Patents

Literature

48 results about "Dimethylbenzylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethylbenzylamine is the organic compound with the formula C₆H₅CH₂N(CH₃)₂. The molecule consists of a benzyl group, C₆H₅CH₂, attached to a dimethylamino functional group. It is a colorless liquid. It is used as a catalyst for the formation of polyurethane foams and epoxy resins.

Full-water-type combined polyether and application method thereof, and polyurethane rigid foam composition

InactiveCN102079803AProcess environmental protectionObvious social benefitsSocial benefitsPolymer science

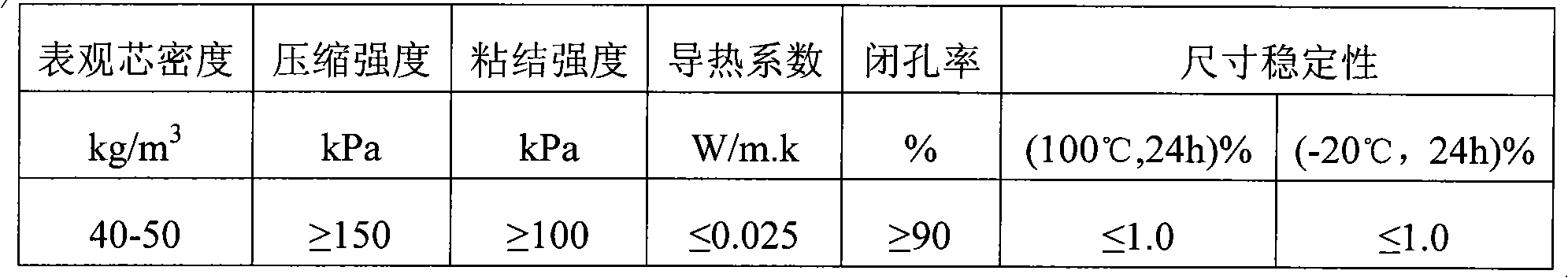

The invention discloses a full-water-type combined polyether and an application method thereof. The full-water-type combined polyether comprises polyether polyol SA380, polyether polyol 310, a foam stabilizer, N,N-dimethylcyclohexylamine, N,N-dimethylbenzylamine and water. The invention also discloses a composition for preparing polyurethane rigid foam. The full-water-type combined polyether disclosed by the invention overcomes the defect that Freon foaming agents used in the existing combined polyether can produce irreversible pollution in the environment, and the defects of foam deformation, higher brittleness and the like when water is used as the foaming agent. The invention provides a full-water-type combined polyether which uses water as the foaming agent; and the prepared combined polyether has the advantages of favorable thermal conductivity, excellent dimensional stability, excellent flowability, excellent demoldability and high compression strength, is especially suitable to be used as a heat insulating material in the field of solar water heaters, and has obvious environmental-protection advantage and social benefit.

Owner:SHANGHAI DONGDA POLYURETHANE

Monocomponent polyurethane adhesive and preparation method and use thereof

InactiveCN101139512ALow reaction temperatureShort reaction timePolyureas/polyurethane adhesivesLaminationPolyurethane adhesiveToluene diisocyanate

The invention relates to a single-component polyurethane binder and a preparing method and application of the binder, and pertains to the technical field of chemical binder. The binder is got by the following procedures: mixing low-hydroxyl-value dehydrated castor oil and polyaryl polymethylene isocyanate as main raw materials with toluene diisocyanate, refined castor oil, and trimethylolpropane-oxypropylene polyether troil; using stannous octanoate, triethylenediamine and N, N-dimethylbenzylamine as complexing catalyst, and 4-tert-butyl-catechol as antioxidant, and allowing them reacting under 50-60 DEG C. The single-component polyurethane binder is for binding color steel sheets and polystyrene foam sheets, is a castor oil type single-component polyurethane binder; the curing flexibility is good, and the contraction rate is high; the binder is of high binding strength for two interfacing surfaces, and is of low cost in term of raw materials.

