Preparation method and application of solid-state electrolyte-coated modified lithium ion battery positive electrode material

A solid-state electrolyte, lithium-ion battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of difficult ultra-thin coating control, rate performance limitations, rough coating effect, etc., to promote lithium ion transport. , The effect of reducing dissolution loss and inhibiting side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

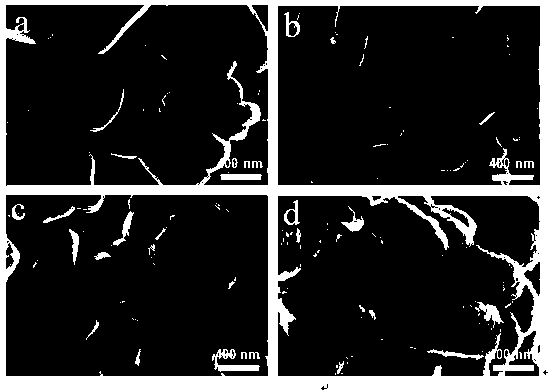

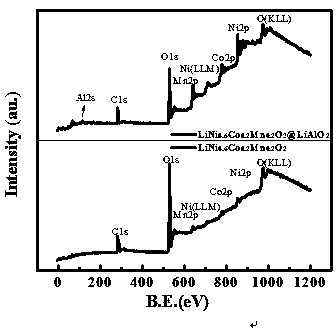

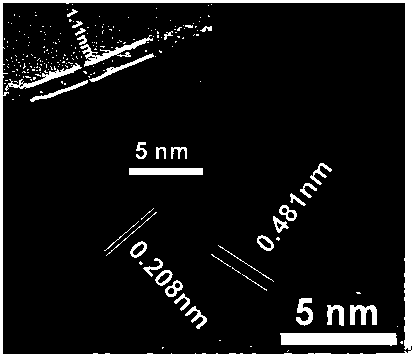

Embodiment 1

[0033] (1) put C 9 h 21 o 3 Al and CH 2Disperse OLi in ethanol, then add an appropriate amount of stabilizer dropwise (stabilizer: ethanol volume ratio: 3:2000), and stir for 1 hour to obtain aluminum metalithium sol;

[0034] (2) Take 0.3 g of cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 Add the above-mentioned sol, transfer it to the inner lining of the polytetrafluoroethylene reactor, stir for 1-2 hours, and directly use the solvothermal method at 120-180°C for 15 hours to obtain the precursor of the solid electrolyte-coated modified positive electrode material;

[0035] (3) Filter the product in step (2), and then wash with absolute ethanol for 3 times, and then keep the filter cake in a blast drying oven at 80°C for 3 hours to obtain LiAlO 2 Precursors for coated cathode materials;

[0036] (4) Calcining the prepared solid electrolyte-coated modified cathode material precursor at 500°C for 4 hours to obtain a solid electrolyte-coated modified lithium-ion battery ca...

Embodiment 2

[0044] (1) put C 12 h 27 o 3 Al and CH 2 Disperse OLi in ethanol, then add an appropriate amount of stabilizer dropwise (stabilizer: ethanol volume ratio: 3:2000), and stir for 1 hour to obtain aluminum metalithium sol;

[0045] (2) Take 0.3 g of cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 Add the above-mentioned sol, transfer it to the inner lining of the polytetrafluoroethylene reactor, stir for 1-2 hours, and directly use the solvothermal method at 120-180°C for 15 hours to obtain the precursor of the solid electrolyte-coated modified positive electrode material;

[0046] (3) Filter the product in step (2), and then wash with absolute ethanol for 3 times, and then keep the filter cake in a blast drying oven at 80°C for 4 hours to obtain LiAlO 2 Precursors for coated cathode materials;

[0047] (4) Calcining the prepared solid electrolyte-coated modified cathode material precursor at 500°C for 4 hours to obtain a solid electrolyte-coated modified lithium-ion battery ...

Embodiment 3

[0051] (1) put C 9 h 21 o 3 Al and LiNO 3 Disperse in ethanol, then add dropwise an appropriate amount of suitable stabilizer (stabilizer: ethanol volume ratio: 3:2000), stir for 1 hour to obtain aluminum metalithium sol;

[0052] (2) Take 0.3 g of cathode material LiNi 0.6 co 0.2 mn 0.3 o 2 Add the above-mentioned sol, transfer it to the inner lining of the polytetrafluoroethylene reactor, stir for 1-2 hours, and directly use the solvothermal method at 120-180°C for 15 hours to obtain the precursor of the solid electrolyte-coated modified positive electrode material;

[0053] (3) Filter the product in step (2), and then wash with absolute ethanol for 3 times, and then keep the filter cake in a blast drying oven at 80°C for 2~4h to obtain LiAlO 2 Precursors for coated cathode materials;

[0054] (4) Calcining the prepared solid electrolyte-coated modified cathode material precursor at 500°C for 4 hours to obtain a solid electrolyte-coated modified lithium-ion battery c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com