Patents

Literature

32results about How to "Good acid resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enamel composition

InactiveUS20050014625A1Good acid resistanceGlass/slag layered productsOven coatingsVitreous enamelPyrolysis

The present invention provides a composition for use in forming an enamel cover coat from which baked-on foods can be removed without the need for pyrolysis or highly alkaline cleaners. The enamel cover coat preferably exhibits no chipping or other surface defects subsequent to a 2.0 mm Plum Jam Test and an acid resistance of A or better according to ISO 2722. The composition according to the invention includes a glass component including at least a first glass frit comprising a low SiO2 glass frit. Preferably, the glass component includes a blend of the first glass frit and at least a second glass frit. Preferably, the first glass frit includes by weight from about 30% to about 45% P2O5, from about 20% to about 40% Al2O3, from about 15% to about 35% Li2O+Na2O+K2O, up to about 15% B2O3, up to about 15% MgO+CaO+SrO+BaO+ZnO, up to about 10% TiO2+ZrO2, and up to about 10% SiO2.

Owner:FERRO FRANCE S A R L

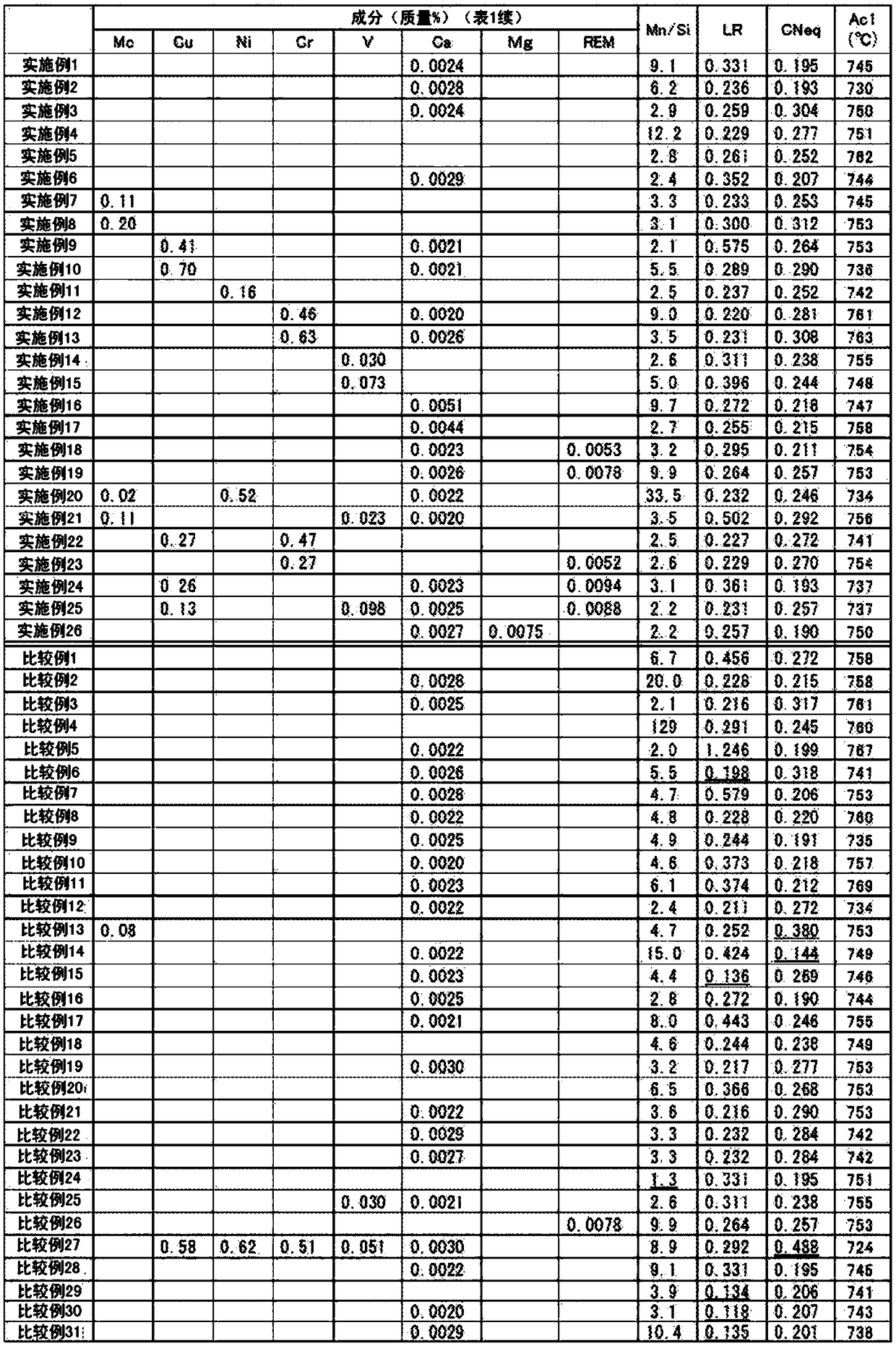

Union yarn of terylene fibers, viscose fibers and bamboo fibers, and production method thereof

The invention provides a union yarn of terylene fibers, viscose fibers and bamboo fibers, and a production method thereof. The union yarn comprises the following components by mass percentage: 78-85%of terylene fibers, 5-15% of viscose fibers and 5-15% of bamboo fibers. Since the union yarn of terylene fibers, viscose fibers and bamboo fibers fully combines the favorable properties of terylene fibers, viscose fibers and bamboo fibers, the respective defects are eliminated. The fabrics made of the union yarn have the advantages of high acid resistance, alkaline resistance, strength, heat resistance, elasticity, wrinkling resistance, wear resistance, hydroscopic property, ventilation property and dyeing property and can resist bacteria, prevent bacteria and resist ultraviolet radiation.

Owner:NANTONG SUZHONG TEXTILE

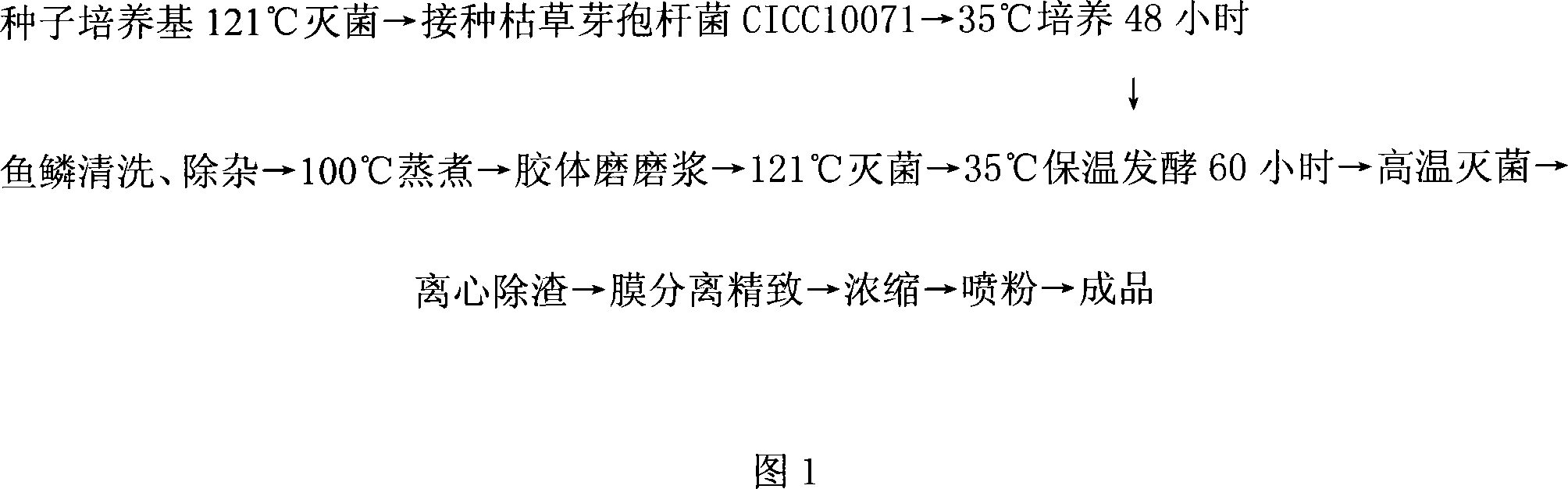

Method for preparing collagen peptide

InactiveCN101240313AGood acid resistanceGood high temperature resistanceMicroorganism based processesFermentationPeptideChemistry

The invention provides a method for preparing fish scale collagen protein peptides comprising the following steps (1) preparing fermentation seeds culture medium, (2) preparing fermentation seeds, (3) processing fish scale, (4) fermenting with constant temperature, (5) separating, (6) delicacy, (7) drying to obtain fish scale collagen protein peptides powder. The preparing process incorporating the invention comparing with other methods is simple, prepared collagen protein peptides can be solved into water complete, its solution in water is low viscosity and also has good flow property in high concentration, has good acid resistant and has no precipitating in acid or alkaline circumference, also has good high temperature resistant which has no precipitating even it is heated up to 100 DEG C.

Owner:湖北瑞邦生物科技有限公司

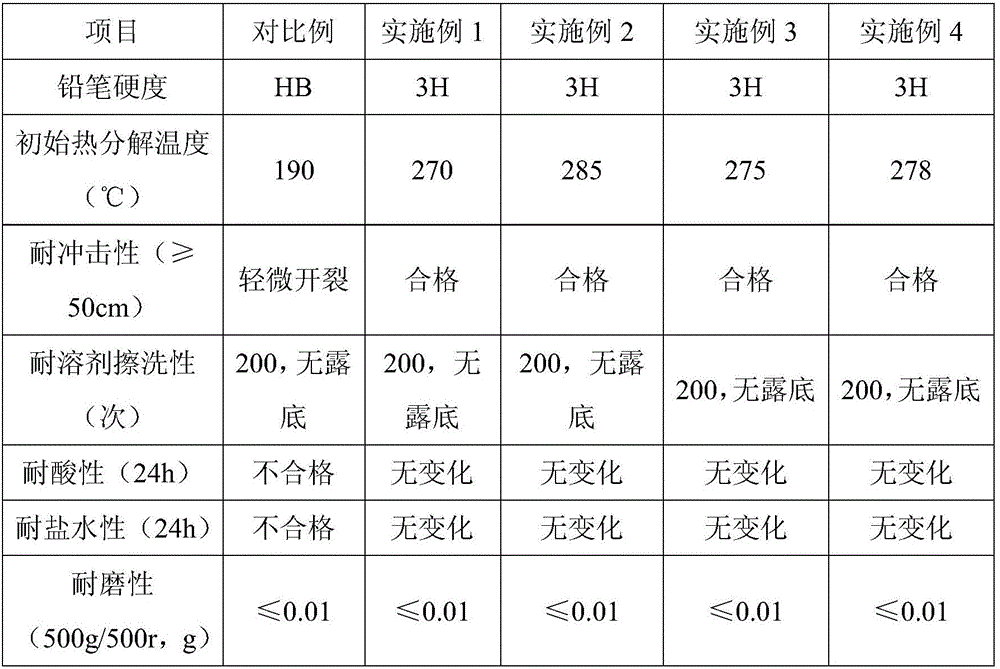

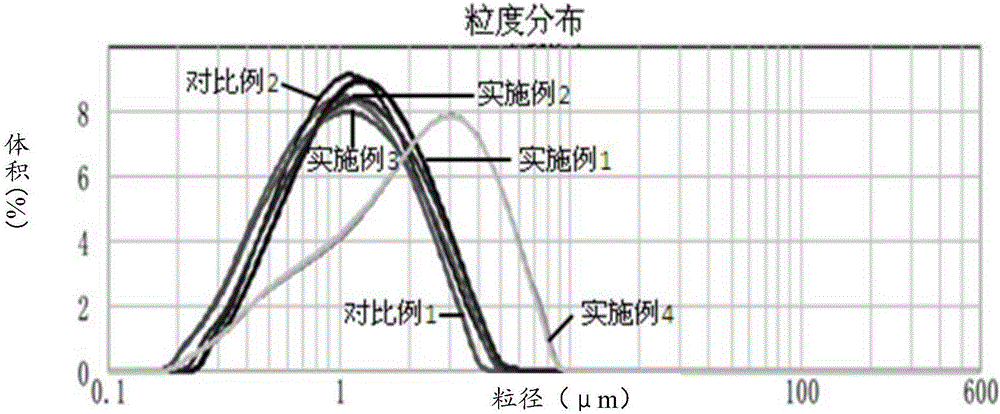

Composite modified aqueous polyurethane, preparation method and applications thereof

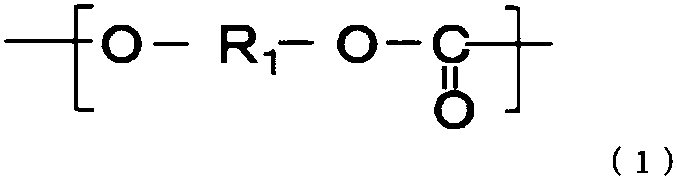

InactiveCN106243314AUniform and stable dispersionAvoid reunionPolyurea/polyurethane coatingsAlcoholCarboxylic acid

