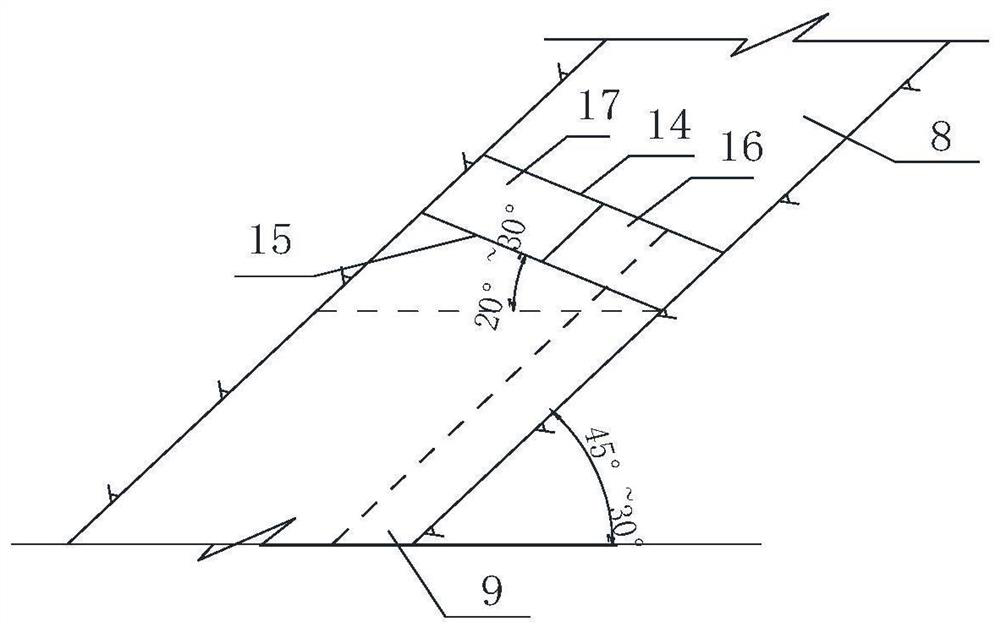

Accurate excavation method for gentle slope inclined shaft

ActiveCN112012751AReduce construction safety risksReduce construction costsClimate change adaptationDirectional drillingAditSlag

The invention discloses an accurate excavation method for a gentle slope inclined shaft. The accurate excavation method comprises the steps that expanding excavation is carried out on a lower adit andan upper adit; a hole guiding and drilling are carried out by a directional drilling machine; a MWD inclinometer and an RMRS rotating magnetic field distance measuring system are adopted for drill bit positioning; hole guiding forward reaming is carried out by a raise boring machine; and then the raise boring machine is used for reverse expanding excavation of a pilot shaft, the pilot shaft is used for slag sliding and is parallel to the bottom of a designed contour line of an inclined shaft bottom plate, forward control of blasting excavation is carried out after the pilot shaft is communicated, and finally, slag sliding is completed. According to the accurate excavation method for the gentle slope inclined shaft, the method of directional drilling, inverse shaft expanding and forward blasting excavation is adopted for the 30-45-degree gentle slope inclined shaft, the pilot shaft is arranged on the inclined shaft bottom plate, the slagging-off efficiency is effectively improved, an included angle between an excavation tunnel face and the horizontal plane is 20-30 degrees, and blasting rock ballast is conveniently accumulated to the bottom and slides to the lower adit along the pilot shaft; the maximum blasting work amount is reduced through segmented blasting, and the rock ballast shaft blocking risk is reduced; forward one-time blasting excavation is carried out, and the blasting procedure construction time is shortened; and the construction efficiency is effectively improved, and the construction safety risk is reduced.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

