Patents

Literature

59results about How to "Increase the allocation ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

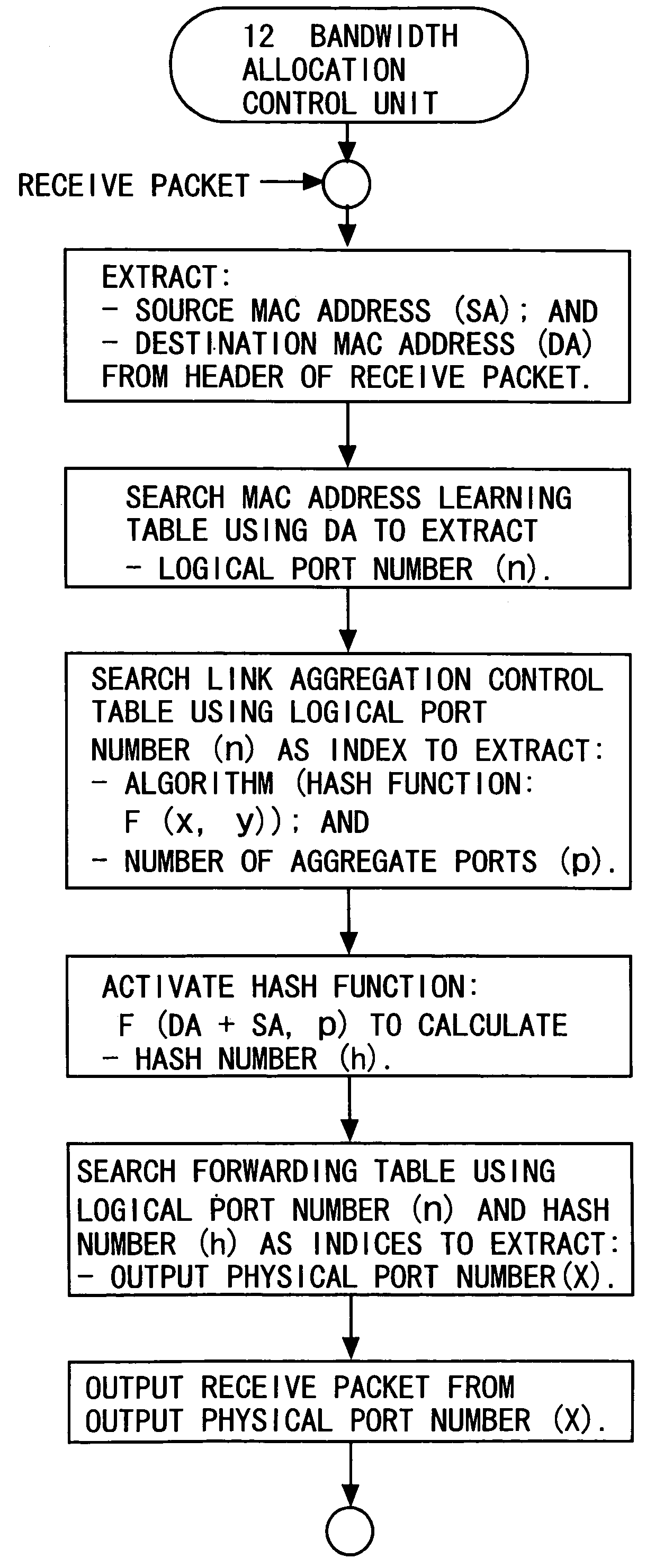

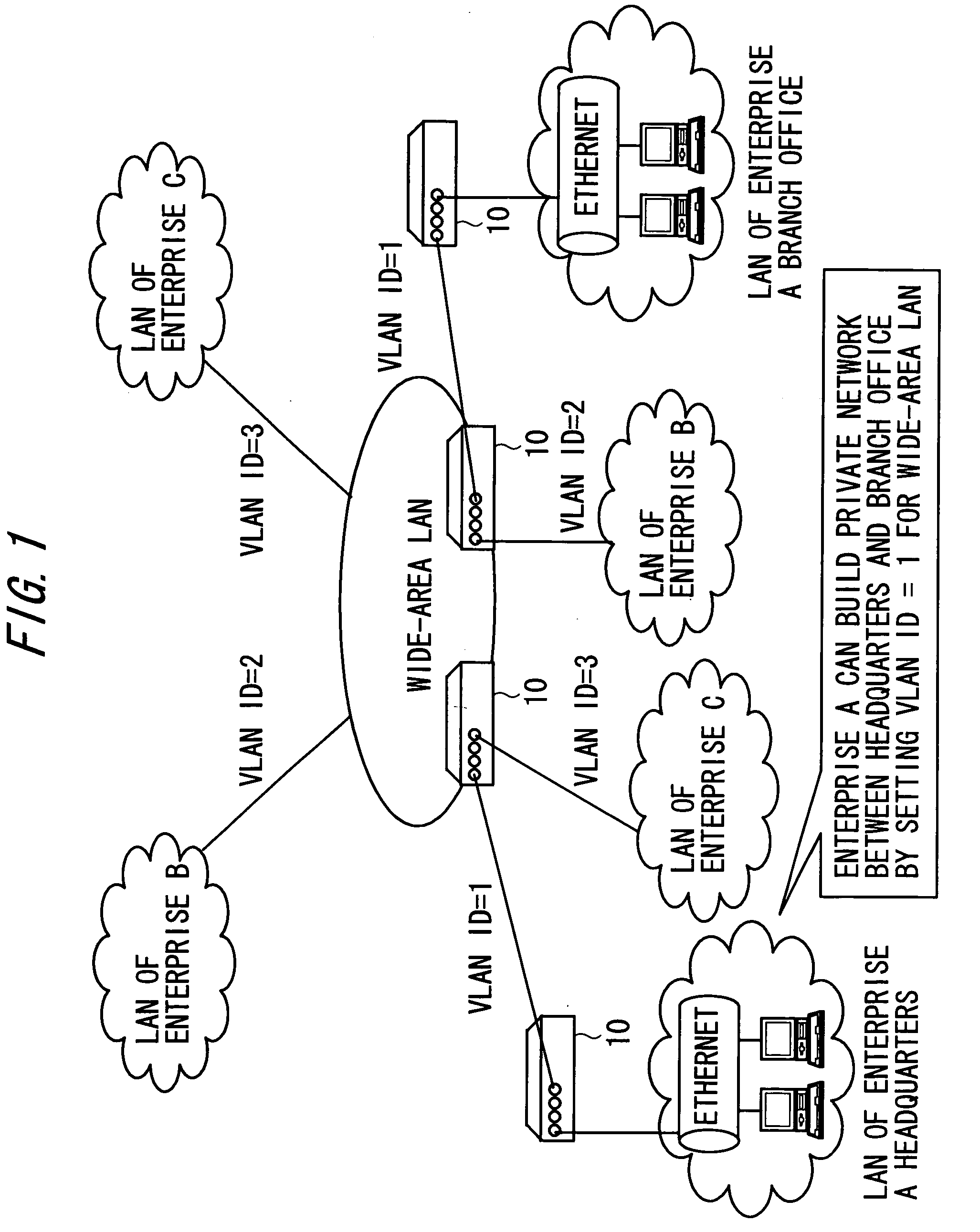

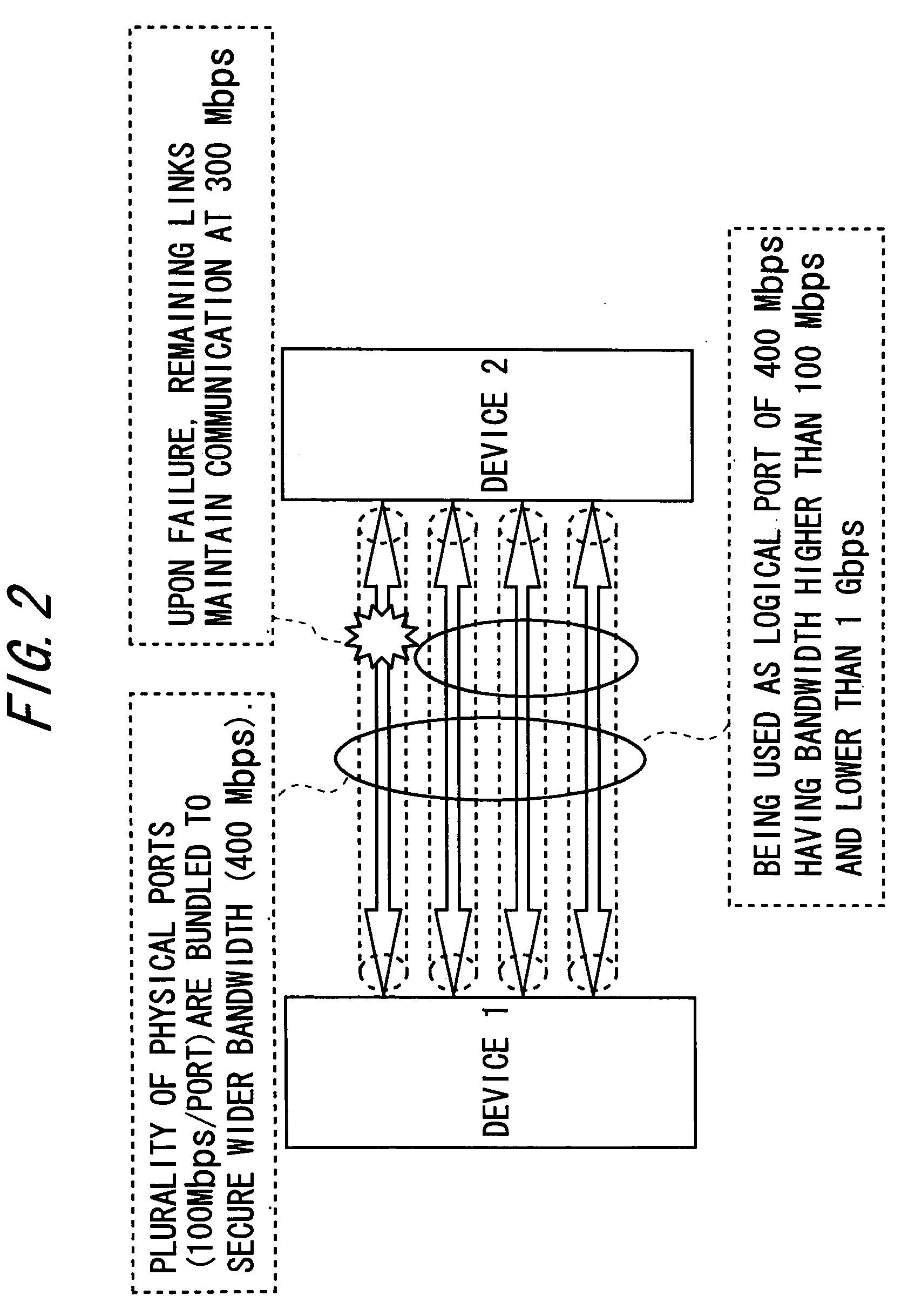

Traffic distribution control device

InactiveUS20050276263A1Process stabilityHigh bandwidthError preventionTransmission systemsTraffic capacityHash function

A data transmission device 10 serving as a traffic distribution control device is a device which, in order to distribute traffic across a plurality of physical ports composing a logical port for link aggregation, uses a hash function to calculate a hash value from a destination address and a source address of a receive packet, and determines a destination physical port. The traffic distribution control device includes a measuring unit 13 that measures an output flow rate of a packet outputted from each of the plurality of physical ports; a calculating unit 14 that calculates a flow rate ratio between the plurality of physical ports with respect to the measured output flow rates; and a first control unit 12 that feeds the calculated flow rate ratio back to a bandwidth distribution ratio between the plurality of physical ports to change numerical allocation of hash values for determining the destination physical port.

Owner:FUJITSU LTD

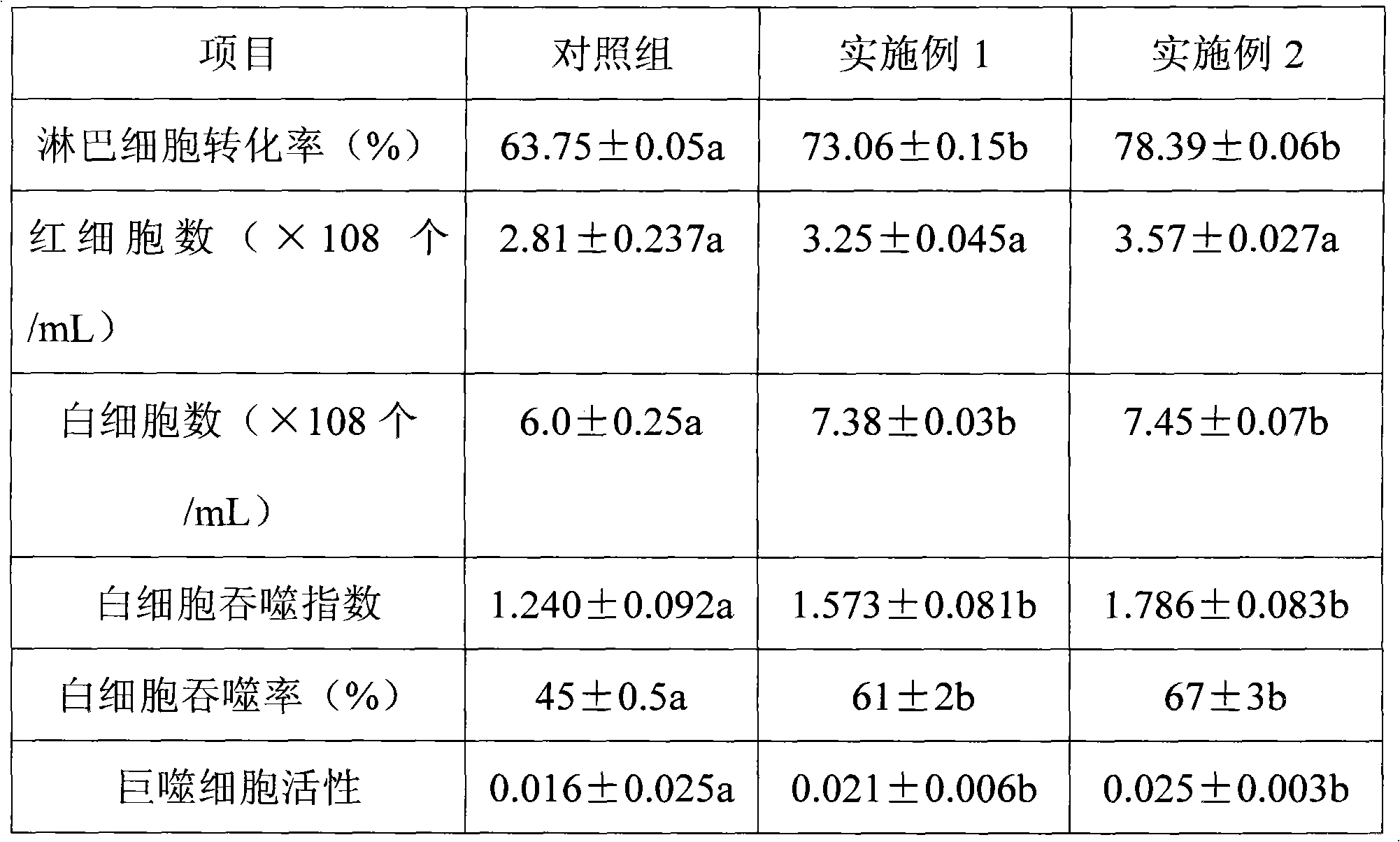

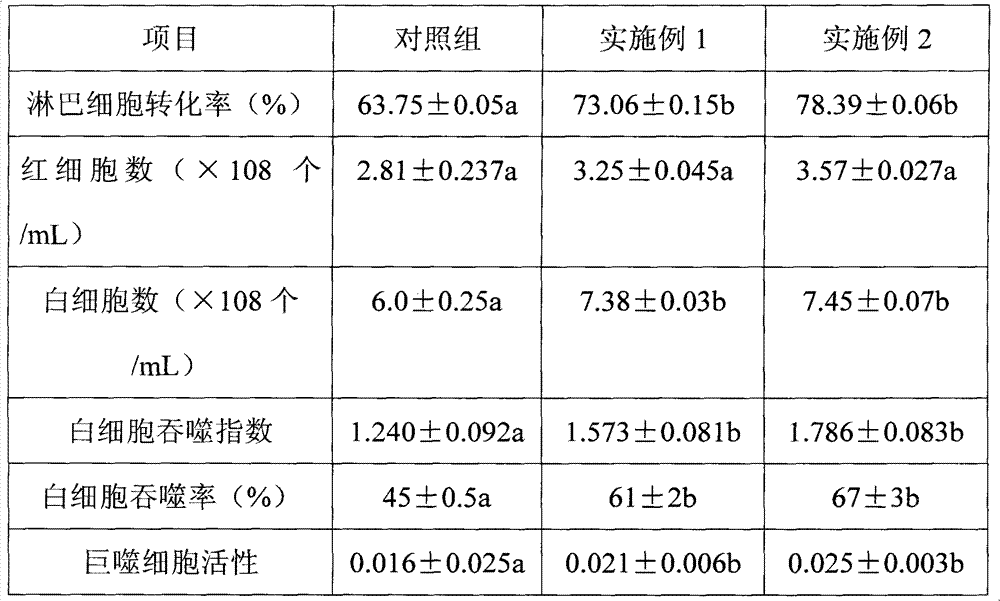

Immune reinforced type grass carp feed

ActiveCN101991024AEnhance immune functionIncrease the allocation ratioFood processingClimate change adaptationDiseaseEpimedium

The invention relates to an aquatic feed, in particularly to a feed for grass carp. The immune reinforced type grass carp feed comprises the following components in percentage by mass: 8-15% of bean pulp, 1-5% of palm kernel cake, 25-35% of rapeseed meal, 5-10% of rice bran, 3-8% of brewer's grains, 10-18% of DDGS (Distillers Dried Grains with Soluble), 10-15% of flour, 5-10% of malt roots and 0.5-1% of premix grass carp compound. In the premix grass carp compound, epimedium and other traditional Chinese medicines are used for aquatic animals for the first time so as to achieve the effect of enhancing the immunologic function of the grass carp; and the traditional Chinese medicines are proportioned reasonably, and thus, the immunity of the grass carp can be enhanced, and the capability ofthe grass carp for resisting and preventing diseases is improved.