The invention discloses a composite modified aqueous polyurethane, a preparation method and applications thereof. The preparation method comprises: 1) adding a small molecule alcohol chain extender and a small molecule carboxylic acid chain extender during a prepolymer preparation process; 2) modifying an acid silica sol by using a silane coupling agent; 3) carrying out a reaction on the modified acid silica sol and an aqueous polyurethane prepolymer to obtain a silica sol modified aqueous polyurethane; 4) modifying graphene by using a silane coupling agent; and 5) carrying out compounding modification, wherein the modified graphene and the silica sol modified aqueous polyurethane are uniformly mixed, and a reaction is performed to obtain the composite modified aqueous polyurethane. According to the present invention, with the method, the silica sol and the graphene can be stably and uniformly dispersed in the aqueous polyurethane, such that the agglomeration among the particles can be avoided; the method is simple and convenient and is easy to industrialize; and the advantages of excellent hardness, excellent flexibility, excellent compactness, excellent impact resistance, excellent corrosion resistance, excellent water resistance and the like are provided after the composite modified aqueous polyurethane forms the film.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

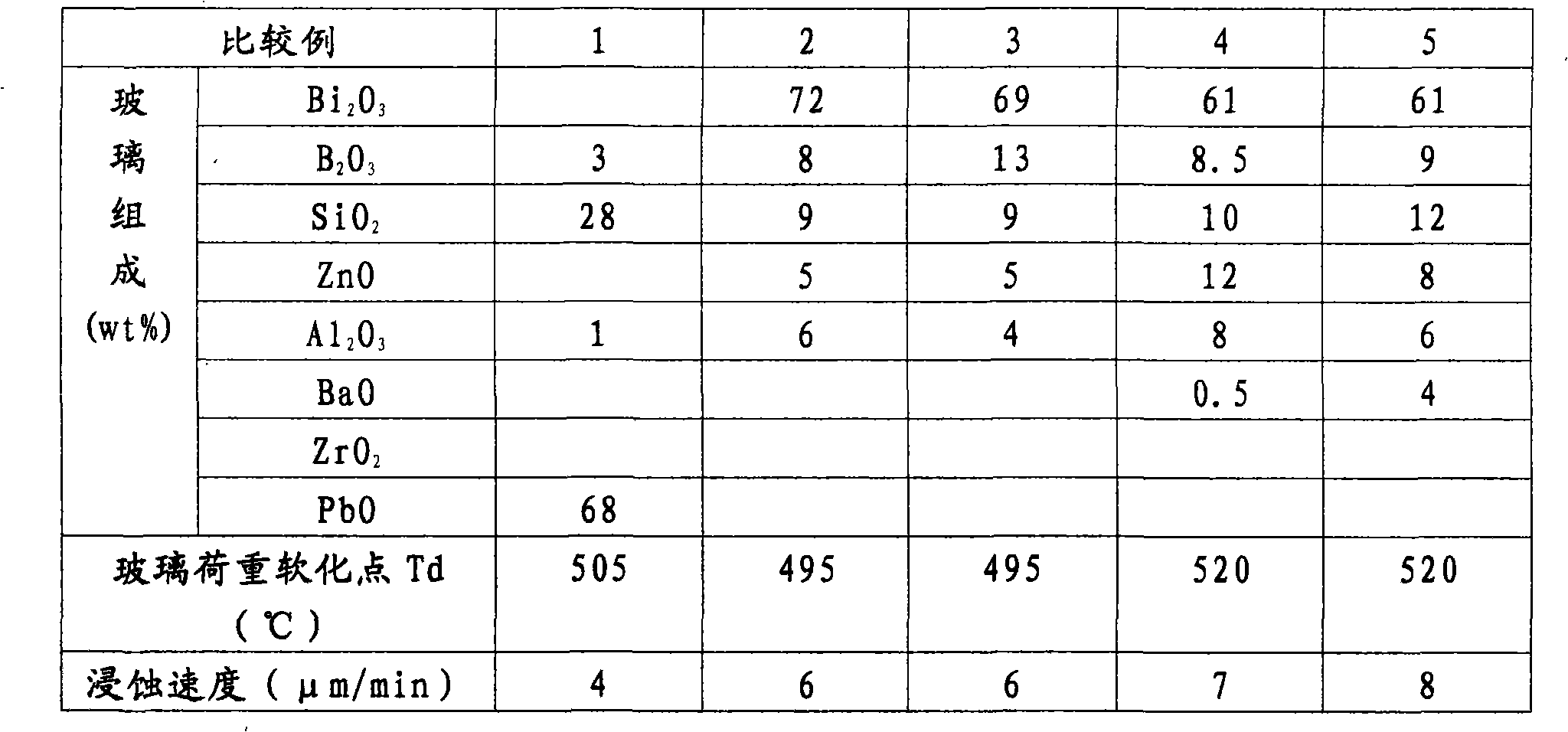

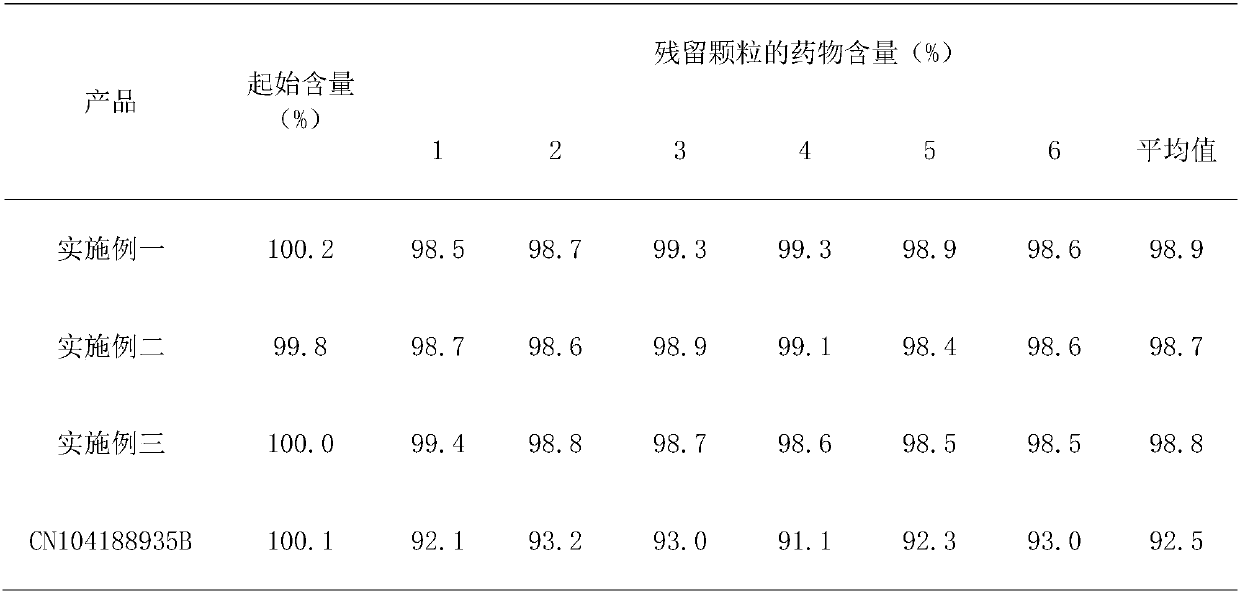

Esomeprazole magnesium enteric pellet capsule and preparation method thereof

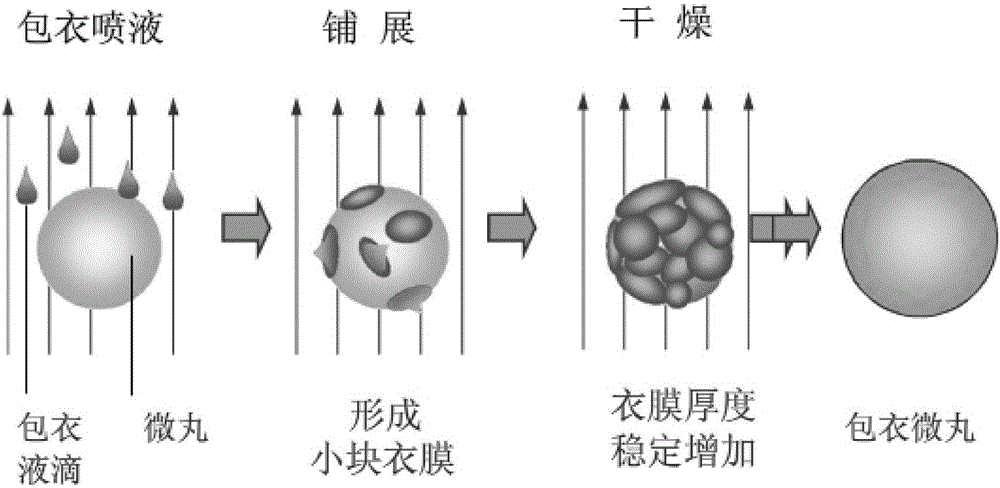

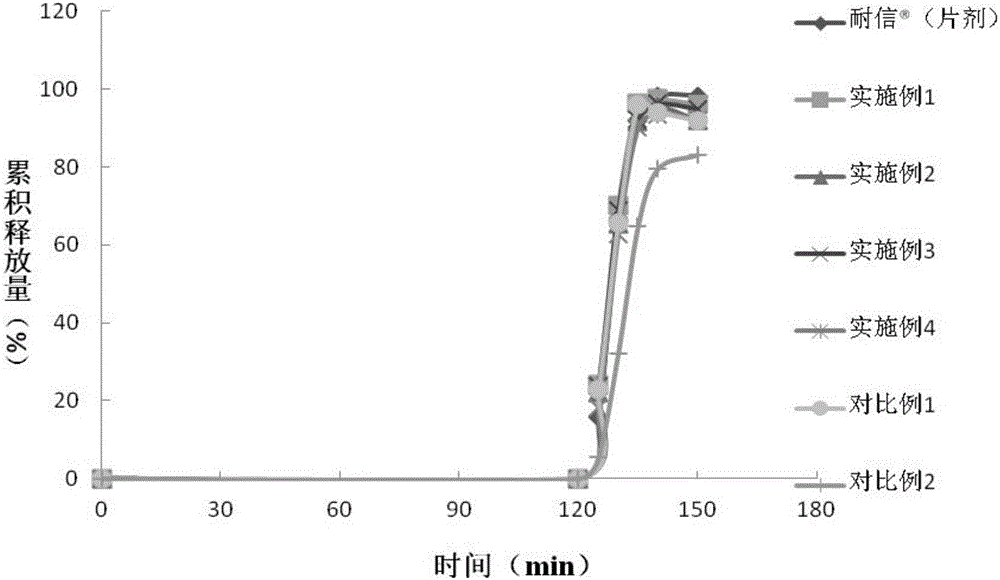

InactiveCN105125517AGood acid resistanceGood releaseOrganic active ingredientsDigestive systemEsomeprazole MagnesiumCoating drugs

The invention discloses an esomeprazole magnesium enteric pellet capsule and a preparation method thereof. The esomeprazole magnesium enteric pellet capsule is formed by filling a capsule with enteric pellets, and each enteric pellet sequentially comprises a blank pellet core, a drug carrying layer, an isolating layer, an enteric layer and a protecting layer from inside to outside. Grain particle and pH value of active drug ingredients of each drug carrying layer are controlled, degradation caused by the fact that active ingredients are combined with acidic enteric coatings is prevented due to using of each isolating layer, adhesion of the enteric pellets is avoided due to using of each protecting layer, and fluidized bed coating technology is adopted, so that the esomeprazole magnesium enteric pellet capsule is high in stability and release degree, remarkable in gastric acid inhibiting effect and supportive of being widely applied in treatment of gastroesophageal reflux disease and digestive ulcer with positive helicobacter pylori. The preparation method is simple, low in production cost, environment friendly and suitable for industrialized production of the esomeprazole magnesium enteric pellet capsule.