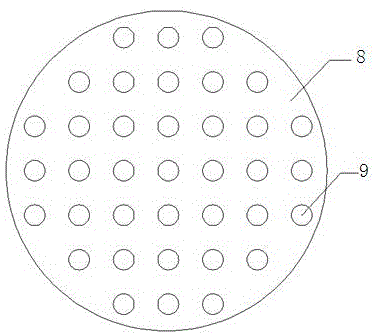

Smelting device for zinc alloy

The invention discloses a smelting device for zinc alloy. The smelting device is composed of vacuum smelting device, a protective atmosphere furnace and a graphite crucible, wherein an air flue, a graphite stirring device and a smelting crucible are arranged in the vacuum smelting device, and the graphite crucible is provided with a mechanical stirring device. A filtering structure is fixed to thearea from the bottom to the top of the side face of the inner surface of the smelting crucible according to the structure that a dirt filtering net is arranged on a pulsator washing machine. The filtering structure is specifically composed of an aluminum oxide ceramic wedge block, an aluminum oxide ceramic outer frame, a primary coarse screen made of aluminum oxide ceramic materials and an onlinefiltering screen made of carbon fiber ceramic composite materials, wherein the outer surface of the primary coarse screen is lined with the online filtering screen. By means of the smelting device, the multi-eutectic and few-dendritic zinc alloy which is high in purity, small in large-size dendritic segregation, uniform in overall grain size refinement and original in structure can be smelted.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

