Patents

Literature

30results about How to "Sparkling no" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation curing epoxy resin powder coating used for ceramic

ActiveCN104151896ASparkling noShedding phenomenon noCoatingsPolyethylene terephthalate glycolGlycerol

The invention discloses a radiation curing epoxy resin powder coating used for ceramic. Raw materials comprise a phenolic epoxy resin, polyvinylidene fluoride, 3-allyl isocyanate, polymethyl methacrylate, methylacryloyl chloride, ethyl acrylate, a photoinitiator, 2-ethylhexylacrylate, acrylic acid, polyethylene terephthalate, a cross-linking agent, glycerol, butanedioic anhydride, titanium dioxide and benzimidazole. Glossiness of a product is 130-150%; hardness is 6-9H; a surface drying time is 1-3 min; a hard drying time is 5-15 min; the product has no blistering or shedding phenomena after being immersed for 5-7 d in a 5% hydrochloric acid solution and does not blister or wrinkle after being immersed for 10-14 d in a saturated calcium hydroxide solution, washing fastness of the product is 1,800-2,000 times; and the product can be widely produced and replace conventional materials continuously.

Owner:ZHEJIANG GUANGHUA NEW MATERIALS

Thermosetting acrylic powder paint for ceramics

The invention discloses thermosetting acrylic powder paint for ceramics. The thermosetting acrylic powder paint for ceramics is prepared from the following raw materials: hydroxyethyl methylacrylate, benzoic acid, acrylic acid, butanol, cumene peroxide, modified polyethylene terephthalate gum, a leveling agent, dimethyl benzene, azodiisobutyronitrile, ethanol amine, a plasticizer, manganese naphthenate, isocyanate, titanium dioxide and styrene. The thermosetting acrylic powder paint for ceramics has glossiness of 130%-150%, a gloss retention rate of 92-96% after manually accelerating ageing for 500 hours, shore hardness of 45-65, no bubbling and dropping phenomena after being soaked in water for 30-60 days, no abnormity after being soaked in 5% hydrochloric acid solution for 25-35 days, adhesion of levels 1-2, impact strength of 500-600N / cm, no bubbling and wrinkling phenomena after being soaked in saturated calcium hydroxide for 30-40 days, a product smelting point of 150-160 DEG C and density of 120-140g / cm<3>.

Owner:盐城市盐龙水务有限公司

Paint, preparation method thereof and coating moulding method

InactiveCN102559041AExtended service lifePeeling offPretreated surfacesSpecial surfacesAlcoholAluminium powder

The invention provides a paint, comprising the following components: 35-60 parts by weight of organic silicon dried heat-resisting paint, 35-60 parts by weight of alcohol acid dried heat-resistant varnish, 25-35 parts by weight of crystalline flake graphite, 10-20 parts by weight of chrysotile asbestos, 30-50 parts by weight of air atomized aluminium powder and right amount of diluent, wherein the diluent is amino paint diluent or dimethylbenzene. The invention also provides a preparation method of the paint and a coating moulding method. The paint provided by the invention is formed by mixing the crystalline flake graphite, the organic silicon dried heat-resisting paint and the like, thus the paint has long life after being coated into a coating, no block stripping, foaming or layering phenomenon is caused, and product quality is greatly improved.

Owner:AVIC PST NANFANG GAS TURBINE COMPLETE MFG & INSTALLATION

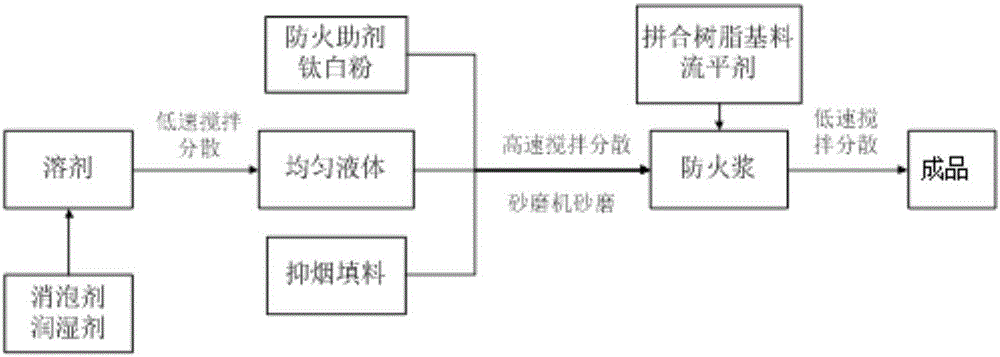

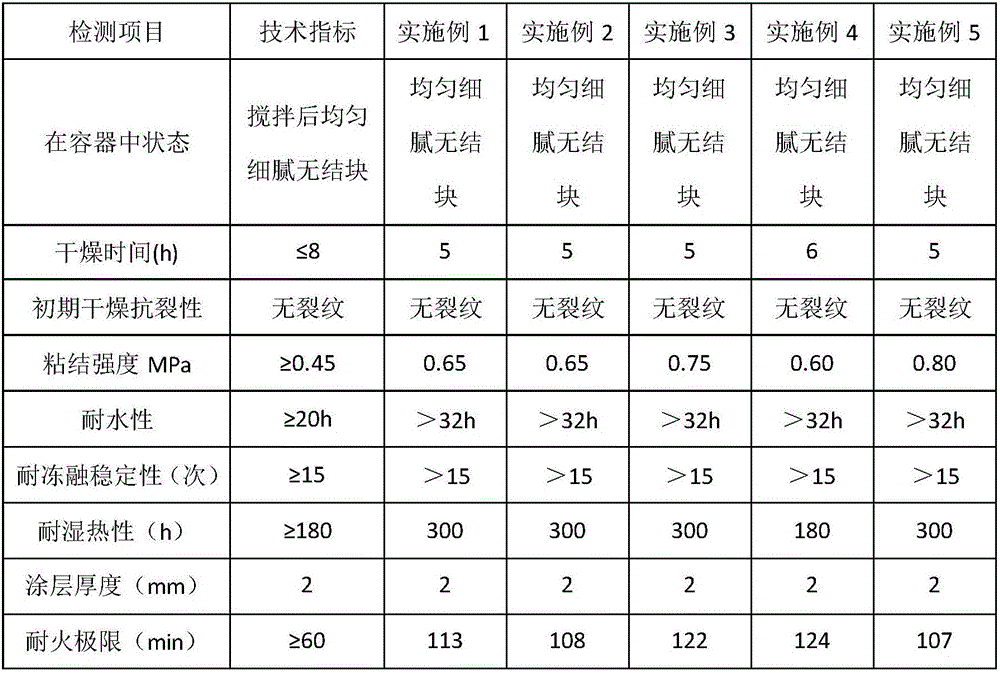

Smoke suppressant type indoor ultrathin fire-resistant paint for steel structure and preparation process thereof

ActiveCN106833208AExtend fire resistance timeImprove fire performanceFireproof paintsPolyester coatingsWeather resistanceArray data structure

