Patents

Literature

182results about How to "Improve wear resistance and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

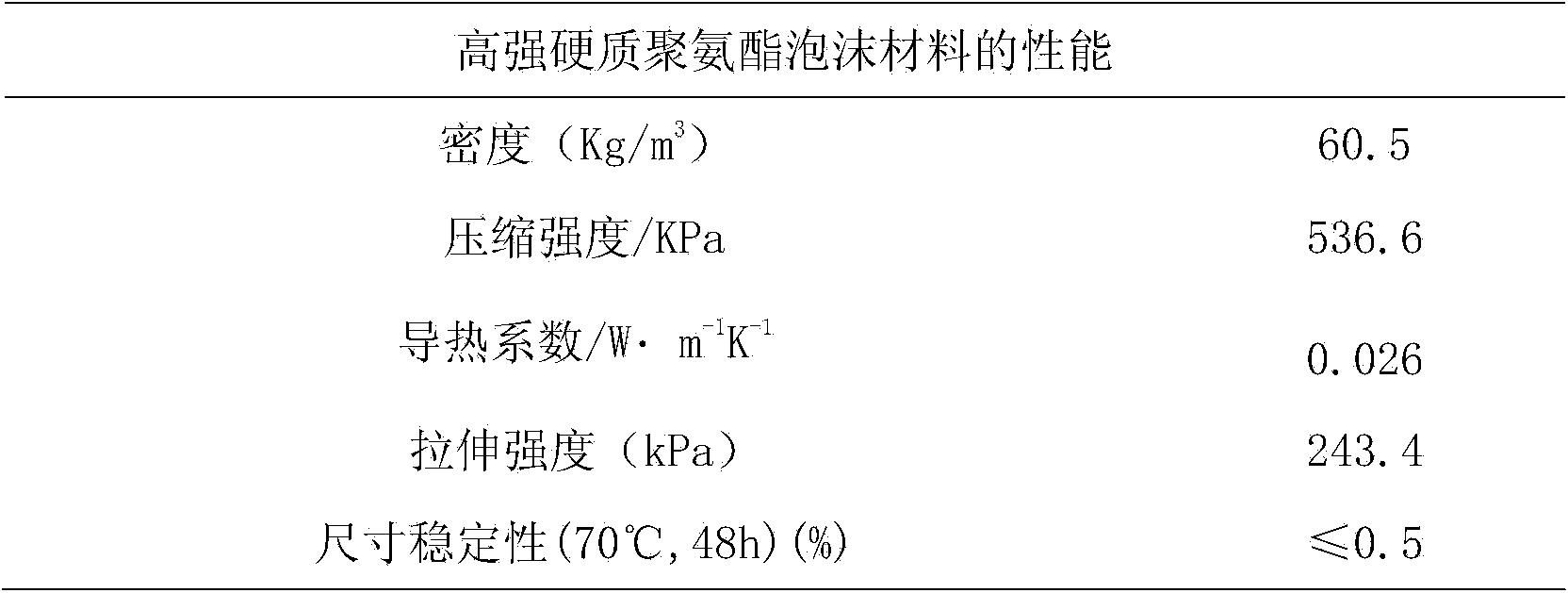

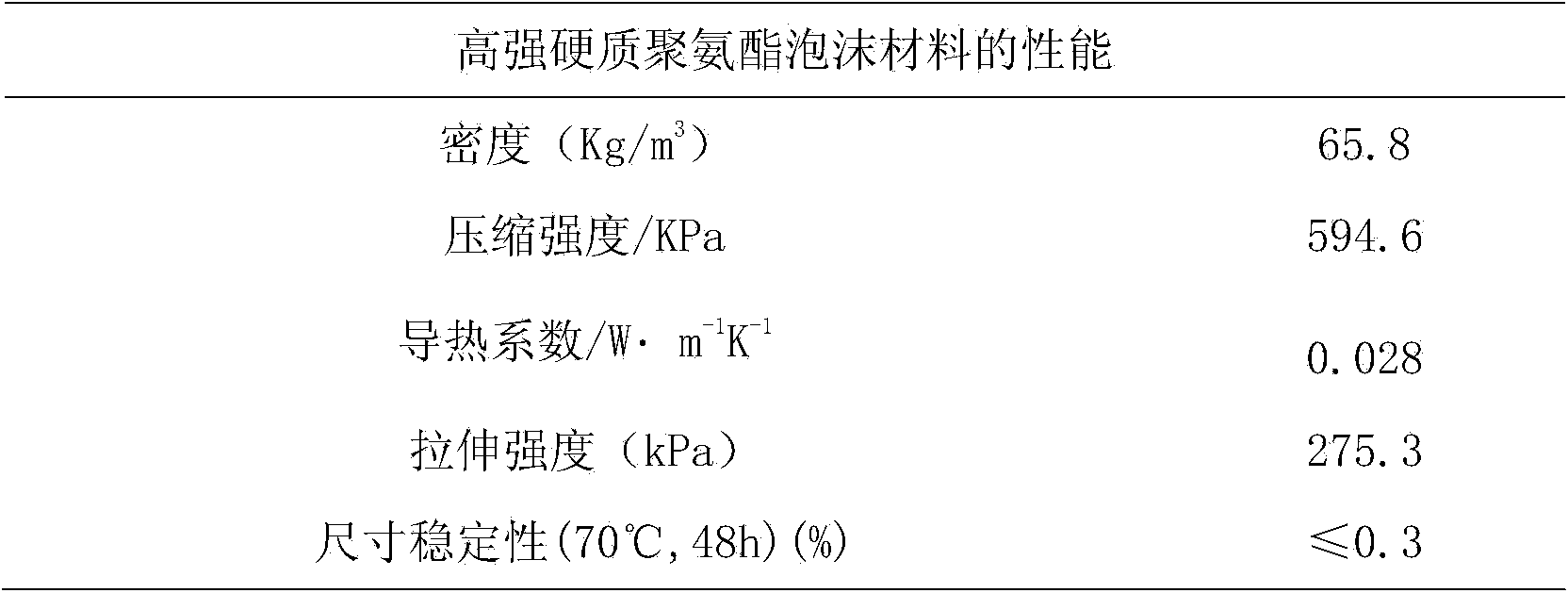

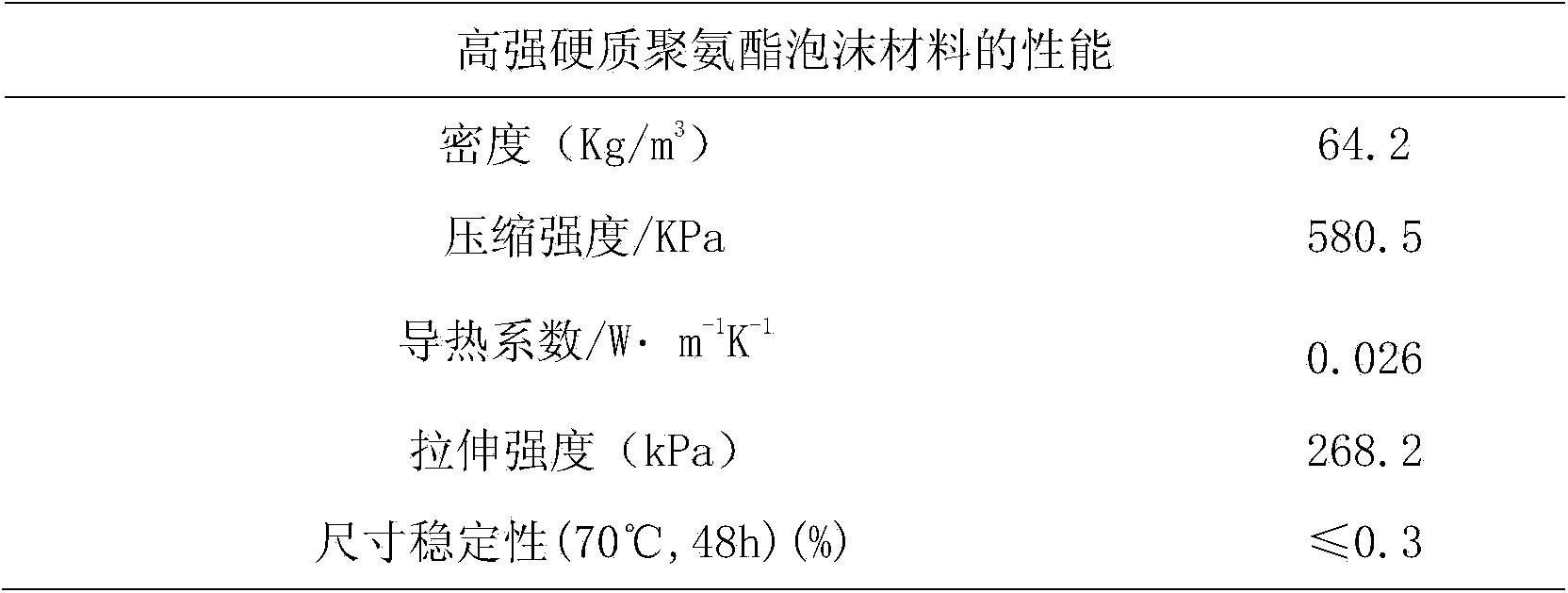

Hard polyurethane foam material and preparation method thereof

The invention discloses a hard polyurethane foam material. The hard polyurethane foam material comprises an A component and a B component, wherein the A component is polymethylene polyphenyl polyisocyanate, and the B component comprises a polyol, a foam stabilizer, a catalyst, a foaming agent, a chain extender, a cross-linking agent and a composite reinforcing material. The hard polyurethane foam material has characteristics of high strength, light weight, low heat conduction, good thermal insulation effects, good sound insulation, foam pores mainly being a closed-pore type, capability of bearing large load, good wear resistance, good corrosion resistance, good dimension stability, and the like, and is suitable for the fields of insulating materials, thermal insulation materials, thermal insulation materials of building walls, sandwich laminated plates, structural materials, sound insulation materials, aviation materials, spaceflight materials, road repairing, and the like. The hard polyurethane foam material can also be used as wood-imitation materials with high strength and high density, and is suitable for manufacturing various furniture, etc..