Owner:广州市海维饲料有限公司

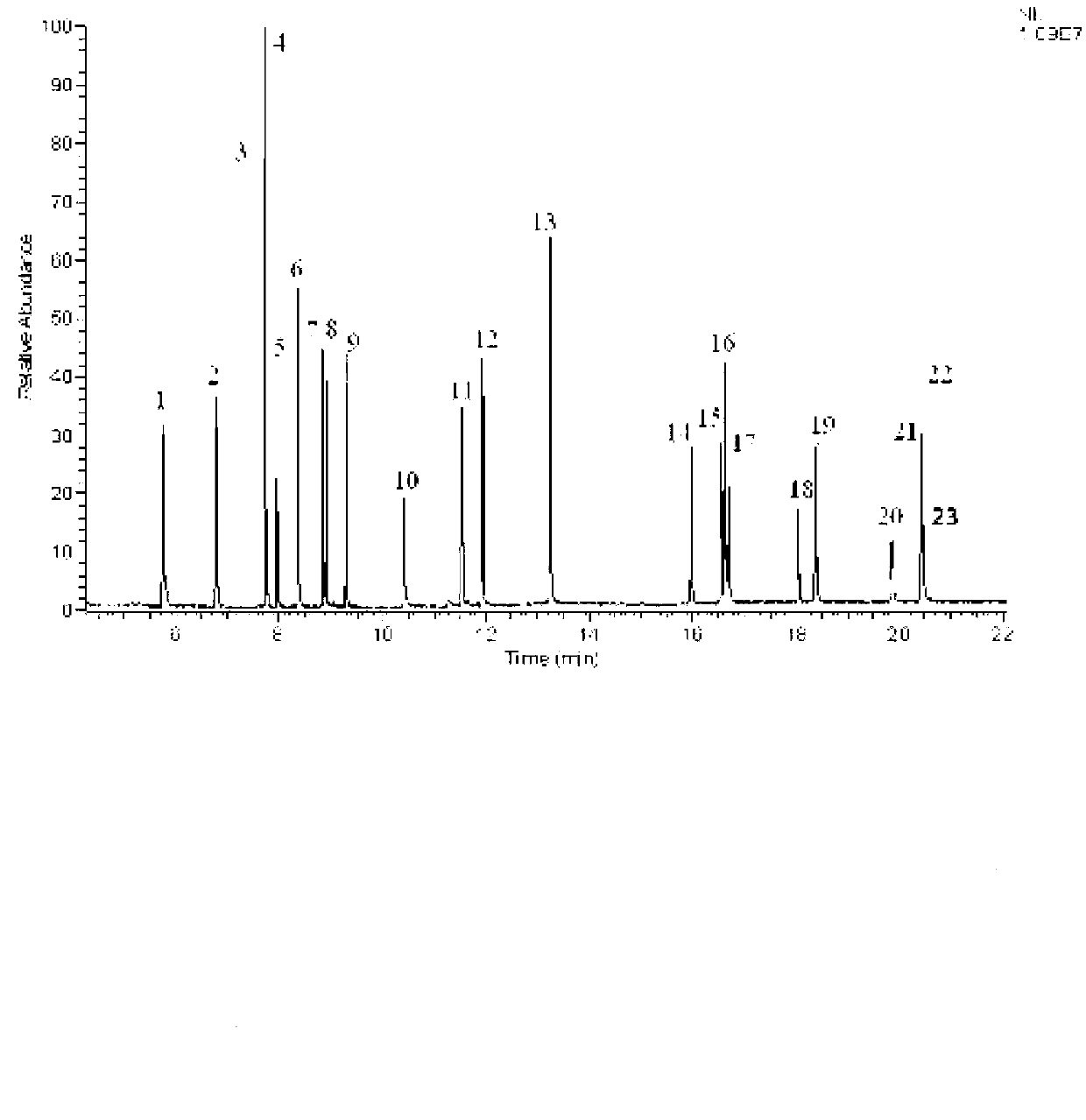

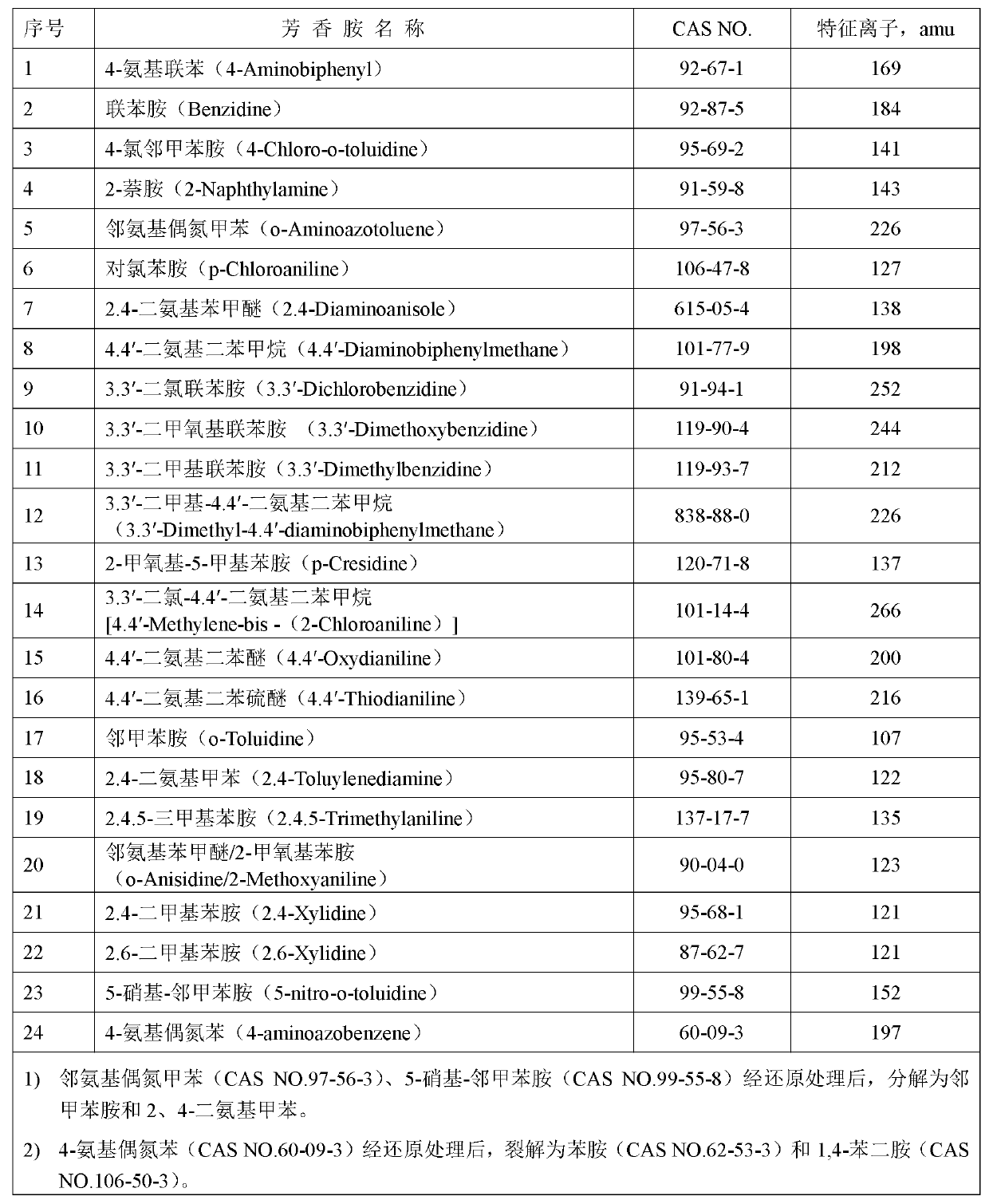

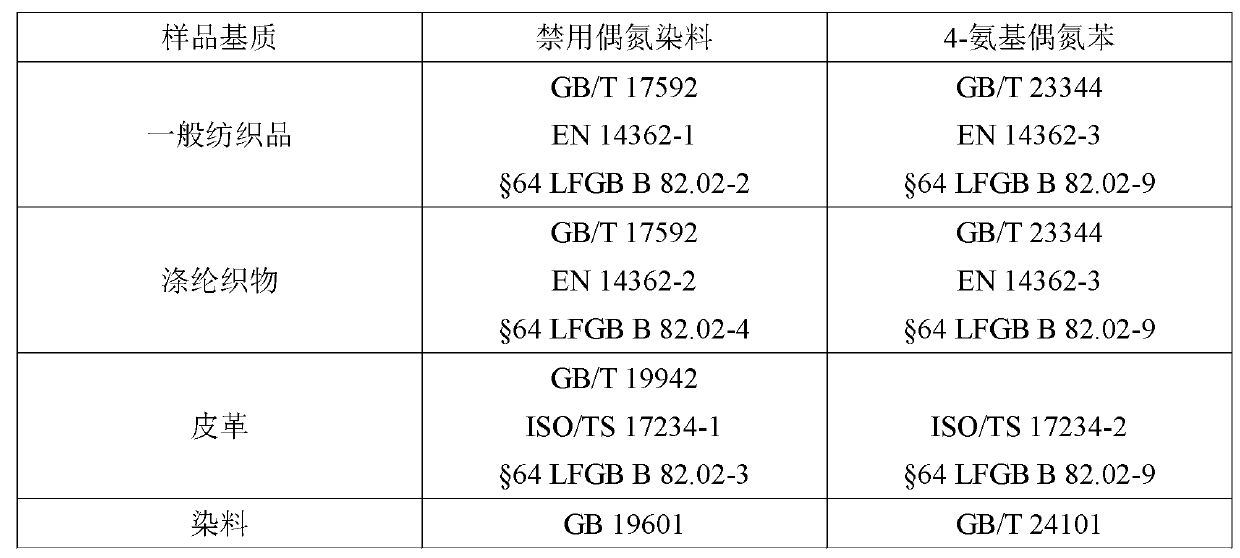

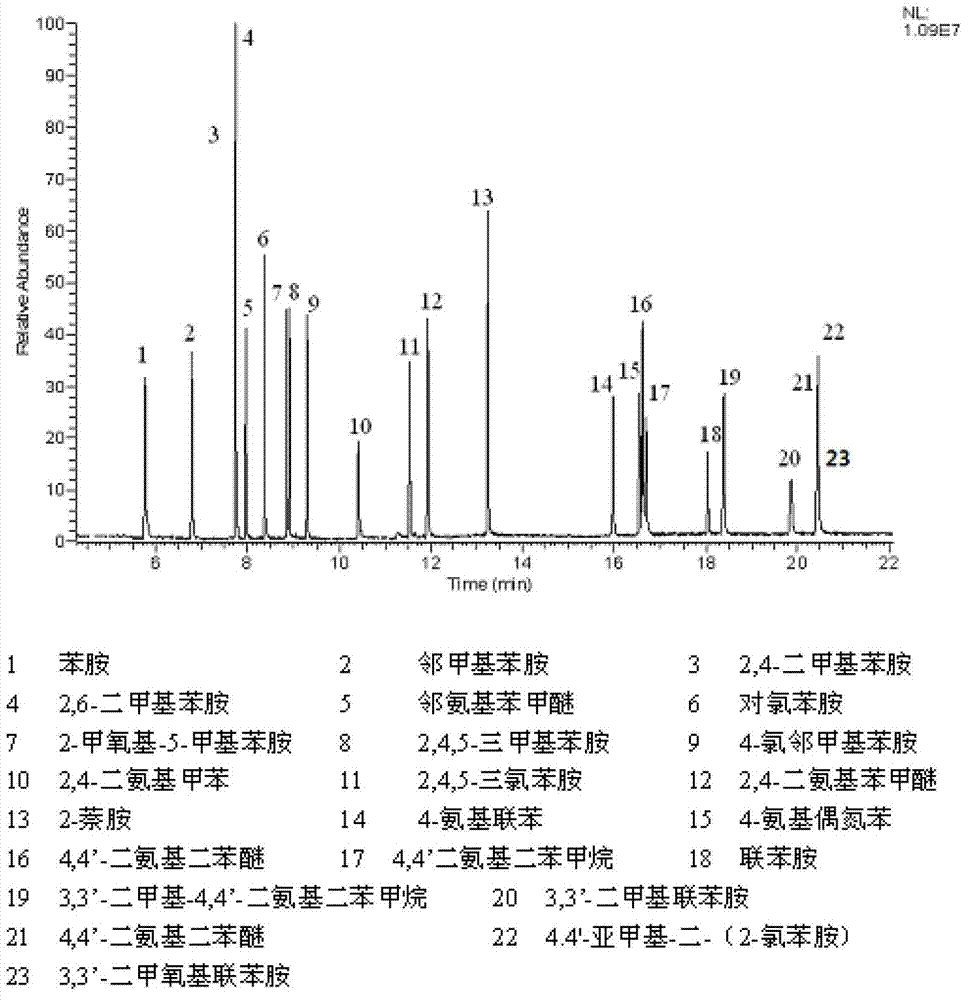

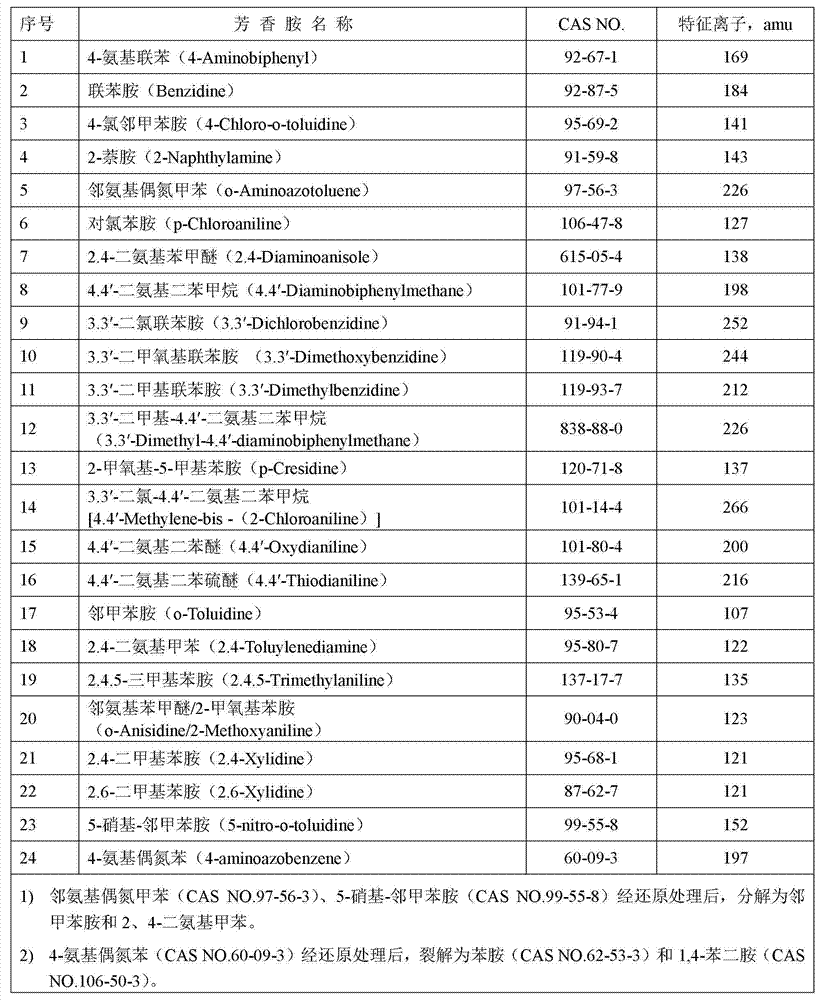

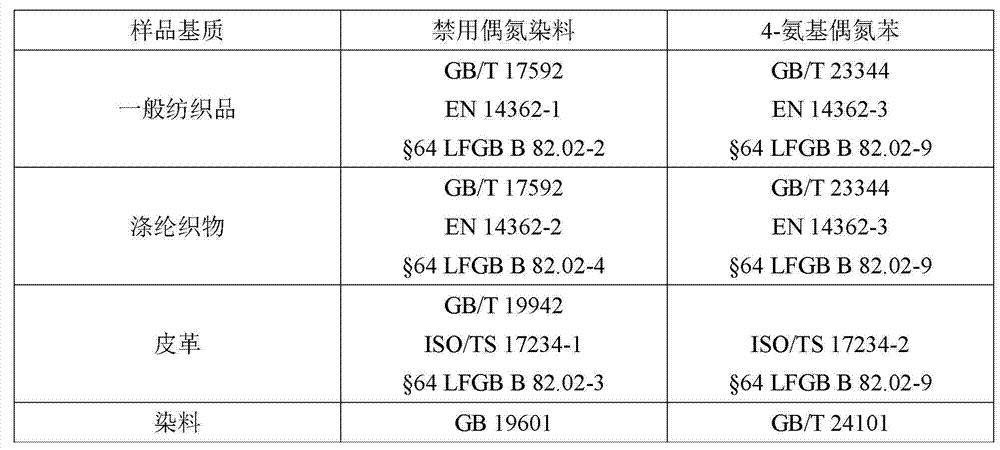

Method for quickly screening and detecting azo dyes forbidden in textile materials, leathers and dyes using gas chromatography mass spectrometry

ActiveCN102798677AReduce processing timeHigh consumption of reagents and materialsComponent separationChemistryMass spectrum analysis

The invention discloses a method for quickly screening and detecting azo dyes forbidden in textile materials, leathers and dyes using gas chromatography mass spectrometry, which comprises the following steps: 1) preparing a sample, 2) subjecting the sample to reduction reaction, 3) extracting the sample, 4) performing the gas chromatography mass spectrometry on the sample, 5) screening decision: compared with the GC-MS analysis result of a standard solution, if the retention time and the mass spectrum of the aromatic amine in the sample keep with standards, the sample is judged as a suspicious positive sample, otherwise it is a negative sample and directly judged as a qualified sample. The sample pre-treatment time is shortened, the cost is reduced, the detection time is shortened, the operation step is simple, the operation is convenient, the operation time is short, the operation cost is low, the detection efficiency is improved; the aromatic amine in the sample is detected by a gas chromatography mass spectrometer, color interference problem is not existed, the sample matrix is effectively prevented from being infected, and the judgment accuracy is high, thus the method is not only suitable for textile materials, but also suitable for other products such as leathers and dyes.

Owner:南京海关工业产品检测中心

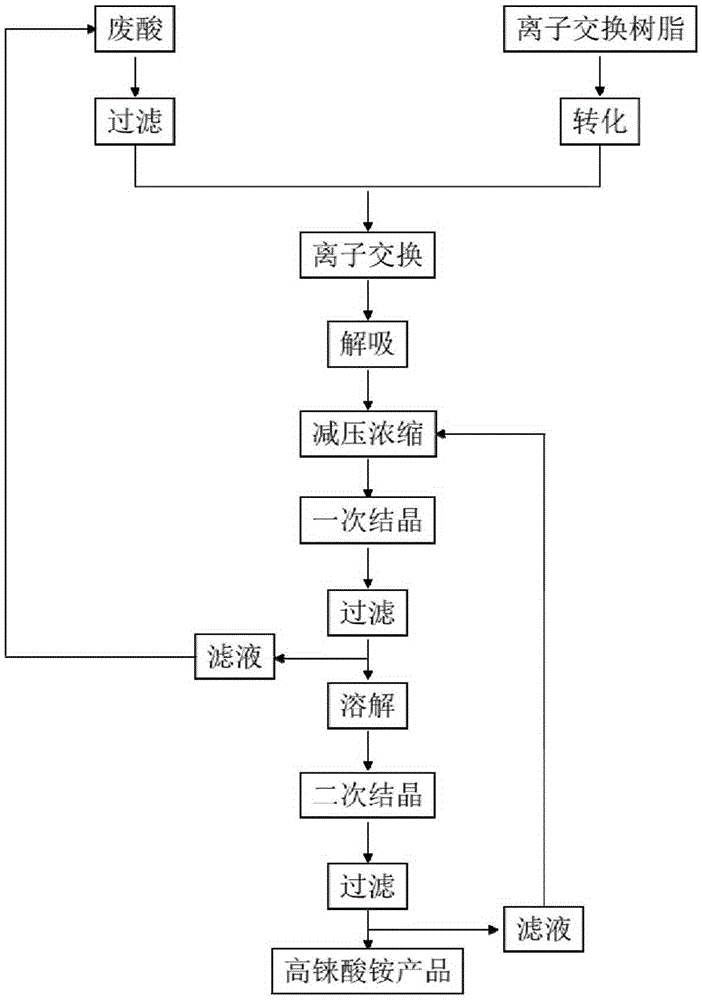

Method for recovering rhenium from molybdenum smelting waste acid

ActiveCN105384195ASimple recycling processSimple and efficient operationRhenium compounds preparationIon exchangeAmmonium sulfate

The invention discloses a method for recovering rhenium from molybdenum smelting waste acid and belongs to the technical field of metal rhenium recovery and recycle. The method comprises 1, filtering molybdenum smelting waste acid, and treating the filtrate by a composite aminoethylene weak basic anion exchange resin column for adsorption until adsorption is saturated, and 2, carrying out desorption on the saturated anion exchange resin column, collecting the desorption liquid and carrying out evaporation crystallization to obtain ammonium perrhenate. The composite aminoethylene weak basic anion exchange resin has large saturation adsorption quantity. The desorption liquid has rhenium content 100 times or more that of waste acid. Compared with the existing extraction method and ion exchange method, the method provided by the invention has a high rhenium recovery rate of 98% or more. Through use of solubility difference of ammonium perrhenate, ammonium molybdate and ammonium sulfate, ammonium perrhenate is purified by evaporation crystallization and ammonium perrhenate purity is 99.9% or more. The method has a simple rhenium recovery process, is environmentally friendly, is convenient for operation and is suitable for large scale production.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

A method for efficiently extracting endocrine disruptors in samples

InactiveCN102288709AIncrease flow rateEfficient extractionComponent separationInorganic saltsPerturbateurs endocriniens

In the method for efficiently extracting endocrine disruptors in a sample of the present invention, the sample to be tested is preliminarily treated by filtering, grinding, homogenizing, ultrasonication, protein precipitation, protein hydrolysis or degreasing to make a sample solution of an aqueous matrix; adjust the pH value of the sample solution, Or add inorganic salts or organic salts to increase the ionic strength of the sample solution to reduce the distribution coefficient of endocrine disruptors in the water phase; use the membrane disc solid phase extraction device to make the sample solution flow continuously or "flow-stop-flow" intermittent Through the activated nylon nanofiber membrane, the endocrine disruptors in the sample are retained by the nylon nanofiber to achieve extraction. The invention synergizes the advantages of solid-phase membrane extraction and nano-adsorption media, and can realize efficient extraction of internally distributed interfering substances in various actual samples with only a few milligrams of nylon nanofiber membrane and hundreds of microliters of elution solvent , The extraction and enrichment process of separation, adsorption, concentration and elution can be completed within a few minutes to ten minutes.

Owner:SOUTHEAST UNIV

Method for slagging, boron removal and purification of metalluragical silicon

ActiveCN102001661AIncrease the allocation ratioHigh boron removal efficiencySilicon compoundsProcess equipmentBoron

The invention discloses a method for slagging, boron removal and purification of metalluragical silicon, comprising the following steps of: selecting a metalluragical silicon material, heating until the metalluragical silicon is completely melted into a silicon solution and adjusting the temperature of the silicon solution; then adding a ternary slagging agent; removing scum on the surface of the silicon solution by stirring and carrying out a heat-insulating reaction; and standing the silicon solution for casting and then obtaining polysilicon, wherein the content of B in the polysilicon meets the solar level requirement. According to the method, complicated blowing equipment can be avoided, the process equipment can be simplified and the cost can be reduced; and the method is convenient for industrial application.

