Hard polyurethane foam material and preparation method thereof

A technology of rigid polyurethane and foam materials, which is applied in the field of building materials, can solve the problems of different reinforcement effects of materials, and achieve the effects of good heat insulation effect, good wear resistance and corrosion resistance, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

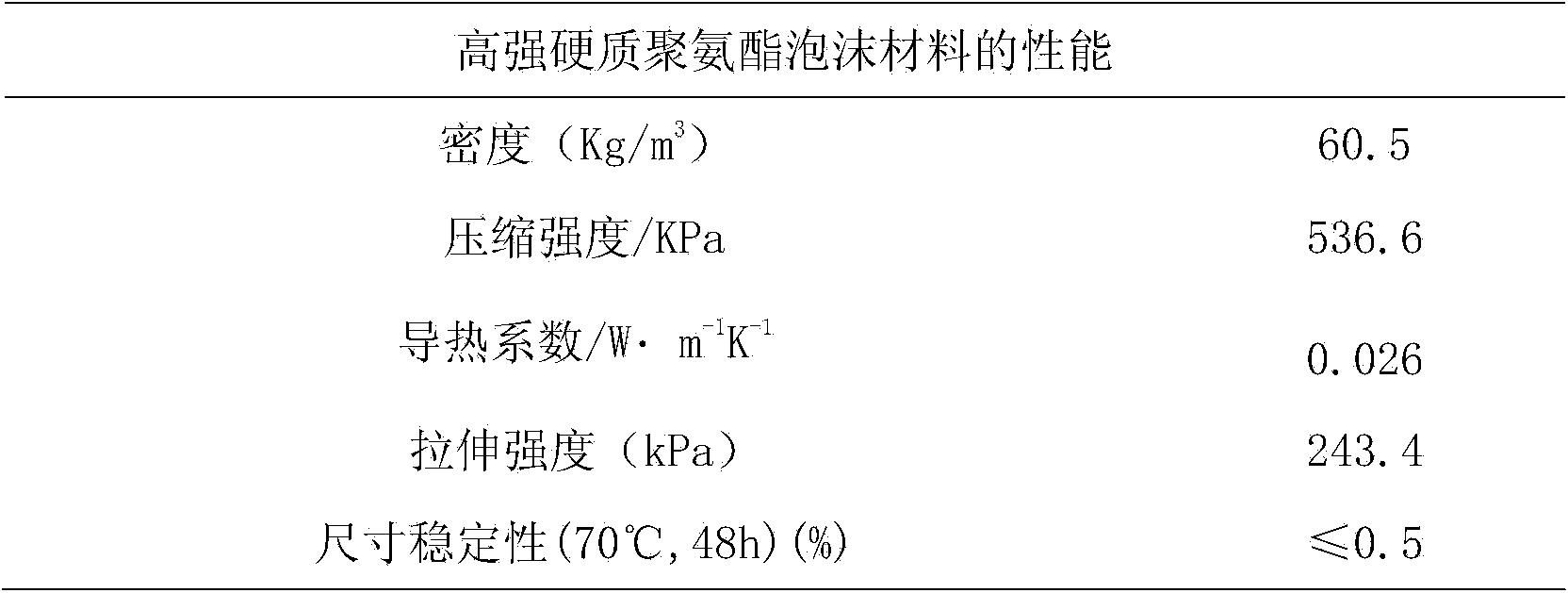

Embodiment 1

[0028] Component A: Weigh 100 parts of polyphenyl polymethylene polyisocyanate PAPI, brand M20S, the mass fraction of NCO is 31.4%, the viscosity (25°C) is 200mPa·s, and the average functionality is 2.7 (BASF (China) Co., Ltd. Company Shanghai Branch).

[0029] Preparation of component B: at a temperature of 25°C, weigh 3.0 parts of foam stabilizer AK-8806, 4.0 parts of diethylenetriamine, 0.8 parts of T-120, 18.0 parts of Solkane365mfc, 5.0 parts of ethylenedi Alcohol, 4.0 parts of triethanolamine, 7.0 parts of glass fiber and 8.0 parts of SiO 2 Add it into the agitator, pre-weigh 75 parts of polyether polyol SU-415M and 25 parts of polyester polyol PS-3802, and stir for 360s with the agitator at a speed of 120r / min.

[0030] Among them, polyether polyol SU-415M has a hydroxyl value of 400-430mgKOH / g, and a viscosity (25°C) of 2000-5000mPa·s (Shandong Bluestar Dongda Chemical Co., Ltd.); polyester polyol PS-3802, a hydroxyl value 380~400mgKOH / g, viscosity (25℃) is 3000±500m...