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

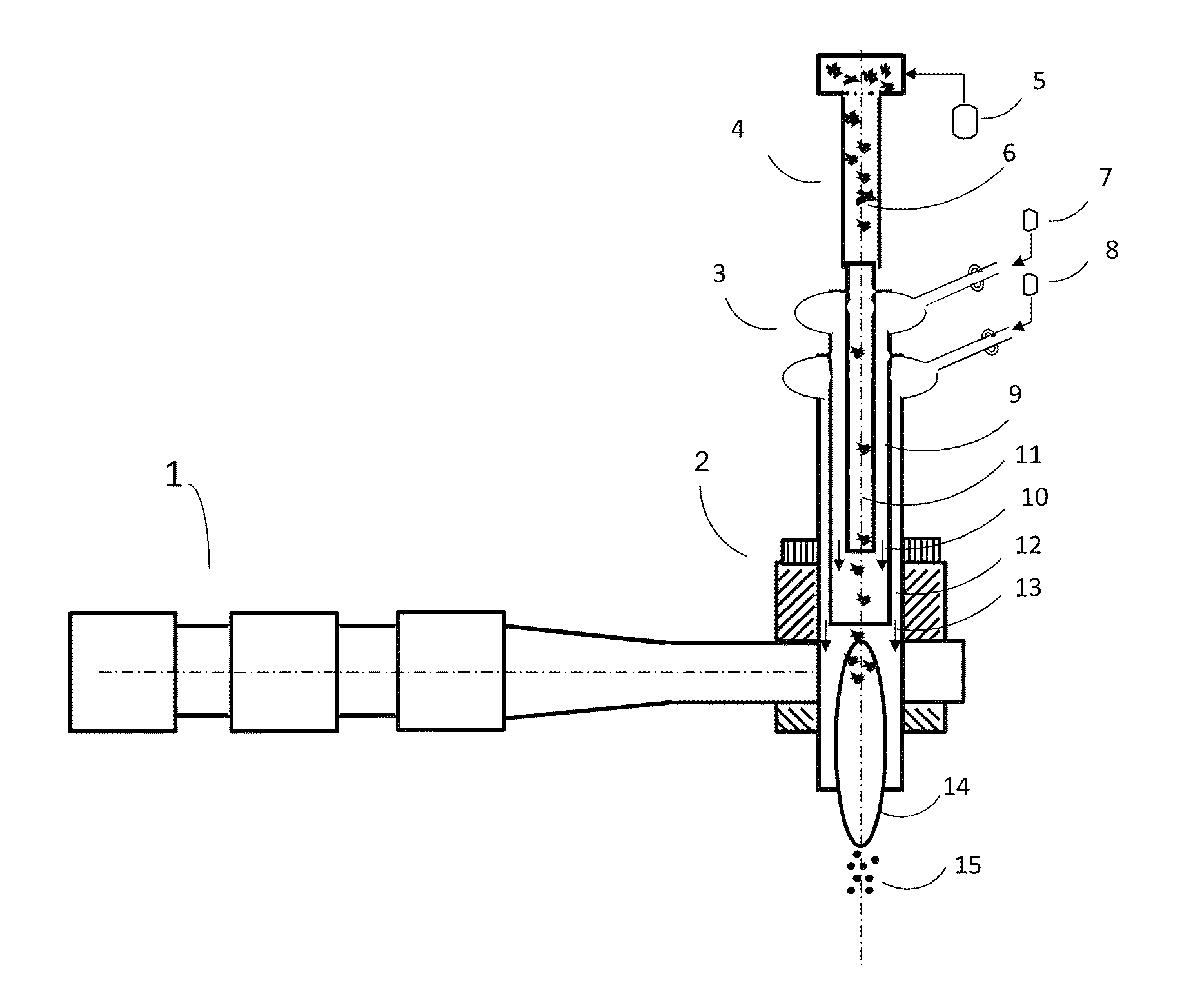

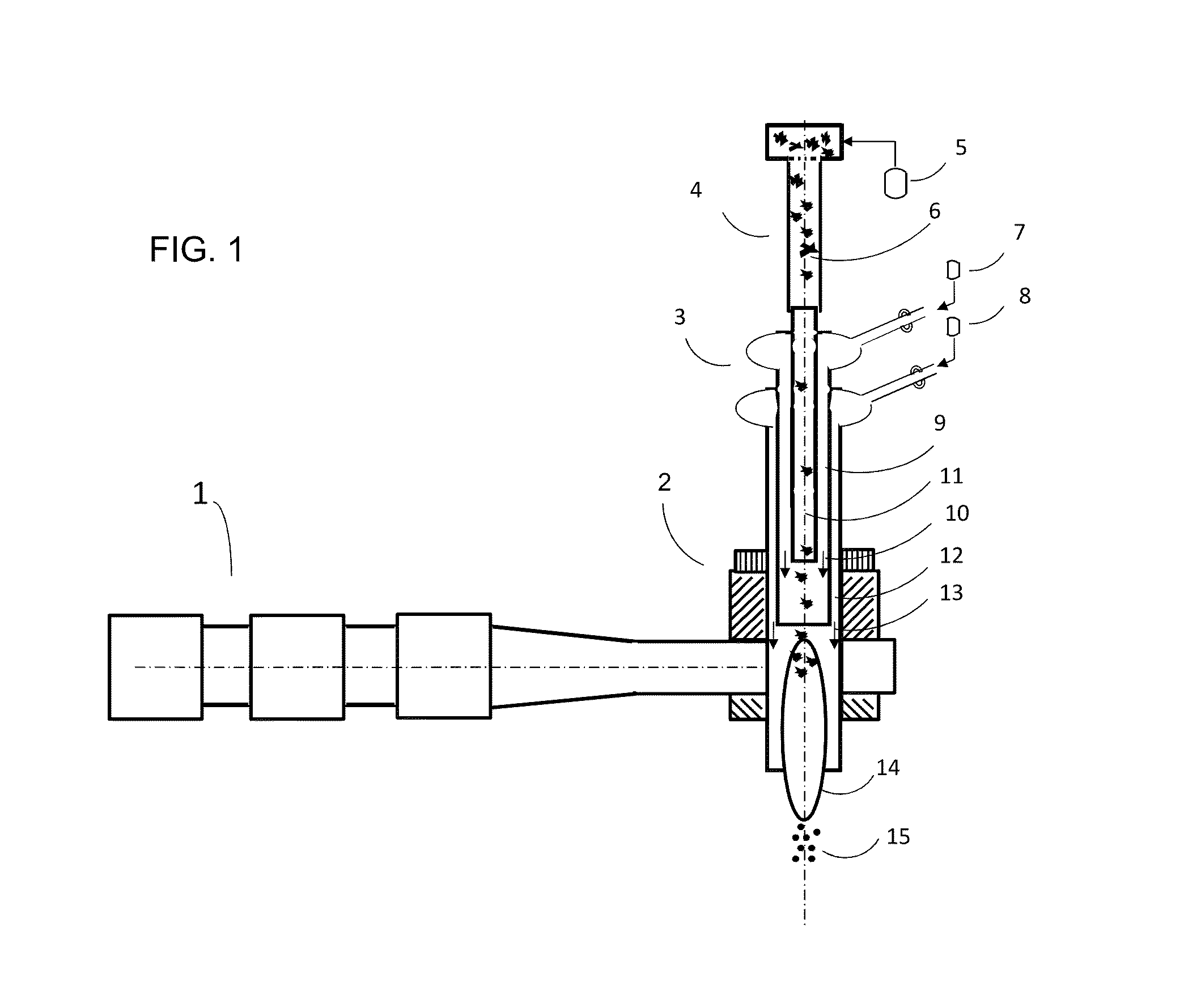

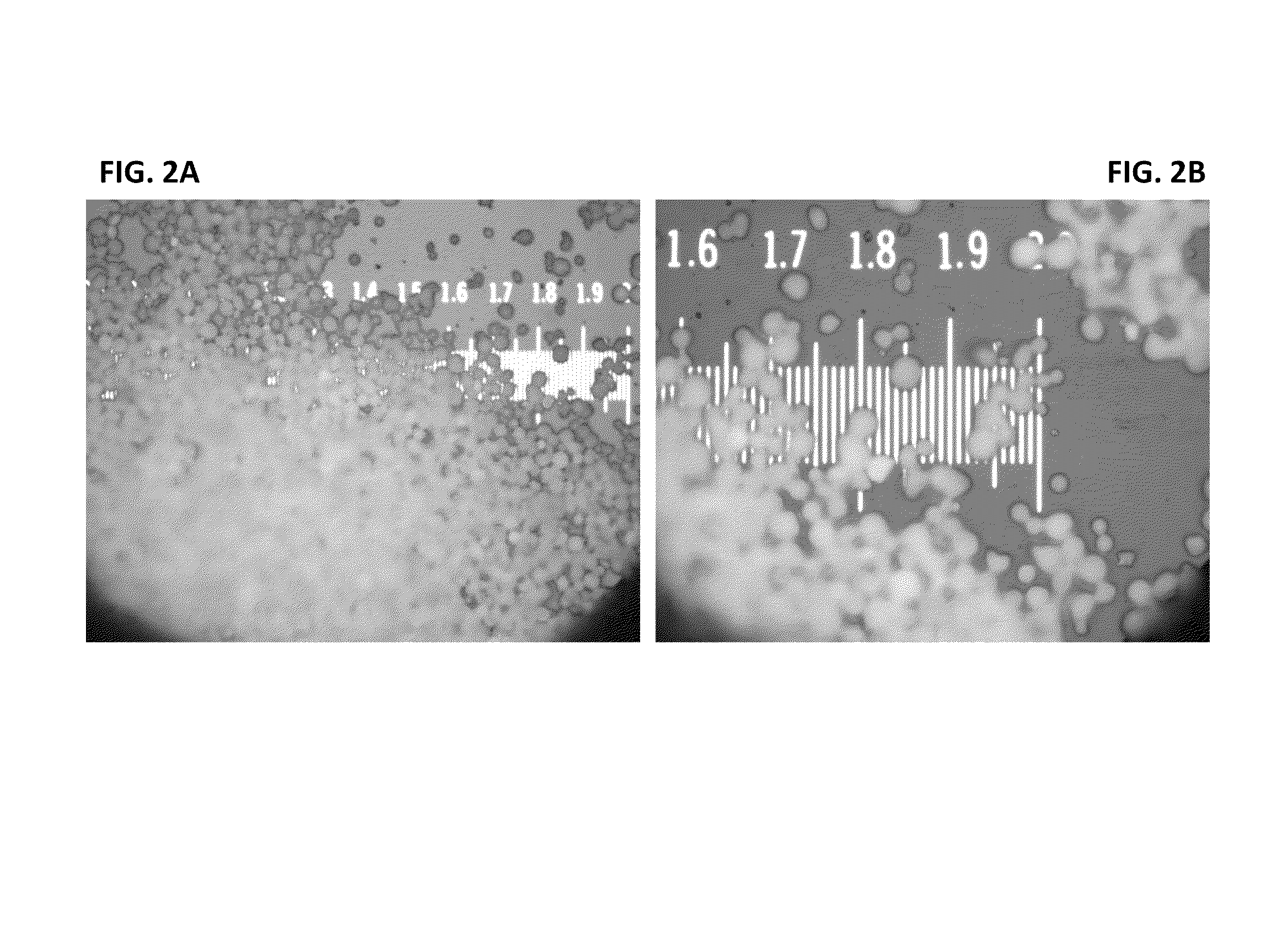

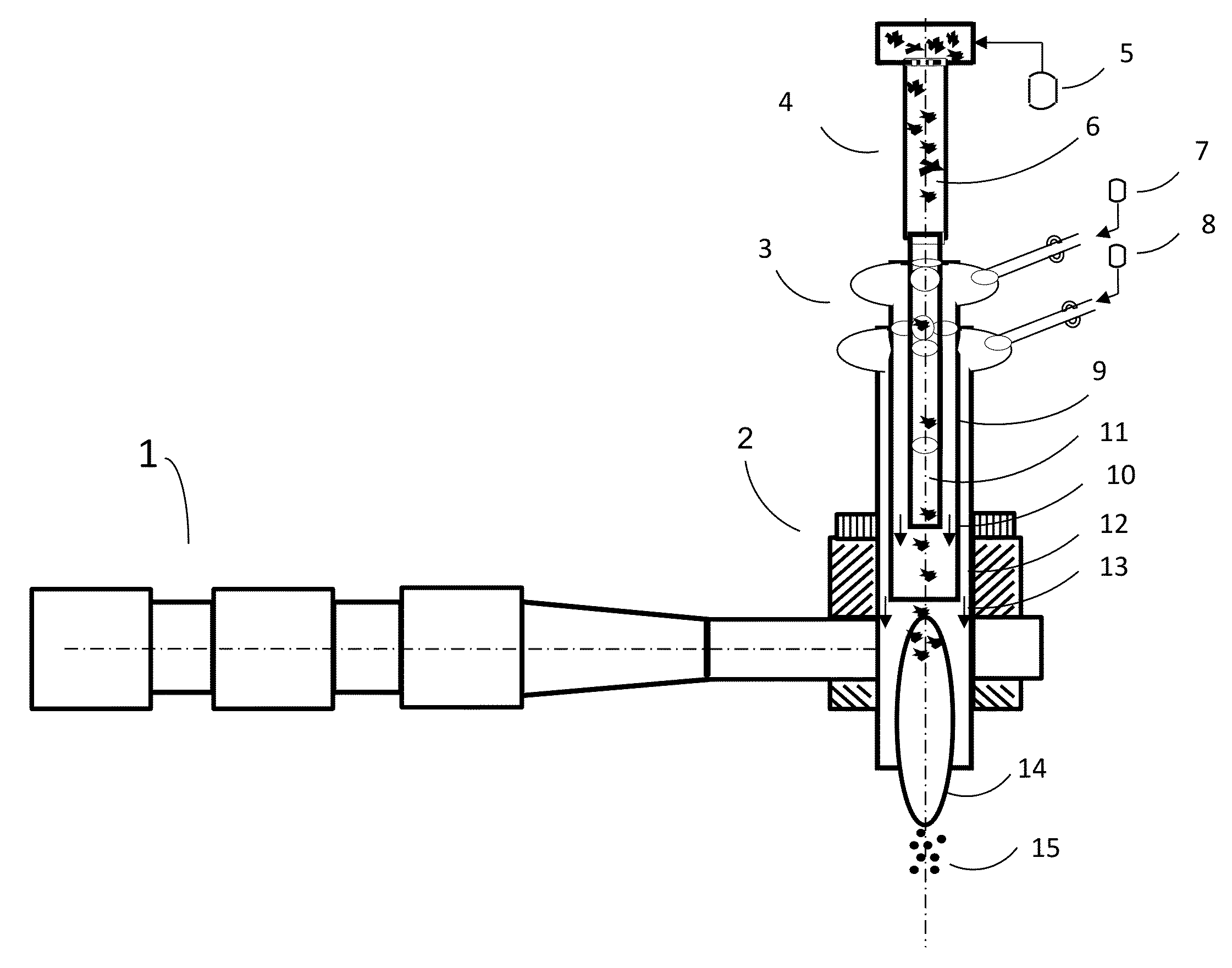

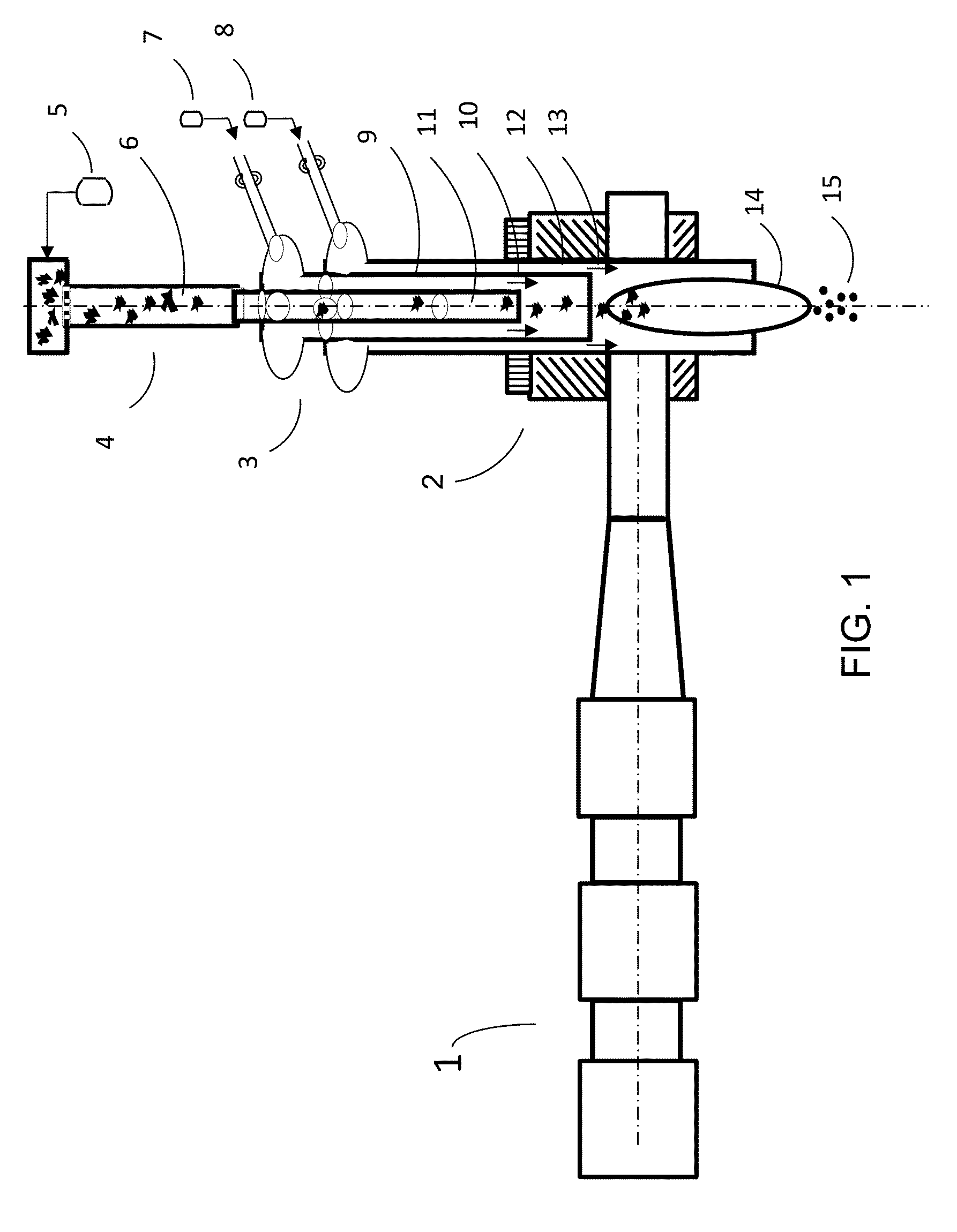

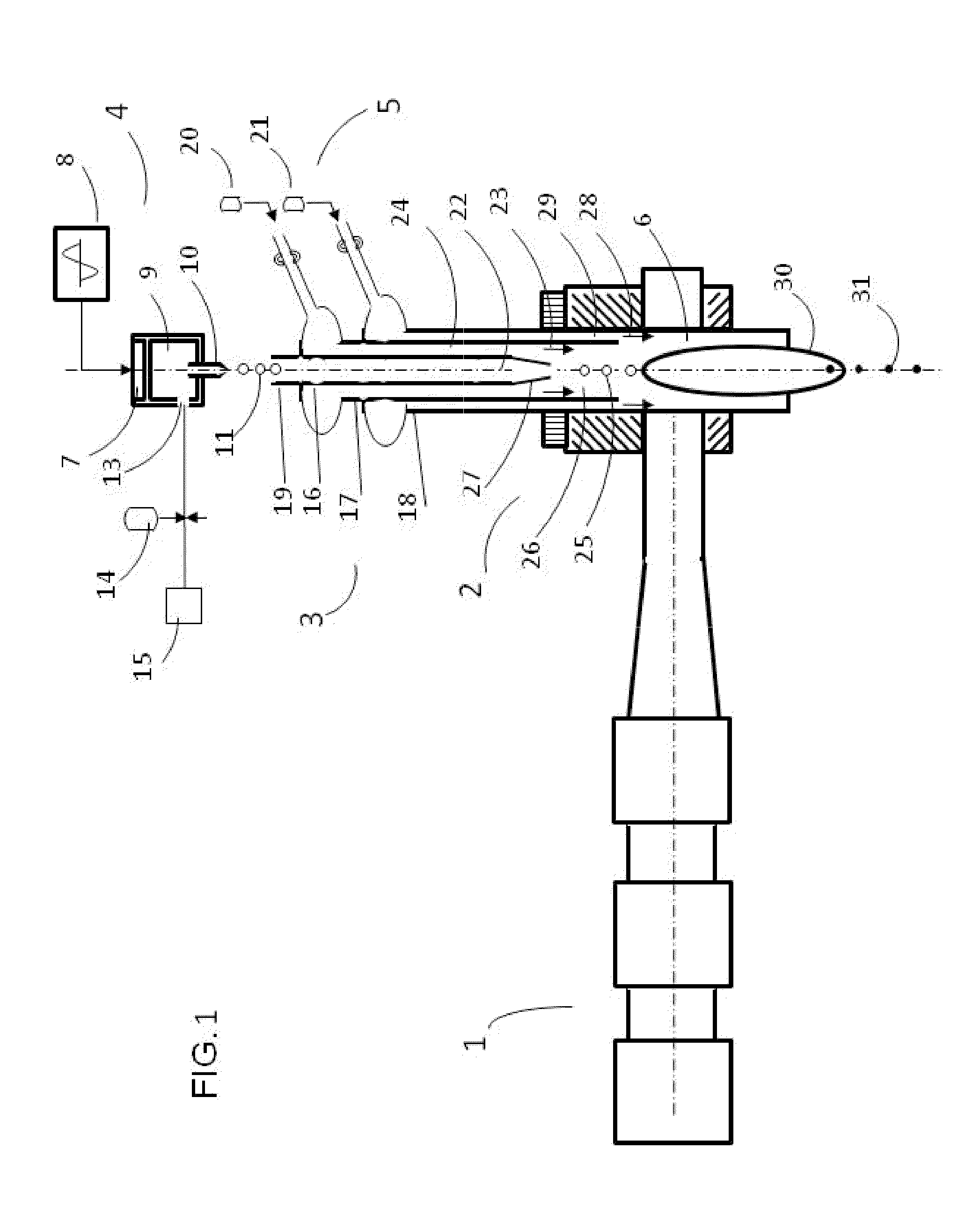

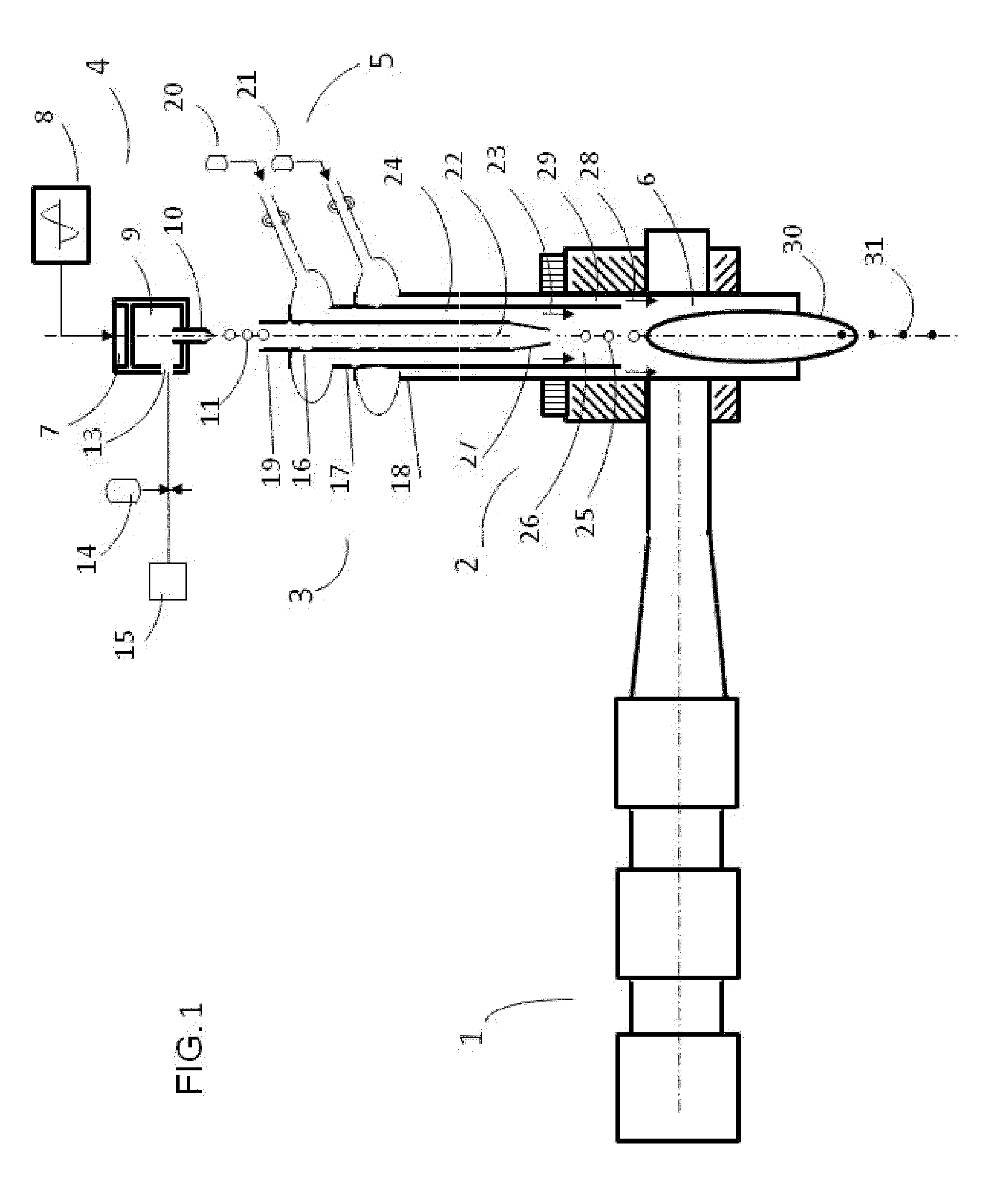

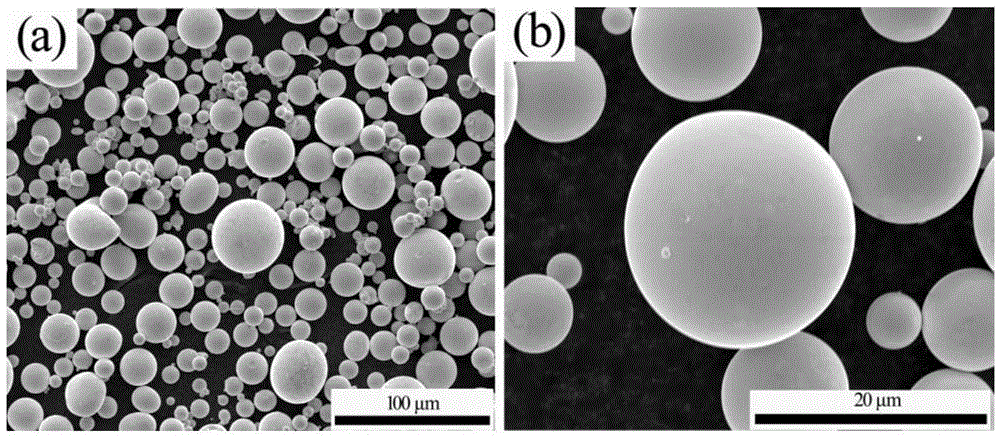

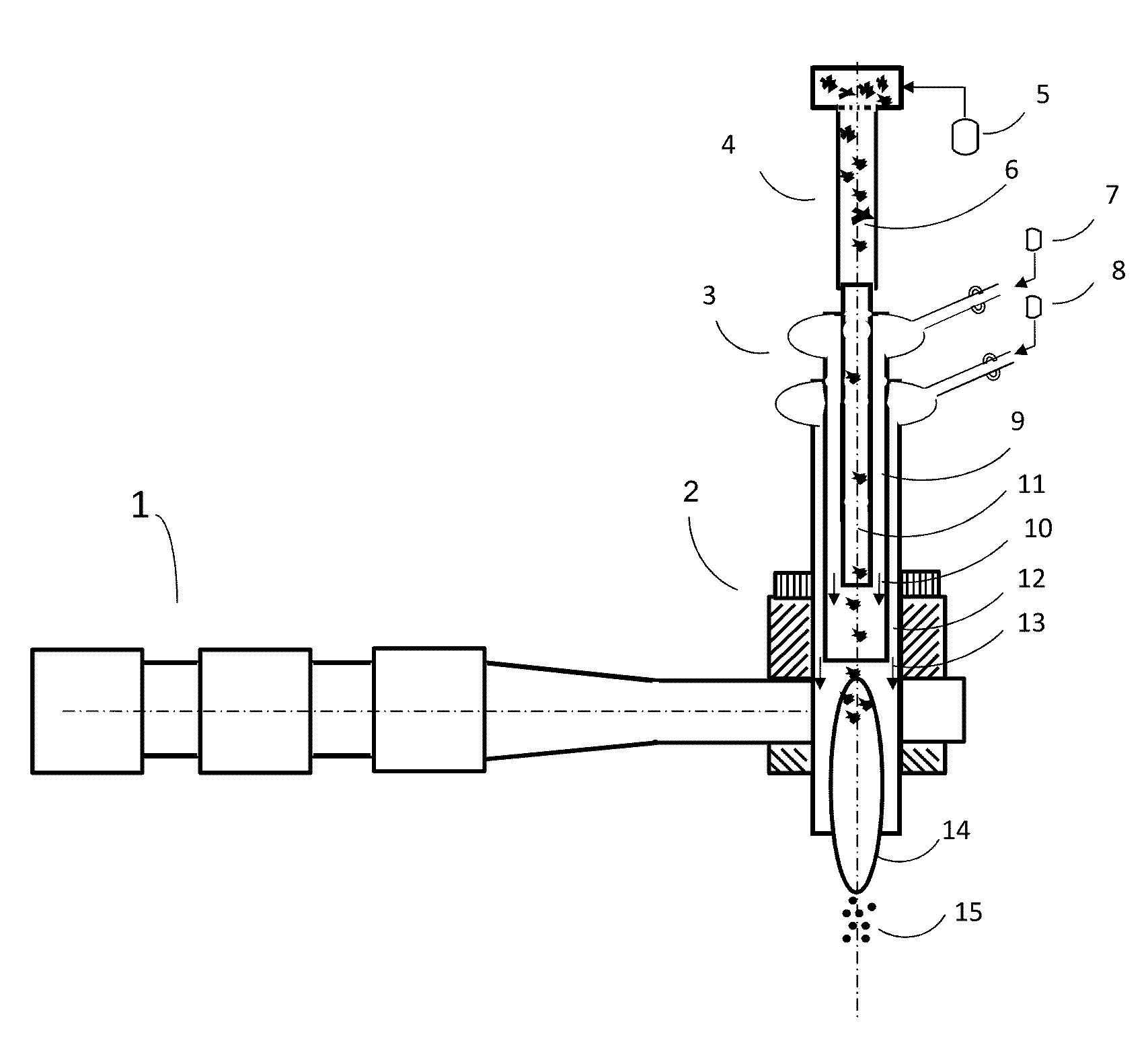

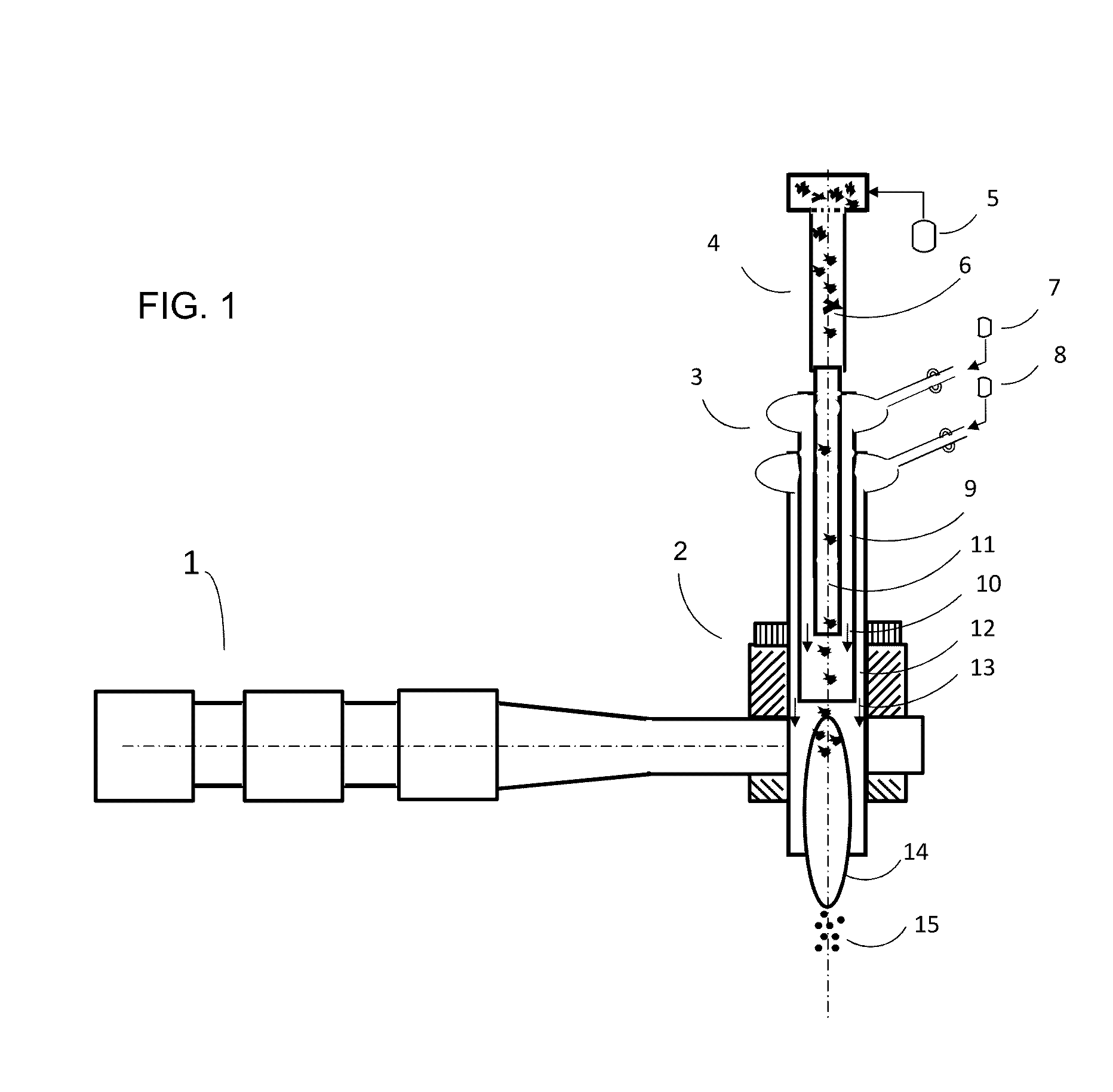

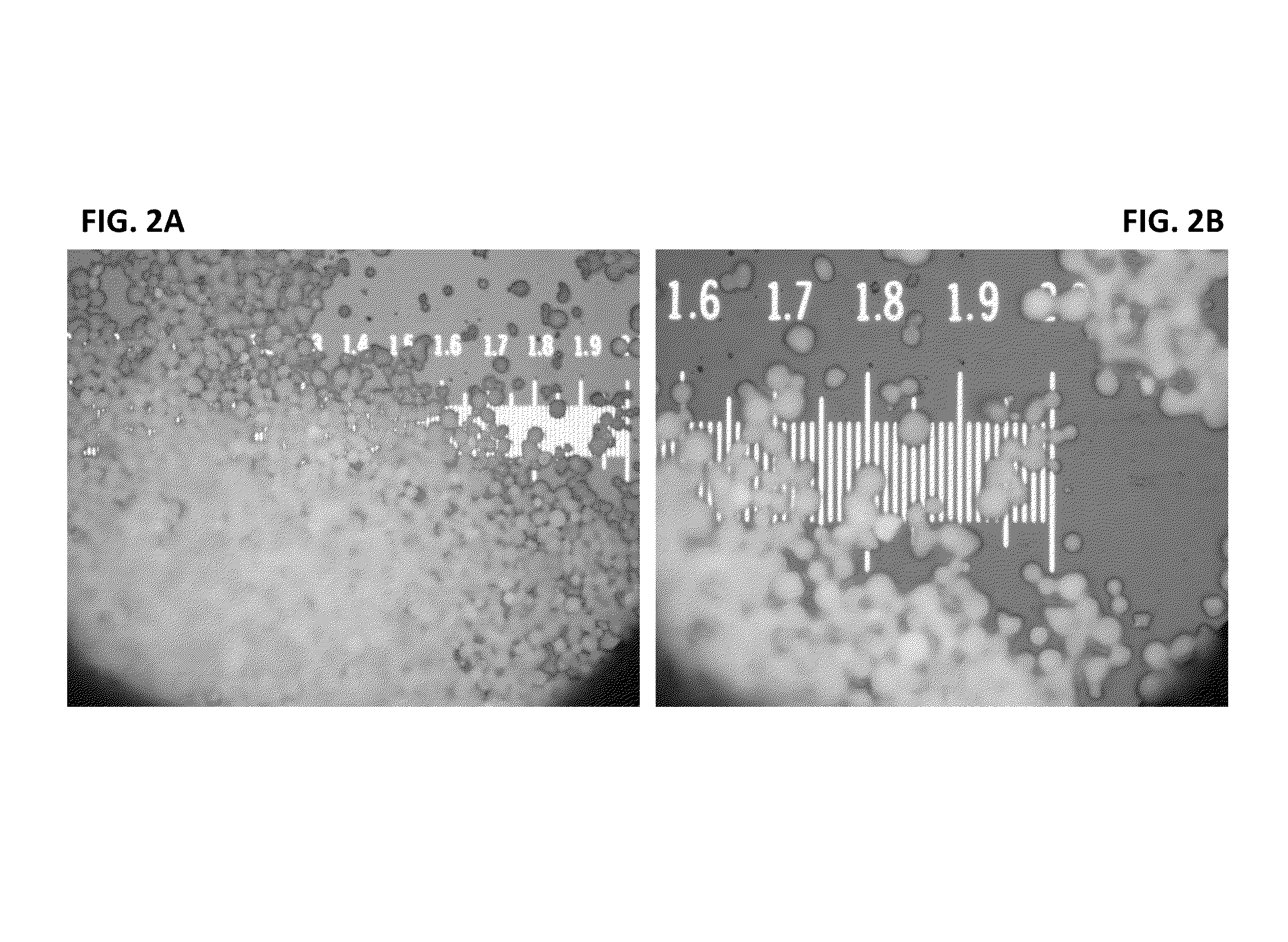

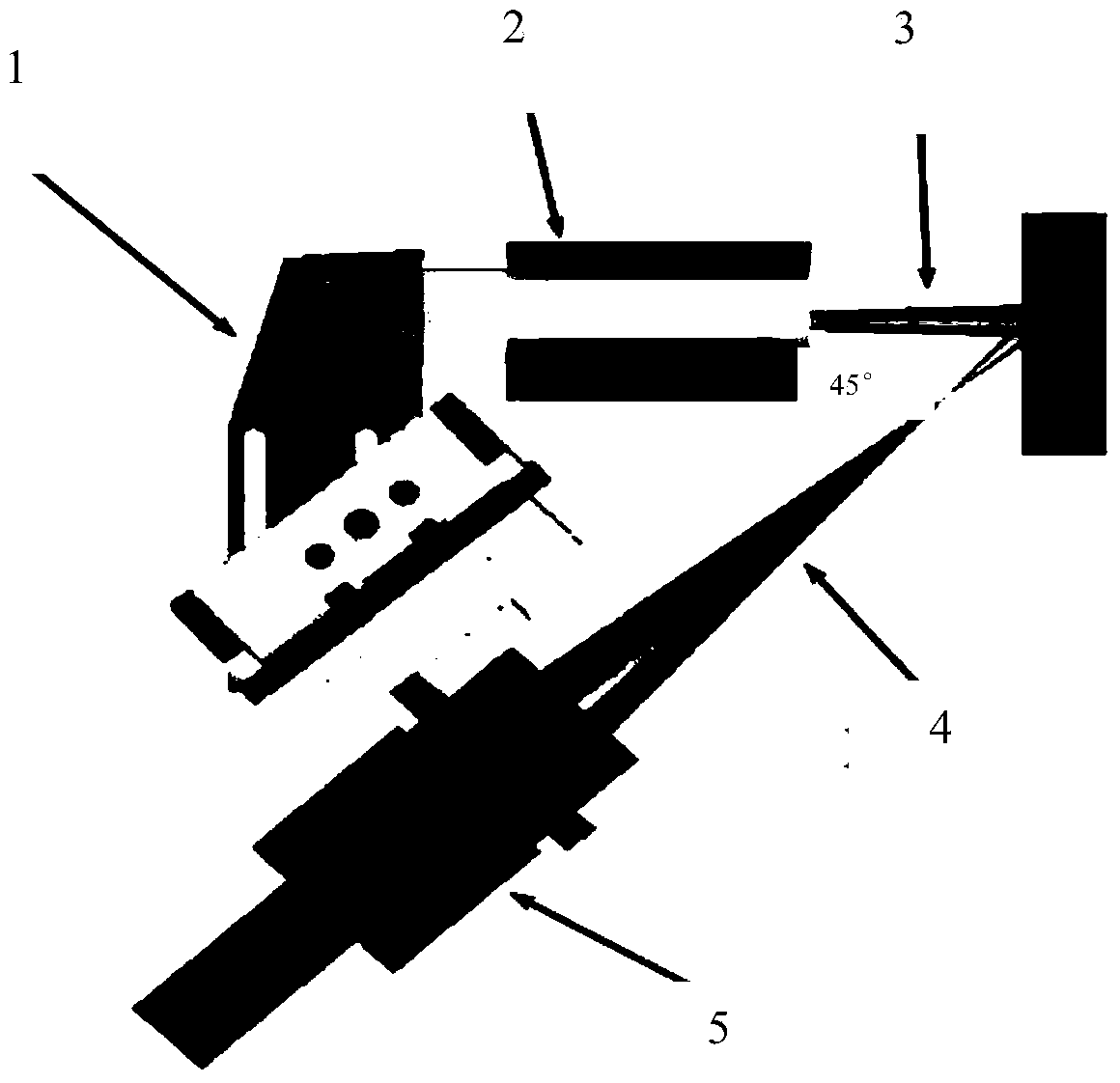

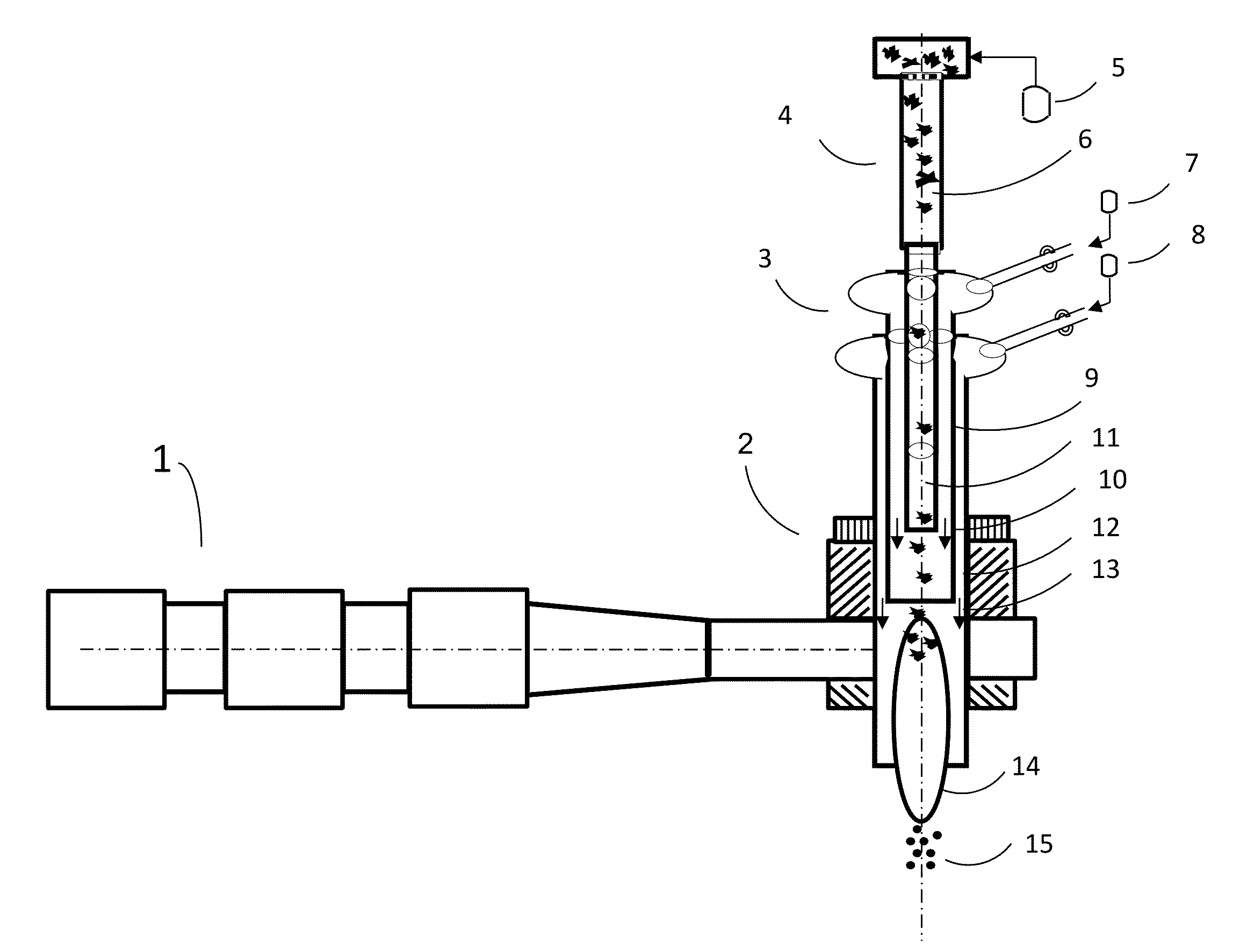

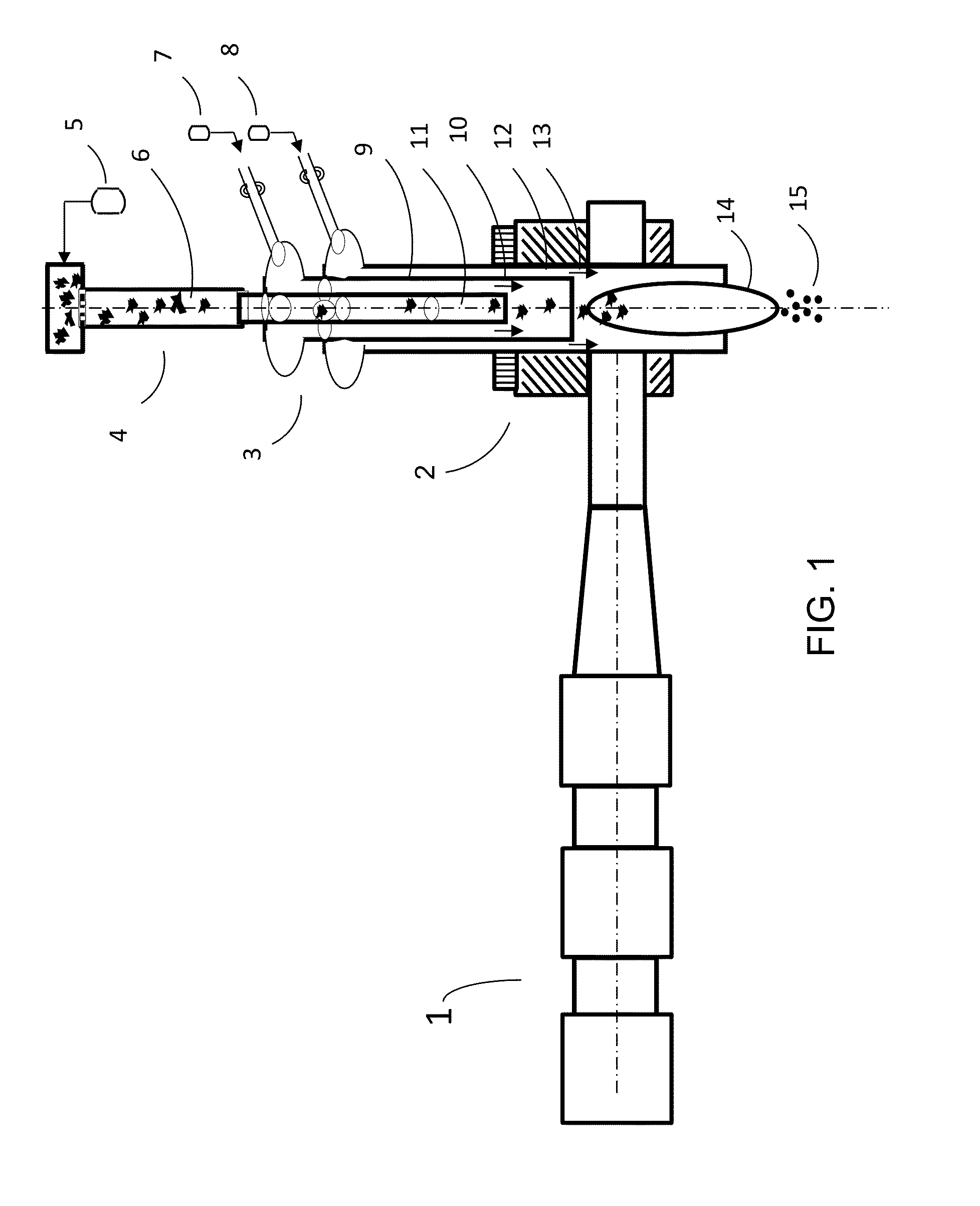

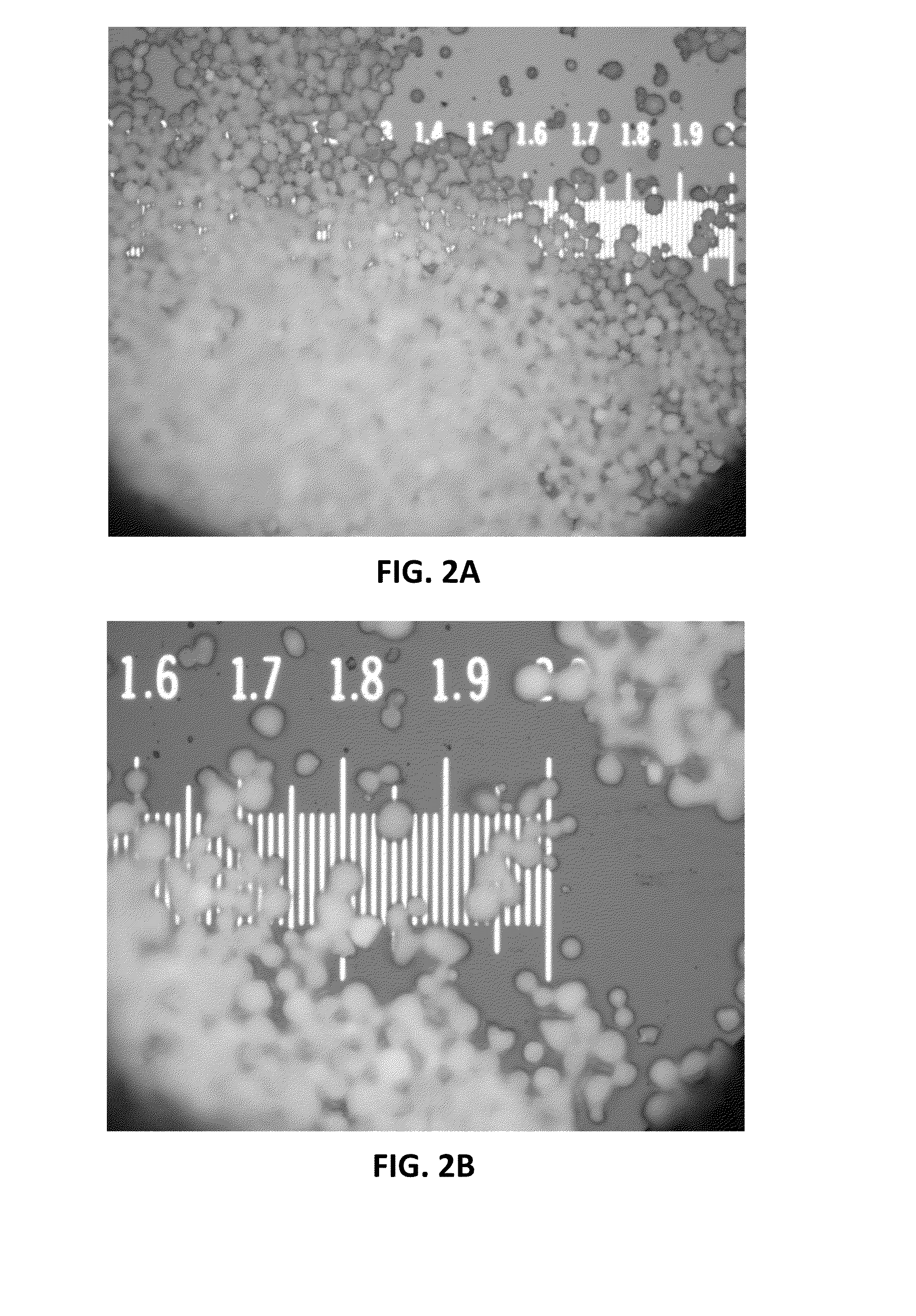

Method for densification and spheroidization of solid and solution precursor droplets of materials using microwave generated plasma processing

ActiveUS9206085B2Uniform densityUniform shapeMolten spray coatingGranulation by liquid drop formationBody fluidMaterial distribution

A method for processing feed material to produce dense and spheroidal products is described. The feed material is comprised of powder particles from the spray-drying technique or solution precursor droplets from ceramic or metallic materials. The feed material is processed using plasma generated from a microwave. The microwave plasma torch employed is capable of generating laminar flow