Owner:广东彼迪药业有限公司

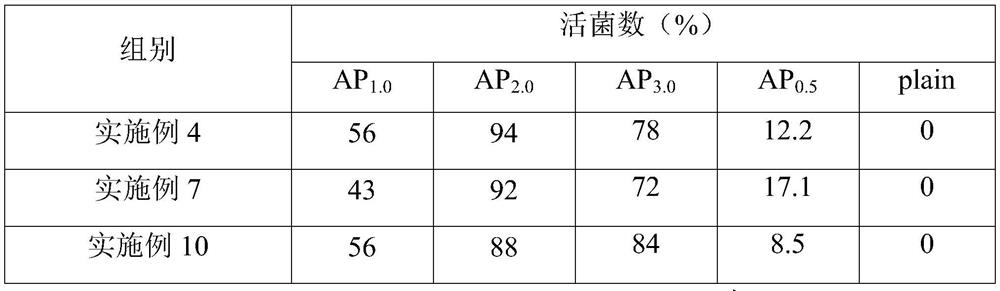

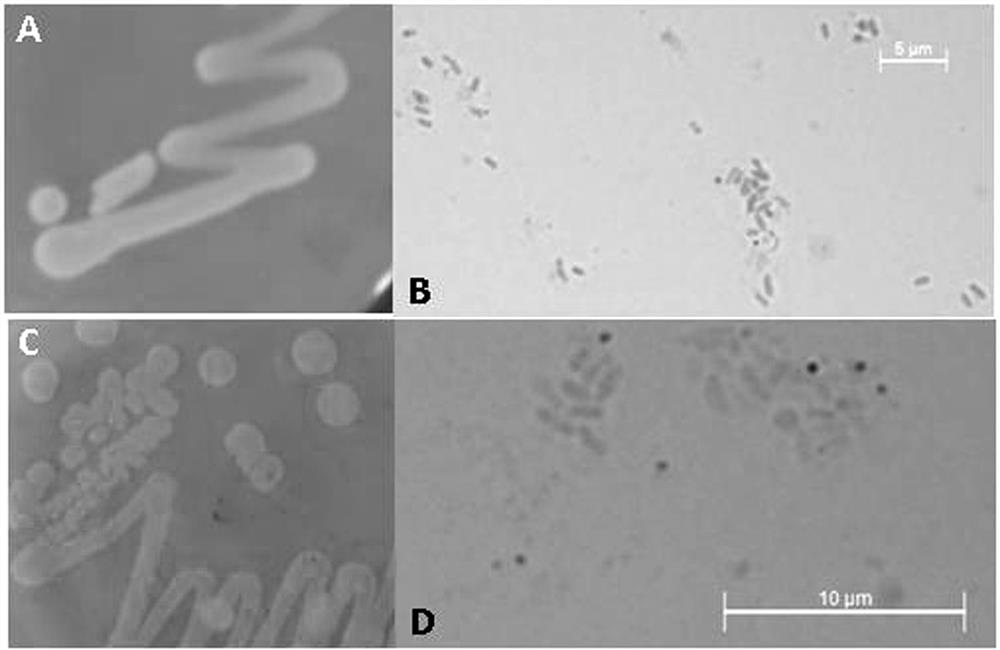

Lactobacillus paracasei 761, application of Lactobacillus paracasei 761, silage additive and silage

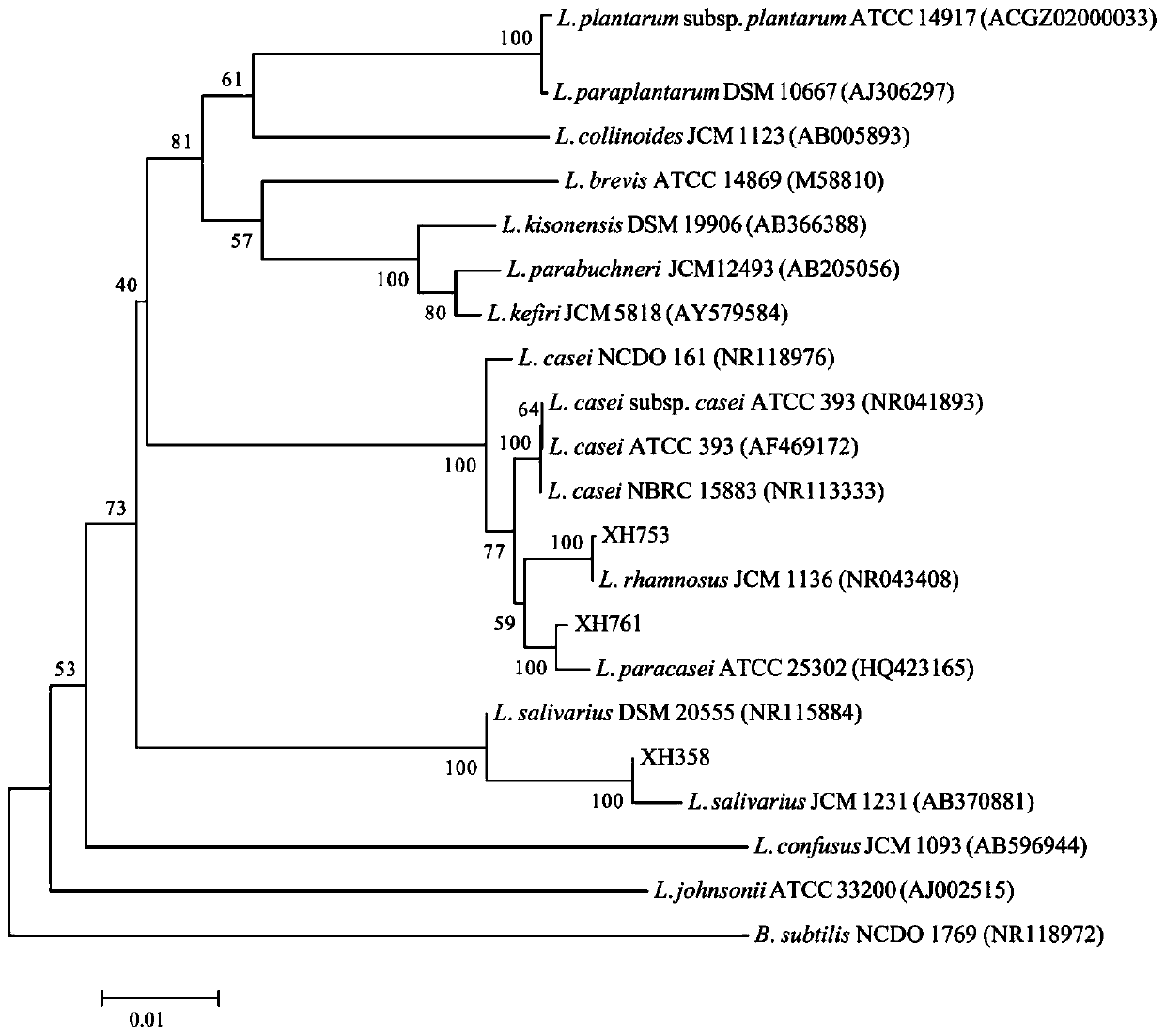

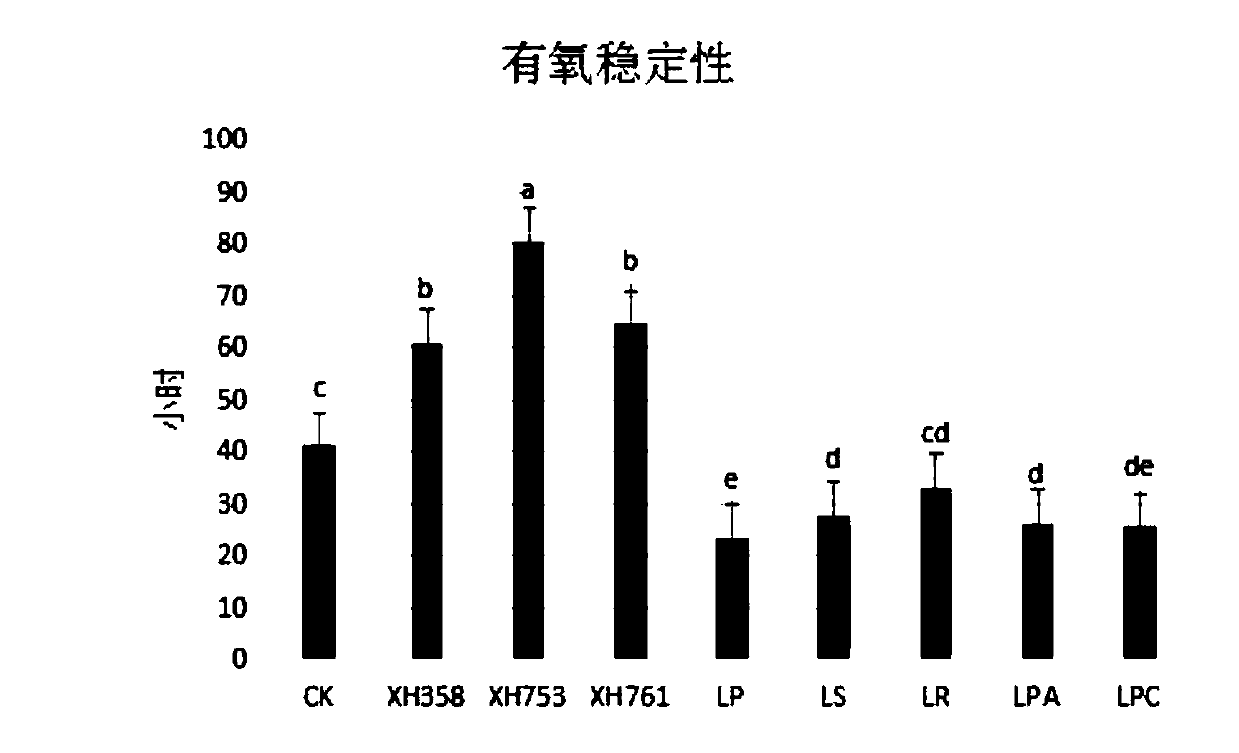

ActiveCN110643544AGood high temperature resistanceGood acid resistanceBacteriaMicroorganism based processesMicrobiologyLactobacillus paracasei

The invention discloses a Lactobacillus paracasei 761, application of the Lactobacillus paracasei 761, a silage additive and silage. The Lactobacillus paracasei 761 is deposited at China General Microbiological Culture Collection Center, and the deposit number is CGMCCNo.18234; the Lactobacillus paracasei 761 can improve the quality of the silage in high-temperature and high-humidity areas, and the silage treated by the Lactobacillus paracasei 761 has better aerobic stability, can reduce pH, aflatoxin B1 and dry matter loss and has good high-temperature resistance and acid resistance and goodadaptability to the environment, under culturing in high-temperature conditions, the growth and acid production of the Lactobacillus paracasei 761 has no significant lag phase, and can achieve rapid acid production to achieve the effect of lower pH .

Owner:SICHUAN AGRI UNIV

Electrode coating and preparation method thereof

ActiveCN102168283AGood acid resistanceResistant to a large amount of gas erosionElectrodesCoordination complexHigh current density

The invention discloses a high-adhesiveness durable electrode coating and a preparation method thereof. The electrode coating is prepared by adding a coordination compound into an iridium-tantalum coating, wherein the coordinator is one, two or three of alkyl group, amino group and nitro-group, and the coordinating element is one of molybdenum (Mo), tin (Sn), platinum (Pt), cobalt (Co), manganese (Mn) and titanium (Ti). The product disclosed by the invention uses the coating obtained from the organic coordination compound containing the elements, thus, can well resist acid, erosion of massive gas and impact of high current density, and has favorable cohesive property with the substrate; the service life of the electrode is prolonged; and the method is simple to operate, does not need complicated substrate pretreatment technology, and does not need a complicated middle layer or the like.

Owner:METALINK SPECIAL ALLOYS CORP

High-ductility, corrosion-resistant and ultra/extra-thick crystalline cemented carbide and preparation method thereof

The invention discloses a high-ductility, corrosion-resistant and ultra / extra-thick crystalline cemented carbide and a preparation method thereof. By taking Coarse WC (wolfram carbide) powder as raw materials, and through separately adding Cr3C2 or adding Cr3C2 and rare earth in a combined mode, and adopting a Co / Ni densely-cladded WC-type composite powder process, ultra / extra-thick crystalline cemented carbides with high ductility and better acid / alkali-resistance and oxidation / corrosion resistance are prepared. The adding amounts of the Cr3C2 and the rare earth are respectively 5-8% and 0.4-0.6% of the total mass fraction of Co / Ni in the cemented carbide. The rare earth can be added in rare earth-cobalt pre-alloyed powder form or in oxide form, and when the rare earth is added in oxide form, the adding amount is calculated by oxides. The composite powder process refers to prepare nano assembling structured Co / Ni densely-cladded WC-type composite powder by using a hydrothermal high pressure hydrogen reduction or hydrazine hydrate aqueous-phase normal-pressure reduction process, and then carry out thermal diffusion homogenization and Co / Ni cladded densification processing on the composite powder in a hydrogen atmosphere by using a nano diffusion sintering effect.

Owner:CENT SOUTH UNIV

Coating composition

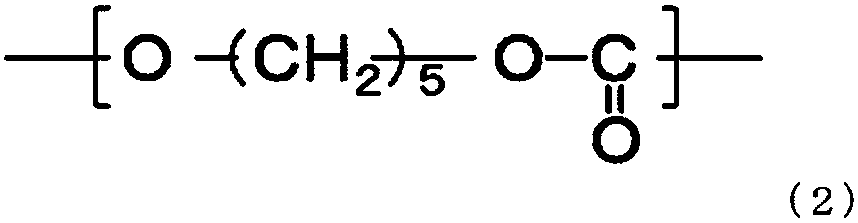

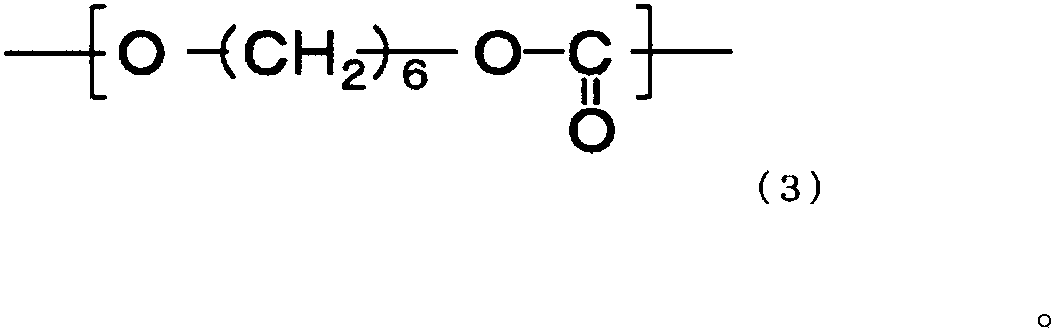

ActiveCN107868598AExcellent initial scratch resistanceGood acid resistancePolyurea/polyurethane coatingsPolycarbonate coatingsPolycarbonateWeather resistance

The invention relates to a coating composition. Provided is a coating composition having excellent initial scratch resistance (abrasion resistance) and abrasion resistance after abrasion damage, and exhibiting excellent weather resistance and acid resistance. The coating composition comprises (a) a hydroxyl group-containing acrylic resin; (b) a polycarbonate polyol and (c) a curing agent, whereinthe polycarbonate polyol (b) has an average hydroxyl number of 2.2 to 3.5 in one molecule and the polycarbonate polyol (b) has a number average molecular weight of 500 to 5,000.

