Method for optimizing cockpit support structures

A supporting structure and cockpit technology, applied in superstructure, design optimization/simulation, superstructure subassembly, etc., can solve problems such as hindering the development process, uneven edges and installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

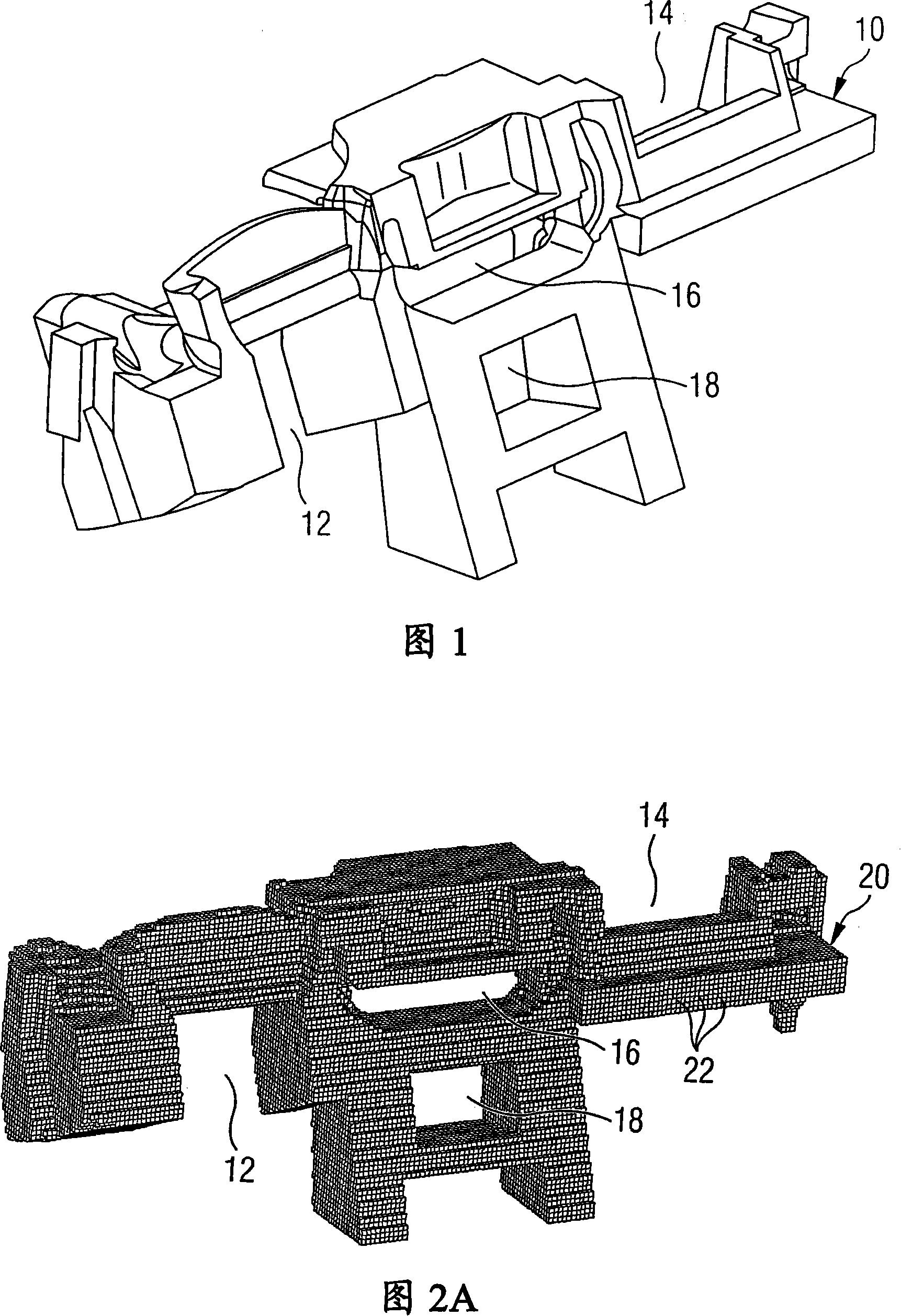

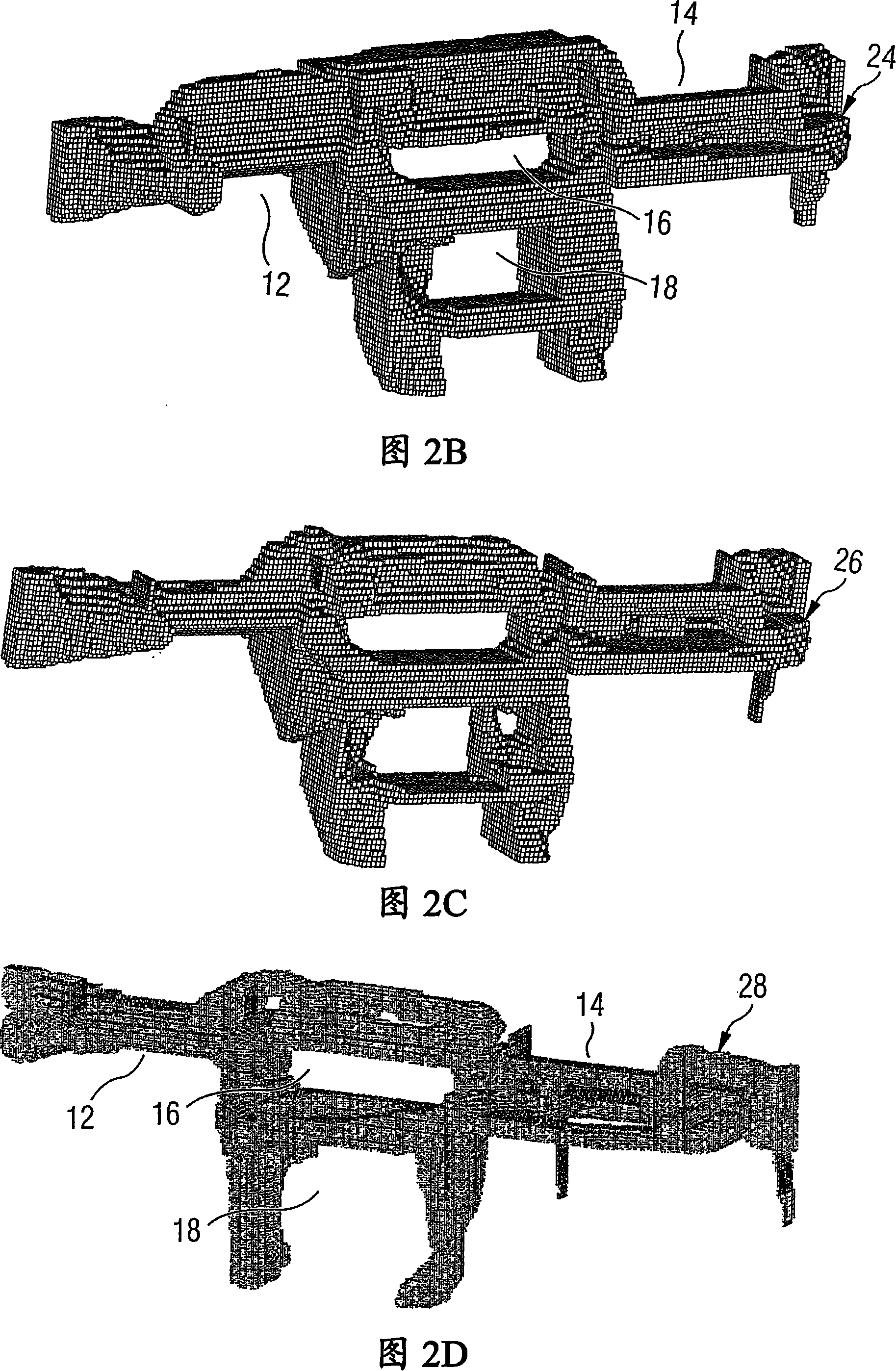

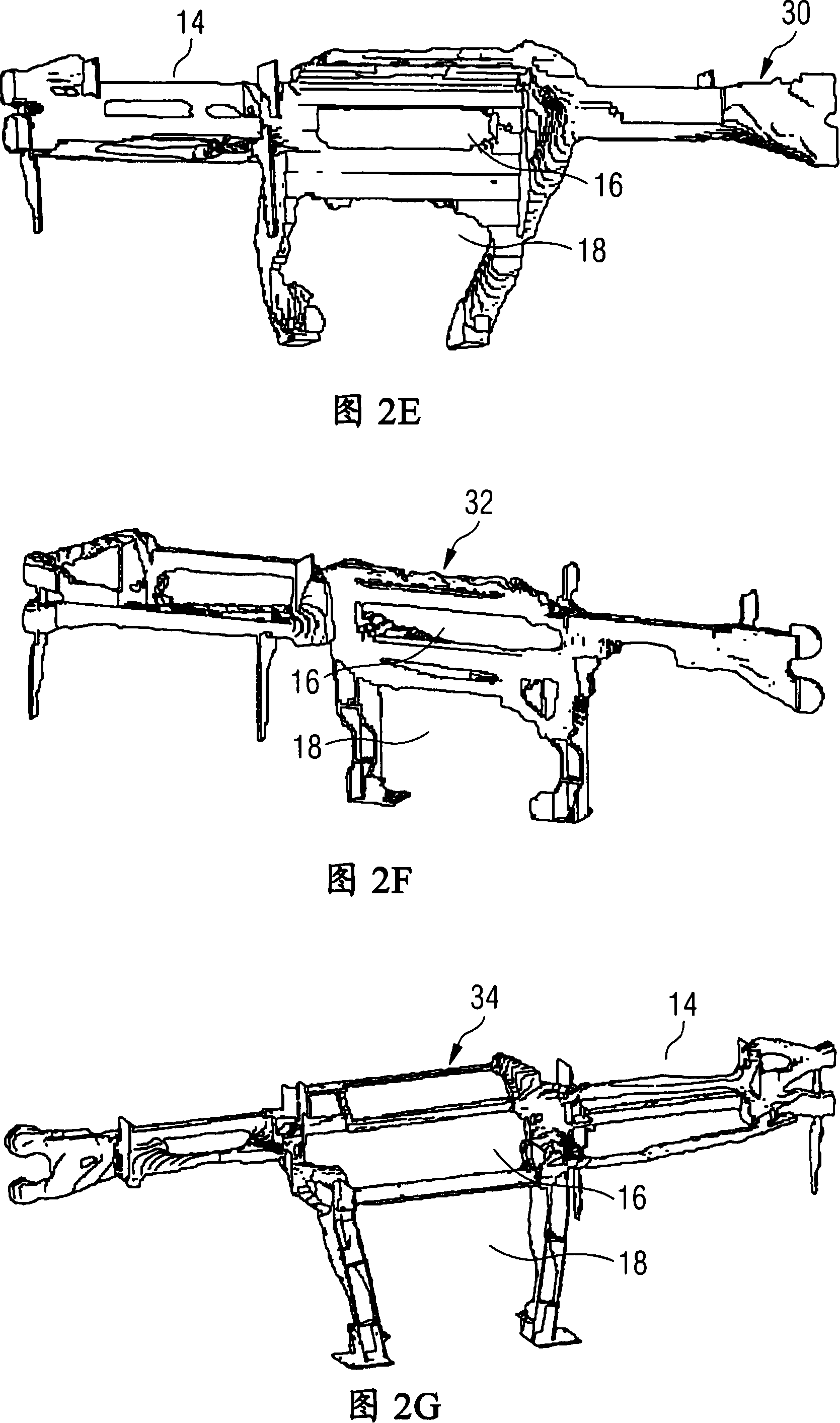

[0024] FIG. 1 shows a perspective view of an installation space 10 as it is created in the region of the cockpit of the vehicle between the bulkhead separating the engine compartment of the vehicle from the cockpit and the cockpit module. The cockpit module forms the visible surface and contains functional components of the vehicle cockpit, such as air conditioning, audio equipment, glove boxes, ashtrays, instrument brackets, etc. Furthermore, installation space remains for other vehicle components such as airbags and steering columns. A cockpit support structure is provided in the installation space 10 , which has to supportably connect the various cockpit modules to the vehicle body. Usually, such a cockpit support structure also has the meaning of supporting the vehicle body, and especially in the case of a side collision, the cockpit support structure must also withstand enormous forces and stabilize the cockpit. Since, for example, recesses 12 for the steering column, ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com