Owner:东海晶澳太阳能科技有限公司

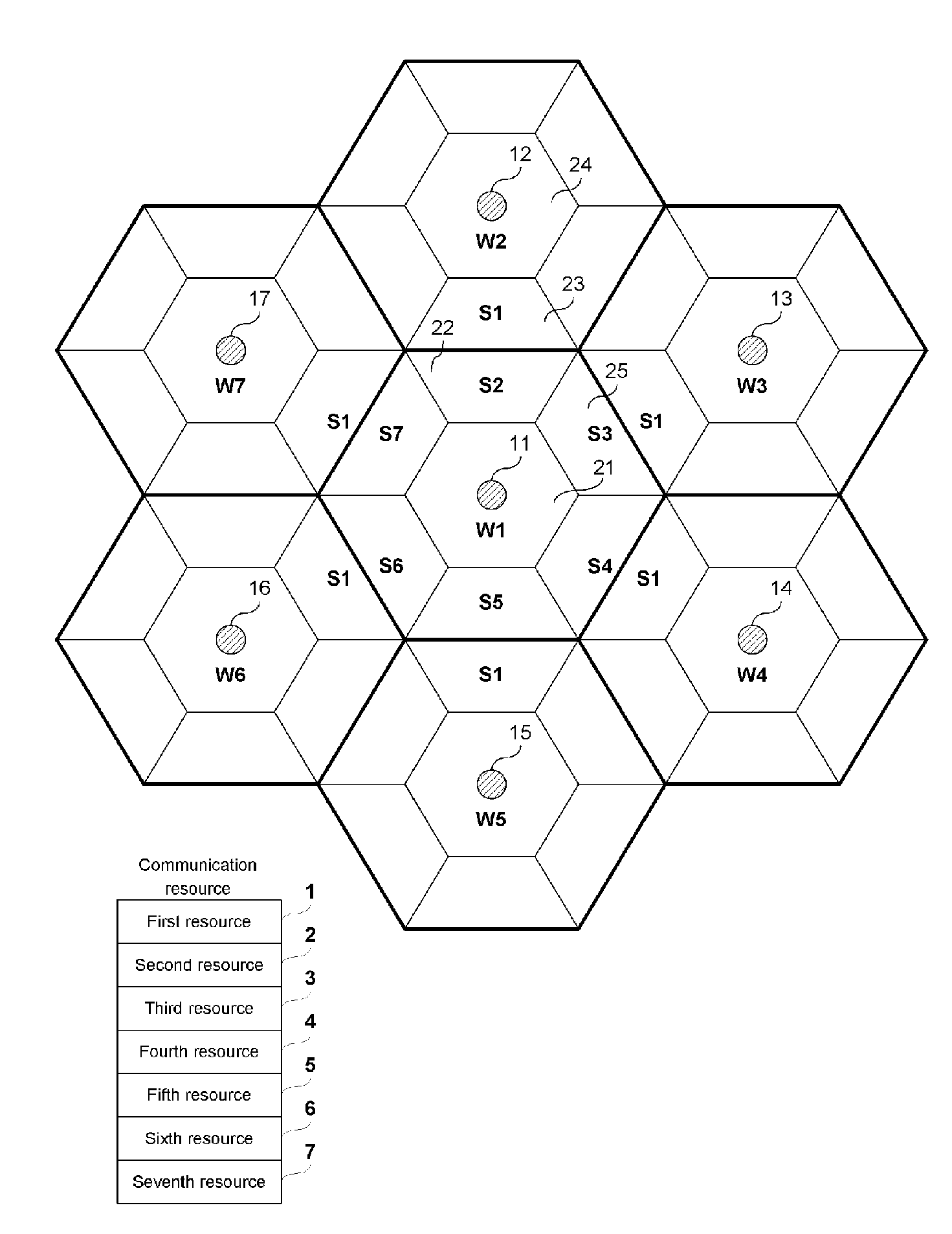

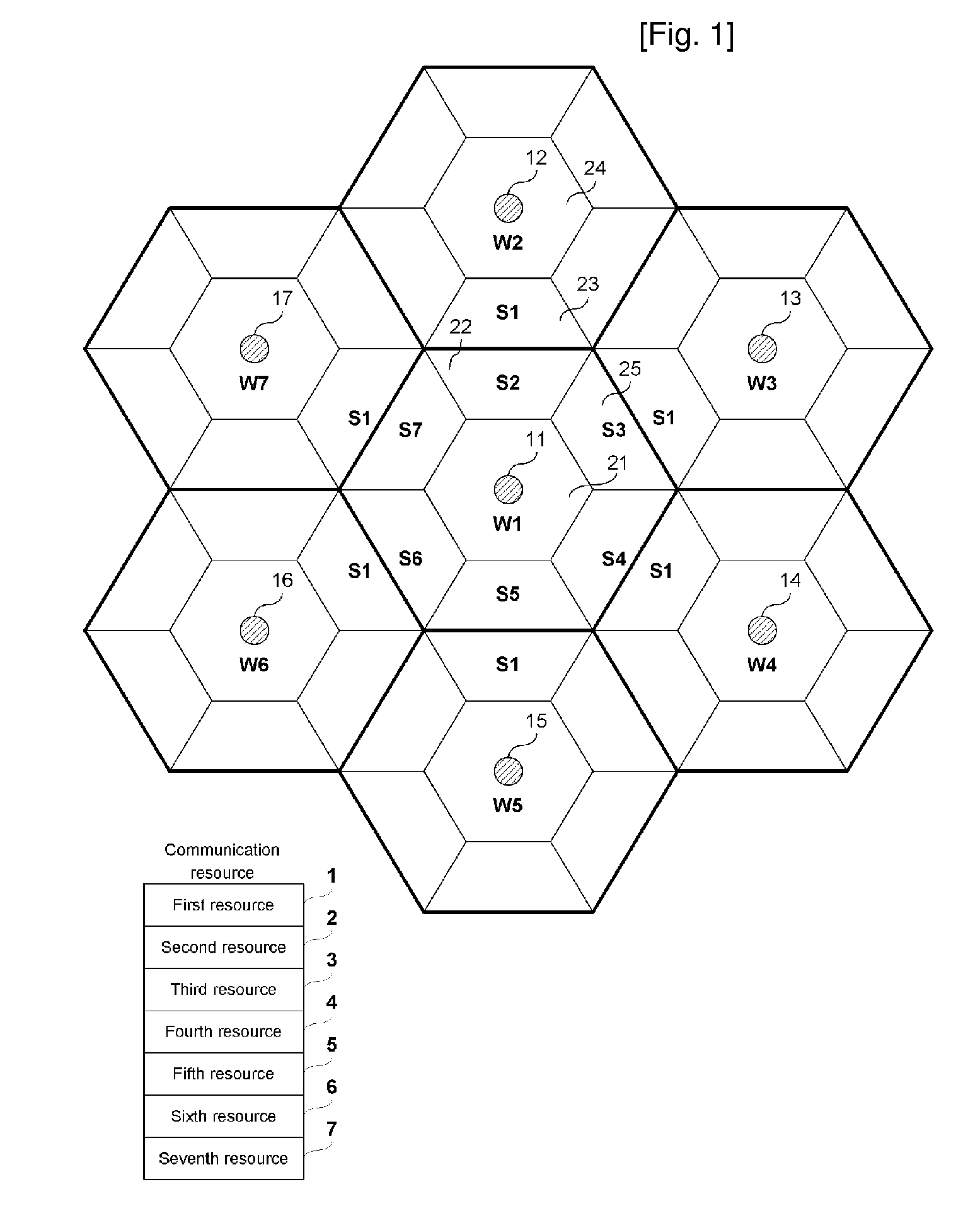

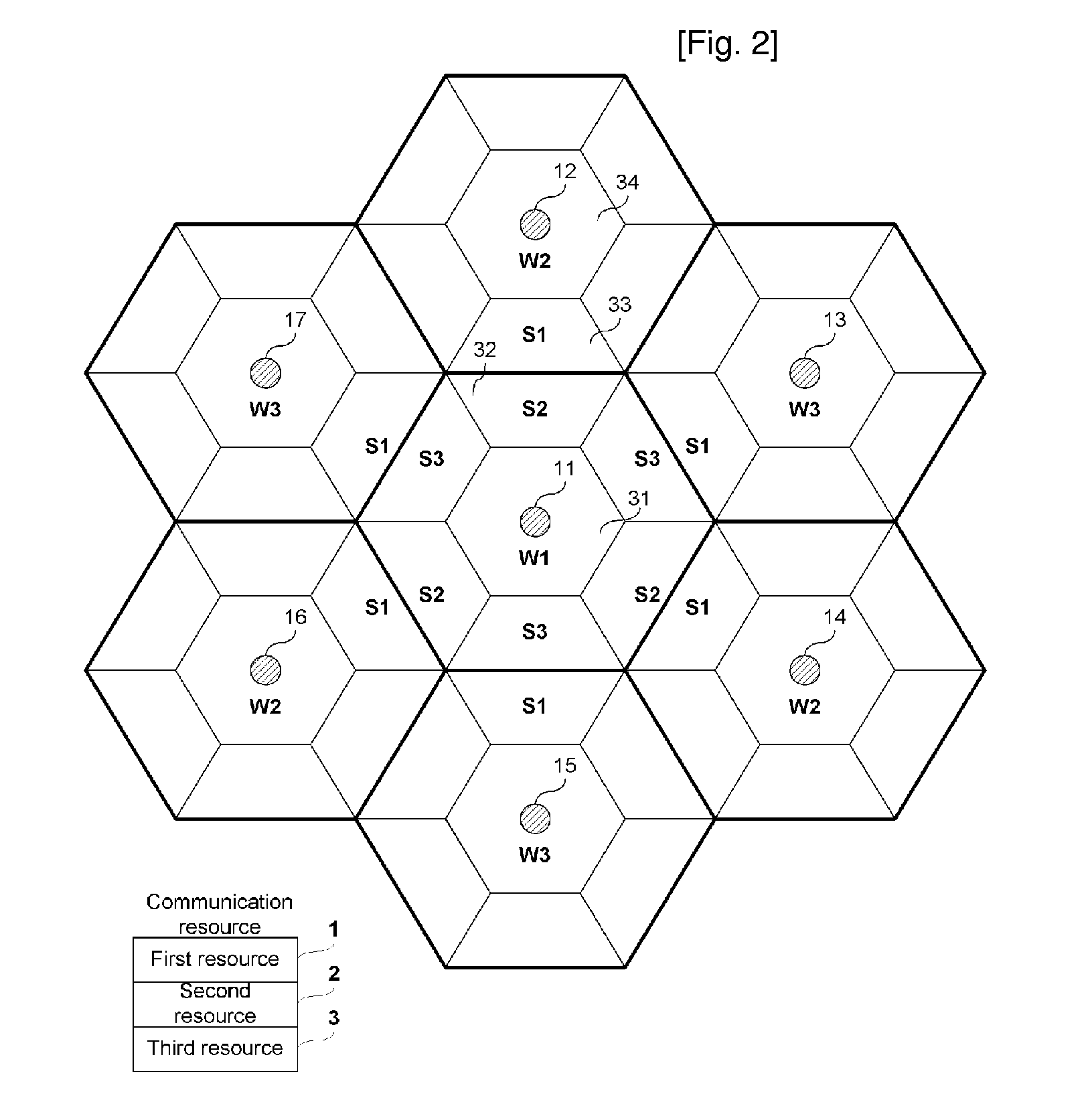

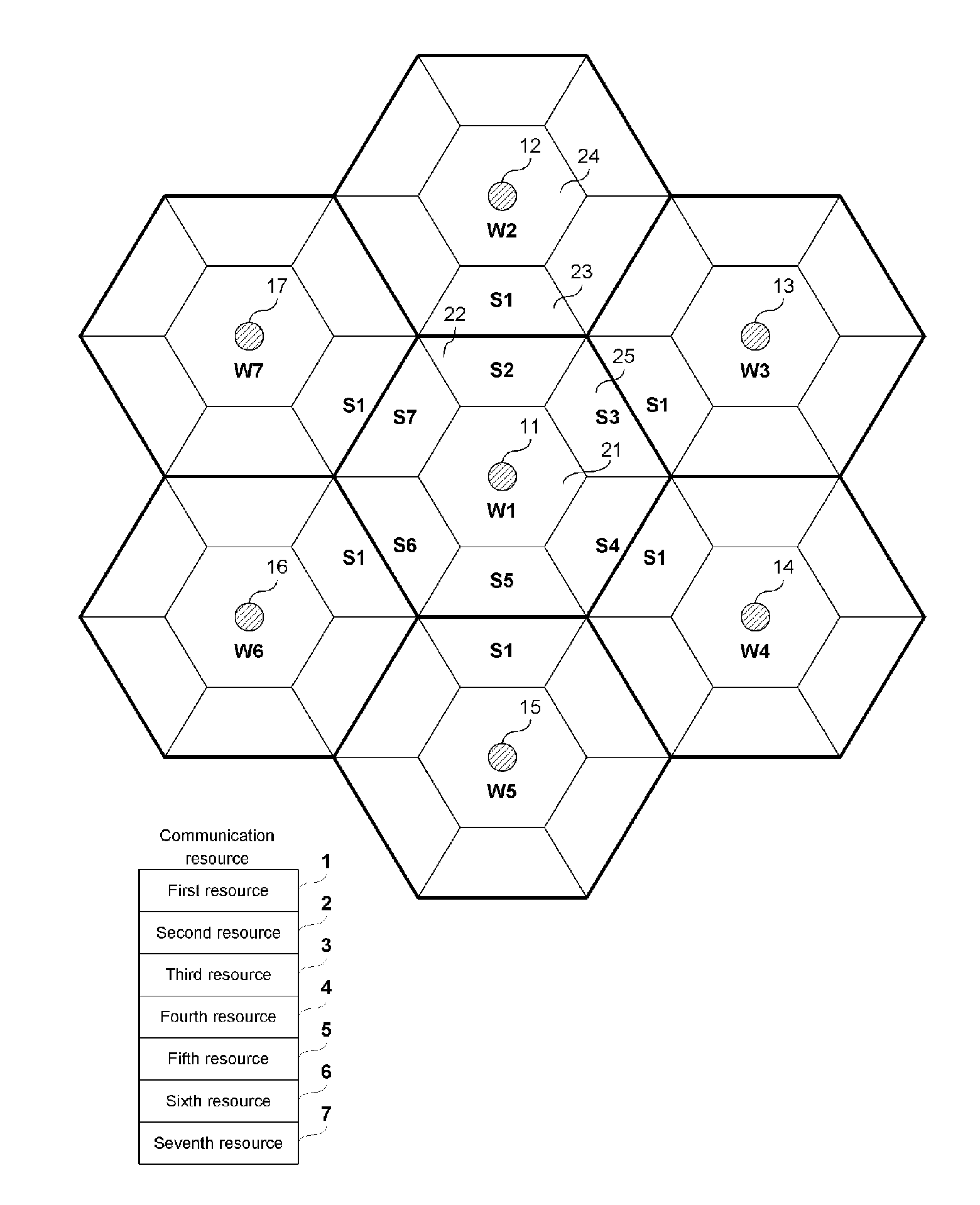

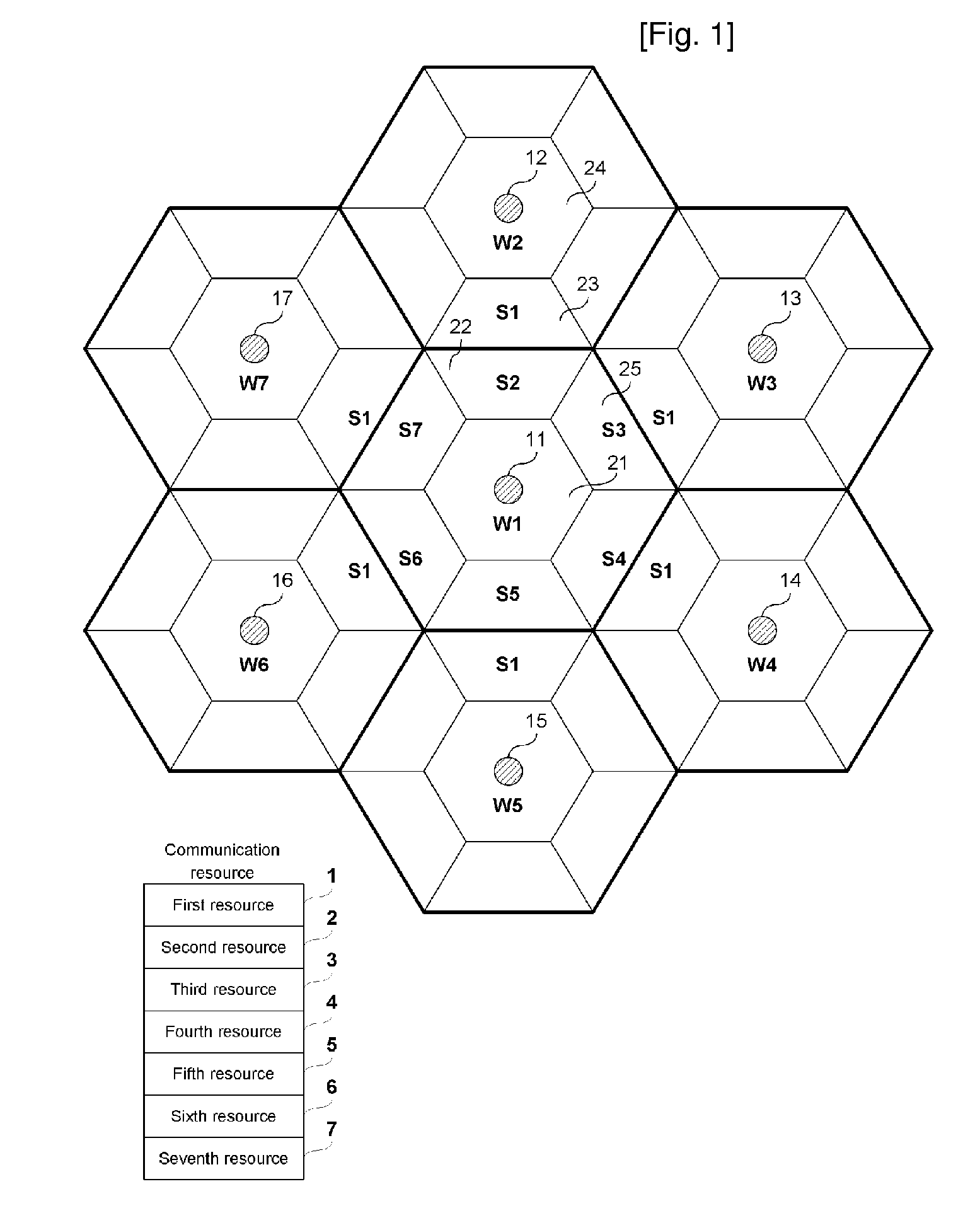

Communication Resource Allocation Method of Base Station

InactiveUS20080225752A1Increase ratioRatio decreaseError preventionTransmission systemsBase stationResource allocation

A communication resource allocation method for solving resource request imbalance content in a cell is provided. Considering a propagation environment, the base station allocates a whispering resource to a whispering area, the whispering resource being one part of the communication resource and the whispering area being a peripheral area of the first base station, and allocates a speaking resource to a speaking area, the speaking resource being other parts of the communication resource and the speaking area being a border area of a cell. When the resource request of the whispering area is increased, the base station further allocates a part of the speaking resource to the whispering area or increases a ratio of the whispering resource. When the resource request of the speaking area is increased, the base station controls a threshold value for identifying the whispering and speaking areas or increases a ratio of the speaking resource.

Owner:ELECTRONICS & TELECOMM RES INST

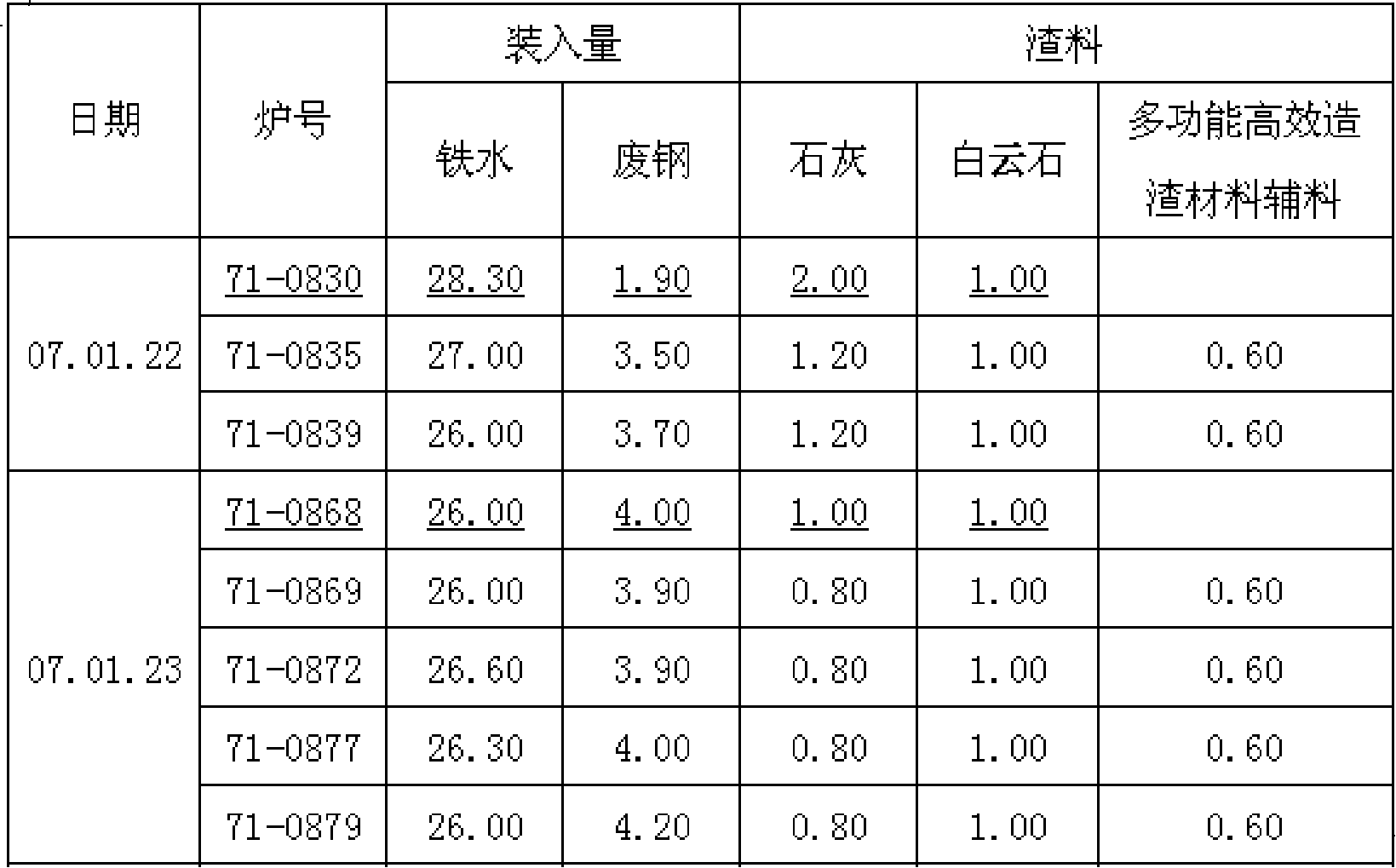

Multifunctional slagging material findings and method for producing the same

InactiveCN101173323ALow melting pointFacilitate chemical reactionsManufacturing convertersProcess efficiency improvementSteelmakingDolomite

The invention relates to a plurality of assistant materials of slagging materials and a preparation method, belonging to metallurgy field, which is characterized in comprising the components in the following weight matching: steel slag of converter 8.0 to 9.5 shares and addition agent 0.5 to 2 shares; wherein, the addition agent comprises the components in the following weight percentage: Na2CO3 is 5.00 to 10.00 percent, FeO is 70.00 to 80.00 percent and BaCO3 is 10.00 to 20.00 percent. The assistant materials of slagging materials can be used in slagging and also used as slugging agent and dephosphorizing agent. The invention achieves the recycle utilization of the steel slag of converter, therefore has the advantages of lowering the amount of waste slag during steel-making, saving the dosages of current slagging material: lime and dolomite and improving the slagging performance, and also has the advantages of slagging rapid, sludging rapid and dephosphorizing effectively. The invention provides a new method to recycle the steel slag of converter for people.

Owner:攀钢集团成都钢铁有限责任公司

Process for separating superfine particles

The invention relates to a method for separating ultra-fine particles, wherein it adjusts the components of dual-liquid system, or adds extractive to adjust the system which can separate ultra-fine particles into upper phase or lower phase; eccentrically treating two phases to obtain ultra-fine particles. And the inventive system can be repeated used. The invention has simple device and low cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

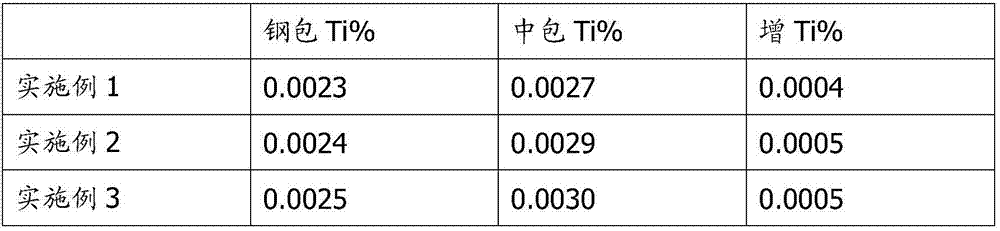

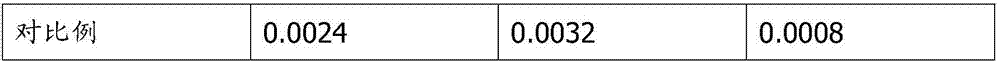

Low-titanium-content double-layer covering agent for silicon steel and use method of low-titanium-content double-layer covering agent

The invention provides a low-titanium-content double-layer covering agent for silicon steel and a use method of the low-titanium-content double-layer covering agent. The low-titanium-content double-layer covering agent comprises an upper layer covering agent part and a lower layer covering agent part; the lower layer covering agent part is contacted with molten steel; the upper layer covering agent part is located above the lower layer covering agent part; the upper layer covering agent part comprises the following raw materials, by weight percentage, 44-62% of SiO2, 2-10% of MgO, 1-10% of CaO, greater than 0 and less than or equal to 7% of Fe2O3, 20-38% of Al2O3, greater than 0 and less than or equal to 1% of C (all), greater than 0 and less than or equal to 0.5% of TiO2, and the balance ignition lost; and the lower layer covering agent part comprises the following raw materials, by weight percentage, 15-25% of SiO2, 3-8% of MgO, 48-68% of CaO, 2-10% of Fe2O3, greater than 0 and less than or equal to 1% of Al2O3, greater than 0 and less than or equal to 1% of C (all), greater than 0 and less than or equal to 0.2% of TiO2, and the balance ignition loss. With the use of the low-titanium-content double-layer covering agent, the content of titanium in molten silicon steel can be reduced effectively.