The invention discloses a smoke suppressant type indoor ultrathin fire-resistant paint for a steel structure. The fire-resistant paint is composed of the following components in parts by weight: 20-35 parts of synthetic resin base material, 25-45 parts of fire-resistant aid, 3-10 parts of titanium white, 5-15 parts of smoke suppressant filler, 1-3 parts of aid and 16-28 parts of solvent. Meanwhile, the invention also discloses a preparation process of the smoke suppressant type indoor ultrathin fire-resistant paint for a steel structure. According to the invention, the synthetic resin base material and the smoke suppressant filler are used, so that the prepared paint has very good fire resistance and excellent water resistance and weather resistance; and almost no toxic irritative gas is discharged in case of fire-induced expansion.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Preparation method for SBS (styrene-butadiene-styrene block copolymer) modified asphalt waterproof material

InactiveCN106751949ASimple processLess investmentBuilding insulationsBituminous waterproofingPhenyl Ethers

The invention discloses a preparation method for an SBS (styrene-butadiene-styrene block copolymer) modified asphalt waterproof material. The method comprises the following steps of step1): weighting matrix asphalt, high purity water, SBS, butadiene styrene rubber, N-Polyoxyethylated-N-octadecylamine, hydrochloric acid, methylbenzene, stearic trimethyl ammonium chloride, polyoxyethylene nonyl phenyl ether, sulphur, polyethylene resin, calcium oxide and carbon tetrafluoride; step2): adding the matrix asphalt into a reaction still provided with a stirrer and a thermometer, heating to 170 to 190 DEG C, adding the SBS, the butadiene styrene rubber, the N-Polyoxyethylated-N-octadecylamine, the hydrochloric acid, the methylbenzene, the stearic trimethyl ammonium chloride after melting, dehydration and filtering, stirring for 15 to 55min with the stirring speed of 800 to 1200r / min; step3): adding the high purity water while stirring, heating to 200 to 220 DEG C, adding residual raw materials for mixing 40 to 80min, then adding the components stirred in the step2) to obtain a mixture, adding the mixture into an emulsifying machine to perform emulsification, cooling to 30 to 40 DEG C and defoaming to obtain the SBS modified asphalt waterproof material. The method disclosed by the invention has the advantages that the process is simple, the equipment invest is small, the energy is saved and the consumption is reduced.

Owner:SUZHOU YUXI NEW MATERIAL TECH

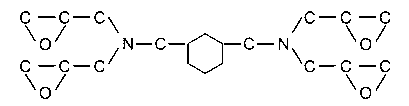

Protective coating for inner cabin of seawater desalination evaporator

InactiveCN108219629AGood adhesionLong corrosion lifeAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

A protective coating for an inner cabin of a seawater desalination evaporator is obtained by mixing a component A and a component B when in use. The component A is formed by mixing 25-45% of epoxy resin, 25.5-50% of a pigment filler, 10-20% of a solvent, 0-5% of a thixotropic agent, 0.5-1.5% of a leveling agent, 0.5-1.5% of a dispersant and 0.5-1.5% of a defoamer, and the component B is a curing agent with the amount 20-40% of the mass of the component A. With use of phenolic resin modified epoxy resin and a modified polyamide curing agent, a heat-resistant, anticorrosion and high-attaching substrate can be produced; at the same time, with use of mica, aluminum powder slurry and other flaky anticorrosion pigment filler, a coating layer produces a micro-grid structure on the basis of the obstructing effect of the flaky filler, prolongs the permeation way of water or Cl-1, thereby enhancing the corrosion resistance of a coating layer; with combination of the two components, the special anticorrosion coating layer has the characteristics of hot seawater corrosion resistance, strong toughness, high adhesion and the like, so that the coating layer is guaranteed to have a long anticorrosion life.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

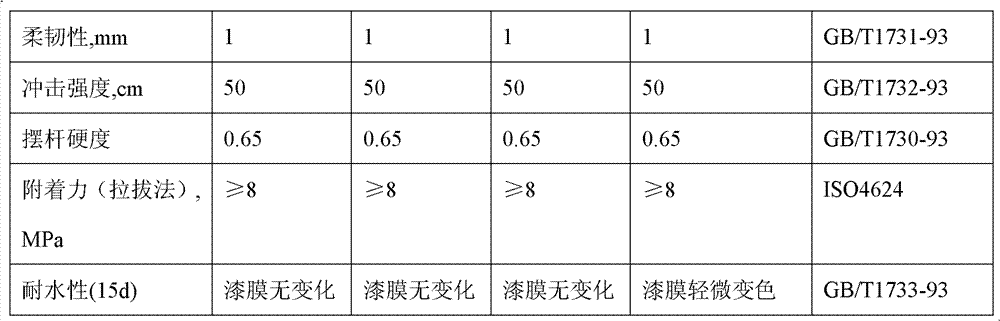

Acrylic carboxyl polyurethane powder coating for ceramic

ActiveCN104312417AIncreased durabilitySparkling noPolyurea/polyurethane coatingsPowdery paintsCyclohexylisocyanateLithium hydroxide

The invention discloses an acrylic carboxyl polyurethane powder coating for ceramic. The coating is prepared from the following raw materials: 1, 6-hexanediol, dehydrated castor oil, dibutyltin dilaurate, glycerol, cyclohexyl isocyanate, lithium hydroxide, an imitator, linseed oil, hexahydrophthalic anhydride, calcium boheic acid, pigments, rosin, dimethyl adipate, toluene diisocynate and methyl methacrylate. The product density is 135-155g / cm<3>, and the coating soaked in water for 60-70 days is free from soaking and falling phenomena. The tensile strength is 20-30MPa, the shore hardness is 40-60, and the coating soaked in a 5% hydrochloric acid solution for 40-60 days is free of abnormalities. The adhesive force is levels 1-2, the impact strength is 550-650N / cm, and the coating soaked in saturated calcium hydroxide for 25-35 days is free from bubbling and wrinkling; the glossiness is 110-130%, and the gloss retention is 92-96% after being manually accelerated and aged for 500 hours.

Owner:XIAN SICONG FINE CHEM

Polyvinyl alcohol washable interior wall coating for building

The invention discloses a polyvinyl alcohol washable interior wall coating for a building. The coating comprises the following components in parts by weight: 100 parts of polyvinyl alcohol, 20-30 parts of polysiloxane, 20-40 parts of formaldehyde, 10-20 parts of chloroethylene, 80-100 parts of water, 5-15 parts of vinyl acetate, 30-40 parts of limestone powder, 15-20 parts of styrene, 25-35 parts of melamine, 15-25 parts of dimethylethanolamine, 60-70 parts of extender pigment, 40-50 parts of a defoamer, 30-50 parts of talcum powder and 45-55 parts of maleic anhydride. According to the coating, the solid content is 30%-40% and the fineness is 60-80 microns; the surface drying time is 0.5-0.8 hour and no bubble and falling phenomena are caused after the coating is soaked in water for 24 hours; the heat resistance is good and no tacky and cracking phenomena are caused after the coating is heated at 90 DEG C for 5 hours; the coating can be washed for 300-500 times, is good in washability and stability, can be produced on a large scale, and continuously replaces an existing material.

