Preparation method of three-dimensional ordered large-hole manganese oxygen 'lithium ionic sieve'

A three-dimensional ordered lithium-ion technology, applied in chemical instruments and methods, manganese compounds, lithium compounds, etc., can solve the problems of low adsorption capacity and poor lithium extraction effect, achieve high adsorption capacity, improve internal and external areas, The effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

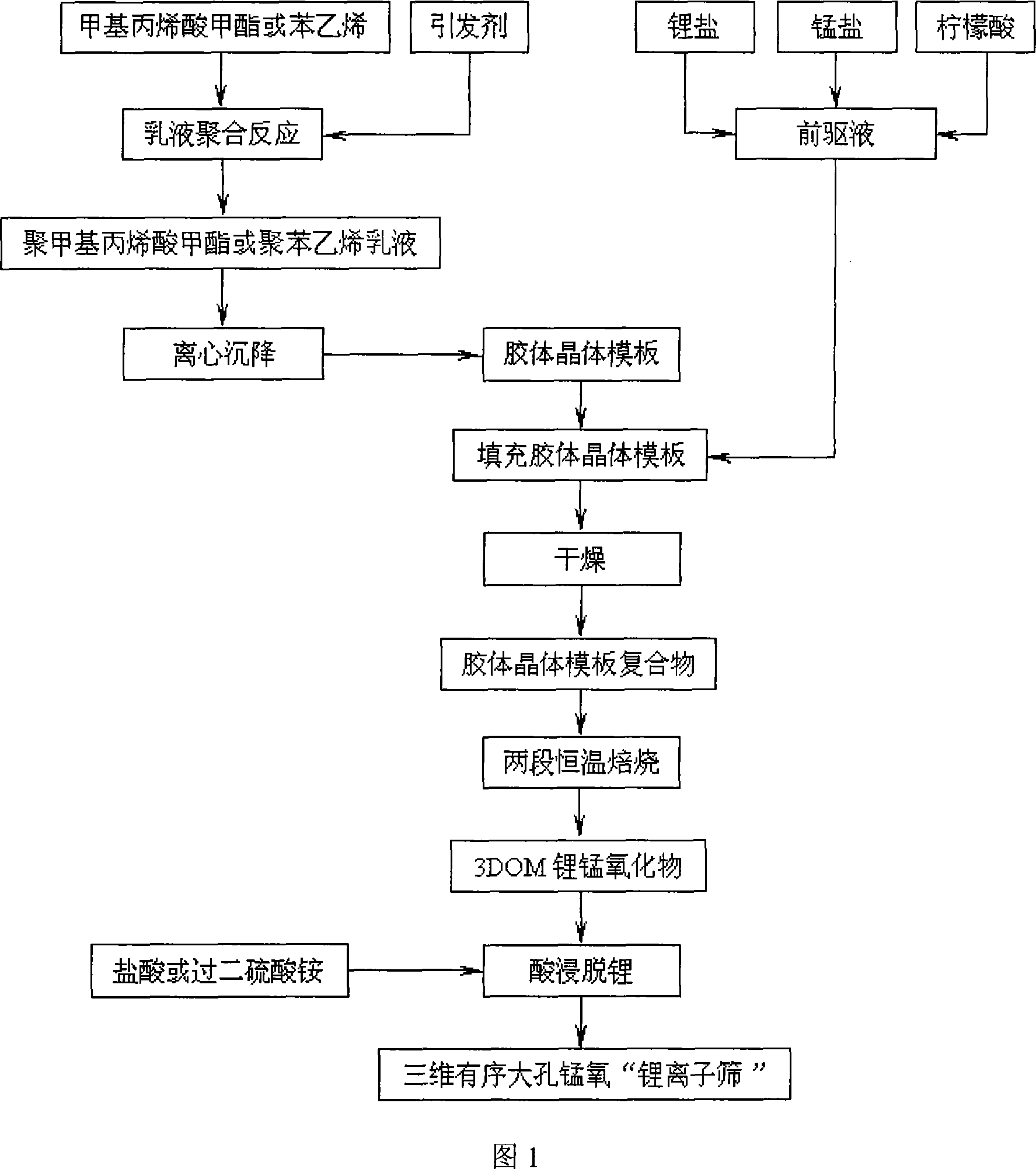

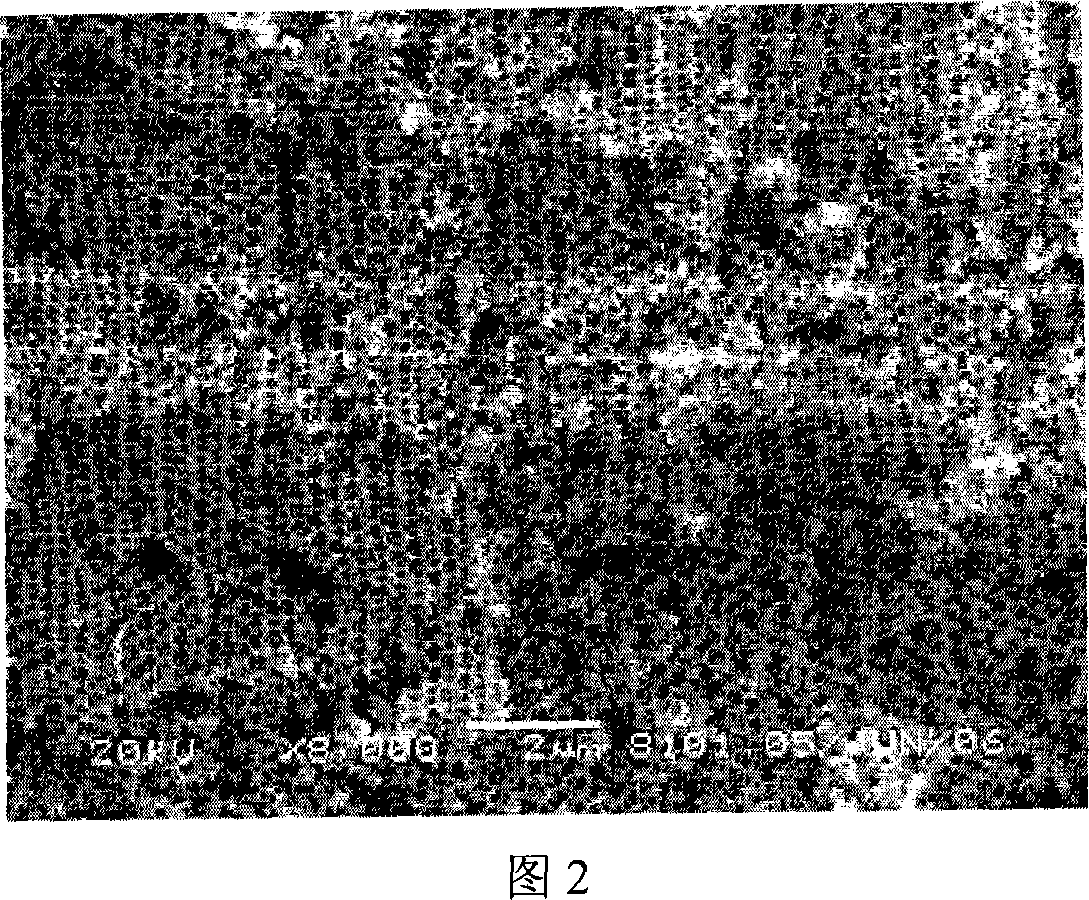

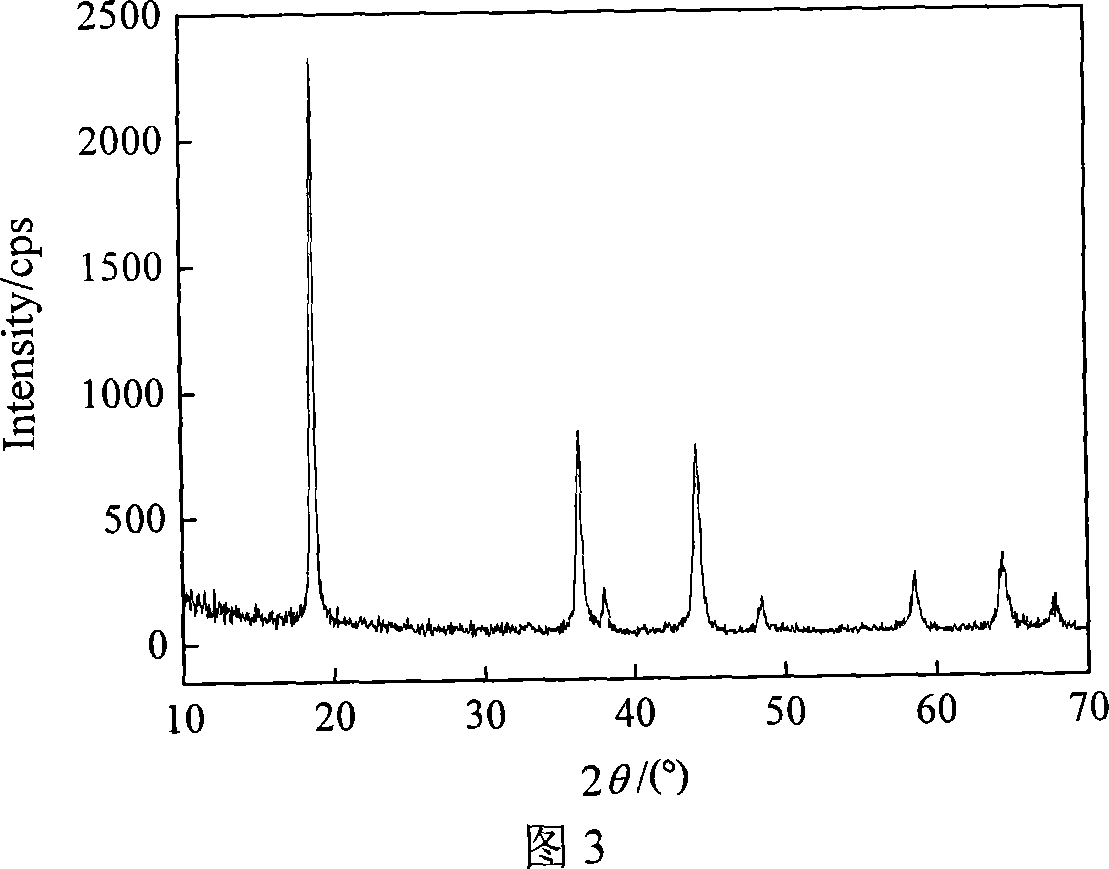

[0023] As shown in Figure 1, Figure 2, Figure 3, and Figure 4, add methyl methacrylate and deionized water into the three-necked flask at a ratio of 1:10, pass through nitrogen protection, and add at a temperature of 70°C and a stirring speed Potassium persulfate initiator was used for