Owner:UNIV OF JINAN

Low density full water blown polyurethane rigid foam

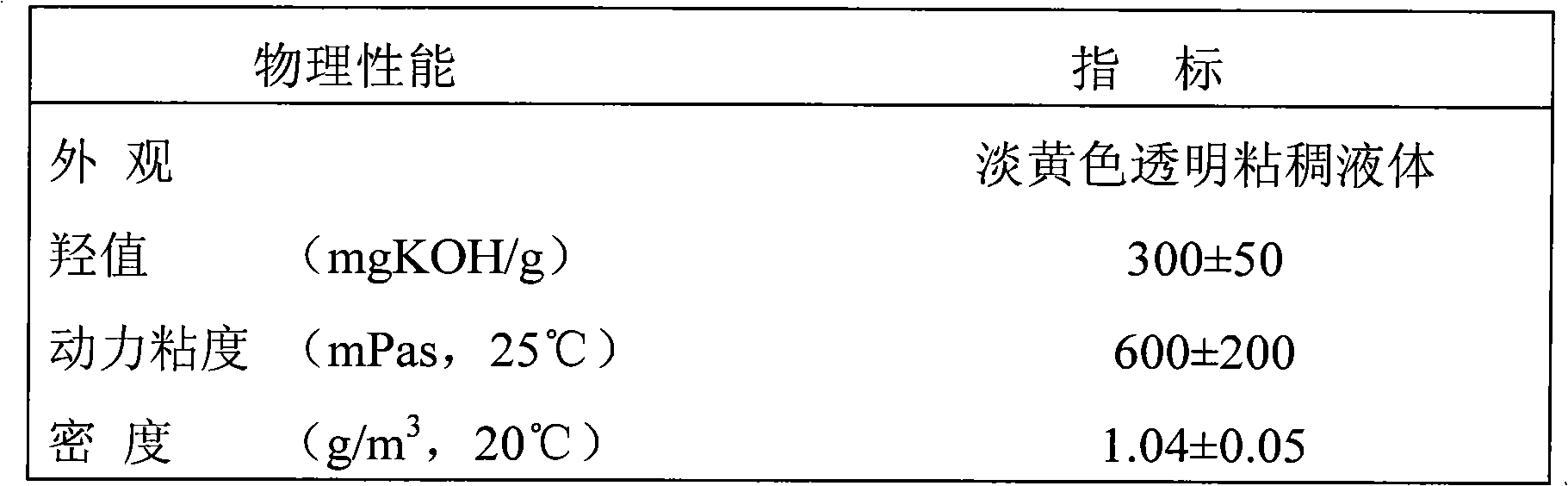

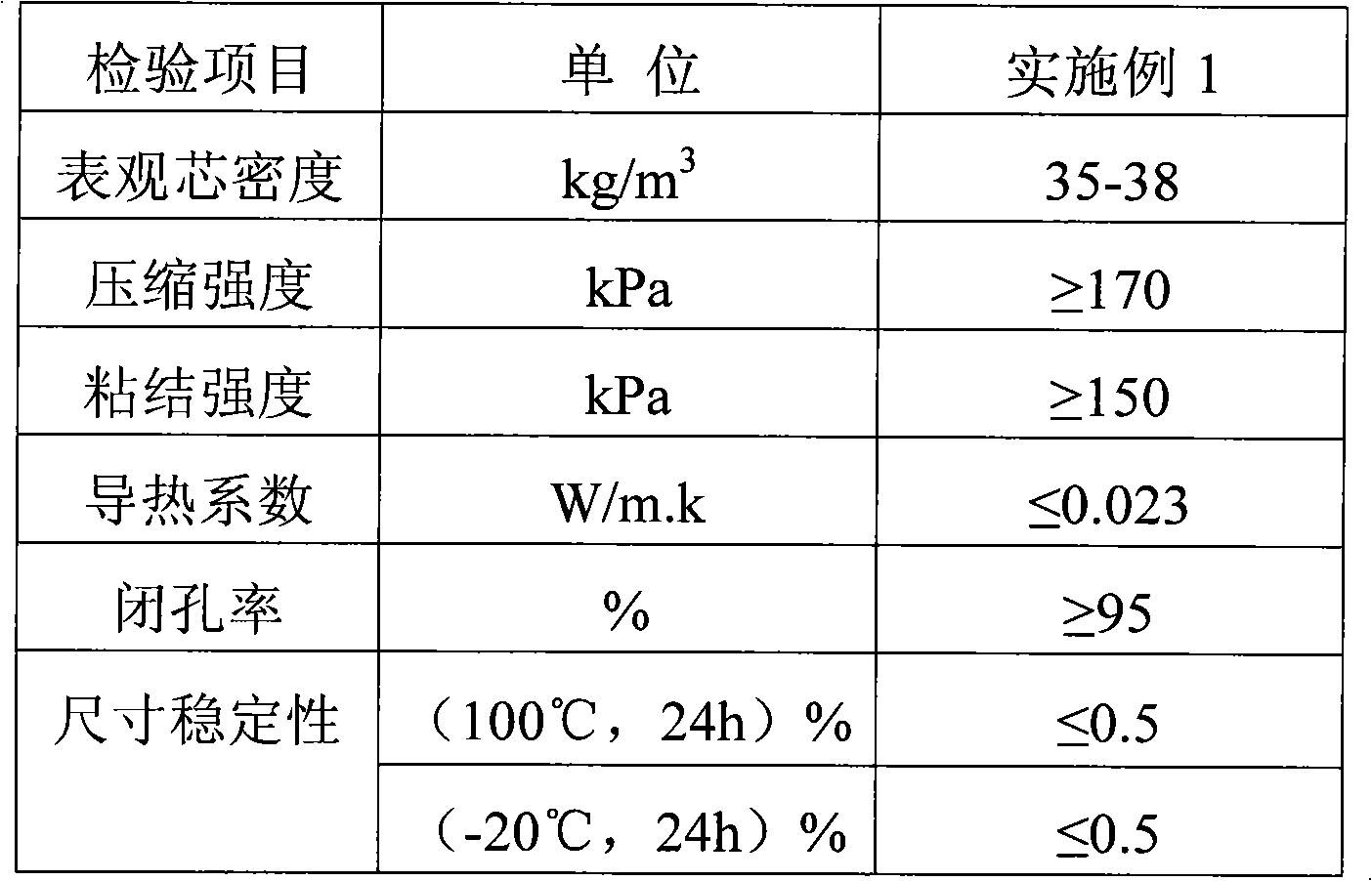

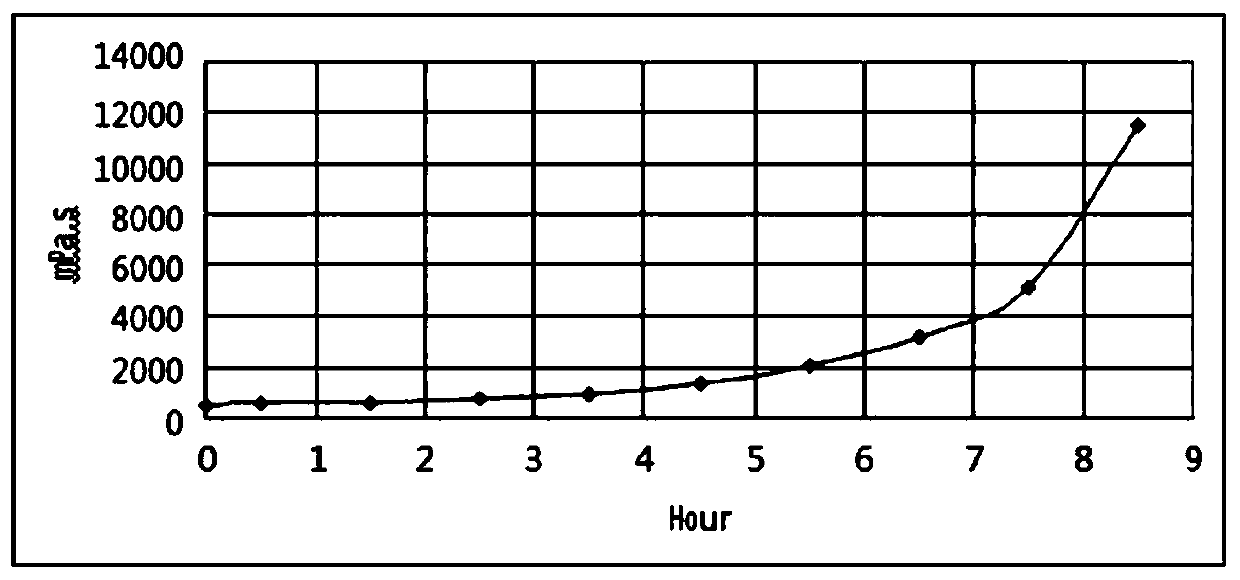

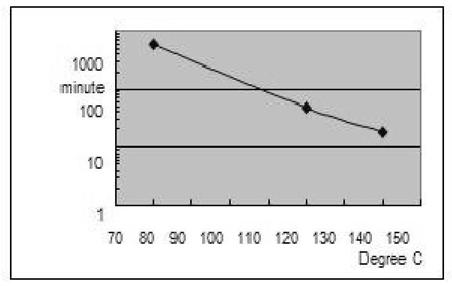

A formulation for preparing a low density, full water blown polyurethane rigid foam includes an isocyanate component; an isocyanate-reactive component comprising from 30-50 wt % of a first polyether polyol having a functionality greater than 5 and an OH value from 350-550 mgKOH / g; from 5 to 25 wt % of a diol having an OH value from 100-300 mgKOH / g; and from 15 to 35 weight percent of a second polyether polyol having a functionality from 3 to 5; further including from 1.5 to 5 wt % of a catalyst selected from dimethylbenzylamine and / or 1,2-dimethyl-imidazole; from greater than 0 to 1 wt % of a trimerization catalyst selected from a glycine salt and / or tris(dimethyl aminomethyl) phenol; greater than 4.1 wt % water as a blowing agent; and any additional constituents selected such that the formulation, excluding the isocyanate component, totals 100 wt % and, the formulation absent the isocyanate component, has a dynamic viscosity from 540 to 864 mPa*s at 20° C. Processing under one-shot conditions can yield a rigid form having a molecular weight per crosslink ratio from 380 to 420. The formulation offers good processability, while the foam shows desirable dimensional stability and mechanical properties at unexpectedly low applied density.

Owner:DOW GLOBAL TECH LLC

High performance modified polyurethane coating

InactiveCN105567073AImprove thermal stabilityImprove heat resistancePolyurea/polyurethane coatingsBenzoic acidSulfolane

The invention discloses a high performance modified polyurethane coating. The coating comprises isophorone diisocyanate, polytetramethylene ether glycol, alkynyl group-containing polyol, phenylboronic acid, trimethylol propane, N,N-dimethylbenzylamine, cerium hydroxide, acidified carbon nanotubes, organic modified montmorillonite, 2,3-dibromo tripropylborate, triethylamine, 3,3'-diamino-4,4'-dihydroxydiphenylsulphone, 1-sulfolane-3-ethoxycarbonyl-5-hydroxypyrazole, 1,4-bis(dimethylhydroxysily)benzene, a leveling agent, methylsilicone oil, a wetting agent, benzoic acid, propylene glycol, dihydroxyacetone, adipic dihydrazide, liquid styrene butadiene rubber, liquid nitrile butadiene rubber and water. The high performance modified polyurethane coating has the advantages of excellent flame retardation performance, high strength, good heat stability, strong adhesion to a substrate, and long service life.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Copper-clad plate reinforced by glass fiber cloth

ActiveCN106189083AHigh dielectric constantImprove flame retardant performanceLaminationLamination apparatusDielectricEpoxy

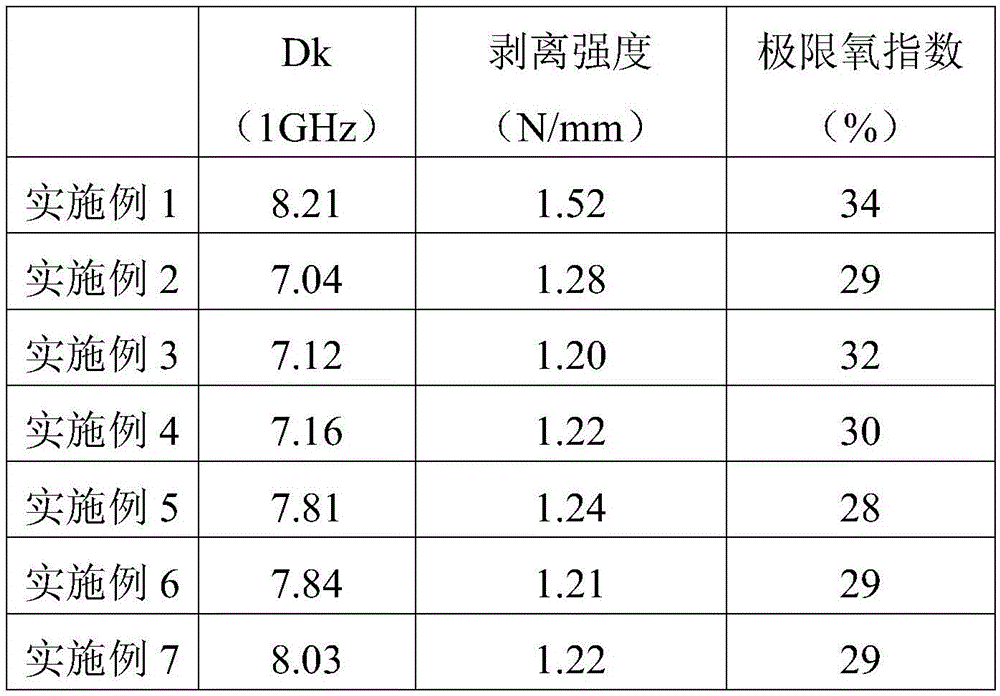

The invention discloses a copper-clad plate reinforced by glass fiber cloth. The copper-clad plate comprises prepreg. The prepreg is obtained by soaking the glass fiber cloth in an epoxy resin adhesive and then dried. The epoxy resin adhesive is prepared from, by weight, 45-55 parts of dicyclopentadiene novolac epoxy resin, 15-25 parts of tetraphenol ethane epoxy resin, 0.3-3 parts of N,N-dimethylbenzylamine, 0.3-3 parts of zinc dioctanoate, 20-80 parts of ethyl acetate, 200-300 parts of high-dielectric-constant filler and 5-15 parts of fire retardant. The copper-clad plate is reinforced by the glass fiber cloth; through the reasonable matching, the types and amounts of the proper high-dielectric-constant filler and the proper fire retardant are preferentially selected, the dielectric constant, flame retardance and stripping strength are improved, comprehensive performance is quite excellent, the filler dispersing effect is good, cost is low, and the copper-clad plate is environmentally friendly and economical.