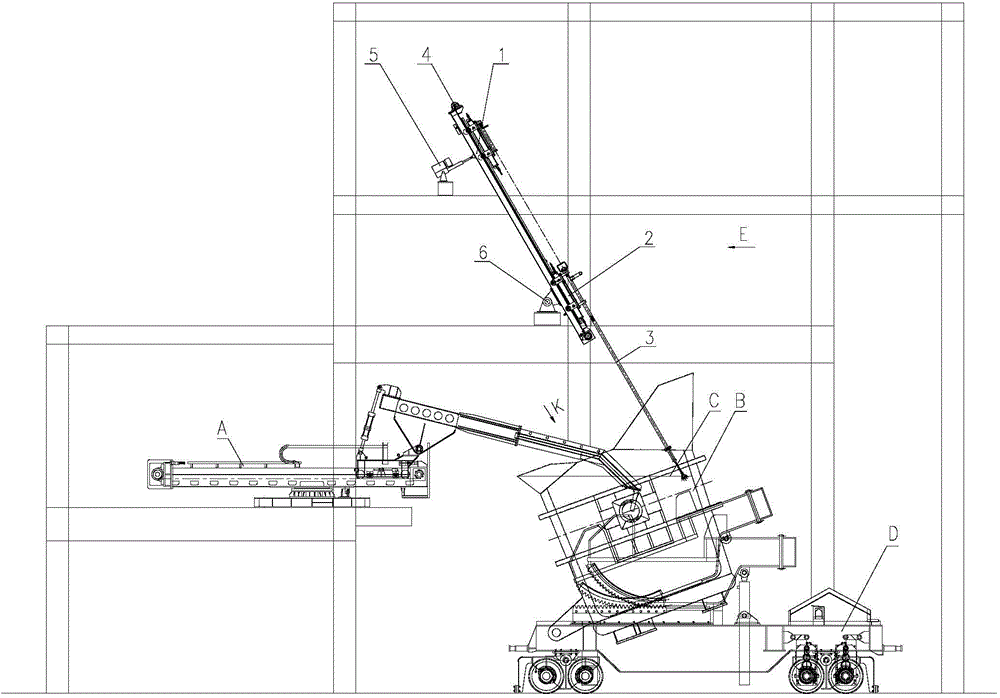

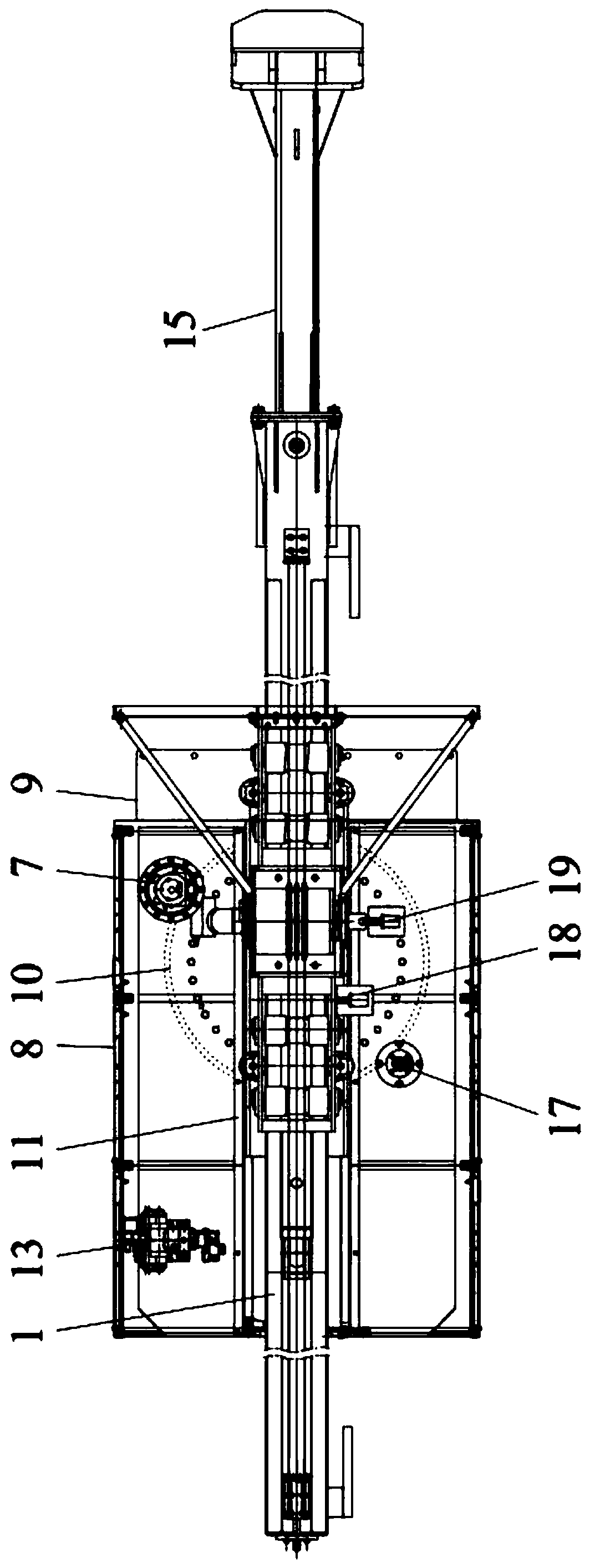

Automatic steel slag drossing machine

PendingCN110842187AFully automatedRealize closed-loop controllable actionCasting cleaning apparatusHydraulic motorProcess engineering

The invention relates to an automatic steel slag drossing machine. A rotation platform, a supporting frame, a sliding casing pipe, a drossing rod, a drossing head, a control valve table, a center rotation connector, a telescopic encoder, an up-down swinging encoder, a rotation encoder, a PLC, a rotation speed reduction motor for driving the rotation platform to drive the drossing head to swing left and right, a telescopic speed reduction hydraulic motor for driving the drossing rod to drive the drossing head to move front and back, and an up-down swinging oil cylinder for driving the sliding casing pipe to drive the drossing head to swing up and down. The PLC is in signal connection with the telescopic encoder, the up-down swinging encoder, the rotation encoder and the control valve table,and closed-loop control is achieved. The automatic steel slag drossing machine is additionally provided with the three encoders, the motion quantity of the drossing head in the three-axis direction is reflected in real time and fed back to the PLC, the PLC controls the corresponding drive mechanisms through the control valve table, and drossing head closed-loop controllable actions are achieved.Automation of the steel slag drossing machine is achieved, and the drossing efficiency is improved.

Owner:南京伊顿派克重工机械有限公司

Method for producing high-quality starch from fresh sweet potatoes

The invention discloses a method for producing high-quality starch from fresh sweet potatoes. The method comprises cleaning for impurity removal, mechanical grinding, uniform stirring with water, mechanical vibration for filtering sweet potato fiber floccules, water removal and oil powder layer scraping after precipitation, beating molding, drying and crushing for preparation of powdery sweet potato starch. The method is simple, is easy to operate, realizes efficient, fast and clean slag removal based on a slag removal vibrating screen, and prevents sweet potato fibers in the filtrate. After precipitation, the oil powder layer is scraped. The starch is clean, bright and white and has no other color. Through slag removal vibrating screen-based filtration, the starch in the sweet potato flocculent fibers are thoroughly released, a yield is high and sweet potato weight is light.

