Patents

Literature

202results about How to "Reduce dissolution loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

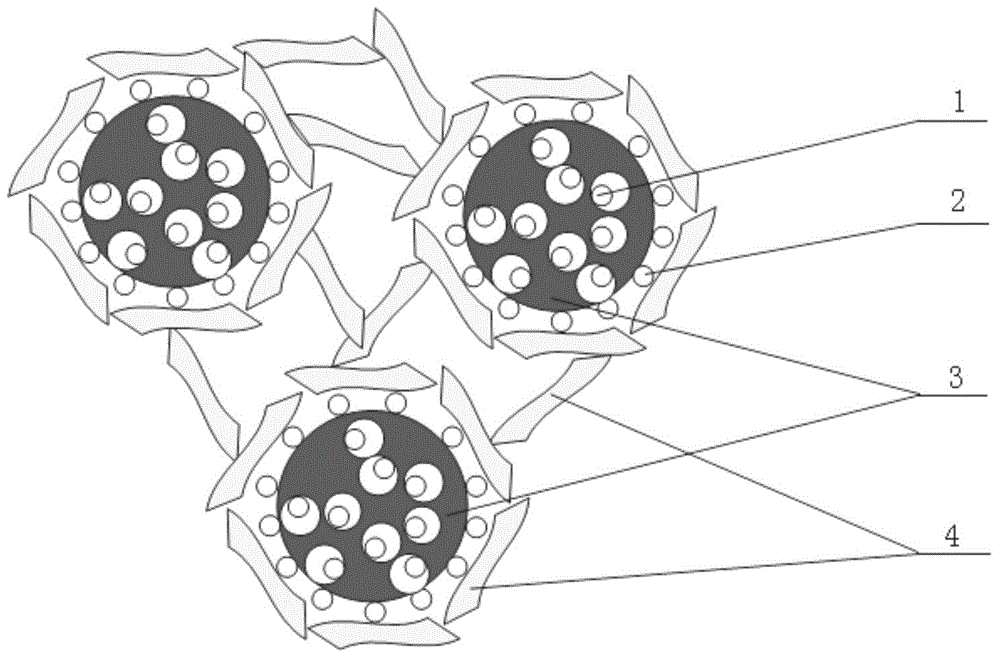

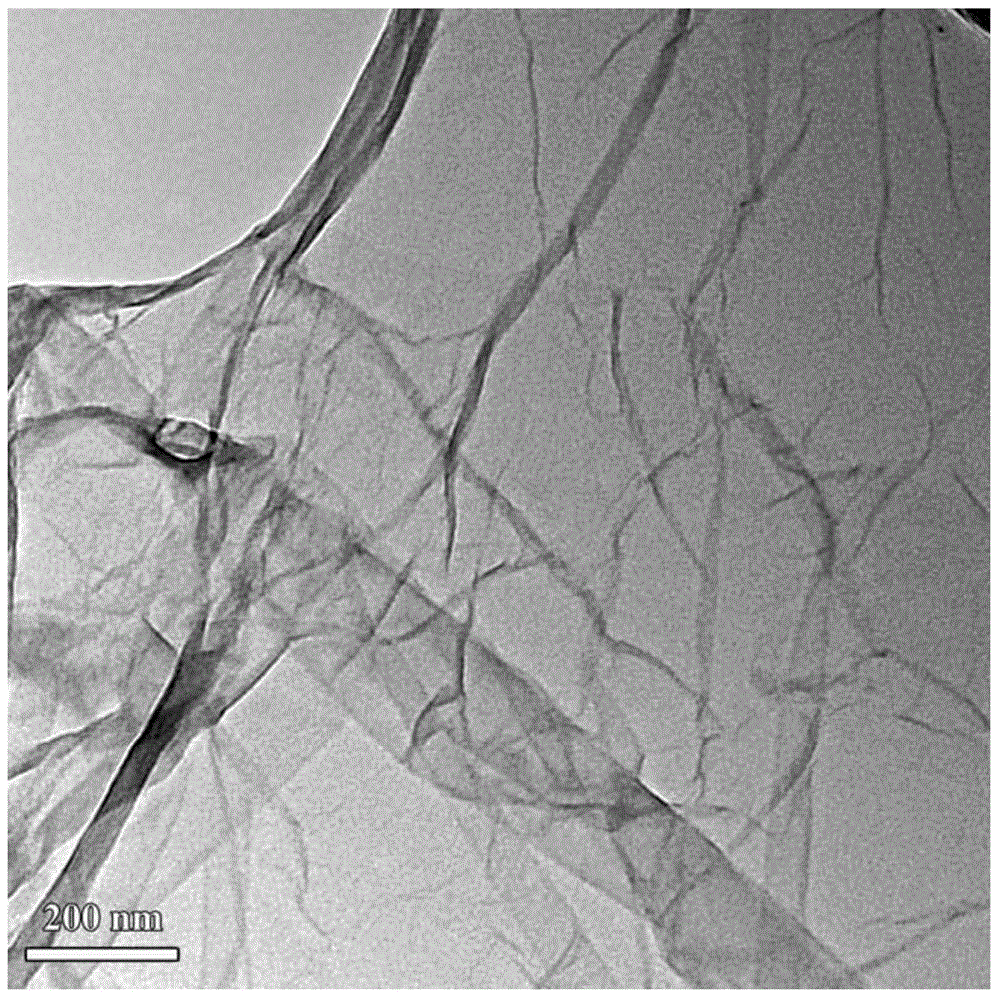

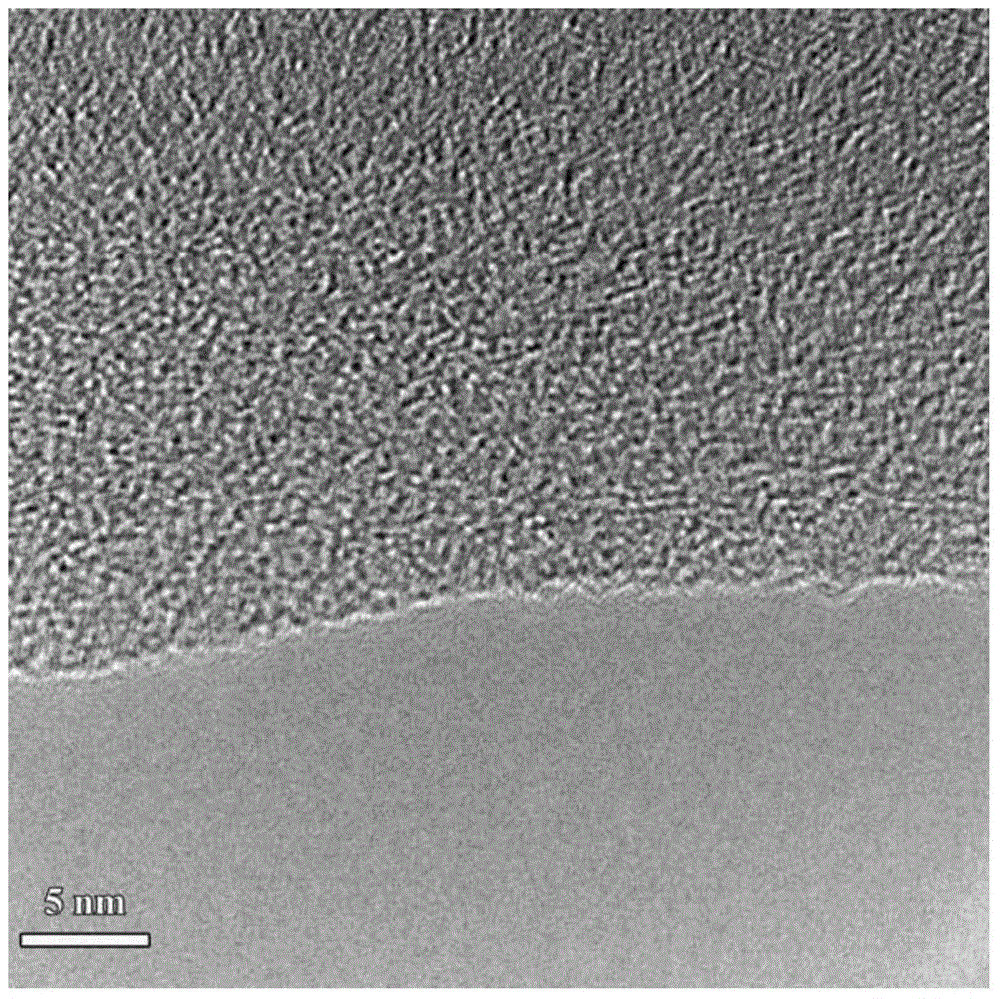

Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

ActiveCN103560235AUnique hierarchical core-shell structureIncrease contentCell electrodesHigh ratePorous carbon

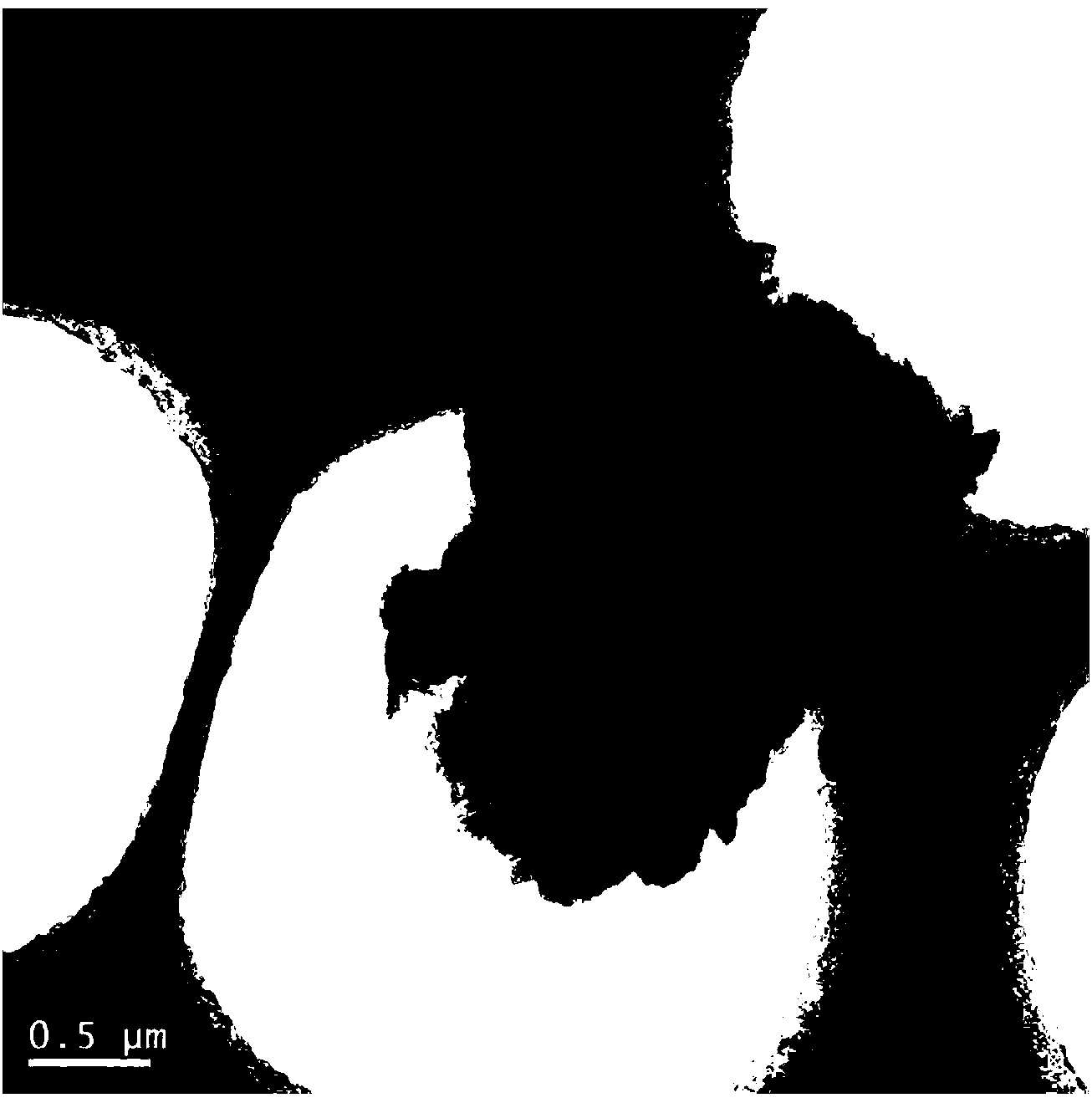

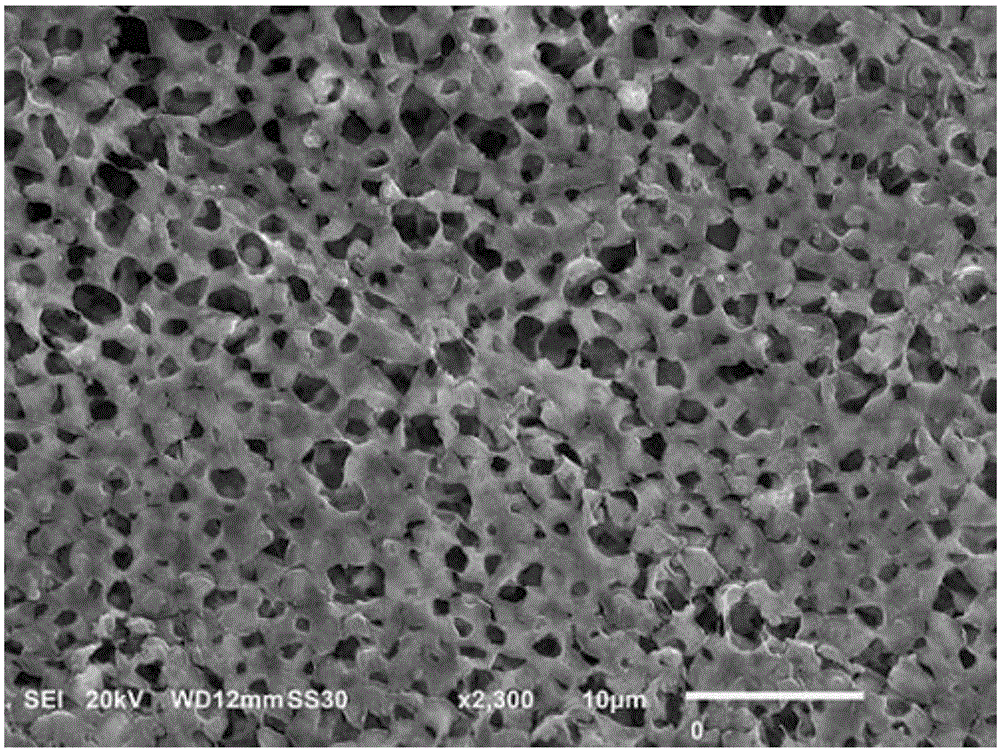

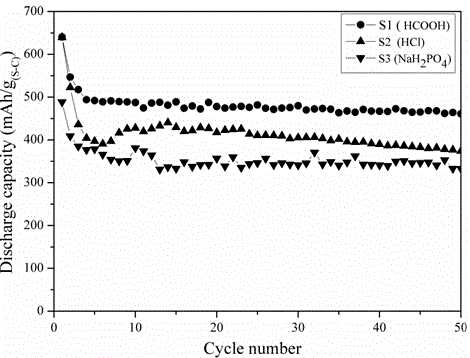

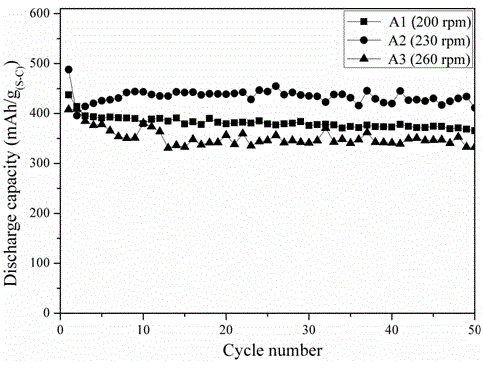

The invention provides a grapheme-coated sulfur / porous carbon composite material and a preparation method thereof, and relates to a grapheme-coated sulfur / porous carbon composite material used as the positive electrode material of a lithium-sulfur secondary battery and a preparation method thereof. The grapheme-coated sulfur / porous carbon composite positive electrode material provided by the invention can be used for solving the technical problem that the existing grapheme-coated sulfur-containing composite material used as the positive electrode material of a lithium-sulfur battery is low in electrochemical properties. The external surface of each of the particles of the grapheme-coated sulfur / porous carbon composite material provided by the invention is evenly covered with a graphene sheet, and a graphene conductive network is formed between the particles; the obtained grapheme-coated sulfur / porous carbon composite material has a hierarchical core-shell structure. The preparation method of the grapheme-coated sulfur / porous carbon composite material is obtained by adding a sulfur / porous carbon composite material to graphene slurry which is stable for a long time and in which graphene sheets are highly dispersed in water for mixing and coating. The positive electrode material has high specific capacity, long cycle life and excellent high-rate performance. Besides, the grapheme-coated sulfur / porous carbon composite material can be used as the positive electrode material of a lithium secondary battery.