in-situ polymerization; microspheres were oriented and ordered by centrifugal sedimentation method to obtain colloidal crystal template; analytically pure lithium chloride (LiCl·H 2 O) 0.6041g, manganese chloride (MnCl 2 4H 2 O) 3.9541g and citric acid (C 6 h 8 o 7 ·H 2 (0) 4.2027g substance, dissolve with distilled water, adjust the pH value of solution with concentrated ammonia water, be made into the precursor solution of 20ml; Immerse the colloidal crystal template in the precursor solution for about 3 minutes, and wait for the solution to fully infiltrate into the gap between the microspheres and the template After complete wetting, the excess solution was removed by suction filtration...

Embodiment 2

[0025] As shown in Figure 1, Figure 5, Figure 6, and Figure 7, add styrene and deionized water into the three-necked flask at a ratio of 1:10, pass through nitrogen protection, and add peroxodisulfuric acid at a temperature of 70°C and a stirring speed Potassium initiator was used for in-situ polymerization; microspheres were oriented and ordered by centrifugal sedimentation method to obtain colloidal crystal template; analytically pure lithium nitrate (LiNO 3 )0.9193g, 50% manganese nitrate [Mn(NO 3 ) 2 ] solution 7.1578g and citric acid (C 6 h 8 o 7 ·H 2 (0) 4.2027g substance, dissolve with distilled water, adjust the pH value of solution with concentrated ammonia water, be made into the precursor solution of 20ml; Immerse the colloidal crystal template in the precursor solution for about 3 minutes, and wait for the solution to fully infiltrate into the gap between the microspheres and the template After complete wetting, the excess solution was removed by suction filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com