Owner:ASAHI KASEI KOGYO KK

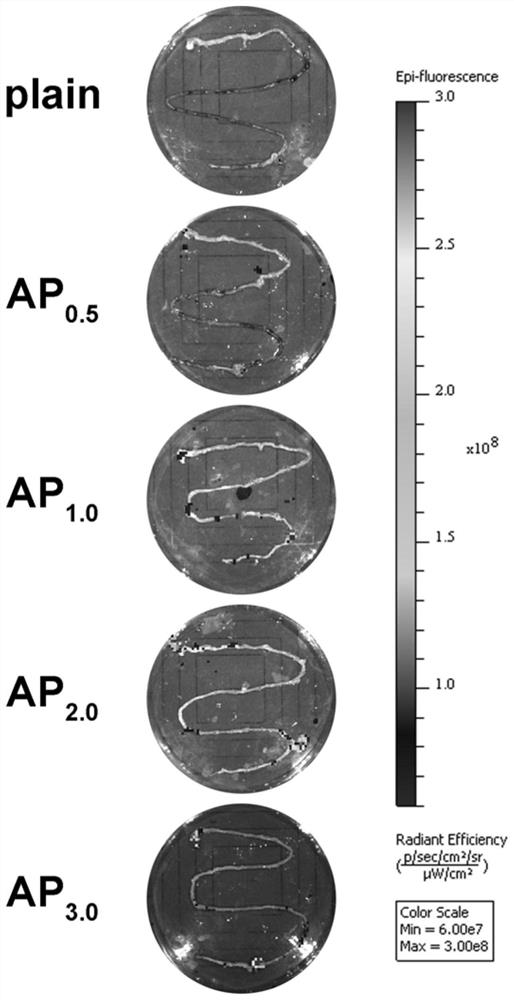

Lead-free low-softening point acid-resistant glass powder for chip component paste and preparation method

The invention provides a lead-free low softening point acid-resistant glass powder for chip component paste and a preparation method thereof. The glass powder comprises the following components in terms of mass percentage: 30-70% Bi 2 o 3 , 20-45% SiO 2 , 1~10% of B 2 o 3 , 0~5% Al 2 o 3 , 0~15% ZnO, 0~5% CaO, 0~10% TiO 2 , 0~5% ZrO 2 , and a total amount of 1 to 10% selected from Na 2 O, K 2 O, or Li 2 One or more alkali metal oxides in O. This kind of glass powder is lead-free, low softening point and acid-resistant, especially suitable for electronic paste of chip components.

Owner:西安宏星电子浆料科技股份有限公司

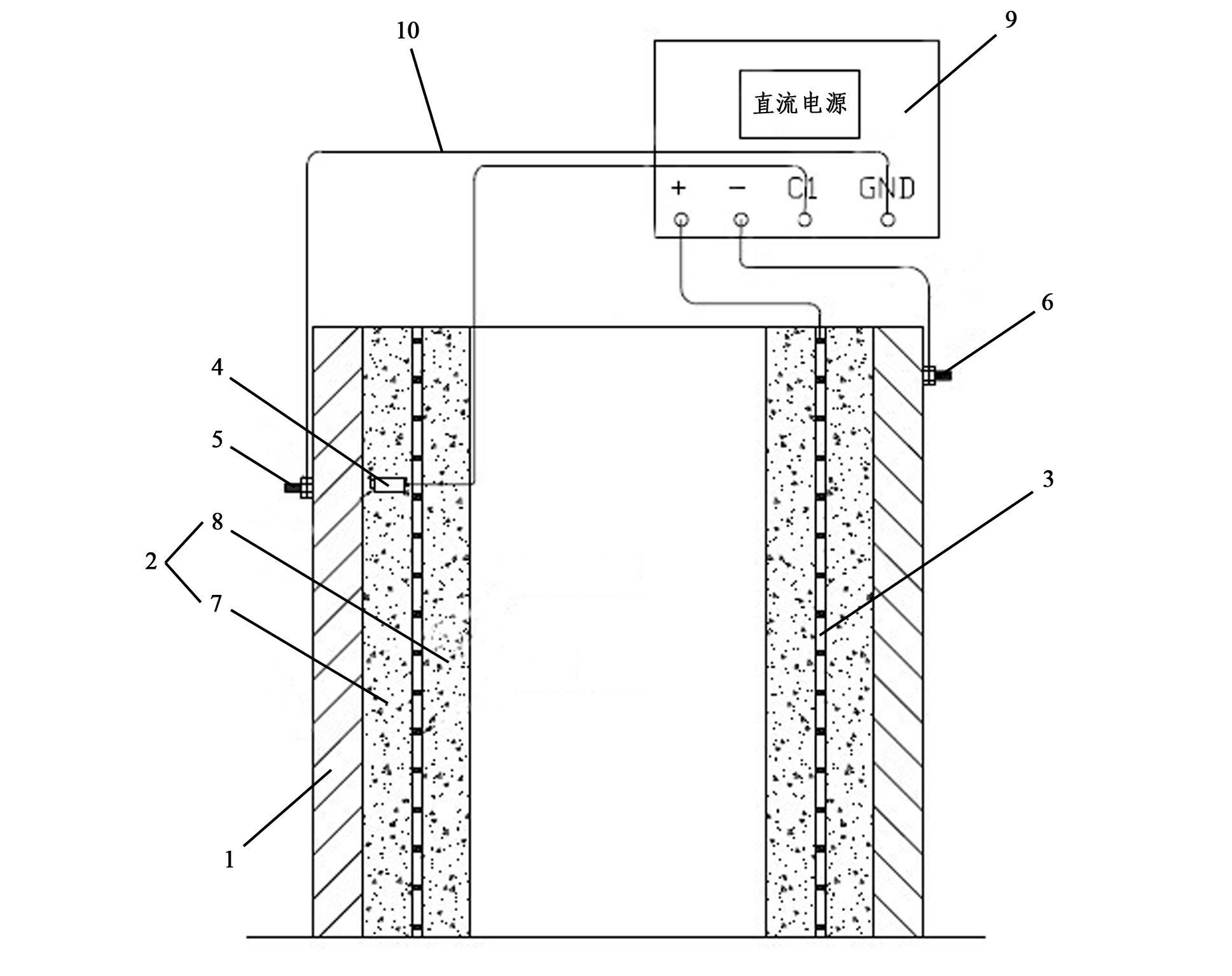

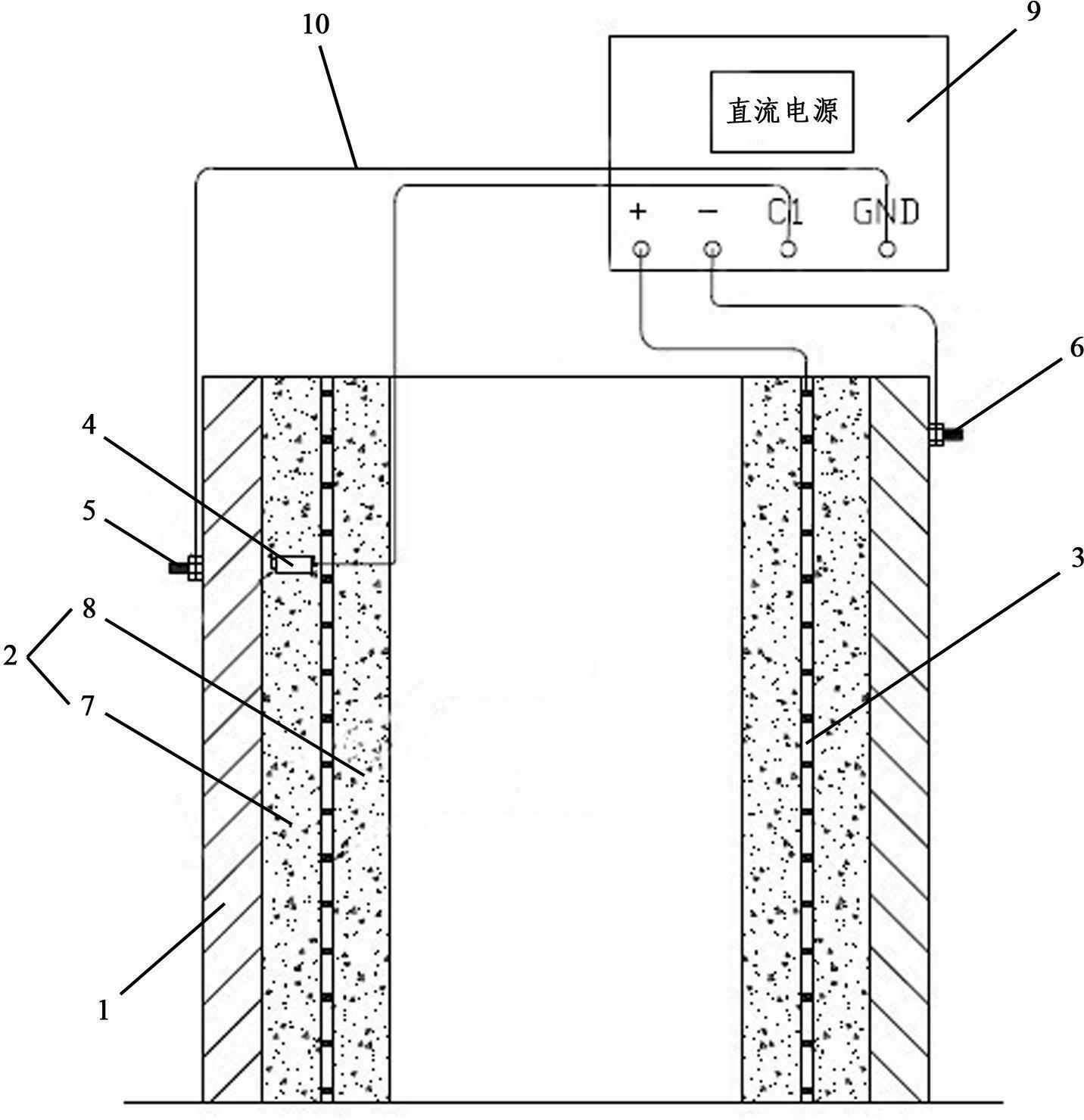

Cathodic protection system of wet desulfurized funnel

The invention relates to a cathodic protection system for a wet desulfurized funnel, which is used for the treatment of corrosion on the wet desulfurized funnel in a thermal power plant. The wet desulfurized funnel comprises a basal body surrounding the funnel, wherein the basal body is provided with an inner wall and an outer wall, an outlet of the wet desulfurized funnel is formed at the end part of the basal body. The cathodic protection system of the wet desulfurized funnel comprises an acid resisting layer which is arranged along the inner wall, an anode screen which is laid in the acid resisting layer, a reference electrode which is embedded in the acid resisting layer, and a measurement grounding device, a cathode and a constant potential rectifier which are arranged on the outer wall of the wet desulfurized funnel, wherein the reference electrode, the measurement grounding device, the cathode, and the anode screen are respectively led out by cables and are connected with the constant potential rectifier. Since the cathodic protection is combined based on the acid resisting layer, corrosion can be effectively resisted, and the acid resisting property is excellent; and meanwhile, the acid resisting layer is compact, flaws are not easy to occur, and the leakage resisting property is good, the load of the funnel can be reduced after the cathodic protection is applied, the service life of the funnel is long, and economic benefits are significant.