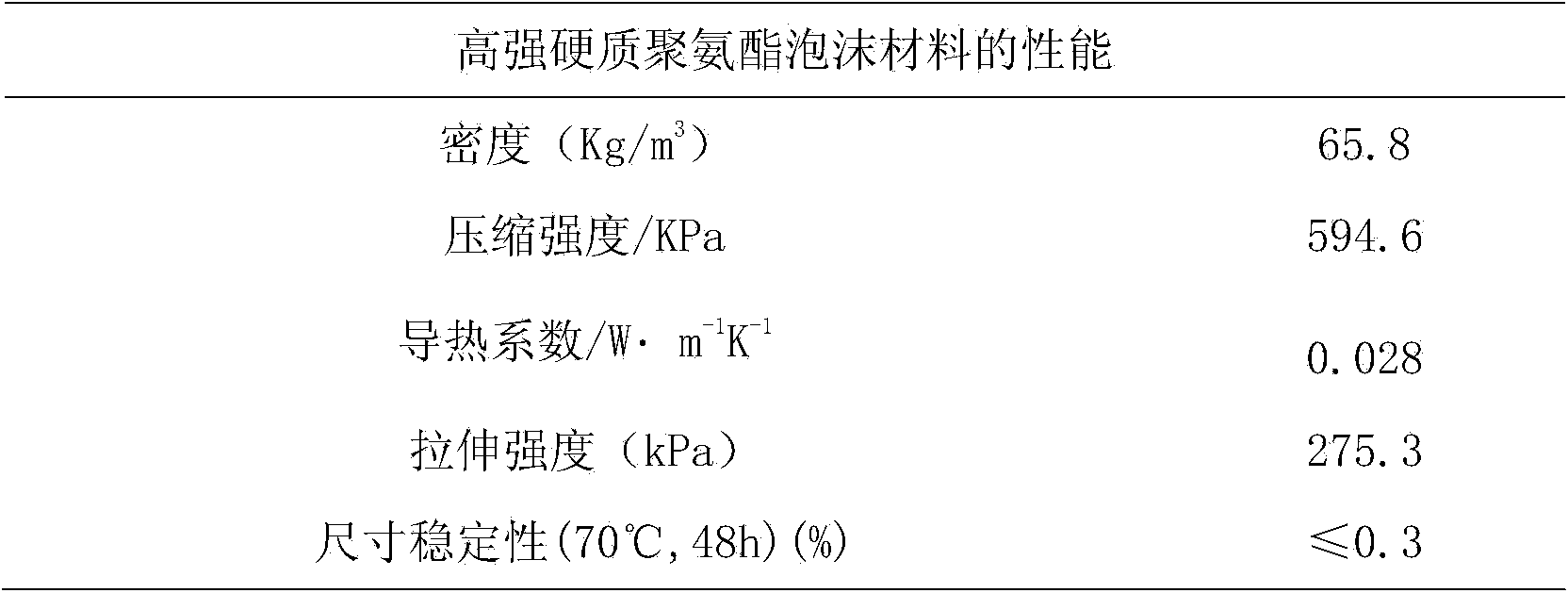

Embodiment 2

[0036] Component A: Weigh 100 parts of polyphenyl polymethylene polyisocyanate PAPI, grade 44V20, the mass fraction of NCO is 30.2-32.0%, the viscosity (25°C) is 150-250mPa·s, and the average functionality is 2.7 (Bayer Chemical).

[0037] Preparation of component B: at a temperature of 25°C, weigh 4.0 parts of foam stabilizer Silbyk TP-3798, 5.0 parts of triethylenediamine, 0.5 parts of T-9, 18.0 parts of HCFC-123, 6.0 parts glycerol, 5.0 parts of trimethylolpropane, 7.0 parts of carbon fiber and 8.0 parts of TiO 2 Add it to the agitator, weigh 75 parts of polyether polyol SU-450L and 25 parts of polyester polyol SKR-410 in advance, and stir it for 360s with the speed of 120r / min.

[0038] Among them, polyether polyol SU-450L, molecular weight 586, hydroxyl value 440-460mgKOH / g, viscosity (25°C) 6000-10000mPa·s (Shandong Bluestar Dongda Chemical Co., Ltd.); polyester polyol SKR-410 , the hydroxyl value is 400-420mgKOH / g, the viscosity (25°C) is 3000±500mPa·s (Qingdao Ruinuo C...

