Oily cold patch asphalt and preparation process thereof

A cold-repairing asphalt and oil-based technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of restricting users' needs in time and increasing user costs, so as to increase early strength and water stability, increase water stability, The effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

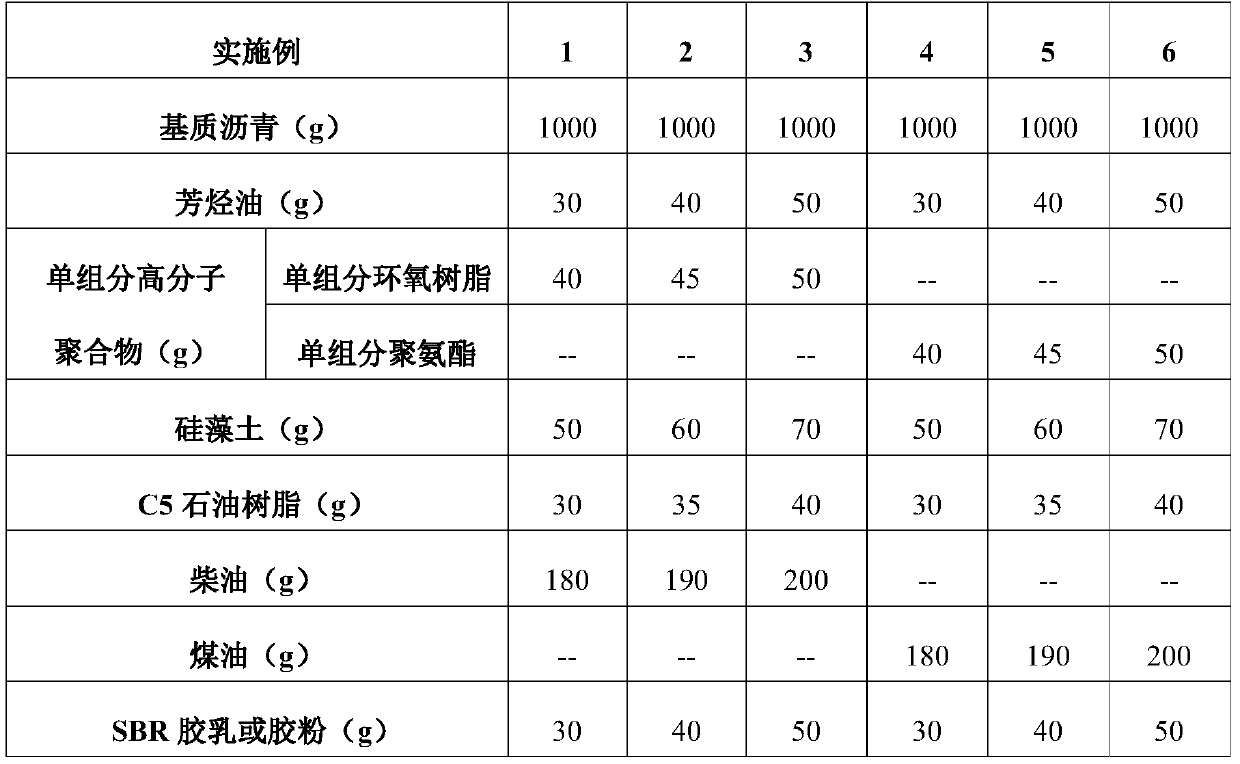

[0024] The present invention provides examples 1 to 6 of an oily cold-patch asphalt, and the ratio of specific raw materials is shown in Table 1.

[0025] Table 1 is a kind of raw material ratio of oil-based cold-patch asphalt Examples 1-6 ("--" indicates that it does not contain)

[0026]

[0027] Because the freezing point of diesel oil is usually -20~-35 ℃, the freezing point of kerosene is generally lower than-30 ℃, so embodiment 1~3 is summer formulation, and embodiment 4~6 is winter formulation.

[0028] Taking Example 1 as an example, the preparation process and application process of oily cold-patch asphalt are described.

[0029] A preparation process of oily cold-patch asphalt. At room temperature, add 30g of aromatic oil to 1000g of base asphalt and stir evenly, then add 30g of SBR latex or rubber powder and 40g of single-component epoxy resin and stir evenly, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com