Owner:江苏百代节能建材有限公司

Outer wall coating for buildings

The invention relates to an outer wall coating for buildings. The outer wall coating is prepared from the following raw materials in parts by weight: 100 parts of an acrylic resin solution, 15-30 parts of zinc naphthenate, 5-10 parts of ultramarine, 20-30 parts of xylene, 15-25 parts of talcum powder, 15-35 parts of glycerol ester of rosin, 5-15 parts of light calcium carbonate, 25-35 parts of a thickening agent, 35-45 parts of titanium dioxide, 50-60 parts of rosin modified phenolic resin, 10-30 parts of hydroxyethyl cellulose, 1-10 parts of fungicide, 5-15 parts of propylene glycol and 10-20 parts of methylbenzene. The outer wall coating for buildings is free of caking, is in a uniform state when being stirred, free of phenomenon such as foaming or powder dropping after the outer wall coating is soaked in water for 15-30 days, smooth in coating surface, free of abnormity when being soaked in alkali water for 15-30 days, long in storage time and can be widely produced and constantly replace existing materials, the surface drying time is 1-2 hours, and the coating film is resistant to brushing and washing for 1200-1800 times.

Owner:广西瑞顺建材有限公司

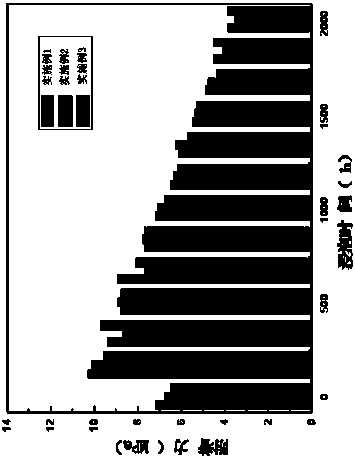

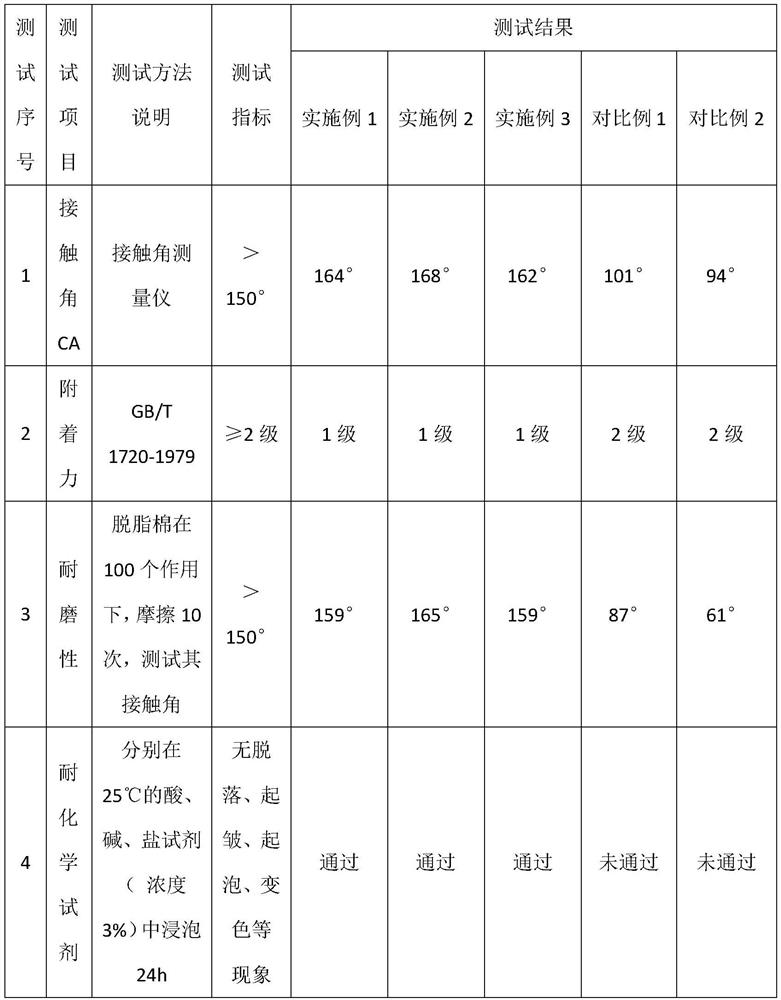

Spherical stain-resistant pin insulator preparation method

InactiveCN113480907ALower surface energyHas a hydrophobic effectCellulose coatingsPin insulatorsMeth-Acrylic resin

The invention discloses a spherical stain-resistant pin insulator preparation method, and relates to the technical field of insulators. The method comprises the steps: preparing an insulator body; preparing a stain-resistant coating material: drying modified nano hydrated silicon dioxide, modified nano silicon nitride and modified mica powder, adding the dried modified nano hydrated silicon dioxide, modified nano silicon nitride and modified mica powder into an organic silicon modified acrylic resin, uniformly mixing, grinding, continuously adding modified polytetrafluoroethylene wax emulsion, uniformly mixing to obtain a mixture I, adding aluminum borate whiskers, nanocrystalline cellulose and glass micro-beads added into modified styrene-acrylic emulsion, uniformly mixing to obtain a second mixture, uniformly mixing the first mixture and the second mixture, and then adding methyltris (methylethylketoximino) silane and ethyl acetate to prepare a stain-resistant coating material; and coating an insulator body with the stain-resistant coating material. According to the invention, that the prepared insulator has a stain-resistant effect and is not easy to generate pollution flashover.

Owner:江西东维电气有限公司

Scrubbing-resistant interior wall coating

The invention relates to a scrubbing-resistant interior wall coating which is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl alcohol resin, 15-25 parts of wollastonite, 10-20 parts of sodium hexametaphosphate, 30-40 parts of mica powder, 60-80 parts of water, 10-20 parts of a flatting agent, 20-40 parts of a coloring pigment, 5-10 parts of n-butyl alcohol, 25-35 parts of tributyl phosphate, 5-10 parts of triethylene tetramine, 15-35 parts of ground calcium carbonate, 10-30 parts of cyclohexanone, 20-30 parts of dibutyl phthalate, 10-20 parts of DOP (dioctyl phthalate) and 5-10 parts of boric acid. The solid content of the product is 30-40%, the fineness is 60-70 mu m, and after surface drying at 25 DEG C for 0.4-0.8 hour and soaking in water for a week, the coating is free of bubble and falling. The scrubbing-resistant interior wall coating is good in heat resistance and free of stickiness and cracking for 7 hours at 90 DEG C. The product is scrubbing-resistant for 500-600 times and can be widely produced to continuously replace existing materials.

Owner:邹城曦轩涂料科技有限公司

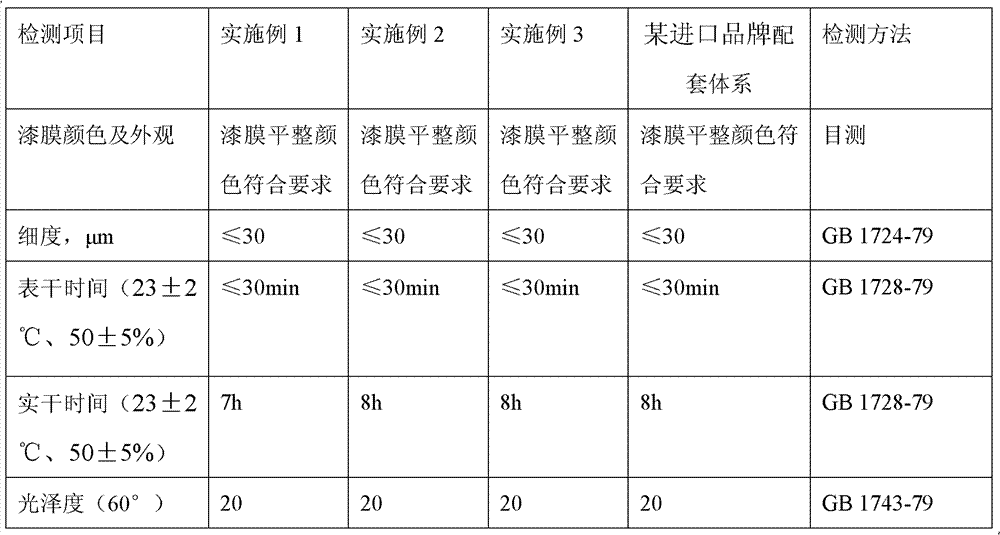

Epoxy priming paint used for moisture resisting megawatt wind-power blades and preparation method thereof