Owner:SUZHOU NUCLEAR POWER RES INST +1

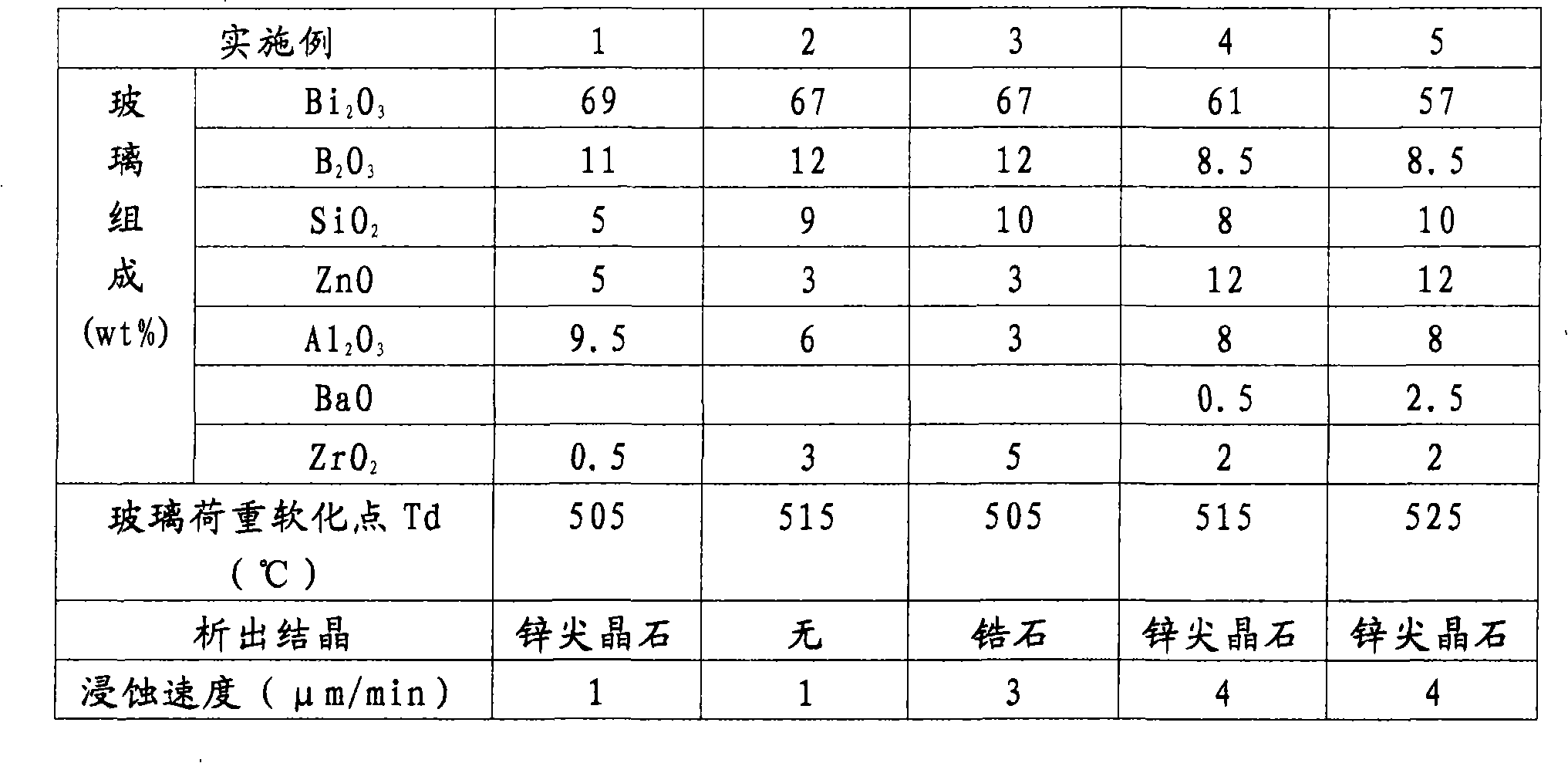

Nonlead glass composition

InactiveCN101277908AGood acid resistanceImprove acid resistanceGas discharge electrodesCeramicsOxideAcid resistance

A non-lead glass composition that solving the problem of conventional Bi2O3 glass with respect to glass softening point and acid resistance, not only can retain the same level of softening point as that of conventionally employed lead glass but also realizes excellent acid resistance. There is provided a nonlead glass composition comprising, in terms of oxide, 55 to 75 wt.% Bi2O3, 5 to 15 wt.% B2O3, 4 to 12 wt.% SiO2, 3 to 12 wt.% ZnO, 3 to 10 wt.% Al2O3 and 0.1 to 5 wt.% ZrO2.

Owner:NIHON YAMAMURA GLASS

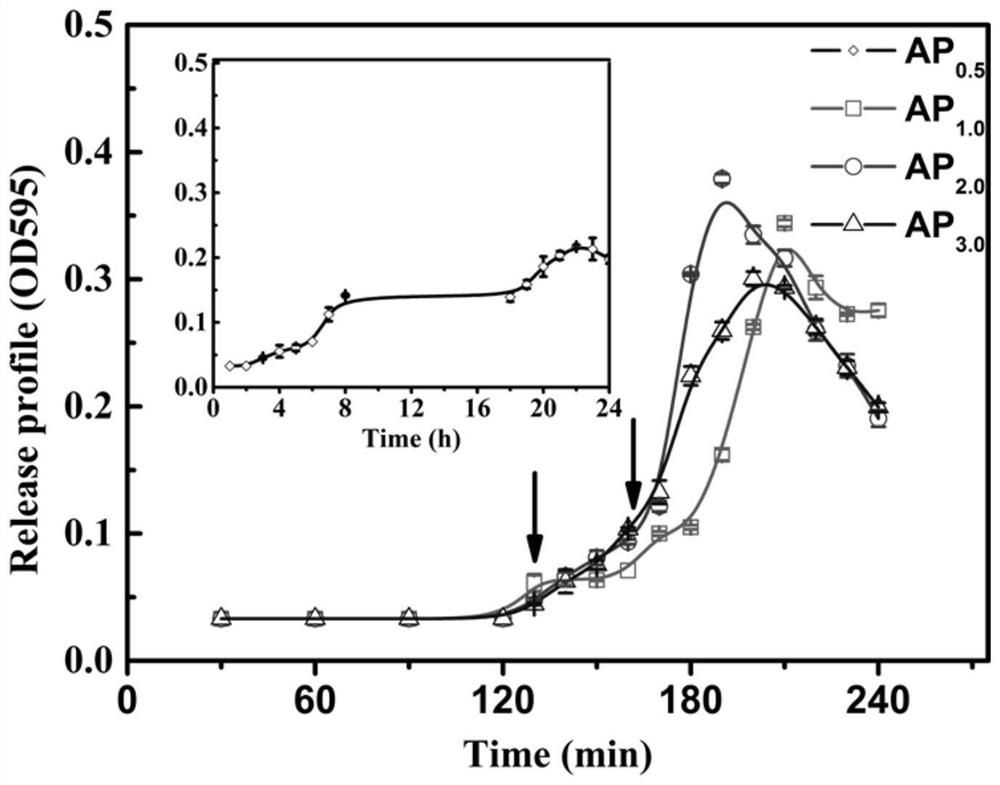

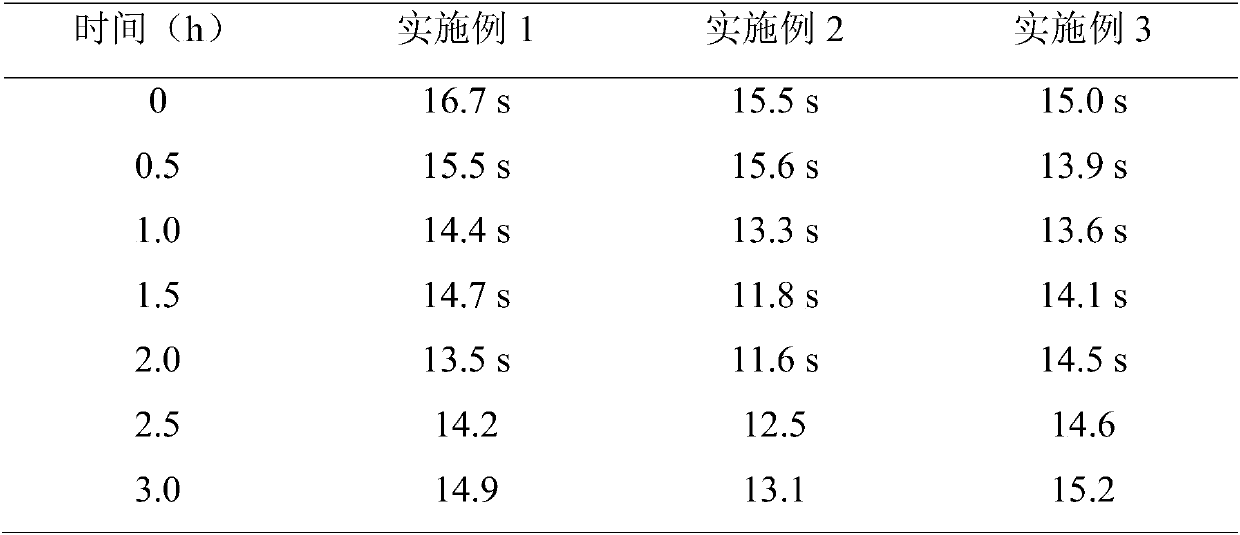

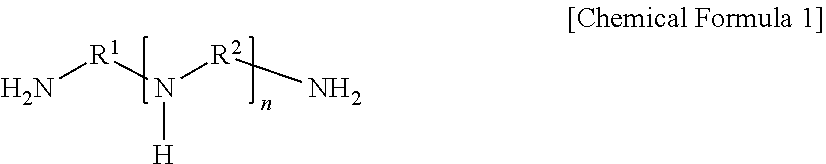

Intestine-targeted oral probiotic preparation and preparation method and application thereof

InactiveCN111714473ADense coating effectGood acid resistanceDigestive systemUnknown materialsBasic amino acidsPolymer chemistry

The invention discloses an intestine-targeted oral probiotic preparation and a preparation method and application thereof. The core of the preparation is a calcium alginate gel inner core containing probiotics, the inner core is alternately coated with basic amino acid polymer layers and a calcium alginate layer from the inner core to the outside, and the outermost layer is the basic amino acid polymer layers; and the preparation contains at least two basic amino acid polymer layers. The microcapsule adopts a multi-layer structure, compared with a single-layer microcapsule, the microcapsule has a denser coating effect and can well embed microorganisms; the microcapsule has better acid resistance, can resist the invasion of gastric acid and bile salt, and significantly improves the survivalrate of bacteria. The multi-layer microcapsule uses a basic amino acid polymer as the outer coating layer, which does not inhibit the disintegration of the microcapsule, but can release the microorganisms in the end of a small intestine quickly, accurately and efficiently, and has excellent targeting ability.

Owner:佛山南溟生物医学材料有限公司

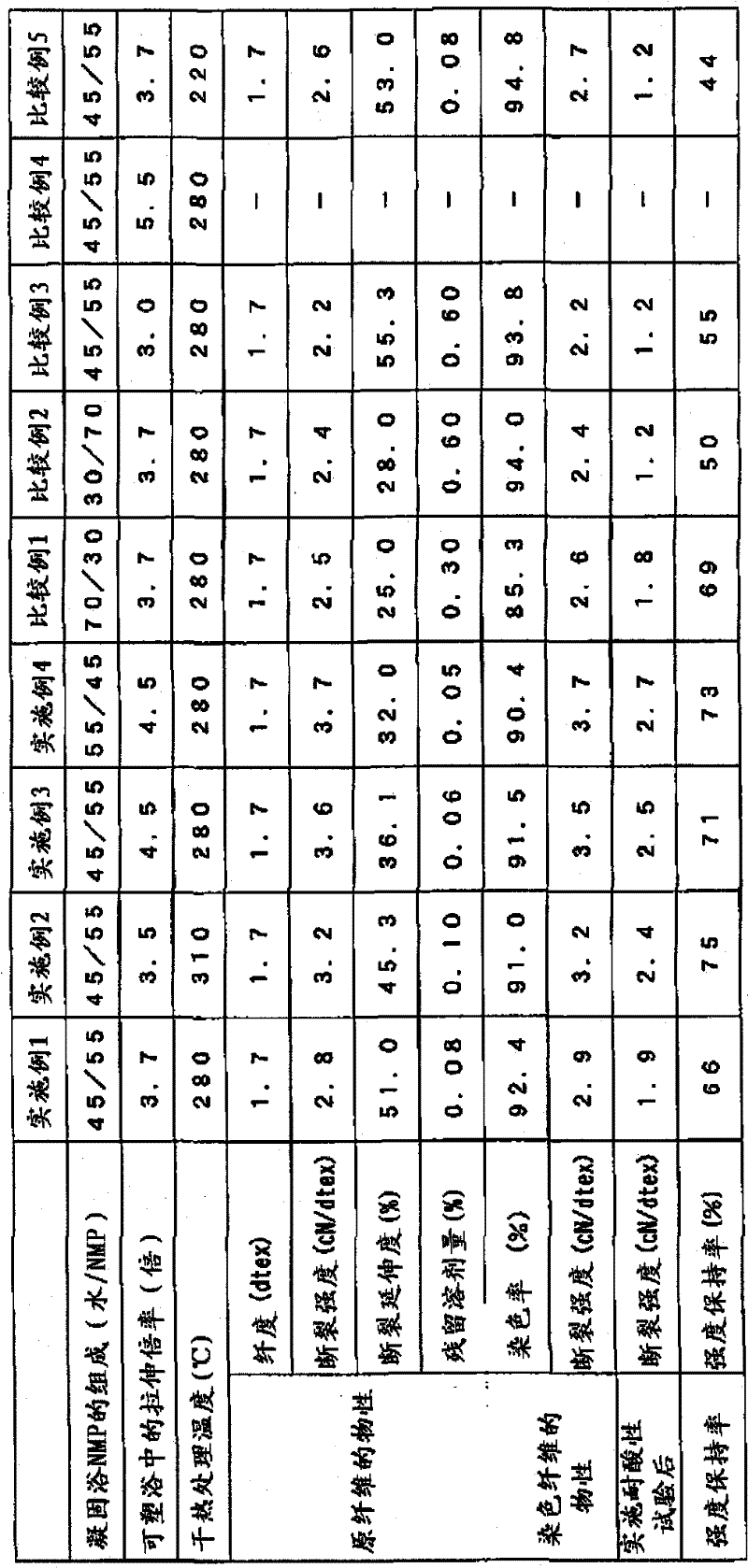

Easily dyeable meta-form wholly aromatic polyamide fiber

ActiveCN102165109AGood dyeabilityGood acid resistanceMonocomponent polyamides artificial filamentChemistryPolyamide fibers

An easily dyeable meta-form wholly aromatic polyamide fiber is provided which has excellent dyeability and excellent acid resistance and is extremely reduced in the content of a residual solvent. The components of a coagulating bath or conditions are suitably controlled so as to result in a coagulated form having no skin core. The resultant fiber is stretched in a plastic state at a specific stretch ratio. After a cleaning step, a dry heat treatment is conducted at a specific temperature.

