Coating composition

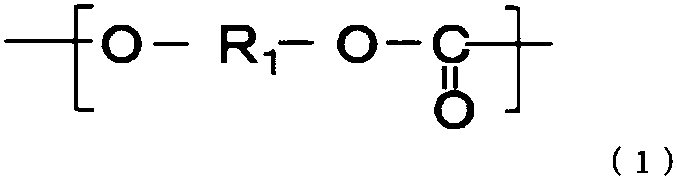

A composition and coating technology, applied in polycarbonate coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as the inability to obtain coating films, and achieve the effects of excellent acid resistance and excellent initial scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

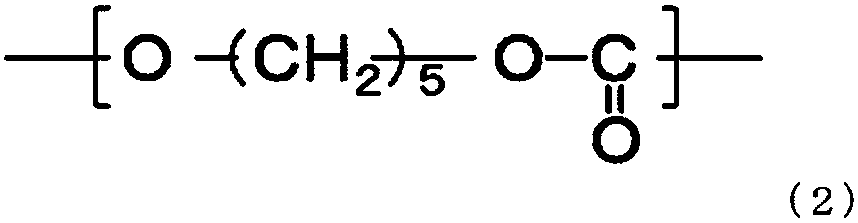

[0135] As a hydroxyl-containing acrylic resin, Setalux 1152 (xylene / methoxypropyl acetate mixed solution, solid content 61% by mass, solid content-equivalent hydroxyl value 139 mgKOH / g, hydroxyl-containing acrylic resin) was added as a hydroxyl-containing acrylic resin. Number average molecular weight (3000) 295 g, polycarbonate polyol PC1 20 g, leveling agent BYK-331 (manufactured by BYK Chemical Co., Ltd.) 2.06 g, dibutyltin dilaurate (manufactured by Air Products Industry Co., Ltd.) 1.2 g, and the mixed solvent of xylene / butyl acetate (70 / 30) as diluent, and after stirring, obtain the coating main agent (the polycarbonate polyol in the main agent except solvent) of 50 mass % of solid content ratio is 10%). Duranate TKA-100 (manufactured by Asahi Kasei Co., Ltd.: hexamethylene diisocyanate-based isocyanurate type curing agent, NCO content = 21.8 wt%, isocyanate group in 1 molecule: 3) was added thereto as a curing agent. It mixed so that NCO / OH molar ratio=1.0 / 1.0, and prod...

Embodiment 2

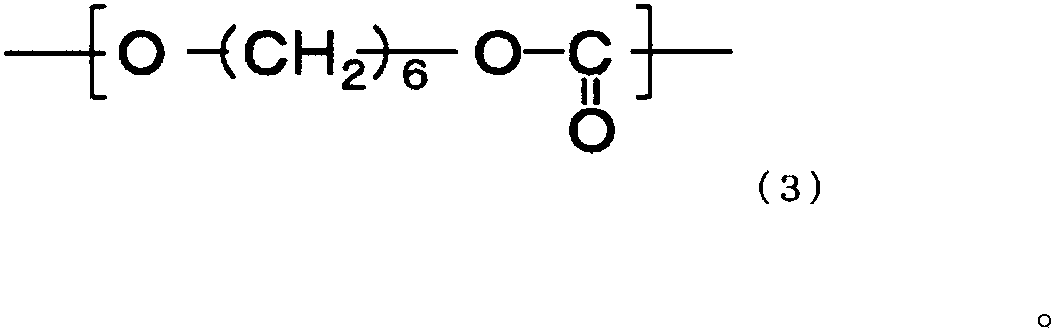

[0137] A coating composition was produced by the method similar to Example 1 except having used polycarbonate polyol PC2 instead of polycarbonate polyol PC1 of Example 1. The coating film performance was evaluated, and the results are shown in Table 1.

Embodiment 3、4

[0139] A coating composition was obtained in the same manner as in Examples 1 and 2 except that the amount of Setalux 1152 added in Example 1 was 230 g and the amount of polycarbonate polyol added was 60 g.

[0140] The coating film performance was evaluated, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com