Owner:HARBIN INST OF TECH

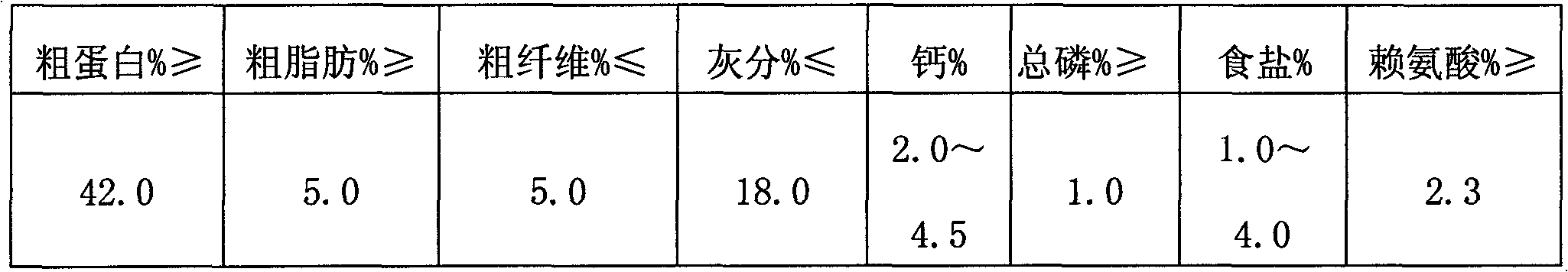

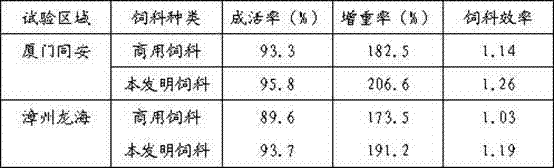

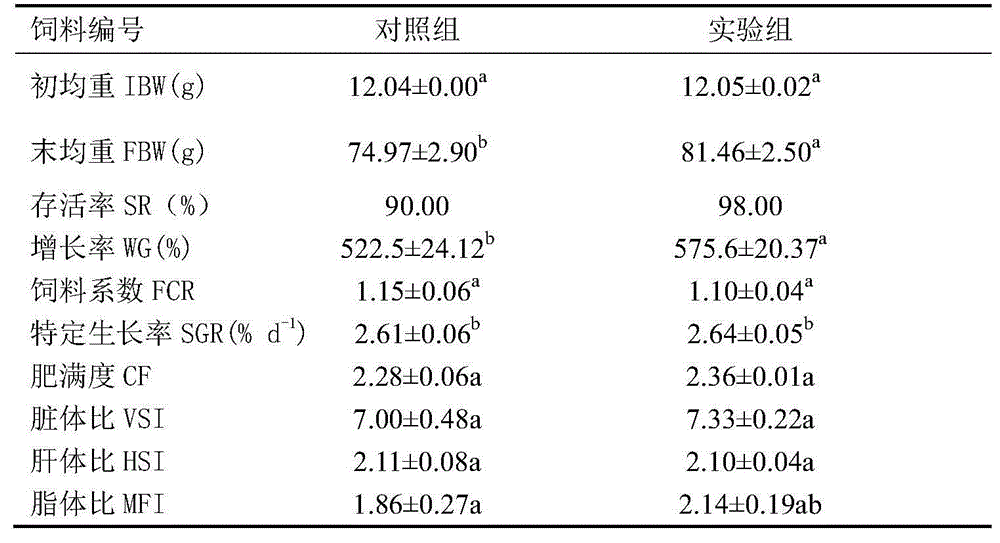

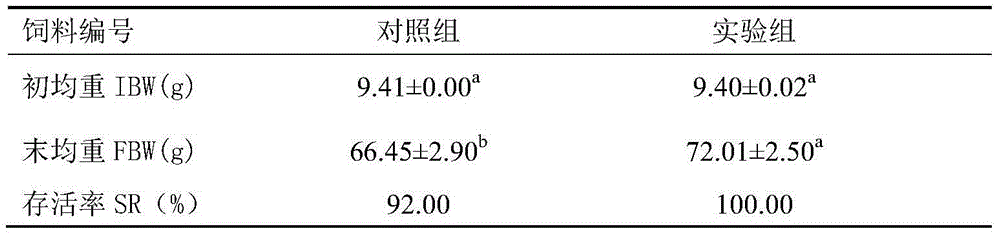

Litopenaeus vannamei compound feed special for winter shed cultivation and preparation method for feed

The invention relates to aquaculture feed, in particular to litopenaeus vannamei compound feed special for winter shed cultivation and a preparation method of the feed. The feed comprises a protein source raw material, a fat source raw material, a sugar source raw material, an antioxidant, a phagostimulant, composite vitamin and composite mineral salt. The invention provides the litopenaeus vannamei compound feed special for winter shed cultivation and the preparation method of the feed, with the advantages of high survival rate, high growth speed, high stability in water, high ingestion speed, convenience for use and low environmental pollution, so as to solve the problems of low growth speed, serious disease, low survival rate and the like of the litopenaeus vannamei during winter shed cultivation at low temperature and promote the healthy development of the litopenaeus vannamei cultivation industry.

Owner:FUJIAN HAID FEEDS +4

Alga immunopotentiation compound feed for litopenaeus vannamei

ActiveCN103355491AImprove palatabilityFast food intakeAnimal feeding stuffBiotechnologyAntimicrobial action

The invention belongs to the field of aquaculture or feed, relates to a aquaculture feed, and especially relates to an alga immunopotentiation compound feed for litopenaeus vannamei. The invention at first provides an immunity strengthening agent for litopenaeus vannamei feed, and the agent is obtained through enzymatic hydrolysis and fermentation of an alga composite. The alga composite is composed of following components in parts by dried weight: 40 to 50 parts of asparagus, 15 to 25 parts of enteromorpha, 10 to 20 parts of ulva lactuca, 5 to 15 parts of laver and 5 to 15 parts of undaria pinnatifida. The invention further prepares a compound feed for litopenaeus vannamei by utilizing the immunity strengthening agent. The alga immunity strengthening agent contains algae polysaccharide, which has the effect of strengthening animal immunity, acrylic acid, terpenes, brominated phenolic and some sulfocompounds, which have the antiseptic effect, and sulphated polysaccharide, which has the antivirus effect. The litopenaeus vannameis fed on the alga immunopotentiation compound feed have a strong anti-stress performance, the body's immunity ability is improved, survival rate is high and culture benefit is remarkable.

Owner:SUN YAT SEN UNIV

Health-care compound feed for prawns and production method thereof

InactiveCN102178078AGuaranteed FreshnessGood digestion and absorption rateFood processingClimate change adaptationAnimal sciencePrawn

The invention discloses a health-care compound feed for prawns and a production method thereof. The invention aims to provide a health-care compound feed for prawns, which can improve immunity in the prawns, utilization rate of feed and water quality, and a production method thereof. The formula of the raw material comprises the following components in part by weigh: 1 to 6 parts of imported white fish meal, 20 to 25 parts of steamed fish meal imported from Taiwan, 2 to 8 parts of steamed fish meal made in China, 18 to 22 parts of high-gluten wheat flour, 15 to 22 parts of peeled soybean pulp, 8 to 15 parts of peanut cakes, 2 to 6 parts of defatted shrimp meal, 1 to 3 parts of beer yeast cream, 1 to 3 parts of soyabean lecithin oil, 0.5 to 2 parts of refined fish oil, 0.5 to 2 parts of monocalcium phosphate and 1 to 4 parts of additive premix. The production method comprises: crushing, primary material mixing, secondary material mixing, hardening and tempering, granulating, braising, aging, drying, cooking, sieving and packaging. The invention can improve the breeding yield of pawns, reduce discharge pollution, improve water environment and the like.