during processing which allows for the production of spheroidal particles with a homogenous materials distribution. This results in products having improved thermal properties, improved corrosion and wear resistance and a higher tolerance to interface stresses.

Owner:6K INC

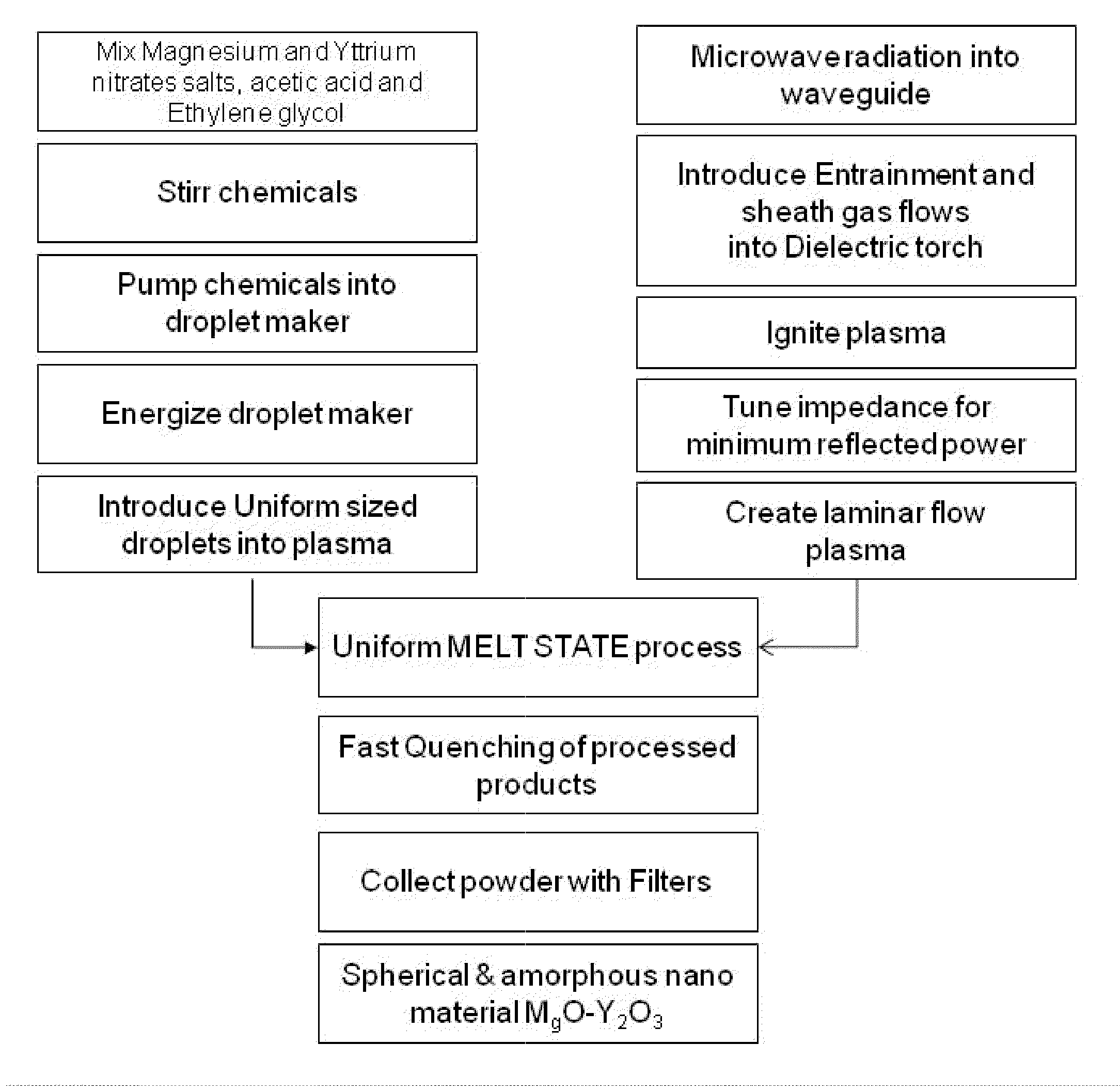

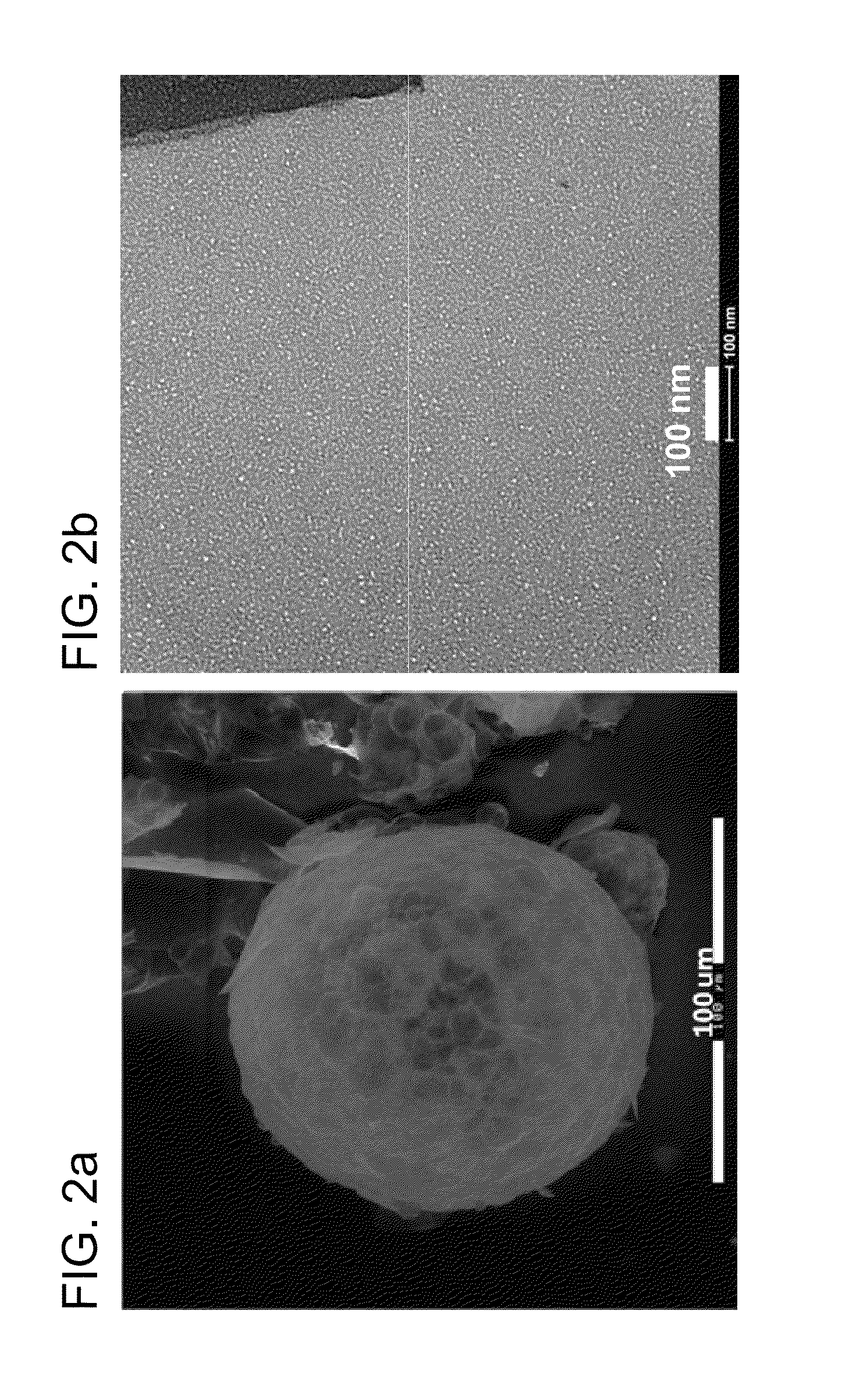

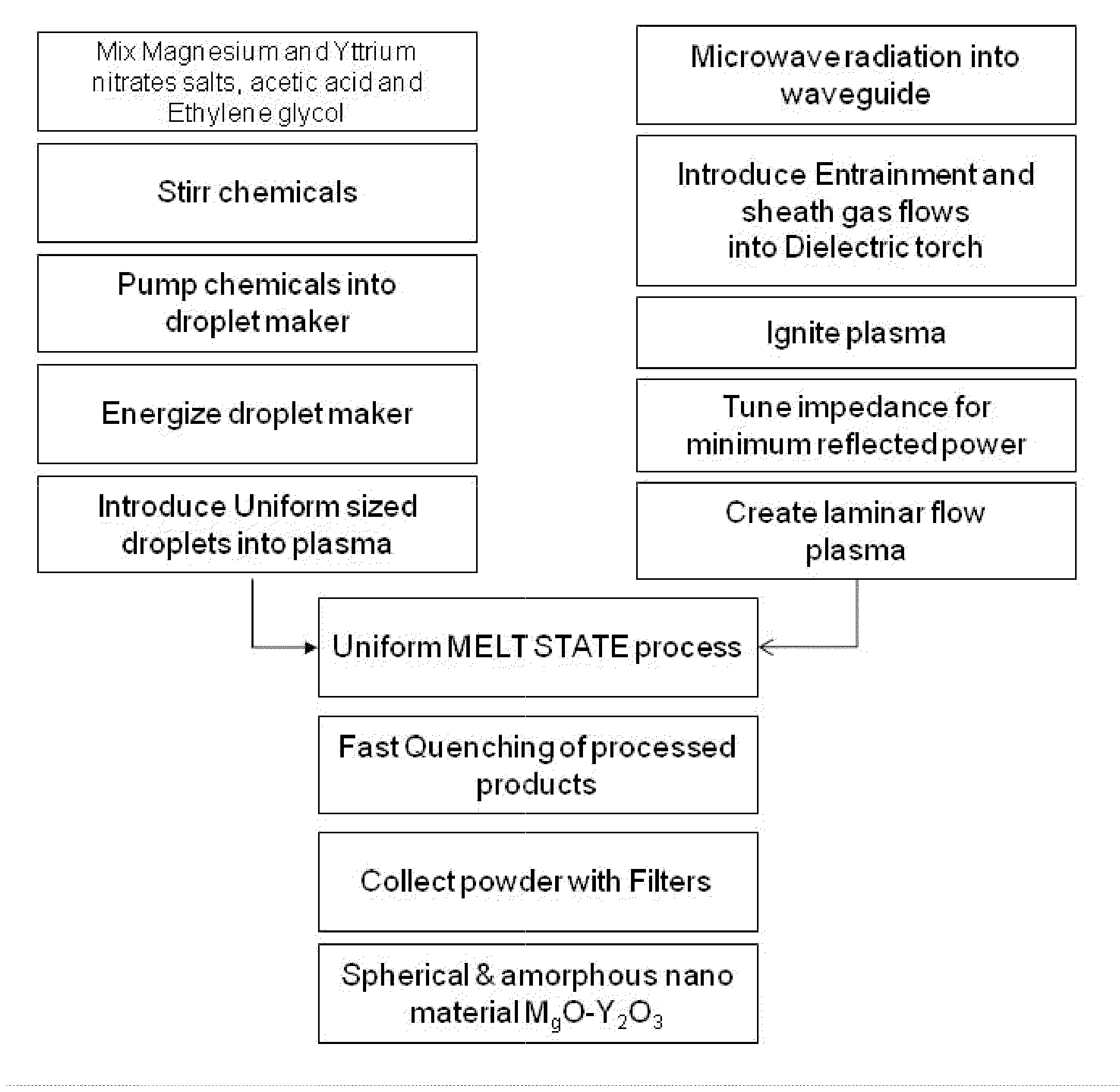

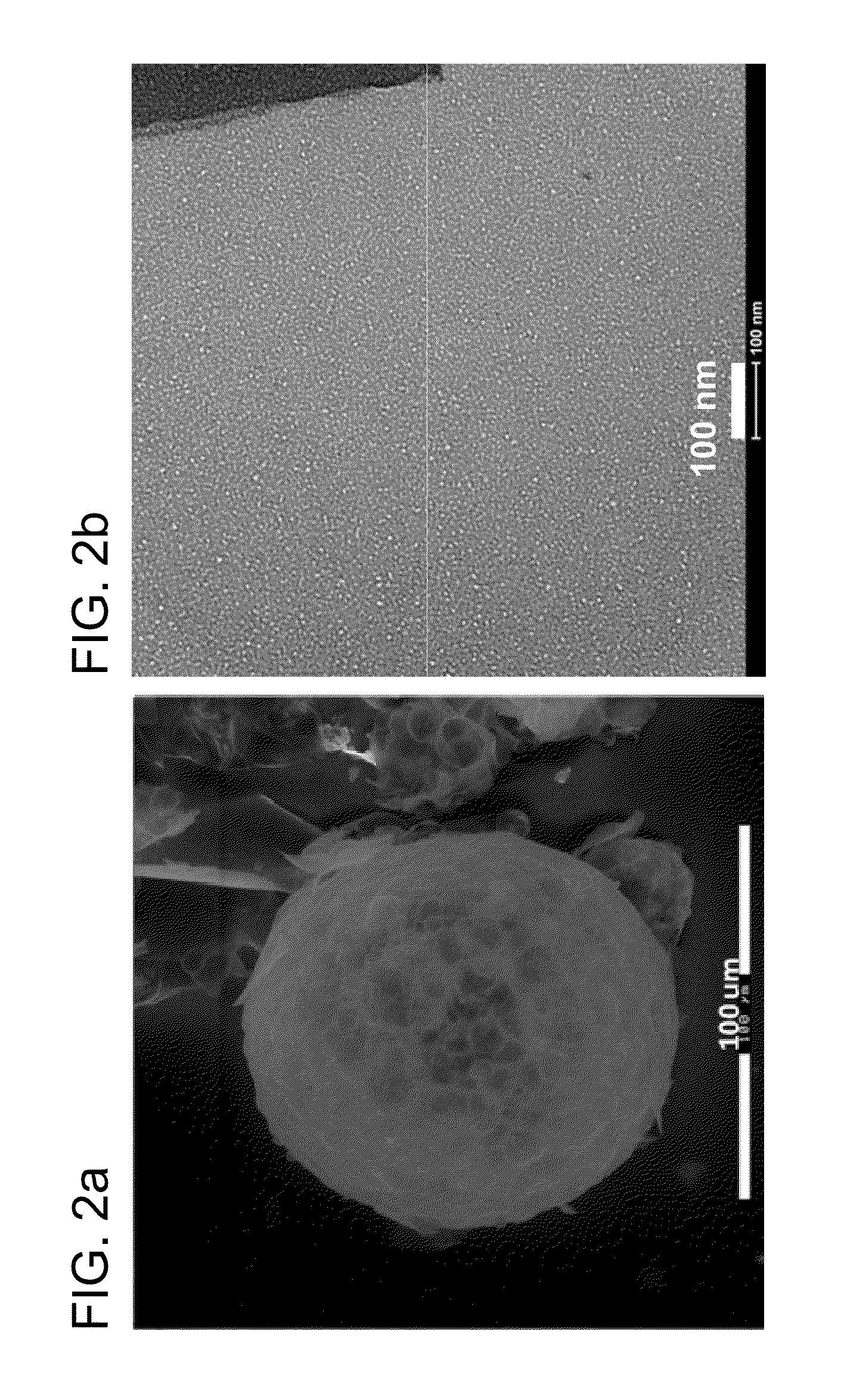

Method for making amorphous particles using a uniform melt-state in a microwave generated plasma torch

ActiveUS8951496B2Improve thermal performanceImprove toleranceCyanogen compoundsNitrogen compoundsMolten stateNon oxide ceramics

Feed material comprising uniform solution precursor droplets is processed in a uniform melt state using microwave generated plasma. The plasma torch employed is capable of generating laminar gas flows and providing a uniform temperature profile within the plasma. Plasma exhaust products are quenched at high rates to yield amorphous products. Products of this process include spherical, highly porous and amorphous oxide ceramic particles such as magnesia-yttria (MgO—Y2O3). The present invention can also be used to produce amorphous non oxide ceramic particles comprised of Boron, Carbon, and Nitrogen which can be subsequently consolidated into super hard materials.