Owner:BEIJING SHOUGANG CO LTD

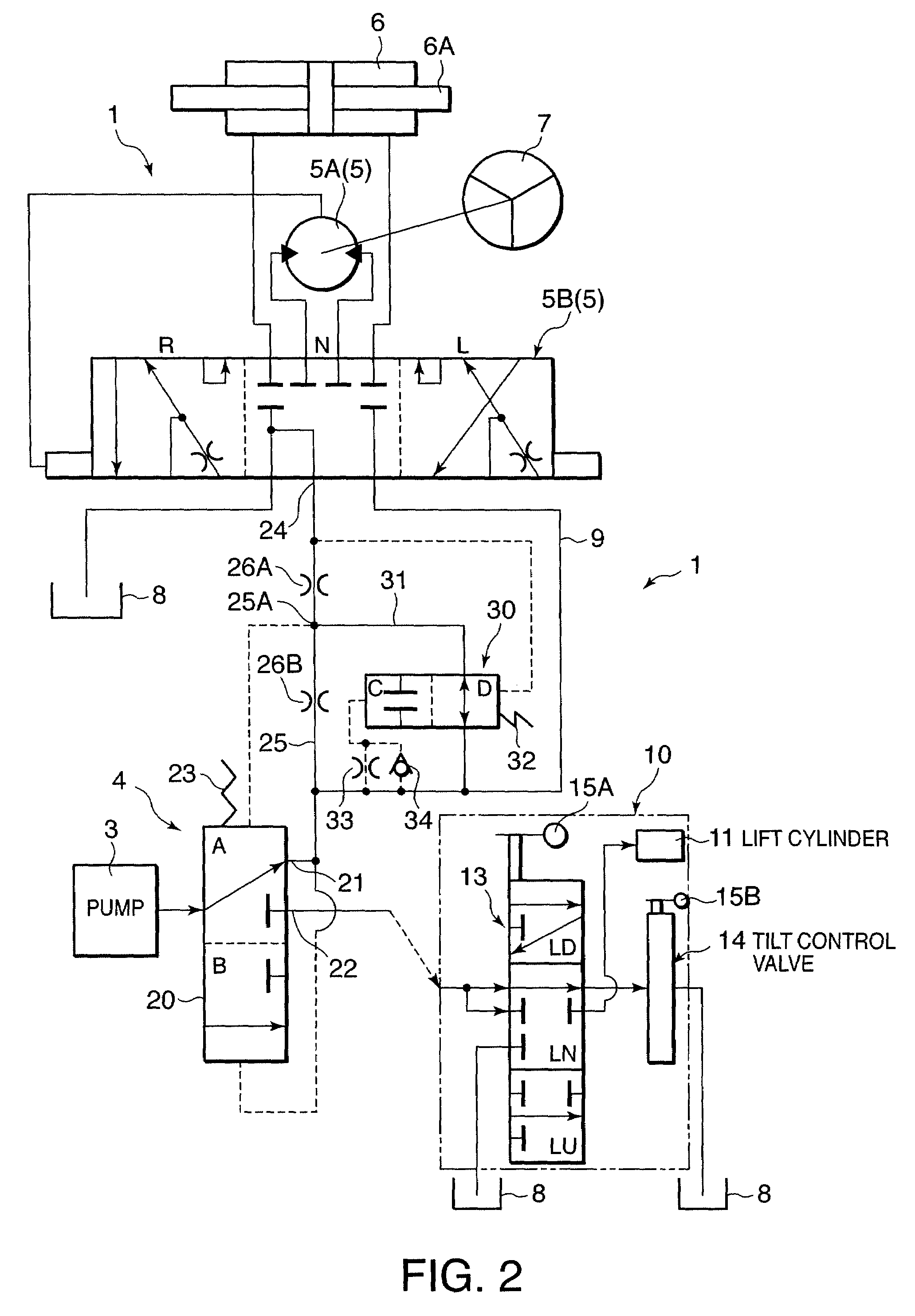

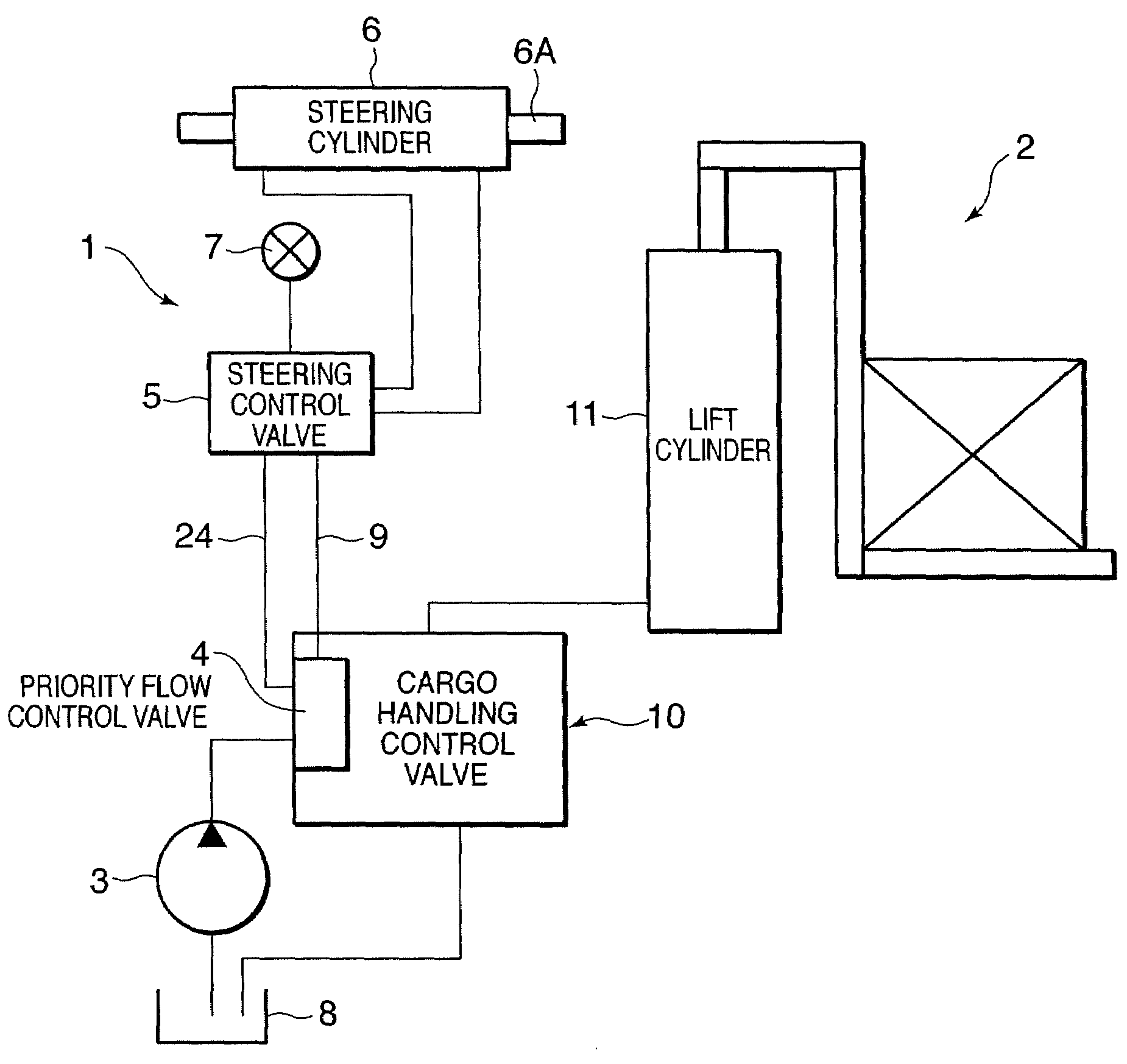

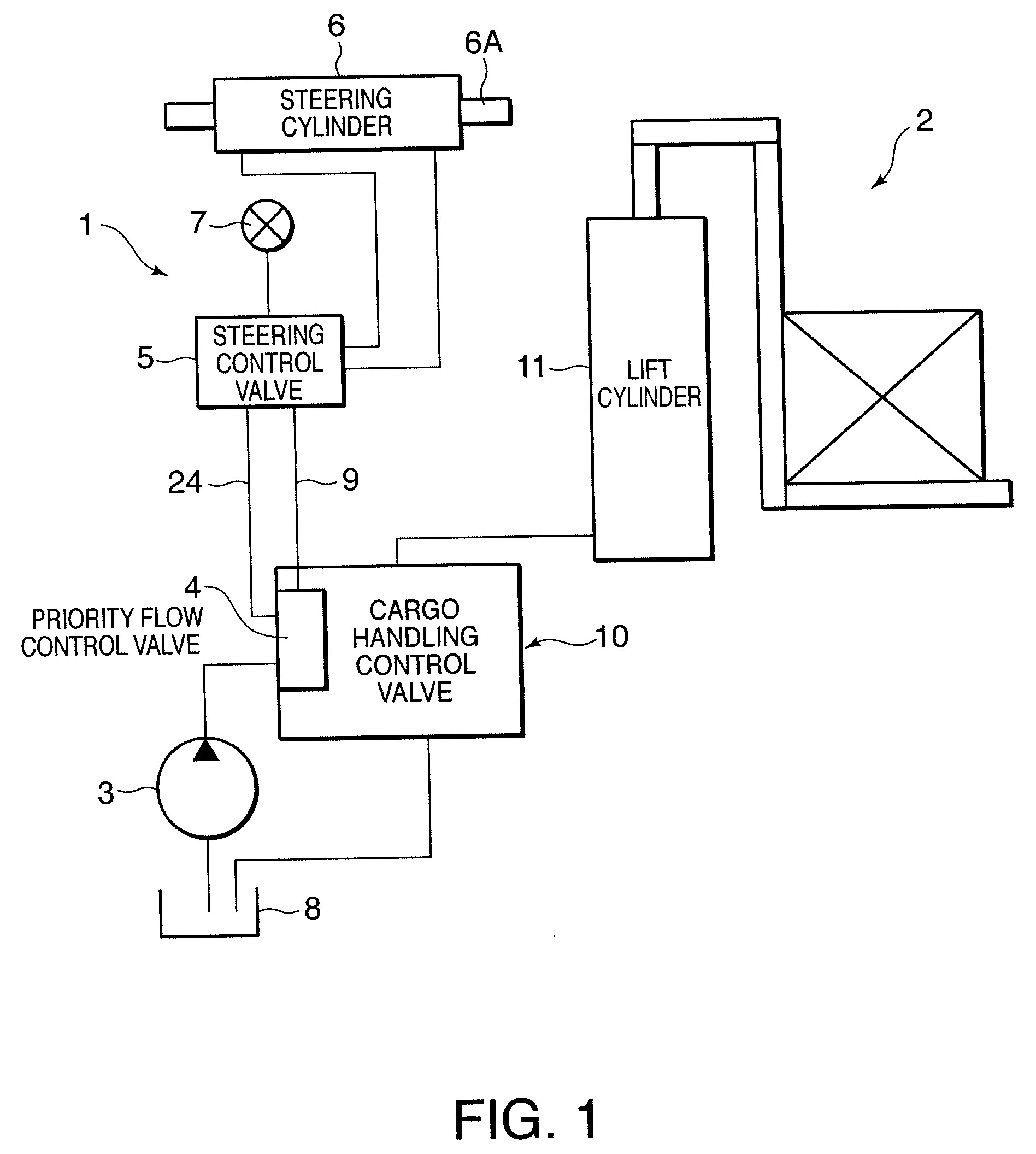

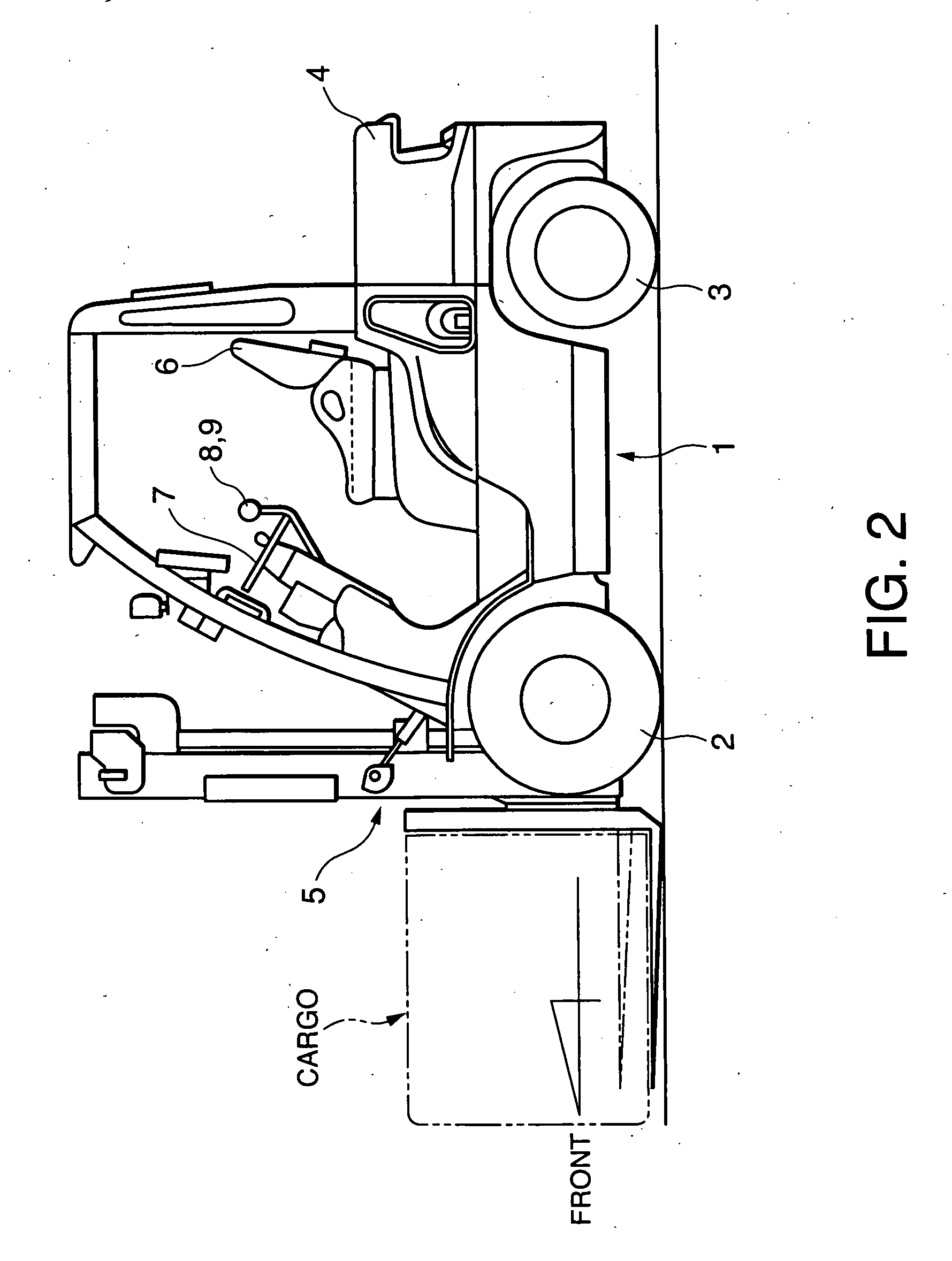

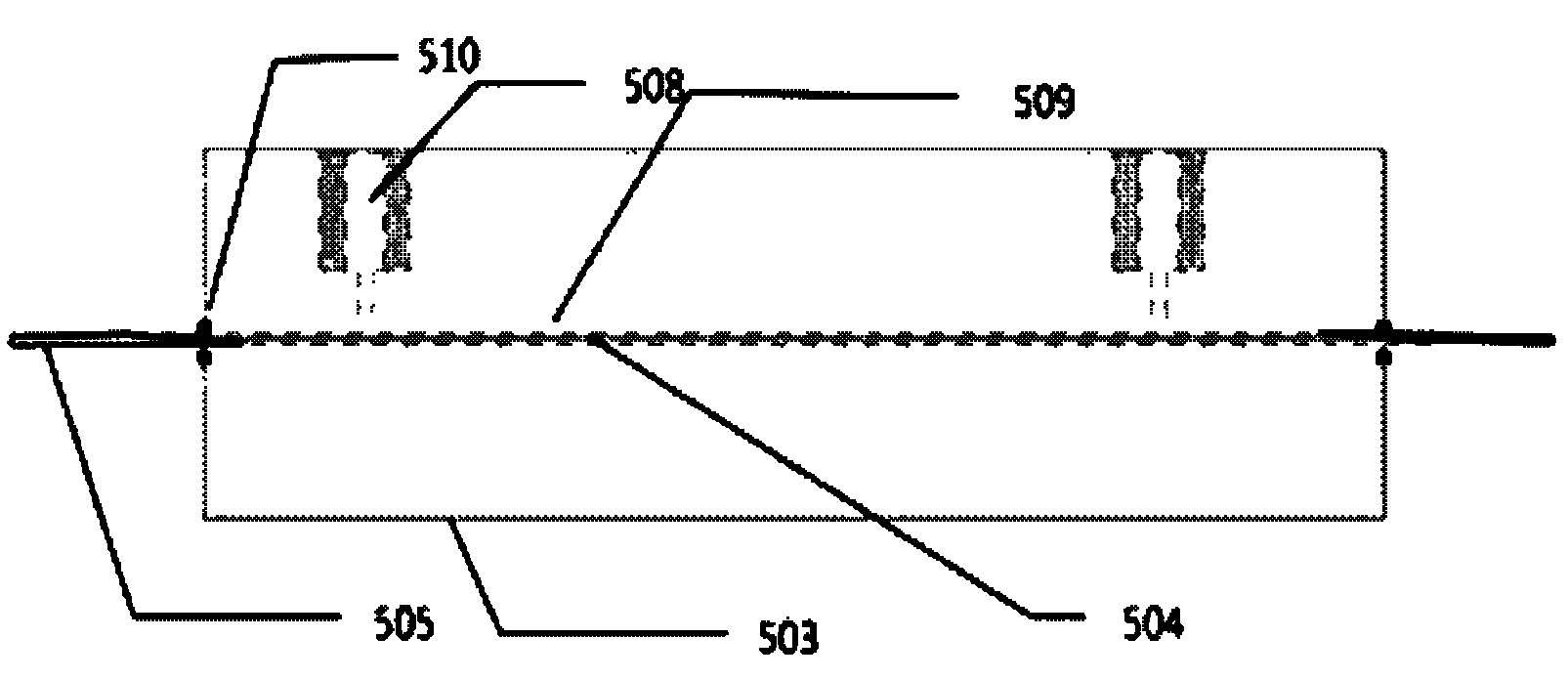

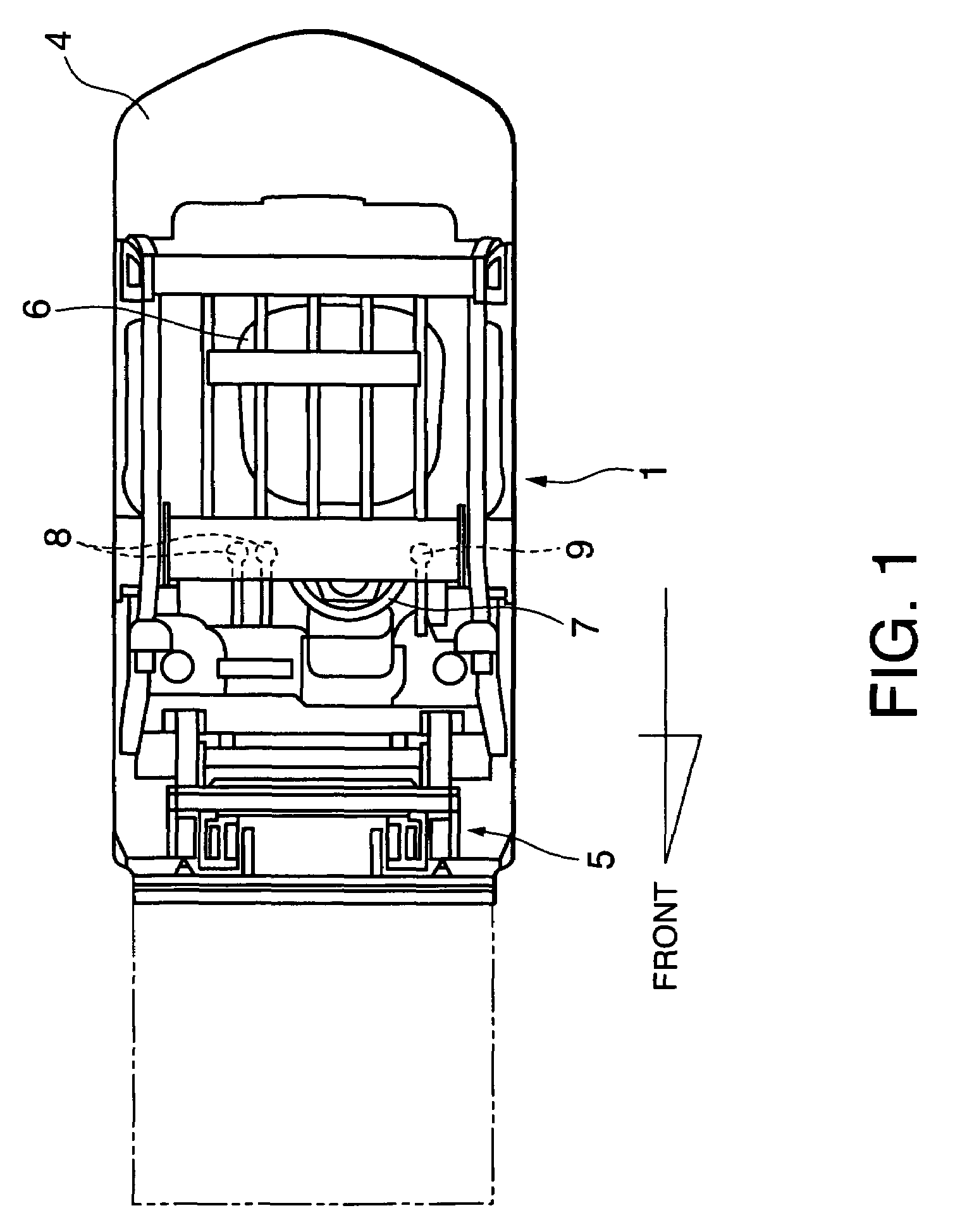

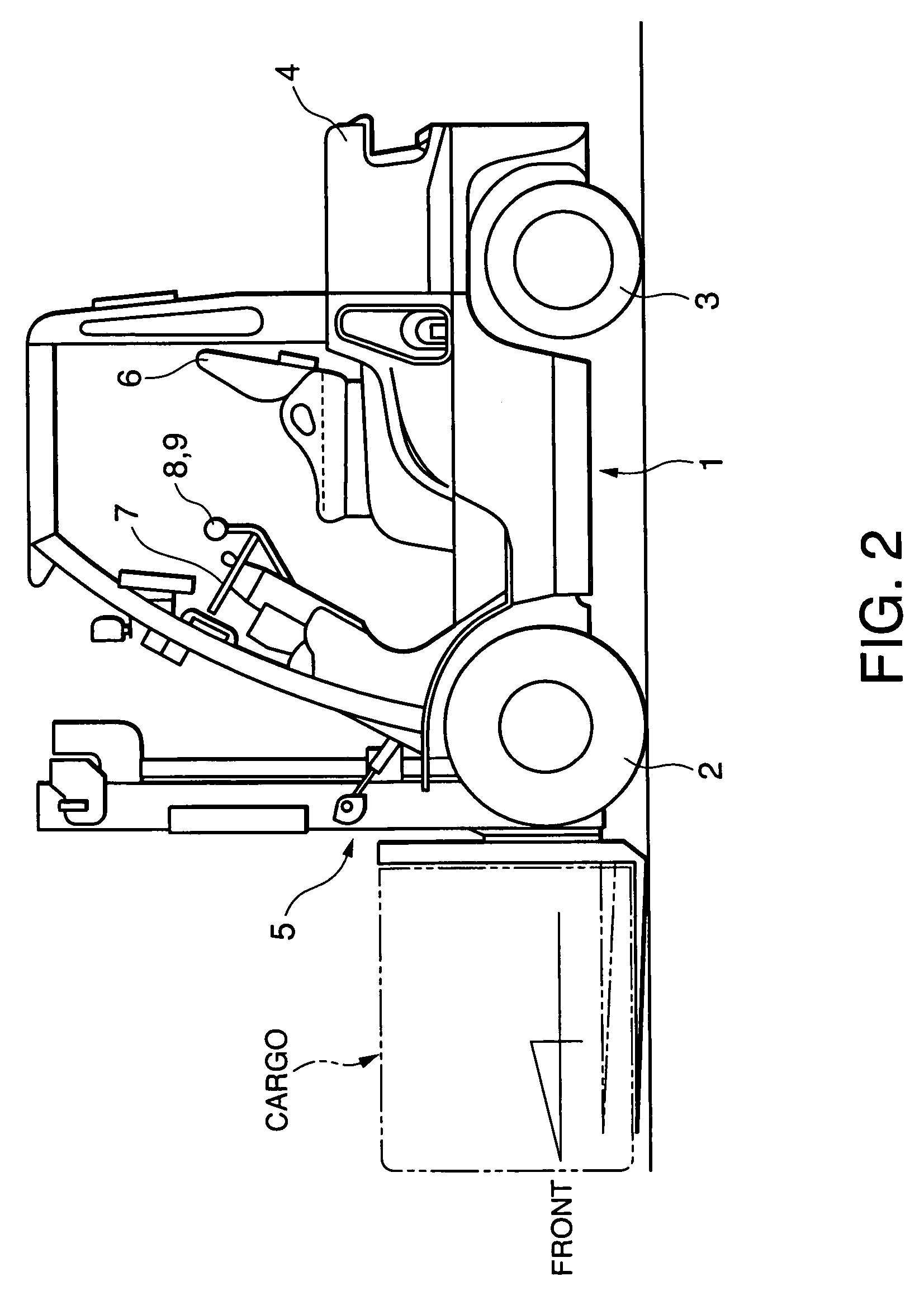

Oil pressure supply circuit for industrial vehicle

ActiveUS7600463B2Guaranteed stable actionIncrease the allocation ratioServomotor componentsRotary clutchesDifferential pressureEngineering

A priority flow rate control valve (4) increases a distribution ratio of pressurized oil to a power steering device (1) of a fork-lift track via a power steering oil passage (9) as a differential pressure between a power steering pressure (PS) in the power steering oil passage (9) and a pilot pressure (LS) decreases. A load signal port (24) which outputs a pressure indicative of a load exerted on the power steering device (1) and the power steering oil passage (9) are connected via two orifices (26A, 26B), and the pilot pressure (LS) pressure is extracted from a point between the two orifices (26A, 26B). By providing a bypass passage (31, 35) which bypasses one of the two orifices (26A, 26B) and a bypass valve (30) which opens and closes the bypass passage (26A, 26B), a response of the priority flow rate control valve (4) can be increased temporarily.