The invention discloses an epoxy priming paint used for moisture resisting megawatt wind-power blades and its preparation method. The priming paint is prepared by mixing a coating part A with a curing agent part B; wherein the portion of the coating part A comprises by weight: 18 to 25 portions of epoxy resin, 50 to 60 portions of pigments and fillers, 2 to 4 portions of anti-settling agent, 1 to1.5 portions of dispersing agent, 1 to 2 portions of antifoaming agent, 0.5 to 1 portions of leveling agent, 0.5 to 1 portions of coupling agent and 15 to 25 portions of organic solvent; the curing agent part B is composed of modified amine and the organic solvent. The priming paint of the invention has the advantages of excellent adhesive force, good flexibility, prominent moisture resistance and good workability, which is especially suitable for coating the megawatt wind-power blades under high humility environment.

Owner:江苏普兰纳涂料有限公司

Novel internal wall paint

InactiveCN104371397AImprove water resistanceImprove adhesionCoatingsCalcium silicatePolyvinyl butyral

The invention relates to a novel internal wall paint which is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl alcohol resin, 15-20 parts of calcium silicate, 25-45 parts of sodium pentachlorophenate, 5-15 parts of calcium oxide, 80-100 parts of water, 10-20 parts of kaolin, 15-25 parts of tinting pigment, 5-10 parts of calcium stearate, 40-50 parts of defoaming agent, 5-10 parts of polyvinyl butyral, 20-30 parts of ethylene glycol monobutyl ether, 10-20 parts of silicon dioxide powder, 20-40 parts of styrene and 10-30 parts of paraffin. The solid content of the product is 30-40%, and the fineness is 60-80 mu m. The fineness of the product is 60-80 mu m, and the surface drying time is 0.5-1 hour. The novel internal wall paint has favorable water resistance, and does not have the phenomenon of blistering or shedding after being immersed in water for 24 hours. The novel internal wall paint has the advantages of high adhesive force and no sloughing; the coated film has the advantages of smooth and uniform appearance, favorable heat resistance and favorable wear resistance; and the novel internal wall paint can be widely produced and continuously substituted for the existing materials.

Owner:ZHEJIANG QIAO XING CONSTR GRP HUZHOU INTELLIGENT SCI & TECH

Unsaturated polyester photocureable coating for ceramics

ActiveCN104194589ASparkling noShedding phenomenon noPolyester coatingsMaleic anhydrideCalcium hydroxide

The invention discloses an unsaturated polyester photocureable coating for ceramics. The coating comprises the following raw materials: epoxy polyurethane, ethylene glycol, ethanol, 1,2-propylene glycol, water, maleic anhydride, a tinting pigment, phthalic anhydride, propylene glycol triacrylate, adipic acid, a cross-linking agent, pentaerythritol, hexanediol diacrylate, trimethylolpropane and trimethylolpropane triacrylate. Glossiness of the product is 130-150%, hardness is 0.9-1, softness is 1-3mm and adhesive force is on 1st grade; the coating is free from phenomenons of bubbling and peeling after being soaked in water for 5-15d, and free from bubbling and wrinkling after being soaked in saturated calcium hydroxide for 1-5d; the coating is acid-resistant within 24-48h and 200# gasoline-resistant within 24h; the coating can be widely produced and continuously replace existing materials.

Owner:广西钦州市张振和坭兴陶艺有限公司

Ultraviolet curing paint for ceramics

ActiveCN104178020ASparkling noShedding phenomenon noPolyurea/polyurethane coatingsCarboxylic saltDrying time

The invention relates to an ultraviolet curing paint for ceramics, which is prepared from polyurethane acrylate, titanium dioxide, trimethylolpropane triacrylate, lithopone, water, talcum powder, tinting pigment, light calcium carbonate, ethyl acrylate, barium sulfate, crosslinking agent, benzoin aether, dimethylpropane carboxylate, diphenyl ketone and trimethoxy silane. The glossiness of the product is 120-130%, the surface drying time is 20-60 seconds, and the solid drying time is 30-40 minutes. The paint does not have the phenomenon of blistering or shedding after being immersed in water for 40-60 days. The paint does not blister or wrinkle after being immersed in saturated calcium hydroxide. The product can resist the friction of a cotton ball soaked in 95% ethanol for 8-12 hours, and can be widely produced and continuously used instead of the existing materials.

Owner:钦州市陶花岛陶艺有限公司

Novel heat-resistant interior wall coating for buildings

The invention discloses a novel heat-resistant interior wall coating for buildings. The novel heat-resistant interior wall coating comprises the following raw materials in parts by weight: 100 parts of polyvinyl alcohol resin, 20-30 parts of sodium hexametaphosphate, 5-10 parts of alkali, 30-40 parts of sodium tripolyphosphate, 80-100 parts of water, 10-20 parts of sodium carboxymethylcellulose, 5-15 parts of borax, 5-10 parts of bentonite, 15-25 parts of lithopone, 5-10 parts of tetrahydrofuran, 50-60 parts of extender pigment, 1-2 parts of butyl acetate, 25-35 parts of talcum powder, 5-25 parts of lead sulfate and 2-10 parts of calcium chloride; the content of solid in the coating is 30-40%; the adhesion of the coating is 100%; the surface drying time is 0.1-0.5 hour; the coating does not bubble and fall off after being immersed in water for 24 hours; the coating is high in heat resistance; the coating is not sticky and is not cracked for 6 hours at 95 DEG C; the coating is flat and smooth and free of powder falling, can be widely produced and can be used for continuously replacing the existing material.

Owner:HUZHOU ZHONGCHEN CONSTR

Novel photo-curable epoxy acrylate resin coating for ceramic

The invention discloses a novel photo-curable epoxy acrylate resin coating for ceramic. The photo-curable epoxy acrylate resin coating is prepared from bisphenol A diglycidyl ether, dibutyl tin oxide, acrylic acid, titanium oxide, triethylamine, neopentyl glycol, a photoinitiator, cyclohexane diol, hydroquinone, terephthalic acid, a crosslinking agent, 1,6-hexanediol, diphenyl ketone, hexanedioic acid and dimethyl ethanolamine as raw materials. The glossiness of a product is 120%-140%, the hardness of the product is 4-6H; the surface drying time is 15-45 seconds, the hard drying time is 5-10 minutes; after the product is soaked in a 5% hydrochloric acid solution for 3-5 days, no bubbling and falling are generated and after the product is soaked in saturated calcium hydroxide for 6-8 days, no bubbling and wrinkling are generated; the product can resist the scraping for 2,000-3,000 times, the adhesion force is at Level 1-2 and the coating can be widely produced and continuously replaces existing materials.