Owner:江门建滔积层板有限公司

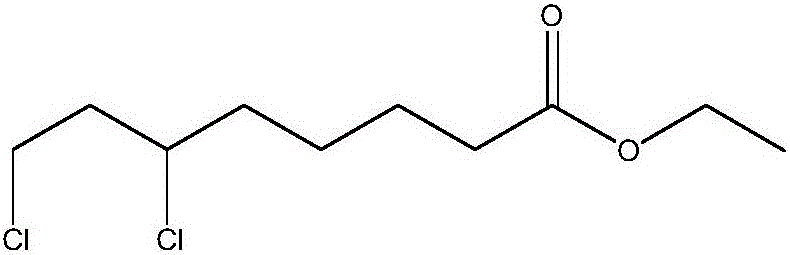

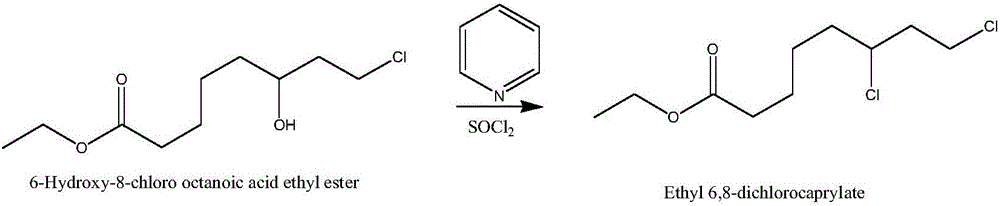

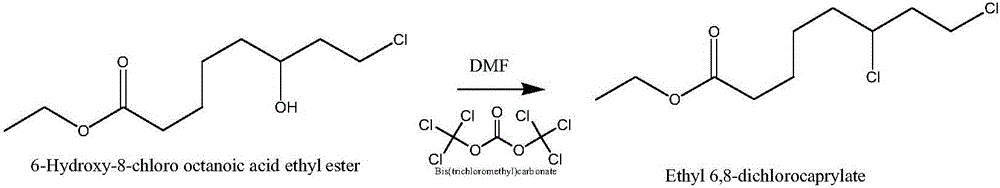

Preparation method of ethyl 6,8-dichlorocaprylate

InactiveCN105693510AEmission reductionImprove chlorination abilityOrganic compound preparationCarboxylic acid esters preparationOrganic solventReaction temperature

The invention relates to a preparation method of ethyl 6,8-dichlorocaprylate, belonging to the technical field of preparation of organic compound intermediates. The preparation method comprises the steps of reacting ethyl 6-hydroxy-8-chlorocaprylate with a chlorination agent in an organic solvent by taking N,N-dimethylbenzylamine as an acid-binding agent, controlling the reaction temperature, maintaining the temperature after the reaction is finished, and controlling the temperature maintaining temperature and the temperature maintaining time to obtain reaction liquid, adding water for layering to obtain an organic phase at an upper layer, carrying out reduced pressure rectification to obtain ethyl 6,8-dichlorocaprylate, adding alkali to a lower layer to regulate pH for layering, and carrying out dehydration on the upper layer by virtue of anhydrous sodium sulphate so as to obtain N,N-dimethylbenzylamine, and recycling. By virtue of the preparation method, the chlorination capacity is improved, the yield reaches about 95%, the cycle use is realized, the discharging of wastewater is reduced, the process route is advanced, the process conditions are reasonable, the operation is simple and safe, the reaction yield is high, the production cost is relatively low, and three wastes are little.

Owner:SUZHOU FUSHILAI PHARMA CO LTD

Method of preparing surfactant by alkali lignin by modification

InactiveCN103755973ARealize rational utilizationImprove protectionTransportation and packagingMixingChlorosulfuric acidHigh pressure

The invention relates to a method of preparing a surfactant by alkali lignin by modification, belonging to the technical field of lignin utilization. The method comprises the following steps: by taking waste alkali lignin in industrial production as a raw material, first, carrying out reaction with dodecyl glycidyl ether and N, N-dimethylbenzylamine in dimethylsulfoxide; and then carrying out reaction with chlorosulfonic acid and neutralizing and dialyzing the product to obtain the alkali surfactant. According to the method provided by the invention, waste alkali lignin in industrial production is effectively utilized to facilitate the environmental protection, and meanwhile, the reaction conditions are mild without high temperature and high pressure conditions, and the reaction conditions are easy to control and adjust, so that the reaction process is simple, the production equipment is relatively simple, the product is low in cost, and the method has a very good industrial application prospect. The surface tension of the lignin surfactant prepared by the method reaches 29.17mN / m, thereby satisfying the active demands on industrial production and daily washing.