Owner:深圳市澳华集团股份有限公司

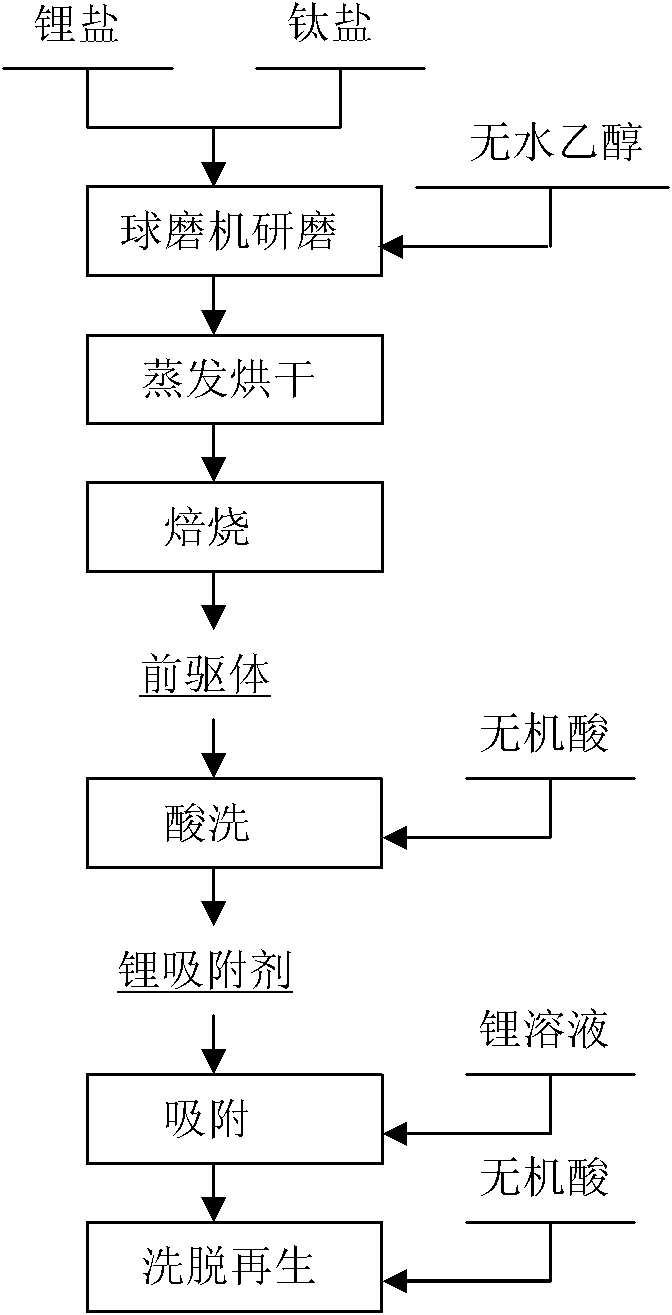

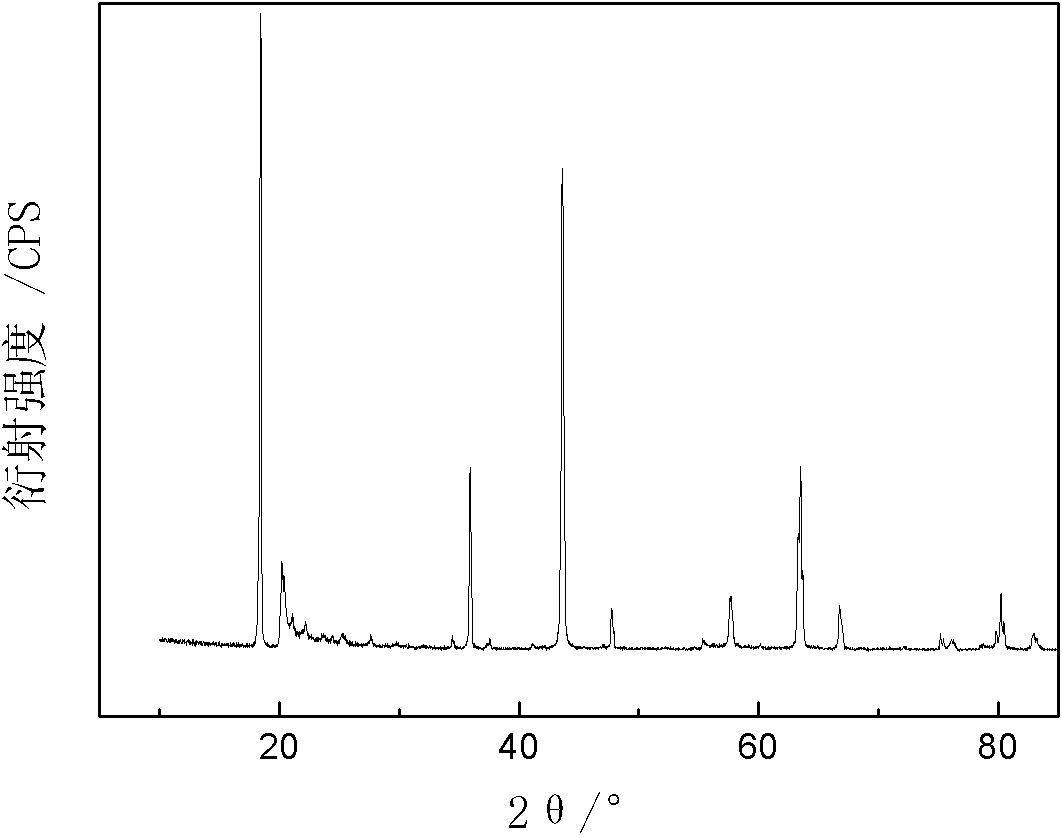

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

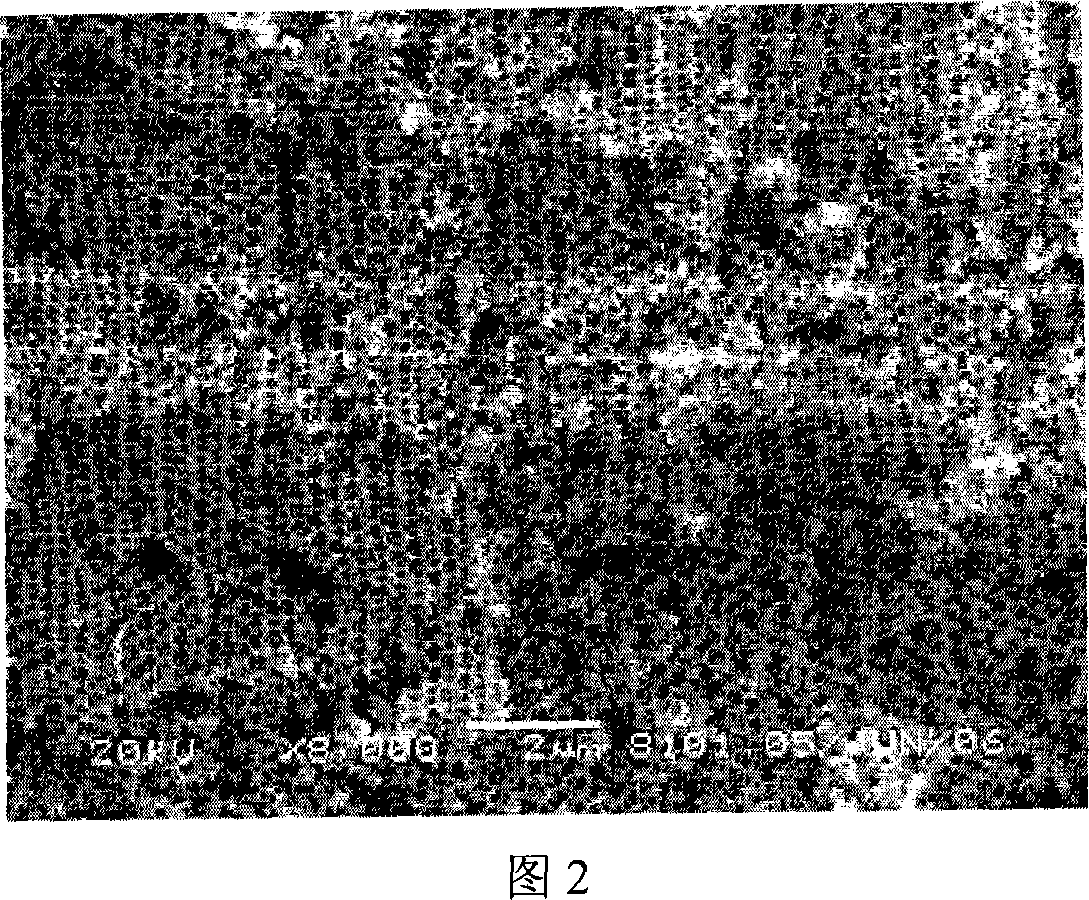

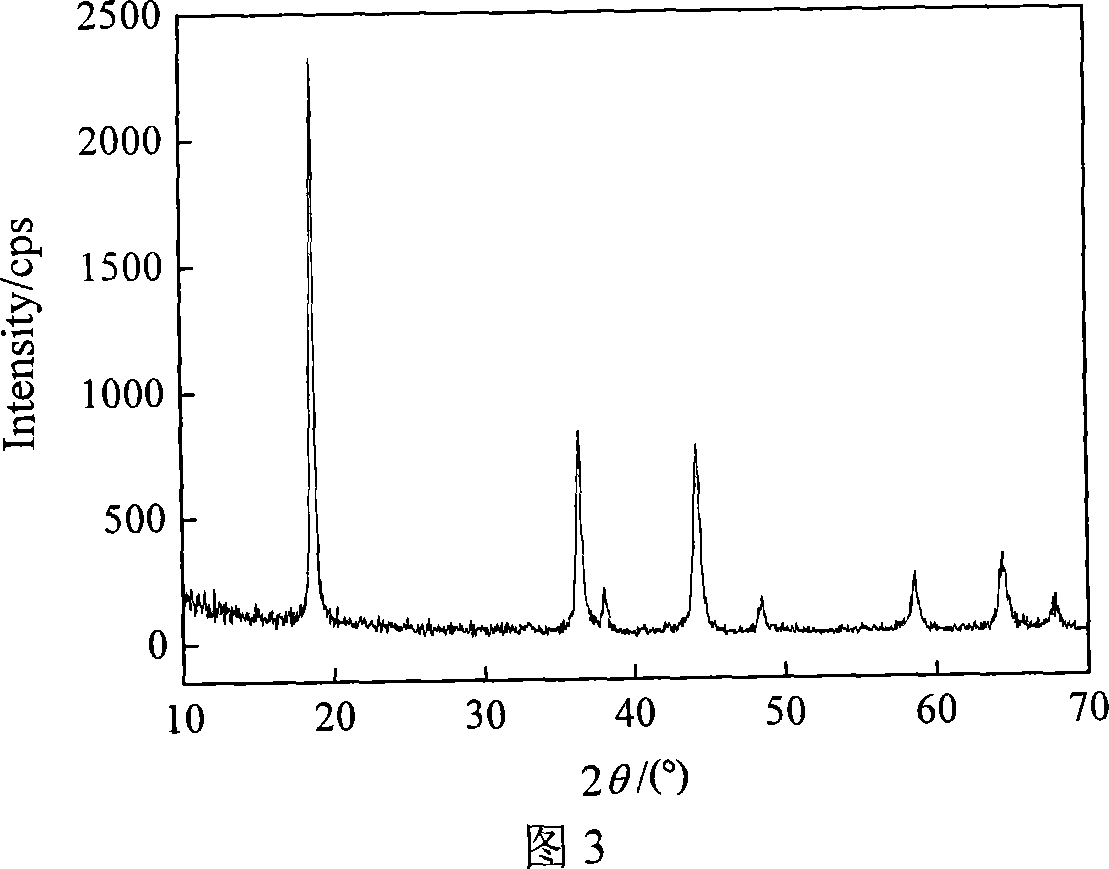

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

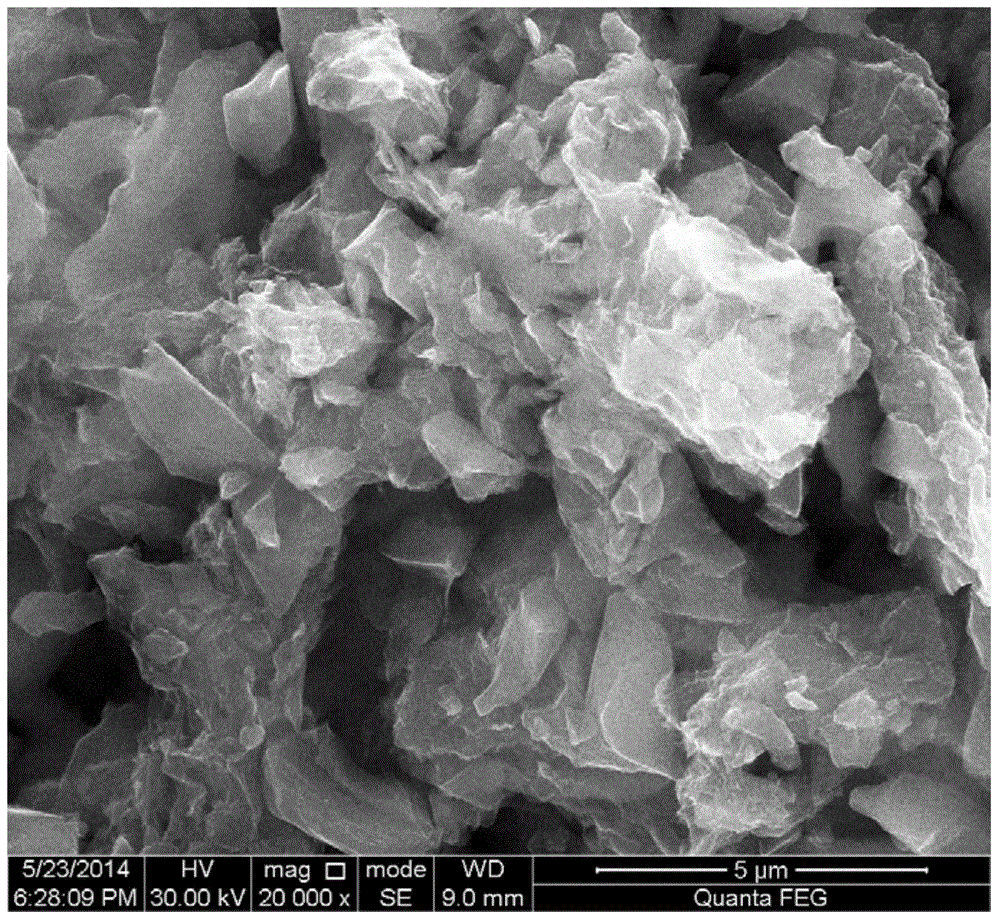

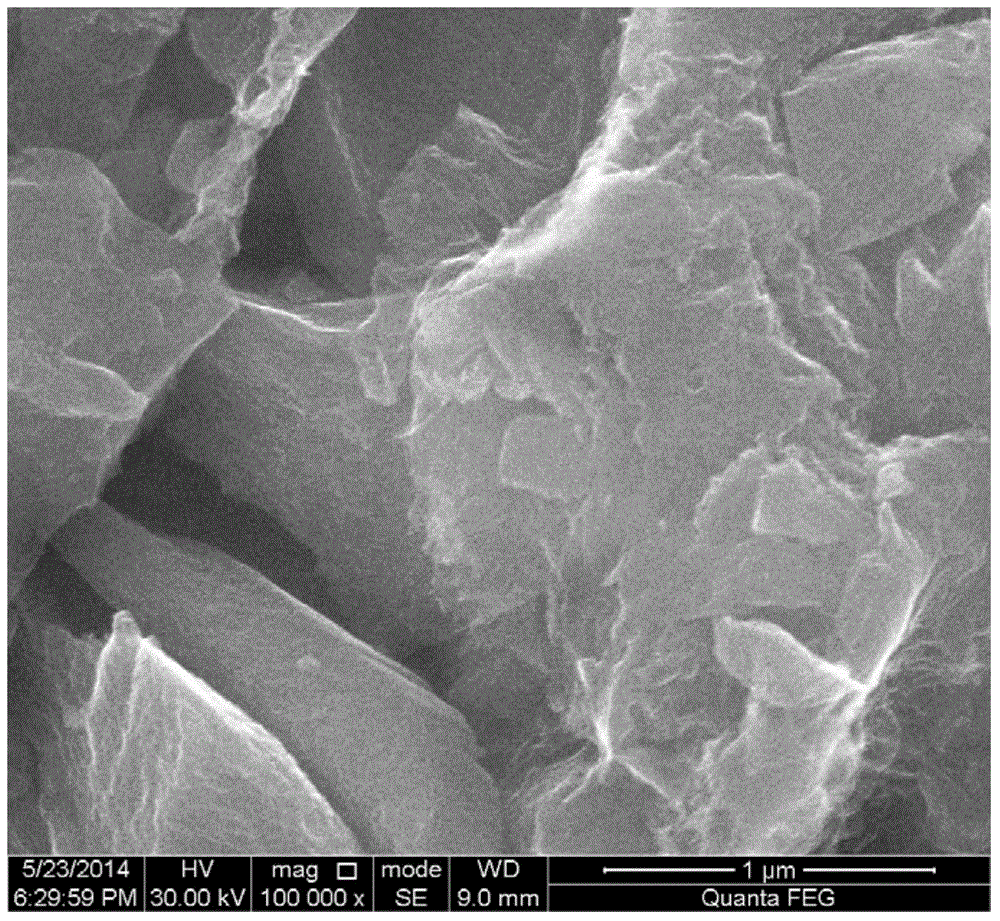

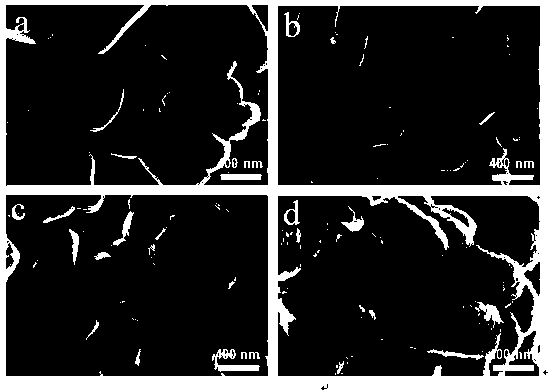

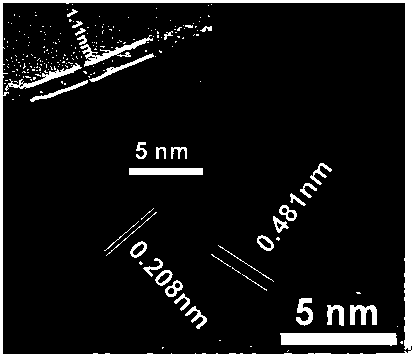

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

ActiveCN104064738AInhibition of dissolution lossPromote wettingCell electrodesSecondary cellsCvd grapheneGraphite oxide

The invention provides a hydrothermal preparation method of a graphene-coated sulfur / porous carbon composite material and relates to a preparation method of the graphene-coated sulfur / porous carbon composite material for a positive electrode material of a lithium-sulfur storage battery. The hydrothermal preparation method is used for solving the technical problem that the electrochemical property of the positive electrode material of an existing lithium-sulfur battery, namely a graphene-coated sulfur-containing composite material, is low. The hydrothermal preparation method comprises the steps of mixing and scattering the sulfur / porous carbon composite material with graphene slurry or oxidized graphene slurry, carrying out hydrothermal synthesis to prepare a hydrogel column, and drying to obtain the graphene-coated sulfur / porous carbon composite material. According to the graphene-coated sulfur / porous carbon composite material prepared by utilizing the hydrothermal preparation method, the outer surfaces of the graphene sheet layers are coated with sulfur / porous carbon composite material particles, a graphene conduction network is generated among the particles, and the obtained graphene-coated sulfur / porous carbon composite material is in a hierarchical core-shell structure; the positive electrode material has the high specific capacity, the long cycle life and the good rate capability; the composite positive electrode material can be used as a positive electrode material in a lithium secondary battery.

Owner:HARBIN INST OF TECH

Polyvinylpyrrolidone modified graphene coated sulfur/porous carbon composite anode material and preparation method thereof

ActiveCN104078685AIncrease contentImprove the utilization rate of active substancesCell electrodesLi-accumulatorsCvd grapheneHigh rate

The invention relates to a polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite anode material and a preparation method thereof, which relates to a sulfur / carbon composite material applied to a lithium-sulfur secondary battery anode material and a preparation method of the composite material, and solves the technical problem of the existing lithium-sulfur battery anode material graphene-coated sulfur-containing composite material that the electrochemical property is low. The polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite material is characterized in that the outer surface of a sulfur / porous carbon composite material particle is uniformly coated with a polyvinylpyrrolidone modified graphene slab layer, a graphene conductive network is formed between every two adjacent particles, and a grading core-shell structure is formed. The preparation method comprises the steps of adding the sulfur / porous carbon composite material into graphene slurry modified by the polyvinylpyrrolidone, and mixing the sulfur / porous carbon composite material with the graphene slurry, and coating the sulfur / porous carbon composite material with the graphene slurry modified by the polyvinylpyrrolidone. The anode material is high in specific capacity, long in cycle life and good in high-rate performance.

Owner:HARBIN INST OF TECH

Special compound fertilizer for broomcorn

InactiveCN104262017AIncrease productionReduce dissolution lossAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmmonium sulfateBacterial agent

The invention discloses a special compound fertilizer for broomcorn. The special compound fertilizer is prepared from the following constituents in parts by weight: 50-65 parts of urea, 33-43 parts of ammonium sulfate, 20-25 parts of monoammonium phosphate, 27-37 parts of potassium sulfate, 15-22 parts of monopotassium phosphate, 7-11 parts of borax, 3-6 parts of zinc-amino acid chelate, 3-6 parts of attapulgite, 5-8 parts of compound sodium nitrophenolate, 5-8 parts of straw, 3-6 parts of bean pulp, 4-6 parts of vinasse, 1-5 parts of a biological bacterial agent and 1-5 parts of a plant growth regulator. The special compound fertilizer for the broomcorn, disclosed by the invention, can increase the yield of the broomcorn, lower dissolved rate of the fertilizer, increase the utilization rate of the fertilizer, improve the fertilizer efficiency, and promote circulating and long-acting absorption and utilization of the crop; the usage amount of the fertilizer can be lowered only in need of one-time application of the fertilizer; besides, the fertilizer can improve the soil properties, eliminate hardening and increase the moisture and fertility preservation capabilities; furthermore, the fertilizer can effectively prevent an eutrophication phenomenon.

Owner:潘虹

Formulation and preparing method of expanded assorted feed for ophiocephalidae

InactiveCN101040668APromote rapid growthImprove digestion and absorption rateFood processingClimate change adaptationYeastWater quality

The invention relates to a formula of compound puffed feed for snakehead mullet and process for preparation, wherein the constituents in the formula comprise (by mass ratio): fish meal 35-50%, fermented soybean waste 10-20%, meat and bones meal 0-12%, silkworm chrysalis powder 0-5%, blood powder 0-5%, brewer's yeast 2-5%, shrimp grease 0-6%, fish oil 1.0-3%, high grade flour 10-20%, liquid phosphatide 1-2%, calcium dihydrogenphoshate 0.5-1.5%, composite vitamin 0.5-1%, compound minerals 0.5-1%, choline chloride 0.3-0.5%. The preparing process consists of proportioning constituents, mixing homogeneously, disintegrating, modulating, palletizing and drying.

Owner:GUANGDONG HENGXING GROUP

Preparation method and application of lithium-titanium type ion sieve composite membrane

InactiveCN106622170AReduce dissolution lossStable structureMembranesSemi-permeable membranesPolyvinylidene fluorideChemistry

The invention provides a preparation method and application of a lithium-titanium type ion sieve composite membrane. The preparation method comprises the following steps: step 1, preparing a lithium ion sieve Li2TiO3 precursor: adding TiO2 and Li2CO3 into absolute ethyl alcohol; after uniformly mixing, drying and baking; washing a baked lithium ion sieve Li2TiO3 with acid, so as to obtain the lithium ion sieve Li2TiO3 precursor; step 2, preparing the lithium-titanium type ion sieve composite membrane: dissolving the lithium ion sieve Li2TiO3 precursor, polyvinylidene fluoride powder and polyethylene glycol into an N-methyl pyrrolidone solution; mechanically stirring and uniformly mixing at constant temperature to prepare a lithium-titanium type ion sieve membrane casting solution; putting the lithium-titanium type ion sieve membrane casting solution into distilled water to obtain the lithium-titanium type ion sieve composite membrane capable of specifically identifying lithium ions. The prepared lithium-titanium type ion sieve composite membrane has good mechanical properties and stable structure and can be used for efficiently and selectively identifying and separating the lithium ions, such as selectively adsorbing and separating the lithium ions from salt lake brine.

Owner:JIANGSU UNIV

Sulfur-carbon composite positive electrode material for lithium-sulfur battery and preparation method of sulfur-carbon composite positive electrode material

ActiveCN104600247AIncrease contentImprove cycle stabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsHigh concentrationCarbon composites

The invention particularly relates to a preparation method of a sulfur-carbon composite positive electrode material for a lithium-sulfur battery. Sodium polysulfide is taken as the raw material, and the nano-scale sulfur particles generated by use of a chemical reaction are promoted to be melted by virtue of high-speed ball milling and go into carbon pores of conductive carbon black, and finally, the sulfur-carbon composite positive electrode material is prepared. The high-performance sulfur-carbon composite material is prepared by use of an in-situ wet ball milling method. According to the preparation method, the operation is simple and easy, the energy consumption is low, the cost is low, an environment-friendly effect is achieved, and the industrial production is easy. The thorough dispersion and fixation of sulfur on a conductive substrate are realized; besides, a high-concentration lithium salt electrolyte is adopted to inhibit the solution of polysulfide, and therefore, the cyclic stability and the active substance utilization rate of the material are improved. As a result, the sulfur-carbon composite material prepared by use of the in-situ wet ball milling method is a positive electrode material which is high in specific capacity, long in cycle life and high in rate performance and can be applied to the field of lithium secondary batteries.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