Owner:TEIJIN LTD

Seed sludge preparing method and sludge processing method

PendingCN109626600APromote enrichmentGood acid resistanceWater treatment parameter controlSludge treatment by de-watering/drying/thickeningWater contentBiology

The invention provides a seed sludge preparing method. Seed sludge is obtained by directly conducting aeration treatment on sludge with rich acidophilic florae on the surface, and the relative abundance of the acidophilic florae on the surface of the seed sludge is 25-35%. The invention further provides a method for processing and dewatering sludge through the seed sludge. The processed sludge hasthe water content lower than 65%. The seed sludge has the good acid resistance and high active recovery rate. When the seed sludge is inoculated to a new sludge environment, the reaction can rapidlyhappen, extra-cellular polymeric substances (EPS) in the sludge system and polysaccharides in cell walls are rapidly consumed, the content and viscosity of sludge organic matter are reduced, the better sludge dewatering effect is achieved, and the sludge settling performance is improved.

Owner:光大水务(深圳)有限公司 +2

Acrylic emulsion for chassis armor coating and preparation method of acrylic emulsion

The invention discloses acrylic emulsion for a chassis armor coating and a preparation method of the acrylic emulsion. The acrylic emulsion is prepared from raw materials in parts by weight as follows: 25-30 parts of seed emulsion, 395-405 parts of butyl acrylate, 348-354 parts of 2-ethylhexyl acrylate, 205-215 parts of methyl methacrylate, 540-560 parts of styrene, 20-25 parts of acrylic acid, 4-7 parts of an emulsifier, 20-25 parts of acrylic acid functional monomers, 4.5-6.5 parts of a thermolysis initiator, 1.3-1.9 parts of an oxidation-reduction initiator system, 0.8-1.0 part of sodium hydrosulfite, 0.020-0.025 parts of an accelerant, 16-20 parts of a pH regulator and 768-867 parts of water, wherein the oxidation-reduction initiator system is prepared from 0.85 -1.15 parts of an inorganic reducing agent and 0.45-0.75 parts of an oxidizing agent. The acrylic emulsion has excellent physical performance and overcomes the defect that common acrylic emulsion cannot have good acid resistance, alkali resistance and engine oil resistance simultaneously.

Owner:郑州安邦达水性材料有限公司

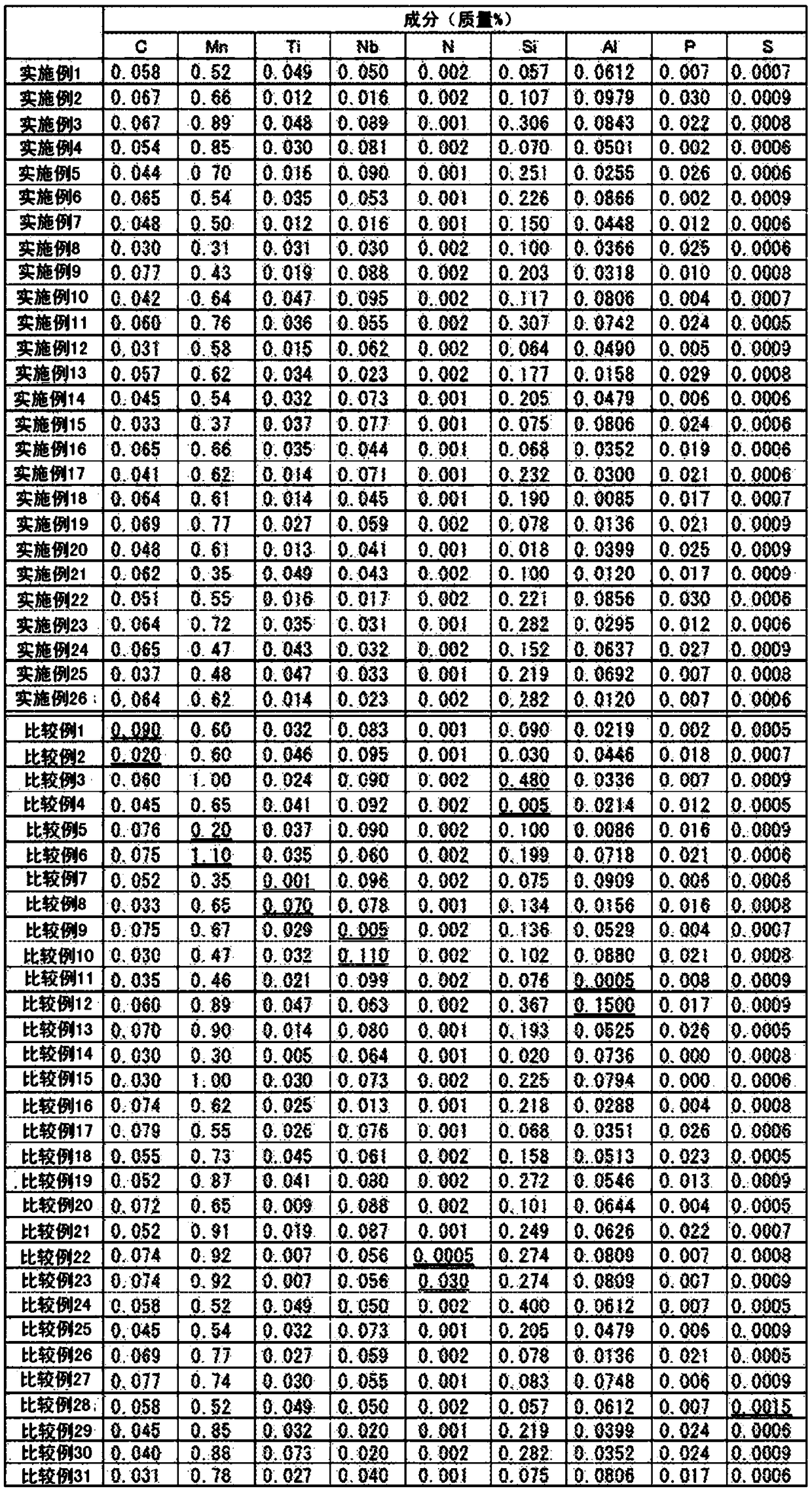

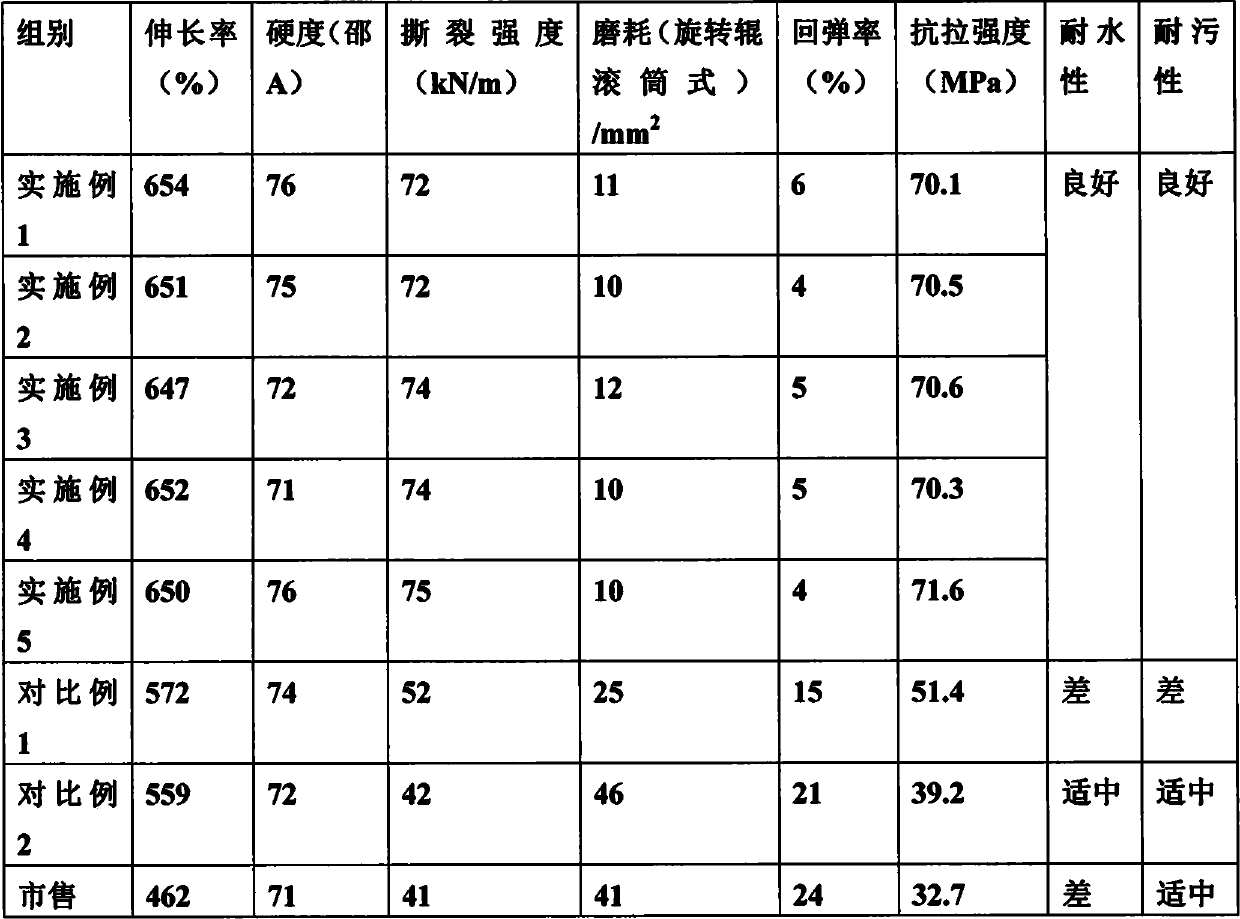

Electroseamed steel pipe for line pipe

InactiveCN109072379AGood acid resistanceLow yield ratioFurnace typesHeat treatment furnacesSteel tubeChemical composition

An electroseamed steel pipe for line pipe wherein: the chemical composition of the base metal section comprises, in mass%, C: 0.030% to less than 0.080%, Mn: 0.30-1.00%, Ti: 0.005-0.050%, Nb: 0.010-0.100%, N: 0.001-0.020%, Si: 0.010-0.450% and Al: 0.001-0.100%, the balance comprising Fe and impurities; CNeq represented by equation (1) is 0.190-0.320; Mn / Si ratio is at least 2.0; LR represented byequation (2) is at least 0.210; and when the metal structure of the base metal section is viewed at a 1000-fold magnification using SEM, the ferrite area ratio is 40-80% and the balance comprises tempered bainite. CNeq=C+Mn / 6+Cr / 5+(Ni+Cu) / 15+Nb+Mo+V... Equation (1) LR=(2.1*C+Nb) / Mn... Equation (2)

Owner:NIPPON STEEL CORP

Corrosion-resisting pipe for conveying chemicals

The invention discloses a corrosion-resisting pipe for conveying chemicals. The corrosion-resisting pipe is characterized by consisting of the following raw materials in parts by weight: 84-90 parts of pvc (poly vinyl chloride) resin, 6-10 parts of furfural resin, 3-4 parts of diisononyl phthalate, 10-12 parts of acrylonitrile-butadiene-styrene copolymers, 1-2 parts of sodium silicoaluminate, 2-3 parts of bentonite, 2-3 parts of carbon fibers, 0.7-1 part of stannous octoate, 1-2 parts of 1-hydroxyethyl-2-oleic imidazoline, 2-3 parts of oxidized polyethylene wax, and 8-15 parts of composite fillers. The corrosion-resisting pipe has excellent resistance to acid, alkali and corrosion and is not affected by moisture and soil acidity and alkalinity, so that the corrosion-resisting pipe does not need any anticorrosion treatment during pipeline laying.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

Halogen-free shell body material for lead storage battery and preparation method

The invention belongs to the technical field of lead storage battery materials and provides a halogen-free shell body material for a lead storage battery and a preparation method. The halogen-free shell body material for the lead storage battery is prepared from the following raw materials in parts by weight: 60 to 80 parts of ABS (Acrylonitrile Butadiene Styrene), 20 to 25 parts of polypropylene, 0.5 to 5 parts of a halogen-free flame retardant, 0.8 to 2.0 parts of an antioxidant, 1.7 to 2.5 parts of a dispersant, 3 to 6 parts of a toughening agent and 1 to 3 parts of a lubricant. The halogen-free shell body material for the lead storage battery has relatively good strength, good impact resistance, ageing resistance and acid resistance and good flame-retarding performance and is suitable for a lead acid battery shell body to use.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Aqueous acrylic water-resistant road marking coating and preparation method thereof

InactiveCN111205726AImprove safety and environmental performanceGood acid resistanceAnti-corrosive paintsMaleic anhydrideAcrylic acid

The invention provides an aqueous acrylic water-resistant road marking coating. The coating is prepared from the following raw materials in parts by weight: 100-200 parts of modified acrylic resin, 1-3 parts of diacetone acrylamide, 1-3 parts of adipic dihydrazine, 5-10 parts of neopentyl glycol, 10-15 parts of maleic anhydride, 3-7 parts of adipate, 10-20 parts of a coalescing agent, 5-10 parts of a dispersing agent and 5-10 parts of a defoaming agent. The preparation method is simple, and the prepared coating is an aqueous coating, has good environmental friendliness and low VOC emission, also has good gloss retention, water resistance, acid resistance and chemical corrosion resistance, can form a film quickly, finely and uniformly, has good strength and mechanical properties after filmforming, and has a wide application prospect.