Owner:BEIJING FORESTRY UNIVERSITY

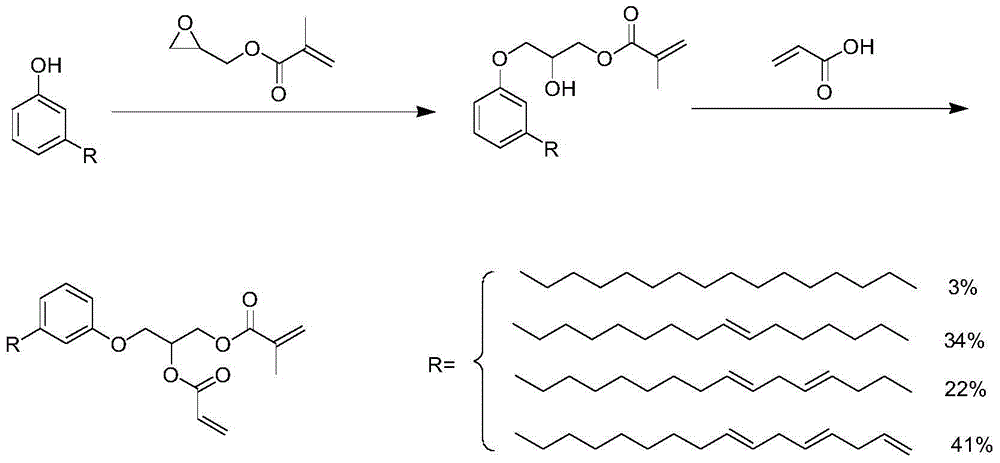

Cardanol unsaturated resin monomer and preparation method thereof

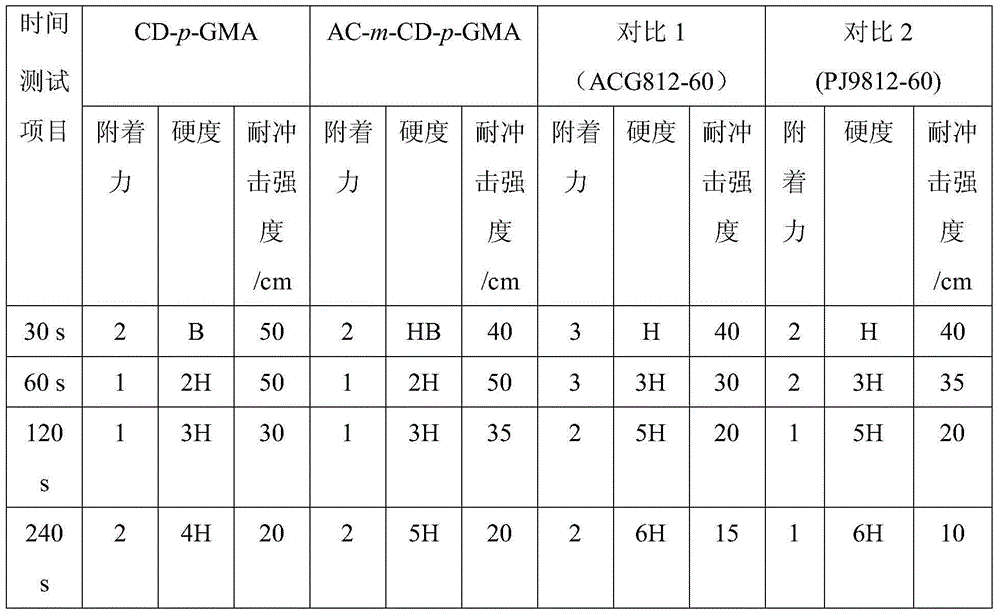

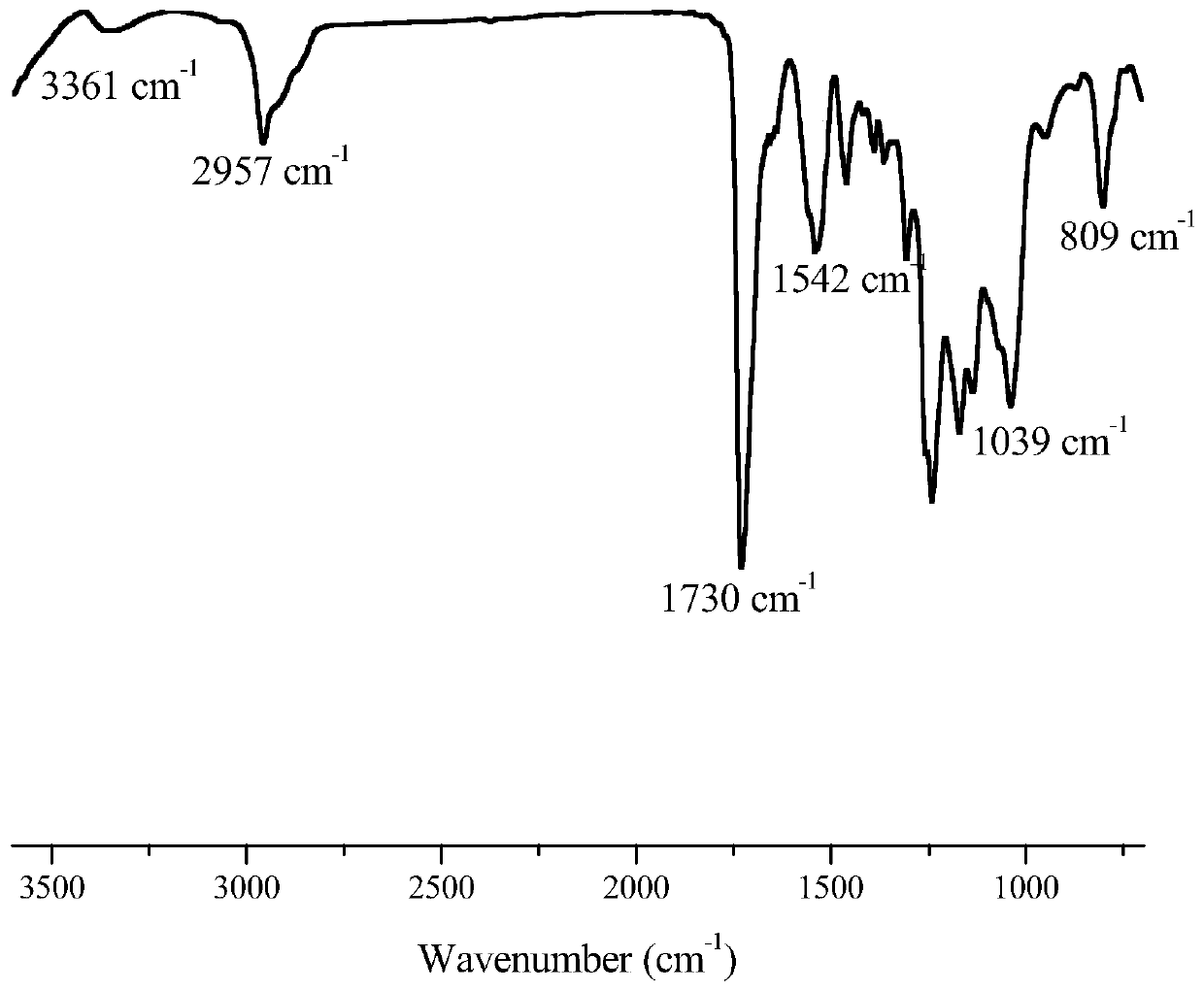

InactiveCN104860823AImprove mechanical propertiesImprove water resistanceOrganic compound preparationCarboxylic acid esters preparationGlycidyl methacrylateEsterification reaction

The present invention provides a cardanol unsaturated resin monomer, which has the following structure formula. The present invention further provides a preparation method of the cardanol unsaturated resin monomer, wherein cardanol and an epoxy group are subjected to a ring-opening etherification reaction by using glycidyl methacrylate and by adopting N,N-dimethylbenzylamine as a catalyst to obtain cardanol polymerization glycidyl methacrylate, and the prepared CD-p-GMA and acrylic acid are subjected to an esterification reaction by adopting a cation exchange resin as a catalyst to obtain the acrylic acid-modified cardanol polymerization glycidyl methacrylate. The cardanol unsaturated resin monomer of the present invention provides characteristics of good mechanical property, excellent mechanical property, and excellent water resistance compared with the resin in the prior art.

Owner:上海美东生物材料股份有限公司

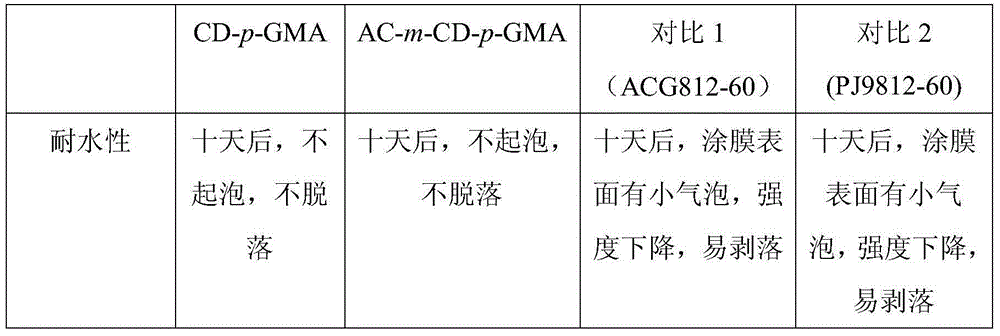

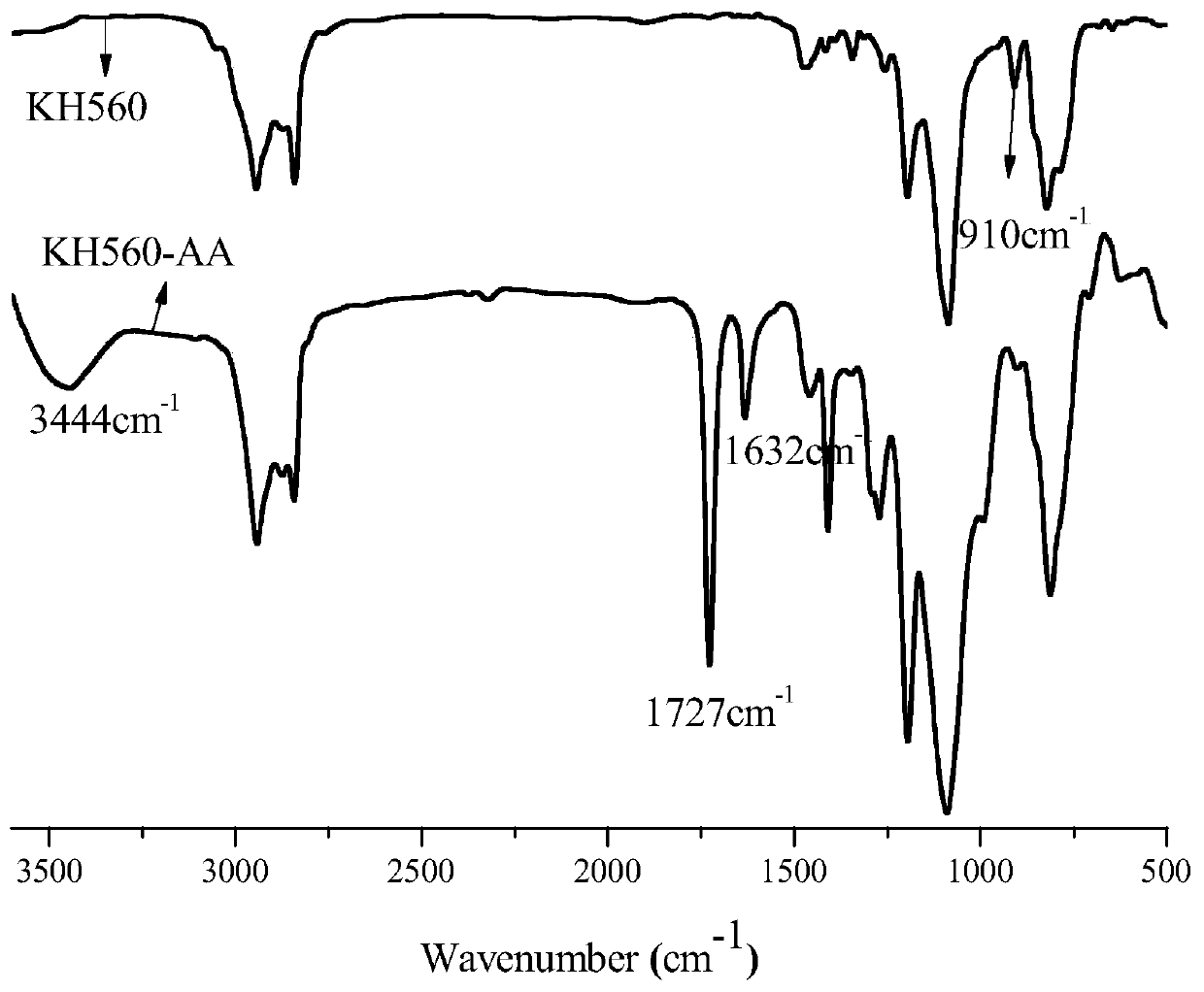

Novel silicon-containing monomer and organosilicone modified waterborne UV-curable polyurethane emulsion containing silicon-containing monomer