Owner:肥西县金桥红薯专业合作社

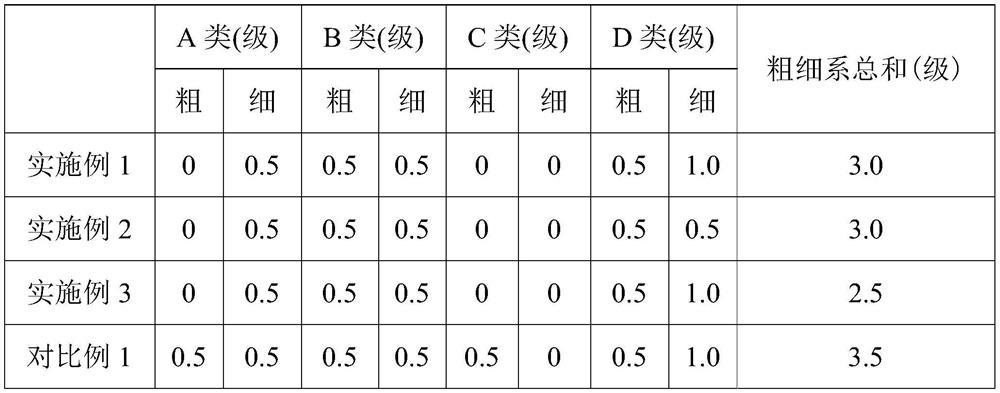

Method for producing low-sulfur and low-phosphorus steel by utilizing semi-molten steel

InactiveCN111926147AImprove componentsStrong desulfurization abilityManufacturing convertersSteelmakingNon-metallic inclusions

The invention relates to a method for producing low-sulfur and low-phosphorus steel by utilizing semi-molten steel. The method comprises the following steps: acquiring low-sulfur and low-phosphorus molten steel by the semi-molten steel through pre-deoxidation, KR desulfurization, converter steelmaking, LF refining and VD vacuum smelting in sequence, and acquiring the low-sulfur and low-phosphorussteel by pouring the low-sulfur and low-phosphorus molten steel, wherein the sulfur content of the molten steel subjected to KR desulfurization is lower than or equal to 0.005%, the rate of slagging-off after KR desulfurization is higher than or equal to 90%, the phosphorus content of the molten steel subjected to converter steelmaking is lower than or equal to 0.004%, 10-30 kg of slagging balls are added into the molten steel per ton during converter steelmaking, the included angle of oxygen gun holes during converter steelmaking is larger than or equal to 13 degrees, and the final temperature of converter steelmaking is lower than or equal to 1620 DEG C. According to the method provided by the invention, the off-site sulfur content is lower than or equal to 0.005% and the rate of dephosphorization during the converter steelmaking of the semi-molten steel reaches 96% or higher. Meanwhile, hydrogen-sulfide-corrosion-resistant continuous-casting round billet non-metallic inclusions produced through the method reach the following levels: class A is lower than or equal to level 0.5; class C is equal to level 0; class B and class C are lower than or equal to level 1.0; and the total thickness of class A, class B, class C and class D is lower than or equal to level 3.0.

Owner:CHENGDE JIANLONG SPECIAL STEEL

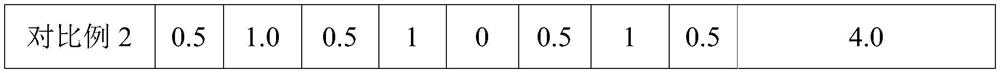

Method for dredging bottom slag in 55% Al-Zn liquid

ActiveCN105695912AImprove slag removal efficiency and slag removal effectEliminate potential safety hazardsHot-dipping/immersion processesSlagMineralogy