Owner:6K INC

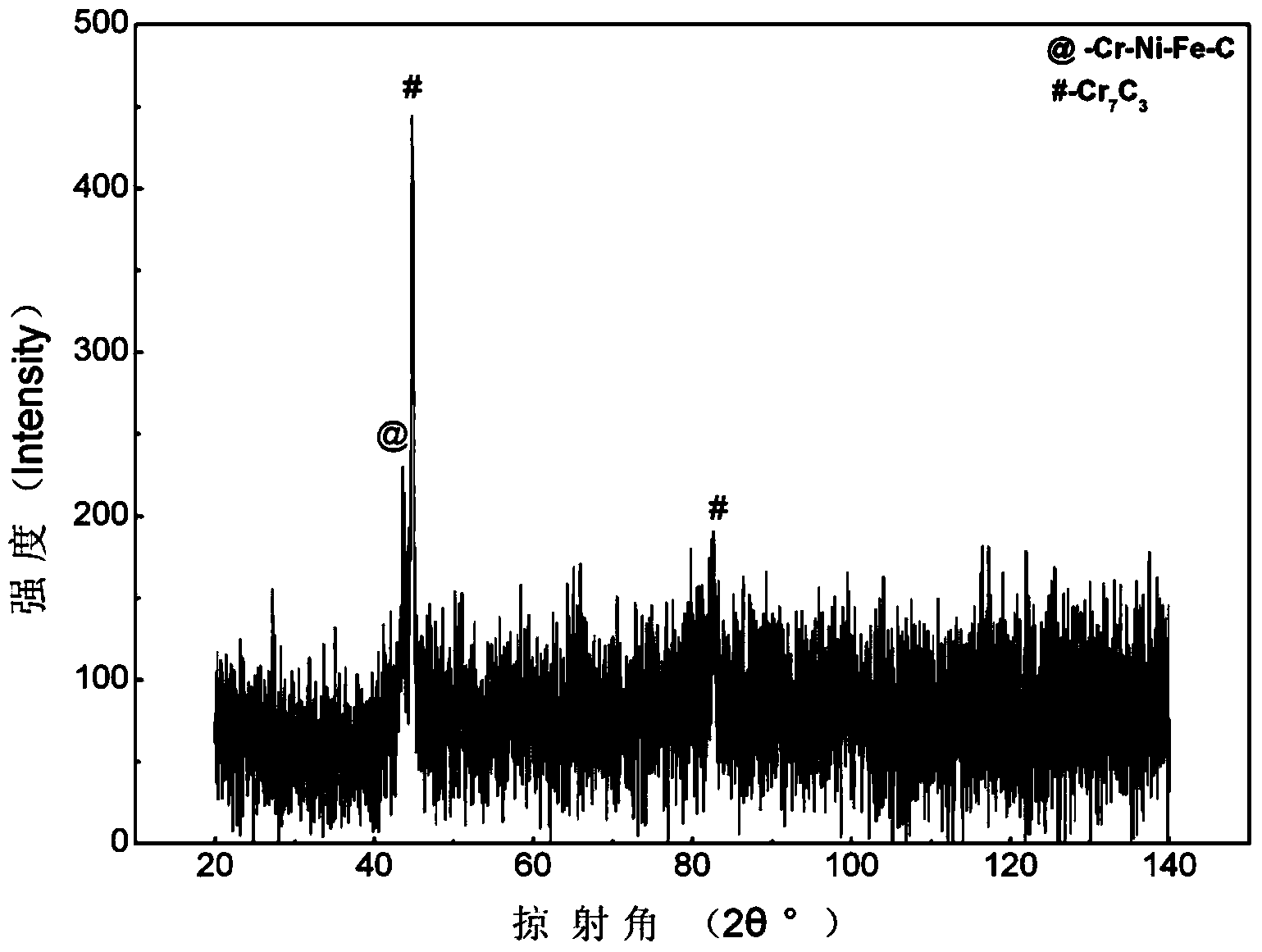

Plasma spray coating on aluminum alloy base surface and preparation method thereof

InactiveCN103643195AGood high temperature oxidation resistanceAvoid excessive oxidationMolten spray coatingChromiumNickel

The invention provides a plasma spray coating on an aluminum alloy base surface, which is composed of the following components in percentage by weight: 14-25% of chromium, 6-15% of nickel, 0.5-1.5% of carbon, 2.0-4.0% of silicon, 0.8-1.5% of manganese and the balance of iron. A Cr7C3 strengthening phase is dispersed in the austenite microstructure of the coating. The experiment proves that the coating has favorable wear resistance and antiseptic property, and is suitable for an aluminum alloy base surface working in a wearing and corrosive environment, such as an automobile engine cylinder made of an aluminum alloy material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

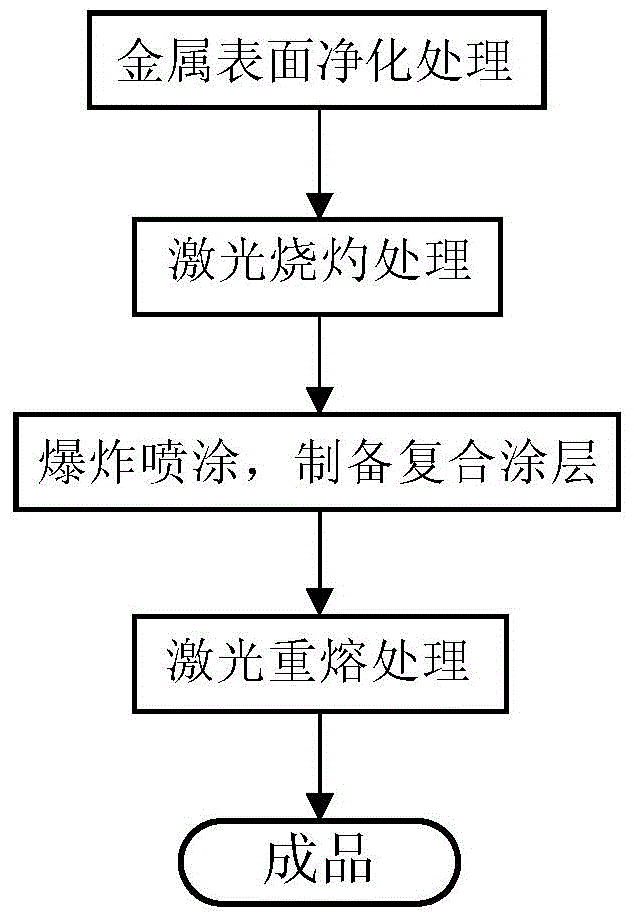

Process for spraying composite coating on metal surface

InactiveCN104789921AReduce porosityImprove microstructureMolten spray coatingWear corrosionLaser burn

The invention discloses a process for spraying a composite coating on a metal surface. The process comprises the following steps: carrying out purification treatment on the metal surface; carrying out laser burning treatment on the metal surface; carrying out explosion spray treatment on the metal surface, and preparing the composite coating; carrying out laser re-melting treatment on the composite coating prepared by an explosion spray process, on the metal surface. According to the combined process for spraying the composite coating on the metal surface, the explosion spray process is compounded with two laser heat treatment processes, so that the binding force of the coating and a matrix can be effectively improved, and the performances of corrosion resistance, wear corrosion and the like of the coating can be further improved.

Owner:上海市机械制造工艺研究所有限公司

Heat resistant and wear resistant power-saving metallic paint

The heat resistant and wear resistant power-saving metal paint is produced through adding successively to stirrer nanoemter glue powder, calgon solution, modifying silica sol, acrylic acid, water soluble silicon oil, modified water glass, compounded stuffing, organic bentonite solution, butyrin, acetylacetone, N,N-methyl methane amide and coupling agent silane solution to obtain nanoemter powder modified micron level paint powder; and then dispersing the paint powder in powerful high speed dispersing machine. The paint has high temperature resistant, wear resistant and other advantages.

Owner:曾庆衿

Method for making amorphous particles using a uniform melt-state in a microwave generated plasma torch

ActiveUS20140155249A1Improve thermal performanceImprove toleranceCyanogen compoundsNitrogen compoundsNon oxide ceramicsMolten state

Feed material comprising uniform solution precursor droplets is processed in a uniform melt state using microwave generated plasma. The plasma torch employed is capable of generating laminar gas flows and providing a uniform temperature profile within the plasma. Plasma exhaust products are quenched at high rates to yield amorphous products. Products of this process include spherical, highly porous and amorphous oxide ceramic particles such as magnesia-yttria (MgO—Y2O3). The present invention can also be used to produce amorphous non oxide ceramic particles comprised of Boron, Carbon, and Nitrogen which can be subsequently consolidated into super hard materials.

Owner:6K INC

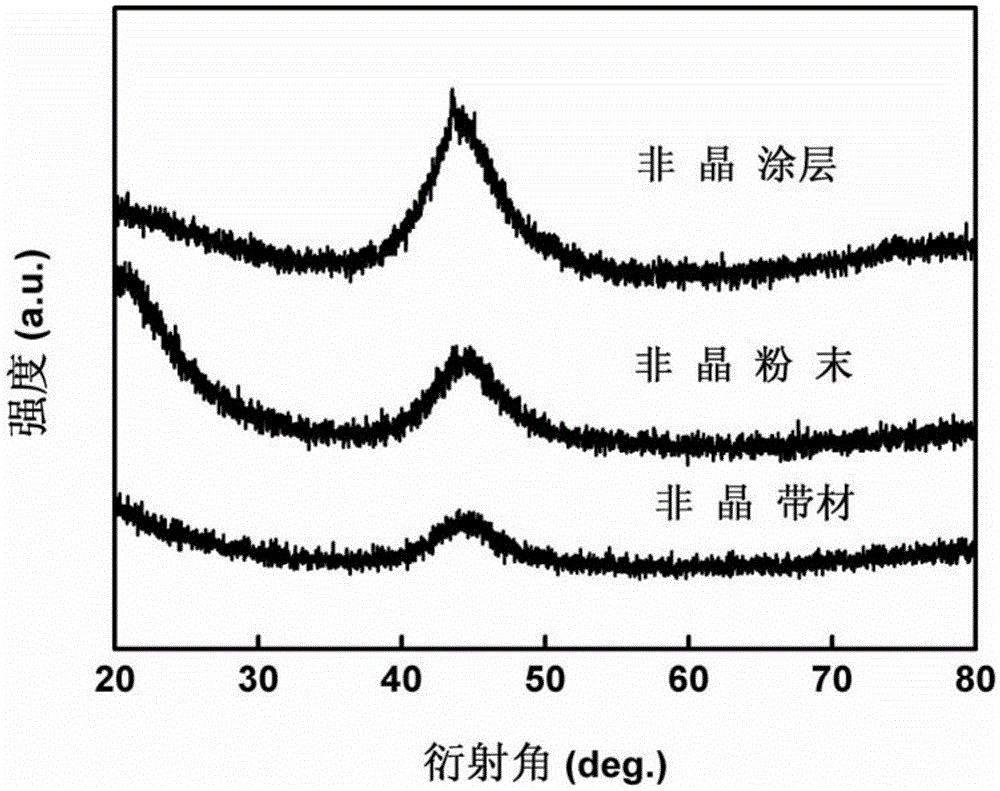

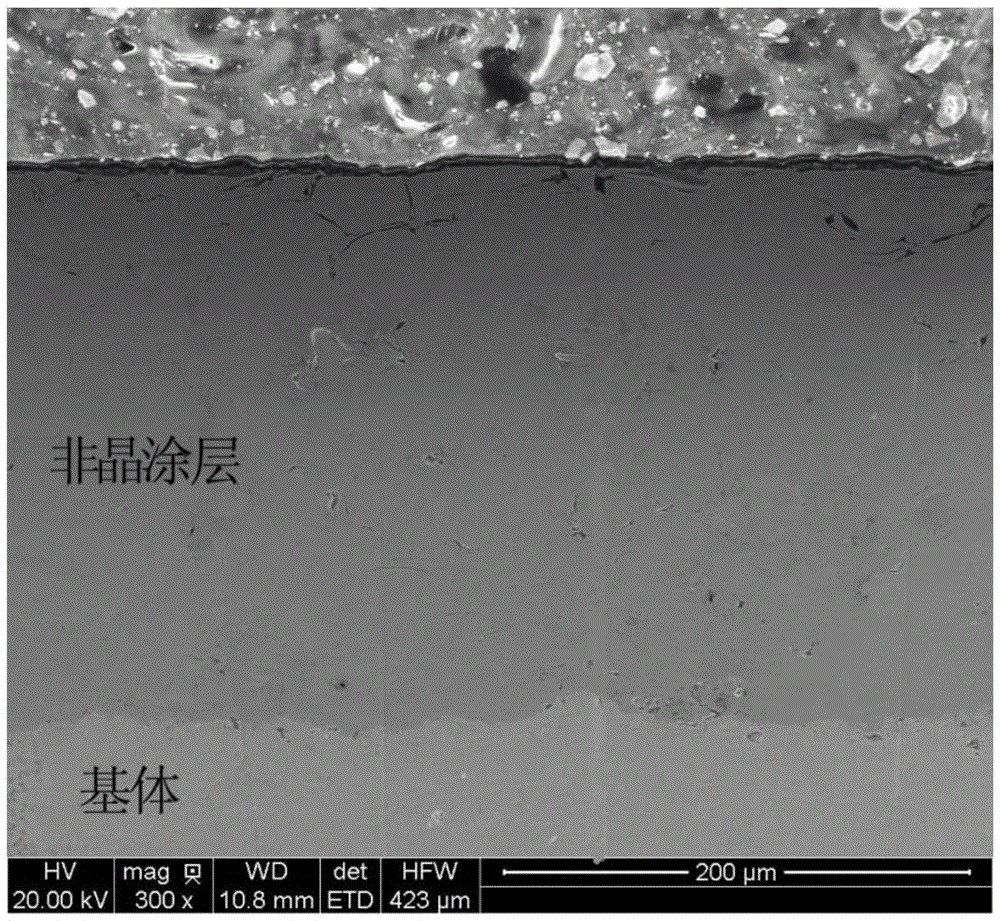

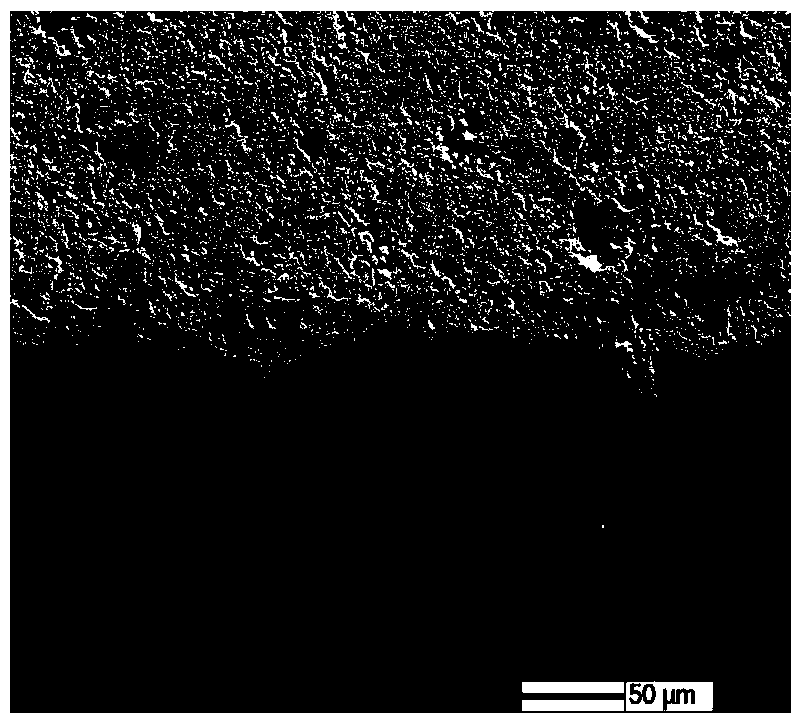

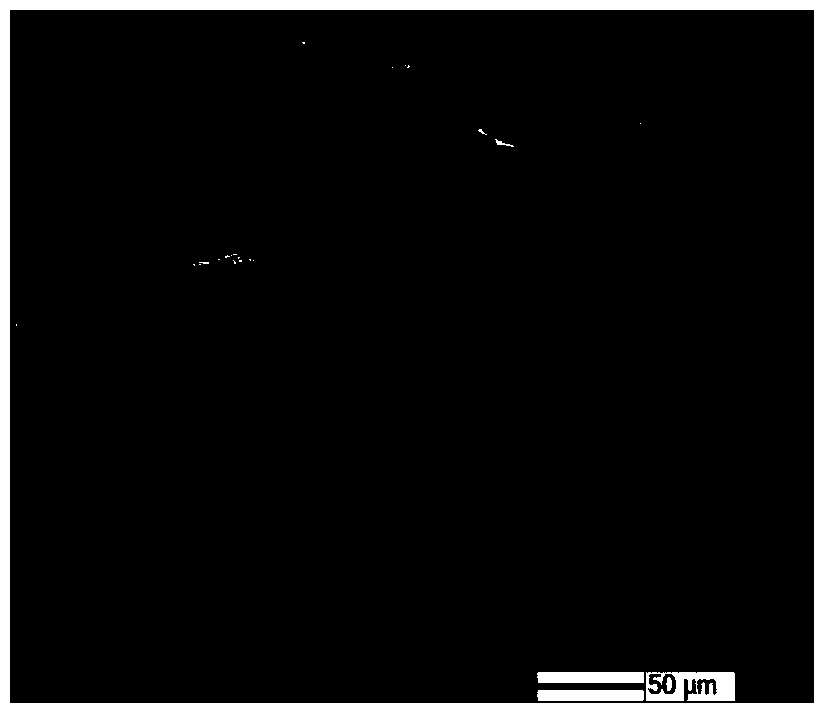

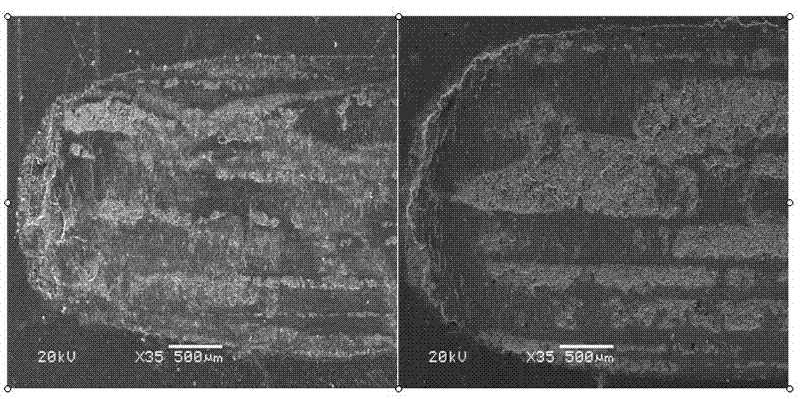

Iron-base amorphous alloy, powder material of alloy and wear-resisting anticorrosion coating of alloy

The invention provides an iron-base amorphous alloy. The chemical formula of the iron-base amorphous alloy is FeaCrbNicModPeCfBgSih, wherein a, b, c, d, e, f, g and h are molar contents of corresponding atoms, b is larger than or equal to 5 and smaller than or equal to 15, c is larger than or equal to 2 and smaller than or equal to 15, d is larger than or equal to 2 and smaller than or equal to 8, e is larger than or equal to 6 and smaller than or equal to 12, f is larger than or equal to 2 and smaller than or equal to 6, g is larger than or equal to 3 and smaller than or equal to 6, h is larger than or equal to 1 and smaller than or equal to 5, and the balance is iron. According to the chemical formula, compounding and smelting are carried out to obtain an ingot casting; then, resmelting is carried out, and through vacuum spraying and cooling, a powder material of the iron-base amorphous alloy is obtained. By means of the supersonic speed flame spraying technology, the iron-base amorphous alloy powder is sprayed to the surface of a base body to prepare an iron-base amorphous alloy coating. The coating is high in amorphous content, low in porosity and oxygen content and high in diamond pyramid hardness and has the good wear-resisting anticorrosion performance and has the wide application prospect in fields of energy, chemical engineering, national defense, aerospace, ships and the like.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

Method for the densification and spheroidization of solid and solution precursor droplets of materials using microwave generated plasma processing

ActiveUS20140131906A1Uniform densityUniform shapePlasma techniqueMetallic materialsMaterial distribution

A method for processing feed material to produce dense and spheroidal products is described. The feed material is comprised of powder particles from the spray-drying technique or solution precursor droplets from ceramic or metallic materials. The feed material is processed using plasma generated from a microwave. The microwave plasma torch employed is capable of generating laminar flow during processing which allows for the production of spheroidal particles with a homogenous materials distribution. This results in products having improved thermal properties, improved corrosion and wear resistance and a higher tolerance to interface stresses.