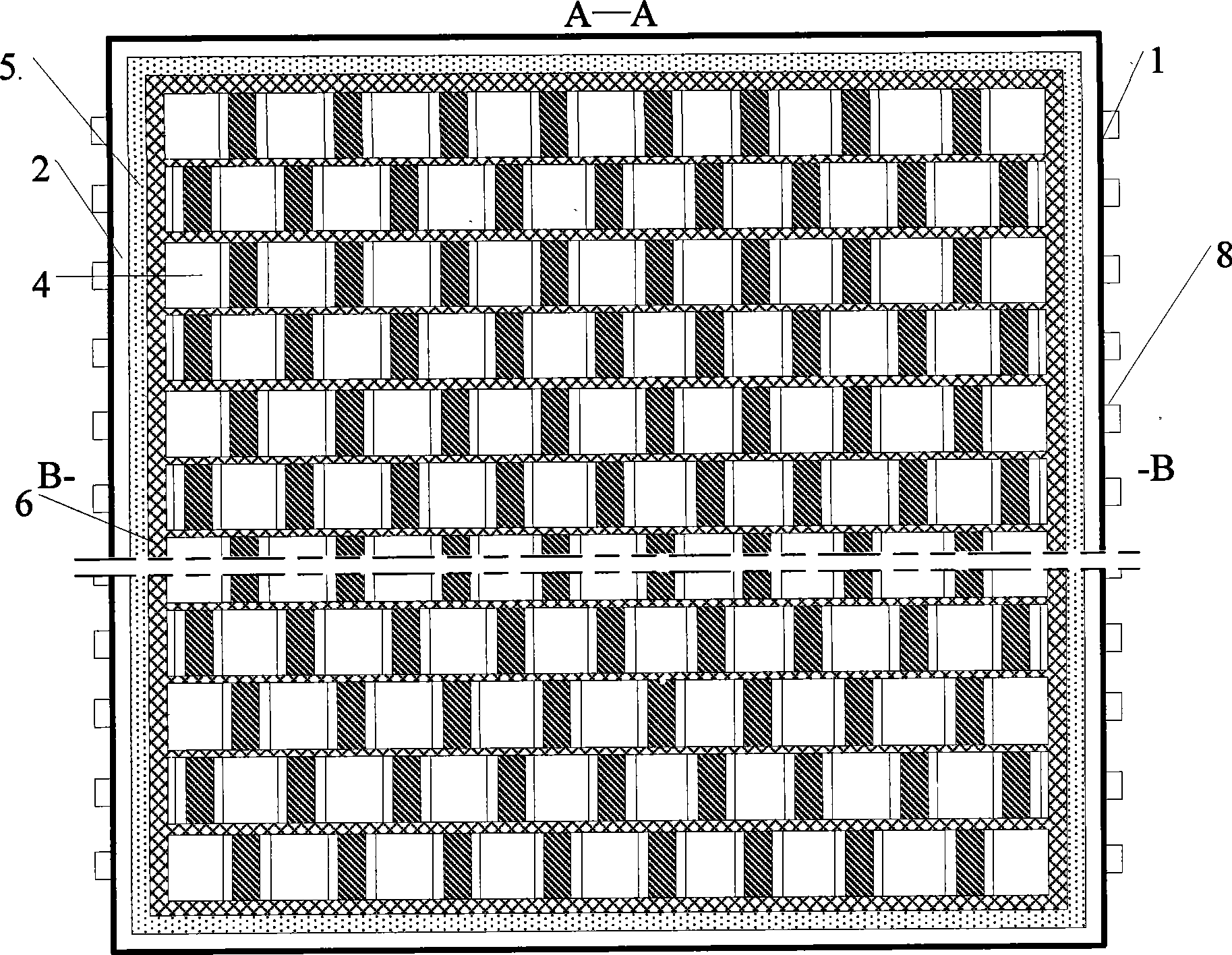

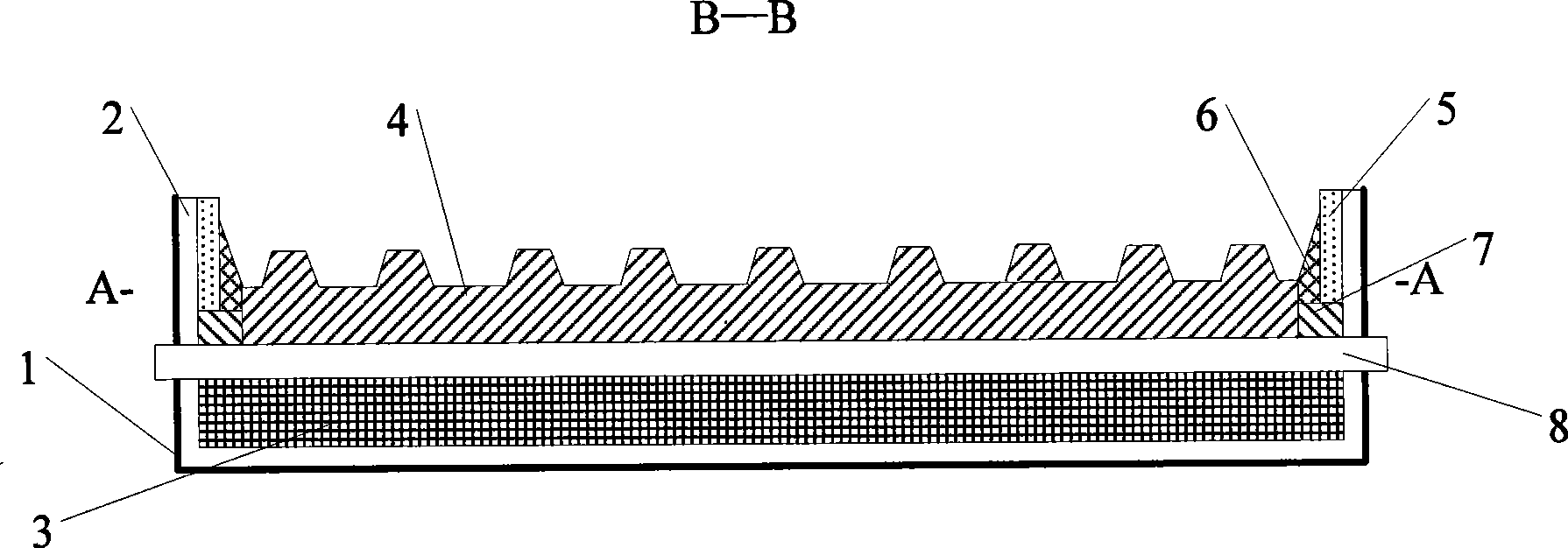

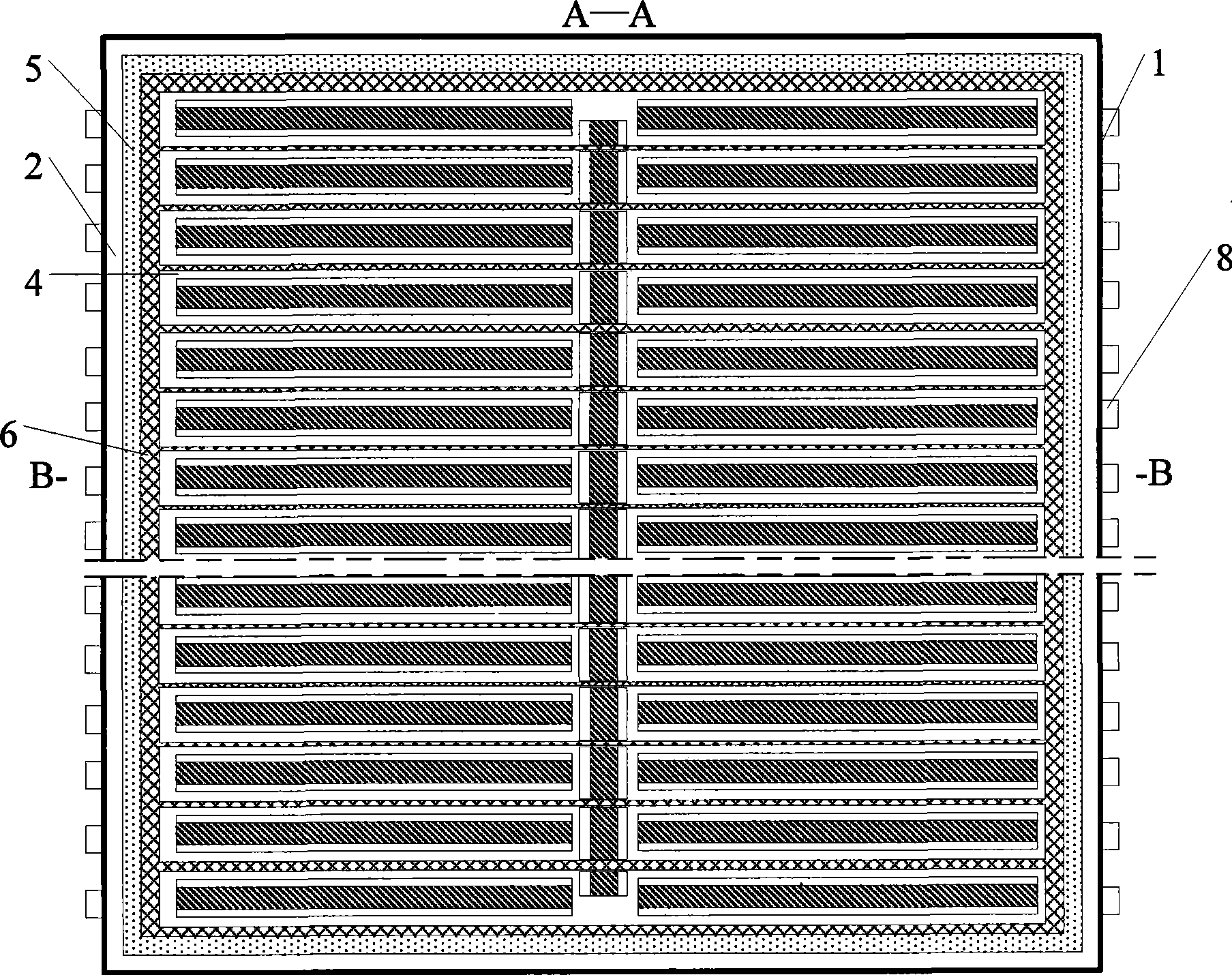

Novel cathode structured aluminum cell with longitudinal and transversal wave damping functions

The invention relates to a novel cathode structure aluminum electrolysis bath with longitudinal and transverse wave decreasing functions, which comprises an electrolysis bath shell, an electrolysis bath lining, a fire-resisting material, a cathode carbon block, a lining carbon brick, carbon tamping paste, fire-resisting concrete, and a cathode carbon bar. The cathode structure aluminum electrolysis bath is characterized in that the top surface of the cathode carbon block is provided with more than one raised structures each of which is connected with the cathode carbon block integrally, and the arranging mode of each raised structure is to be parallel to the axial direction of the cathode carbon block, vertical to the axial direction of the cathode block, or adopt a mixed mode of the two. The novel cathode structure aluminum electrolysis bath with the longitudinal and the transverse wave decreasing functions can slow down the flow speed of cathode aluminum fluid in the transverse direction and the longitudinal direction in the electrolysis bath and reduce the fluctuation height of the aluminum fluid surface in the transverse direction and the longitudinal direction, improve the stability of the aluminum fluid surface of aluminum, reduce the solution loss of the aluminum, reduce the electric energy consumption for aluminum electrolysis production, and prolong the service life of the novel cathode structure electrolysis bath.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

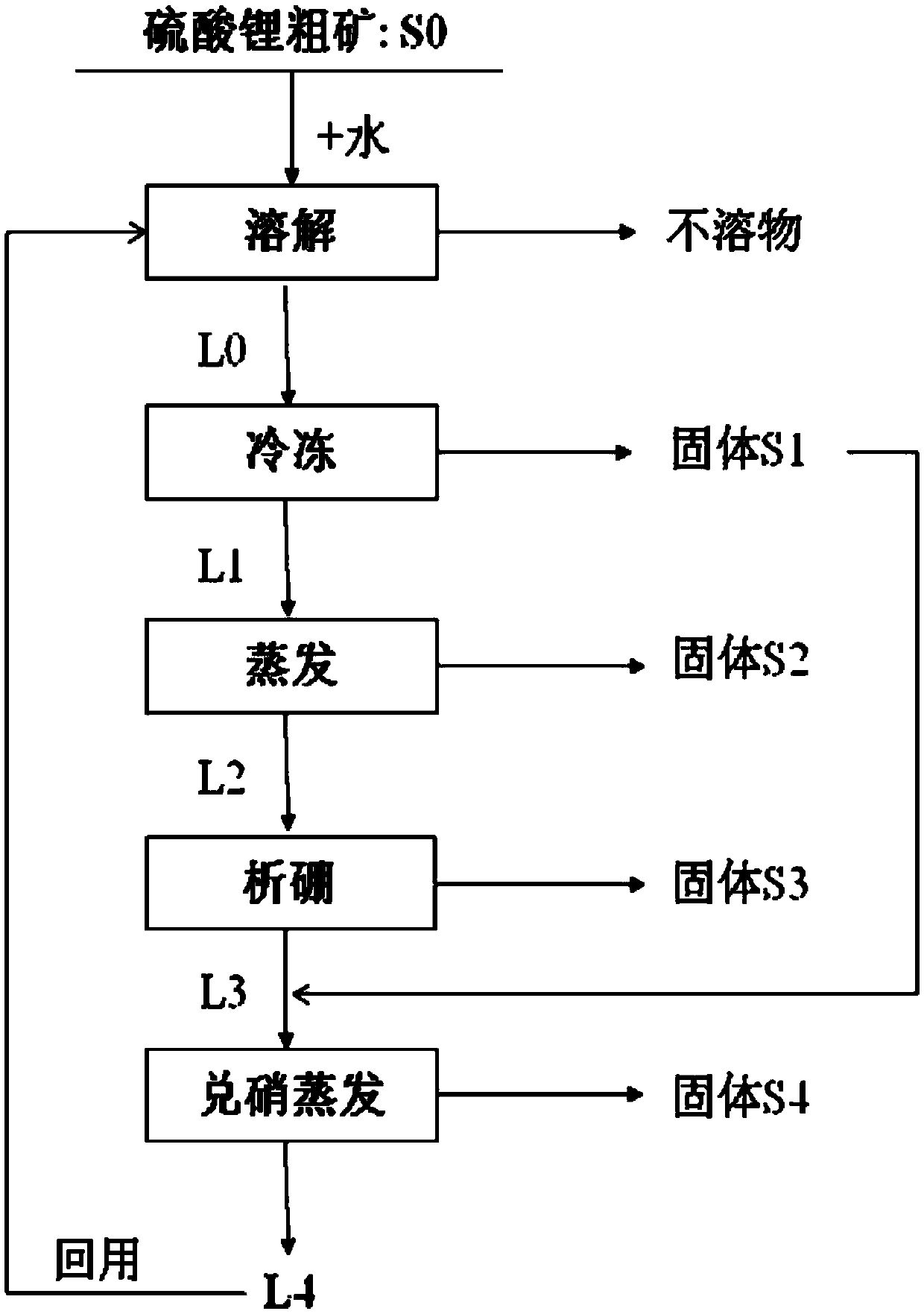

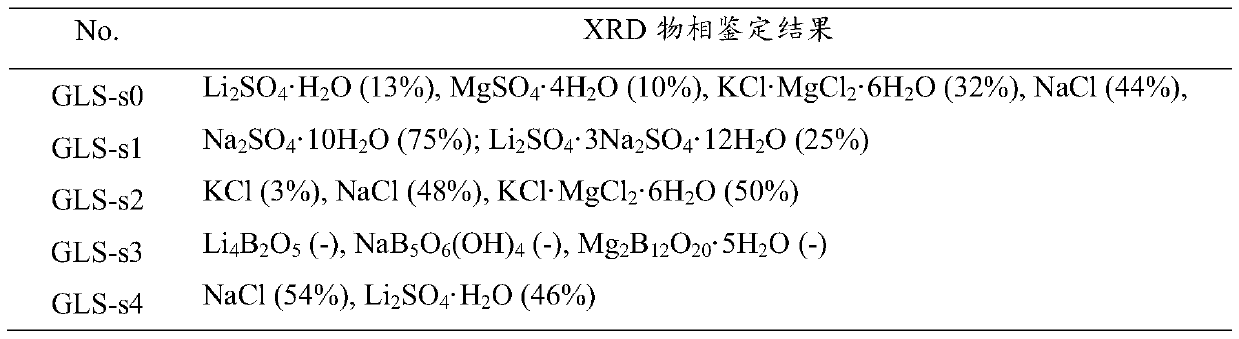

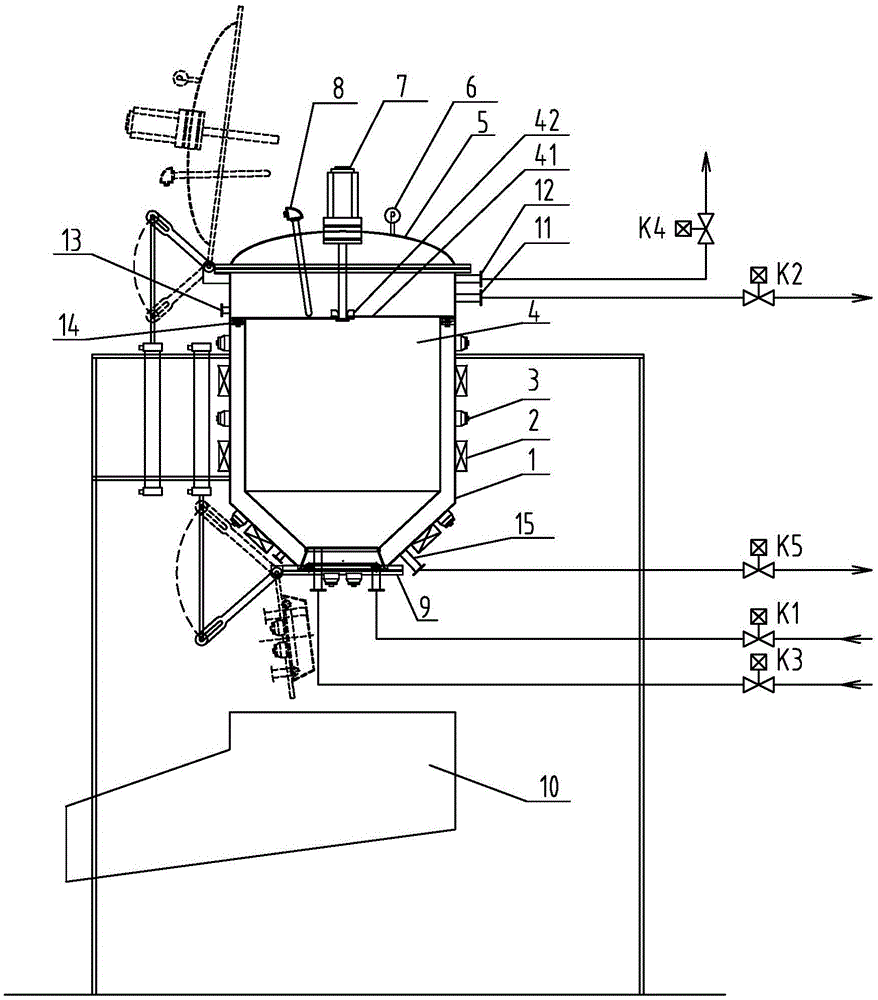

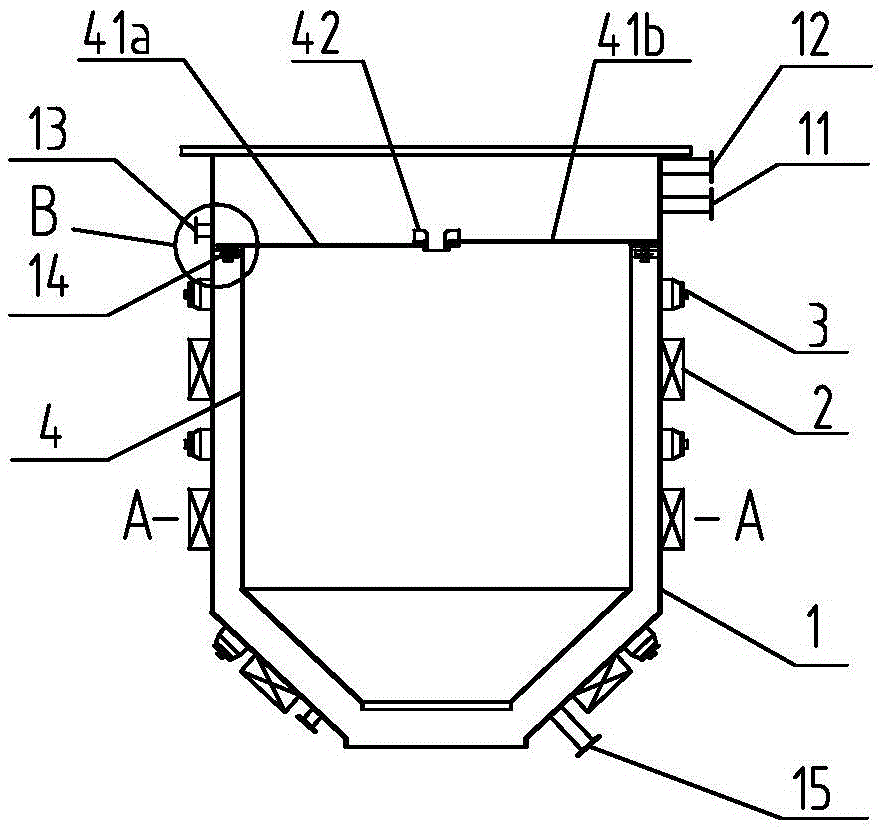

Method for purifying lithium sulfate crude ore

ActiveCN105502440AHigh yieldSimple process routeMagnesium chloridesAlkali metal chloridesLithium sulphateMirabilite