Owner:HUZHOU ZHONGCHEN CONSTR

Novel water resistant interior wall coating for building

The invention discloses a novel water resistant interior wall coating for a building. The novel water resistant interior wall coating for the building is prepared from the following raw materials in parts by weight: 100 parts of sweet potato powder, 20-30 parts of formaldehyde, 10-20 parts of sodium hydroxide, 15-25 parts of sodium hexametaphosphate, 30-40 parts of sulfuric acid, 35-45 parts of tributyl phosphate, 70-80 parts of water, 10-20 parts of ethanol, 20-40 parts of a color pigment, 25-35 parts of magnesium chloride, 40-50 parts of castor oil, 5-10 parts of tetrahydrofuran, 60-80 parts of a extender pigment, 30-40 parts of barium chloride, 40-60 parts of talc and 20-50 parts of sodium methylene bis-naphthalene sulfonate. According to the novel water resistant interior wall coating for the building disclosed by the invention, the product solid content is 35-40 percent, and the fineness is 40-60 microns; the surface drying time is 0.6-1h, the novel water resistant interior wall coating does not have the phenomena of bubbling and powder removal after being soaked in water for 24h, is brushed without sagging, does not have the phenomena of tackiness and cracking at the temperature of 90 DEG C for 5h, has the viscosity to be 40-60s and the adhesion to be 100 percent, is smooth in appearance of a coating and can be widely produced and used for continuously replacing the traditional materials.

Owner:HUZHOU ZHONGCHEN CONSTR

Architectural water-resistant acrylate outer wall paint

The invention relates to an architectural water-resistant acrylate outer wall paint which is prepared from the following raw materials in parts by weight: 100 parts of acrylic resin solution, 20-30 parts of nitrocellulose, 5-15 parts of butyl acetate, 10-30 parts of methyl ethyl ketone, 30-40 parts of maleic anhydride, 15-35 parts of n-butanol, 25-35 parts of ethylene glycol, 10-20 parts of tinting pigment, 20-30 parts of calcium carbonate, 15-25 parts of pentaerythritol, 20-40 parts of deionized water, 25-35 parts of mold preventive, 15-35 parts of cobalt naphthenate and 10-30 parts of acrylic acid. The product does not have any hard lump, and is in a uniform state while being stirred. The solid content is 50-60%, the surface drying time is 1-2 hours, and the solid drying time is 18-20 hours. The paint does not have the phenomenon of blistering or shedding after being immersed in water for 2-3 weeks, and does not have any abnormity after being immersed in alkaline water for 5-7 days. The scrubbing resistance of the coated film is 1500-2000 times; and the paint can be widely produced and continuously used instead of the existing materials.

Owner:SUZHOU YUFAN NEW MATERIAL TECH

Alkali-resistant acrylic resin powder paint for new ceramics

InactiveCN104693936ASparkling noShedding phenomenon noPowdery paints(Hydroxyethyl)methacrylateAcrylic resin

The invention discloses an alkali-resistant acrylic resin powder paint for new ceramics, which is prepared from butyl acrylate, pyridine, ethylhexyl-2-acrylate, urea, ethyl acrylate, butanol, a leveling agent, xylene, hydroxyethyl methacrylate, phthalic anhydride, a plasticizer, silicon oil, isopropanol, titanium white and methyl methacrylate. The coated film glossiness is 100-120%, the Shore hardness is 50-60H, and the coated film does not have the phenomena of blistering and shedding after being immersed in water for 30-40 days. The tensile strength is 20-30 MPa, and the coated film does not have abnormalities after being immersed in a 5% hydrochloric acid solution for 25-35 days. The adhesion is Grade 1-2, the impact strength is 500-600 N / cm, and the coated film does not blister or wrinkle after being immersed in saturated calcium hydroxide for 20-30 days. The scrub resistance is 1200-1500 times.

Owner:HUZHOU ZHONGCHEN CONSTR

Composite resin material capable of resisting high and low temperatures and high-energy radiation environment, and preparation method thereof

ActiveCN103264555AGood high and low temperature resistanceNo change in tensile strengthSynthetic resin layered productsHigh energyCompound (substance)

The invention discloses a composite resin material capable of resisting high and low temperatures and a high-energy radiation environment, and a preparation method of the composite resin material, belonging to the field of an organic resin and chemical fiber composite material and preparation thereof. The composite resin material comprises a base layer and a composite layer closely combined with the base layer, wherein the base layer is a fabric taking heterocyclic aromatic polyamide fibers as a main material; and the composite layer is made of m-xylylenediamine tetra-glycidyl-amine epoxy resin and / or reinforced resin taking m-xylylenediamine tetra-glycidyl-amine epoxy resin as a matrix material. The preparation method sequentially comprises the following steps of: gluing in a two-step method, cold press molding, hot press curing, carrying out heat preservation at a constant temperature, and cooling to obtain the finished product. The resin-based fiber composite material disclosed by the invention is capable of resisting high and low temperatures and high-energy radiation.

Owner:四川辉腾科技股份有限公司

Wall decoration coating as well as preparation method and application thereof

The invention discloses a wall decoration coating, which is prepared from the following ingredients in parts by mass: 30 to 65 parts of a filling agent, 10 to 35 parts of superfine slag powder, 0.2 to 3 parts of magnesium aluminum silicate, 0.02 to 0.8 part of poly high-energy latex powder, 10 to 35 parts of white cement, 0.05 to 0.5 part of a water reducing agent, 0.1 to 1.5 parts of a water retaining agent, 0.1 to 1.5 parts of waterproof powder and 0.05 to 1 part of an anti-alkali agent. The wall decoration coating has the excellent properties of no yellowing and discoloration, environmental protection, permanent alkali resistance, water resistance, mildew resistance, difficult shedding and the like, and the product has the advantages of low comprehensive cost and long service life; and the coating has the advantages of no caking, uniformity, no barrier in blade coating during construction, no crack in early dry crack resistance, manual polishing, no bubbling, cracking and powder falling phenomena within 48 hours, and environmental protection indexes exceeding national standards. The invention also discloses a preparation method and application of the wall decoration coating, the preparation is simple, the construction is simple and convenient, the comprehensive cost is low, and the wall decoration coating can replace putty wall surfaces and latex paint.

Owner:何志刚

Ultraviolet photocuring alkene unsaturated polyester coating for ceramic

The invention discloses an ultraviolet photocuring alkene unsaturated polyester coating for ceramic. The coating is prepared from the following raw materials: bisphenol A butyl acetate glyceryl ether, carboxymethylcellulose, methylene-succinic acid, lithopone, n-butyl acetate, calcium carbonate heavy, a photosensitizer, talcum powder, acrylic acid, ultramarine, a cross-linking agent, sodium silicate, methacryloyloxyethyl isocyanate, zinc oxide and dibulytin dilaurate. The glossiness of the product, namely the ultraviolet photocuring alkene unsaturated polyester coating is 110-130%, and the coating coated in amyl acetate in 1-3 days is free from bubbling and shedding phenomena. The coating is acetone-resistant and is free from abnormalities after being rubbed by a cotton ball soaked by 5% ammonium water for 24-48 hours. The coating is free from bubbling and wrinkling after being soaked in a 95% ethanol solution for 12-36 hours. The scrub resistance of the product reaches 600-800 times, and can be widely produced and continuously replace existing materials.