Owner:6K INC

Anti-abrasion and anti-corrosion composite functional coating layer

The invention belongs to the technical field of thermal-sprayed coating layers and relates to a composite functional coating layer capable of resisting abrasion and corrosion. The coating layer consists of the chemical components such as NiCrAlY alloy powder, metallurgical TiC powder and rare-earth oxide La2O3 powder, wherein the adding amount of the NiCrAlY alloy powder accounts for 49.5-80 percent of the weight of the powder of the whole coating layer; the adding amount of the metallurgical TiC powder accounts for 19.5-50 percent of the weight of the materials of the coating layer; the adding amount of the rare-earth oxide La2O3 powder accounts for 0.5-5 percent of the weight of the materials of the coating layer. Metallurgical combination is realized, so that the bonding strength of the coating layer is high, and organization is compact; therefore, compared with the common coating layer, the coating layer has the advantages that the abrasion resistance and the corrosion resistance are greatly improved. The coating layer disclosed by the invention is processed by a plasma composite spraying technology such as laser and atmosphere instead of an independent thermal spraying technology; in order to fulfill the aim of realizing coating layer metallurgical combination, due to the metallurgical combination, the coating layer combining strength can be improved, and the high compactness of the organization of the coating layer is realized; due to the high combining strength and the low porosity, the coating layer is long in service life and high in abrasion resistance and corrosion resistance.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

