Extraction and separation method of lithium isotope

A lithium isotope and separation method technology, applied in the direction of improving process efficiency, can solve problems such as expensive production equipment, harsh production conditions, and difficulty in abundance, and achieve the effects of increasing abundance, reducing dissolution loss, and increasing distribution ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The extraction and separation method of lithium isotope provided by the present embodiment comprises the following steps:

[0057] 1. Preparation of organic extraction phase: the ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborophosphate [BMIm] [BF 4 ] and the diluent anisole are mixed with each other according to the volume ratio of 3:7, and then the extractant benzo-15-crown-5 is added to obtain an organic extract phase with an extractant concentration of 0.1mol / L.

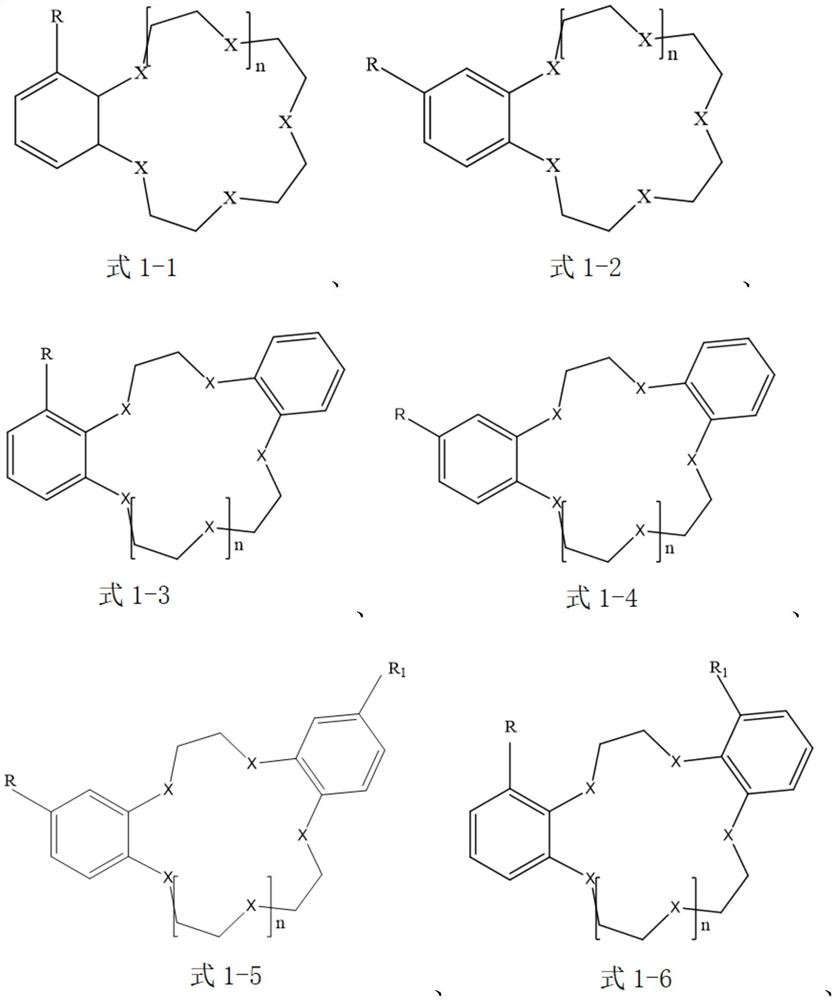

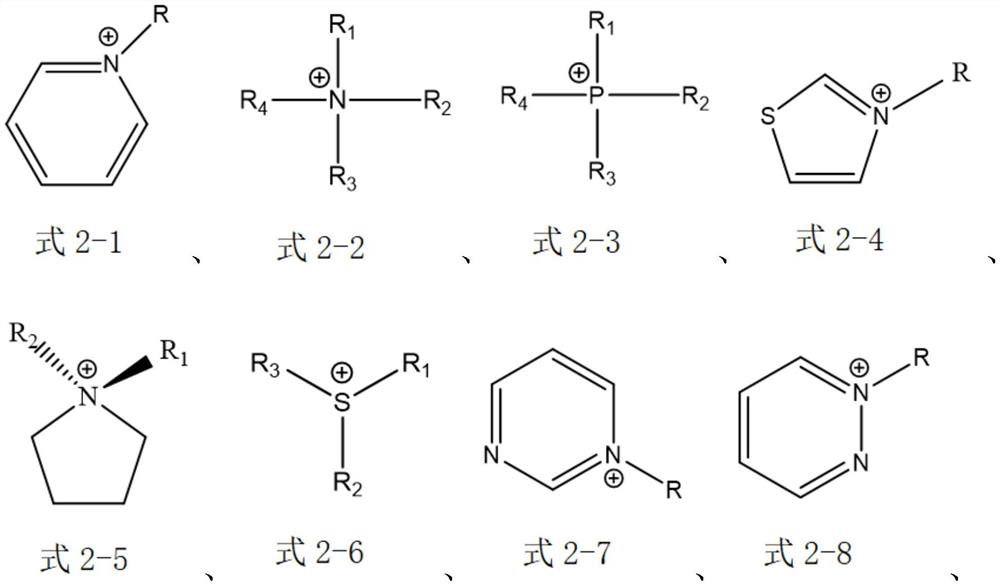

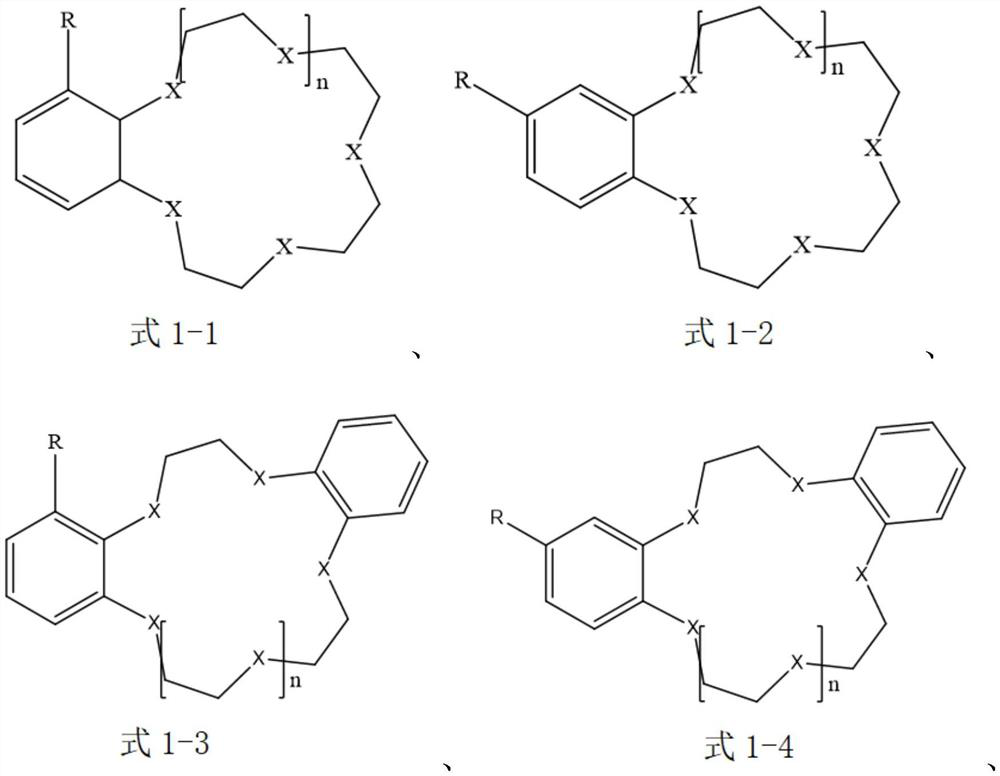

[0058] It should be noted that in this example, the extractant is selected as benzo15-crown-5, that is, the compound of the aforementioned formula 1-1; the cation in the ionic liquid is selected as the compound of the aforementioned formula 2-9, and the anion is selected as [PF 4 ] - .

[0059] Second, the preparation of lithium salt solution phase: the lithium salt Li[NTf 2 ] dissolved in water to prepare a lithium salt solution with a concentration of 0.2mol / L.

[0060] 3. Extraction: putting...

Embodiment 2

[0065] The extraction and separation method of lithium isotope provided by the present embodiment comprises the following steps:

[0066] 1. Prepare the organic extraction phase: the ionic liquid N-butylpyridine bis(trifluoromethanesulfonyl)imide salt [BPy][NTf 2 ] and the diluent chloroform are mixed with each other according to the volume ratio of 4:6, and then the extractant 4-aminobenzo-15-crown-5 is added to obtain an organic extract with an extractant concentration of 0.2mol / L.

[0067] It should be noted that in this example, the extractant is selected as 4-aminobenzo-15-crown-5, that is, the compound of the aforementioned formula 1-2; the cation in the ionic liquid is selected as the compound of the aforementioned formula 2-1, and the anion Select as [(SO 2 CF 3 ) 2 N] - .

[0068] Second, the preparation of lithium salt solution phase: the lithium salt CF 3 COOLi is dissolved in water to prepare a lithium salt solution with a concentration of 1mol / L.

[0069]3....

Embodiment 3

[0074] The extraction and separation method of lithium isotope provided by the present embodiment comprises the following steps:

[0075] 1. Prepare the organic extraction phase: the ionic liquid 1-butyl-3-methylimidazole bistrifluoromethanesulfonylimide salt [BMIm][NTf 2 ] and the diluent 1,1,2-trichloroethane are mixed with each other according to the volume ratio of 5:5, and then the extractant 4-bromobenzo-15-crown-5 is added to obtain an extractant concentration of 0.3mol / The organic extract phase of L.

[0076] It should be noted that in this example, the extractant is selected as 4-bromobenzo-15-crown-5, that is, the compound of the aforementioned formula 1-2; the cation in the ionic liquid is selected as the compound of the aforementioned formula 2-9, The anion is selected as [(SO 2 CF 3 ) 2 N] - .

[0077] 2. Prepare the lithium salt solution phase: dissolve the lithium salt LiI in water to prepare a lithium salt solution with a concentration of 2 mol / L.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com