Owner:NISSAN FORKLIFT CO LTD

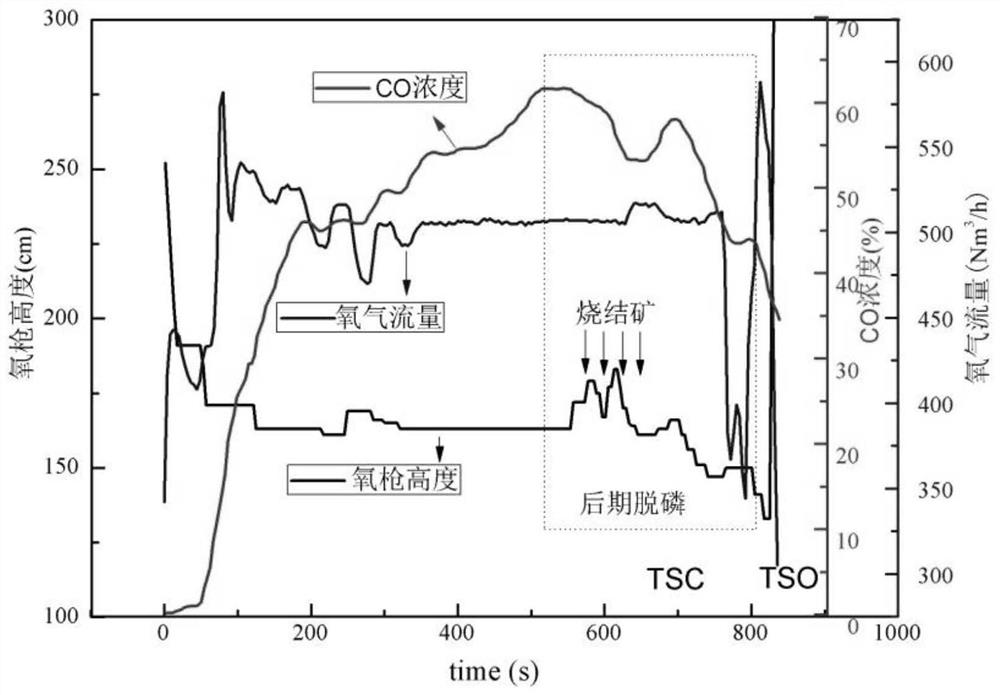

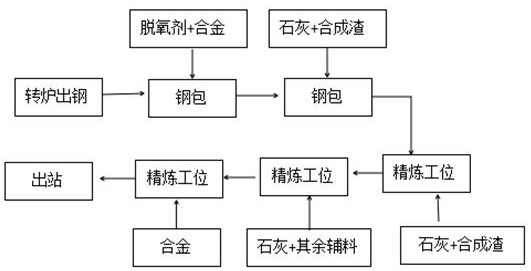

Converter later-stage low-temperature tapping efficient dephosphorization method

PendingCN112609034AReduce steel consumptionImprove dephosphorization efficiencyManufacturing convertersElectric furnaceSlagManufacturing engineering

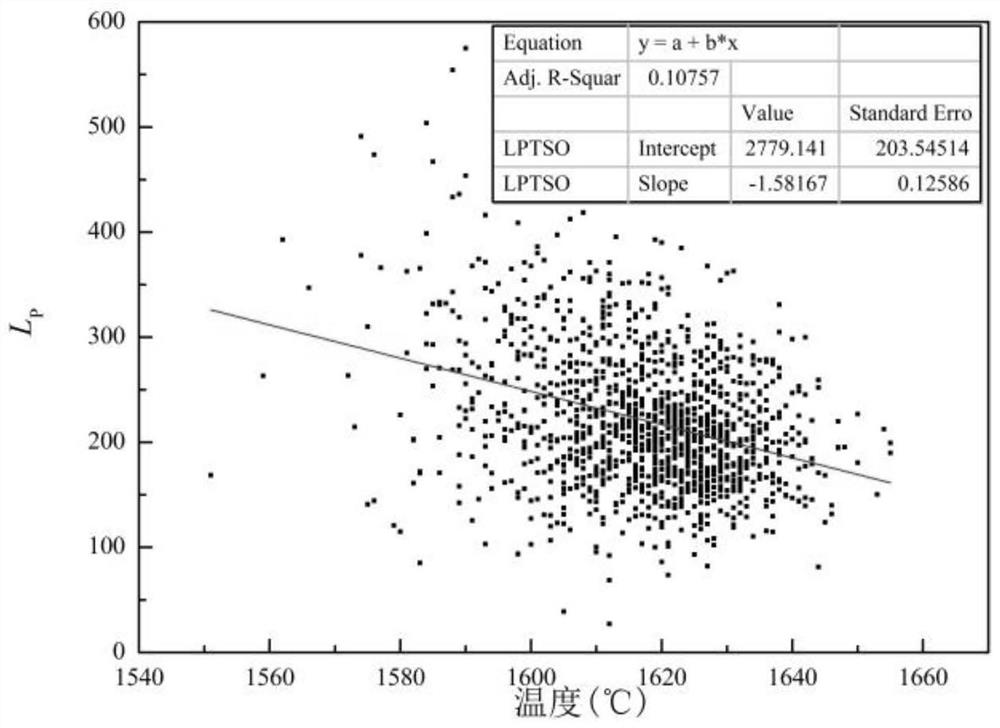

The invention discloses a converter later-stage low-temperature tapping efficient dephosphorization method. The method comprises the following steps that Si, Mn and part of iron in slag are oxidized by adopting high lance position and large oxygen flow in the early stage of blowing; with the continuation of oxygen blowing, CO gas generated by chemical reaction of carbon and oxygen enables the early-stage slag to be prone to emerge, the lance position is raised, and the oxygen flow is reduced; the lance position is lowered in the middle stage of blowing; in the middle and later stages of smelting, the lance position is increased for slag adjustment, a part of sinter is added in multiple batches, the dephosphorization effect of the slag is good, and meanwhile good thermodynamic and dynamic conditions are achieved; and then a sublance is put down for TSC, and in the later stage of smelting, the final TSO temperature is controlled to be 1590-1620 DEG C . According to the method, an in-furnace efficient dephosphorization production process under a converter end-point low-temperature tapping condition is provided, and by reducing tapping end-point temperature, the distribution ratio of phosphorus in slag and steel in the later stage of smelting of a converter is increased, and therefore the dephosphorization efficiency in the later stage of smelting is improved.

Owner:LIUZHOU IRON & STEEL

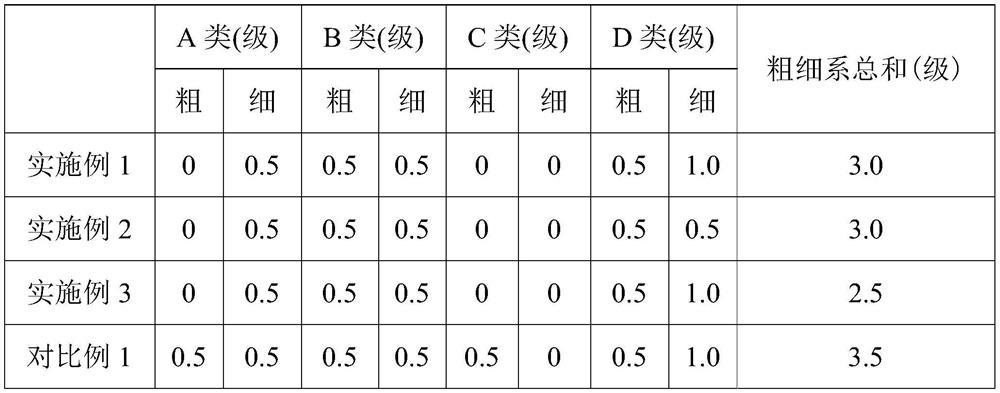

Method for producing low-sulfur and low-phosphorus steel by utilizing semi-molten steel

InactiveCN111926147AImprove componentsStrong desulfurization abilityManufacturing convertersSteelmakingNon-metallic inclusions

The invention relates to a method for producing low-sulfur and low-phosphorus steel by utilizing semi-molten steel. The method comprises the following steps: acquiring low-sulfur and low-phosphorus molten steel by the semi-molten steel through pre-deoxidation, KR desulfurization, converter steelmaking, LF refining and VD vacuum smelting in sequence, and acquiring the low-sulfur and low-phosphorussteel by pouring the low-sulfur and low-phosphorus molten steel, wherein the sulfur content of the molten steel subjected to KR desulfurization is lower than or equal to 0.005%, the rate of slagging-off after KR desulfurization is higher than or equal to 90%, the phosphorus content of the molten steel subjected to converter steelmaking is lower than or equal to 0.004%, 10-30 kg of slagging balls are added into the molten steel per ton during converter steelmaking, the included angle of oxygen gun holes during converter steelmaking is larger than or equal to 13 degrees, and the final temperature of converter steelmaking is lower than or equal to 1620 DEG C. According to the method provided by the invention, the off-site sulfur content is lower than or equal to 0.005% and the rate of dephosphorization during the converter steelmaking of the semi-molten steel reaches 96% or higher. Meanwhile, hydrogen-sulfide-corrosion-resistant continuous-casting round billet non-metallic inclusions produced through the method reach the following levels: class A is lower than or equal to level 0.5; class C is equal to level 0; class B and class C are lower than or equal to level 1.0; and the total thickness of class A, class B, class C and class D is lower than or equal to level 3.0.

Owner:CHENGDE JIANLONG SPECIAL STEEL

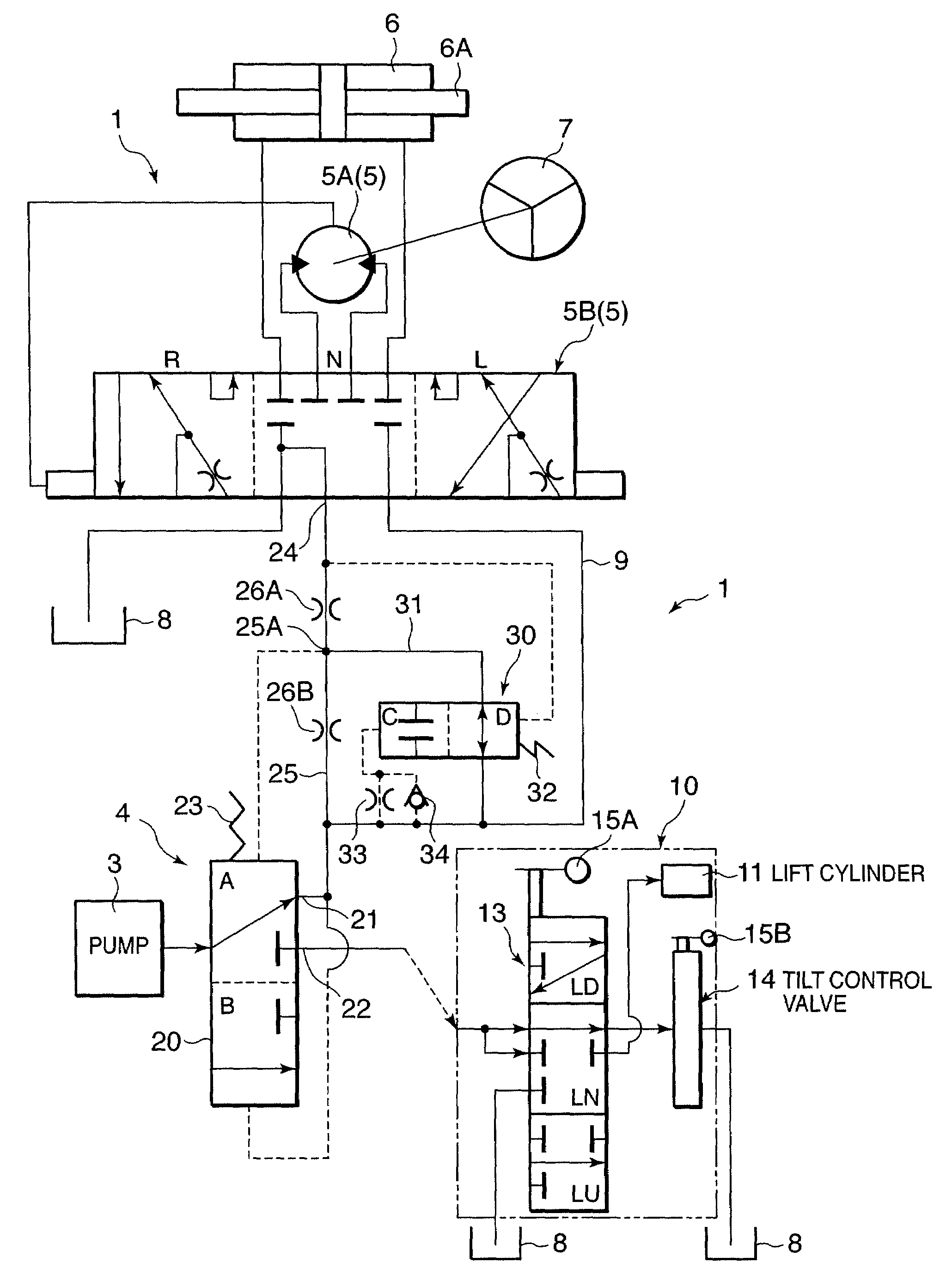

Oil pressure supply circuit for industrial vehicle

ActiveUS20080060354A1Guaranteed stable actionIncrease the allocation ratioServomotor componentsRotary clutchesDifferential pressureEngineering

A priority flow rate control valve (4) increases a distribution ratio of pressurized oil to a power steering device (1) of a fork-lift track via a power steering oil passage (9) as a differential pressure between a power steering pressure (PS) in the power steering oil passage (9) and a pilot pressure (LS) decreases. A load signal port (24) which outputs a pressure indicative of a load exerted on the power steering device (1) and the power steering oil passage (9) are connected via two orifices (26A, 26B), and the pilot pressure (LS) pressure is extracted from a point between the two orifices (26A, 26B). By providing a bypass passage (31, 35) which bypasses one of the two orifices (26A, 26B) and a bypass valve (30) which opens and closes the bypass passage (26A, 26B), a response of the priority flow rate control valve (4) can be increased temporarily.

Owner:NISSAN FORKLIFT CO LTD

Environment-friendly high-purity cerium dioxide extraction method

ActiveCN107758719AReduce pollutionInterchangeableRare earth metal oxides/hydroxidesRare earth metal compounds preparation/treatmentRare earthCerium

The invention belongs to the technical field of separation and purification of rare earth, and particularly relates to an environment-friendly high-purity cerium dioxide extraction method. The methodcomprises the following steps: (1) extracting: mixing a cerium chloride material liquid and an extracting agent at the volume ratio of 1:(1.2-1.5), extracting, separating, adding hydrotalcite whose weight is 4-6% of the weight of the extracting agent at the same time, conducting ultrasonic dispersion for 20-30 minutes, leaving to stand, then separating, recycling a solid phase, inputting an organic phase into a reextraction procedure; (2) reextracting: taking an oxalic acid solution, wherein the volume of the oxalic acid solution is 1.5-2.0 times the volume of the organic phase, reextracting at the temperature of 50-60 DEG C, conducting ultrasonic dispersion for 20-30 minutes, filtering to obtain a precipitate; (3) oxidizing: firing and oxidizing the obtained precipitate at the temperatureof 1000-1100 DEG C for 12-15 hours, and obtaining the high-purity cerium dioxide. The method abandons the traditional alkaline saponification causing serious ammonia nitrogen pollution, and the artificial hydrotalcite is used to implement ion exchange in the extraction process, so that the balanced acidity of the system is maintained, and the environmental pollution is reduced.

Owner:DEQING XINGBANG RARE EARTH NEW MATERIALS

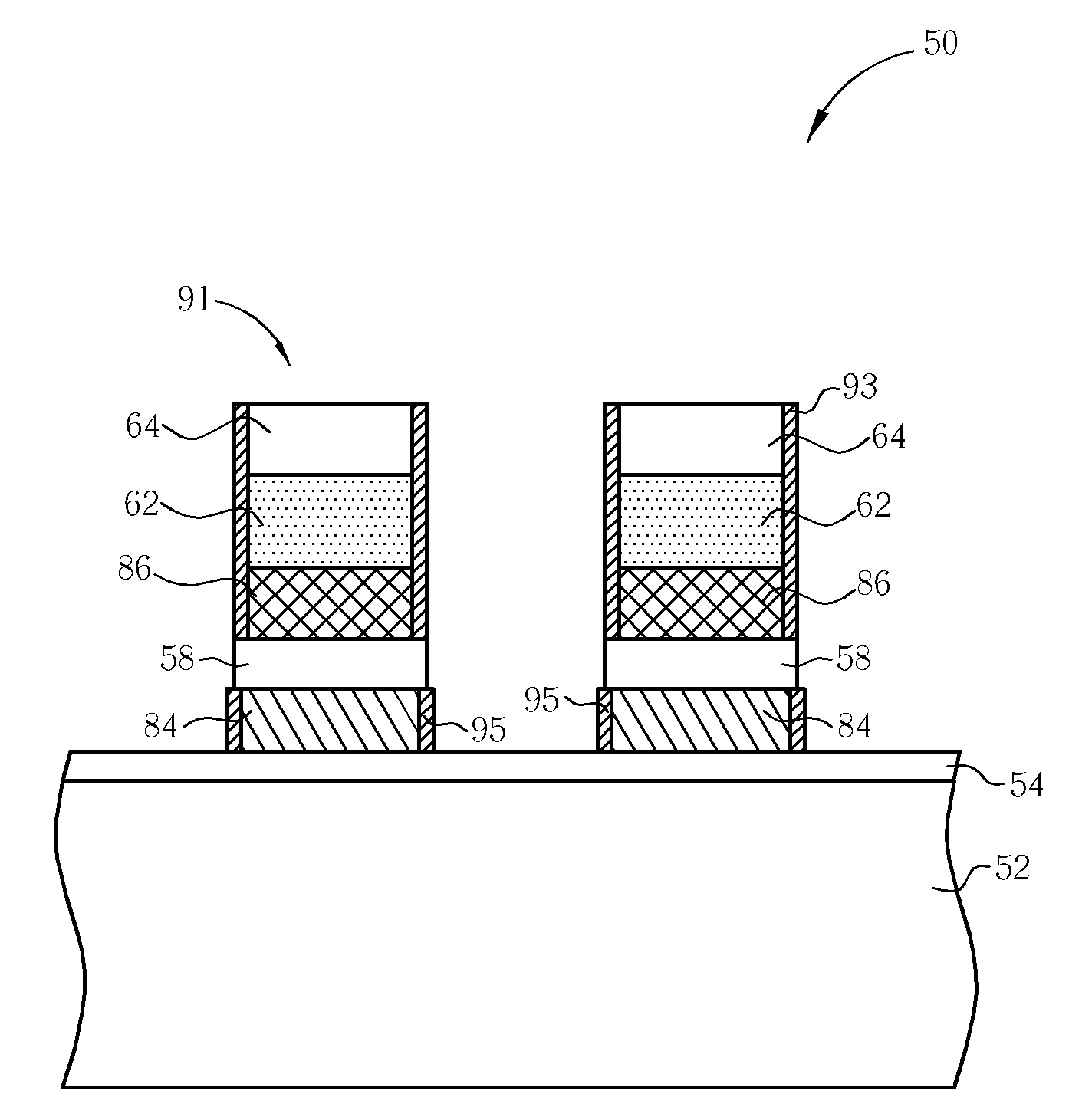

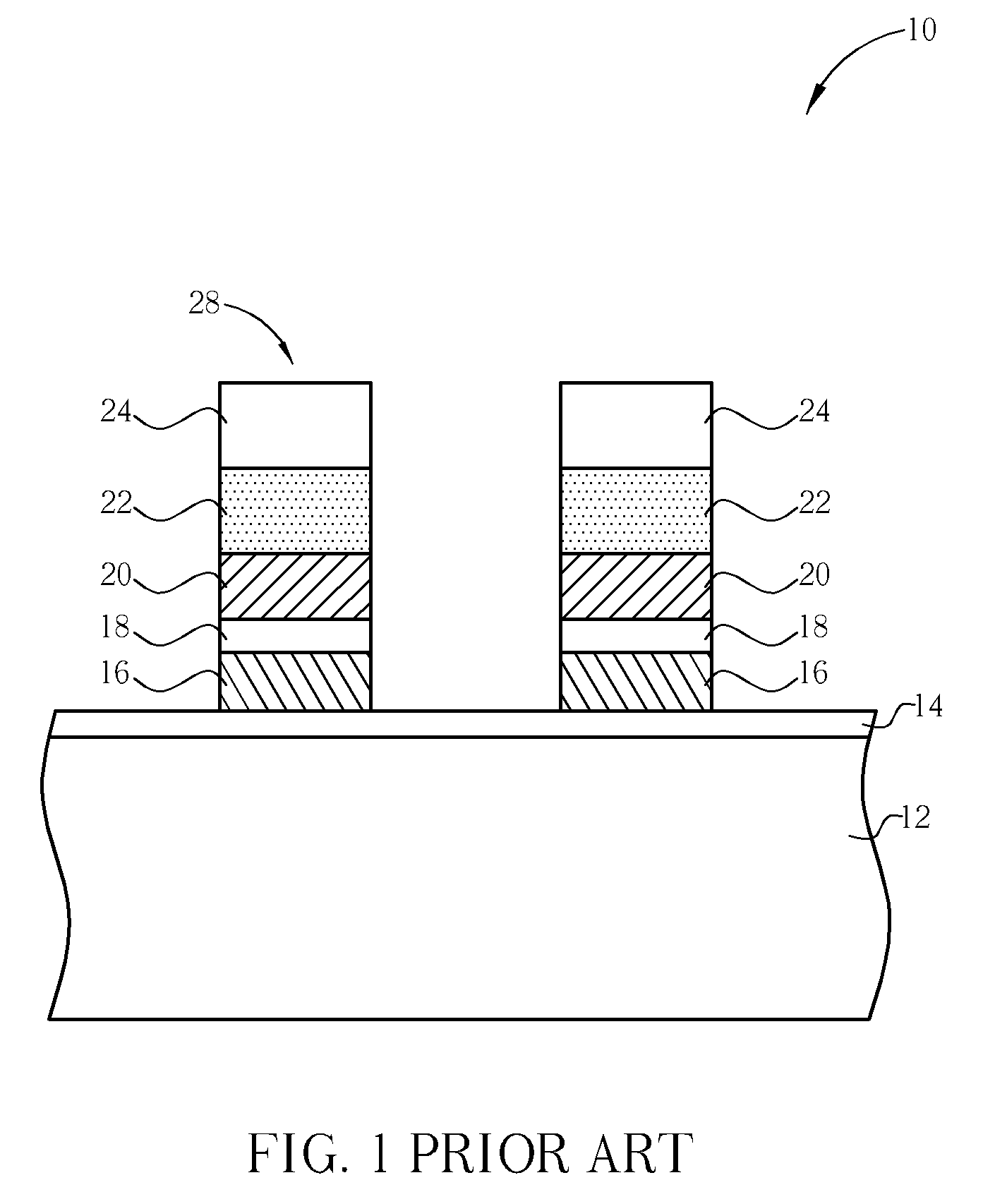

Method of fabricating flash memory

InactiveUS20090130808A1Improves silicon/tungsten distribution ratioHigh resistance of word lineSolid-state devicesSemiconductor/solid-state device manufacturingDielectric layerSemiconductor

A method of fabricating a flash memory includes successively forming a floating gate insulating layer, a floating gate material layer, a dielectric layer, a control gate material layer, a silicide layer, and a hard mask layer on a semiconductor substrate, patterning the hard mask layer, removing portions of the silicide layer, the control gate material layer, the dielectric layer, and the floating gate material layer not covered by the hard mask layer to form a stacked structure, forming a silicon cap layer covering the surface of the stacked structure, and performing a thermal process.