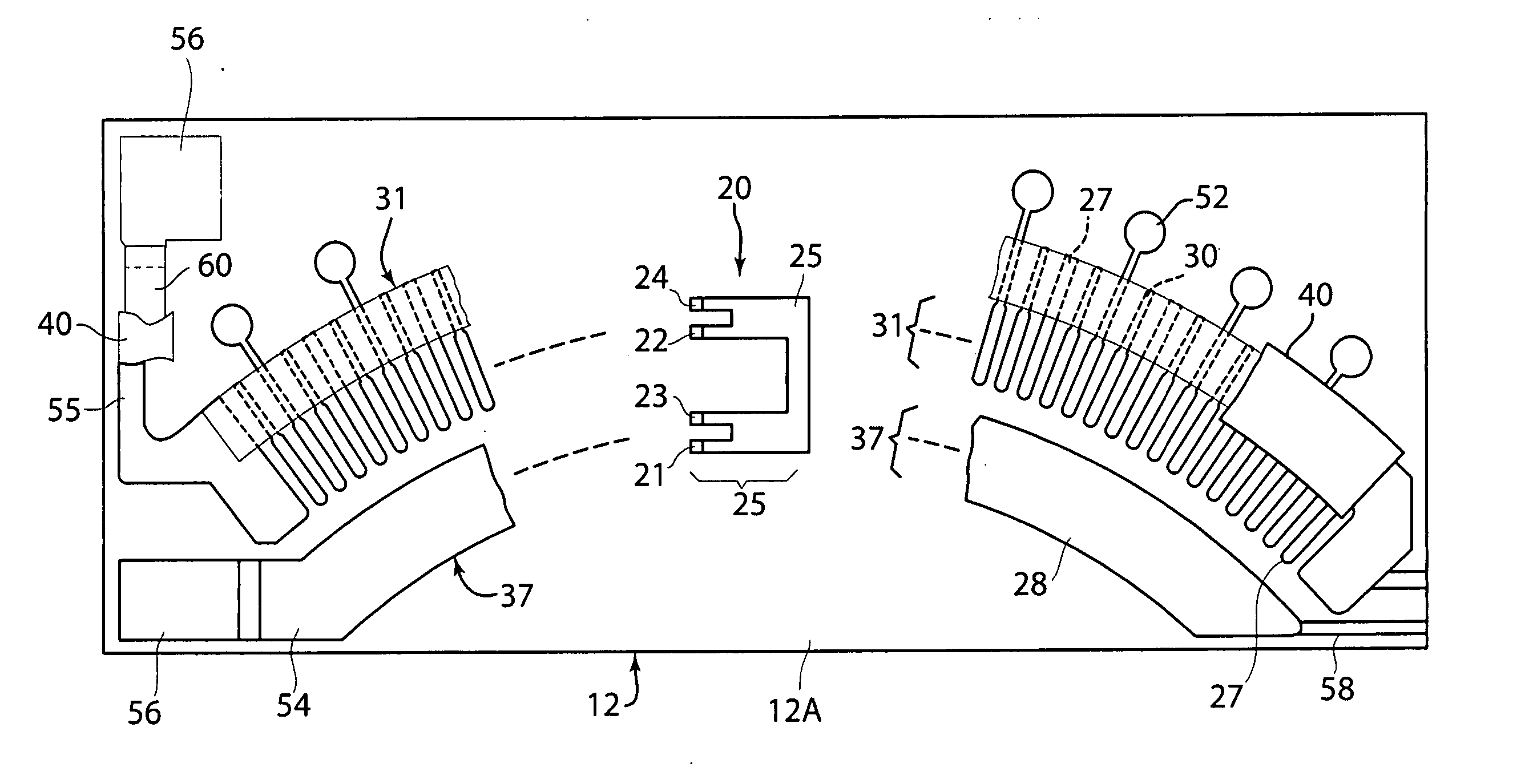

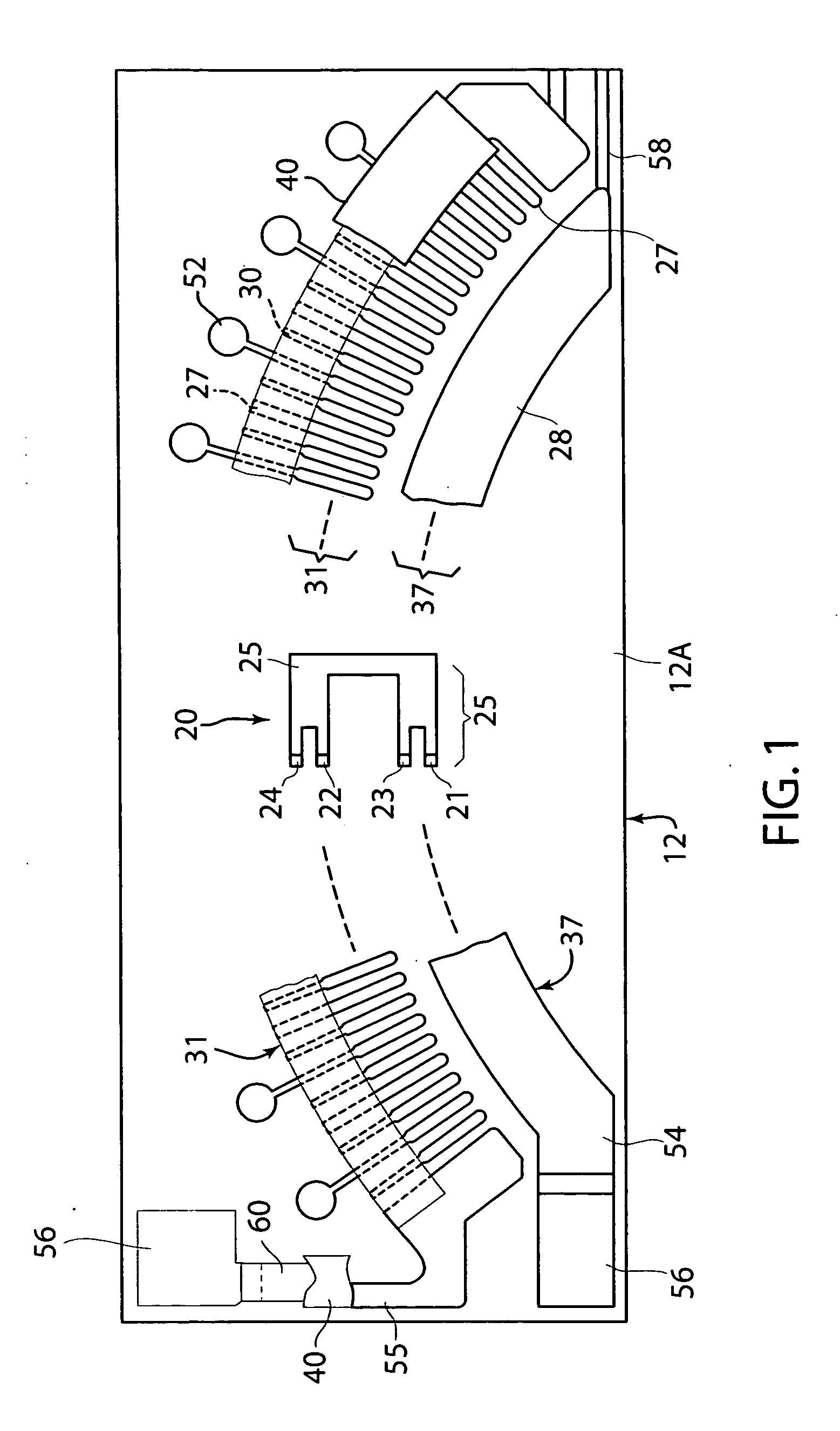

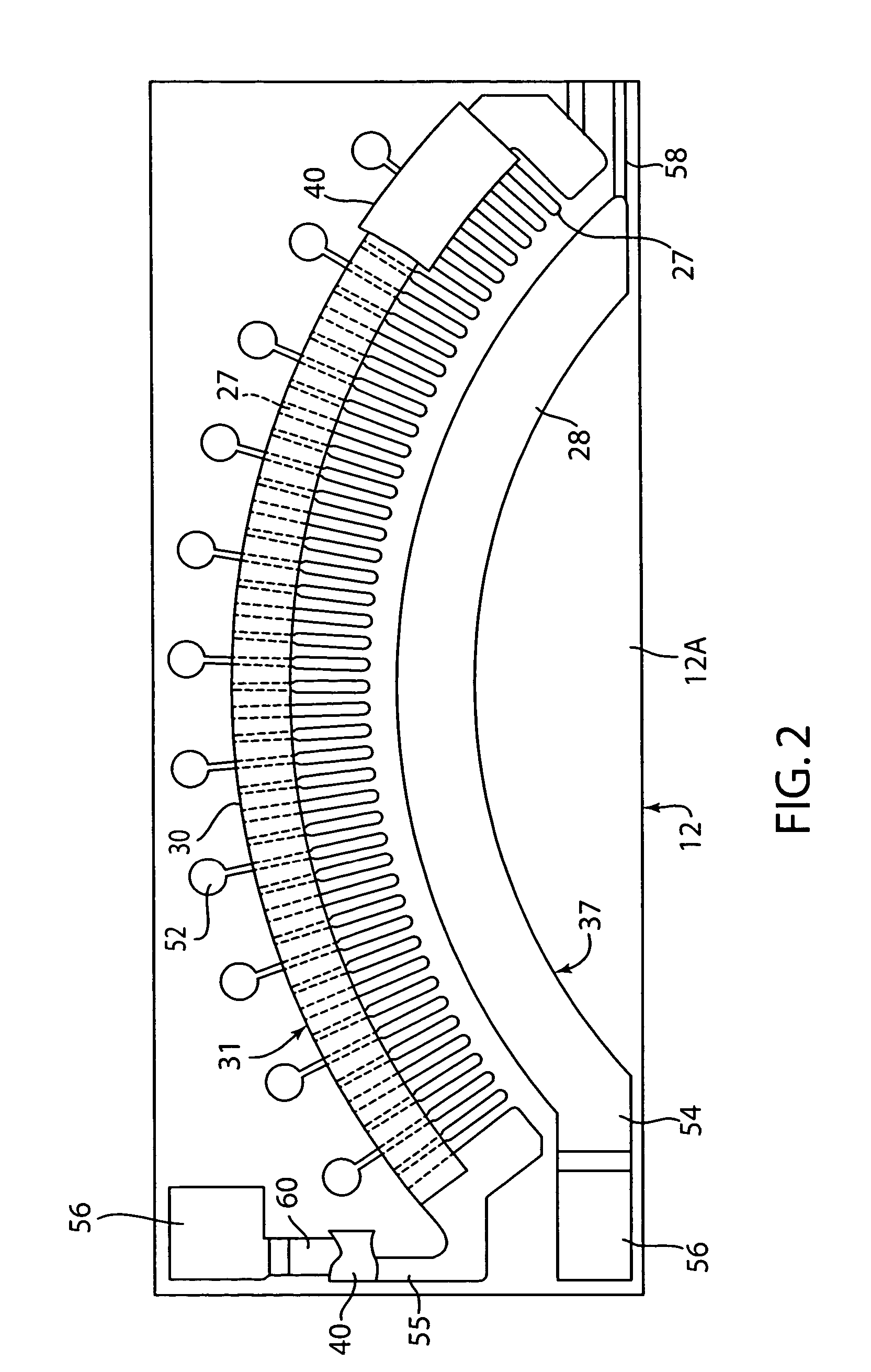

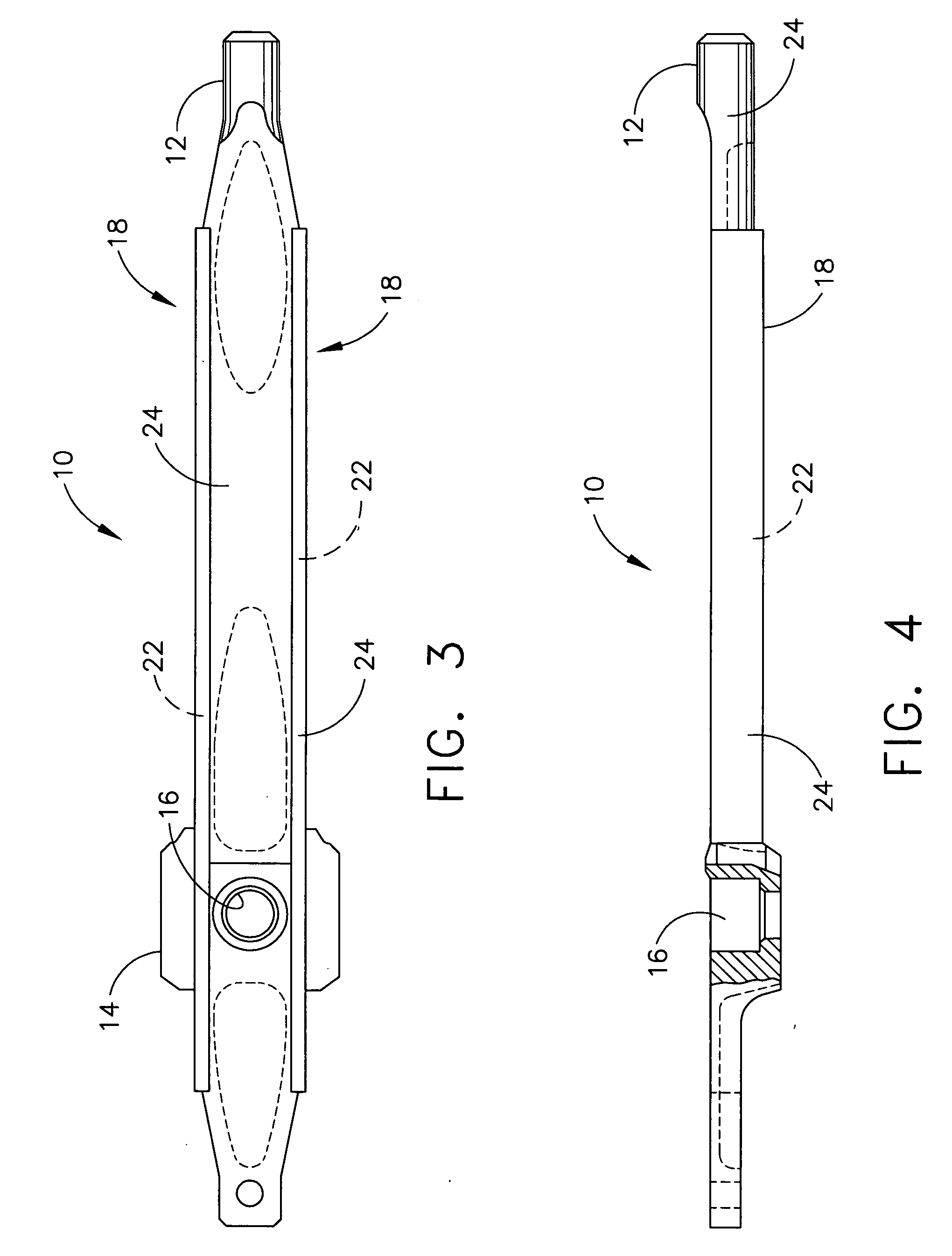

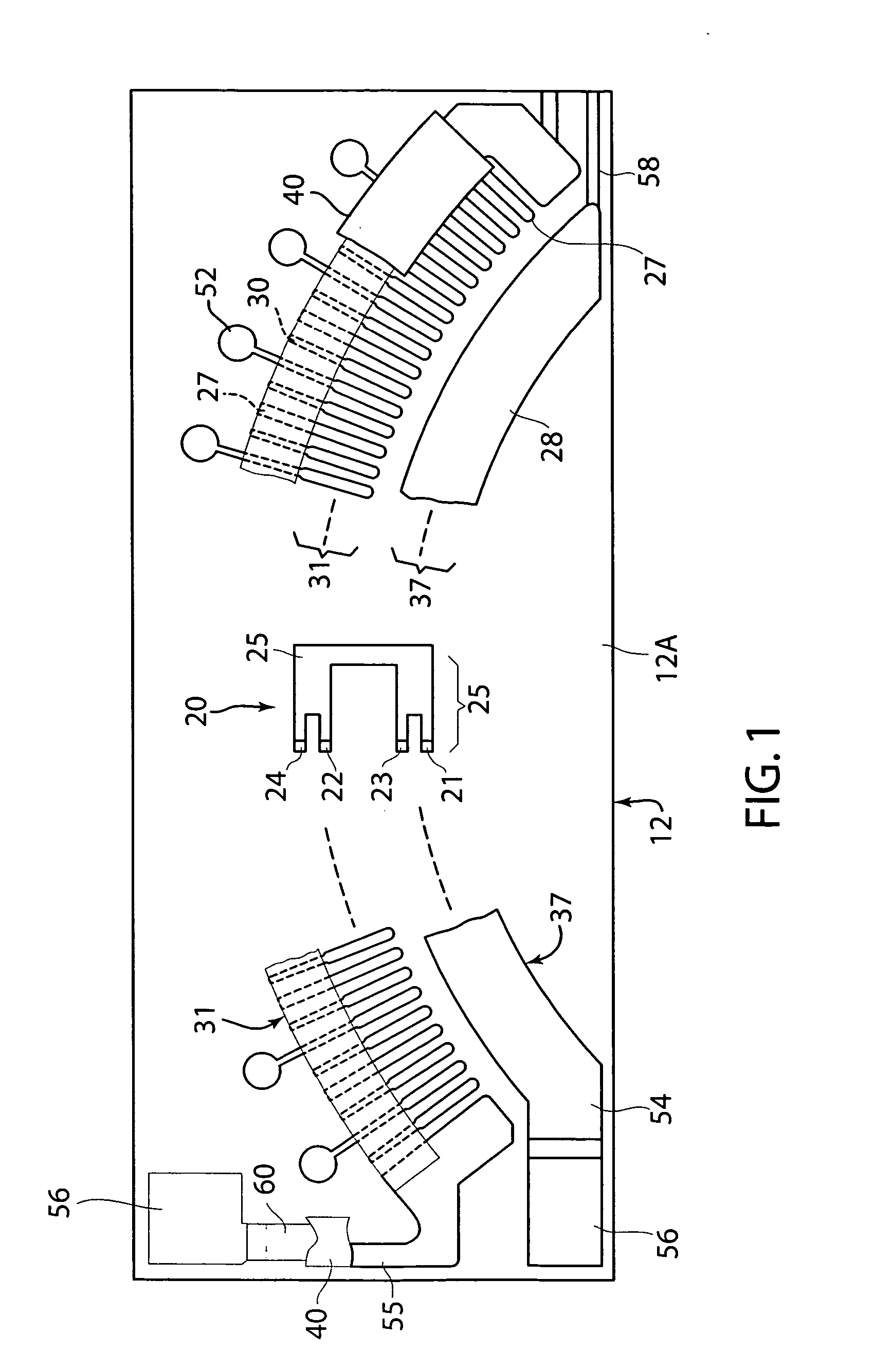

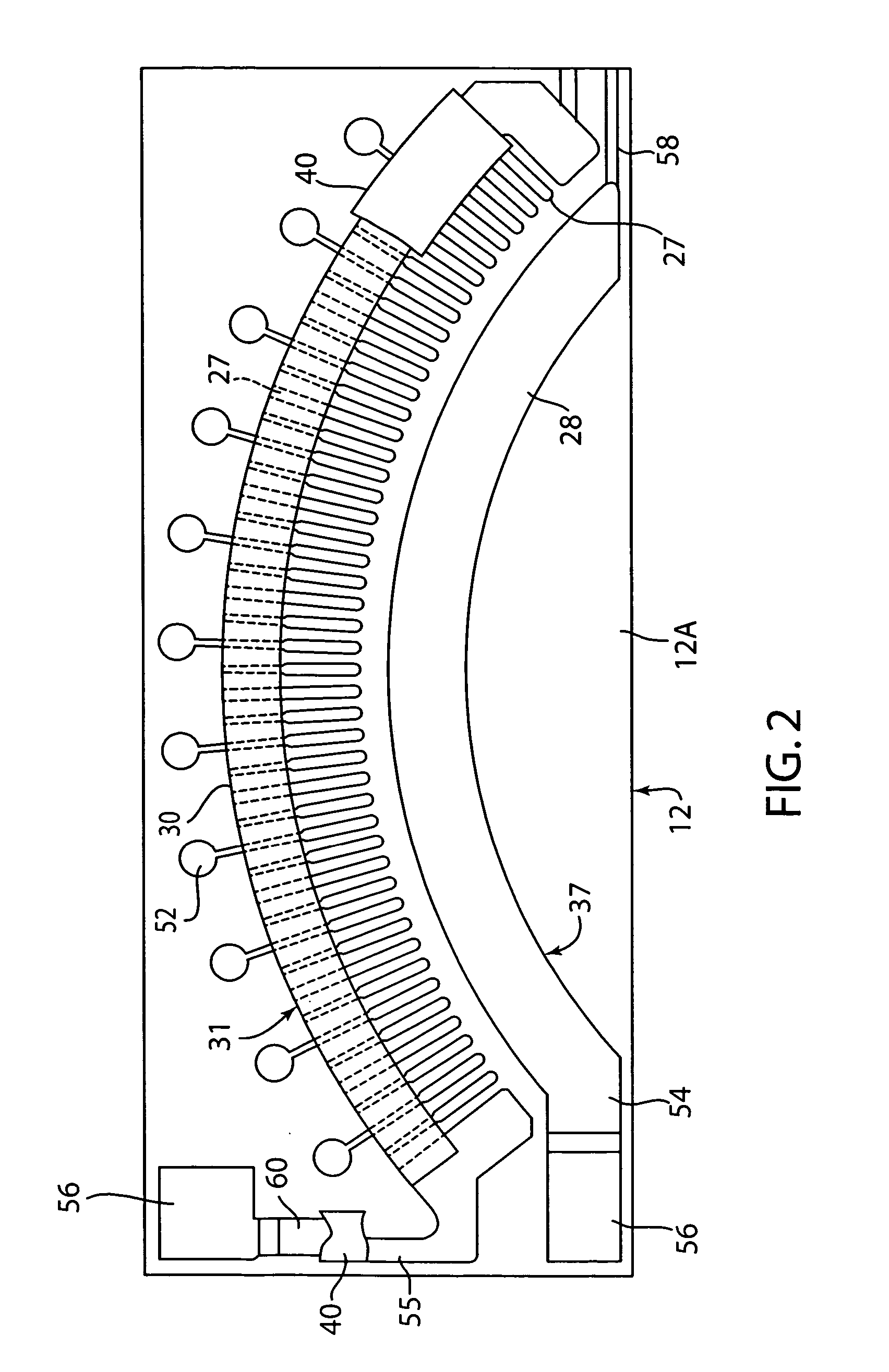

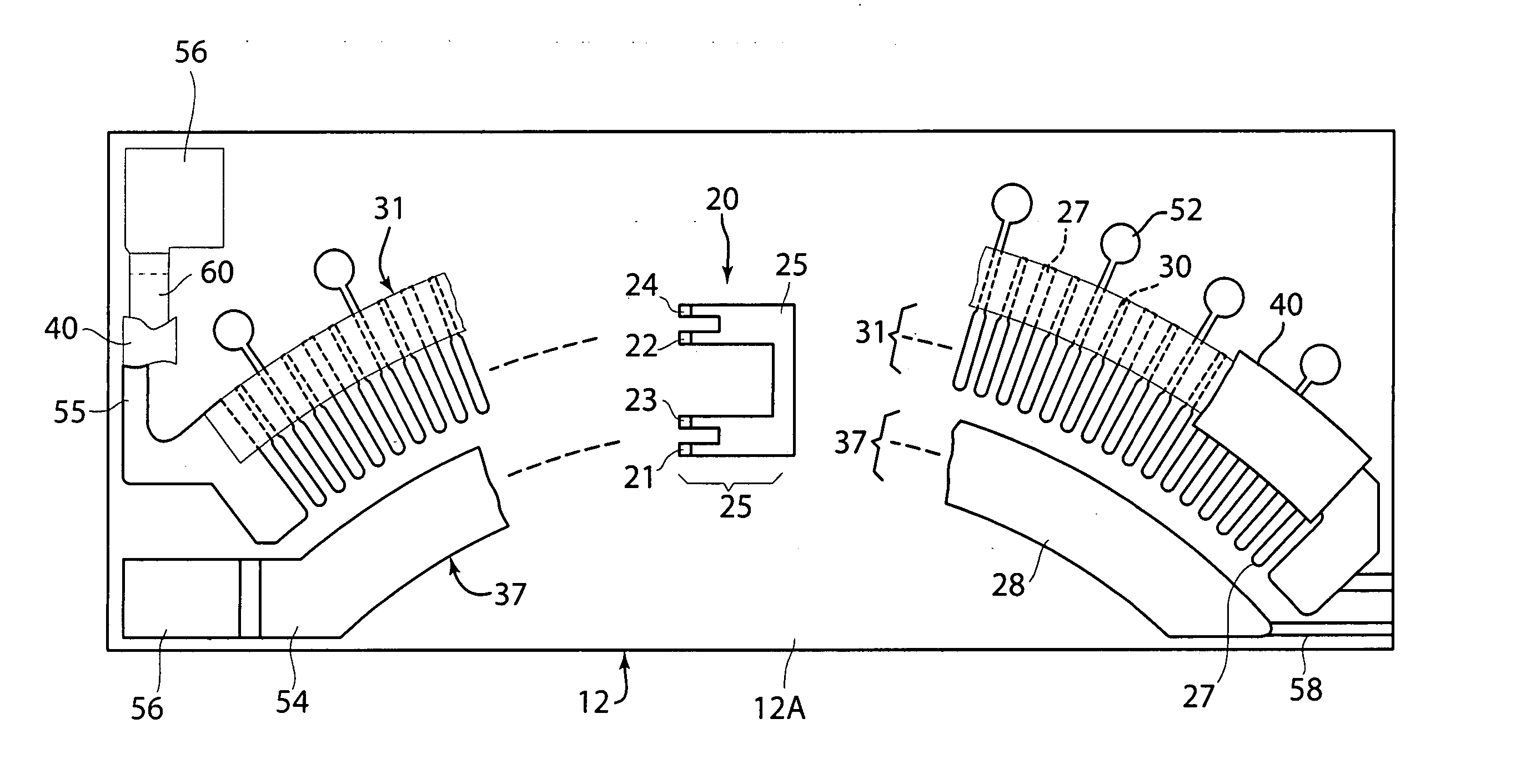

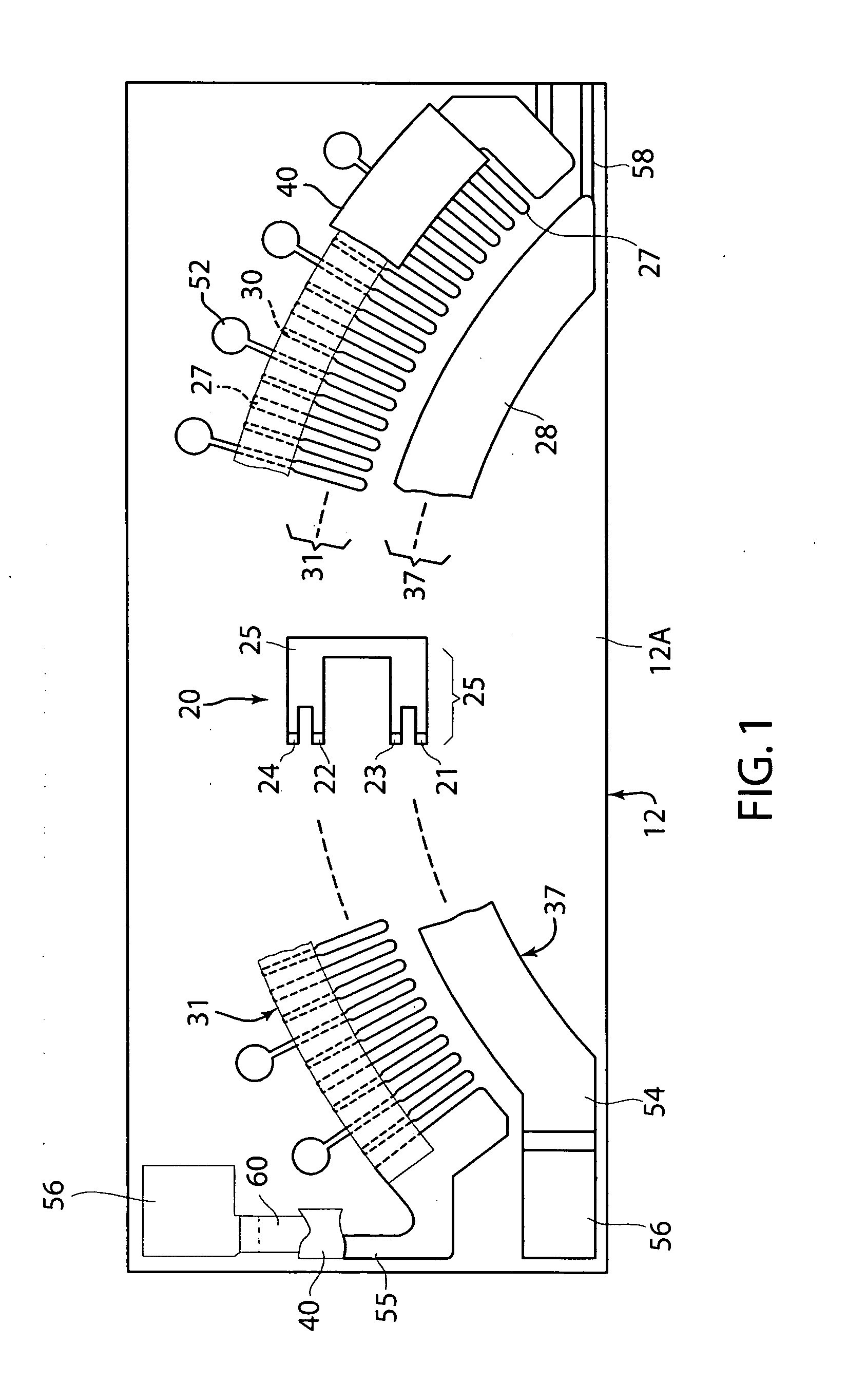

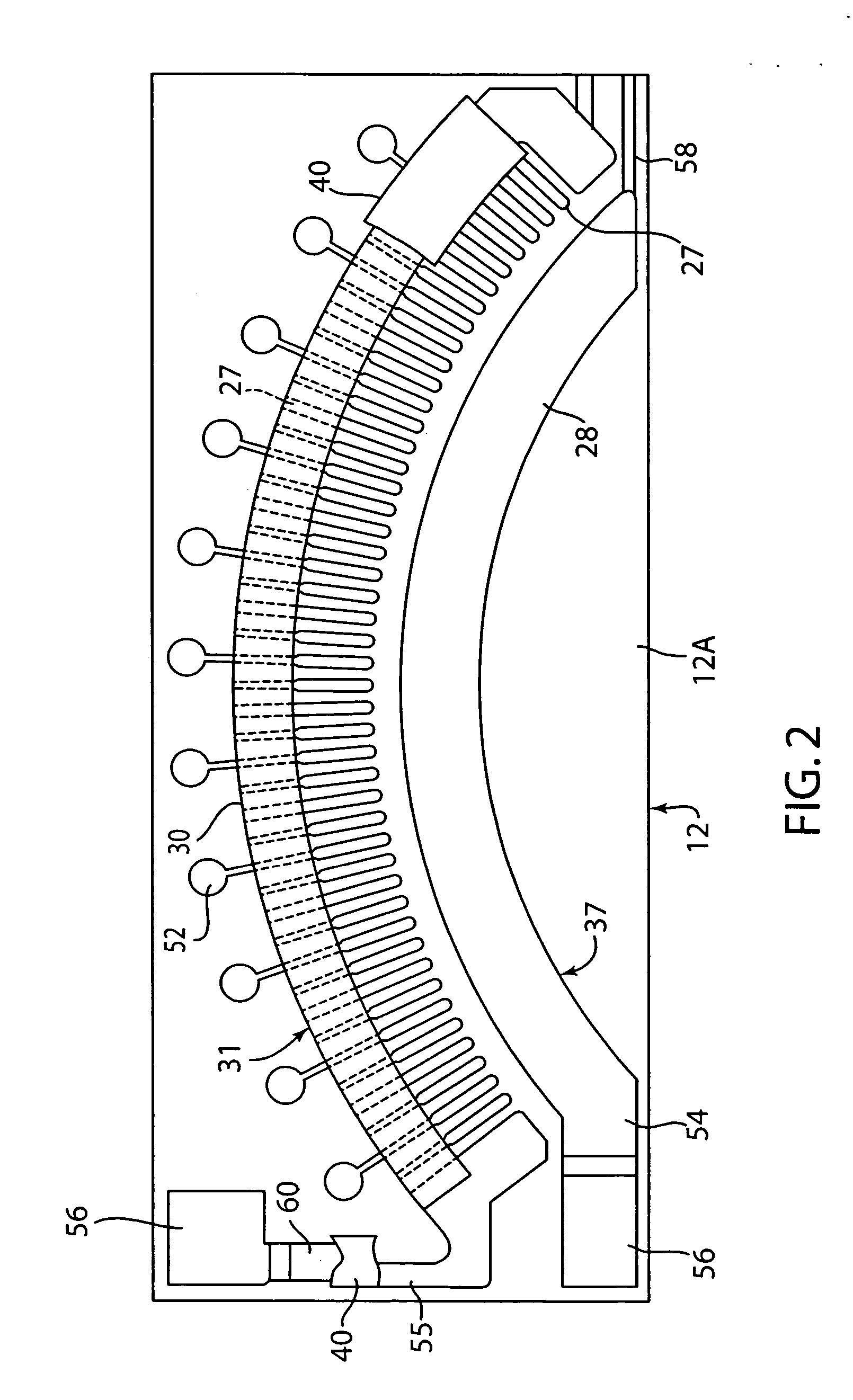

Fuel tank resistor card having improved corrosion resistance

InactiveUS20050040929A1Improve wear resistance and corrosion resistanceAvoid corrosionFixed resistors with intervening connectorsPrinted circuit aspectsSulfurFuel tank

A resistor card for a fuel level sensor has improved resistance to corrosion and wear. The resistor card has a substrate with a resistive layer and a conductive layer. A nickel layer covers the conductive layer. A nickel-gold alloy layer covers the nickel layer. The nickel-gold alloy layer protects the conductive layer from sulfur corrosion and improves wear resistance.

Owner:CTS CORP ELKHART

Epoxy resin-based wear-resistant anticorrosive material

ActiveCN102504672AImprove wear resistance and corrosion resistanceStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention provides an epoxy resin-based wear-resistant anticorrosive material which is prepared by an ultrasonic dispersion and mechanical blending technology by taking epoxy resin as a matrix and nano palygorskite-alumina as filler, belonging to the technical field of composite materials. The epoxy resin-based wear-resistant anticorrosive material provided by the invention has excellent wear resistance and corrosion resistance and good adhesion, and thus can be used as a composite coating to be applied to the material surface of a mechanical part so as to improve the wear resistance and corrosion resistance of the mechanical part and prolong the service life of the metal part.

Owner:东莞市亮舍建材有限公司

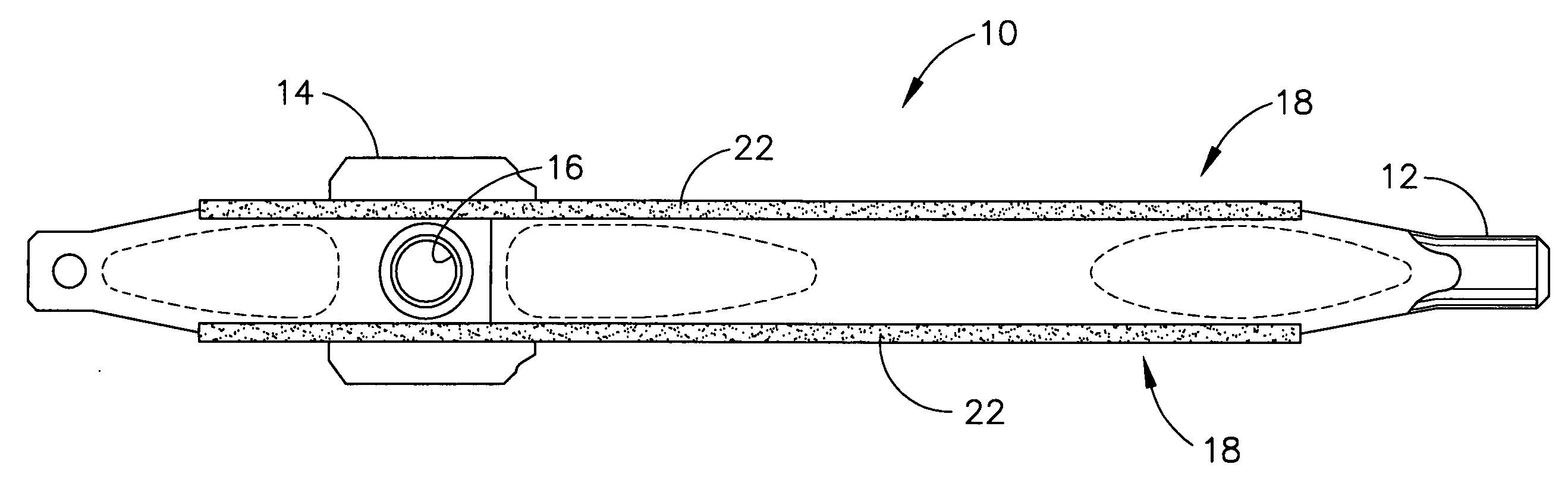

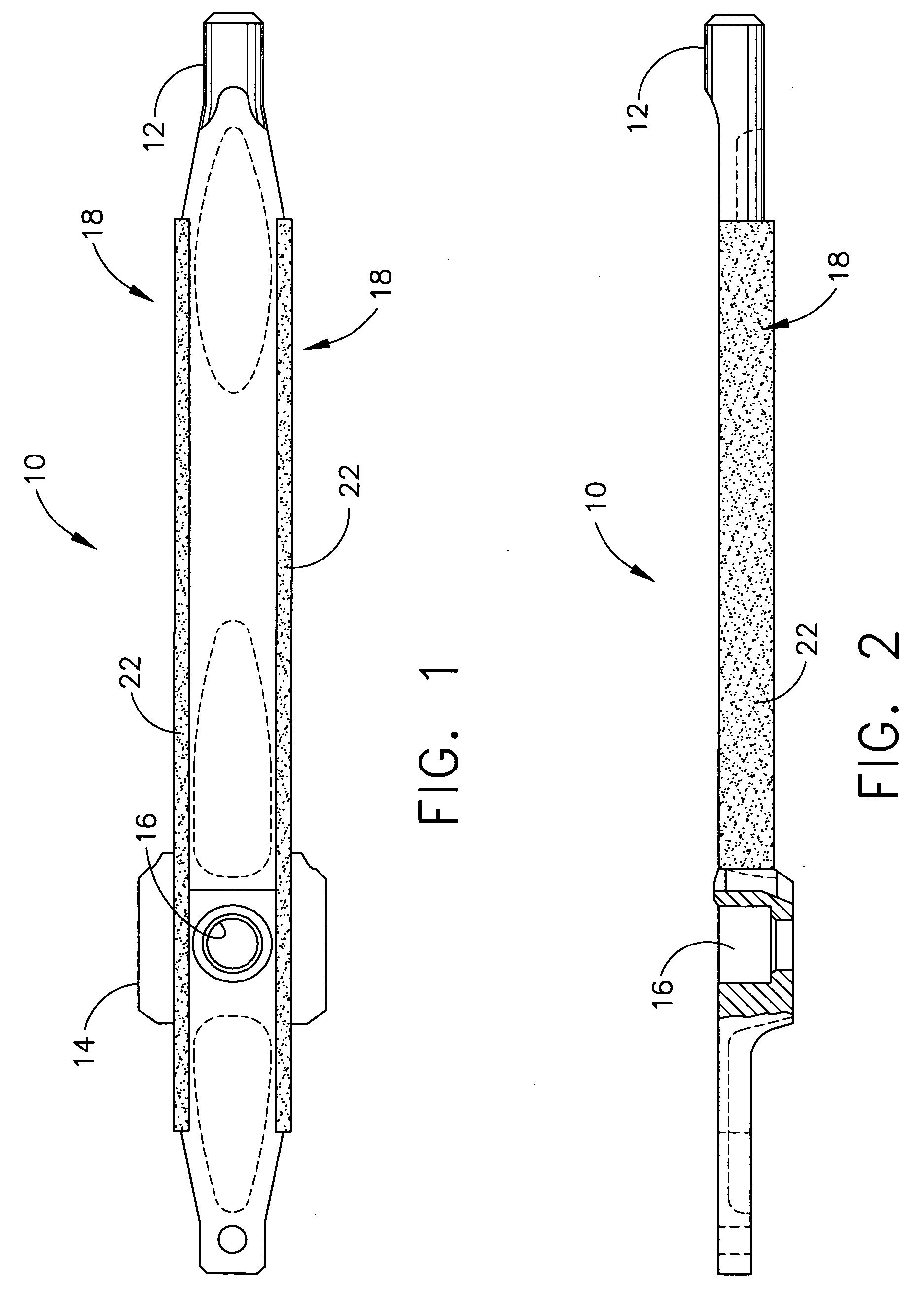

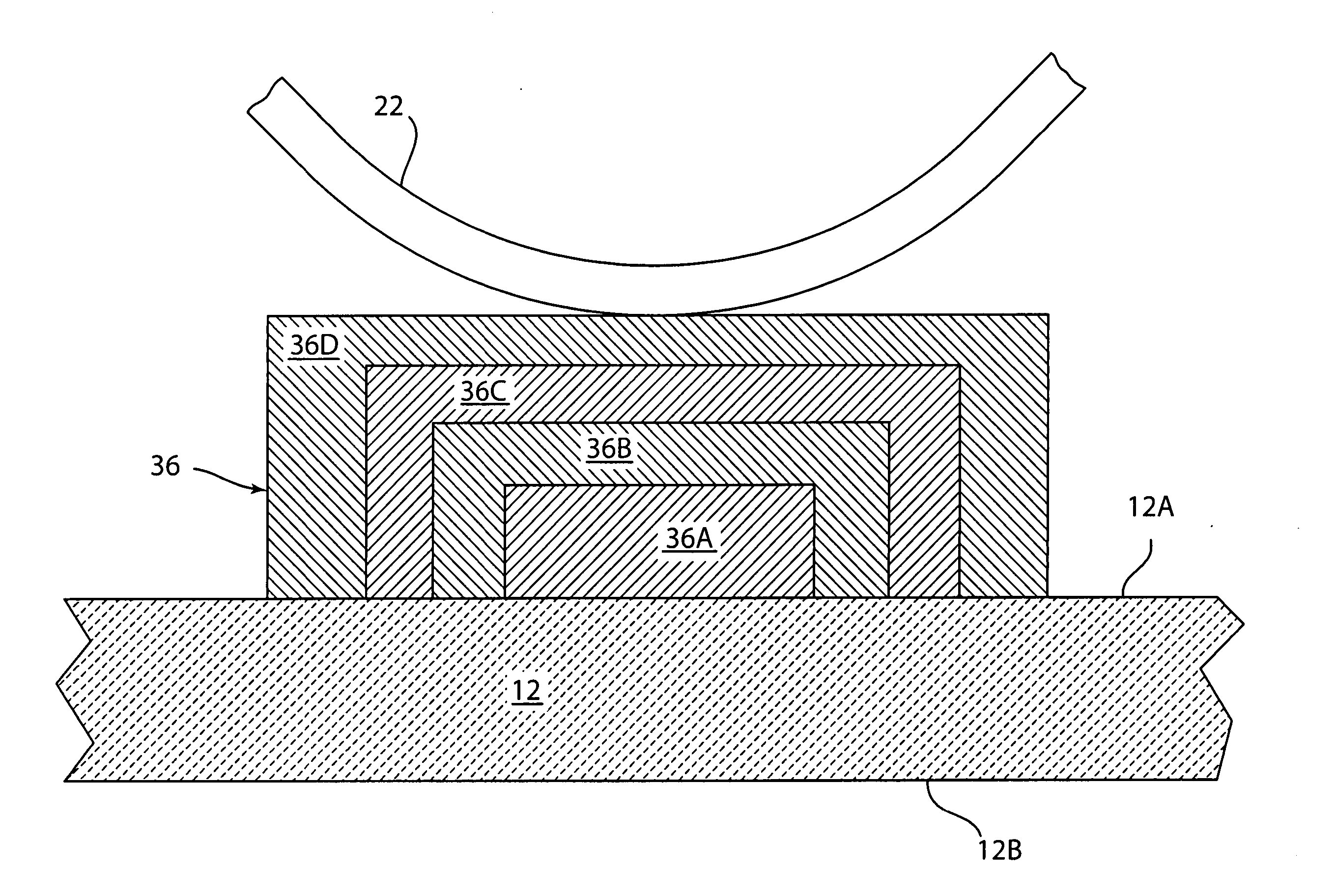

Aircraft wheel part having improved corrosion resistance

InactiveUS20050264090A1Improve corrosion resistanceImprove wear resistanceLiquid surface applicatorsMolten spray coatingThermal sprayingCobalt

A steel member (10) having wear and corrosion resistance through a combination of coatings is disclosed, the steel member (10) being a hardened and tempered steel member having a high tensile strength, at least one selected portion (18) of the steel member (10) coated by thermal spraying with a tungsten carbide-cobalt composition (22) to provide wear and corrosion resistance, the tungsten carbide-cobalt composition (22) being approximately 78-90% tungsten carbide and approximately 10-19% cobalt, and a sacrificial ceramic-metallic coating (24) on the steel member (10) to provide corrosion resistance for the steel member (10). A method of coating a steel member (10) is also disclosed.

Owner:HONEYWELL INT INC

Fuel tank resistor card having improved corrosion resistance

InactiveUS20050040930A1Improve wear resistance and corrosion resistanceAvoid corrosionFixed resistors with intervening connectorsPrinted circuit aspectsSulfurFuel tank

A resistor card for a fuel level sensor has improved resistance to corrosion and wear. The resistor card has a substrate with a resistive layer and a conductive layer. A nickel layer covers the conductive layer. A nickel-gold alloy layer covers the nickel layer. The nickel-gold alloy layer protects the conductive layer from sulfur corrosion and improves wear resistance.

Owner:CTS CORP ELKHART

Part for a timepiece movement

The invention relates to a pivot pin for a timepiece movement including at least one pivot at at least one of the ends thereof, characterized in that said at least one pivot is formed of a composite material having a metallic matrix including at least one metal selected from among nickel, titanium, chromium, zirconium, silver, gold, platinum, silicon, molybdenum, aluminium or an alloy of the above metals, said matrix being charged with hard particles selected from among WC, TiC, TaC, TiN, TiCN, Al2O3, ZrO2, Cr2O3, SiC, MoSi2, Al N or a combination thereof, so as to limit the sensitivity of the pin to magnetic fields.The invention concerns the field of timepiece movements.

Owner:OMEGA SA

Two-phase stainless steel

InactiveCN1412337AStrong acid and alkali corrosion resistanceImprove wear resistance and corrosion resistanceAcid corrosionStress corrosion cracking

The composition of biphase stainless steel is formed from (wt%) 0.01-0.12% of C, 4.0-8.0 % of Mn, 12.0-25.0% of Cr, 0.20-1.5% of Al, 0.5-3.0% of Ni, 0.4-3.0% of Mo, Cu is greater than or equal to 1.0%, 0.2-2.5% of Si, 0.05-0.3% of N, 0.02-0.05% of Re, S is greater than of equal to 0.03%, P is greater than or equal to 0.035% and the rest is Fe. Said biphase stainless steel can resist alkali corrosion, resist acid corrosion, specially it can resist stress corrosion cracking under the condition of resisting chlorine ion and in oxidative acid medium, can resist seam currosion and resist cavity corrosion, and its strength is high and toughness is good, etc.

Owner:陈才金

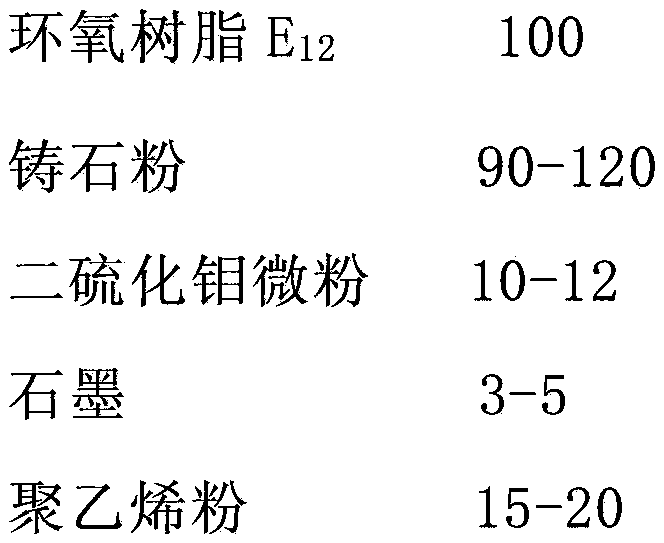

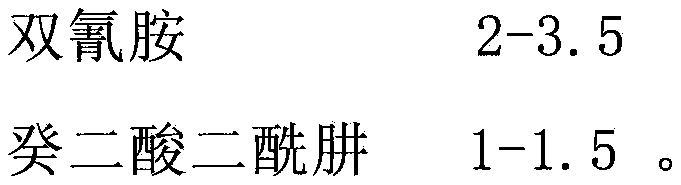

Production method of wear-resistant anti-corrosion inner-coating oil pipe

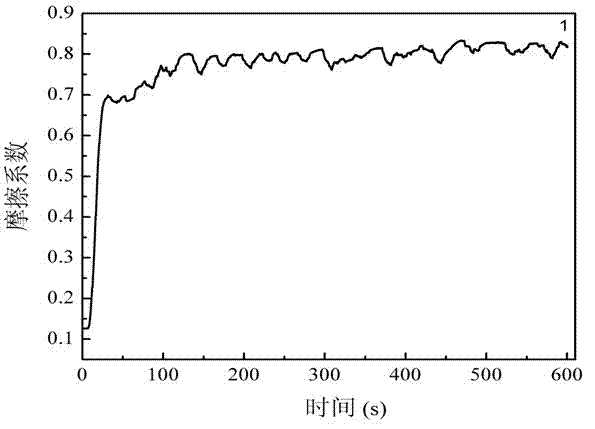

ActiveCN104069999AImprove bindingHigh tensile strengthAnti-corrosive paintsSpecial surfacesEpoxyFriction reduction

The invention relates to a production method of a wear-resistant anti-corrosion inner-coating oil pipe. The coating of the oil pipe comprises, by weight, 100 parts of epoxy resin E12, 90-120 parts of glass-ceramic powder, 3-5 parts of graphite; 10-12 parts of molybdenum disulfide micro powder, 15-20 parts of polyethylene powder, 2-3.5 parts of dicyandiamide and 1-1.5 parts of sebacic acid dihydrazide. The production method includes: deoiling and sand blasting, mixing, preheating, static spraying, curing, forming, polishing, inspecting, powder recycling and the like. By the method which is short in curing time, friction coefficient between a sucker rod and the inner wall of the oil pipe can be lowered evidently, friction reduction and abrasion resistance are achieved, the anti-corrosion performance of the inner wall of the oil pipe can be increased evidently, the inner diameter of the oil pipe is unchanged, pipe wall scaling and paraffin precipitation are restrained, and the oil pipe is good in high temperature resistance, long in service life, and the like.

Owner:PETROCHINA CO LTD

Biphase stainless steel

InactiveCN101429629AStrong acid and alkali corrosion resistanceHigh strengthChemical compositionSodium thiocyanate

The invention relates to a two phase stainless steel, which comprises the following chemical components in weight percent: 0 to 0.12 percent of C, 4.0 to 8.0 percent of Mn, 12.0 to 25.0 percent of Cr, 0.20 to 1.5 percent of Al, 0.5 to 3.0 percent of Ni, 0.4 to 3.0 percent of Mo, 0 to 1.0 percent of Cu, 0.2 to 2.5 percent of Si, 0.05 to 0.3 percent of N, 0.02 to 0.05 percent of Re, less than or equal to 0.03 percent of S, less than or equal to 0.035 percent of P, and the balance being Fe. The two phase stainless steel has the advantages of high strength, good toughness, excellent wear resistance and corrosion resistance, in particular the superiorities of stress corrosion cracking resistance, complete corrosion resistance, intergranular corrosion resistance, and pitting corrosion resistance and vacuole corrosion resistance in sea water in solutions such as strong base (such as NaOH), chlor-alkali (NH4Cl), oxidizing acid (such as HNO3), sodium thiocyanate, phosphate solution, good hot and cold processability, and low cost.

Owner:顾贤良

Fuel tank resistor card having improved corrosion resistance

InactiveUS20050035843A1Improve wear resistance and corrosion resistanceAvoid corrosionFixed resistors with intervening connectorsPrinted circuit aspectsSulfurFuel tank

A resistor card for a fuel level sensor has improved resistance to corrosion and wear. The resistor card has a substrate with a resistive layer and a conductive layer. A nickel layer covers the conductive layer. A nickel-gold alloy layer covers the nickel layer. The nickel-gold alloy layer protects the conductive layer from sulfur corrosion and improves wear resistance.

