Preparation method and application of lithium-titanium type ion sieve composite membrane

A technology of ion sieve and composite membrane, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of difficult industrial operation, hindering commercial application, poor fluidity and permeability, etc., to achieve no secondary pollution, cost Low, stable adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) TiO 2 and Li 2 CO 3 Add it into absolute ethanol according to the concentration ratio of the substance at 1.00, mix well, put it in a drying oven at 85°C and dry it, then raise the temperature of the product to 850°C at a heating rate of 5°C / min, and keep it for 24 hours. Roasting in the air, the lithium ion sieve LiTiO3 can be obtained. The prepared lithium ion sieve Li 2 TiO 3 In 0.1mol / L HCl solution, magnetically stirred at 60°C to carry out exchange adsorption reaction, take 2.0mL supernatant at regular intervals, and measure Li + concentration, then centrifuged and washed with ethanol several times and placed in an oven to obtain the metatitanic acid-type adsorbent H 2 TiO 3 .

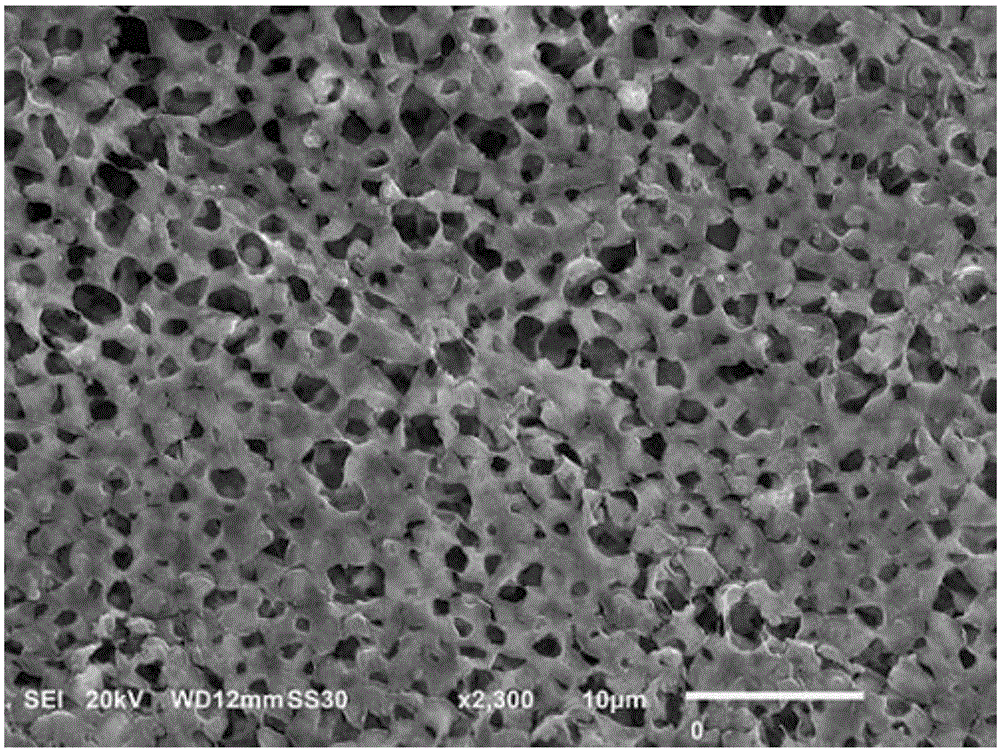

[0022] (2) Preparation of lithium-manganese ion sieve composite membrane: 0.25g lithium ion sieve H 2 TiO 3 The precursor, 1.5g of polyvinylidene fluoride (PVDF) powder, and 0.5g of polyethylene glycol were dissolved in 30mL of N-methylpyrrolidone (NMP) solution, and stirred m...

Embodiment 2

[0024] (1) TiO 2 and Li 2 CO 3 Add it into absolute ethanol according to the concentration ratio of the substance at 1.02, mix well, put it in a drying oven at 85°C and dry it, then raise the temperature of the product to 850°C at a heating rate of 5°C / min, and keep it for 24 hours. Roasting in the air, the lithium ion sieve Li 2 TiO 3 . The prepared lithium ion sieve Li 2 TiO 3 In 0.1mol / L HCl solution, magnetically stirred at 60°C to carry out exchange adsorption reaction, take 2.0mL supernatant at regular intervals, and measure Li + concentration, then centrifuged and washed with ethanol several times and placed in an oven to obtain the metatitanic acid-type adsorbent H 2 TiO 3 .

[0025] (2) Preparation of lithium manganese ion sieve composite membrane: 0.5g lithium ion sieve H 2 TiO 3 The precursor, 3g of polyvinylidene fluoride (PVDF) powder, and 1g of polyethylene glycol were dissolved in 30mL of N-methylpyrrolidone (NMP) solution, and stirred mechanically at...

Embodiment 3

[0028] (1) TiO 2 and Li 2 CO 3Add it into absolute ethanol according to the concentration ratio of the substance at 1.05, mix evenly, put it in a drying oven at 85°C and dry it, then raise the temperature of the product to 850°C at a heating rate of 5°C / min, keep it for 24 hours, and Roasting in the air, the lithium ion sieve Li 2 TiO 3 . The prepared lithium ion sieve Li 2 TiO 3 In 0.1mol / L HCl solution, magnetically stirred at 60°C to carry out exchange adsorption reaction, take 2.0mL supernatant at regular intervals, and measure Li + concentration, then centrifuged and washed with ethanol several times and placed in an oven to obtain the metatitanic acid-type adsorbent H 2 TiO 3 .

[0029] (2) Preparation of lithium-manganese ion sieve composite membrane: 1g lithium ion sieve H 2 TiO 3 The precursor, 6g of polyvinylidene fluoride (PVDF) powder, and 2g of polyethylene glycol were dissolved in 30mL of N-methylpyrrolidone (NMP) solution, and after mixing by mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com