InactiveCN110452260AGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsEmulsionHydroxybenzoate Ethers

The invention discloses a novel silicon-containing monomer and an organosilicone modified waterborne UV-curable polyurethane emulsion containing the silicon-containing monomer. The novel silicon-containing monomer comprises the following components in parts by weight: 100 parts of acrylic acid, 0.3 part of N,N-dimethylbenzylamine, 100 parts of gamma-glycidyl ether oxypropyl trimethoxysilane, and 0.5 part of p-hydroxyanisole. The novel silicon-containing monomer simultaneously containing various functional groups of hydroxyl, siloxane and carbon-carbon double bond (C=C) in the molecular structure is prepared by a reaction of gamma-glycidyl ether oxypropyl trimethoxysilane (tau-glycidyl ether oxypropyl trimethoxysilane) with acrylic acid (AA), then the novel silicon-containing monomer is used as a novel blocking agent to modify polyurethane to prepare the photo-curable polyurethane emulsion.

Owner:FUQING HONGBAO CHEM CO LTD

Cathode electrophoresis paint with high outdoor weather resistance and preparation method thereof

InactiveCN104559667AGood weather resistanceHigh film glossPaints for electrolytic applicationsEpoxy resin coatingsPhosphateEthylene propylene rubber

The invention discloses a cathode electrophoresis paint with high outdoor weather resistance. The cathode electrophoresis paint is characterized by being prepared from the following raw materials in parts by weight: 30-35 parts of epoxy resins, 18-26 parts of methylated amino resins, 4-7 parts of dimethylbenzylamine, 5-8 parts of maleic anhydride, 12-15 parts of isobutyl alcohol, 7-9 parts of butyl acrylate, 8-11 parts of ethoxyl metacrylic acid ester phosphate, 0.3-0.7 part of sodium antimonite, 1-2 parts of nano aluminum nitride, 13-17 parts of carbon black, 3-6 parts of graphite particles, 2-4 parts of expanded perlite, 2.1-3.5 parts of carboxymethylcellulose, 6-9 parts of ethylene propylene rubbers, 1.2-2.5 parts of silane coupling agents KH560, 12-16 parts of auxiliaries, 16-20 parts of ethylene glycol monoethyl ether acetate, 8-11 parts of propylene glycol monomethyl ether and 55-65 parts of deionized water. The cathode electrophoresis paint is scientific and reasonable in proportioning; epoxy resins and methylated amino resins are subjected to graft modification and are added into the raw materials, and other effective components are used at the same time, so that the prepared cathode electrophoresis paint has the advantages of high weather resistance, high coating luster, high modification property, security, environmental friendliness and the like; by utilizing the prepared coated object, the high weather resistance can be maintained under a poor outdoor environment, so that a higher requirement on coating performance can be met.

Owner:刘玉

Thermal-insulation material for prefabricated building exterior walls

InactiveCN107399949ALow thermal conductivityStrong crack resistanceCeramicwareSodium bicarbonateCrack resistance

The invention discloses a thermal-insulation material for prefabricated building exterior walls. The thermal-insulation material is prepared from 100 parts by mass of a composite material and 120-140 parts of a curing agent through reacting and foaming, wherein the composite material is prepared from the following components in parts by mass: 85 to 100 parts of ordinary Portland cement, 55 to 62 parts of slag Portland cement, 6 to 9 parts of fly ash, 14 to 18 parts of expanded perlite, 16 to 24 parts of polypropylene fiber, 0.8 to1.5 parts of ash calcium powder, 40 to 55 parts of melamine formaldehyde resin, 48 to 54 parts of a polyurethane oligomer, 4 to 6 parts of polyacrylamide, 38 to 42 parts of sodium bicarbonate, 15 to 22 parts of a phosphorus-containing flame retardant and 1.1 to 1.4 parts of N, N-dimethylbenzylamine, wherein the curing agent is toluene diisocyanate. The thermal-insulation material has the advantages of being low in thermal conductivity, high in cracking resistance, deformation-free and cracking-free and can be applied to exterior wall external insulation of building energy-saving projects.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Pig manure deodorant

InactiveCN104645385AEfficient removalGuaranteed freshDispersed particle separationDeodrantsAgricultural sciencePig breeding

The invention discloses a pig manure deodorant. The pig manure deodorant comprises the following substances by mass: 0.5 to 1 part of alkylbenzyldimethylammonium chloride, 10 to 20 parts of ethylene glycol, 3 to 5 parts of citric acid diethyl ester and 40 to 60 parts of ethanol, with the balance being deionized water. The deodorant provided by the invention can effectively remove smelly substances in pig manure and has a sterilizing function, thereby guaranteeing the living environment of pigs to a certain extent while removing the stink of the manure. The deodorant has the advantages of easy availability of raw materials, producibility and low use cost.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

Anti-compression 3D printing building material

InactiveCN107673723ALow costReduce energy consumptionAdditive manufacturing apparatusToluene diisocyanateMixed materials

The invention discloses an anti-compression 3D printing building material. The anti-compression 3D printing building material comprises, by weight, 25 to 45 parts of a graphite compound, 35 to 45 parts of paper mill sludge, 20 to 40 parts of foundation soil, 50 to 60 parts of mine tailing, 100 to 110 parts f a filling material, 3 to 5 parts of condensated sodium silicate, 1 to 2 parts of fatty alcohol polyoxyethylene ether, 2 to 4 parts of sodium oleate, 2 to 4 parts of copper sulphate, 2 to 4 parts of aluminum sulfate, 2 to 4 parts of sodium chloride, 2 to 4 parts of silver nitrate, and 40 to60 parts of water. The graphite compound is prepared from following steps: polyethylene wax, graphite powder, dibutyltin dilaurate, and toluene diisocyanate are mixed, an obtained mixture is heated and stirred, epoxy soybean oil is added for uniform mixing, phthalic anhydride and N,N-dimethylbenzylamine are added for mixing, an obtained mixed material is heated, stirred, filtered, and smashed, ammoniacal liquor and absolute ethyl alcohol are added for uniform mixing, ethyl orthosilicate is added for stirring, an obtained product is added into liquid paraffin at stirring states drop by drop, and cooling, separating, and washing are carried out so as to obtain the graphite compound.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

Insulation polyurethane acrylate plastic paint and preparation method thereof

InactiveCN103289560AReduce selection costImprove insulation performancePolyurea/polyurethane coatingsAluminium chloridePolymer science

The invention discloses an insulation polyurethane acrylate plastic paint and a preparation method thereof. The insulation polyurethane acrylate plastic paint comprises the following components: by weight, 20-30 parts of polyurethane acrylate, 5-8 parts of a photosensitizer, 5-10 parts of a sensitizer, 10-20 parts of stabilizers, 2-3 parts of calcium sulfite, 1-2 parts of benzophenone, 2-8 parts of N,N-dimethylbenzylamine, 5-14 parts of 2-trans-3,7-dimethyl-2,6- octadiene-1-ol, 6-12 parts of dimethyl distearylammonium chloride, 1-2 parts of aluminum chloride hexahydrate, 10-12 parts of acrylonitrile-butadiene-styrene and 1-13 parts of methacrylic acid. The insulation polyurethane acrylate plastic paint has the advantages of low cost, good insulation properties, low content and low toxicity of volatile matter, low high-temperature dielectric loss, good stability and good resistance properties.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Decabromodiphenyl ether flame-retardant flocking adhesive

ActiveCN103881628ARaw materials are easy to getSimple processNon-macromolecular adhesive additivesEster polymer adhesivesEpoxyBenzoyl peroxide

The invention discloses a decabromodiphenyl ether flame-retardant flocking adhesive which is characterized by comprising the following components in parts by weight: 525-550 parts of methyl acrylate, 186-210 parts of hydroxypropyl methacrylate, 260-300 parts of ethyl acrylate, 9-15 parts of acrylic acid, 16-20 parts of N-methacrylamide, 190-220 parts of E-S1 epoxy resin, 11-15 parts of benzoyl peroxide, 11-13 parts of N-dimethylbenzylamine, 350-380 parts of vinyl acetate, 9-15 parts of decabromodiphenyl ether, 7-12 parts of sodium polyacrylate and 3-5 parts of aluminum sulfate. The decabromodiphenyl ether flame-retardant flocking adhesive has the advantages of available raw materials, low cost, environmental friendliness and good effects, and is convenient to use convenience.