Owner:CTS CORP ELKHART

Method for densification and spheroidization of solid and solution precursor droplets of materials using microwave generated plasma processing

ActiveUS20140342093A1Improve thermal performanceImprove toleranceLiquid surface applicatorsMolten spray coatingBody fluidMaterial distribution

A method for processing feed material to produce dense and spheroidal products is described. The feed material is comprised of powder particles from the spray-drying technique or solution precursor droplets from ceramic or metallic materials. The feed material is processed using plasma generated from a microwave. The microwave plasma torch employed is capable of generating laminar flow during processing which allows for the production of spheroidal particles with a homogenous materials distribution. This results in products having improved thermal properties, improved corrosion and wear resistance and a higher tolerance to interface stresses.

Owner:6K INC

Weldable, crack-resistant co-based alloy and overlay method

ActiveUS20080193675A1Solve the lack of ductilityImprove corrosion resistancePretreated surfacesArc welding apparatusAlloyWear resistance

A method for imparting wear- and corrosion-resistance to a metal component comprising overlaying the component with a ductile Co-based alloy comprising between about 0.12 wt % and about 0.7 wt % C, between about 20 wt % and about 30 wt % Cr, between about 10 wt % and about 15 wt % Mo, between about 1 wt % and about 4 wt % Ni, and balance of Co, without forming cracks during the alloy's solidification.

Owner:KENNAMETAL INC

Hard phase forming alloy powder, wear resistant sintered alloy, and production method for wear resistant sintered alloy

InactiveUS20100008812A1Low costImprove wear resistance and corrosion resistancePhase formationWear resistant

A hard phase forming alloy powder, for forming a hard phase dispersed in a sintered alloy, consists of, by mass %, 15 to 35% of Mo, 1 to 10% of Si, 10 to 40% of Cr, and the balance of Co and inevitable impurities. A production method, for a wear resistant sintered alloy, includes preparing a matrix forming powder, the hard phase forming alloy powder, and a graphite powder. The production method further includes mixing 15 to 45% of the hard phase forming alloy powder and 0.5 to 1.5% of the graphite powder with the matrix forming powder into a raw powder. The production method further includes compacting the raw powder into a green compact having a predetermined shape and includes sintering the green compact. A wear resistant sintered alloy exhibits a metallic structure in which 15 to 45% of a hard phase is dispersed in a matrix. The hard phase consists of, by mass %, 15 to 35% of Mo, 1 to 10% of Si, 10 to 40% of Cr, and the balance of Co and inevitable impurities.

Owner:HITACHI POWDERED METALS COMPANY

Surface treatment method for loop back rolls of hot continuous rolling units

InactiveCN102896458AExtended service lifeImprove wear resistance and corrosion resistanceMolten spray coatingArc welding apparatusStrip steelAlloy

The invention discloses a surface treatment method for loop back rolls of hot continuous rolling units, and the method comprises the following steps of: firstly, carrying out cleaning pretreatment on the surface of a loop back roll, and carrying out overlay welding on the surface of the loop back roll by using a hard-surface alloy welding wire so as to form a middle transition layer with the thickness of 2-3 mm, wherein the overlay welding current is 380-450A, the voltage is 26-30V, and the overlay welding speed is 300-400 mm / min; then, preparing a work coating with the thickness of 0.5-2 mm by using a spray welding remelting way, wherein the work coating is made of a Ni-based alloy powder material, the distance between a spray gun and the surface of a workpiece is 250 mm, the powder feeding speed is 50-150 g / min, and the gas pressures of acetylene and oxygen are respectively 0.1-0.3 MPa and0.1-0.5 MPa; and finally, carrying out remelting treatment on the work coating by using an oxyacetylene flame gun, wherein the flow rates of acetylene and oxygen are respectively 1 kg / cm<3> and 4.5 kg / cm<3>, and the remelting temperature is 800-1200 DEG C. The method disclosed by the invention can be used for improving the wear resistance and corrosion resistance of the surfaces of loop back rolls, prolonging the service lives of the loop back rolls, ensuring the normal operation of hot continuous rolling units, and improving the quality and production efficiency of strip steel rolling.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

Hard sintered alloy

PCT No. PCT / JP97 / 02722 Sec. 371 Date Feb. 8, 1999 Sec. 102(e) Date Feb. 8, 1999 PCT Filed May 5, 1997 PCT Pub. No. WO98 / 05802 PCT Pub. Date Aug. 5, 1997A hard sintered alloy having not only a wear resistance, a high corrosion resistance and a heat resistance but also a sufficiently high strength and a high tenacity in a wide temperature region from normal temperature to a high temperature is provided. In a sintered alloy comprising a hard phase containing mainly 35-95% of Mo2 NiB2 type complex boride, and a binding phase of hard phase binding Ni group constituting the rest, 0.1-8% of Mn with respect to the whole composition is. added, whereby a hard sintered alloy having a high strength, a high tenacity and a high corrosion resistance is obtained. Furthermore, the addition of W serves to further improve the wear resistance and mechanical characteristics, the addition of Cr and / or V the corrosion resistance and mechanical characteristics, the addition of Cu the corrosion resistance, the addition of Co the oxidation resistance and high temperature characteristics, and the addition of Nb, Zr, Ti, Ta and Hf the mechanical characteristics and corrosion resistance.

Owner:TOYO KOHAN CO LTD

High wear-resisting iron-base thermal spraying coating material and preparation method thereof

InactiveCN104831208AGood high temperature oxidation resistanceImprove densification performanceMolten spray coatingCrazingSpray coating

The present invention discloses a high wear-resisting iron-base thermal spraying coating material, the high wear-resisting iron-base thermal spraying coating powder is made of a metal material, the metal material comprises the following the chemical components by weight: 10-18% of Cr, 0.20-0.50% of C, 0.8-2.0% of Si, 1.5-3.0% of Mn, 0.62-0.88% of Al, 0.55-0.87% of Ti, 0.5-2.0% of Ni, Mn and Ni with the total content of 3.2-3.6%, at least one of Mo and W with the total content of 1-8%, 0.41-0.63% of lanthanum rare earth, and balance of Fe and unavoidable impurities; the coating microstructure is Cr7C3 strengthening phase dispersed austenite, the lanthanum rare earth comprises the following the components by mass: 4-11% of cerium, 10-13% of terbium, 15-22% of gadolinium, 12-15% of praseodymium and balance of lanthanum, the total content of the cerium, terbium, gadolinium, praseodymium and lanthanum is 100%, and the iron-base composite coating powder has good high temperature oxidation resistance, can avoid excessive oxidation in the process of spraying so as to improve the compactness of internal combination of the sprayed coating, the sprayed coating is moderate in pore size and smooth and round in shape, the production of cracks can be effectively reduced, and the tank body oil storage function can be well played.

Owner:SUZHOU TONGMING MACHINERY

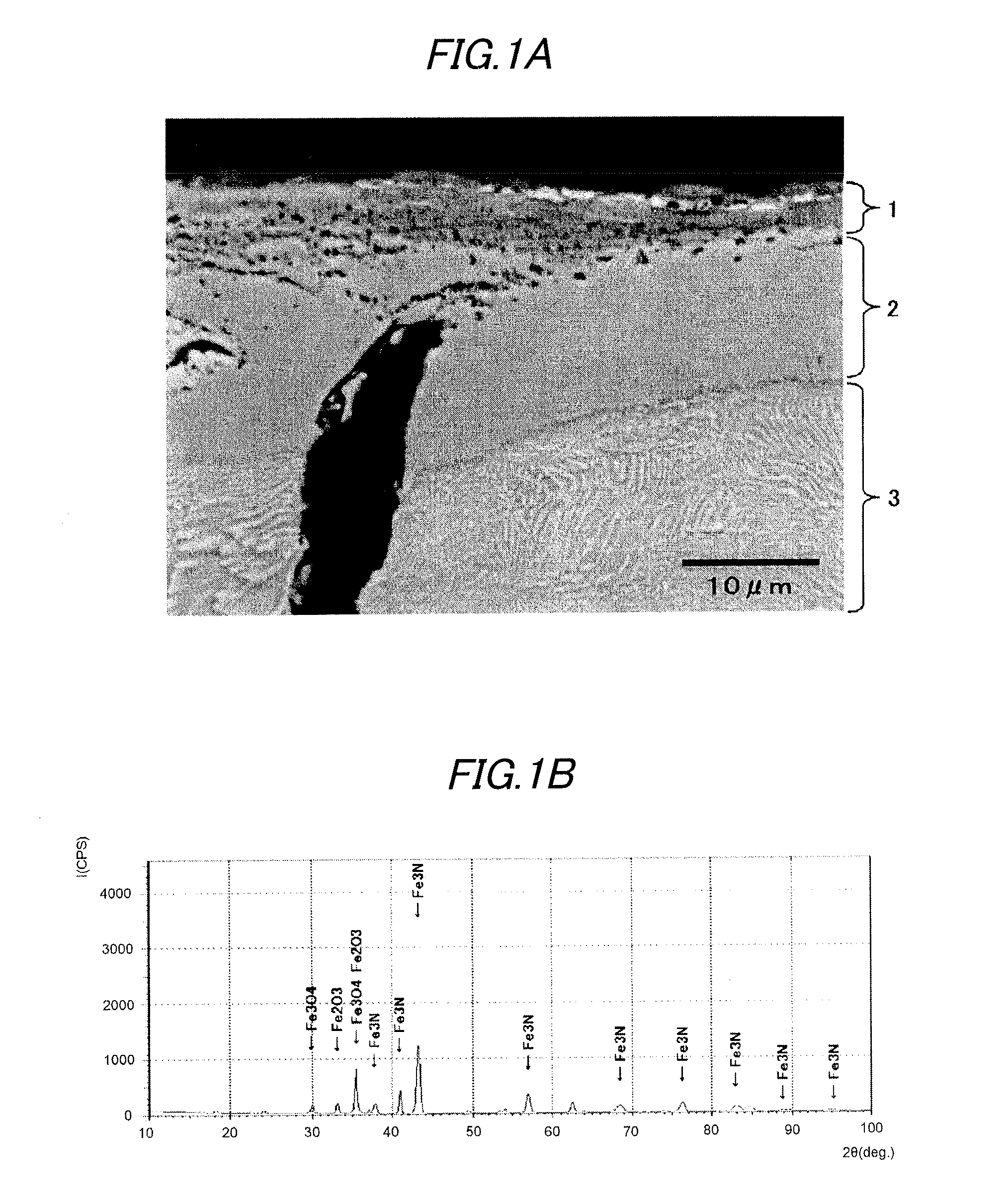

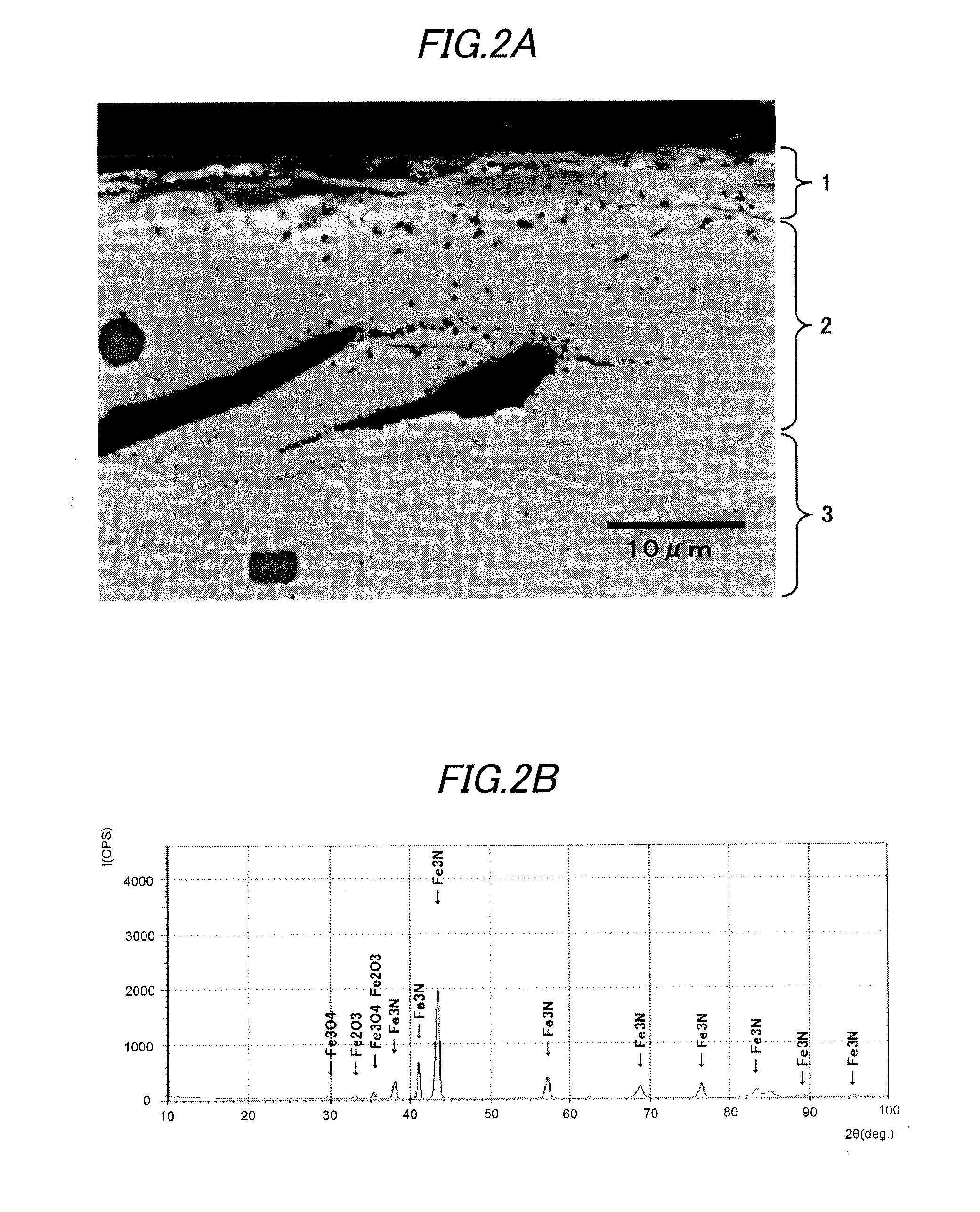

Vehicular disc brake rotor and manufacturing method of vehicular disc brake rotor

ActiveUS20140060983A1Improve corrosion resistanceIncrease frictionBraking discsSolid state diffusion coatingFrictional coefficientDynamometer

A vehicular disc brake rotor is provided with a cast-iron base, a nitrogen diffusion layer formed on the cast-iron base, a nitrogen compound layer formed on the nitrogen diffusion layer, and an iron oxide layer including Fe3O4 and formed on the nitrogen compound layer. In a burnish and a first re-burnish of a “Passenger car-Braking device-Dynamometer test procedures” (which is based on JASO C 406:2000), a change ratio of a frictional coefficient between the burnish and the first re-burnish is 10% or less.