The present invention relates to a method for dredging bottom slag in 55% Al-Zn liquid. The method comprises the following steps: 1) hanging out a sank roller furnace nose zinc pot equipment, and taking out of the strip steel; 2) cooling an aluminum-zinc liquid in a zinc pot from 600 + / - 3 DEG C to 591 DEG C at a rate of 5 DEG C / h; 3) after slag dredging, rising the temperature of the aluminum-zinc liquid from 591 DEG C to 785 DEG C at an average heating rate of 40 DEG C / h; 4) reducing the temperature of aluminum-zinc liquid from 785 DEG C to 650 DEG C at an average cooling rate of 13 DEG C / h; 5) rising the temperature of the aluminum-zinc liquid to 785 DEG C at an average rate of 35 DEG C / h; 6) reducing the temperature of the aluminum-zinc liquid from 785 DEG C to 645 DEG C at an average cooling rate of 10 DEG C / h; 7) repeating the steps 5) and 6) according to data obtained from exploration slag; 8) cooling at an average rate of 15-20 DEG C / h, and 9) raising the temperature of the aluminum-zinc liquid to 600 + / - 3 DEG C with 80% of zinc the pot power, and naturally cooling to 590 DEG C; and repeating this process 3-5 times, wherein the number of times can be increased depending on the circumstances of dredging.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