Owner:桐乡宏晨工业设计有限公司

Construction adhesive and preparation method thereof

InactiveCN108822745AHigh strengthImprove tensile propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotassium persulfateEpoxy

The invention provides a construction adhesive and a preparation method thereof. The adhesive is composed of the following raw materials in percentages by mass: 40-60% of polyvinyl alcohol, 5-20% of epoxy resin, 5-10% of hydroxymethyl cellulose, 4-12% of vinyl acetate, 5-10% of polyacrylamide, 1-2% of potassium persulfate, 0.5-1% of N,N-dimethylbenzylamine, 3-5% of an alkaline liquid, 0.5-1% of asurfactant, 0.5-1% of a modifier, and the balance water. The adhesive provided by the invention has high-strength tensile properties, does not contain an aldehyde compound, and has high safety and environmental protection performance.

Owner:四川文希科技有限公司

Thin-film capacitor encapsulating epoxy resin

InactiveCN109161372AAvoid crackingExtended service lifeNon-macromolecular adhesive additivesEpoxy resin adhesivesAluminium hydroxideReactive diluent

The invention discloses a thin-film capacitor encapsulating epoxy resin which is characterized by comprising the following components in parts by weight: 35-40 parts of epoxy resin, 3-4 parts of glassfiber, 1-2 parts of a reactive diluent, 50-55 parts of a fused silicon powder, 3-4 parts of aluminium hydroxide, 2-3 parts of white carbon black, 2-3 parts of a curing agent, 0.01-0.02 parts of dimethylbenzylamine, 5-6 parts of a high performance filler and 0.3-0.5 parts of the aluminium hydroxide. The invention has the advantages of low probability of cracking, long product service life and improved product quality.

Owner:安徽长容电子有限公司

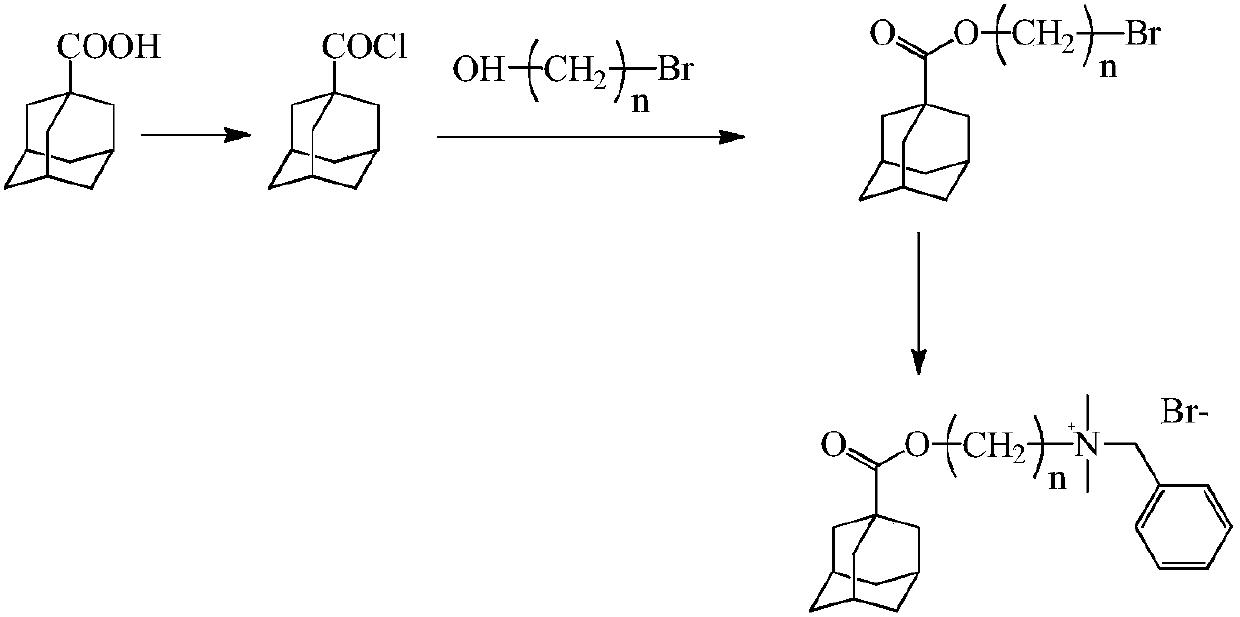

Adamantane-containing quaternary ammonium salt ionic liquid and preparation method thereof

InactiveCN109879765AEnhance amphipathicWill not affect the subject-guest combinationOrganic compound preparationTransportation and packagingQuaternary ammonium cation1-adamantanecarbonyl chloride

The invention relates to an adamantane-containing quaternary ammonium salt ionic liquid and a preparation method thereof. The structural formula of the adamantane-containing quaternary ammonium salt ionic liquid designed and prepared by the invention is shown in the specification, and in the formula, n is equal to 6, 9 or 11. According to the adamantane-containing quaternary ammonium salt ionic liquid disclosed by the invention, 1-adamantanecarboxylic acid is used as a raw material, and the ionic liquid is prepared by the following three steps: firstly, carrying out acylating chlorination reaction on 1-adamantanecarboxylic acid and thionyl chloride to synthesize 1-adamantanecarbonyl chloride, carrying out esterification reaction on the 1-adamantanecarbonyl chloride and OH(CH2)nBr, and thencarrying out quaternization with N,N-dimethylbenzylamine to form the adamantane-containing quaternary ammonium salt ionic liquid. The adamantane-containing quaternary ammonium salt ionic liquid obtained in the invention has the characteristics of mild reaction conditions, easily available raw materials and high product purity, and has potential application prospects in the fields of supramolecular chemistry, catalysis, batteries, nano materials and the like.

Owner:HEZHOU UNIV

Flame-retardant high toughness epoxy resin casting material and preparation method thereof

InactiveCN110128788AGood mechanical properties of epoxyImprove mechanical propertiesCore shellToughness

The invention discloses a flame-retardant high toughness epoxy resin casting material. The epoxy resin casting material comprises 100 wt% of a resin and 80 wt% of a curing agent; the resin includes 5-85 wt% of a bisphenol A type epoxy resin 128 and 15-95 wt% of a core-shell toughening agent DY040; and the curing agent includes 1-40 wt% of methyltetrahydrophthalic anhydride, 1-60 wt% of methylhexahydrophthalic anhydride, 0.1-0.4 wt% of N,N-dimethylbenzylamine and 1-35 wt% of an OD-PN reactive flame retardant. The epoxy resin casting material has the good mechanical properties and good processability of the bisphenol A epoxy resin; and the curing agent of the epoxy resin system is modified, so the flame retardation performance of a cured material of the whole casting material is enhanced.

Owner:福建克雷斯波精细化工有限公司

3D printing building material

InactiveCN107746240AIncrease the added value of recycled productsLow costSolid waste managementSlagNitrogen gas

The invention discloses a 3D printing building material including, by weight, 110-120 parts of an aggregate, 45-65 parts of coal slag, 4-12 parts of pottery clay, 5-15 parts of asbestos, 5-15 parts ofdesulfurization gypsum, 1-6 parts of titanium diboride, 1-2 parts of copper sulfate, 2-6 parts of a binder, 1-2 parts of calcium nitrate, 1-2 parts of potassium carbonate, 1-2 parts of silver nitrateand 30-50 parts of water. A graphite powder composite is prepared through the steps of: 1) mixing disproportionated rosin, graphite powder, dibutyltin dilaurate and toluene diisocynate, heating and stirring the mixture under protection by nitrogen gas, adding epoxidized soybean oil, and uniformly mixing the components; 2) adding phthalic anhydride and N,N-dimethylbenzylamine, mixing the components, heating and stirring the mixture, filtering and washing the mixture, drying the mixture and crushing the mixture; 3) adding ammonia water and anhydrous ethanol, uniformly mixing the components andadding tetraethoxysilane with stirring; 4) dropwise adding the mixture to liquid paraffin under stirring status, and after the mixture is all added, continuously stirring the mixture, and cooling andseparating the mixture; 5) washing a solid product with petroleum ether and anhydrous ethanol to obtain the graphite powder composite.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

Epoxy acrylate coating for ceramic

The invention discloses an epoxy acrylate coating for ceramic. The epoxy acrylate coating comprises the following raw materials: epoxy resin, zinc acetate, methacrylic acid, phthalic anhydride, acrylic acid, toluene, a photosensitizer, tin tetrachloride, hydroquinone, zinc oxide, an activator, titanium dioxide, N, N-dimethylbenzylamine, barite powder and styrene. The surface drying time of the product, namely the epoxy acrylate coating is 15-25 seconds, the hard drying time of the product is 5-10 minutes, the adhesion force is at Level 1-3 and the hardness is 4-6H; after the product is soaked in water for 10-20 days, no bubbling and falling phenomena are generated; the coating resists the scrubbing for 1500-2500 times and can be widely produced and continuously replace existing materials.