Owner:AKEBONO BRAKE IND CO LTD

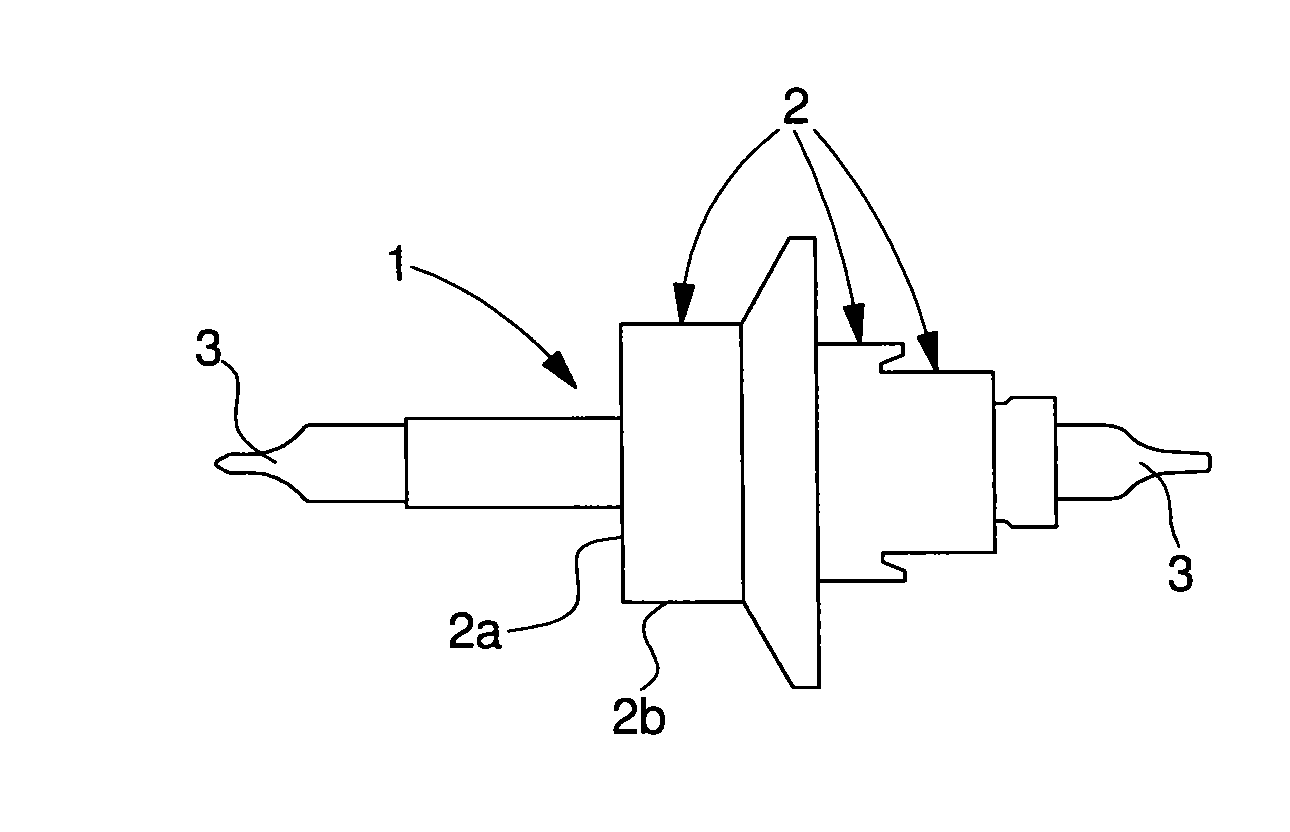

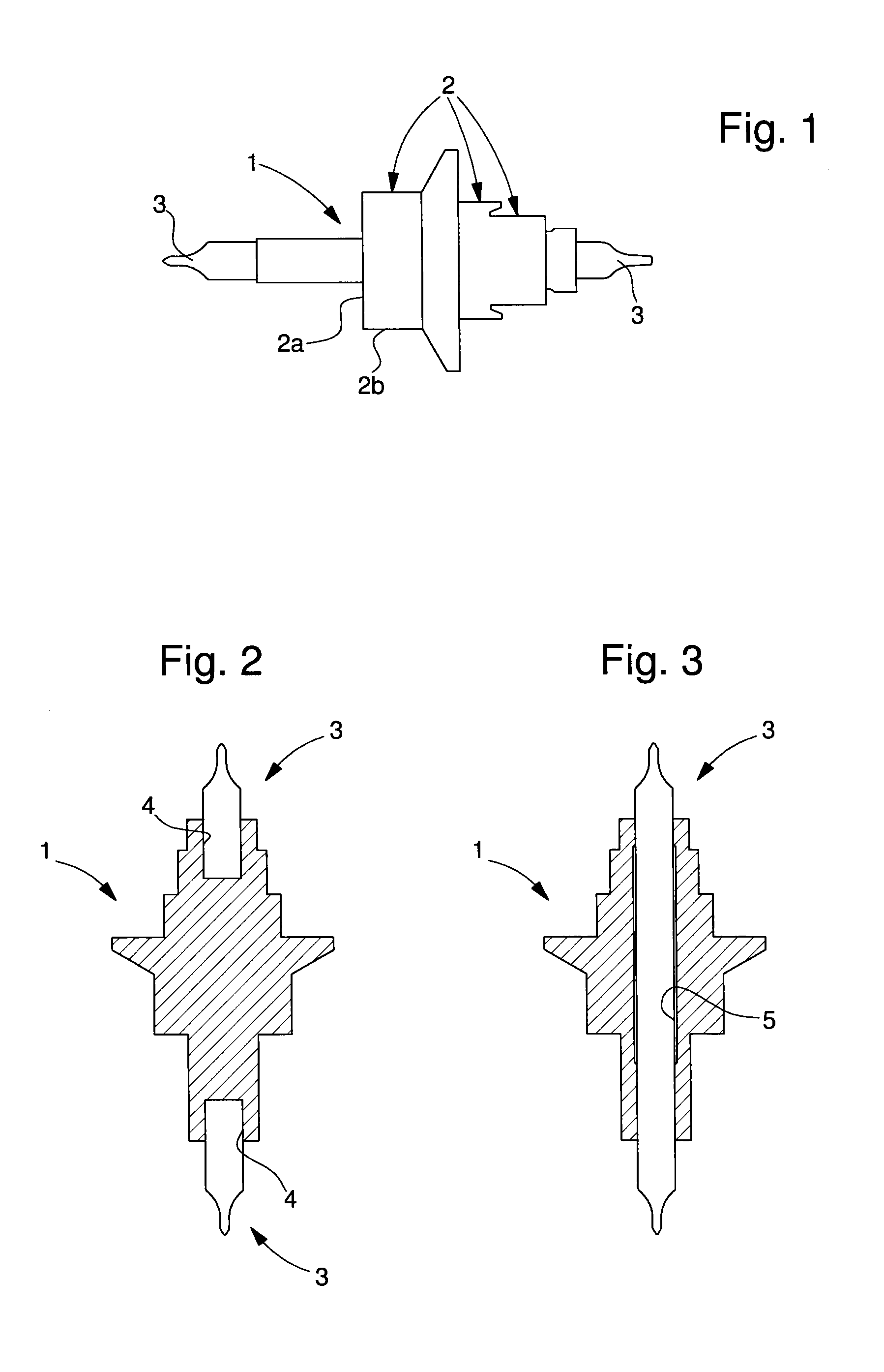

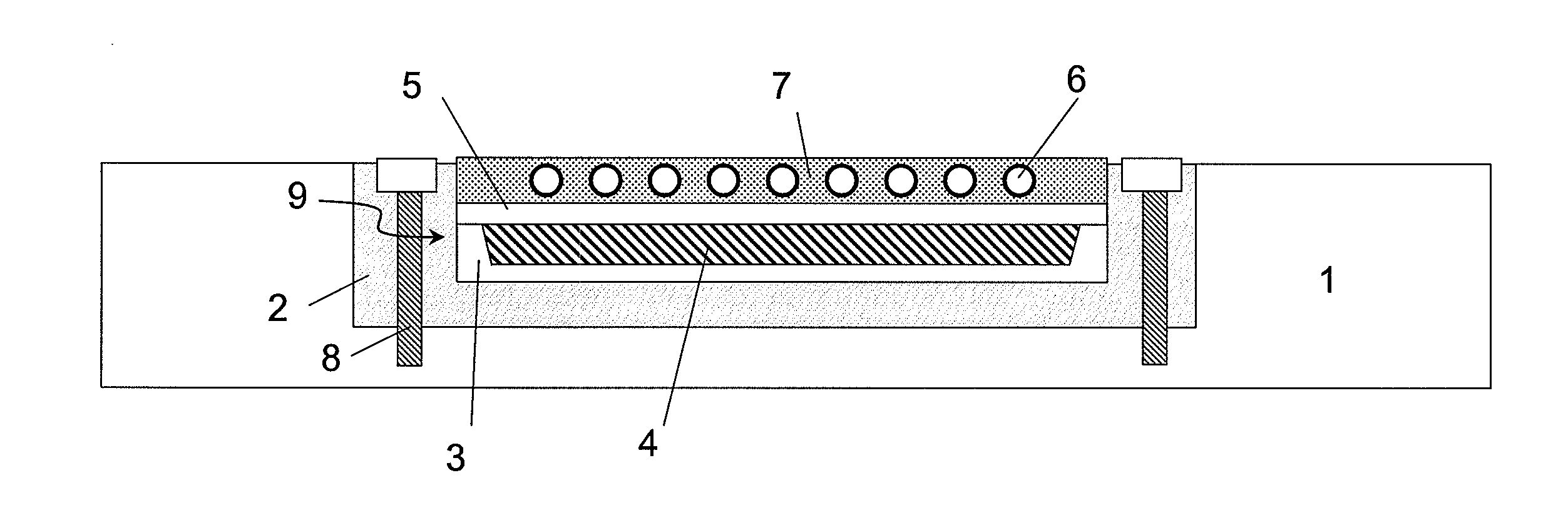

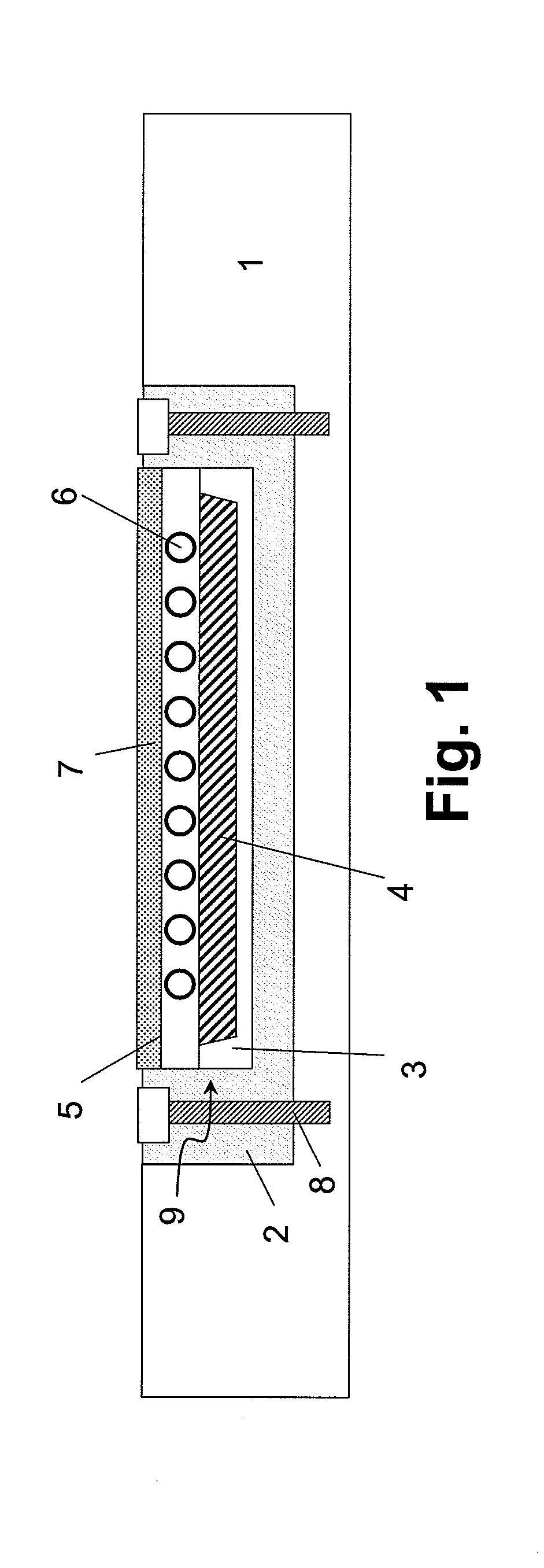

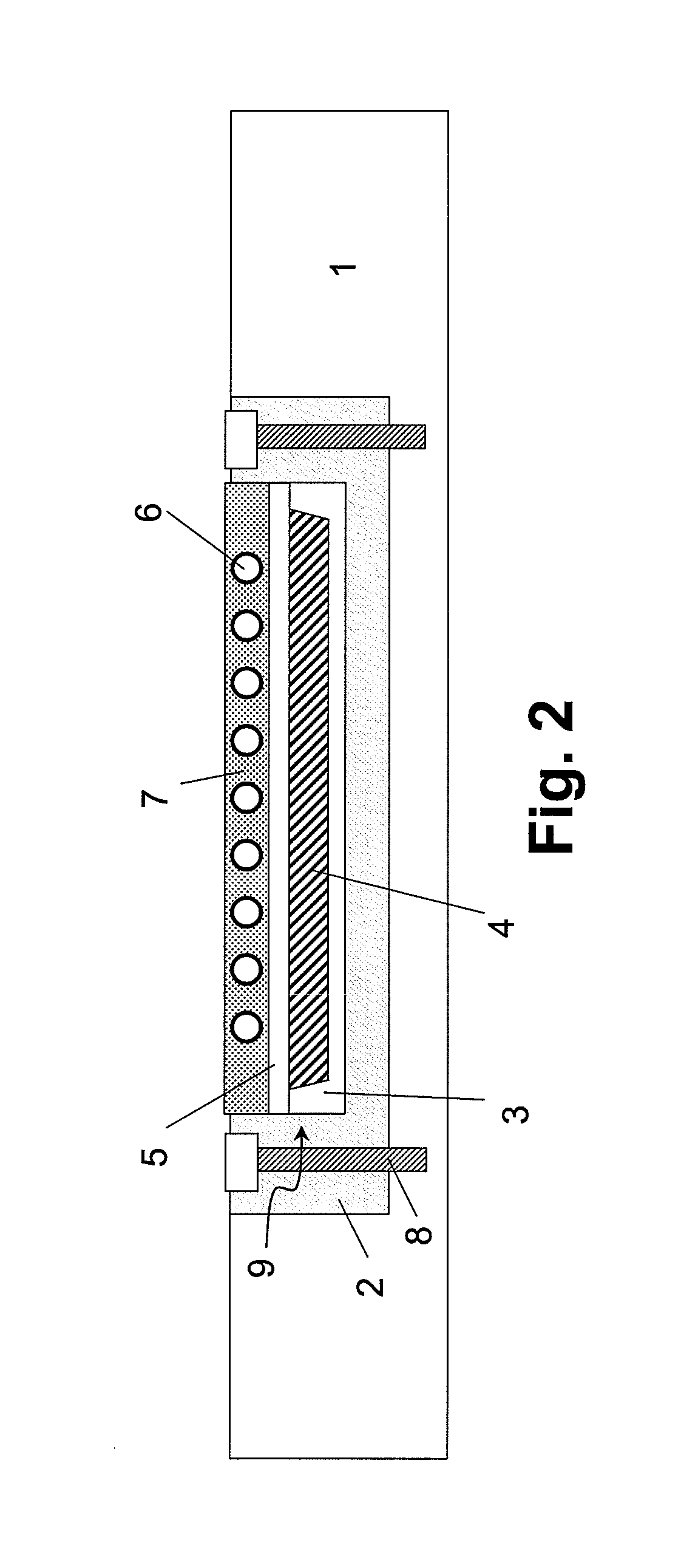

Casting, molding or pressing tool with temperature control medium channels

InactiveUS20110229595A1Improved propertyImprove wear resistance and corrosion resistanceLiquid surface applicatorsMolten spray coatingTemperature controlEngineering

In a method of producing a casting, molding or pressing tool (1) or tool insert (2) with at least one material layer (3, 5, 7) and with temperature control medium channels (6) arranged in the at least one material layer (3, 5, 7), the temperature control medium channels (6) are introduced into the at least one material layer (3, 5, 7) using a thermal spray process (2).

Owner:LINDE AG

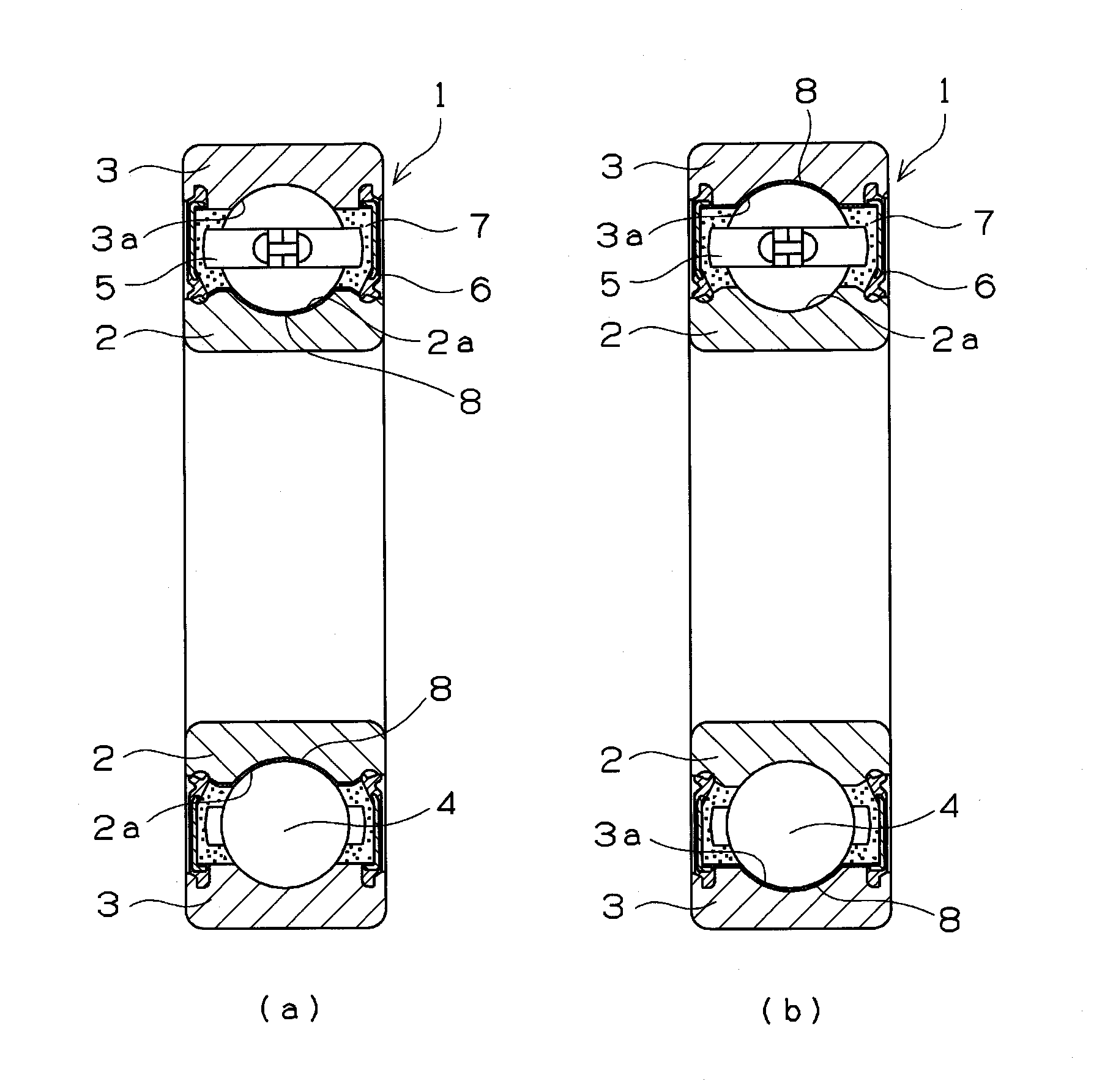

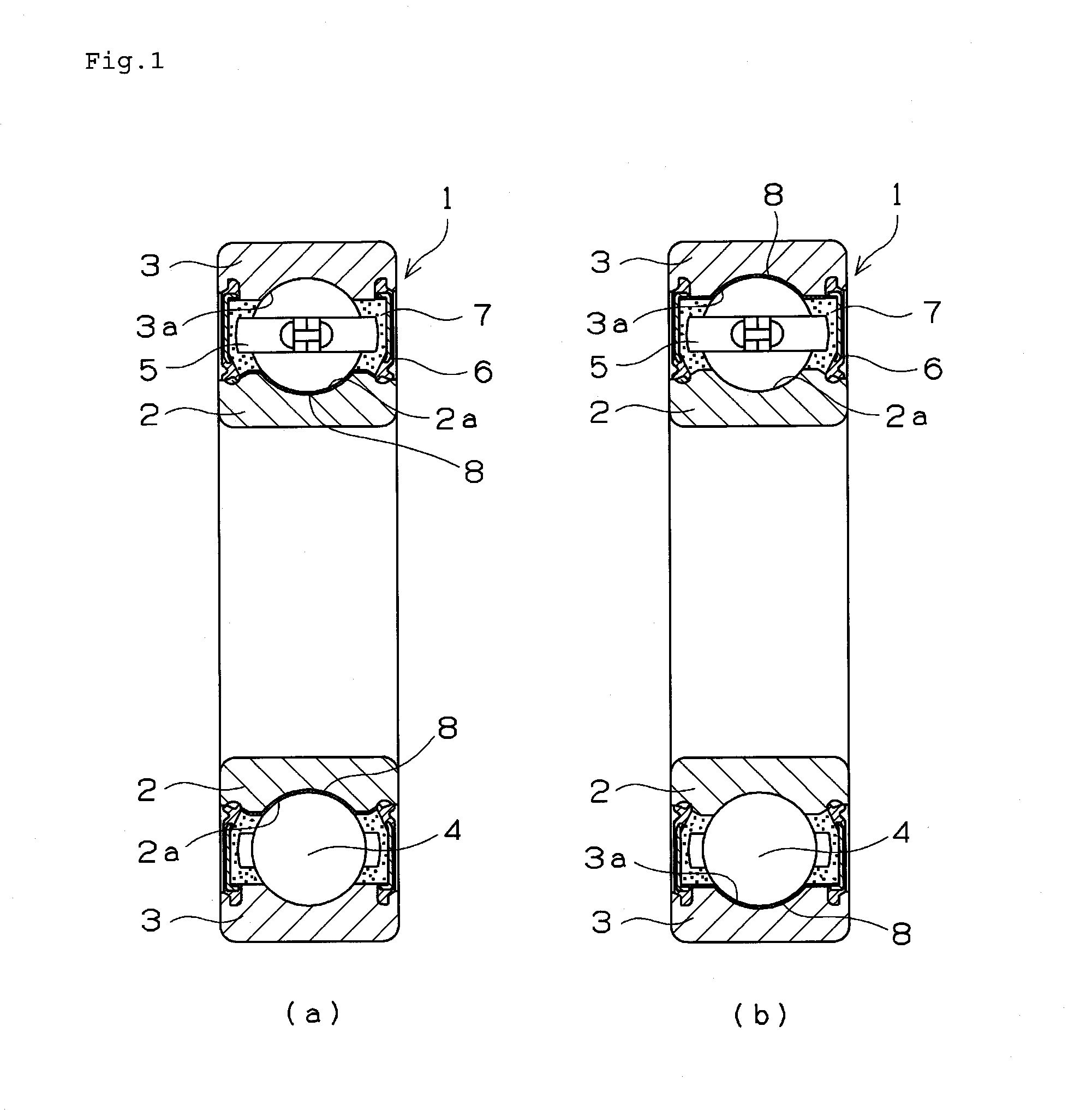

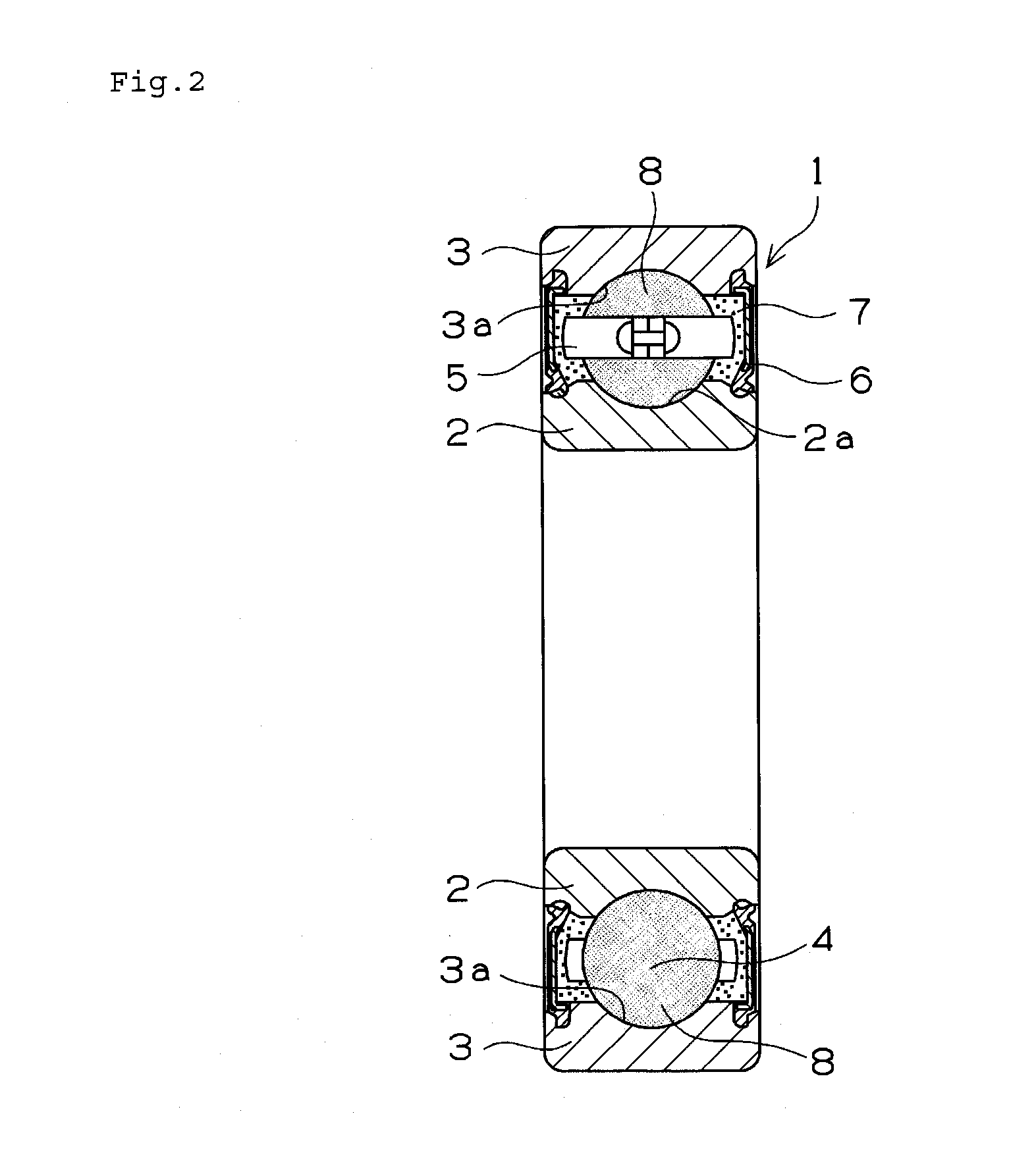

Hard film, hard film formed body, and rolling bearing

ActiveUS20140219595A1Improve adhesionDifficulty concentratingRolling contact bearingsLayered productsSurface layerHydrogen

The present invention provides a hard film which has high wear resistance and excellent peeling resistance and can be prevented from peeling off a base material over a long period of time and a hard film formed body on which the hard film is formed. A hard film (8) has a structure composed of a first mixed layer (8a), consisting mainly of Cr and WC, which is formed directly on a raceway surface (2a) of an inner ring (2) (base material) of a rolling bearing, a second mixed layer (8b), consisting mainly of WC and DLC, which is formed on the first mixed layer (8a), and a surface layer (8c), consisting mainly of DLC, which is formed on the second mixed layer (8b). In the first mixed layer (8a), a content rate of the Cr becomes continuously or stepwise lower and that of the DLC becomes continuously or stepwise higher from a side of the base material toward a side of the second mixed layer (8b). In the second mixed layer (8b), a content rate of the WC becomes continuously or stepwise lower and that of the DLC becomes continuously or stepwise higher from a side of the first mixed layer (8a) toward a side of the surface layer (8c). A content of hydrogen in the second mixed layer (8b) is set to 10 to 45 atomic percent.

Owner:NTN CORP

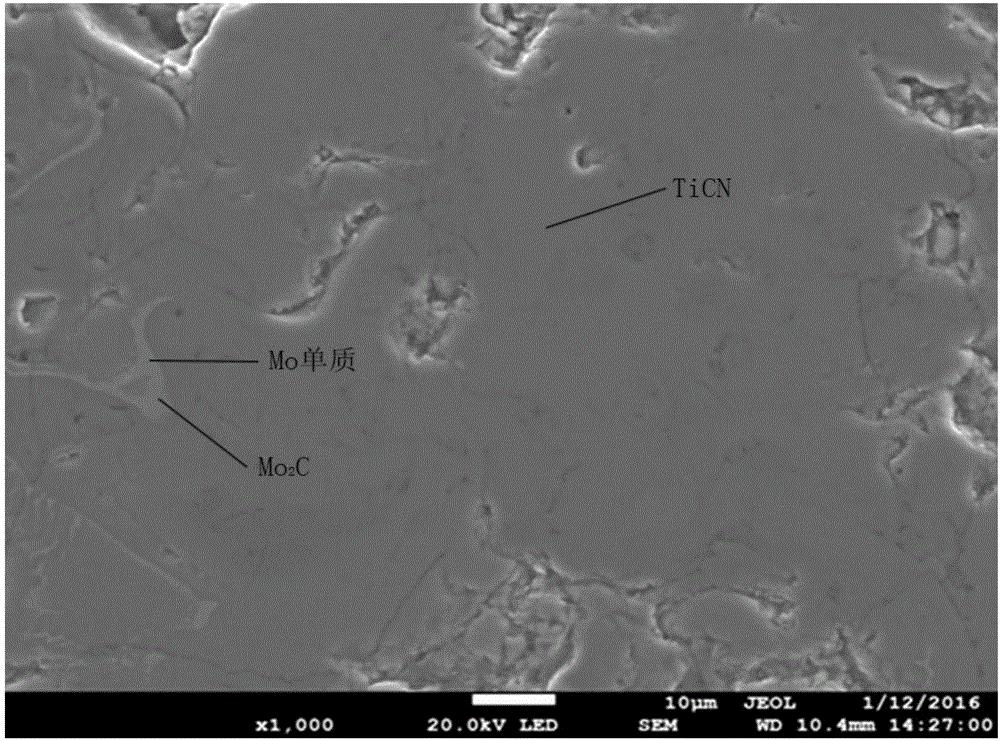

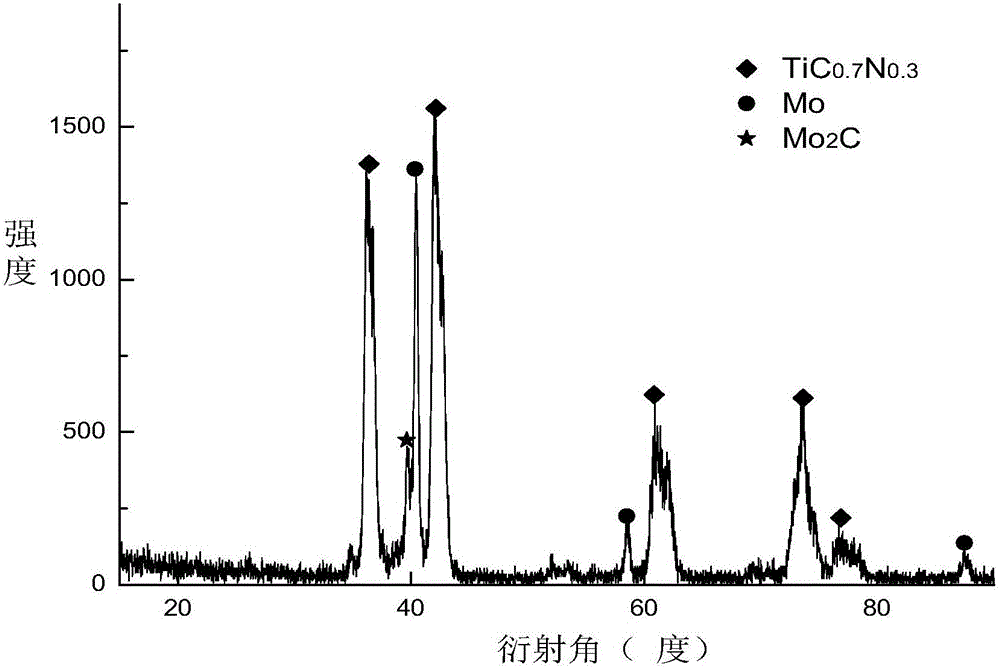

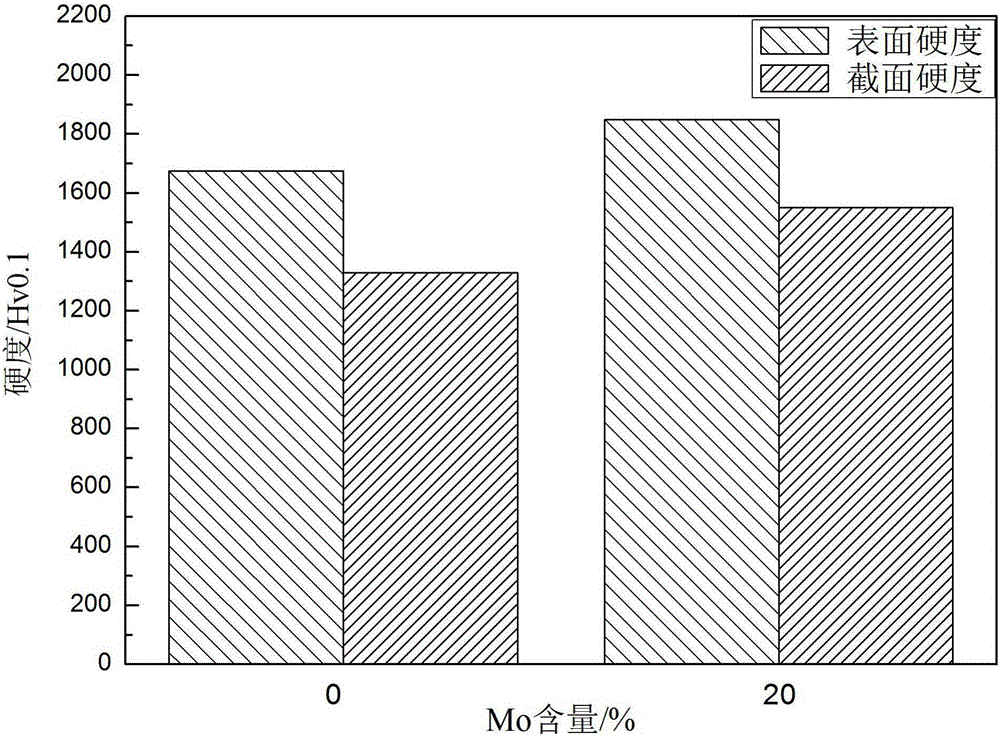

Preparation method of Mo-containing TiCN-based composite coating

InactiveCN106435444AHigh hardnessImprove wear resistanceMolten spray coatingCeramic compositeHardness

The invention discloses a preparation method of a Mo-containing TiCN-based composite coating. The method comprises the following steps that firstly, the surface of a substrate sample is roughened; secondly, Ti / C composite powder and Mo powder are mechanically blended to obtain original feed composite powder; thirdly, the surface of a substrate is pre-coated with Ni-10%wtAl self-refluxing alloy power, so that a base layer with the thickness being 90-120 [mu]m is obtained; and fourthly, the surface of the base layer is coated with the original feed composite powder, so that a TiCN-Mo metal-based ceramic composite coating with the thickness being 300-500 [mu]m is obtained. The plasma-spraying TiCN-Mo metal-based ceramic composite coating is high in hardness, good in abrasion resistance and corrosion resistance, suitable for workpieces, such as cutters, drill bits, moulds and the like in the fields of machinery, automobile making, aerospace and the like, under abrasive and corrosive environment conditions, and the plasma-spraying TiCN-Mo metal-based ceramic composite coating has extremely wide application prospects.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com