The invention provides a method for purifying lithium sulfate crude ore. The method comprises the following steps: step I, mixing the lithium sulfate crude ore S0 with excessive water to ensure that soluble ingredients in the lithium sulfate crude ore are just dissolved completely, and carrying out solid-liquid separation to obtain a solution L0; step II, freezing the solution L0 to separate out mirabilite, and carrying out solid-liquid separation to obtain a solution L1 and a solid S1; step III, evaporating the solution L1 to separate out a solid phase, and carrying out solid-liquid separation to obtain a solution L2 and a solid S2; step IV, allowing the solution L2 to stand still in a sealed condition for 7 to 50 days at 0 to 40 DEG C to separate out borate, and carrying out solid-liquid separation to obtain a solution L3; step V, mixing the solid S1 obtained in the freezing process in the step II with the solution L3, and evaporating the mixture at 0 to 40 DEG C to separate lithium sulfate concentrate.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

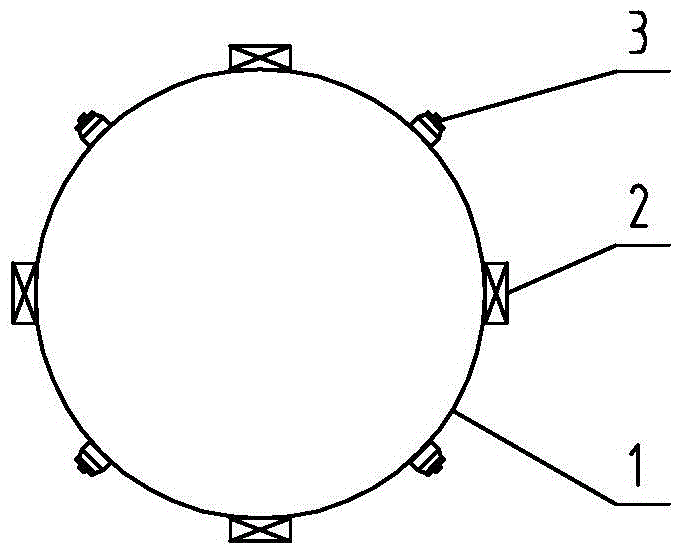

Microwave and ultrasonic wave assisted cocoon cooking device and method for cooking cocoons

ActiveCN105648542ASolve for uniformitySolve heatingSilk filament obtainingUltrasonic assistedCoupling

A microwave and ultrasonic wave assisted cocoon cooking device comprises a cocoon cooking barrel outer drum, a microwave generator, an ultrasonic wave generator, a cocoon cooking barrel inner drum, an upper cover of the cocoon cooking barrel outer drum, a lower cover of a cocoon cooking barrel discharge opening, and a cocoon cooking barrel; a plurality of microwave generators and ultrasonic wave generators are distributed on the outer side of the cocoon cooking barrel outer drum; the cocoon cooking barrel inner drum is made of punching hole meshes or mesh materials, and a cover of the cocoon cooking barrel inner drum consists of two semi-circular sector cover plates made of punching hole meshes or mesh materials and connected through a coupling at the circle center; the cover of the cocoon cooking barrel inner drum can be opened or closed in a rotational manner; a pressure gage and a temperature measurer are mounted on the upper cover of the cocoon cooking barrel outer drum; the lower cover of the cocoon cooking barrel discharge opening is connected with a hot water inlet pipe and is equipped with a porous steam coil and the ultrasonic wave generator; the filature cocoon cooking device has a compact and reasonable structure and is high in integration, and a cocoon cooking of the device adopts a microwave assisted direct-streaming technology and an ultrasonic wave assisted cocoon cooking technology at the same time, so that inner, middle and outer layers of cocoons are heated uniformly, the energy is saved, the consumption is reduced, and the cocoon cooking is shortened.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

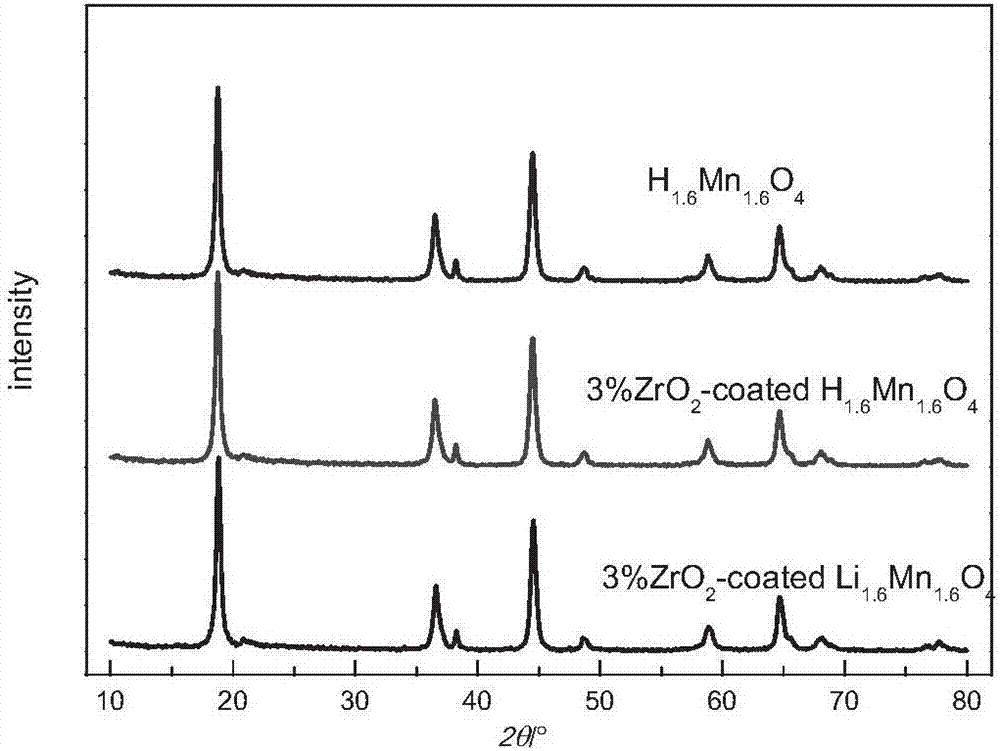

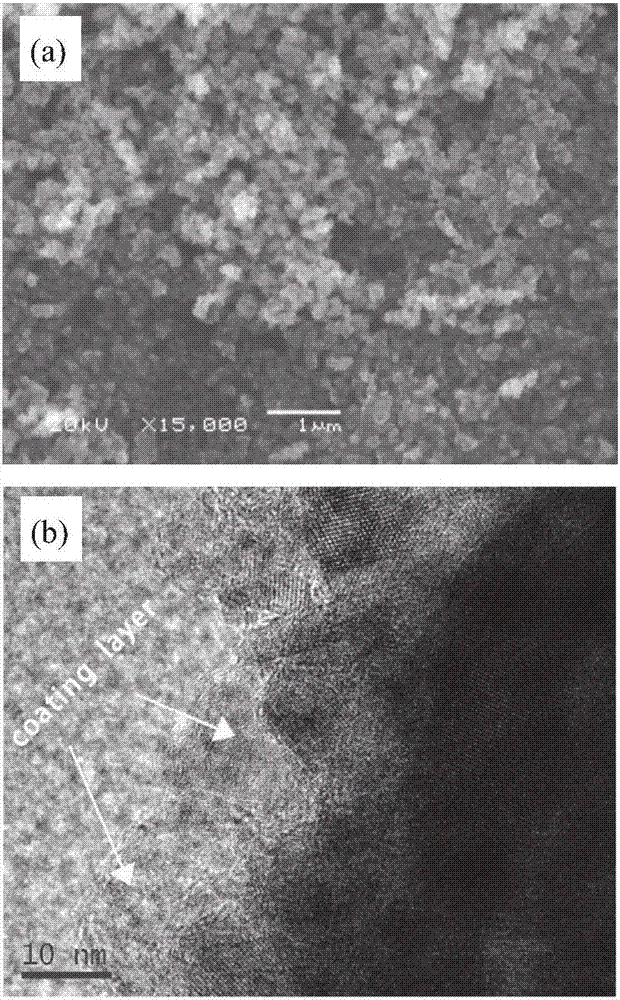

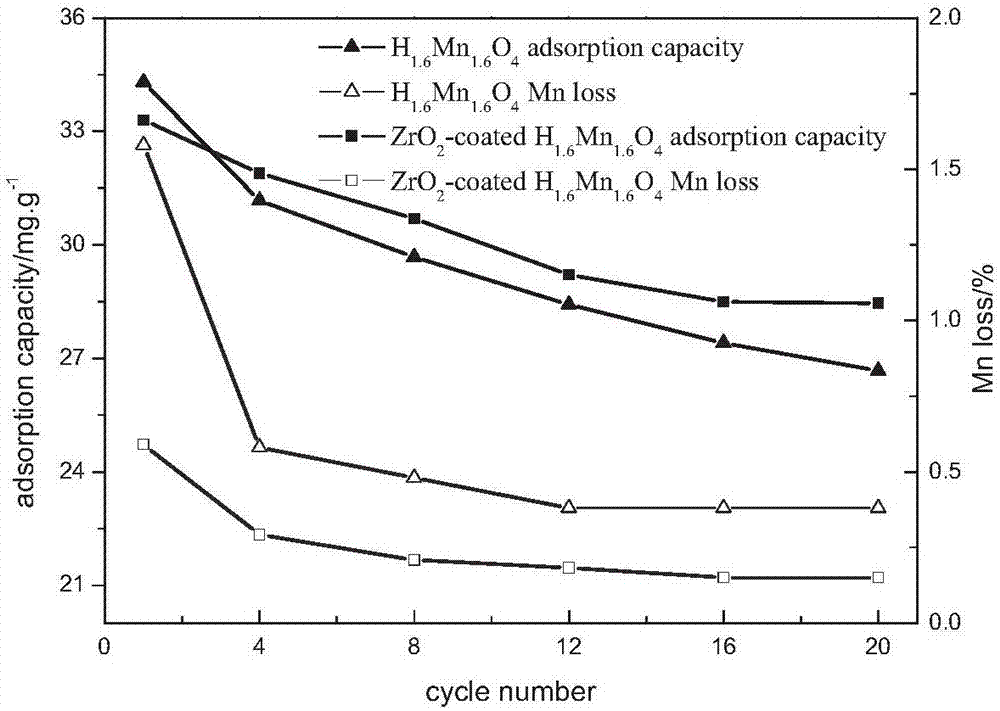

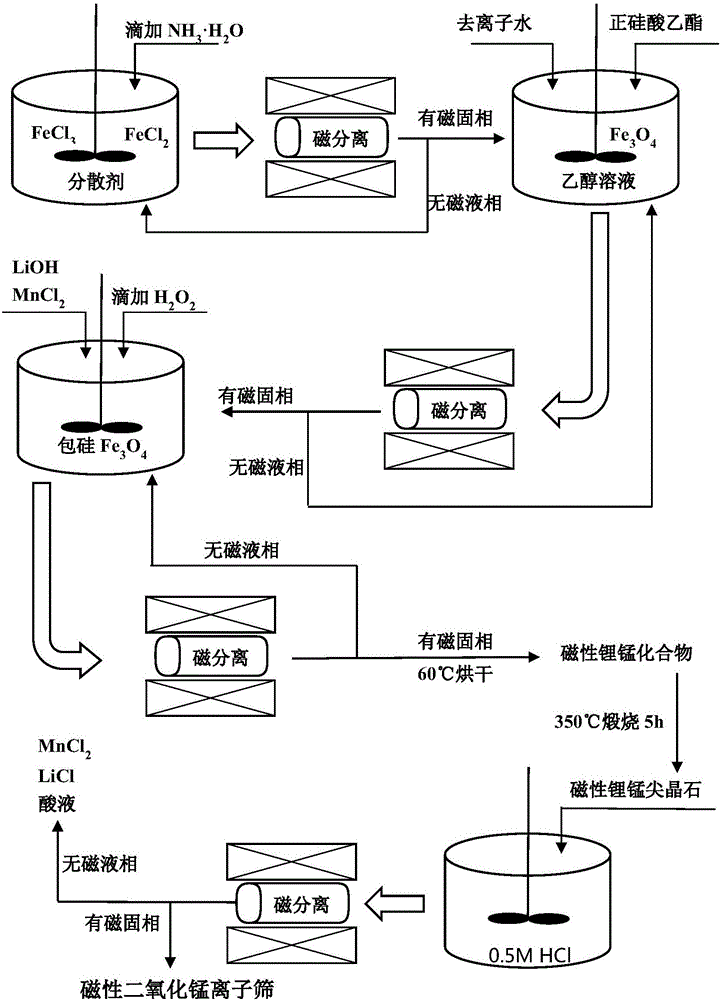

Zirconium dioxide-coated manganese lithium ion sieve as well as preparation method and application thereof

InactiveCN107376827AGuaranteed adsorption effectGood acid corrosion resistanceOther chemical processesWater/sewage treatment by sorptionSorbentManganese

The invention provides a zirconium dioxide-coated manganese lithium ion sieve which has a core-shell structure, wherein a core is made of H1.6Mn1.6O4, and a shell layer is made of ZrO2. In addition, the invention further discloses a preparation method which comprises the following steps: dispersing Li1.6Mn1.6O4 into solution containing a Zr source, removing a solvent and roasting, so as to obtain a ZrO2 lithium ion sieve precursor; removing Li from the ZrO2 lithium ion sieve precursor, then performing solid-liquid separation, washing and drying, so as to obtain the zirconium dioxide-coated manganese lithium ion sieve. According to the zirconium dioxide-coated manganese lithium ion sieve, the problems that a manganese lithium ion sieve is poor in acid corrosion resistance, large in manganese solution loss, unstable in structure and poor in cycling performance are solved. The obtained lithium ion sieve product is high in adsorption capacity of lithium ions, stable in structure and long in service life, so that the lithium ion sieve provided by the invention is an efficient lithium extraction adsorbent of salt lake brine or sea water. The zirconium dioxide-coated manganese lithium ion sieve is simple and clean in preparation processes, free of side reaction in a preparation process and good in product performance, thereby being suitable for industrial production.