Owner:POWERCHIP SEMICON CORP

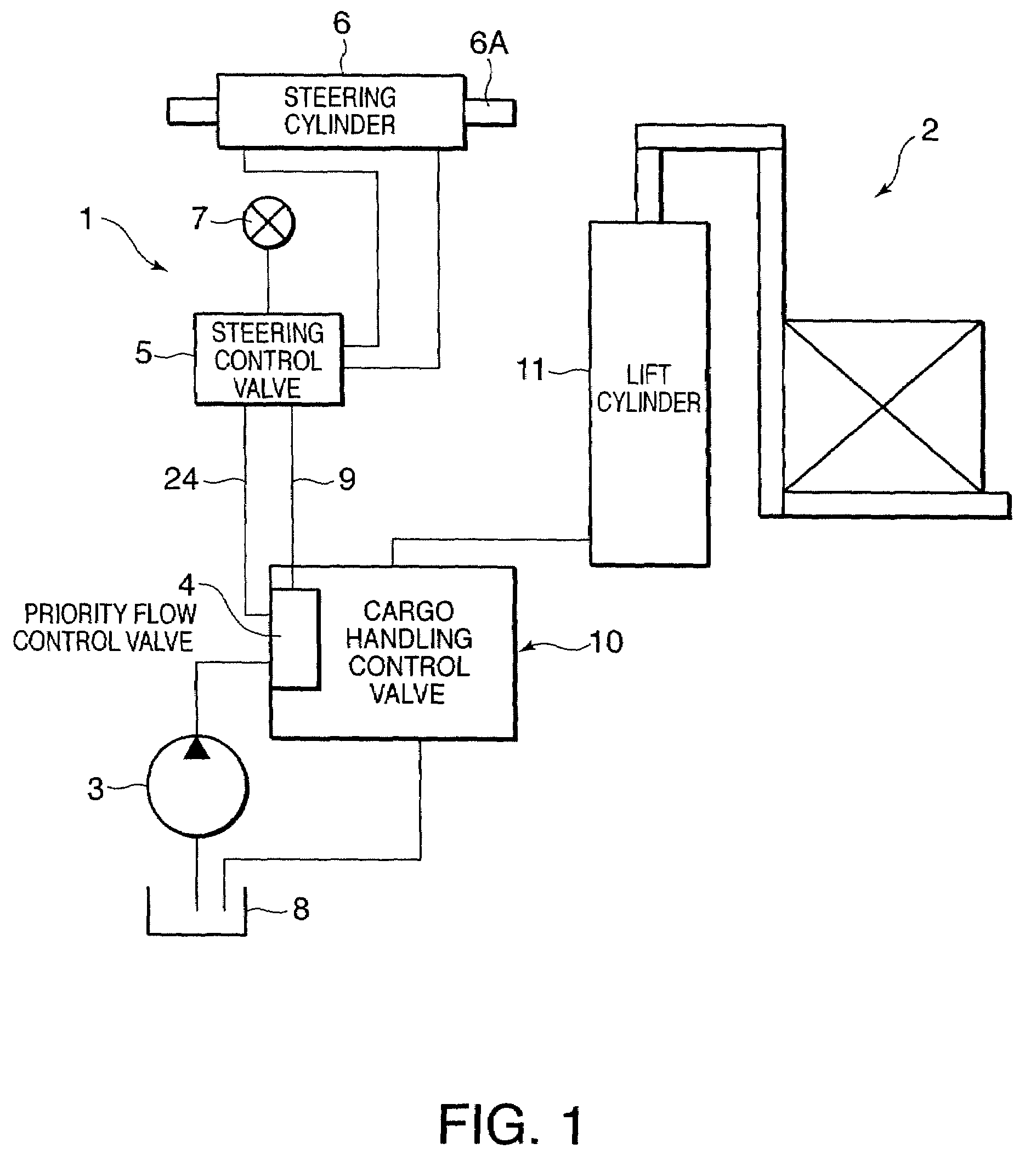

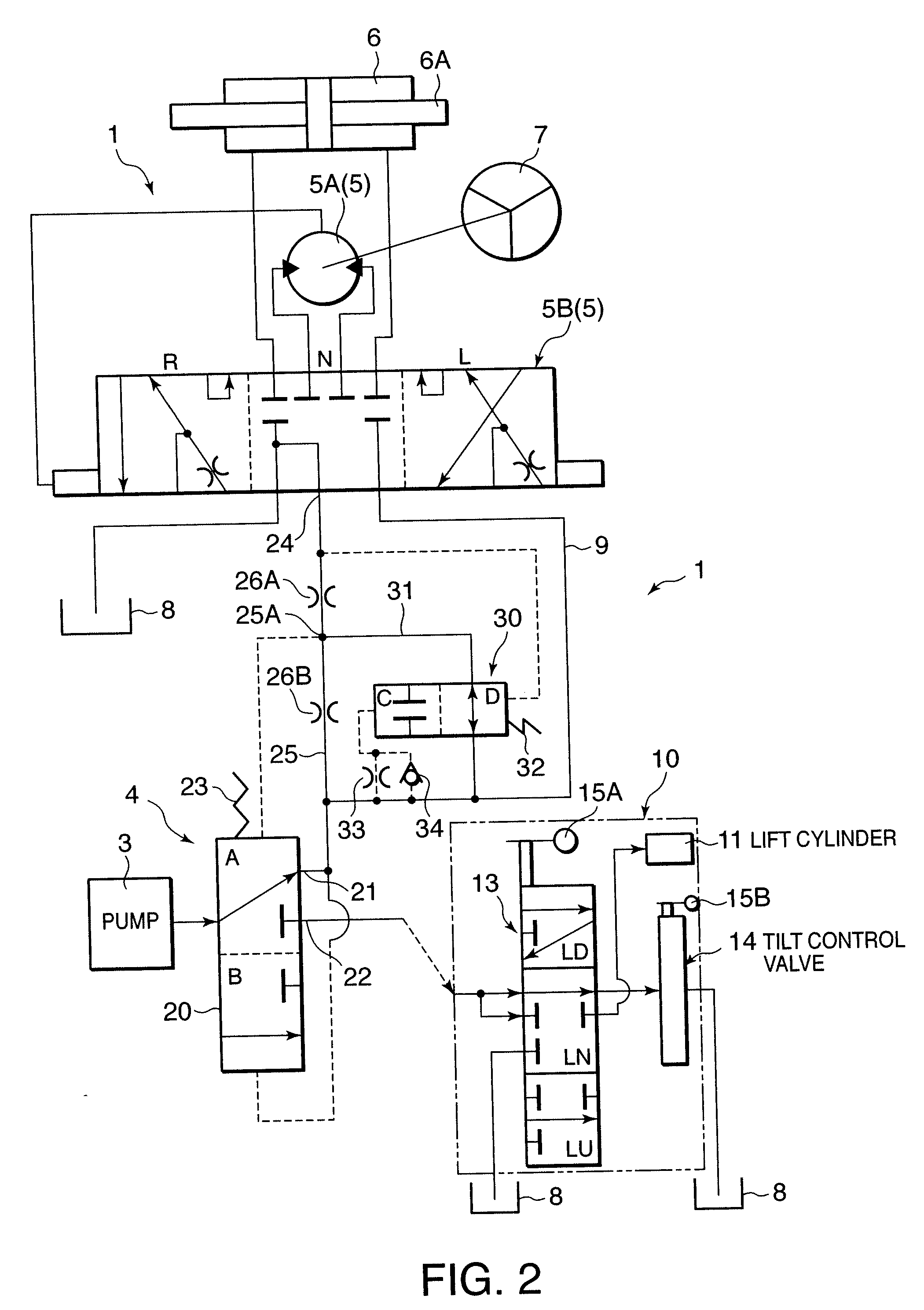

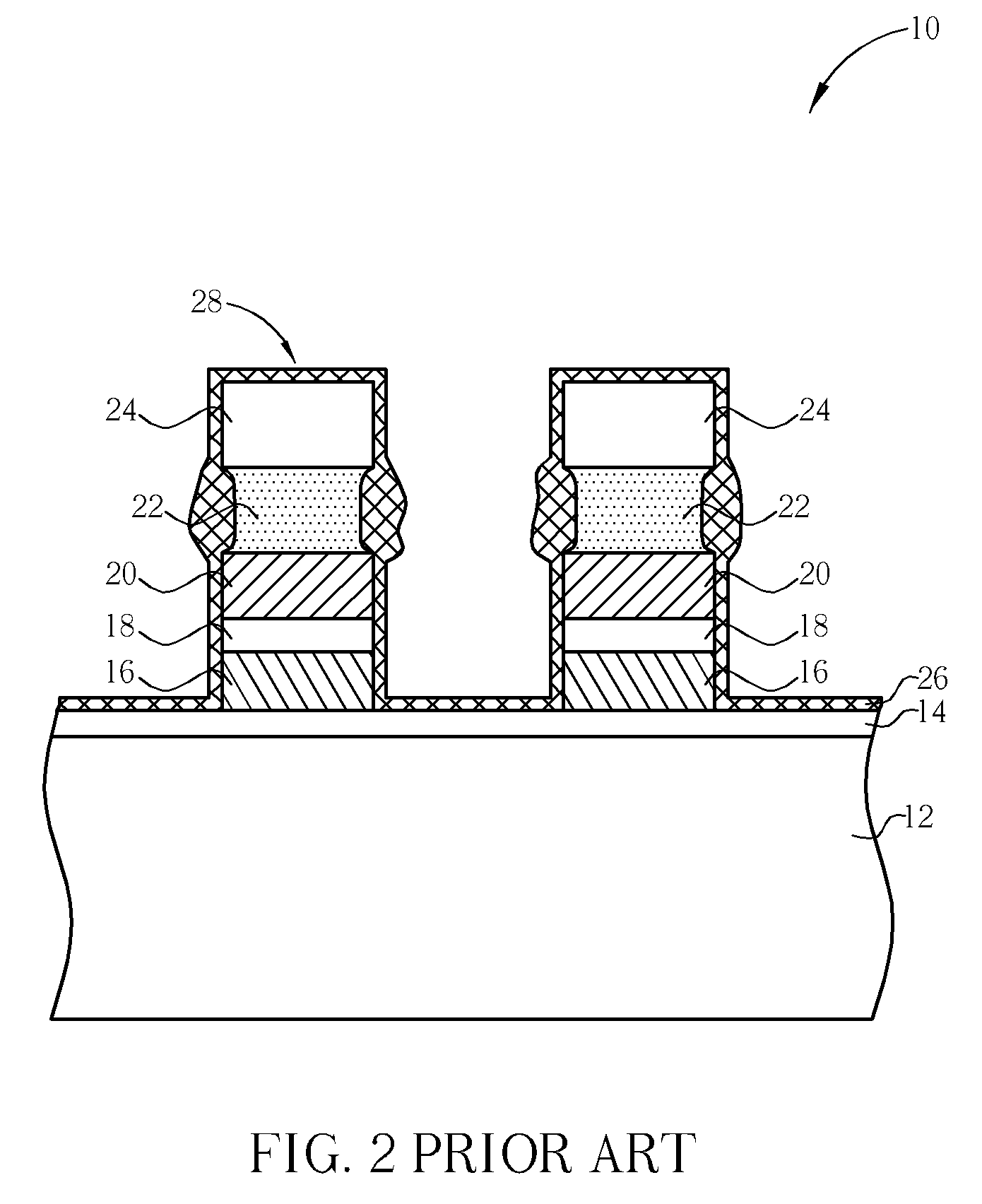

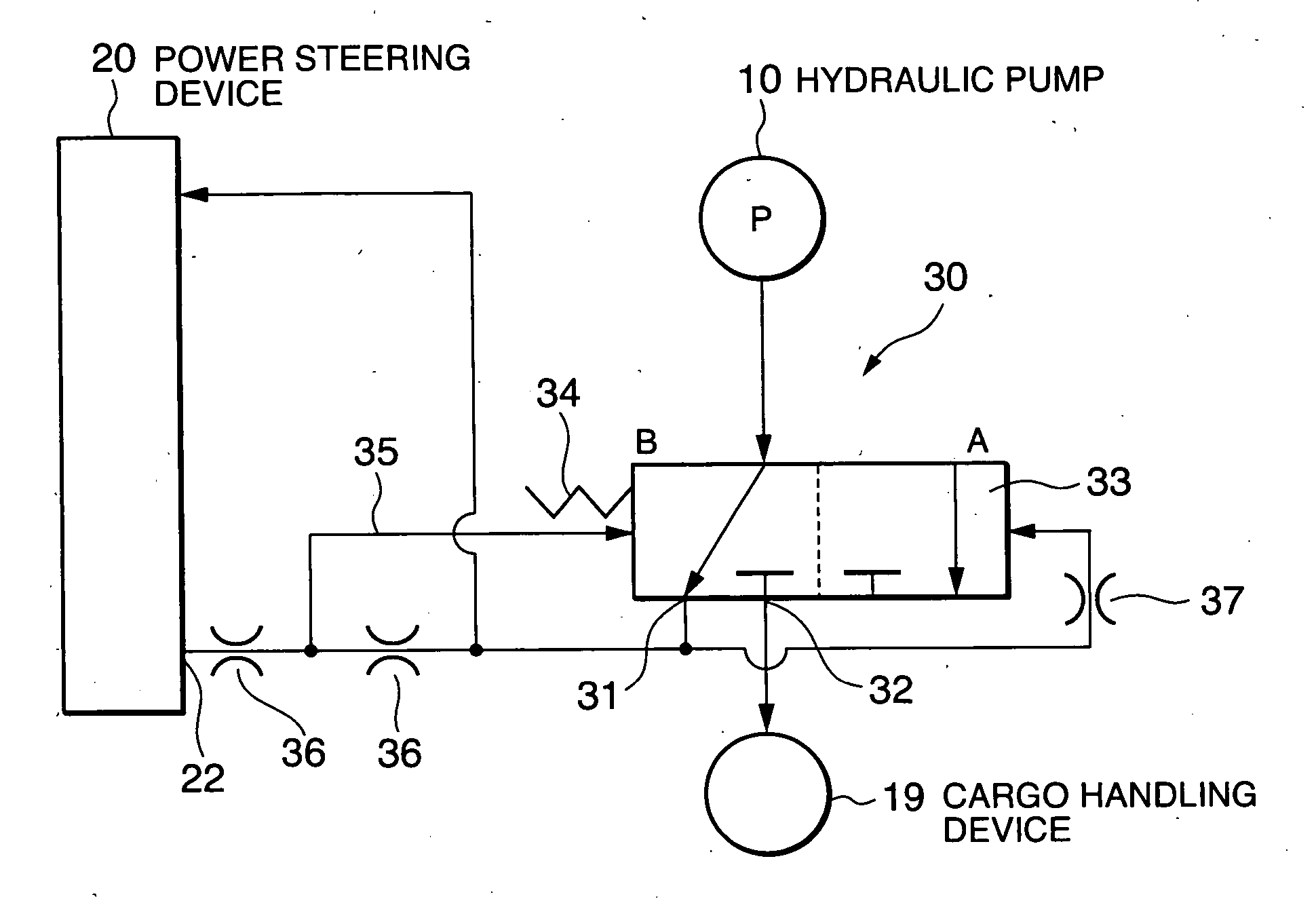

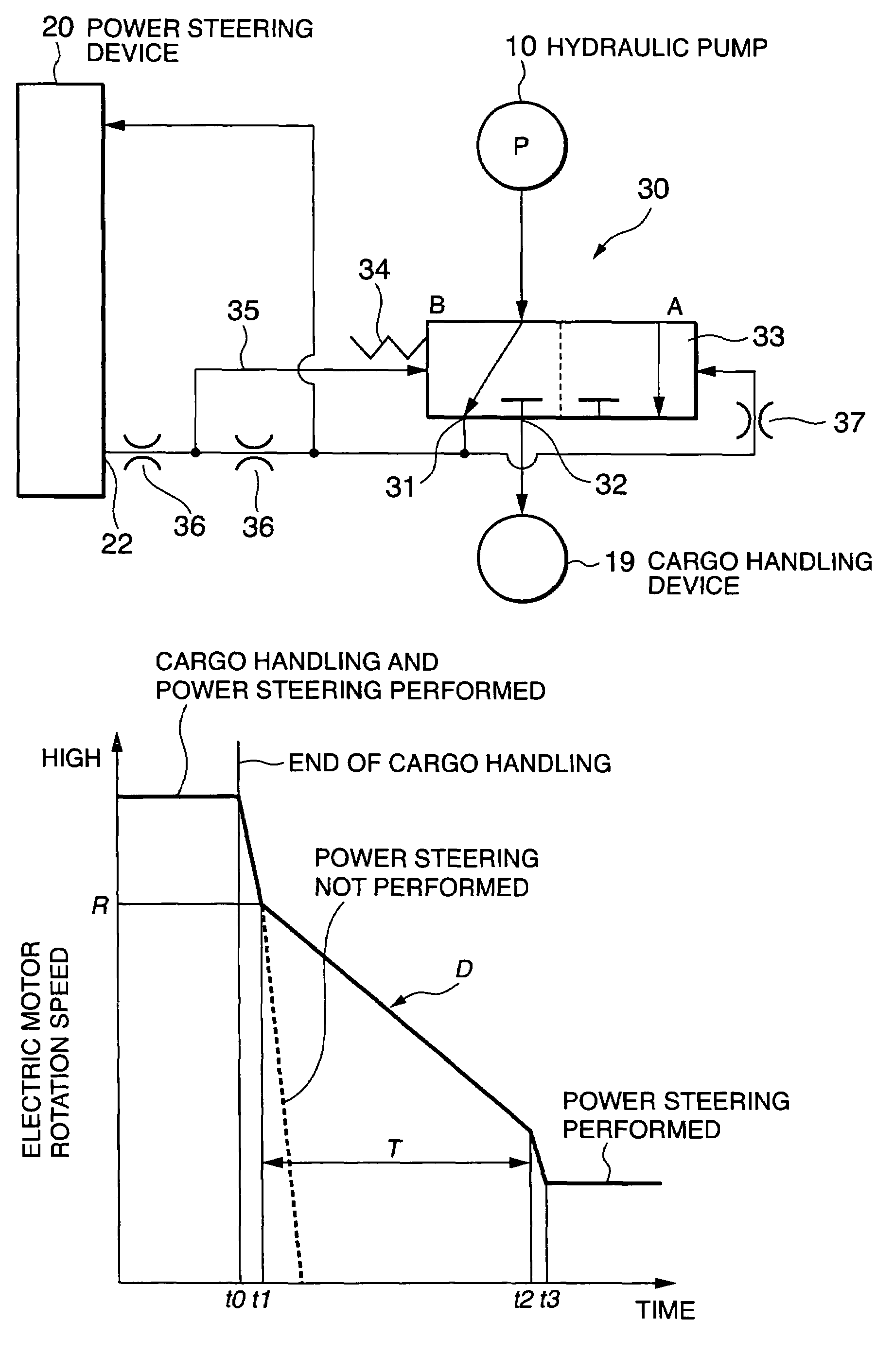

Hydraulic pressure supply control in industrial vehicle

ActiveUS20060260301A1Prevent kickbackReduce rateFluid couplingsLifting devicesPower steeringEngineering

A priority flow rate control valve (30) distributes pressurized working oil discharged from a hydraulic pump (10) driven by an electric motor (11) to a power steering device (20) first, and distributes the residual pressurized working oil to a cargo handling device (19). The rotation speed of the electric motor (11) and the distribution ratio of the pressurized working oil of the priority flow rate control valve (30) vary depending on the operation states of these devices (19, 20). By decreasing the rotation speed of the electric motor (11) at a rate smaller than a normal decrease rate when the cargo handling device (2) stops operation in a state where the power steering device (20) and the cargo handling device (19) are in operation, a kickback in a steering wheel (7) due to a response delay of the priority flow rate control valve (30) can be prevented.

Owner:NISSAN FORKLIFT CO LTD

Immune reinforced type grass carp feed

ActiveCN101991024BEnhance immune functionIncrease the allocation ratioFood processingClimate change adaptationDiseaseEpimedium

The invention relates to an aquatic feed, in particularly to a feed for grass carp. The immune reinforced type grass carp feed comprises the following components in percentage by mass: 8-15% of bean pulp, 1-5% of palm kernel cake, 25-35% of rapeseed meal, 5-10% of rice bran, 3-8% of brewer's grains, 10-18% of DDGS (Distillers Dried Grains with Soluble), 10-15% of flour, 5-10% of malt roots and 0.5-1% of premix grass carp compound. In the premix grass carp compound, epimedium and other traditional Chinese medicines are used for aquatic animals for the first time so as to achieve the effect of enhancing the immunologic function of the grass carp; and the traditional Chinese medicines are proportioned reasonably, and thus, the immunity of the grass carp can be enhanced, and the capability of the grass carp for resisting and preventing diseases is improved.

Owner:广州市海维饲料有限公司

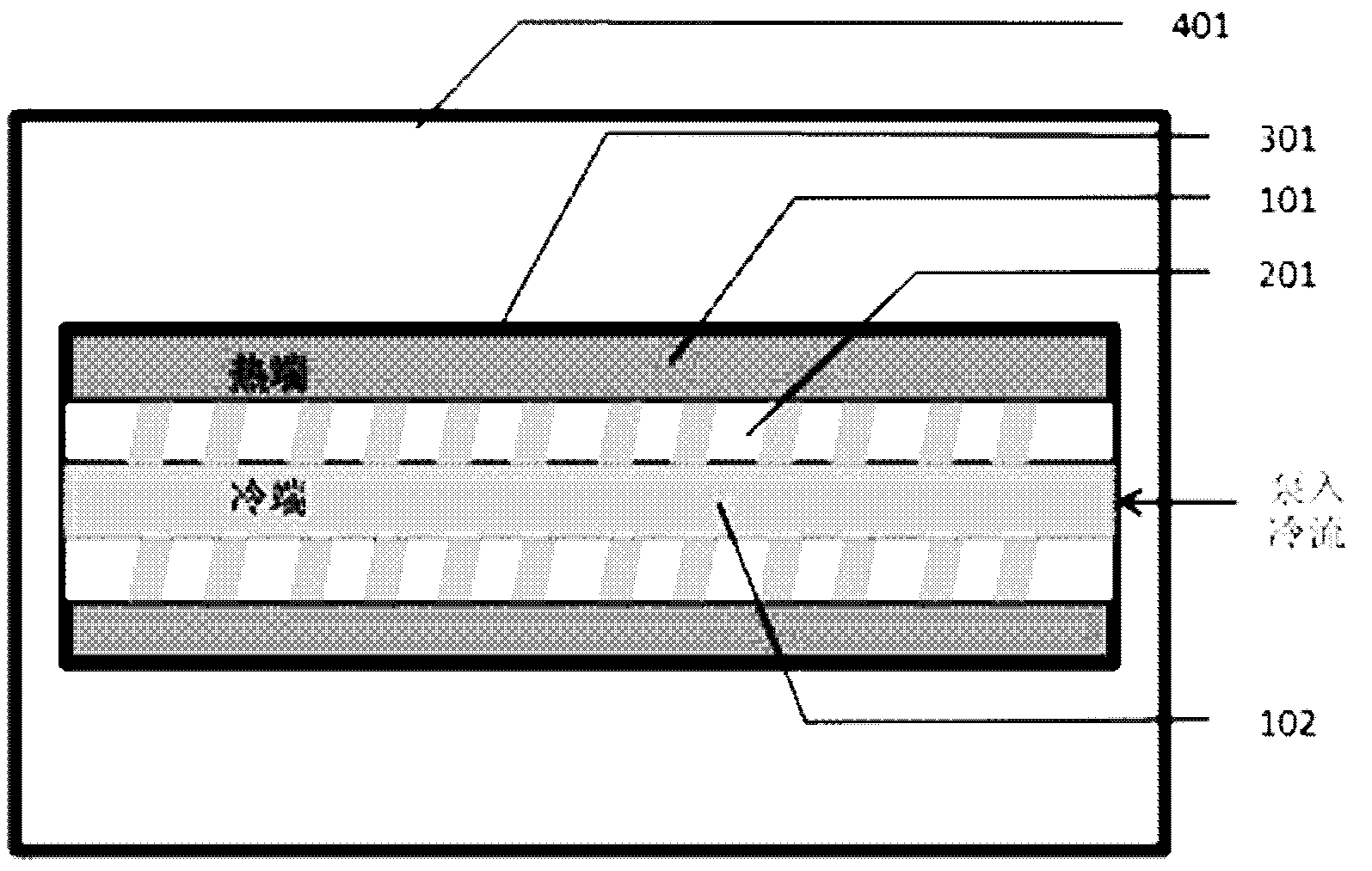

Temperature gradient liquid-liquid-liquid microextraction method

ActiveCN103127742AIncrease the allocation ratioImprove extraction efficiencyLiquid solutions solvent extractionLiquid layerFiber

The invention relates to a temperature gradient liquid-liquid-liquid microextraction method. The temperature gradient refers to that a temperature difference exists between a receiving phase and a supplying phase (sample) of the liquid-liquid-liquid microextraction, wherein the receiving phase is a hot end and the supplying phase is a cold end. The site of the liquid-liquid-liquid microextraction is a coaxial tube-shell-type channel. Liquid layer segregation is supplied by a hollow fiber pipe, wherein the lateral wall of the fiber pipe is provided with micropores or is free from pores. Liquid which is neither immiscible with the liquid of the supplying phase nor the receiving phase is arranged on the surface of the hollow fiber pipe in a loaded mode. An outer shell body is sleeved outside the hollow fiber pipe, wherein the inner diameter of the outer shell body is larger than the outer diameter of the hollow fiber pipe. The supplying phase passes through the interior of the hollow fiber pipe, and the receiving phase is filled in a cavity between the hollow fiber pipe and the outer shell body. The outer shell body is heated so that the receiving phase is heated, thus the temperature gradient between the receiving phase and the supplying phase is achieved and used as mass transfer power, and an extraction recovery rate is improved.

