Method for refining and quickly slagging low-carbon low-silicon aluminum-containing killed steel

An aluminum-killed steel, low-carbon and low-silicon technology, applied in the field of alloy steel, can solve the problems of reducing the aluminum recovery rate, affecting the slagging effect, delaying the refining slagging time, etc., and achieve the effect of improving the foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

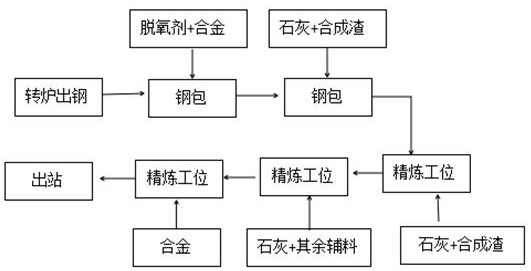

Image

Examples

Embodiment 1

[0020] A method for rapid slag formation in the refining of low-carbon, low-silicon and aluminum-containing killed steel: the refining mode is set to 100t molten steel / furnace, and the total amount of slag is strictly regulated to be 1-1.3t / furnace during the refining production process. Among them, the amount of lime slag is controlled at about 900kg, and the total amount of refined synthetic slag added is controlled at about 150kg.

[0021] The selected low-carbon, low-silicon and aluminum-containing killed steel is ML08Al; the composition of the molten steel at the end of the converter includes the weight percentage of C: 0.06%, Mn: 0.10%, P: 0.020%, S: 0.025%, and the end point temperature is 1620°C.

[0022] Add 302kg of lime slag, 50kg of refined synthetic slag, and the rest according to the original process during the tapping process of the converter. Feed 300m aluminum wire.

[0023] The refining entry temperature is 1588°C. During the refining process, 610kg of lime ...

Embodiment 2

[0026] The refining mode is the same as that of Example 1, the steel type is ML08Al, the components of molten steel at the end point of the converter include: C: 0.04%, Mn: 0.06%, P: 0.016%, S: 0.023%, and the end point temperature is 1645°C. During the tapping process, 303kg of lime slag is added, 50kg of refined synthetic slag is added, and the rest are carried out according to the original process. Refining entry temperature is 1605°C. During the refining process, a total of 650kg of lime is added, 100kg of refined synthetic slag is added, and the rest is carried out according to the original process. The original process is all the same as in Example 1; wherein, the composition of the refining synthetic slag is percentage by weight: metal aluminum: 50%, Al 2 o 3 : 35%, CaO: 15%, the particle size of metal aluminum <5mm.

[0027] The slagging time is 13 minutes, and the refining slag composition is (weight percent): CaO: 55%, SiO 2 : 6%, Al 2 o 3 : 29%, MgO: 8%, FeO: 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com