Owner:CENT SOUTH UNIV

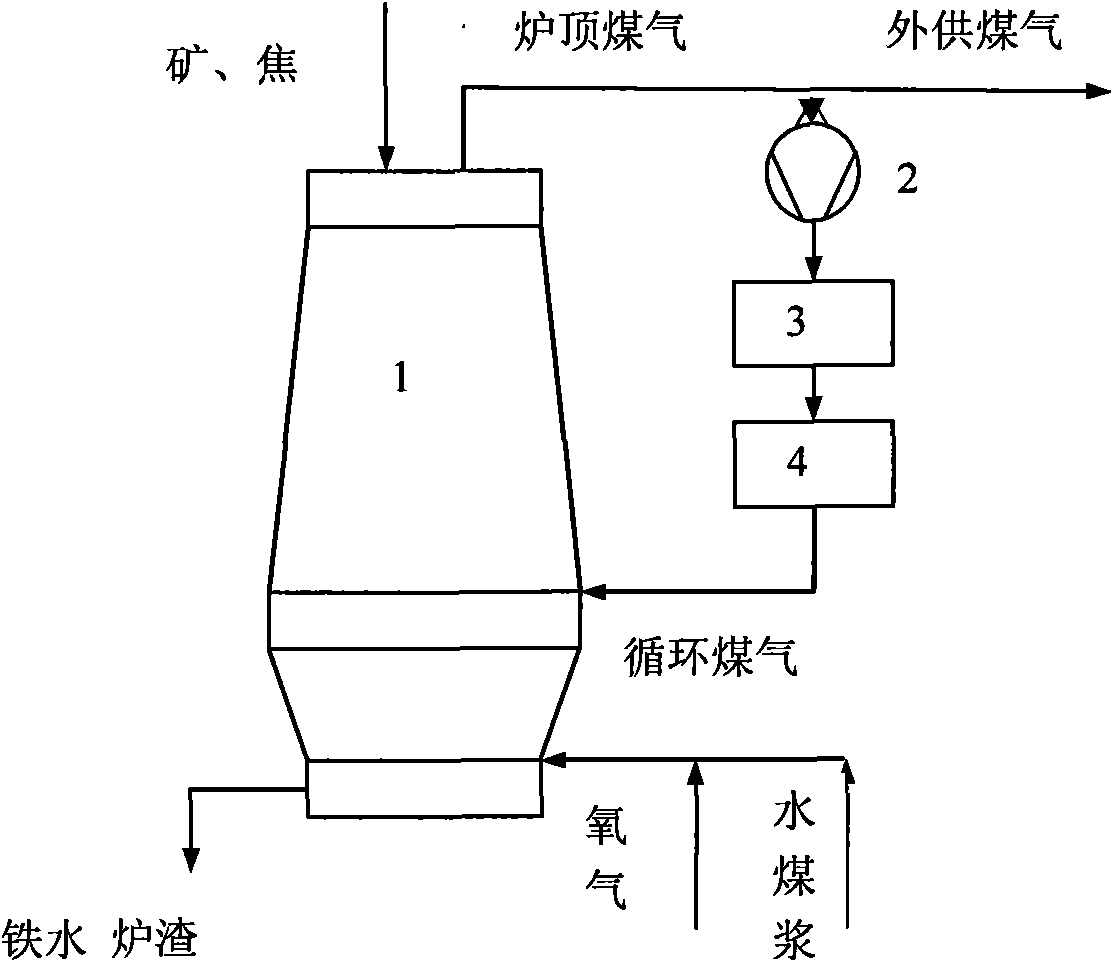

Oxygen blast furnace iron-making process adopting water-coal-slurry as fuel

InactiveCN101555533AImprove productivityReduce adverse effectsBlast furnace detailsDecompositionCoal dust

The invention belongs to the field of ferrous metallurgy and relates to a blast furnace iron-making process using water-coal-slurry as fuel and reducer for iron-making. The process using water-coal-slurry is simple and safe, and the injecting process of water-coal-slurry provides convenience for accurate control and precise measurement. A water-coal-slurry oxygen blast furnace utilizes normal-temperature oxygen and water-coal-slurry as fuel which is injected into the blast furnace so as to partially displace coke and coal dust; the injected amount of oxygen is 200 to 500 Nmt HM, the injected amount of water-coal-slurry is 200 to 400 Nm / t HM, the required weight ratio between coal and water in the water-coal-slurry is 7:3, and the required thermal value of the water-coal-slurry is larger than 20 MJ / kg. The water-coal-slurry is decomposed and burnt to generate water-gas reaction in a circulation zone of a blast-furnace tuyere, the absorbed heat can be adopted to solve the problem of 'lower hot' caused by smelting with prior oxygen blast furnaces, and a large amount of gas generated by the decomposition and burning of the water-coal-slurry raises and can relieve the problem of 'upper cold' caused by the full-oxygen injection of the blast furnace; and the water-coal-slurry oxygen blast furnace contains rich H2 so as to enhance the penetrating power and reduction performance of blast-furnace coal gas, raise the indirect reduction degree of the blast furnace and reduce the emission amount of CO2 by 200 to 500 Nm / t HM. The process reduces both manufacturing cost and pollution to environment.

Owner:UNIV OF SCI & TECH BEIJING

Perfect compound feed with low nitrogen and phosphorus emissions for feeding culter alburnus and preparation method of perfect compound

InactiveCN104381657ASufficient sourceScalable productionFood processingClimate change adaptationPhytaseVegetable oil

Owner:JIANGXI AGRICULTURAL UNIVERSITY

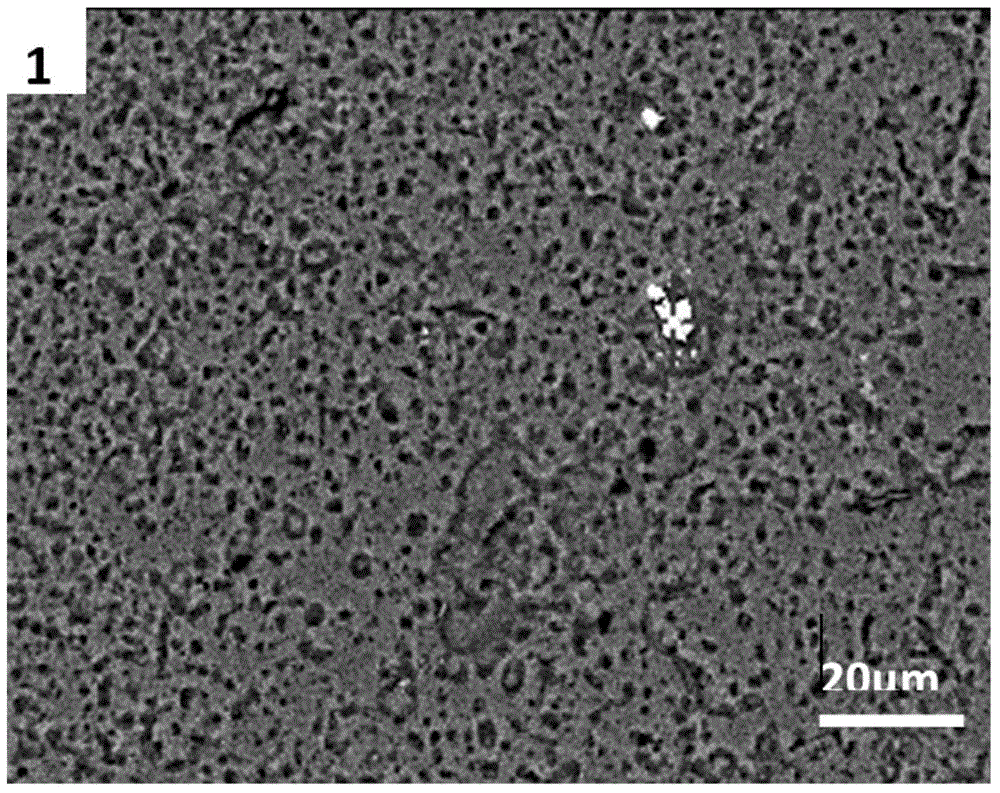

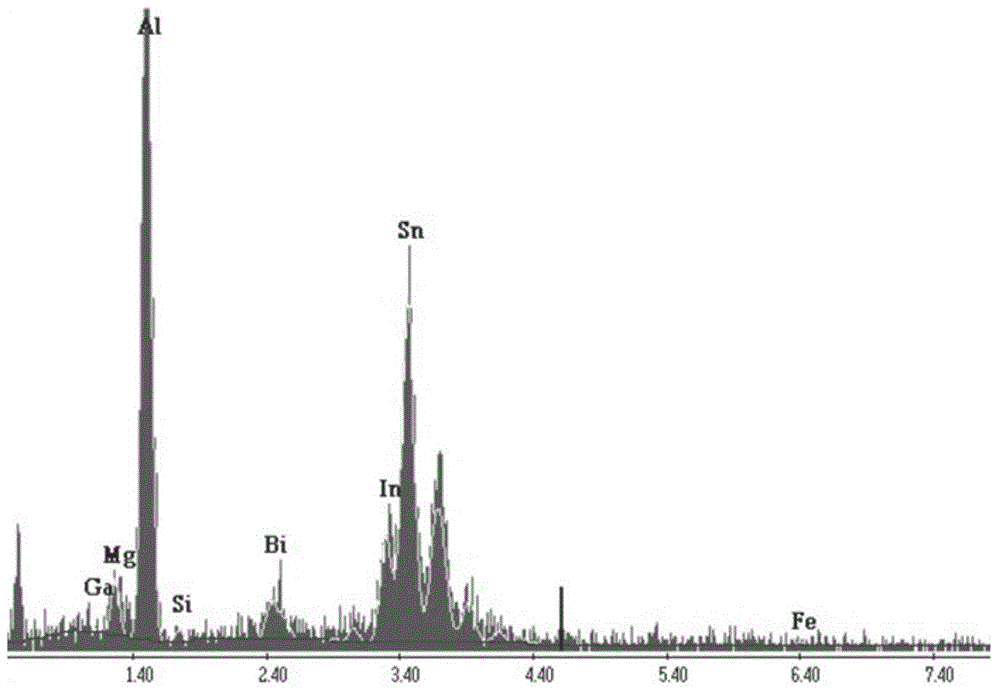

Rare-earth-modified aluminium alloy anode plate and preparation method thereof

ActiveCN104561673AReduce hydrogen evolution corrosion rateImprove solid solubilityHigh current densityCerium

The invention discloses a rare-earth-modified aluminium alloy anode plate and a preparation method thereof. The anode plate is prepared from raw materials such as an aluminium block, a magnesium block, a bismuth granule, a tin granule, a gallium granule, an indium granule, a lanthanum granule and a cerium granule in the mass ratio of (96.6-99.31):(0.5-2):(0.1-1):(0.05-0.2):(0.01-0.1):(0.01-0.05):(0.01-0.03):(0.01-0.02). Proper amounts of various alloy elements are weighed according to the formula during alloy casting and molten in a resistance furnace crucible at the temperature of 750-800 DEG C, and then alloy melt is poured into a water-cooling steel mold for use. The solid solution temperature in alloy solid solution heat treatment is in a range of 500-560 DEG C, and the solid solution time is in a range of 5-8 h. The single-pass rolling temperature in an alloy rolling machining technology is in a range of 400-450 DEG C, and the single-pass deformation is in a range of 35-45%. The rare-earth-modified aluminium alloy anode plate is low in self-corrosion speed and high in electrochemical activity during high-current-density discharging and meets performance requirements of high current efficiency, stable discharging and small hydrogen evolution amount during movement of an alkaline aluminum battery.

Owner:西安聚束智能技术有限公司

Method for refrigerating filature with no need of boiling cocoons

InactiveCN1446951AModerately absorbentReduce adhesive forceMechanical treatmentEngineeringThermal water

A cold storage method without boiling for reeling silk includes cold storage of fresh cocoon, loading in netted basket, putting in vacuum tank, vacuumizing, hot water osmosis, discharging water and repeating relative steps. Its advantages are high efficiency and high quality.

Owner:SICHUAN UNIV TIANYOU BIOLOGIC ENG

Compound feed of Rana catesbeiana and preparation method thereof

ActiveCN103875992AEasy feedingReduce dissolution lossFood processingClimate change adaptationBiotechnologyWeight gaining

The invention discloses a compound feed of Rana catesbeiana and a preparation method of the compound feed. The compound feed comprises the following components in percentage by weight: 20%-35% of red fish meal, 3%-10 % of extruded soybeans, 20%-30% of soybean meal, 5%-10% of peanut meal, 1%-5% of beer yeast, 3%-10% of meat and bone meal, 3%-5% of rice protein powder, 19%-26% of high gluten flour, 1%-2% of sodium dihydrogen phosphate, 0.5%-2% of soybean oil, 0.5%-2% of deep sea fish oil, 0.3%-0.6% of choline chloride, 0.05%-0.3% of lysine, 0.02%-0.1% of methionine, 0.2%-0.5% of multi-vitamin and 0.5%-1% of composite mineral salt. The compound feed of Rana catesbeiana is low in price; when the compound feed is used for feeding of Rana catesbeiana, the survival rate, the weight gain rate and the feed efficiency are improved; furthermore, the ingestion of Rana catesbeiana is good, and the solution loss of the feed in water can be reduced; the feed utilization rate of Rana catesbeiana is high, and the waste of feed resources can be reduced; after the compound feed is used, Rana catesbeiana has the characteristics of rapid growth, good body sizes and less morbidity.

Owner:JIMEI UNIV

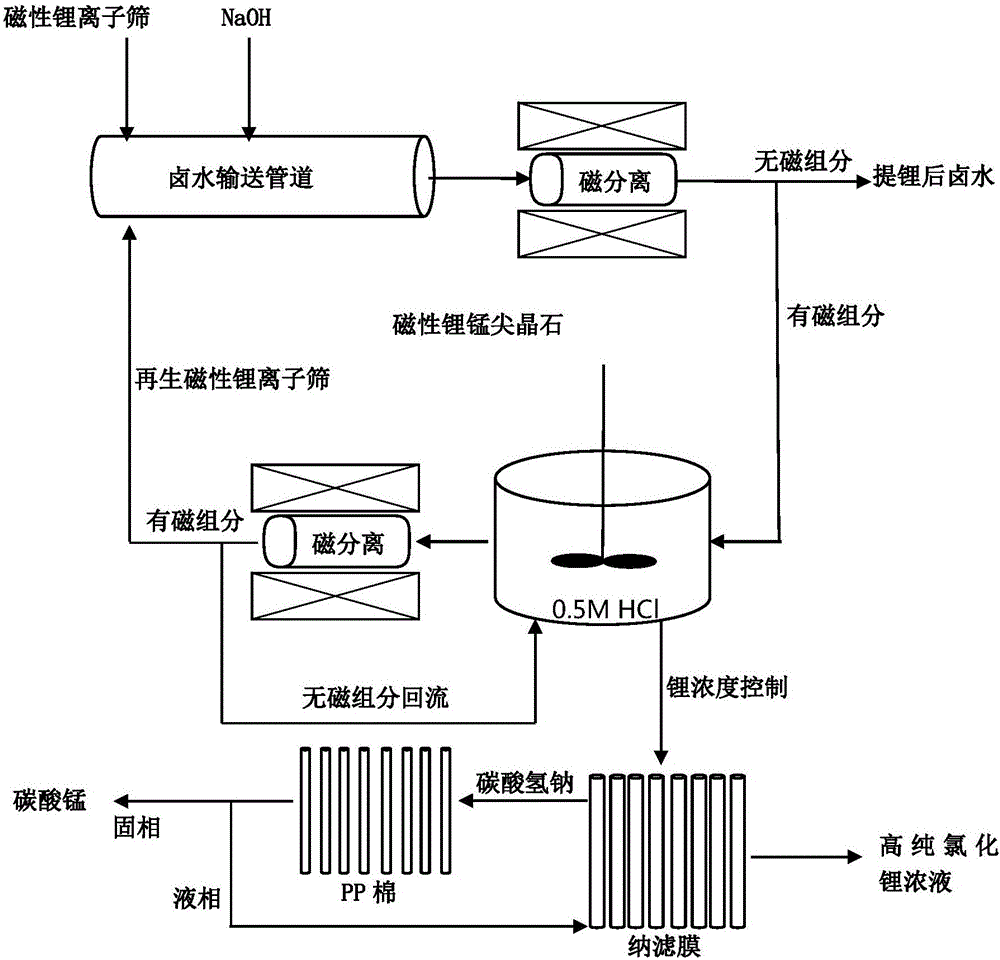

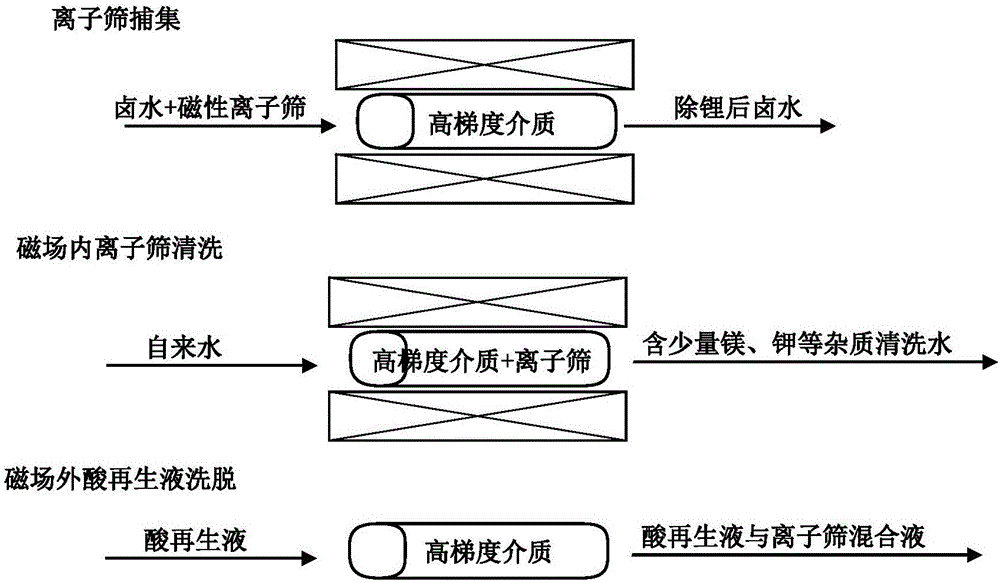

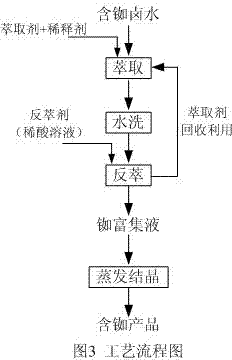

Method for extracting lithium from bittern and preparing high-purity lithium concentrate

ActiveCN106345394AEfficient separationEasy to separateOther chemical processesIron compoundsSodium bicarbonateDesorption

The invention discloses a method for extracting lithium from bittern and preparing a high-purity lithium concentrate. The method is characterized by comprising the following steps: adding a 0.5-20kg / t magnetic lithium ion sieve into a bittern conveying pipeline, and adjusting the pH value to be higher than or equal to 5.0; separating the magnetic lithium ion sieve from the bittern by a magnetic separation system; feeding the magnetic lithium ion sieve into a desorption activation link; performing magnetic separation of the ion sieve and the desorption liquid again; feeding the magnetic lithium ion sieve into the raw bittern, and extracting lithium again; circulating the desorption liquid repeatedly until the lithium concentration is higher than or equal to 3g / l, and enabling the desorption liquid to pass through a nanofiltration membrane, wherein the filtered part of the nanofiltration membrane is the high-purity concentrate with purity of higher than or equal to 99%, and a lithium carbonate product is directly prepared; repeatedly circulating the intercepted part of the nanofiltration membrane by a nanofiltration link until the manganese-lithium ratio is greater than 2:1; adding sodium bicarbonate to prepare a manganese carbonate product; separating with PP cotton; and returning the lithium liquid to feed water to the nanofiltration membrane. In the invention, high-purity lithium concentrate can be prepared by use of the magnetic lithium ion sieve and by combining the magnetic separation and membrane separation technology; and in the process, the lithium concentration links such as solarization and reverse osmosis are not needed.