Owner:重庆南派克仪表科技有限公司

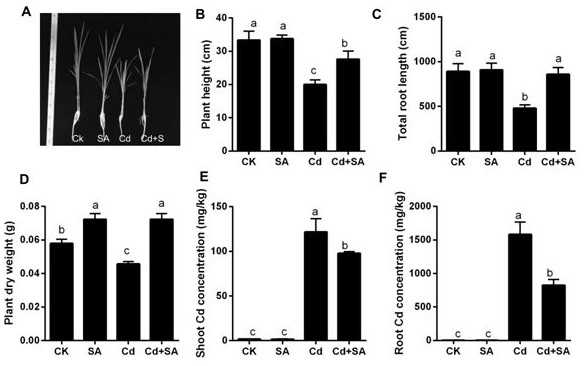

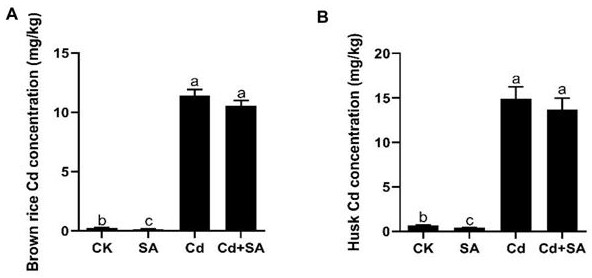

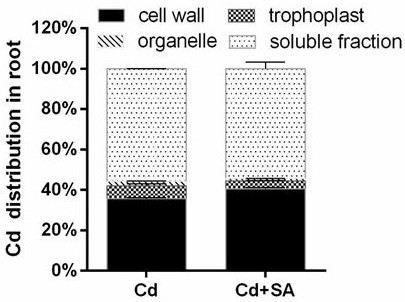

Rice seedling culture solution added with exogenous salicylic acid and application of rice seedling culture solution

ActiveCN113105293AReduce absorptionReduce accumulationCalcareous fertilisersMagnesium fertilisersSalicylic acidNutrient solution

The invention discloses a rice seedling culture solution added with exogenous salicylic acid and application of the rice seedling culture solution. According to the rice seedling culture solution added with the exogenous salicylic acid, the exogenous salicylic acid is added on the basis of a rice nutrient solution formula, and the addition amount is 100 [mu]mol / L<-1>. The cadmium content of root systems and overground parts of rice seedlings is reduced; the rice seedling culture solution is used for regulating pectin synthesis, deesterification and lignin synthesis to reduce cadmium accumulation of rice plants and relieve poison of cadmium stress to rice seedlings; the rice seedlings are cultured in the rice seedling culture solution for 10 days, the pectin content and deesterification degree of roots are increased, free carboxyl in pectin is increased, and the adsorption and combination capacity of cell walls to cadmium is enhanced; meanwhile, root lignin content is increased, the cell walls are thickened, and cadmium ions are prevented from entering cells. The invention discloses and verifies an important rice Cd regulation mechanism, and provides theoretical guidance and a feasible scheme for safe production of cadmium-polluted rice field soil.

Owner:CHINA NAT RICE RES INST

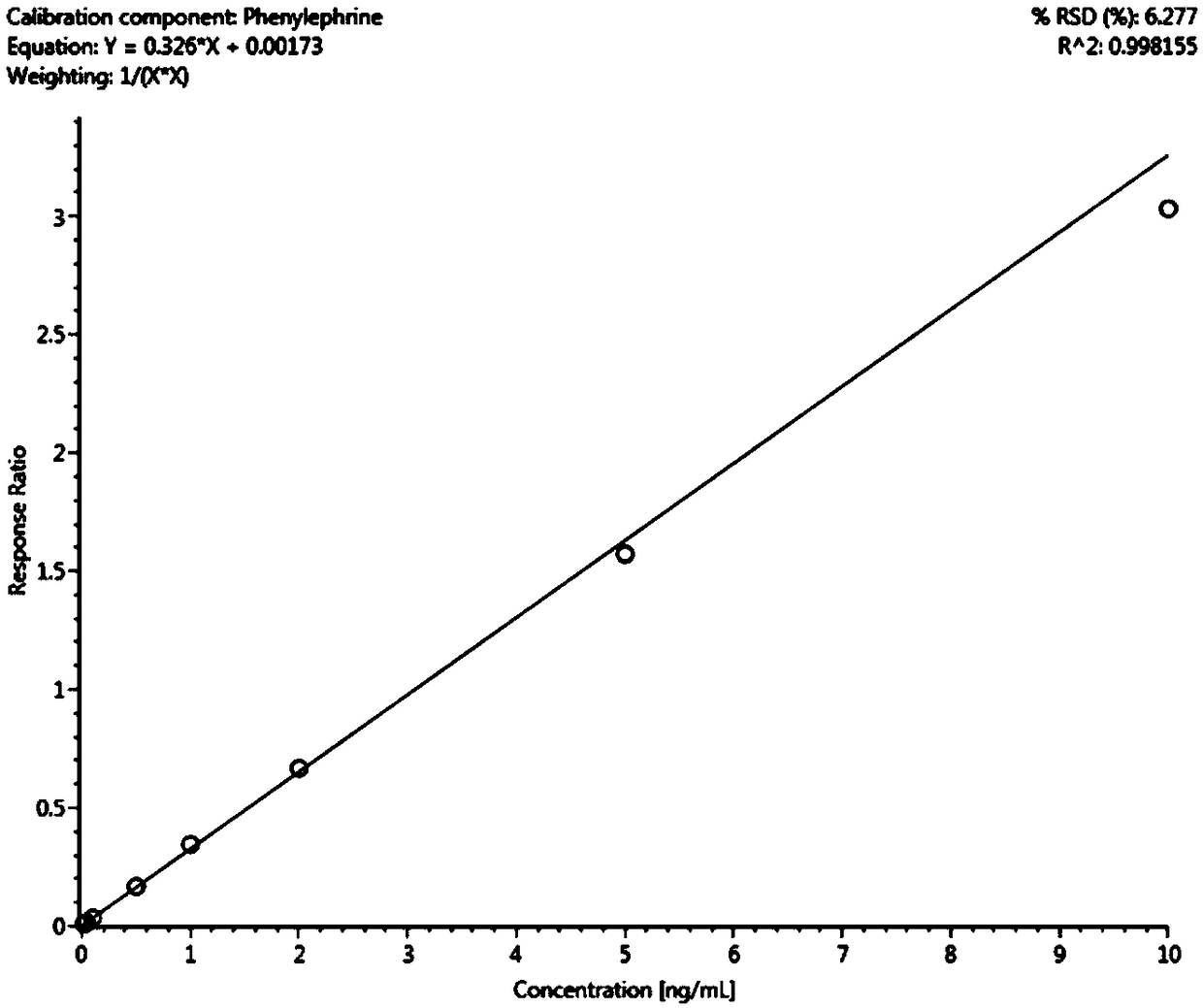

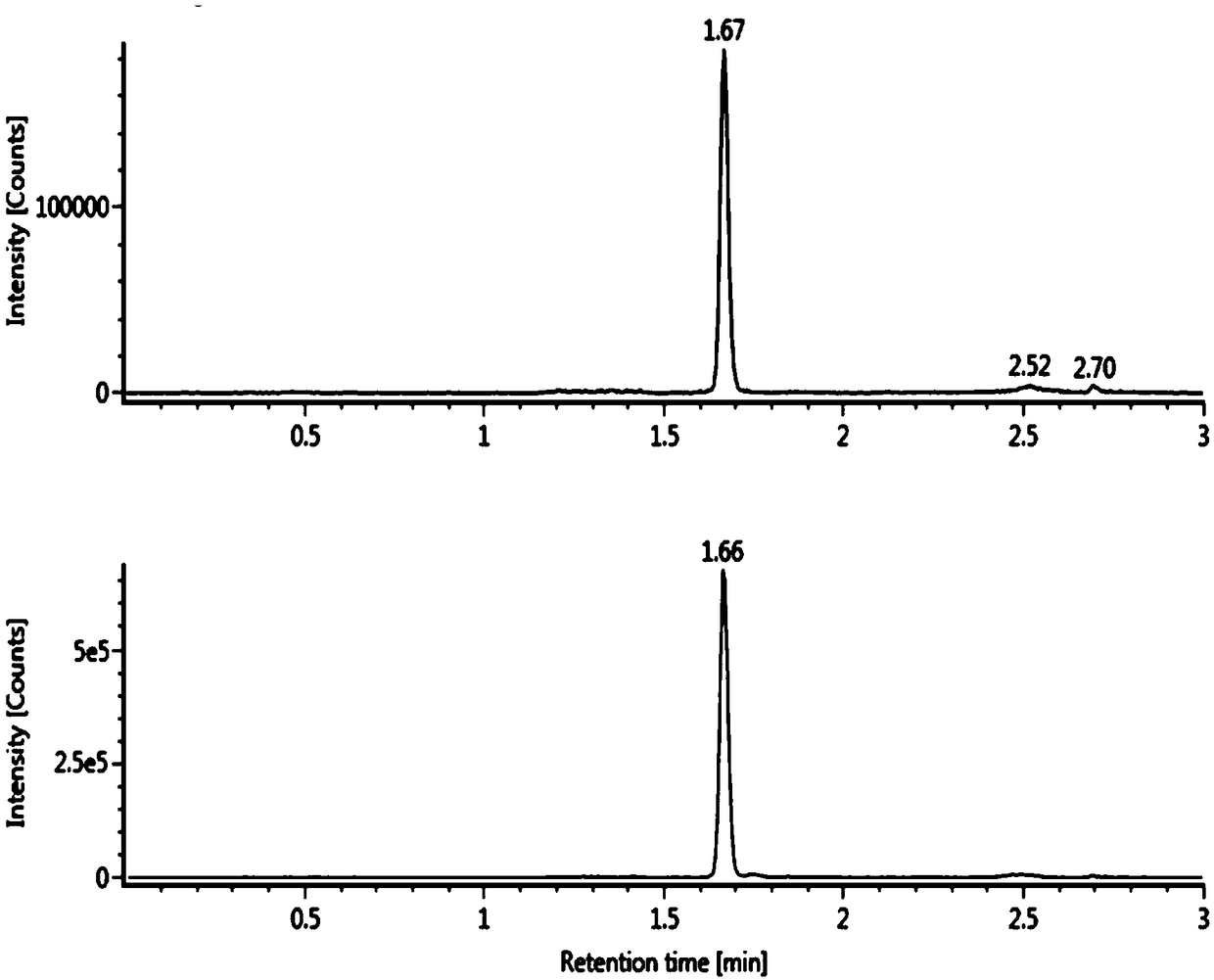

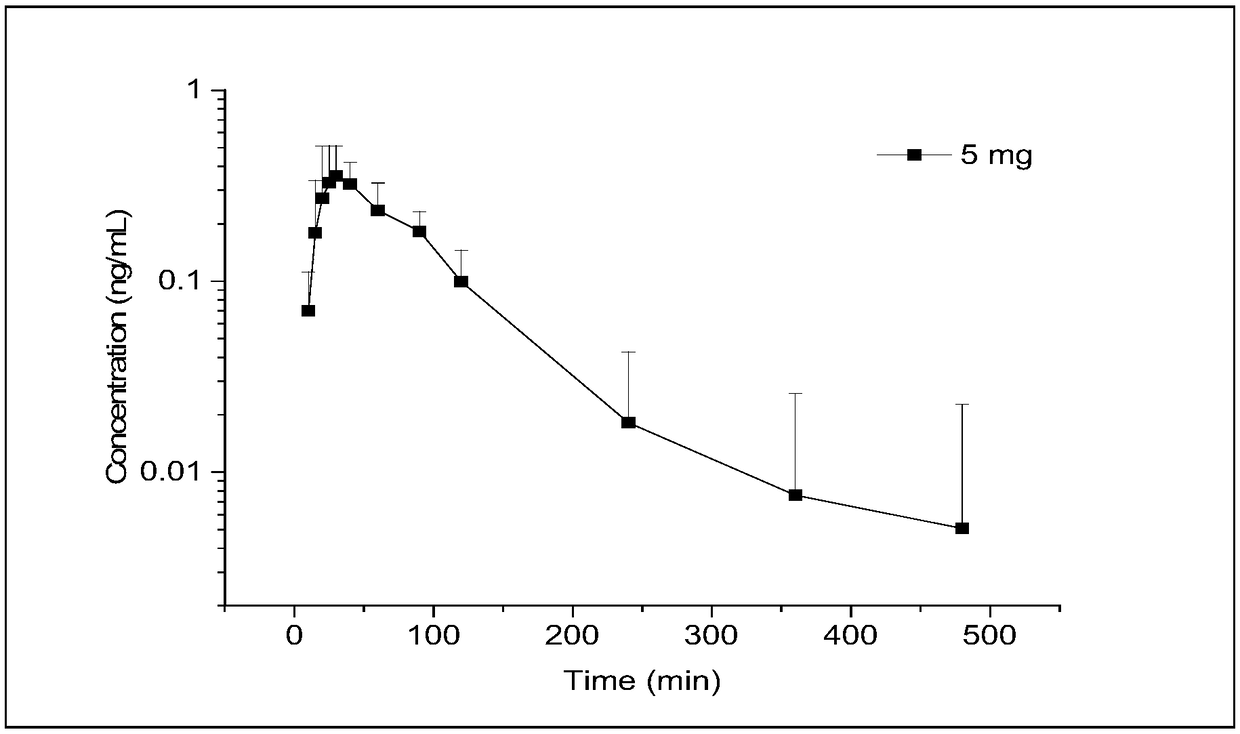

Method for measuring concentration of phenylephrine in plasma by LC-MS/MS, and pretreatment method of sample

ActiveCN109187832AImprove precipitation effectImprove stabilityComponent separationDansyl chloridePretreatment method

The invention relates to the technical field of medical detection, and specifically relates to a method for measuring the concentration of phenylephrine in plasma by LC-MS / MS. The method comprises thefollowing steps: primary extraction: adding an internal standard working solution and an extracting solution into a sample, centrifugally layering the solution after mixing the solutions uniformly, and collecting the supernatant to obtain first supernatant; derivatization reaction: concentrating and drying the first supernatant, adding a NaHCO3 buffer salt for dissolution, and then adding an acetonitrile solution of dansyl chloride to perform a derivatization reaction; and secondary extraction: adding the extracting solution into the reaction solution after the derivatization reaction for secondary extraction, centrifuging to obtain second supernatant, concentrating and drying the second supernatant, and redissolving the product to obtain a sample solution. By adoption of the pretreatment method of the sample provided by the invention, the extraction rate of low-level phenylephrine can be maximally improved, the interference of a plasma matrix is effectively removed, the specificityis improved, the minimum detection limit is reduced to 0.02ng / ml, and the sensitivity is increased to 0.1nM to adapt to the detection requirements of the concentration of the low-concentration phenylephrine in drug clinical studies.

Owner:CHINA RESOURCES SANJIU MEDICAL & PHARMA

Hydraulic pressure supply control in industrial vehicle

ActiveUS7353649B2Reduce rateIncrease the allocation ratioFluid couplingsLifting devicesSteering wheelHydraulic pump

A priority flow rate control valve (30) distributes pressurized working oil discharged from a hydraulic pump (10) driven by an electric motor (11) to a power steering device (20) first, and distributes the residual pressurized working oil to a cargo handling device (19). The rotation speed of the electric motor (11) and the distribution ratio of the pressurized working oil of the priority flow rate control valve (30) vary depending on the operation states of these devices (19, 20). By decreasing the rotation speed of the electric motor (11) at a rate smaller than a normal decrease rate when the cargo handling device (2) stops operation in a state where the power steering device (20) and the cargo handling device (19) are in operation, a kickback in a steering wheel (7) due to a response delay of the priority flow rate control valve (30) can be prevented.