Owner:盐城市盐龙水务有限公司

Colored gloss coating for ceramic

The invention discloses a colored gloss coating for ceramic. The colored gloss coating comprises the following raw materials in parts by weight: 100 parts of butyl acrylate, 10-30 parts of polypropylene glycol, 35-55 parts of olive oil, 15-25 parts of 2,4-benzophenone diisocyanate, 80-100 parts of water, 15-35 parts of hydroxyethyl acrylate, 5-15 parts of coloring pigment, 20-40 parts of N-vinyl pyrrolidone, 5-15 parts of potash soap, 40-50 parts of triisocyanate, 1-5 parts of cross-linking agent, 1-10 parts of benzoin diethyl ether, 10-20 parts of urea, 3-7 parts of benzophenone and 5-25 parts of clay. The gloss of the colored gloss coating is 100-120%, the hardness of the colored gloss coating is 5-7H, the surface drying time of the colored gloss coating is 30-40 seconds, the hard drying time is 20-30 minutes, no foaming or dropping phenomenon is generated after the colored gloss coating is soaked in water for 30-60 days, no bubble or shrinkage is generate after the colored gloss coating is soaked in saturated calcium hydroxide for 10-20 days, no color change or powdering phenomenon after the colored gloss coating is radiated for 100 hours in ultraviolet light, and the colored gloss coating can be widely produced to replace conventional materials.

Owner:SUZHOU SHENGPULA NEW MATERIAL SCI & TECH

Manufacturing method for metal-based copper clad laminate

InactiveCN106585044AImprove thermal conductivityImprove cooling effectLaminationLamination apparatusRough surfaceThermal spraying

The invention discloses a manufacturing method for a metal-based copper clad laminate. The manufacturing method includes the steps that 1, a metal substrate and a copper clad are provided, and a resin composition of an insulating layer is prepared; 2, with Al2O3 or AlN or BeO or SiC dry powder being a raw material, thermal spraying is carried out on the surface of the metal substrate at ultrahigh temperature through thermal spraying equipment; 3, the resin composition is ground, and then the rough surface of the copper clad is coated with the resin composition through a coating machine to be baked; 4, the copper clad, coated with resin, of the semi-solidified state resin layer and the metal substrate after thermal spraying treatment are put between two mirror surface steel plates to be overlapped and put in a hot press to be subjected to vacuum pressing. According to the method, by carrying out thermal spraying treatment on the surface of the metal substrate, the bonding force with the copper clad coated with the resin is improved, the thickness of the insulating layer can be reduced on the premise of not lowering pressure-resistant capacity, and therefore the heat-conduction, heat-dissipation and pressure-resistant properties of the metal-based copper clad laminate can be improved.