Owner:衢州永正锂业科技有限公司

Cocoon cooking method for preparing high-quality grade-6A raw silk

InactiveCN102517644ASolve bottlenecksUniform penetrationAnimal materialSilk filament obtainingMolecular clusterCooking methods

The invention discloses a cocoon cooking method for preparing high-quality grade-6A raw silk, which comprises the following steps: firstly carrying out vacuum infiltration on a silkworm cocoon by utilizing alkaline ionized water with a pH value of 7.5-8.5, then impregnating the silkworm cocoon subjected to the vacuum infiltration by utilizing acidic ionized water with a pH value of 4.5-6.5, cooking the impregnated silkworm cocoon in a machine and adding a certain amount of acidic ionized water at the low-temperature infiltration part. Compared with the background art, the cocoon cooking method has the advantages that a water molecular cluster of the alkaline ionized water is small, the surface tension is small, the infiltration is strong, the water is easy to enter an adhesive part of silk glue, so that the infiltration on a cocoon shell is uniform to be beneficial to improving the clean index of the raw silk; and as the silkworm cocoon subjected to the vacuum infiltration is impregnated by utilizing the acidic ionized water, the surface of the silkworm cocoon subjected to the vacuum infiltration is converted from alkalescence to neutrality or weak acidity so as to be beneficial to reducing the silk glue melting loss on the outer layer of the silkworm cocoon, thereby the cohesion indicator of the raw silk is improved. The cocoon cooking method has the advantages of simplicity, environment friendliness and no pollution.

Owner:ZHEJIANG JIAXIN JINSANTA SILK KNITTING +1

Method for recycling metallic lithium from waste lithium ion batteries

ActiveCN108504868AAvoid environmental pollutionReduce dissolution lossMetallic lithiumTributyl phosphate

The invention provides a method for recycling metallic lithium from waste lithium ion batteries. According to the method, an extraction system is formed by ionic liquid and tributyl phosphate, and selective extraction is conducted on aqueous phase leachate containing nickel ions, cobalt ions, manganese ions and lithium ions, so that the recovery rate of the metallic lithium is effectively increased. The volume ratio of the ionic liquid to the tributyl phosphate is not greater than 1: 1; and the pH value of the aqueous phase leachate containing the lithium ions is not greater than 7. The methodis easy to operate and efficient; after reverse extraction, the extraction system can be utilized cyclically; compared with a traditional wet method recycling process, the defects that plenty of acid-base solutions are consumed, and a great amount of waste water is generated are effectively avoided; and the good application prospect is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

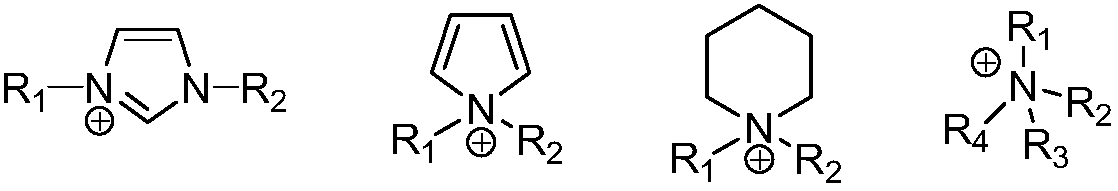

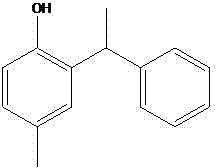

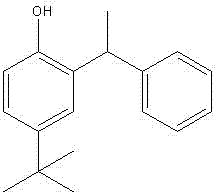

Novel rubidium-potassium separating extracting agent and separating method

InactiveCN103882227AMild extraction conditionsFast phase separationOrganic chemistryOrganic compound preparationPhysical chemistrySolvent

The invention relates to a novel rubidium-potassium separating extracting agent 4-methyl-2-(alpha-methylbenzyl) phenol and a rubidium-potassium separating method. 4-methyl-2-(alpha-methylbenzyl) phenol is taken as the extracting agent, and solvent oil such as D60, and the like, is taken as a diluent for extracting and separating rubidium in alkalescent high-potassium brine, wherein single-stage extraction rate of the rubidium can be over 85%, a rubidium-potassium separating coefficient can be over 30; enriched liquor obtained by reversely extracting an organic phase loaded with rubidium through acid liquor can be evaporated and concentrated to prepare rubidium salt products such as RuCl, RuNO3, and the like. Compared with the normal rubidium extracting agent 4-tertiary butyl-2-(alpha-methylbenzyl) phenol, the novel extracting agent 4-methyl-2-(alpha-methylbenzyl) phenol has the advantages of being high in separating efficiency, simple in synthetic method, low in price, mild in extracting condition, and the like. The extracting agent is applicable to underground brine, salt lake brine and solid ore-decomposed rubidium-containing liquor.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

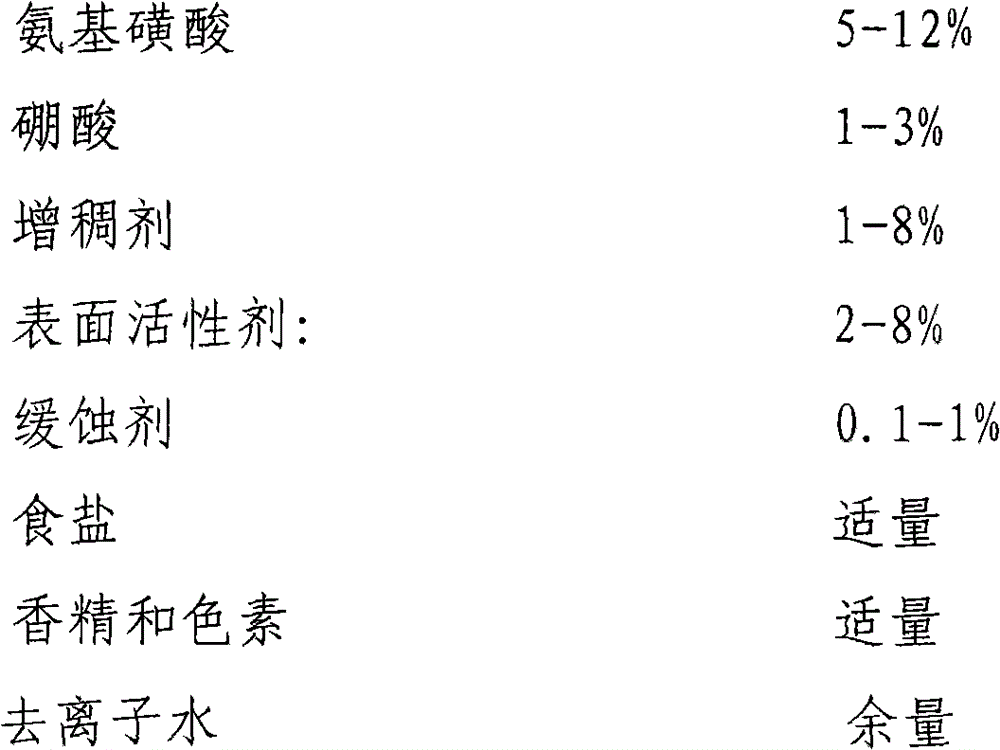

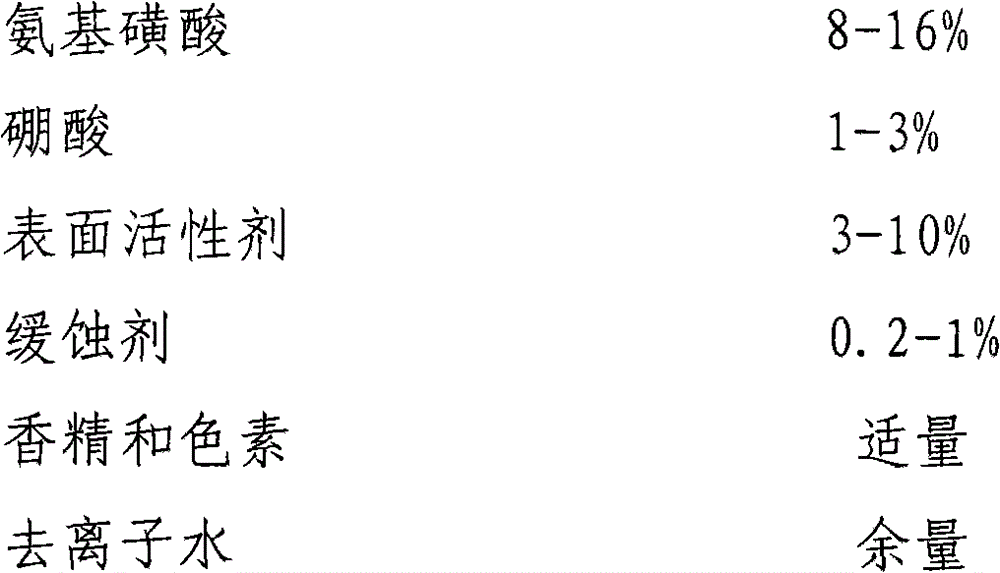

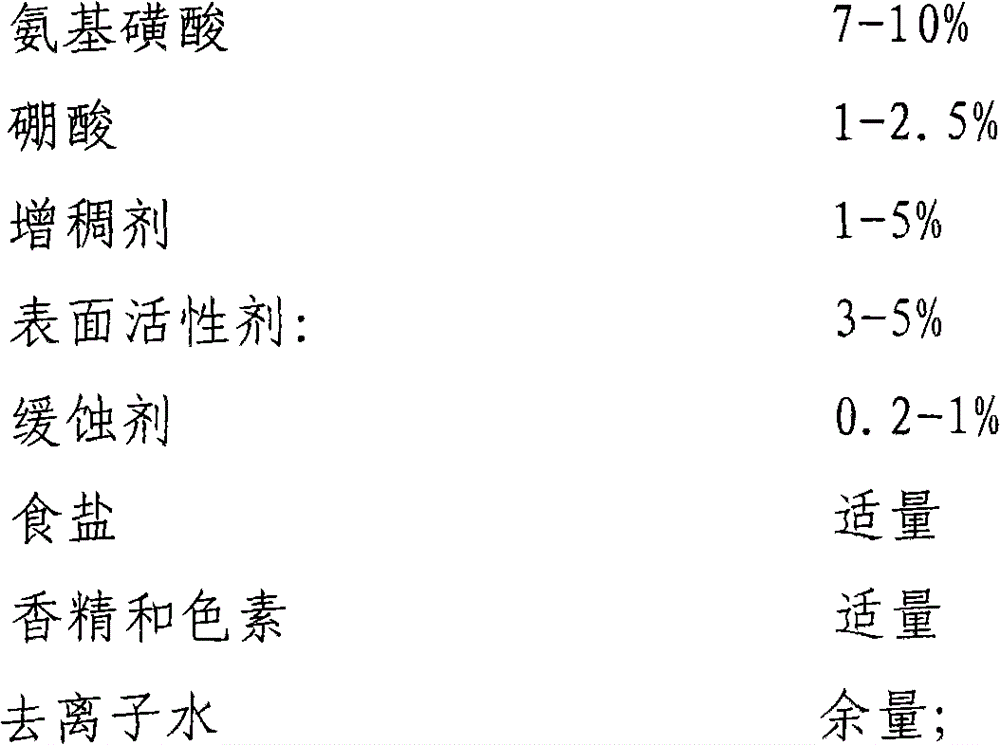

Matched cleaning agent for vacuum drainage pipelines of airplane toilets and preparation method and cleaning process of matched cleaning agent

ActiveCN102746958AHigh viscosityGood wall hangingHollow article cleaningSurface-active non-soap compounds and soap mixture detergentsJet aeroplaneVertical plane

The invention relates to the field of aerospace, in particular to a matched cleaning agent for vacuum drainage pipelines of airplane toilets. The cleaning agent comprises a cleaning agent I and a cleaning agent II which are matched and synergistic for graded cleaning. The cleaning agent I which is an acidic thixotropic cleaning agent and good in wall cling performance is used for cleaning firstly, is capable of effectively removing scale on inclined planes or vertical planes of a pipeline system and can be used for pipe leakage detection; and then the cleaning agent II which is low in viscosity, good in liquidity and high in scaling capability is used for cleaning. The invention further discloses a preparation method of the matched cleaning agent and a cleaning process using the matched cleaning agent. The matched cleaning agent is capable of effectively removing iron rust, water scale, urine scale and other dirt of the vacuum and circulating toilets and plays a protecting role in metal pipelines without corroding the pipelines.

Owner:北京雅迪力特航空新材料股份公司

Compound premix for aquatic products and preparation method of compound premix

The invention relates to a compound premix for aquatic products. The compound premix is prepared from the following raw materials based on the percentage by mass of air dried substances: 10%-15% of a seaweed organism active extract, 5%-10% of a composite acidifier, 5%-10% of compound probiotics powder and the balance of a carrier. The invention also provides a preparation method. The method comprises the following steps: (1) carrying out superfine grinding on raw materials of the seaweed organism active extract, carrying out ultrasonic-microwave synergistic extraction, filtering, wherein filtrate is taken as an extract liquid, carrying out enzymolysis and fermentation on filter residues, so as to obtain a fermentation liquid, respectively carrying out freeze drying on the extract liquid and the fermentation liquid, and then mixing at the ratio; and (2) carrying out superfine grinding on the carrier, and then evenly mixing the ground carrier with the composite acidifier, the compound probiotics powder and the seaweed organism active extract. According to the premix disclosed by the invention, marine algae resources can be effectively utilized; protease can be secreted; digestive absorption of protein is facilitated; the anti-stress ability and the disease resistance of organisms are enhanced; and the growth speed of aquatic livestock is improved, so that the culture cost is reduced and the culture benefits are significantly improved.

Owner:GUANGDONG HAID GROUP

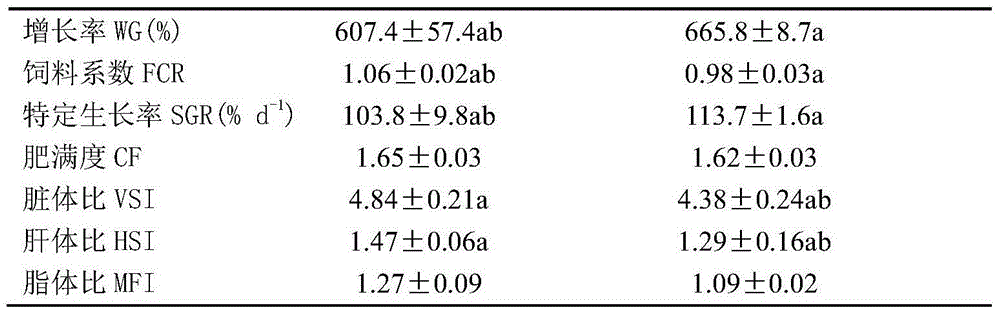

Preparation method of three-dimensional ordered large-hole manganese oxygen 'lithium ionic sieve'

InactiveCN101062473AImprove adsorption capacityImproved internal and external areasOther chemical processesLithium compoundsAdhesivePolystyrene

The invention relates to the making of 3DOM. It is made through synthesizing polymethyl methacryate or polystyrene pattern lumber, using Li and Mn front drive solution to stuff glue crystalline, through two sections of constant temperature baking to get 3DOM, using acid or peroxy-disulfate to perform acid etch. The result is that the product is the low density material in small blocks, unnecessary to add adhesive with high adhesive feature, using ammonium peroxy-disulfate to remove Li, reduced in Mn ion damage, improved adhesive feature, showing three dimensional porous frame structure, significantly improved in drive power inside the screen and the outside surface of the micro hole adhesive, being a dual hole channel with both macro and micro holes.

