Treatment method for improving surface corrosion and wear resistance of pig iron casting

A corrosion-resistant and wear-resistant technology for pig iron castings, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as corrosion and wear, economic losses, etc., to improve corrosion and wear resistance and improve quality , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

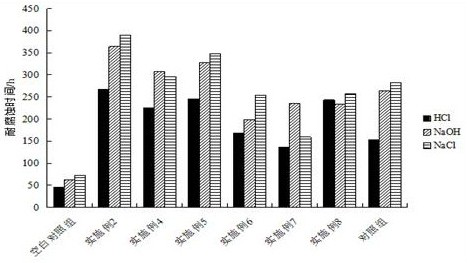

Examples

Embodiment 1

[0041] A treatment method for improving the corrosion and wear resistance of the surface of pig iron castings, comprising the steps of:

[0042] (1) Mud water immersion treatment:

[0043] Put river mud and pure water together in a mixing tank according to the weight-to-volume ratio of 1g:20mL, stir and mix evenly, then immerse the pig iron casting in the muddy water obtained, after ultrasonic treatment for 1 hour, filter the pig iron casting, and remove the muddy water on the surface of the pig iron casting Clean and dry for later use; the number of live bacteria in the river mud is 3000CFU / mL; during ultrasonic treatment, the frequency of ultrasonic wave is controlled to be 20kHz;

[0044] (2) Microwave activation treatment:

[0045] Place the pig iron casting obtained after soaking in muddy water in step (1) in a microwave environment for microwave activation treatment, and treat it at 400W for 20 minutes;

[0046] (3) Freezing treatment:

[0047] Take out the pig iron c...

Embodiment 2

[0053] A treatment method for improving the corrosion and wear resistance of the surface of pig iron castings, comprising the steps of:

[0054] (1) Mud water immersion treatment:

[0055] The river mud and pure water are placed in the stirring tank together according to the weight volume ratio of 1g:25mL and stirred evenly, then the pig iron casting is immersed in the muddy water obtained, after ultrasonic treatment for 1.5h, the pig iron casting is filtered, and the pig iron casting surface is Clean the muddy water and dry it for later use; the number of viable bacteria in the river mud is 4000CFU / mL; the frequency of the ultrasonic wave is controlled at 50kHz during ultrasonic treatment;

[0056] (2) Microwave activation treatment:

[0057] Place the pig iron casting obtained after soaking in muddy water in step (1) in a microwave environment for microwave activation treatment, and treat it at 450W for 25 minutes;

[0058] (3) Freezing treatment:

[0059] Take out the pi...

Embodiment 3

[0065] A treatment method for improving the corrosion and wear resistance of the surface of pig iron castings, comprising the steps of:

[0066] (1) Mud water immersion treatment:

[0067] Put river mud and pure water together in a mixing tank according to the weight-to-volume ratio of 1g:30mL, stir and mix evenly, then immerse the pig iron casting in the obtained muddy water, after ultrasonic treatment for 2 hours, filter the pig iron casting, and remove the muddy water on the surface of the pig iron casting Clean up and dry for later use; the number of live bacteria in the river mud is 5000CFU / mL; during ultrasonic treatment, the frequency of ultrasonic wave is controlled to be 80kHz;

[0068] (2) Microwave activation treatment:

[0069] Place the pig iron casting obtained after soaking in mud water in step (1) in a microwave environment for microwave activation treatment, and treat it at 500W for 30 minutes;

[0070] (3) Freezing treatment:

[0071] Take out the pig iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com