Owner:SUZHOU SHENGPULA NEW MATERIAL SCI & TECH

Novel consolidated nano-diamond butadiene grinding disc and preparation technology thereof

A novel consolidated nano-diamond butadiene grinding disc is manufactured by a basic raw material and added nano-diamond butadiene, wherein the basic raw material is prepared from the following components in percentage by weight: 55-60% of modified E-54 epoxy resins and methyl tetrahydrophthalic anhydride, 0.5-1% of N,N-dimethylbenzylamine, 3.5-4% of a plasticizer, 30-35% of a filler and 5-6% of a pore-forming agent, the addition quantity of the nano-diamond butadiene is 15-33wt% of the basic raw material, and the mass ratio of E-54 epoxy resins to methyl tetrahydrophthalic anhydride is 10:9. The consolidated nano-diamond butadiene grinding disc of the invention is high in processing efficiency; in the grinding process of the consolidated nano-diamond butadiene, the utilization rate of grinding materials is high, the cost is low and the pollution to environment is low; and after the grinding of the consolidated nano-diamond butadiene grinding disc, the grinding materials cannot be embedded into the surface of a processed workpiece, and the subsequent cleaning and processing of the workpiece are conveniently carried out.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Synthesizing method of perfluoro(2-methyl-3-pentanone) and application

InactiveCN107445811AHigh purityHigh synthetic yieldFire extinguisherPreparation from heterocyclic compoundsIsomerizationOrganic synthesis

Owner:航天康达(北京)科技发展有限公司

Preparation and recovery method of recyclable epoxy asphalt

ActiveCN113801490BRealize full chain applicationIncrease temperatureBuilding insulationsPolymer scienceOligomer

The invention discloses a method for preparing and recovering recyclable epoxy asphalt, and relates to a method for preparing and recovering epoxy asphalt. 75-90 parts of base asphalt is heated to a fluid state, and 50-70 parts of maleic anhydride and 0.1-0.5 parts of 2,4,7,9-tetramethyl-5-decyne-4,7-diol are added to react to obtain Component A; mix 90-110 parts of furan-containing difunctional epoxy oligomer with 2-10 parts of N,N-dimethylbenzylamine to obtain component B; take 140-160 parts of A-component and 90-120 parts B component; B component is preheated at 60-80°C and stirred evenly when A component is cooled to the same temperature; the blend is solidified to obtain recyclable epoxy asphalt. The epoxy asphalt at the end of the use period is heated to a fluid state at 120°C; add regenerant and stir thoroughly; recure at 70°C for 24 hours to obtain recycled epoxy asphalt. Based on the reversible principle of dynamic covalent bonds, an epoxy asphalt that can be recycled based on the temperature regulation mechanism was prepared.

Owner:HARBIN INST OF TECH

High heat dissipation mobile phone charger casings

The invention discloses high heat dissipation mobile phone charger casings. The high heat dissipation mobile phone charger casings comprise the following raw materials in parts by weight: 80-100 partsof polyvinyl chloride, 20-30 parts of ethylene propylene diene monomer, 1-2 parts of acetyl tributyl citrate, 2.5-4.5 parts of compatibilizer, 2-4 parts of dibenzoyl peroxide, 0.4-0.8 part of dimethylbenzylamine , 45-55 parts of filler, 1.5-2.5 parts of antioxidant and 2-3 parts of light stabilizer, wherein the compatibilizer comprises, by weight, 10-14 parts of clay compound, 6-12 parts of sepiolite powder, 8-16 parts of rectorite powder, 4-8 parts of hollow glass microspheres, 3-6 parts of potassium titanate whisker and 3-6 parts of calcite powder; and the clay compound is prepared by usingthe following process: heating phospholipid and acetic acid with stirring, adding hydrogen peroxide with stirring, performing cooling, adjusting the system to be neutral, then adding clay, tetradecyltrimethylammonium bromide, silane coupling agent and water, heating the mixture to reflux with stirring, performing filtration, performing washing, and drying the filter cake to a constant weight to obtain the clay compound.

Owner:天长市优信电器设备有限公司

Low density full water blown polyurethane rigid foam

A formulation for preparing a low density, full water blown polyurethane rigid foam includes an isocyanate component; an isocyanate-reactive component comprising from 30-50 wt % of a first polyether polyol having a functionality greater than 5 and an OH value from 350-550 mgKOH / g; from 5 to 25 wt % of a diol having an OH value from 100-300 mgKOH / g; and from 15 to 35 weight percent of a second polyether polyol having a functionality from 3 to 5; further including from 1.5 to 5 wt % of a catalyst selected from dimethylbenzylamine and / or 1,2-dimethyl-imidazole; from greater than 0 to 1 wt % of a trimerization catalyst selected from a glycine salt and / or tris(dimethyl aminomethyl) phenol; greater than 4.1 wt % water as a blowing agent; and any additional constituents selected such that the formulation, excluding the isocyanate component, totals 100 wt % and, the formulation absent the isocyanate component, has a dynamic viscosity from 540 to 864 mPa*s at 20° C. Processing under one-shot conditions can yield a rigid form having a molecular weight per crosslink ratio from 380 to 420. The formulation offers good processability, while the foam shows desirable dimensional stability and mechanical properties at unexpectedly low applied density.