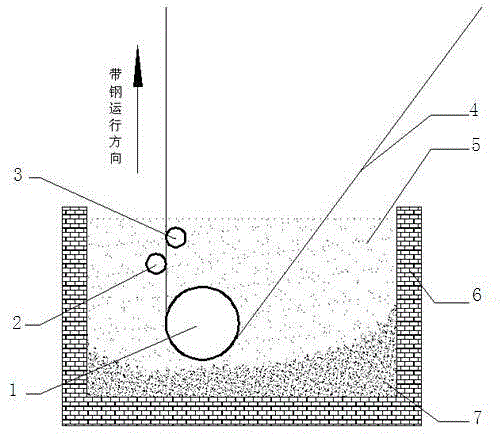

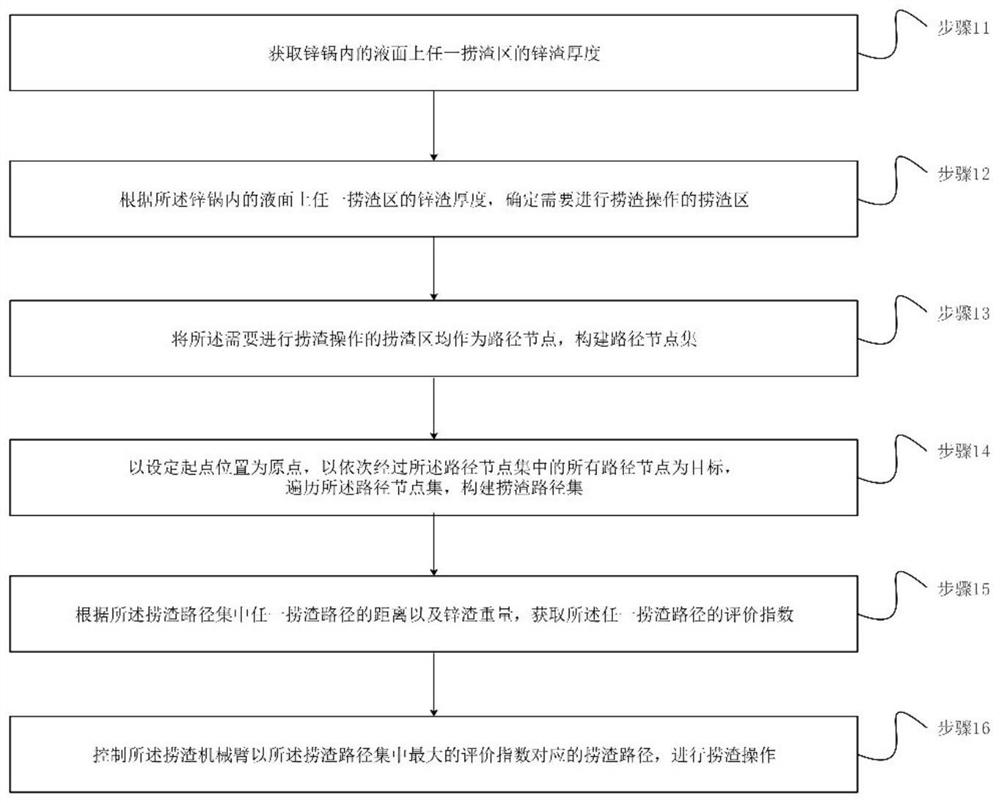

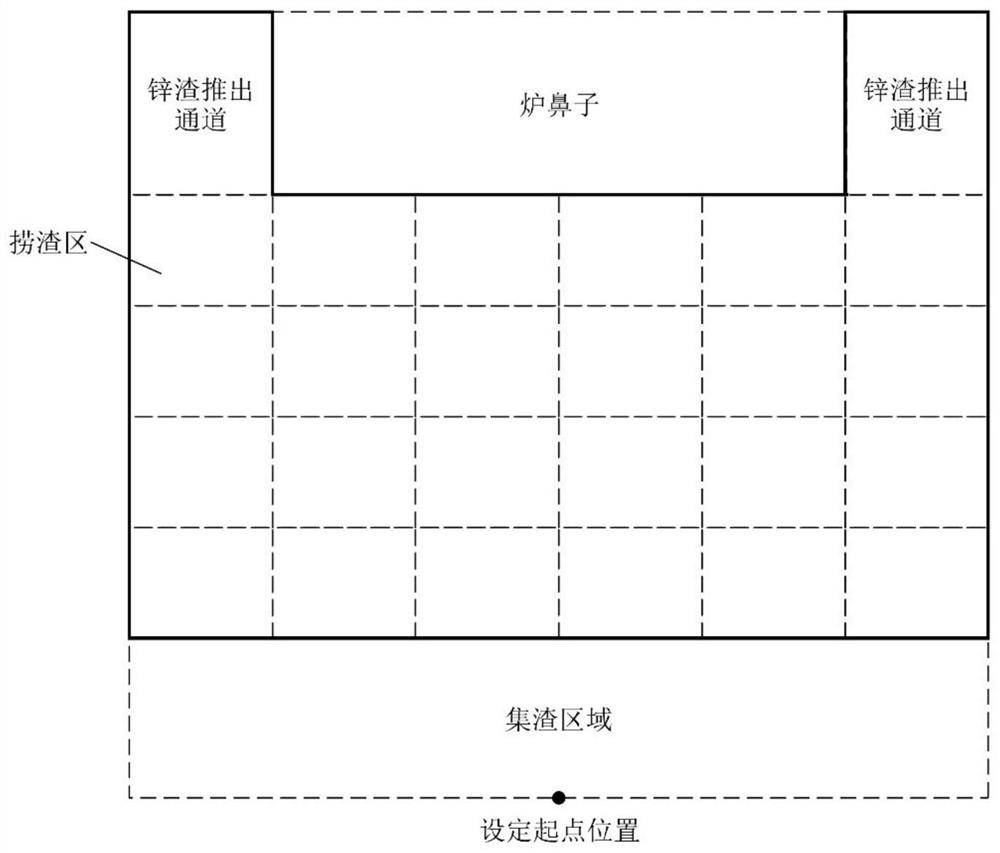

Intelligent slag salvaging control method and device

ActiveCN112207820AHigh slag removal efficiencyHot-dipping/immersion processesProgramme-controlled manipulatorSlagControl engineering

The invention relates to the technical field of hot galvanizing, in particular to an intelligent slag salvaging control method and device. The method comprises the steps that the zinc slag thicknessesof all slag salvaging areas on the liquid level in a zinc pot are obtained; the slag salvaging areas needing to be subjected to slag salvaging operation are determined; all the slag salvaging areas needing to be subjected to slag salvaging operation are used as path nodes, and a path node set is constructed; the path node set is traversed, and a slag salvaging path set is constructed; the evaluation index of each slag salvaging path is obtained according to the total length of each slag salvaging path in the slag salvaging path set and the weight of the zinc slag; and a slag salvaging mechanical arm is controlled to execute slag salvaging operation according to the slag salvaging path corresponding to the maximum evaluation index in the slag salvaging path set. According to the method, the slag salvaging control of the slag salvaging mechanical arm is converted into the optimal path problem about how to achieve the shortest path and the maximum slag salvaging quality on the premise that the upper limit exists in the single-time slag salvaging capacity, the slag salvaging path with the maximum evaluation index is used for controlling the slag salvaging mechanical arm to conduct slag salvaging operation, and therefore the slag salvaging operation efficiency of the slag salvaging mechanical arm is improved.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com