Owner:王春林

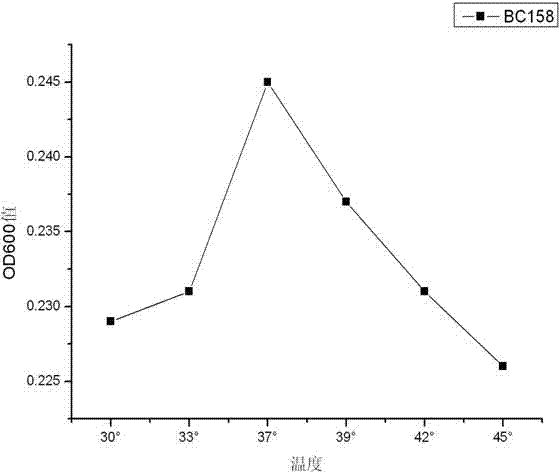

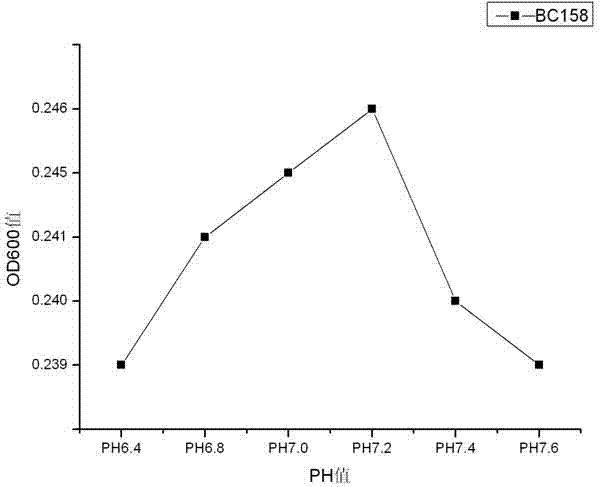

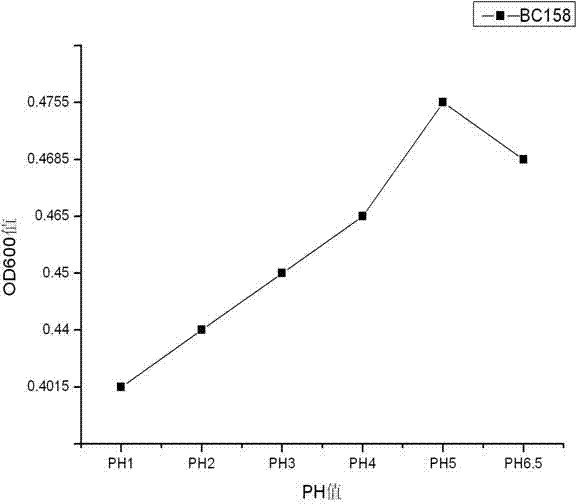

Bacillus cereus and probiotics powder thereof as well as preparation and application of probiotics powder

ActiveCN103525718BGood acid resistanceGood antibacterial activityBacteriaAnimal feeding stuffBacillus sp. BIFermentation broth

A kind of Bacillus cereus and its probiotic powder and the preparation and application of the bacteria powder, the Bacillus cereus BC158 with the preservation number of CGMCC No. 7433 obtained from the feces of healthy piglets, which has a good Excellent acid resistance, bile salt resistance, high adhesion, high safety, has certain inhibitory effect on common intestinal pathogenic bacteria, and the bacteria can produce amylase, protease, cellulase; Bacillus cereus probiotics The preparation of powder adopts the four-stage cultivation process of step-by-step amplification, and the ventilation and agitation deep liquid fermentation technology realizes the high-density cultivation of Bacillus cereus BC158. high-density recovery; the preparation method is simple and low-cost, the spore rate in the prepared probiotic powder is above 95%, and the live bacteria content of Bacillus cereus is 3×109-5×1010CFU / g, which can be applied to animals Feed additives for farming.

Owner:河南省岳氏精忠科技有限公司

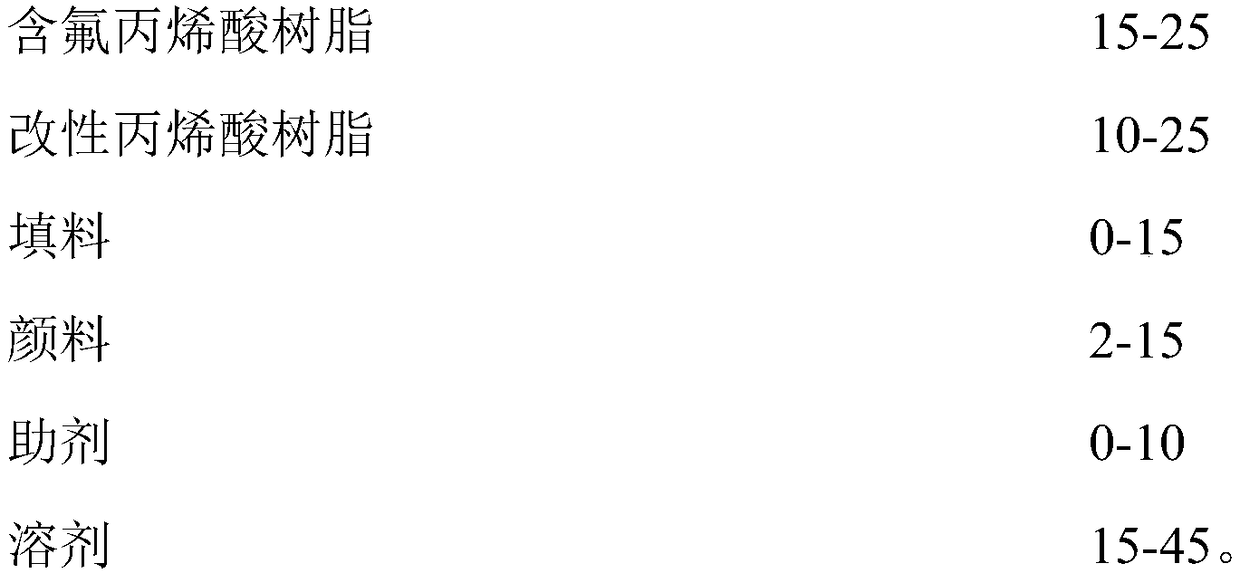

Anticorrosive mirror back protecting coating and preparation method thereof

ActiveCN109337490AGood acid resistanceIncrease surface free energyAnti-corrosive paintsSolventChemistry

The invention discloses an anticorrosive mirror back protecting coating and a preparation method thereof, and relates to the field of mirror back protecting coatings. The coating comprises the following raw materials in percent by weight: 15-25% of fluorine-containing acrylic resin, 10-25% of modified acrylic resin, 0-15% of fillers, 2-15% of a pigment, 0-10% of an auxiliary agent and 15-45 % of asolvent. Through the use of the fluorine-containing acrylic resin and the modified acrylic resin as main film-forming substances, the anticorrosive mirror back protecting coating has a high film-forming speed, excellent corrosion resistance, acid and alkali resistance and water resistance, can be applied to shower coating, spray coating or roll coating, adopts a simple and easily operated coatingprocess, and has a good coating effect.

Owner:广东鑫皇冠新材料有限公司

Acid-resistant nano-separation membrane having enhanced flow rate, and method for manufacturing same

ActiveUS20200094196A1Increase flow rateGood acid resistanceMembranesReverse osmosisSmelting processAcid resistance

The present invention relates to an acid-resistant nanomembrane with an improved flow rate and a method of producing the acid-resistant nanomembrane, and more particularly, to an acid-resistant nanomembrane with an improved flow rate, which can also be used under strong-acid and high-temperature conditions for the recovery of rare metals, valuable metals, and the like generated in a smelting process and which exhibits both excellent flow rate and excellent acid resistance, and a method of producing the acid-resistant nanomembrane.

Owner:TORAY ADVANCED MATERIALS KOREA

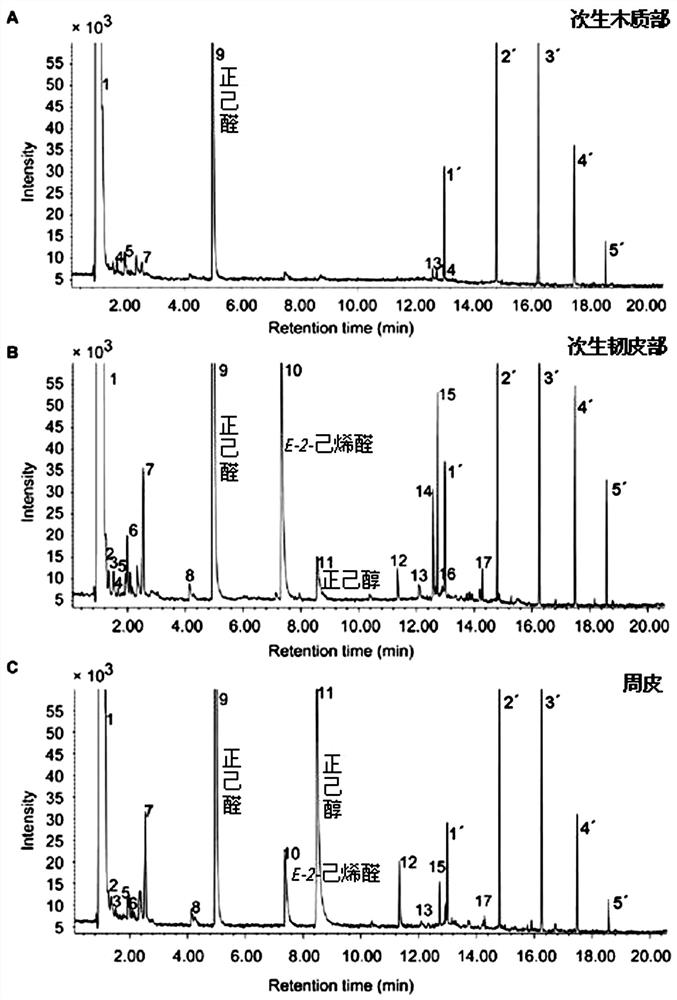

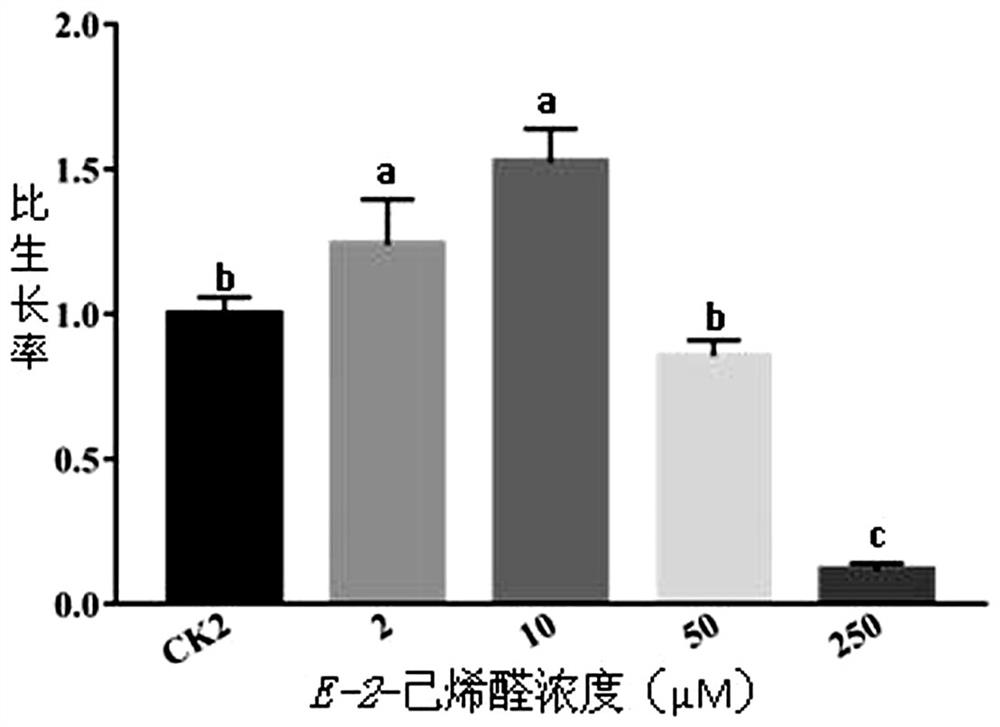

Astragalus growth-promoting endophytic bacteria and its growth-promoting method and application

ActiveCN108467839BGrowth inhibitionLower levelPlant growth regulatorsBacteriaBiotechnologyMedicinal herbs

The invention belongs to the field of astragalus growth-promoting technology, and provides astragalus growth-promoting endophytic bacteria and its growth-promoting method and application in order to solve the current problems of astragalus membranaceus growth promotion and quality improvement. Promoting endophytes are: Sphingobacterium ( Sphingobacterium sp. ) strain KSCO1 and Pseudomonas phrysalis ( Pseudomonas poae ) strain KSCO2; on November 21, 2017, it was preserved in the General Microbiology Center of China Microbiological Culture Collection Management Committee, and the preservation numbers are: CGMCC No.14945, CGMCC No.14946. 2~10μM E‑2 ‑Hexenal and 5-625 μM n-hexanol promoted the growth of KSC01, and 25-625 μM n-hexanol promoted the growth of KSCO2. A green, environment-friendly pesticide component with no medicinal material residue is provided for the cultivation of Chinese medicinal material Astragalus membranaceus.