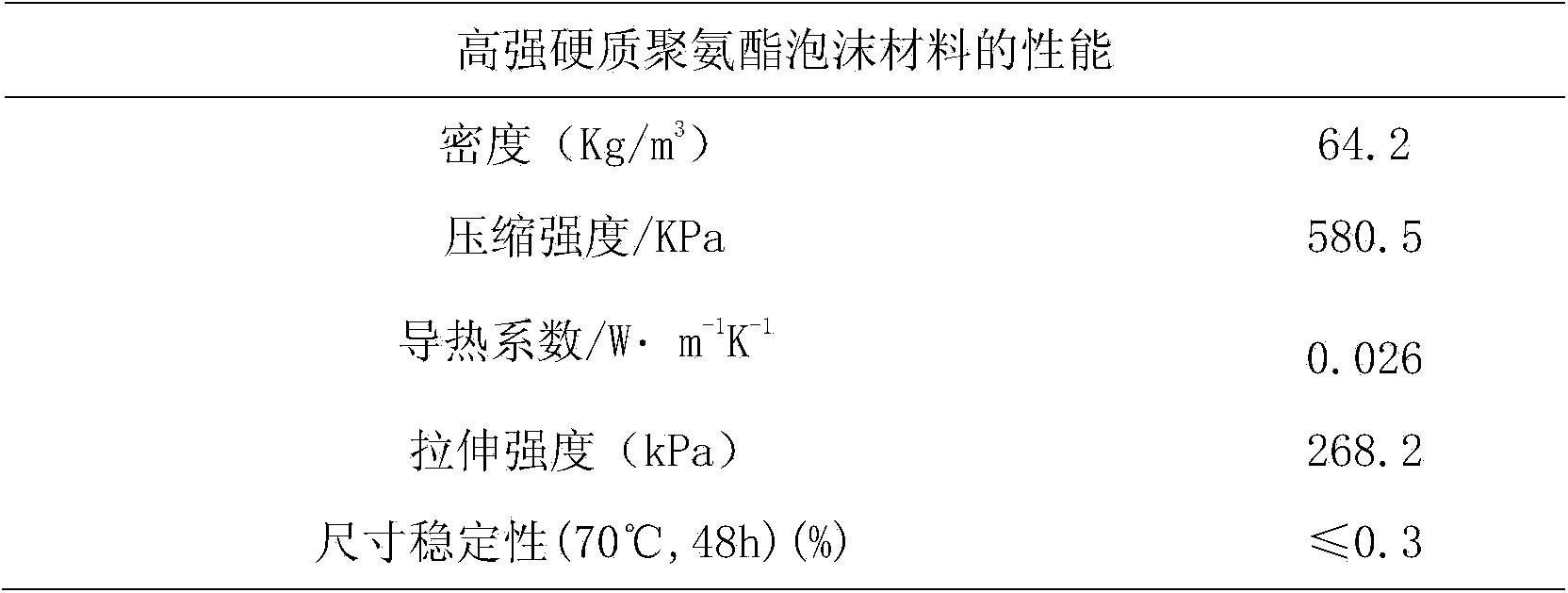

Embodiment 3

[0044] Component A: Weigh 110 parts of polyphenyl polymethylene polyisocyanate PAPI, brand PM-200, the mass fraction of NCO is 30.8%, the viscosity (25°C) is 166mPa·s, and the average functionality is 2.6 (Yantai Wanhua ).

[0045] Preparation of component B: at a temperature of 25°C, weigh 4.5 parts of foam stabilizer AK-6618, 6.5 parts of N,N-dimethylbenzylamine, 1 part of T-12, and 20 parts of cyclopentyl Alkane, 6.0 parts of 3,5-dimethylthiotoluenediamine, 8.0 parts of bis-2-(hydroxypropyl) aniline, 8.0 parts of glass fiber and 10.0 parts of SiC were added to the stirrer, and 70 parts were weighed in advance. 1 part of polyether polyol DD-4110 and 30 parts of polyester polyol SKR-400C, stirred by a stirrer for 360s at a speed of 120r / min.

[0046] Among them, polyether polyol DD-4110 has a hydroxyl value of 430-470mgKOH / g, and a viscosity (25°C) of 3000-6000mPa·s (Shandong Bluestar Dongda Chemical Co., Ltd.); polyester polyol SKR-400C, a hydroxyl value 390~410mgKOH / g, vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com