Method for producing low-sulfur and low-phosphorus steel by utilizing semi-molten steel

A technology for molten steel and steel products, which is applied in the field of producing low-sulfur and low-phosphorus steel products, and can solve the problems of increased consumption of S-corroded line pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

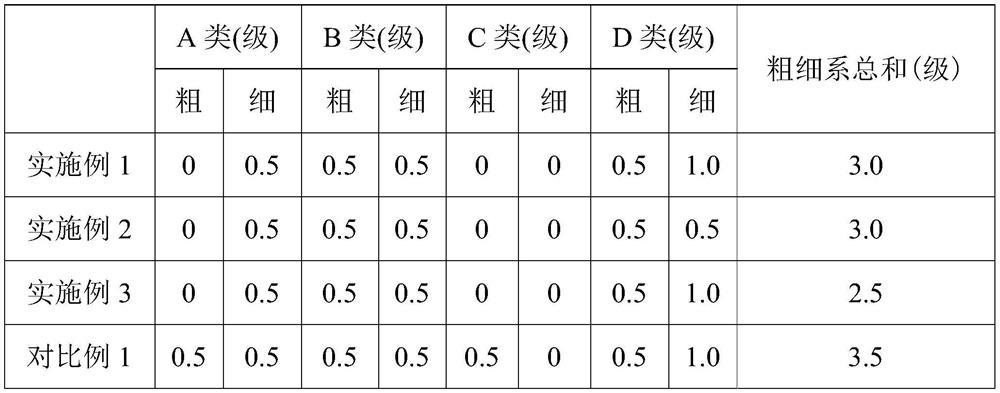

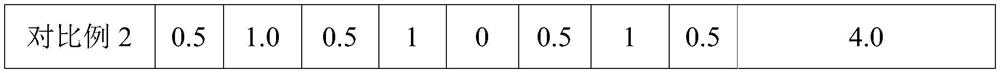

Examples

Embodiment 1

[0061] This embodiment provides a method for producing low-sulfur and low-phosphorus steel using semi-liquid steel. The method includes: semi-liquid steel is sequentially subjected to pre-deoxidation, KR desulfurization, converter steelmaking, LF refining and VD vacuum smelting to obtain low-sulfur and low-phosphorus molten steel. The low-sulfur and low-phosphorus molten steel is poured to obtain the low-sulfur and low-phosphorus steel;

[0062] Wherein, the sulfur content in molten steel after KR desulfurization is 0.005%; the slag removal rate after KR desulfurization treatment is 90%; the phosphorus content in molten steel after converter steelmaking is 0.004%; Add 20kg of slag balls per ton of molten steel in the steel; the included angle of the oxygen lance hole in the converter steelmaking is 13°; the end temperature of the converter steelmaking is 1620°C; Deoxidation; Calcium oxide and calcium fluoride are added in the KR desulfurization; the addition amount of the calc...

Embodiment 2

[0065] This embodiment provides a method for producing low-sulfur and low-phosphorus steel using semi-liquid steel. The method includes: semi-liquid steel is sequentially subjected to pre-deoxidation, KR desulfurization, converter steelmaking, LF refining and VD vacuum smelting to obtain low-sulfur and low-phosphorus molten steel. The low-sulfur and low-phosphorus molten steel is poured to obtain the low-sulfur and low-phosphorus steel;

[0066] Wherein, the sulfur content in molten steel after KR desulfurization is 0.002%; the slag removal rate after KR desulfurization treatment is 95%; the phosphorus content in molten steel after converter steelmaking is 0.002%; Add 10kg of slag balls per ton of molten steel in the steel; the included angle of the oxygen lance hole in the converter steelmaking is 15°; the end temperature of the converter steelmaking is 1520°C; Deoxidation; calcium oxide and calcium fluoride are added in the KR desulfurization; the addition of the calcium oxi...

Embodiment 3

[0069] This embodiment provides a method for producing low-sulfur and low-phosphorus steel using semi-liquid steel. The method includes: semi-liquid steel is sequentially subjected to pre-deoxidation, KR desulfurization, converter steelmaking, LF refining and VD vacuum smelting to obtain low-sulfur and low-phosphorus molten steel. The low-sulfur and low-phosphorus molten steel is poured to obtain the low-sulfur and low-phosphorus steel;

[0070] Wherein, the sulfur content in the molten steel after the KR desulfurization is 0.0037%; the slag removal rate after the KR desulfurization treatment is 98%; the phosphorus content in the molten steel after the converter steelmaking is 0.001%; the converter smelting Add 30kg of slag balls per ton of molten steel in the steel; the included angle of the oxygen lance hole in the converter steelmaking is 20°; the end point temperature of the converter steelmaking is ≤1570°C; Deoxidation; Calcium oxide and calcium fluoride are added in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com