Owner:SHANXI UNIV

Manufacturing method of novel metal door and window profile

The invention discloses a manufacturing method of a novel metal door and window profile, which comprises the following steps: 1) preparing metal raw materials: sequentially pouring copper, silicon, magnesium, manganese and zinc into a smelting furnace, heating, and preserving heat after the metal is completely smelted to obtain mixed metal I; adding rare earth into the mixed metal I, stirring and heating to obtain mixed metal II; nickel, chromium, titanium, boron, zirconium and strontium are sequentially added into the second mixed metal, then the second mixed metal is transferred into a refining furnace to be refined, and a first material is obtained; the first material is poured into a mold to be cooled to the normal temperature and then subjected to quenching and hot rolling treatment, and a second material is obtained; and (2) door and window sectional material manufacturing: cutting the second material into a door and window blank, performing engraving or die casting work on the blank through an engraving machine or a die casting machine, then coloring the blank, and finally cutting the door and window sectional material along a blanking line.

Owner:怀化林源门窗幕墙有限公司

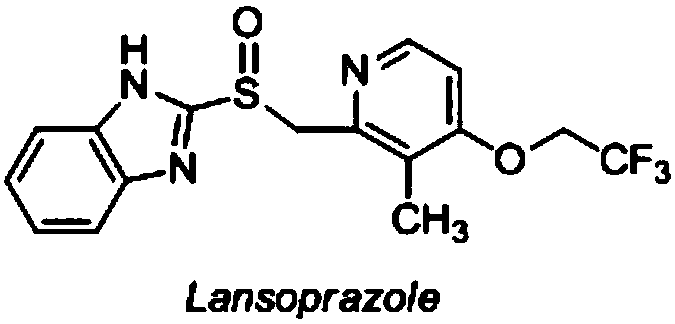

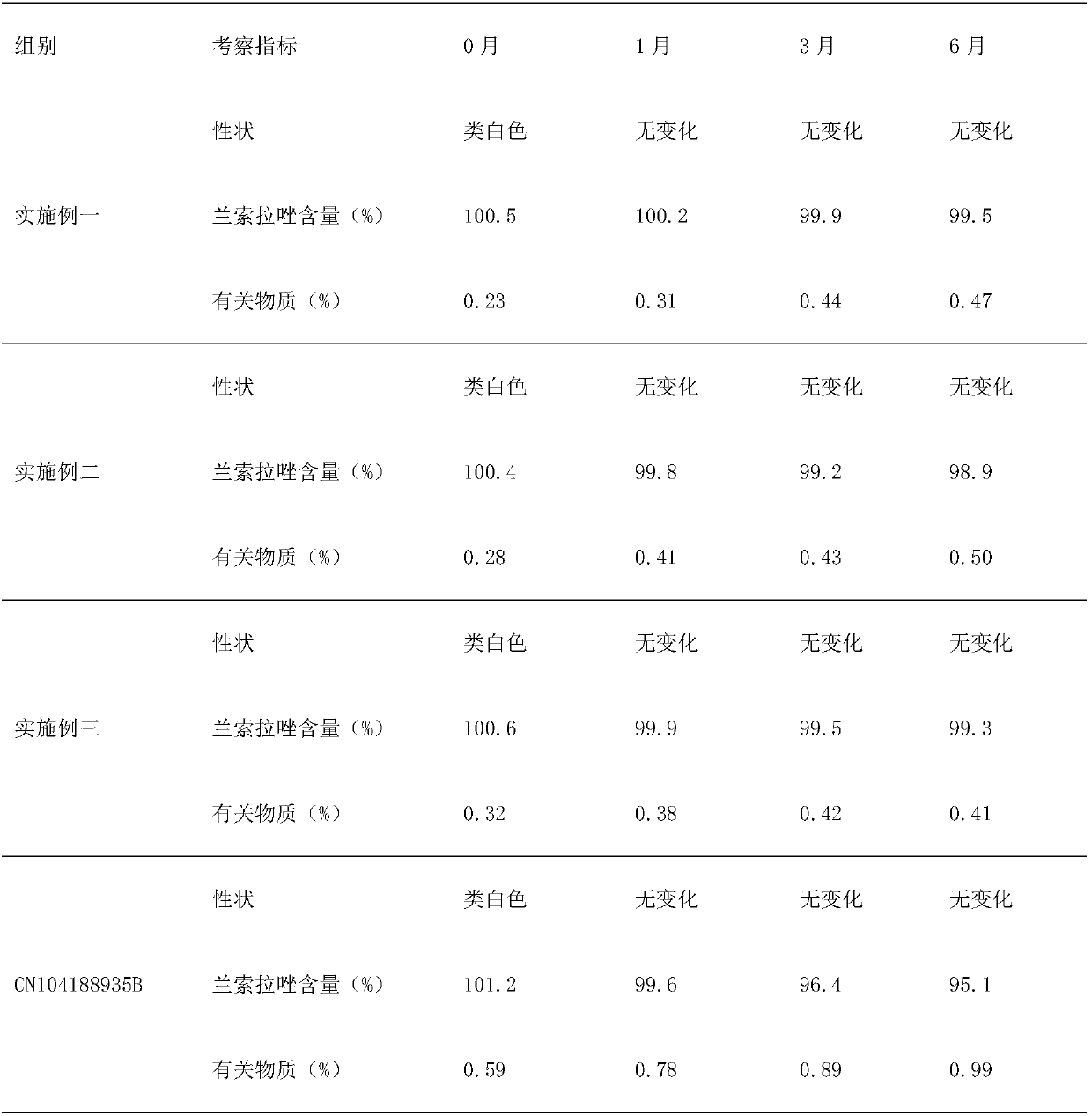

Lansoprazole enteric-coated tablet

InactiveCN107693503AGood acid resistanceGood stabilityOrganic active ingredientsDigestive systemProtein syntheticsCalcium carbonate

The invention provides a lansoprazole enteric-coated tablet, which is prepared from lansoprazole, a filler, an enteric coating layer, a disintegrating agent and a binding agent. The filer is calcium carbonate; the enteric coating layer is hydroxypropyl methyl cellulose phthalate; the disintegrating agent is microcrystalline cellulose; the binding agent is alginic acid. The invention discloses a preparation method of the lansoprazole enteric-coated tablet and new application of the lansoprazole enteric-coated tablet on improving liver protein synthesis.

Owner:NANJING ZHENGLIANG MEDICAL TECH

Acid-proof anti-yellowing hook-and-loop fastener and preparation method thereof

The invention discloses an acid-proof anti-yellowing hook-and-loop fastener and a preparation method thereof. The preparation method of the acid-proof anti-yellowing hook-and-loop fastener comprises the steps of conducting dip dyeing, cleaning and finishing through a cleaning and finishing agent; dehydrating the cleaned chinlon hook-and-loop fastener, and whitening the chinlon hook-and-loop fastener in a whitening finishing liquid; dehydrating the chinlon hook-and-loop fastener subjected to whitening finishing; preparing an anti-oxidation finishing agent, and carrying out anti-oxidation finishing on the chinlon hook-and-loop fastener; carrying out acid-proof anti-yellowing coating on the finished chinlon hook-and-loop fastener; and drying the sprayed chinlon hook-and-loop fastener. According to the acid-proof anti-yellowing hook-and-loop fastener and the preparation method thereof provided by the invention, the acid-proof anti-yellowing hook-and-loop fastener is good in acid-proof performance, the acid-proof anti-yellowing coating adhesive is safe, odorless, not prone to falling off, and lasting in effect, the hook-and-loop fastener is high in strength and difficult to permeate and erode by acid liquor or other chemicals, and damage to the hook-and-loop fastener is greatly reduced.

Owner:福建恒春织造股份有限公司

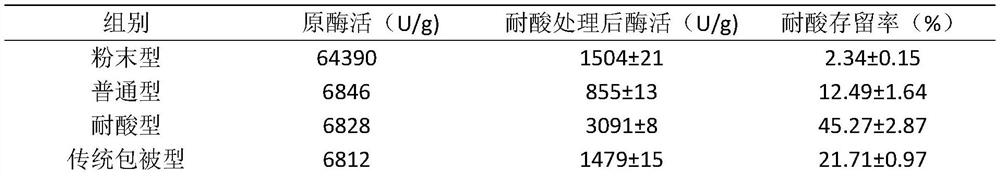

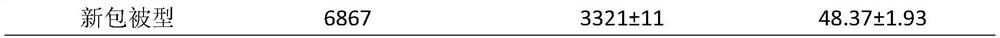

Acid-resistant enzyme preparation particles and preparation method thereof

PendingCN114767639AGood acid resistanceIncreased enzyme activity retentionPeptide/protein ingredientsInorganic non-active ingredientsEnzymeOrganosolv

The invention discloses an acid-resistant enzyme preparation particle, the raw materials of the particle comprise a solid raw material composed of a powdery enzyme preparation and an auxiliary material, and an enteric emulsion, the powdery enzyme preparation and the auxiliary material are uniformly mixed, then the enteric emulsion is added, granulation and drying are performed after uniform mixing, and the acid-resistant enzyme preparation particle can be obtained. The enzyme preparation particles are good in acid resistance, compared with a traditional coating method, acid-resistant tests prove that the enzyme activity retention rate is increased by 23%, and application of the enzyme preparation in animal bodies is better facilitated. Compared with a traditional coating mode, the preparation method disclosed by the invention is simple to operate, low in equipment requirement and free from the use risk of an organic solvent, the production cost is greatly saved, and the energy consumption is reduced.

Owner:TIANJIN BIOFEED TECH CO LTD

High-temperature anti-corrosion coating of railway track base plate tool steel material

InactiveCN112608659AImprove high temperature resistanceImprove corrosion resistanceFireproof paintsAnti-corrosive paintsFiberFirming agent

The invention discloses a high-temperature corrosion-resistant coating of a railway track base plate tool steel material, which comprises a first high-temperature corrosion-resistant coating, a second high-temperature corrosion-resistant coating and a third high-temperature corrosion-resistant coating. The following components of the first high-temperature corrosion-resistant coating in parts by weight: 50-80 parts of epoxy resin, 4-22 parts of a curing agent, 6-18 parts of a functional filler, 0.5-3 parts of a pigment, 1-4 parts of an antifoaming agent, 0.5-2 parts of a degassing agent, 1-4 parts of a leveling agent, 3-4 parts of a sand streak agent, 0.5-1.5 parts of a dispersant and 1-5 parts of graphene. The second high-temperature corrosion-resistant coating is prepared from the following components in parts by weight: 50-90 parts of aluminum oxide powder, 5-7 parts of aluminum oxide fibers and 20-40 parts of zinc white powder. By arranging the first high-temperature anti-corrosion coating, the second high-temperature anti-corrosion coating and the third high-temperature anti-corrosion coating, the high temperature resistance and corrosion resistance of the high-temperature anti-corrosion coatings are effectively improved, and therefore the service life of the base plate material is prolonged.

Owner:JIANGSU JINYANG MACHINERY

Treatment method for improving surface corrosion and wear resistance of pig iron casting

InactiveCN112301211AImprove corrosion and wear resistanceGood acid resistanceCleaning using liquidsSurface corrosionCorrosion resistant

The invention discloses a treatment method for improving the surface corrosion and wear resistance of a pig iron casting, and belongs to the technical field of pig iron casting surface treatment. Thetreatment method comprises the following step (1) of mud water soaking treatment; the step (2) of microwave activation treatment; the step (3) of freezing treatment; the step (4) of dipping treatment;and the step (5) of laser shock wave strengthening treatment. According to the treatment method for improving the surface corrosion and abrasion resistance of the pig iron casting, the pig iron casting treated through the method has high resistance to acid, alkali and salt corrosion, the quality of the pig iron casting is effectively improved, and the service life of the pig iron casting is prolonged.

Owner:安徽省含山县威建铸造厂(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com