Owner:XIANGTAN UNIV

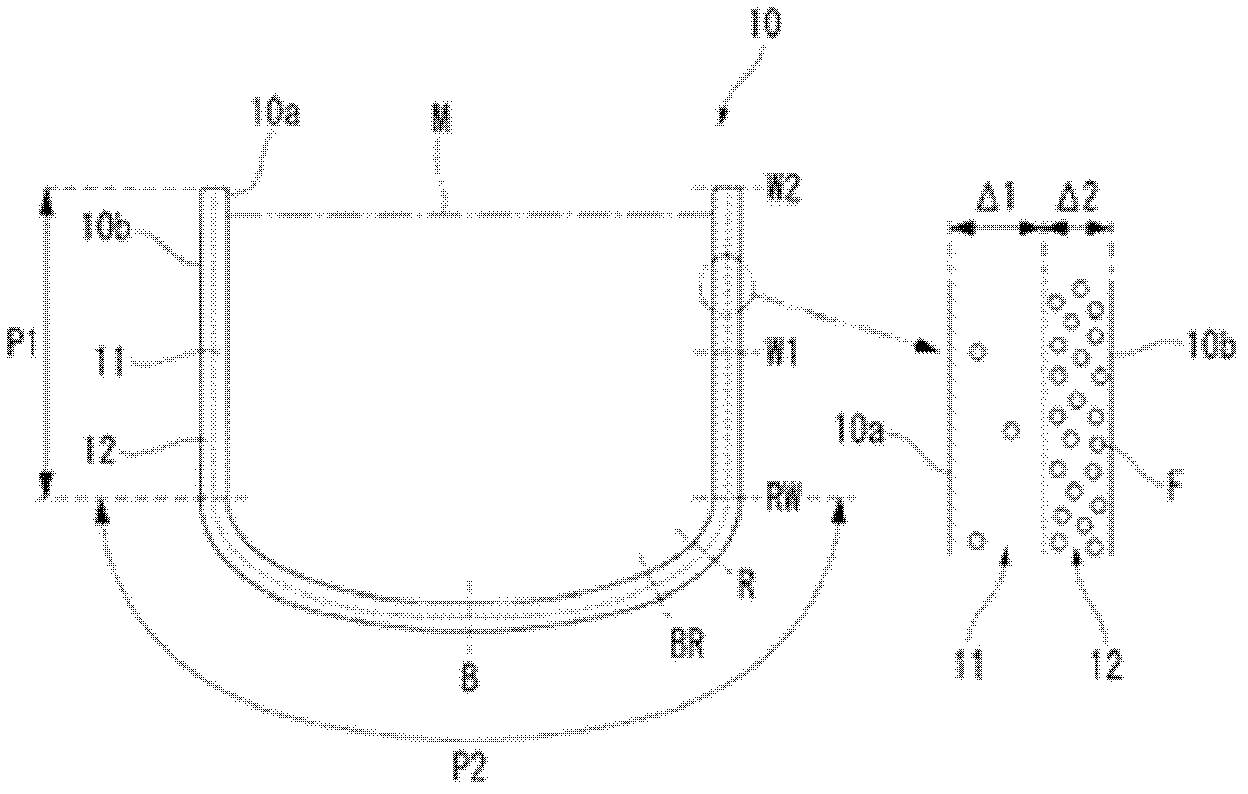

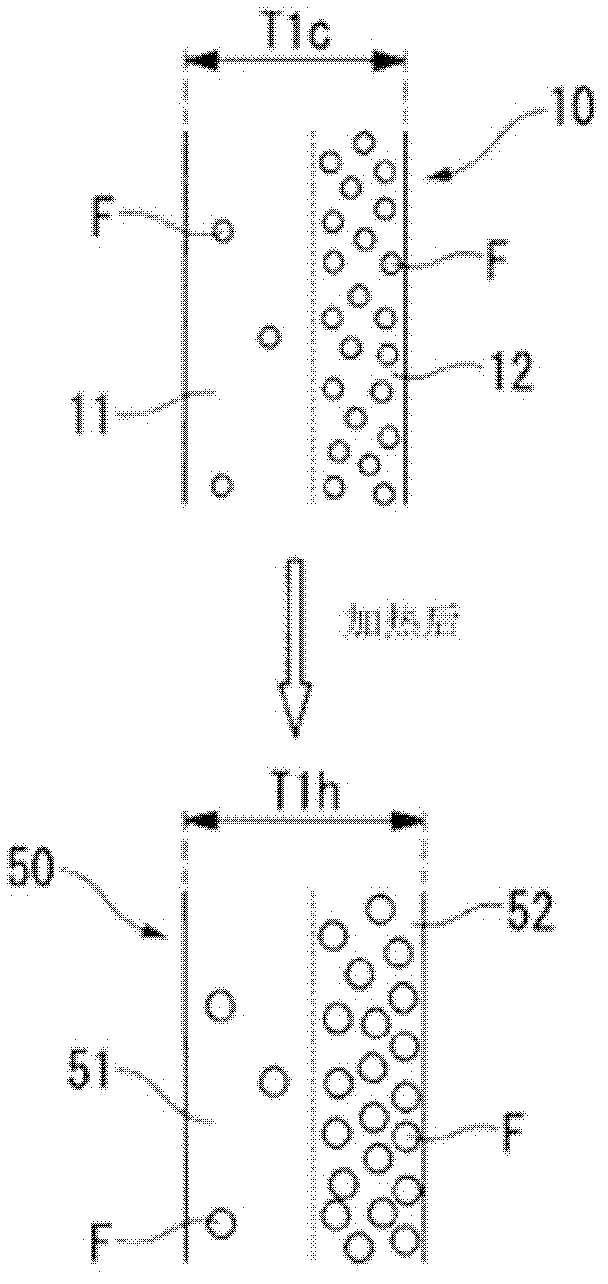

Vitreous silica crucible

ActiveCN102485971ALittle change in thicknessAvoid thermal expansionPolycrystalline material growthBy pulling from meltCrucibleCorrosion

Provided is a vitreous silica crucible which is resistant to deformation and corrosion even when heated at high temperature for a long time. There is provided a vitreous silica crucible of the present invention including a substantially cylindrical straight body portion, a curved bottom portion, and a corner portion smoothly connecting the straight body portion and the bottom portion, wherein a wall of the vitreous silica crucible includes, from an inner surface side, a transparent layer and a bubble-containing layer, and a ratio of a thickness of the bubble-containing layer with respect to a thickness of the transparent layer at an intermediate position between an upper end and a lower end of the straight body portion is 0.7 to 1.4.

Owner:SUMCO CORP

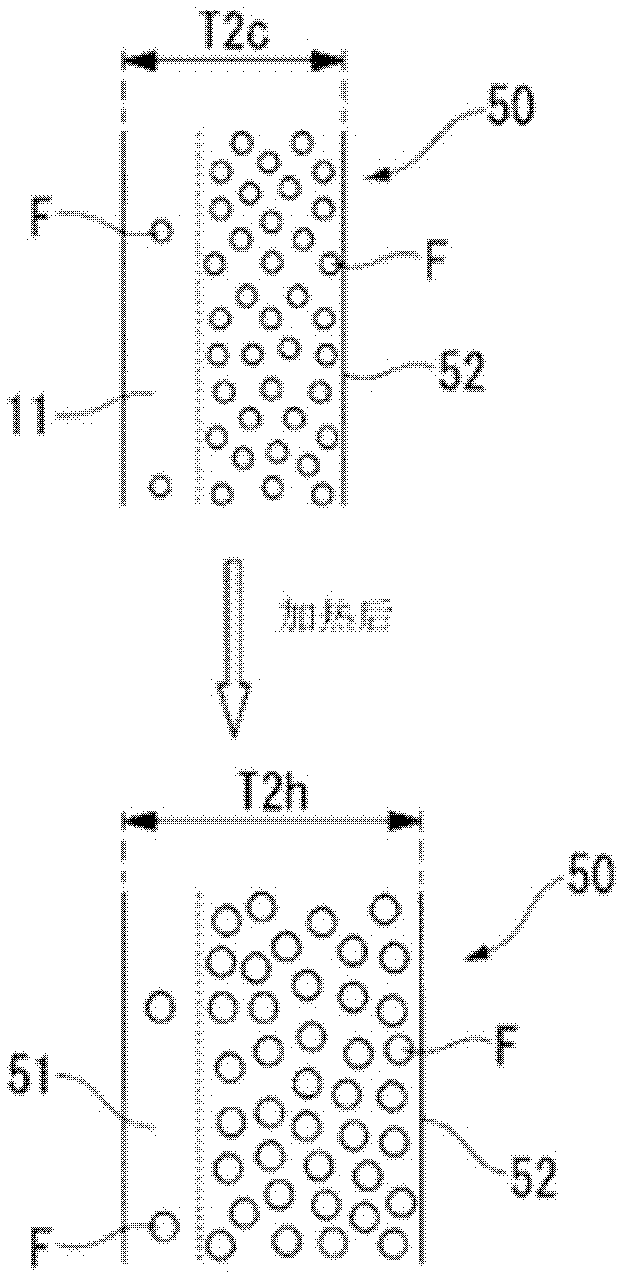

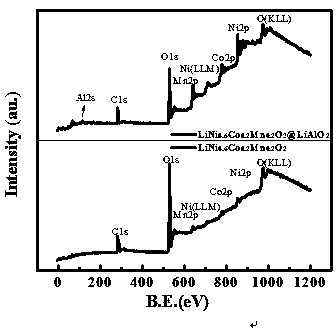

Preparation method and application of solid-state electrolyte-coated modified lithium ion battery positive electrode material

ActiveCN107681147AGood stabilityLong cycle lifeSecondary cellsPositive electrodesCyclic stabilityPolytetrafluoroethylene

The invention discloses a preparation method and application of a solid-state electrolyte-coated modified lithium ion battery positive electrode material, and belongs to the field of a lithium ion battery electrode material. The preparation method comprises the steps of (1) dispersing an aluminum source and a lithium source in an organic solvent under a certain condition, and dropwise adding an appropriate amount of stabilizer to obtain lithium aluminate sol; (2) adding an appropriate amount of the positive electrode material into the sol, transferring the mixture to a lining of a polytetrafluoroethylene reaction kettle, and obtaining a solid-state electrolyte-coated modified positive electrode material precursor by directly employing a solvothermal method; and (3) performing calcination on the prepared solid-state electrolyte-coated modified positive electrode material precursor to obtain an ultrathin solid-state electrolyte-coated modified lithium ion battery positive electrode material which is compact and uniform and is high in stability. The solid-state electrolyte-coated modified lithium ion battery positive electrode material has favorable cycle stability, excellent rate performance and reliable safety, and the preparation method has the characteristics of low cost, environmental friendliness and the like, is simple to operate and can be used for industrial production ona large scale.

Owner:TIANJIN NORMAL UNIVERSITY

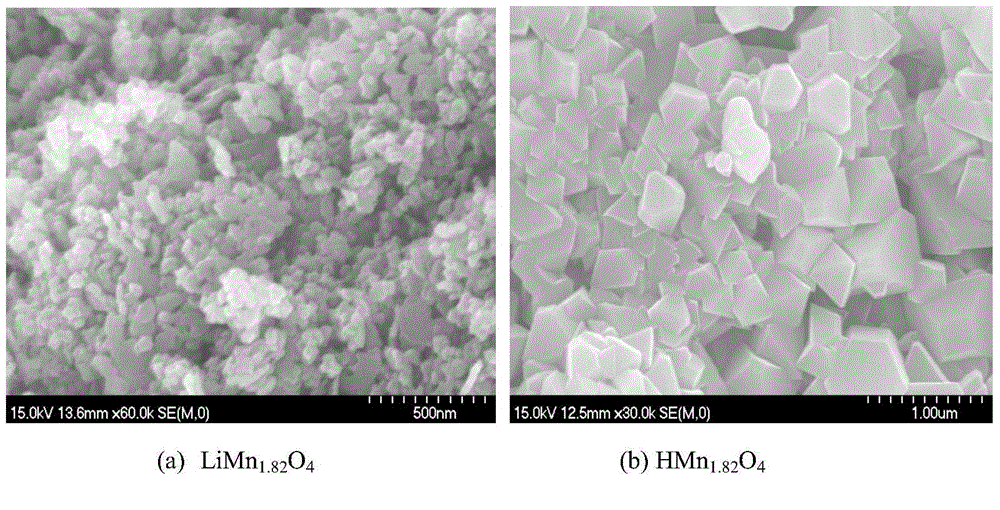

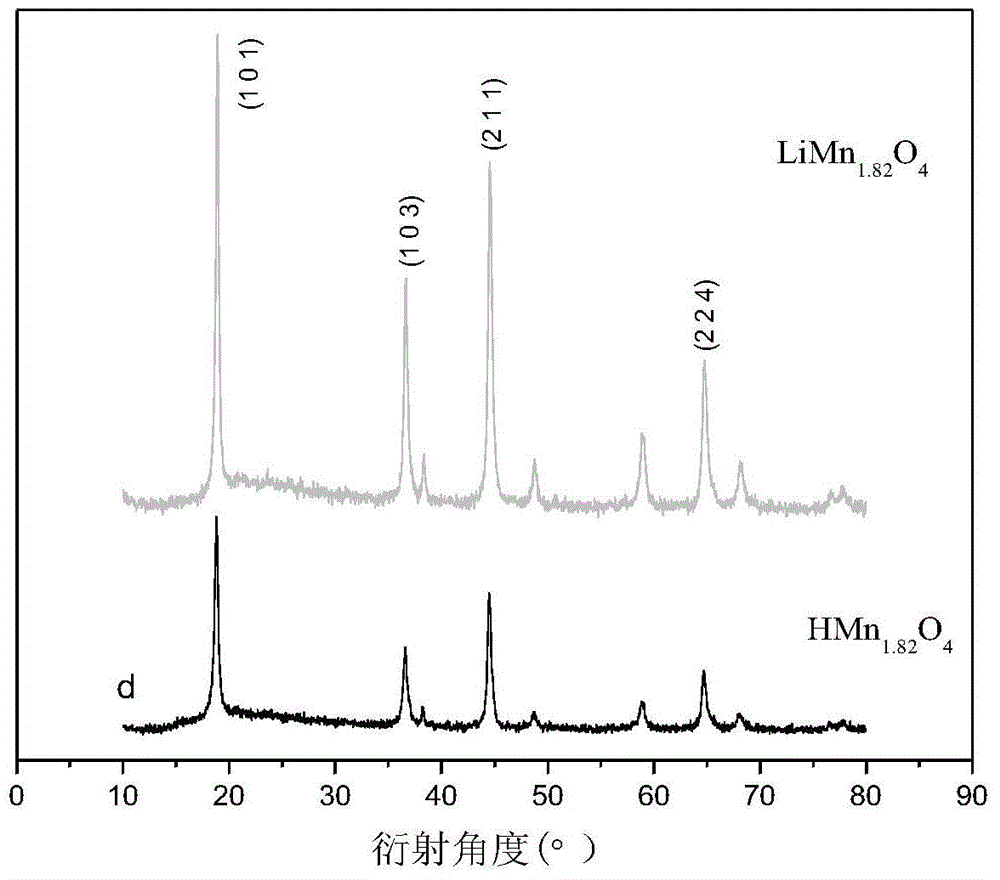

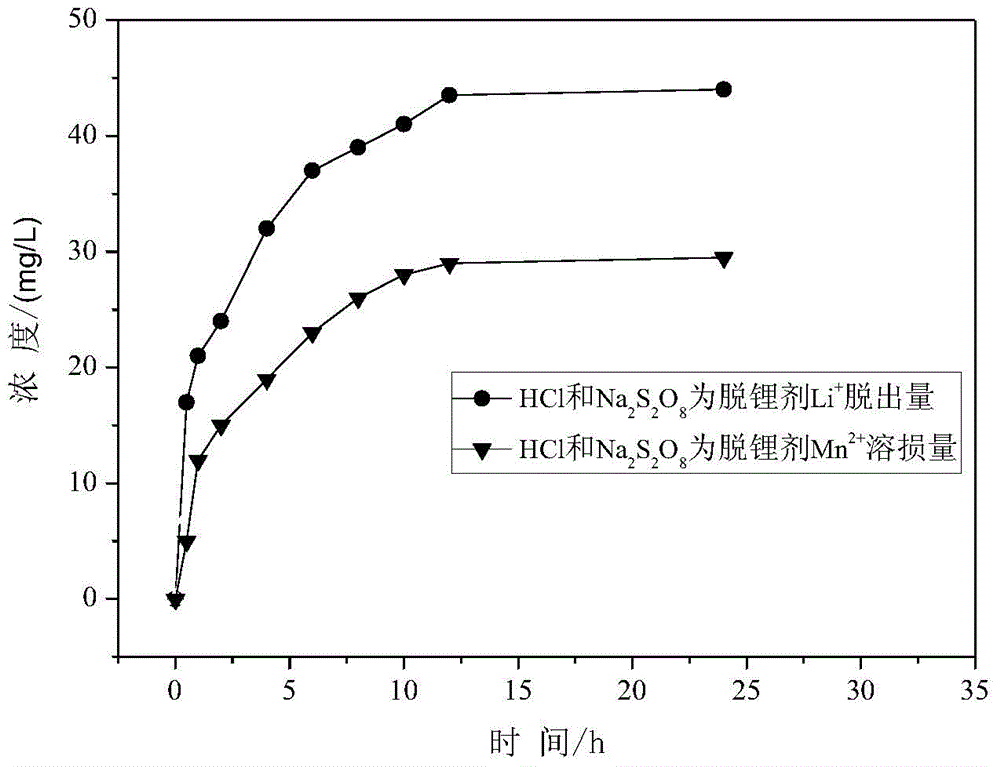

Method for preparing manganese-based lithium-ion sieve adsorbent

InactiveCN104941569ARaw materials are easy to getLow costOther chemical processesAlkali metal oxides/hydroxidesPersulfateSorbent

The invention discloses a method for preparing a manganese-based lithium-ion sieve adsorbent. The method comprises the following steps: adopting lithium hydroxide and divalent manganese salt as raw materials, dissolving the raw materials in an ethanol solution with volume fraction being 2-10%, stirring uniformly, adding H2O2 and lithium hydroxide, synthesizing an intermediate through the low-temperature hydrothermal method, obtaining lithium-ion sieve precursor through low-temperature roasting, and performing solvent dipping on the precursor to elute lithium ions so as to obtain the corresponding lithium-ion sieve adsorbent. According to the invention, the lithium-ion sieve precursor is ordered in structure and uniform in particle; hydrochloric acid and persulfate are adopted as a dipping agent of the precursor, so that the elution effect to lithium ions is good, and the manganese dissolution loss rate is greatly reduced. The whole preparation process is mild in condition and easy to control; the obtained ion sieve is high in purity and adsorbing capacity and excellent in stability, and has excellent application prospects.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com