Owner:DOW GLOBAL TECH LLC

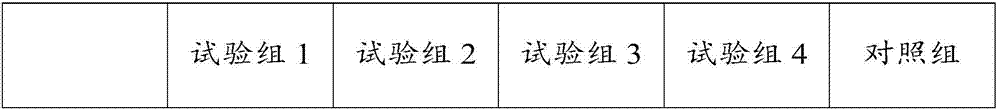

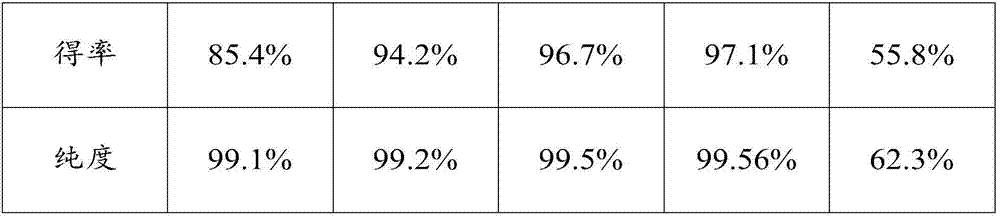

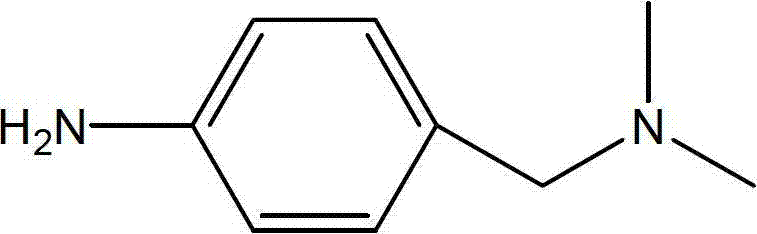

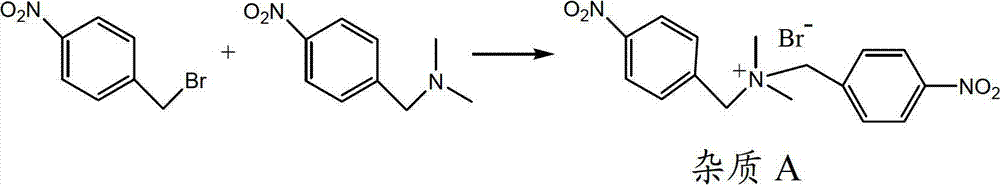

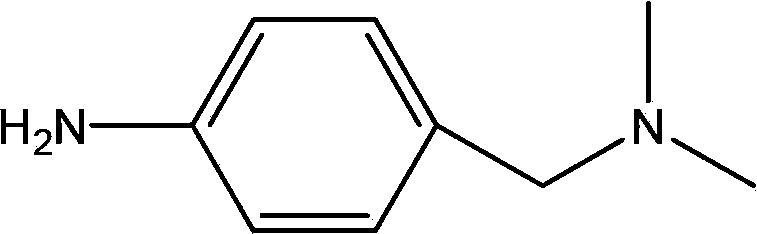

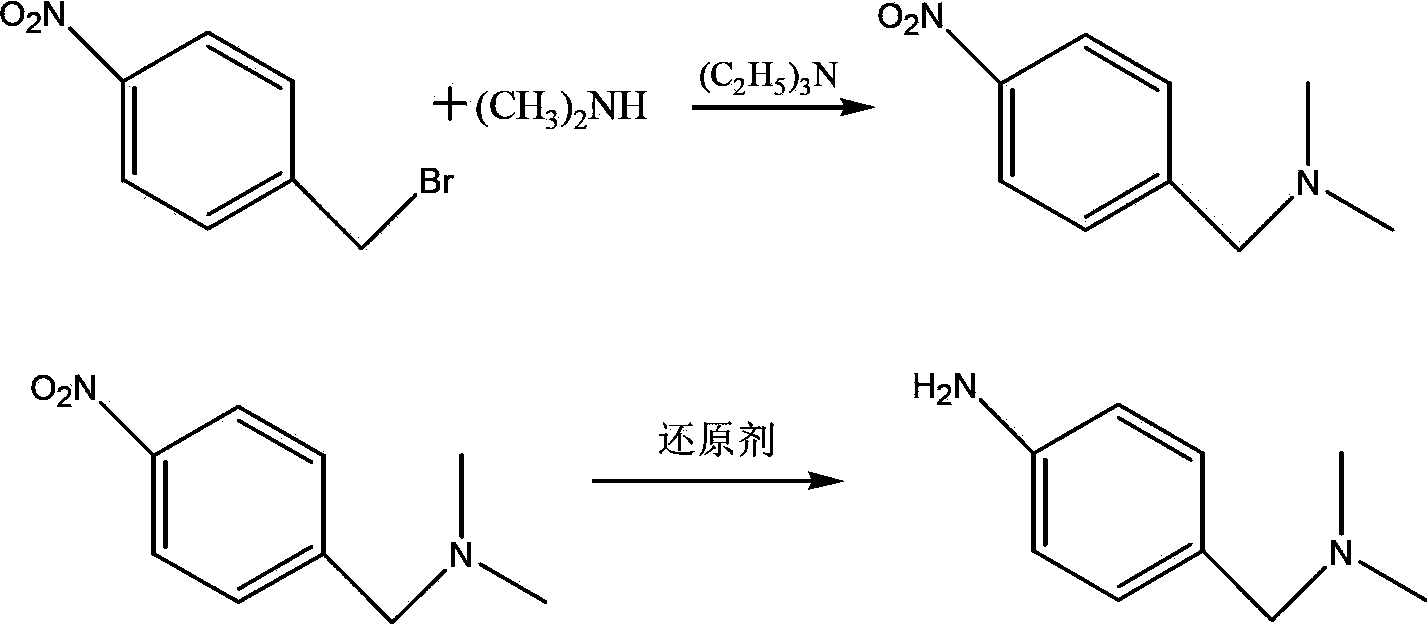

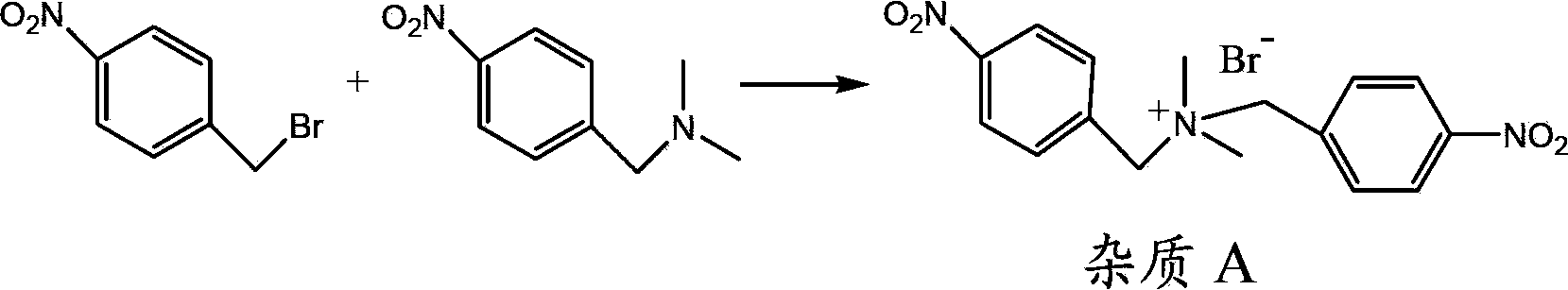

Process for preparing 4-amino-N, N-dimethylbenzylamine

ActiveCN102964256AHigh purityHigh yieldOrganic compound preparationAmino compound preparationBenzoyl bromideSide reaction

The invention provides a process for preparing 4-amino-N,N-dimethylbenzylamine. The process comprises the steps of: (1) adding solutions of 4-nitro benzyl bromide or 4-nitro benzyl bromide in an organic solvent in batches into an organic solvent containing dimethylamine and triethylamine to obtain 4-nitryl-N,N-dimethylbenzylamine, wherein the single batch feeding amount of 4-nitro benzyl bromide and the molar percentage of dimethylamine in the reaction system are smaller than 7 percent; (2) reducing 4-nityl-N,N-dimethylbenzylamine by using a reducing agent to obtain 4-amino-N,N-dimethylbenzylamine. According to the process, the side reaction mechanism and the effective control method of a new impurity bis(nitrobenzyl)-dimethyl ammonium bromide are studied, the reaction conditions are optimized, the entire process is simple and easily implemented, and the purity and yield of the product are high; and the process is suitable for industrial production.

Owner:ZHEJIANG HISOAR PHARMA

Preparation method of wet-mixed mortar with high water retention rate

The invention discloses a preparation method of wet-mixed mortar with a high water retention rate. The preparation method comprises the following steps: stirring coal cinder, tailings machine-made sand, cement, diatomite, a castor oil complex substance and water, adding a plastic stabilizing agent, glass fiber, a retarder and a water reducing agent, and uniformly stirring the materials to obtain wet-mixed mortar with a high water retention rate. The castor oil complex substance is prepared by the following process: mixing castor oil, dibutyltin dilaurate and toluene diisocyanate, carrying outheating and stirring under the protection of nitrogen, adding epoxidized soybean oil, carrying out stirring continuously, adding phthalic anhydride and N,N-dimethylbenzylamine, and carrying out heating and stirring to obtain the castor oil complex substance. The preparation method of the wet-mixed mortar with a high water retention rate, provided by the invention, not only realizes reasonable utilization of resources and reduces the environmental pollution caused by waste stone chips, but also reduces the production cost of the mortar, enhances the water retention rate and viscosity of the mortar, prolongs the setting time of the mortar, and ensures use continuity of the mortar.

Owner:来安县塔鑫建材有限公司

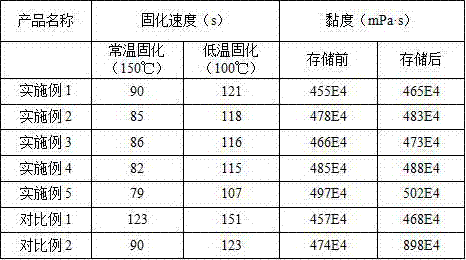

Preparation method of adhesive plastering piece with rapid solidification and easy storage

InactiveCN107541169ALittle change in viscosityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceDiglycidyl ether

The invention provides a preparation method of an adhesive plastering piece with rapid solidification and easy storage. The method comprises the following steps: (1) surface mounting adhesive components are weighed according to parts by weight: (2) N-2-methylimidazole-N'-(P-cyanophenyl)carbamide, dicyandiamide, aminated lignin and epoxy resin are mixed by a planetary mixer, the materials are grinded by a three-roller, and mixed paste is obtained; (3) N,N-Dimethylbenzylamine, ethylene glycol diglycidyl ether, 1,4-butanediol diglycidyl ether, pentaerythritol glycidyl ether, and polyethylene waxare added into the planetary mixer, high temperature stirring is carried out, and after stirring is carried out till complete dissolving, cooling is carried out; (4) a mixed paste body, mercaptan terminated liquid butyronitrile rubber, nanometer calcium carbonate, and a pigment are mixed, and a reaction is carried out. The adhesive plastering piece with rapid solidification and easy storage can bestored for a long time without influencing performance of the adhesive plastering piece, and the solidification speed is fast.

Owner:樊之雄

Process for preparing 4-amino-N, N-dimethylbenzylamine

ActiveCN102964256BHigh purityHigh yieldOrganic compound preparationAmino compound preparationBenzoyl bromideSide reaction

The invention provides a process for preparing 4-amino-N,N-dimethylbenzylamine. The process comprises the steps of: (1) adding solutions of 4-nitro benzyl bromide or 4-nitro benzyl bromide in an organic solvent in batches into an organic solvent containing dimethylamine and triethylamine to obtain 4-nitryl-N,N-dimethylbenzylamine, wherein the single batch feeding amount of 4-nitro benzyl bromide and the molar percentage of dimethylamine in the reaction system are smaller than 7 percent; (2) reducing 4-nityl-N,N-dimethylbenzylamine by using a reducing agent to obtain 4-amino-N,N-dimethylbenzylamine. According to the process, the side reaction mechanism and the effective control method of a new impurity bis(nitrobenzyl)-dimethyl ammonium bromide are studied, the reaction conditions are optimized, the entire process is simple and easily implemented, and the purity and yield of the product are high; and the process is suitable for industrial production.

Owner:ZHEJIANG HISOAR PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com