Owner:NISSAN FORKLIFT CO LTD

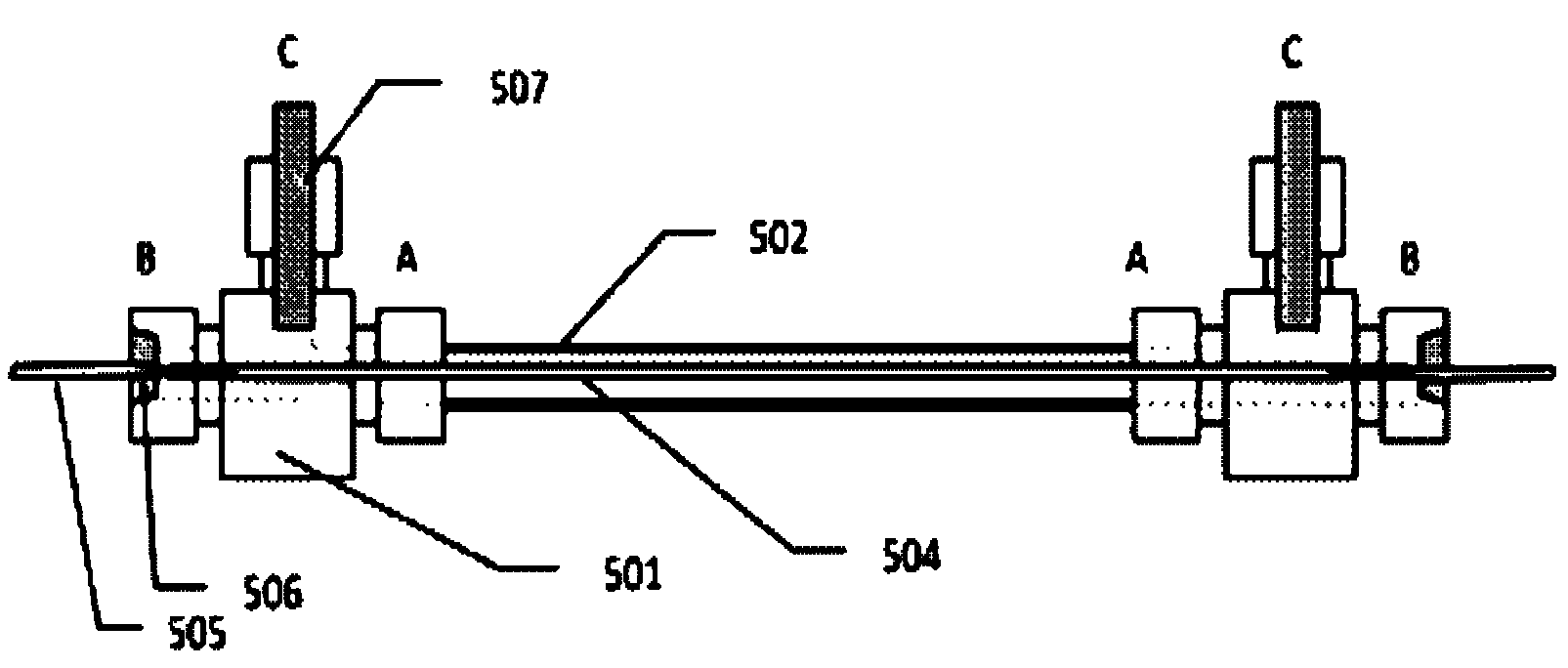

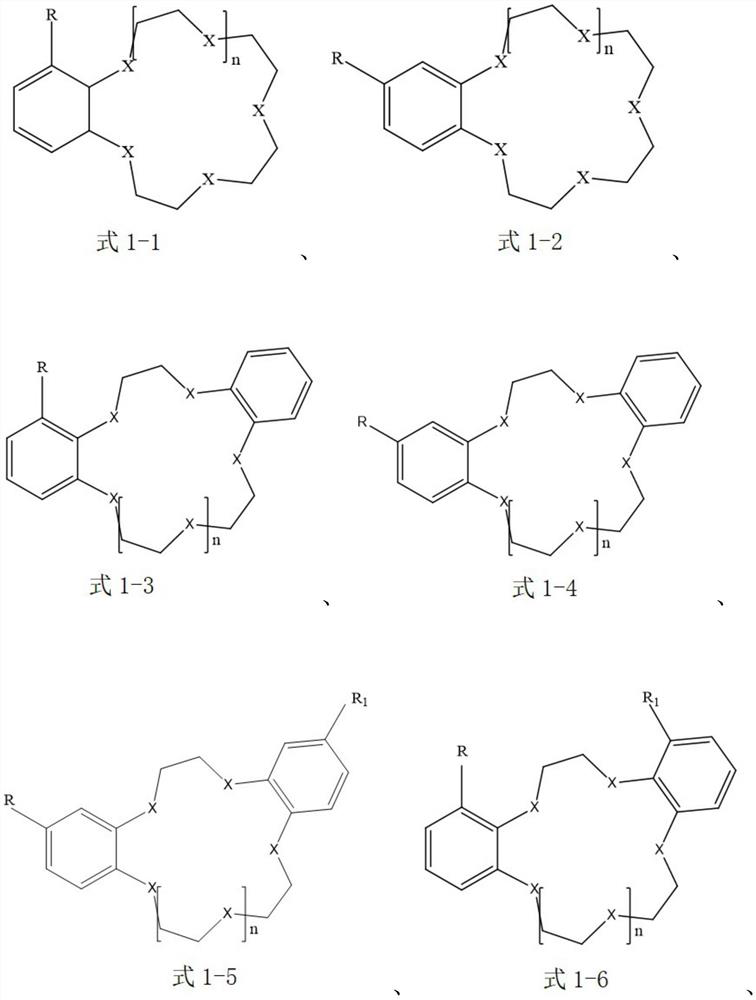

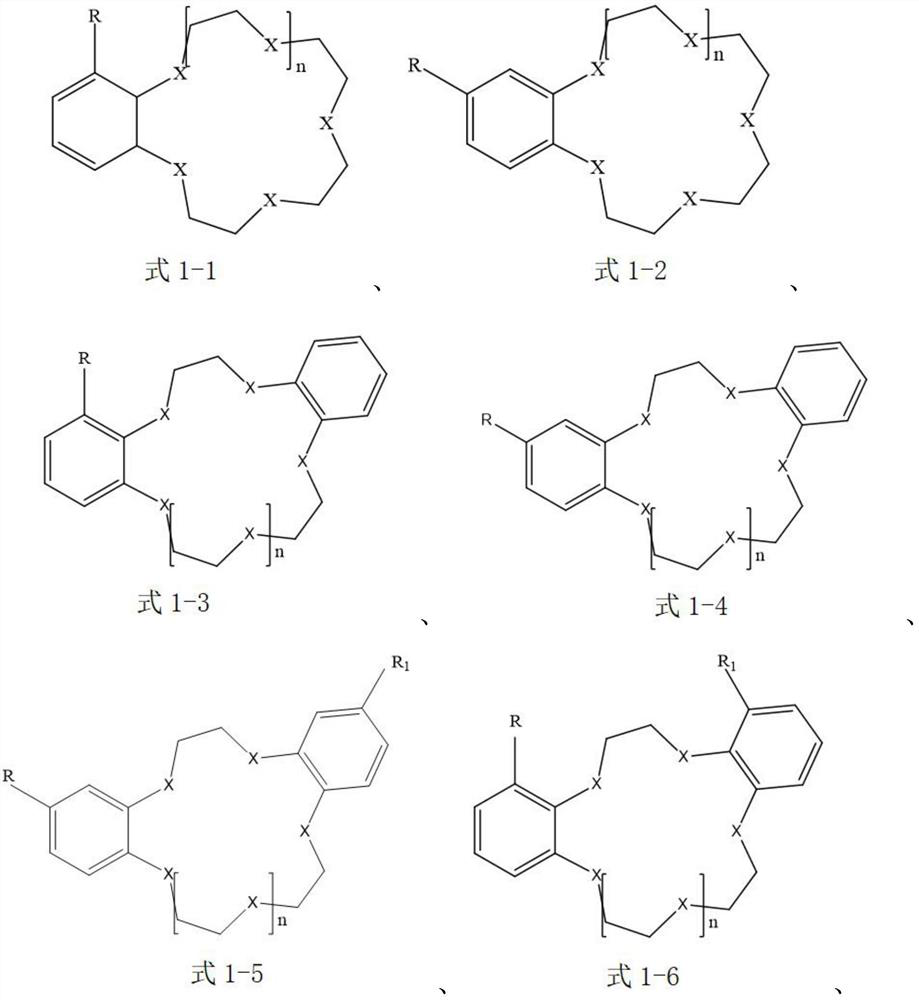

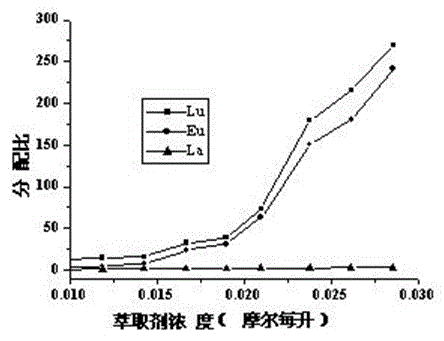

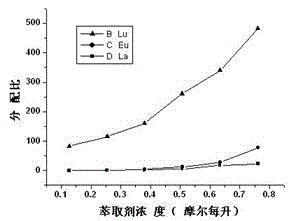

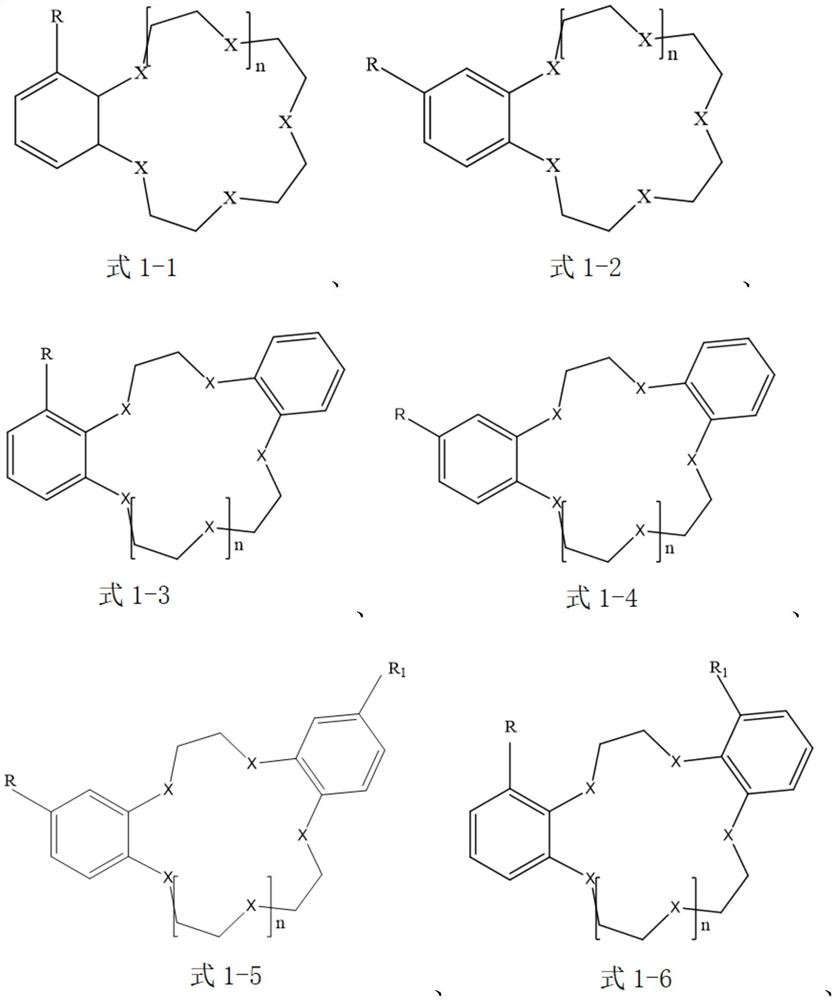

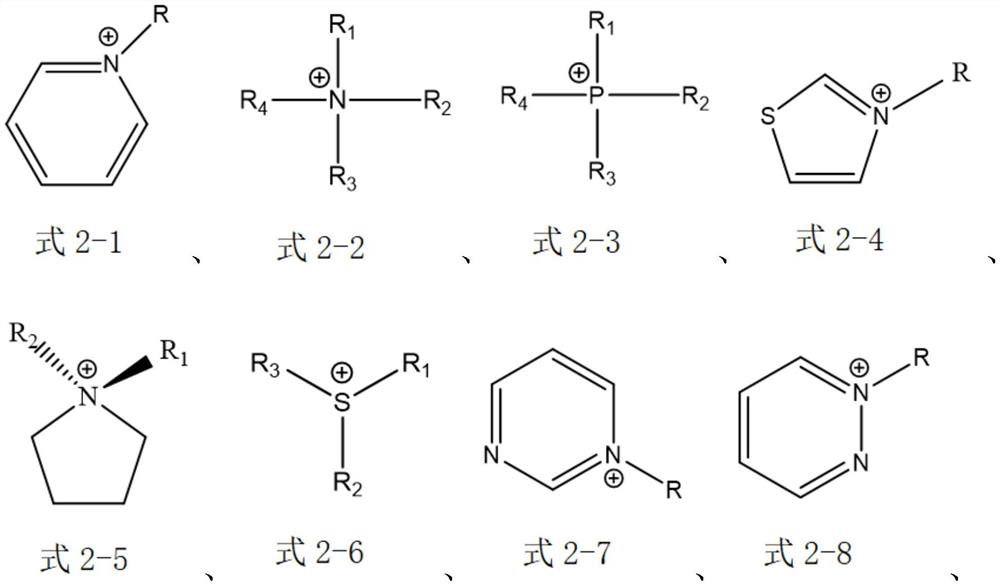

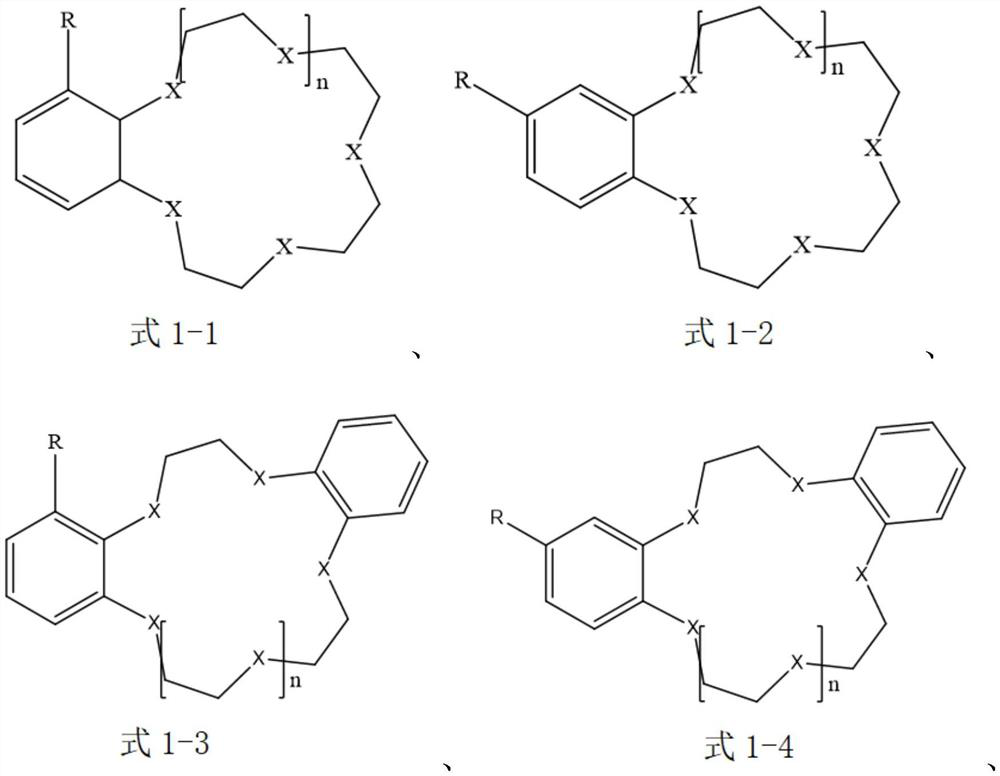

Extraction system for separating lithium isotopes

The invention discloses an extraction system for separating lithium isotopes. The extraction system for separating the lithium isotopes comprises an organic extraction phase which is used for extracting and separating the lithium isotopes based on a flotation column and a lithium salt solution phase, and the organic extraction phase comprises an extraction agent, an ionic liquid and a diluent which are mixed with one another; the extraction agent is selected from one or more than two of compounds shown as the following formulas 1-1 to 1-7; the ionic liquid comprises negative ions and positiveions; the positive ions are selected from one or more than two of positive ions represented by the following formulas 2-1 to 2-10, and the negative ions are selected from one or more than two of [PF6]-, [(SO2CF3) 2N]-, [(SO2CF2CF3) 2N]-, [CF3SO3]-, [CH3COO]-and [BF4]-. According to the extraction system for separating the lithium isotopes, the abundance of 6Li single-stage separation can be effectively improved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Efficient extraction method for high-purity lanthanum oxide

The invention relates to an efficient extraction method for high-purity lanthanum oxide. The efficient extraction method comprises the following steps of (1) extraction: mixing a lanthanum oxide feedliquid with an extraction agent at a volume ratio of 1:(2.5-3.5) for extraction separation, carrying out ultrasonic dispersion for 10-15 min, and carrying out separation after standing, wherein the extraction agent comprises the following raw materials including, by volume, 20%-24% of P507, 10%-15% of 1,2,5-thiadiazole-3,4-dithiol and the balance kerosene; (2) back extraction: carrying out back extraction on an oxalic acid solution with the organic-phase volume being 3.0-4.0 times at 50-60 DEG C, carrying out ultrasonic dispersion for 20-30 min, carrying out precipitation, and carrying out filtration to obtain a precipitate; and (3) oxidation: carrying out burning oxidation on the obtained precipitate at 800-900 DEG C for 12-15 h so as to obtain lanthanum oxide. According to the efficientextraction method provided by the invention, a specific amount of 1,2,5-thiadiazole-3,4-dithiol is added into an extraction system; through cooperation between the 1,2,5-thiadiazole-3,4-dithiol and the P507, the hydrophobicity of a lanthanum extraction complex can be higher; and accordingly, the entry into an organic phase can be easier, and the extraction efficiency and the distribution ratio canbe improved.

Owner:DEQING XINGBANG RARE EARTH NEW MATERIALS

Converter low-alkalinity residue high-efficiency dephosphorization method

InactiveCN103571998ASpeed up meltingSlow reaction speedManufacturing convertersLime productionFurnace temperatureAlkalinity

The invention discloses a converter low-alkalinity residue high-efficiency dephosphorization method. A residue remaining method is adopted, so that the FeO content in the residue is improved; a low-lance position operation is adopted in an early blowing stage, so that the temperature of a molten bath is improved, melting of lime is accelerated, primary residues are rapidly formed, and phosphorus is rapidly removed by utilizing high FeO content and low furnace temperature in the early stage. When the Si and Mn oxidizing period is basically ended and a C-O2 reaction begins, the oxygen supply strength is reduced, and soft blow is properly caused, so that the number of reflection streams is increased, the impact area is enlarged, the C-O2 reaction speed is reduced, the FeO content in the residue is increased, the generation of C2s on the lime surface is reduced, and a terminal dephosphorization rate is guaranteed under the conditions that the slag alkalinity and lime addition amount are low by adopting low alkalinity R of less than 2.0. According to a method for adjusting the lance position and controlling the oxygen supply strength, the smelting temperature is controlled, a phosphorus distribution ratio is increased, and the dephosphorization efficiency is improved; the method has the advantages of simple process, simplicity in operation and good dephosphorization effect and can be widely applied to serving as a dephosphorization method in a steel plant.

Owner:XI LIN IRON & STEEL GRP

Method for refining and quickly slagging low-carbon low-silicon aluminum-containing killed steel

ActiveCN113832290APrecise control of alkalinityIncrease the allocation ratioManufacturing convertersProcess efficiency improvementMetallic aluminumSlag

The invention discloses a method for refining and rapidly slagging low-carbon low-silicon aluminum-containing killed steel, and belongs to the technical field of alloy steel. The method comprises the following steps: adding the refining synthetic slag accounting for 28-35% of the total amount of a converter and lime slag accounting for 28-35% of the total amount of the converter in the tapping process of the converter; adding the residual refining synthetic slag and lime slag in the refining process; the total amount ratio of the refining synthetic slag to the lime slag is 1: (5-7); the refining synthetic slag is prepared from the following components in percentage by weight: 20-50% of metal aluminum, 35-60% of Al2O3 and 10-20% of CaO, and the granularity of the metal aluminum is less than 5 mm. According to the method, white slag operation is achieved within 15 minutes in the refining process, the generated white slag has sufficient time for desulfuration and inclusion removal in the later stage of refining, and meanwhile cost can be reduced and efficiency can be improved.

Owner:山西新泰钢铁有限公司

Communication resource allocation method of base station

InactiveUS8213335B2Increase the allocation ratioIncrease resourcesError preventionFrequency-division multiplex detailsResource allocationBase station

A communication resource allocation method for solving resource request imbalance content in a cell is provided. Considering a propagation environment, the base station allocates a whispering resource to a whispering area, the whispering resource being one part of the communication resource and the whispering area being a peripheral area of the first base station, and allocates a speaking resource to a speaking area, the speaking resource being other parts of the communication resource and the speaking area being a border area of a cell. When the resource request of the whispering area is increased, the base station further allocates a part of the speaking resource to the whispering area or increases a ratio of the whispering resource. When the resource request of the speaking area is increased, the base station controls a threshold value for identifying the whispering and speaking areas or increases a ratio of the speaking resource.

Owner:ELECTRONICS & TELECOMM RES INST

Method for quickly screening and detecting azo dyes forbidden in textile materials, leathers and dyes using gas chromatography mass spectrometry

ActiveCN102798677BReduce processing timeShorten the soaking timeComponent separationRetention timeGas phase

The invention discloses a method for quickly screening and detecting azo dyes forbidden in textile materials, leathers and dyes using gas chromatography mass spectrometry, which comprises the following steps: 1) preparing a sample, 2) subjecting the sample to reduction reaction, 3) extracting the sample, 4) performing the gas chromatography mass spectrometry on the sample, 5) screening decision: compared with the GC-MS analysis result of a standard solution, if the retention time and the mass spectrum of the aromatic amine in the sample keep with standards, the sample is judged as a suspicious positive sample, otherwise it is a negative sample and directly judged as a qualified sample. The sample pre-treatment time is shortened, the cost is reduced, the detection time is shortened, the operation step is simple, the operation is convenient, the operation time is short, the operation cost is low, the detection efficiency is improved; the aromatic amine in the sample is detected by a gas chromatography mass spectrometer, color interference problem is not existed, the sample matrix is effectively prevented from being infected, and the judgment accuracy is high, thus the method is not only suitable for textile materials, but also suitable for other products such as leathers and dyes.

Owner:南京海关工业产品检测中心

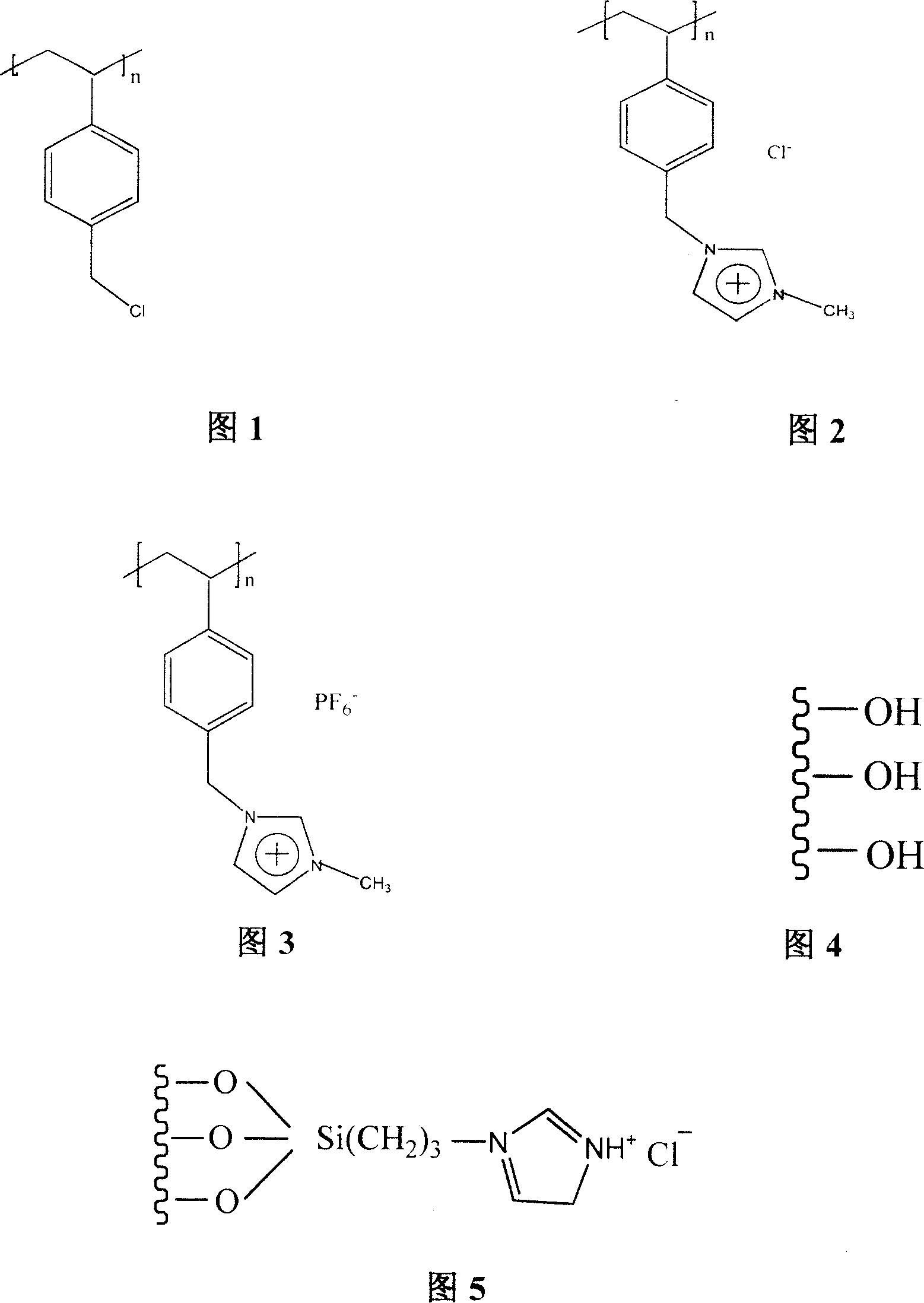

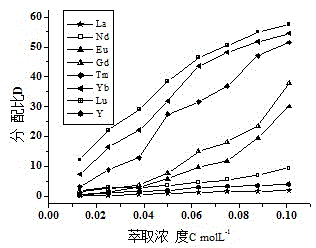

Heavy rare earth and light rare earth separation method and extraction agent

InactiveCN103451427BAvoid the limitations of low solubilityLess quantityProcess efficiency improvementRare-earth elementNitrate

The invention discloses a heavy rare earth and light rare earth separation method and a heavy rare earth and light rare earth separation extraction agent. The method includes the step of conducting extraction on a rare earth element and nitrate mixed aqueous solution through imidazolyl ionic liquid where the extraction agent is dissolved or chloroform where the extraction agent is dissolved or a 1-pentanol diluent where the extraction agent is dissolved so that heavy rare earth elements can be extracted and yttrium and light rare earth elements can be kept in the aqueous phase, wherein the extraction agent which is used is 1-methylimidazole shown in the chemical formula 1 or 2-methylimidazole shown in the chemical formula 2 when the diluent is the imidazolyl ionic liquid or the chloroform, and the extraction agent which is used is 2-methylimidazole shown in the chemical formula 2 when the diluent is the 1-pentanol diluent. The heavy rare earth and light rare earth separation method and the heavy rare earth and light rare earth separation extraction agent have the advantages that the extraction agent is low in price and can be easily obtained, the extraction system is simple, the extraction efficiency is high, the amount of the extraction agent which is used is small, and the specificity is strong.

Owner:LANZHOU UNIVERSITY

Extraction and separation method of lithium isotope

ActiveCN111850297BIncrease the allocation ratioReduce dissolution lossProcess efficiency improvementLithiumPhysical chemistry

The invention discloses a method for extracting and separating lithium isotopes, comprising: mixing an extractant, an ionic liquid and a diluent with each other to prepare an organic extraction phase, and the extractant is selected from the compounds shown in formulas 1-1 to 1-7; The ionic liquid is composed of anions and cations, the cations are selected from the cations shown in formulas 2-1 to 2-10, and the anions are selected from [PF 6 ] ‑ , [(SO 2 CF 3 ) 2 N] ‑ , [(SO 2 CF 2 CF 3 ) 2 N] ‑ , [CF 3 SO 3 ] ‑ , [CH 3 COO] ‑ and [BF 4 ] ‑ One or more of the following; dissolving the lithium salt in the solvent to prepare a lithium salt solution phase; placing the organic extraction phase and the lithium salt solution phase into a flotation column for extraction, and then separating and obtaining the extracted organic phase; The organic phase after extraction is back-extracted with the back-extraction liquid to obtain the enriched organic phase. 6 Li stripping solution. The extraction and separation method of lithium isotopes provided by the present invention can effectively improve the 6 Abundance of Li single-stage separations.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com