Owner:广东全宝科技股份有限公司

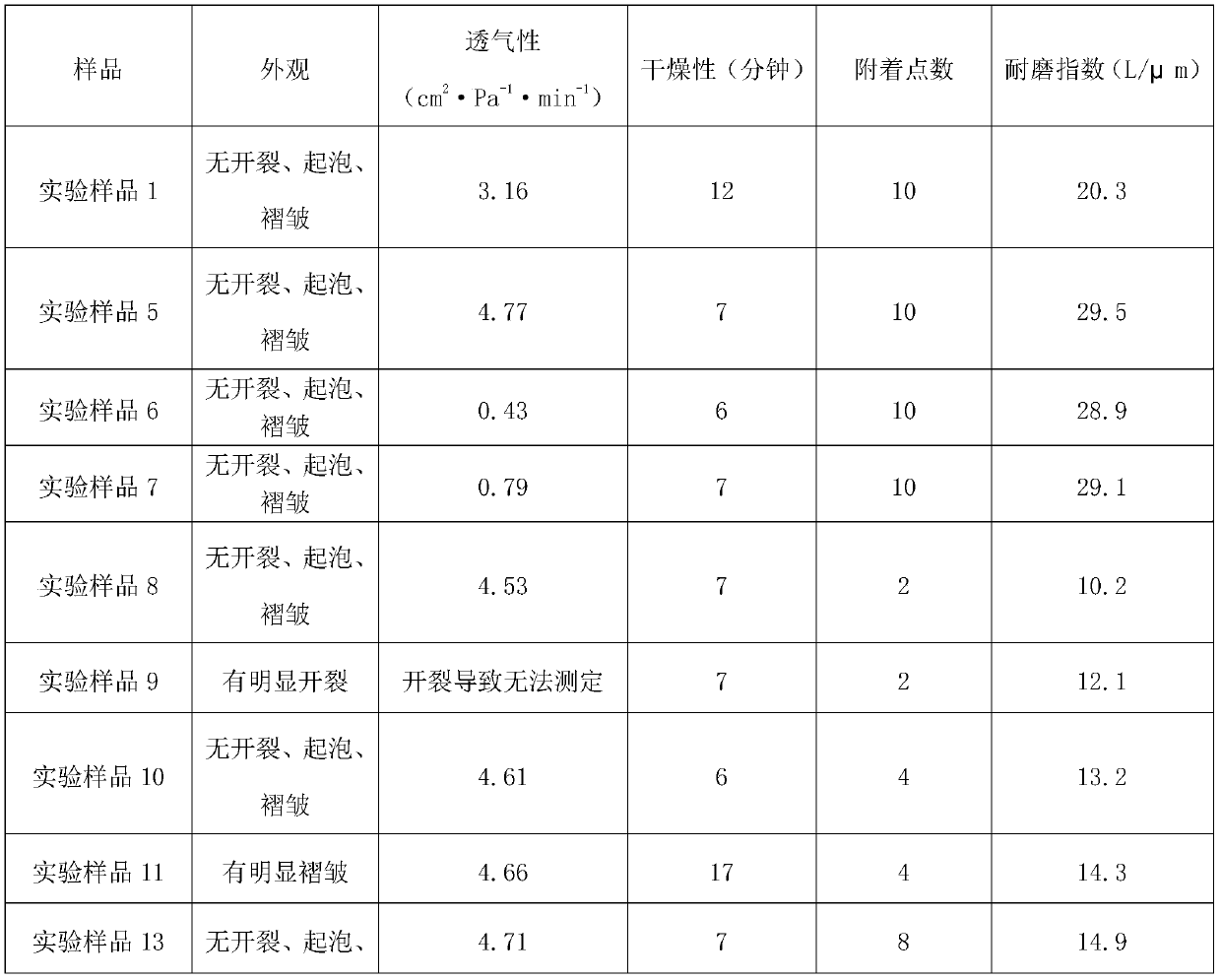

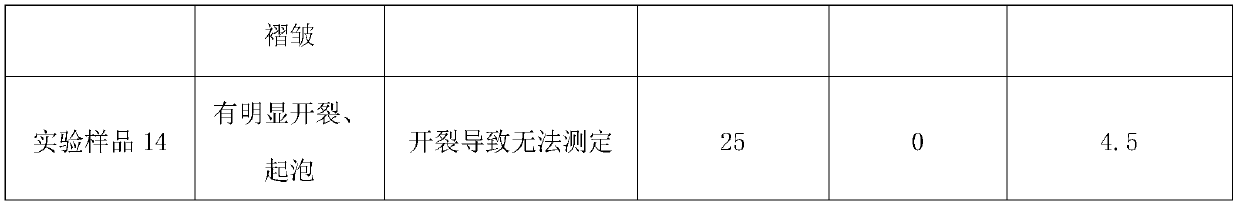

Multifunctional coating for casting and preparation method thereof

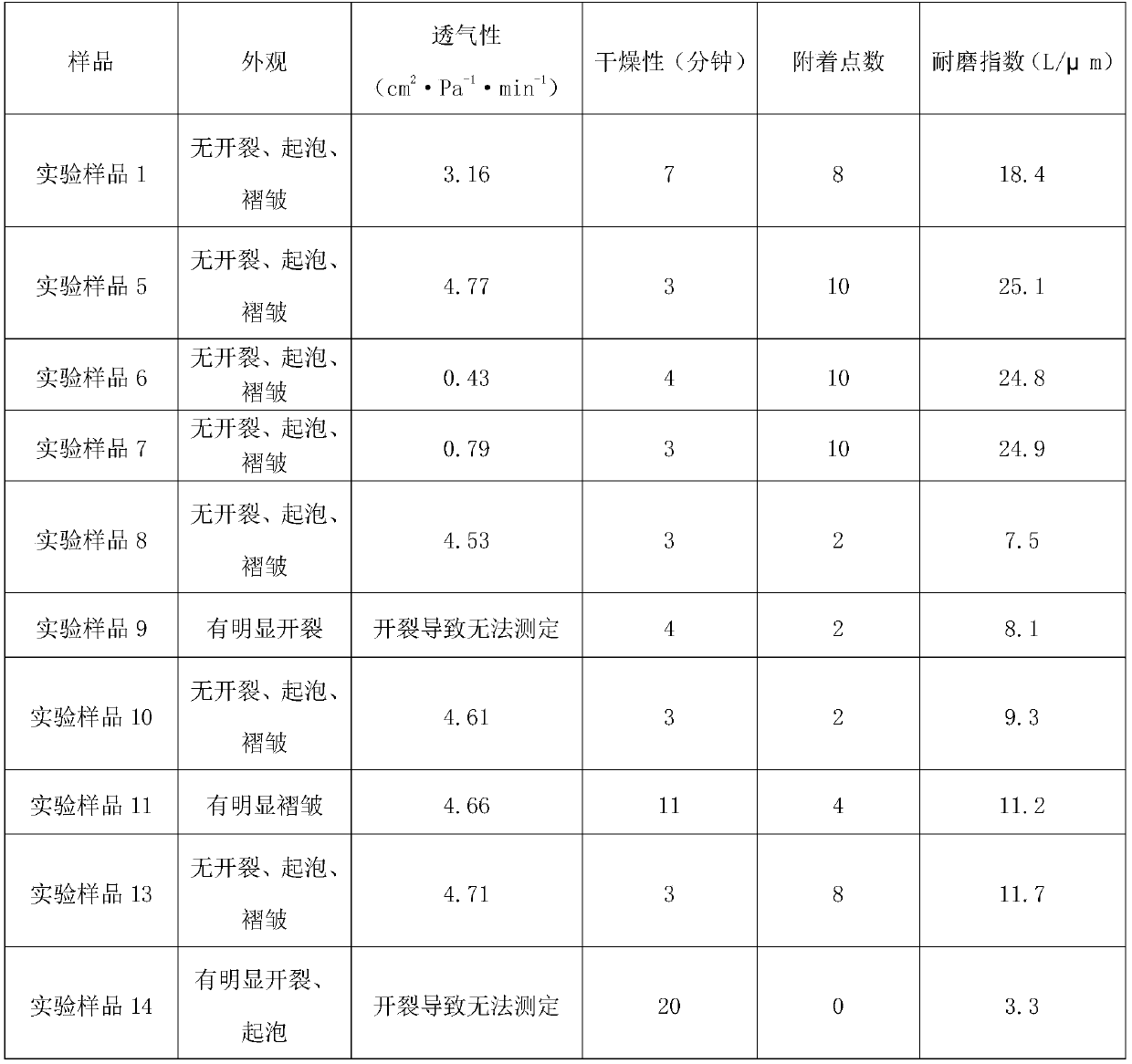

The invention provides a multifunctional coating for casting and a preparation method thereof and particularly relates to the technical field of casting coatings. The method comprises the steps that firstly, a polystyrene fused solution is adopted for firing a compound, quartz sand powder and bentonite wrap the compound in batch in sequence, a wrapping compound is prepared, then powder of plasterof paris, sweet wormwood herb wax, trehalose and zinc oxide crystal whiskers are added to the wrapping compound, and the multifunctional coating for casting is prepared. The coating can be simultaneously used for two processes of lost foam casting and V-method casting, after coating is completed, cracks, bubbles and wrinkles do not exist, and the multifunctional coating for casting has the advantages of being resistant to wear, high in drying speed, adhesive force and air permeability and the like. The sand burning, shrinkage porosity and pore defects of a casting can also effectively prevented. The other aim of the invention is to provide the preparation method of the multifunctional coating for casting. The method is easy to operate, stable in process and suitable for large-scale production, and parameters can be controlled.

Owner:柳州市一乐科技有限公司

Ultraviolet curing acrylic ester composition paint used for ceramic

ActiveCN104152034ASparkling noShedding phenomenon noPolyurea/polyurethane coatingsPolyester coatingsPolyesterUltraviolet

The invention discloses an ultraviolet curing acrylic ester composition paint used for ceramic. The ultraviolet curing acrylic ester composition paint includes following raw materials: urethane acrylate, magnesium oxide, polyester acrylate, zinc oxide, water, light calcium carbonate, a crosslinking agent, quartz powder, dibutyltin dilaurate, sodium hydroxide, a coupling agent, benzoin ethyl ether, epoxy acrylate, diphenyl ketone and trimethylolpropane triacrylate. The paint is 110%-130% in glossiness, is 5-8 H in hardness, is 25-35 s in a surface drying time and 20-30 min in actual drying time, is free of a blistering and dropping phenomenon after being soaked in water for 30-50 days, is free from blistering and wrinkling after being soaked in a saturated calcium hydroxide solution for 5-15 days, is good in anti-wear performance and can be widely produced and replace conventional materials.

