Non-contact metal liquid surface slag layer electromagnetic automatic treatment device and method

A metal liquid surface, non-contact technology, applied in non-electric variable control, metal material coating process, coating, etc., can solve problems such as rough coating, zinc tumor, and affecting the quality of galvanized layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

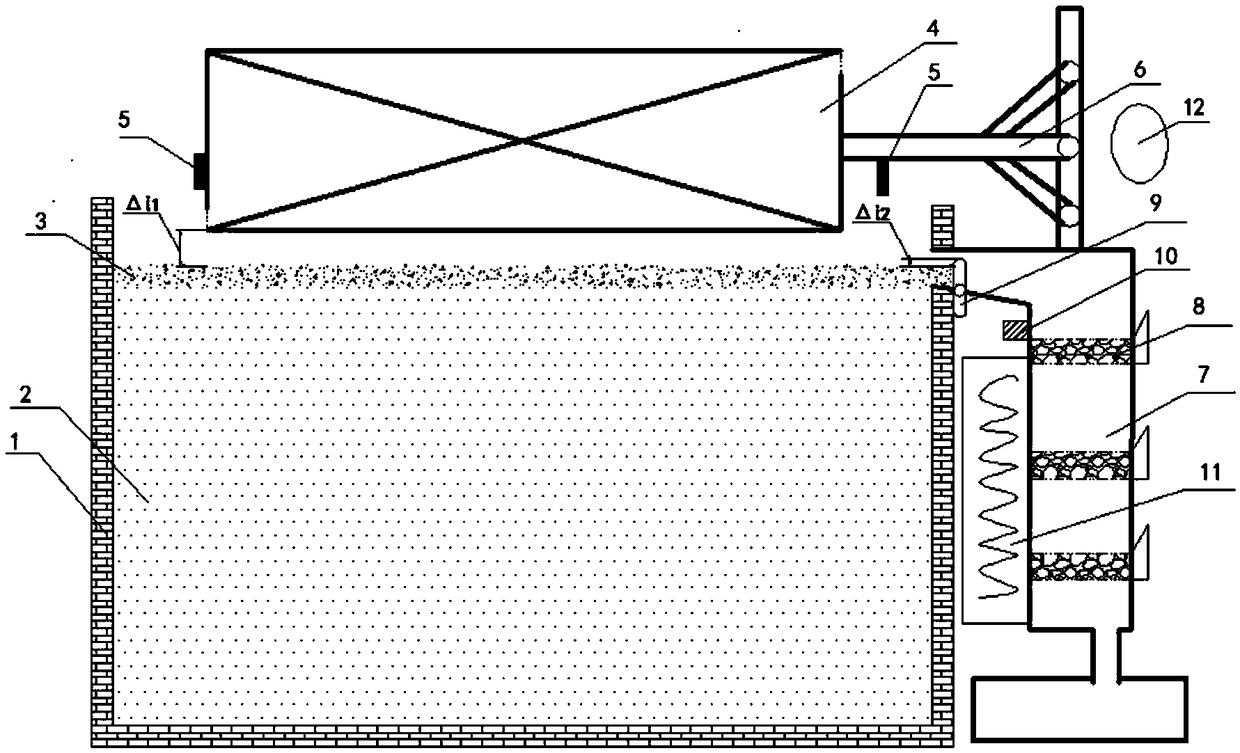

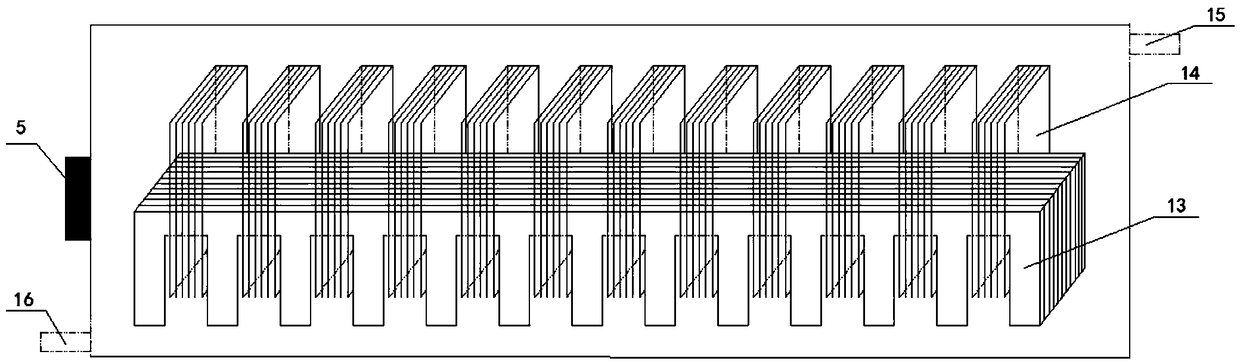

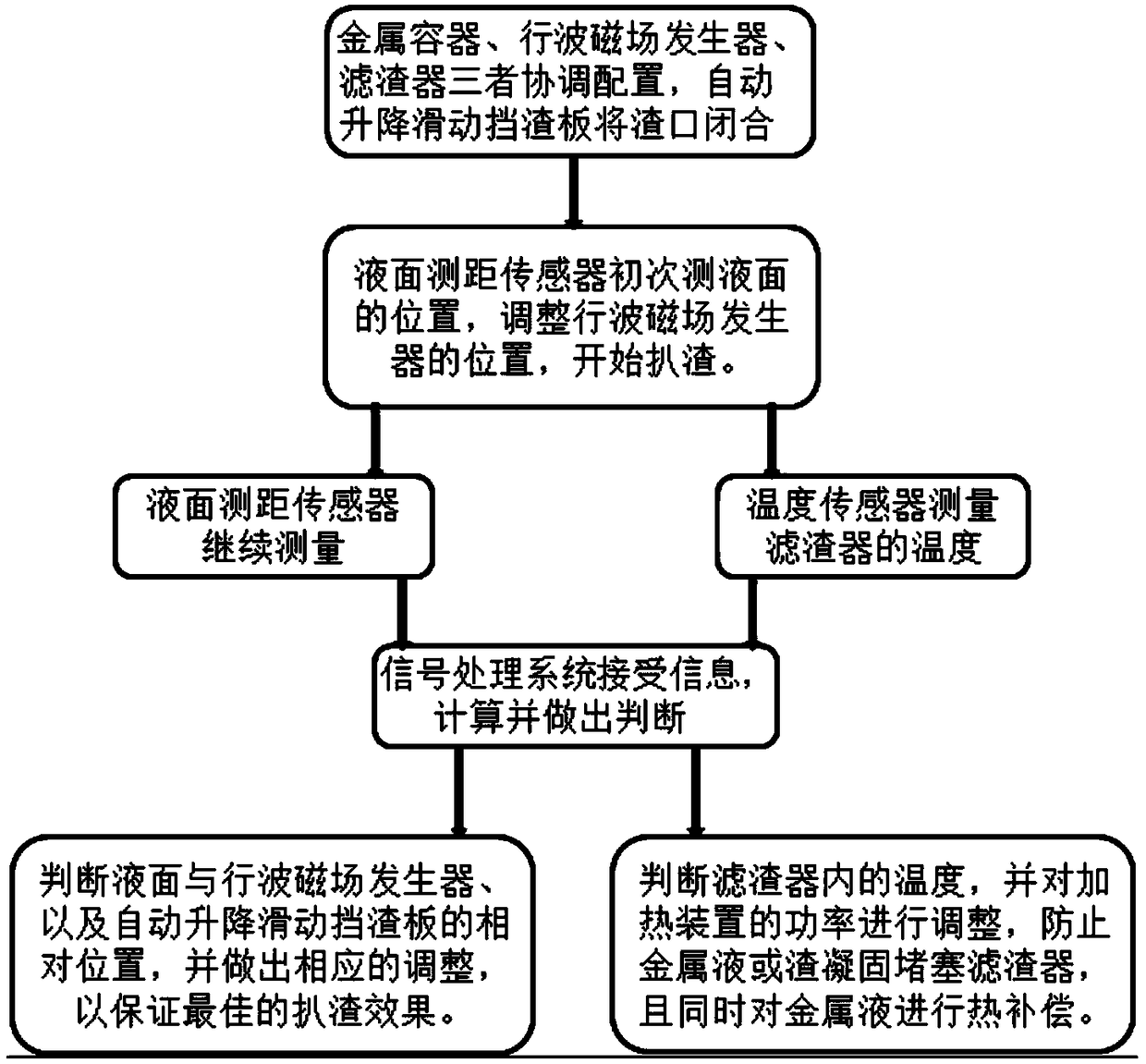

[0047] In this example, see Figure 1 ~ Figure 3 , a non-contact electromagnetic automatic processing device for molten metal level slag layer, comprising a signal processing system 12, an automatic lifting and sliding slag retaining plate 9 and a molten metal container 1 with a slag port, in the molten metal container 1 with a slag port The molten metal 2 is loaded inside, and the slag layer 3 floats on the surface of the molten metal 2. The automatic lifting and sliding slag stopper 9 is set at the position of the slag mouth of the molten metal container 1 with a slag mouth, forming a liftable slag stop device , the signal processing system 12 can control the height of the upper edge of the automatic lifting and sliding slag retaining plate 9, and is provided with a non-contact metal liquid surface slag layer electromagnetic automatic slag removal processing device 20, and a non-contact metal liquid surface slag layer electromagnetic automatic slag removal The slag processin...

Embodiment 2

[0068] This embodiment is basically the same as Embodiment 1, especially in that:

[0069] In this example, see Figure 4 , the non-contact metal liquid surface slag layer electromagnetic automatic treatment device is arranged in the hot dip coating device, and the molten metal container 1 with the slag mouth is used as the container of the hot dip coating device at the same time, and the molten metal container 1 with the slag mouth The molten metal 2 is used as the metal plating solution of the hot-dip plating process, and the metal base strip 17 to be treated in the hot-dip plating process passes through the first conveying roller 19 in the furnace nose 18 of the molten metal container 1 with a slag mouth, so that the metal base strip 17 is immersed in In the molten metal 2 in the molten metal container 1 with the slag mouth, the metal substrate 17 part immersed in the molten metal 2 is subjected to hot-dip plating through the sinking roller 21 arranged in the molten metal 2...

Embodiment 3

[0078] This embodiment is basically the same as the previous embodiment, and the special features are:

[0079] In this embodiment, the non-contact metal liquid surface slag layer electromagnetic automatic treatment device is arranged in the hot dip coating device, and the metal liquid container 1 with the slag opening is used as the hot dip coating device container at the same time, and the slag opening is used as the container of the hot dip coating device. The molten metal 2 in the molten metal container 1 is used as the metal plating solution of the hot-dip plating process, and the traveling wave magnetic field generator 4 is arranged at a position of 10 mm from the workpiece to be processed in the hot-dip plating process, and is to be processed in the hot-dip plating process At least one side of the workpiece is provided with a traveling wave magnetic field generator 4 . In this embodiment, the non-contact metal liquid level slag layer electromagnetic automatic treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com