Owner:王帅

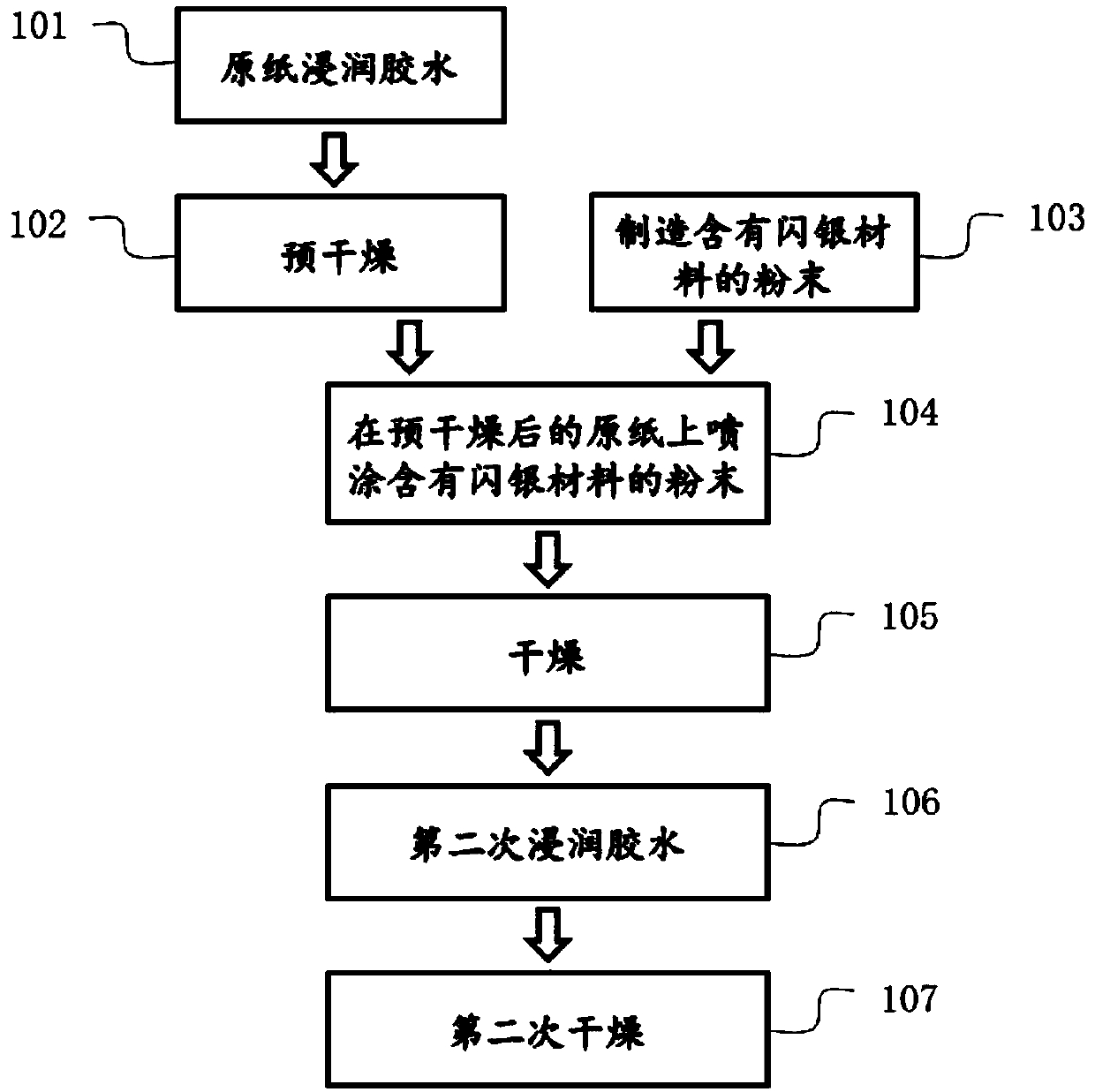

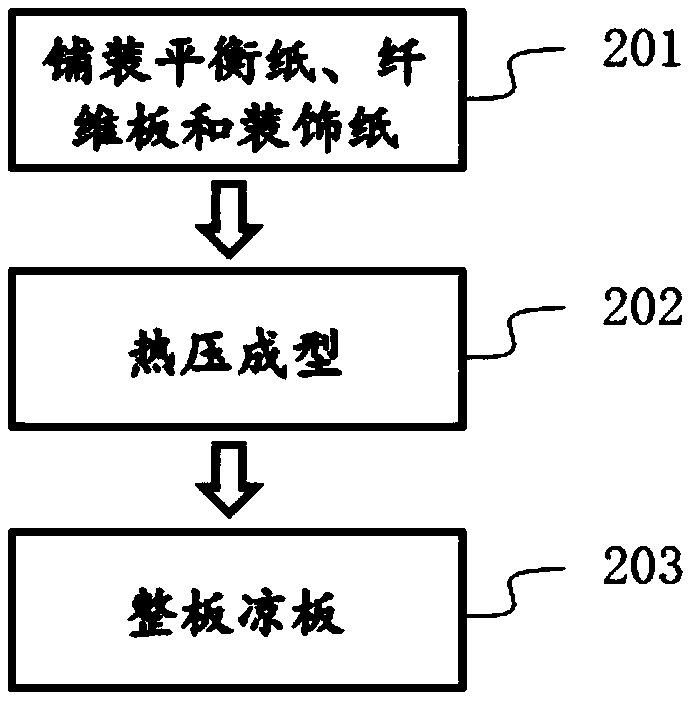

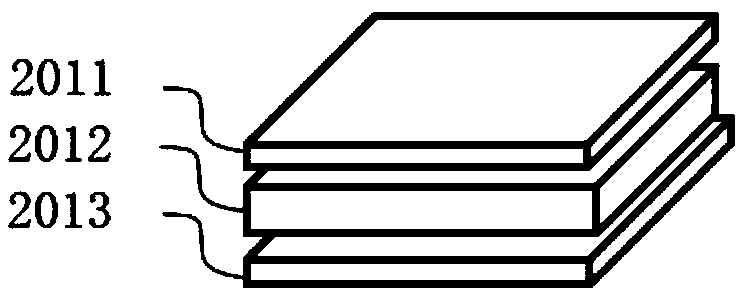

Manufacturing methods for decorative paper with silver-flash effect on surface and for reinforced wood floor

InactiveCN110434948ASparkling noDry flower phenomenon noSpecial visual effect coatingsLaminationPulp and paper industryWhite Spots

The invention provides manufacturing methods for decorative paper with a silver-flash effect and for a reinforced wood floor. The manufacturing method for the decorative paper with the silver-flash effect comprises the following steps of infiltrating raw paper with glue; spraying powder containing a silver flash material on the raw paper obtained after being infiltrated with the glue; drying the raw paper obtained after being sprayed with the powder to obtain the decorative paper with the silver-flash effect. The manufacturing method for the reinforced wood floor comprises the following stepsof sequentially stacking and laying balance paper, a fiber board and the decorative paper sprayed with the silver flash material from bottom to top to obtain a laminated structure; and performing hot-press forming on the laminated structure to form the wood floor with the silver-flash decoration effect. According to the manufacturing methods, the problem of white spots and blistering generated after the silver-flash decorative paper is applied to the reinforced wood floor is solved.

Owner:广西柏景地板有限公司

Aluminum silicon carbide material nickel plating method

InactiveCN108588691ANo pollution in the processSparkling noVacuum evaporation coatingSputtering coatingOptical microscopeChemical plating

The invention discloses an aluminum silicon carbide material nickel plating method. The method comprises the steps of plating multiple nickel layers; conducting film plating through a physical vapor deposition method after render plating and then conducting render plating again; conducting cleaning before and after render plating; conducting film plating through chemical plating; conducting bakingand heat treatment to complete nickel plating after completion of film plating. The aluminum silicon carbide material nickel plating method is simple in process, convenient to operate, low in cost, high in efficiency, wide in application range, free of environmental pollution and capable of achieving industrial production. The obtained plating layers are bright, smooth, uniform and compact and are free of blistering, stripping and cracks through optical microscope observation.

Owner:西安朗赛精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com