Spherical stain-resistant pin insulator preparation method

A technology of pin insulators and insulators, which is applied in the direction of pin insulators, insulators, coatings, etc., can solve the problems of easy dirt accumulation on the surface, insufficient surface smoothness, and influence on airflow, etc., to achieve improved hydrophobicity, excellent hydrophobicity, The effect of reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

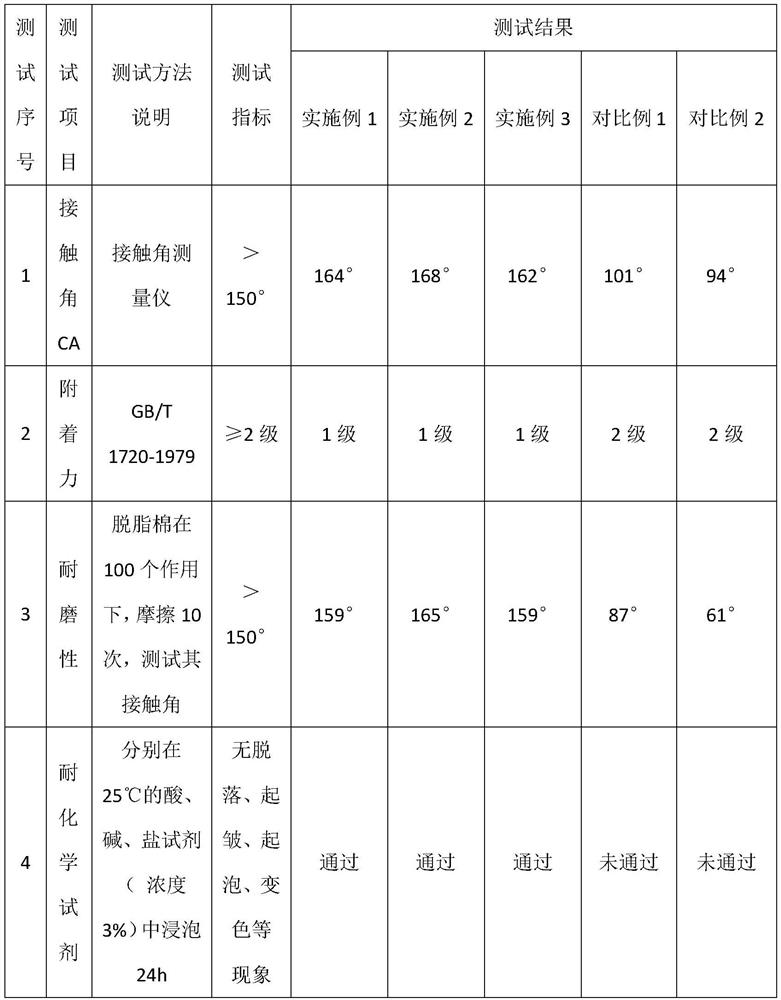

Examples

Embodiment 1

[0027] A method for preparing a spherical pollution-resistant pin insulator, comprising the following steps:

[0028] S1. Prepare the insulator body;

[0029] S2, prepare antifouling paint, comprise:

[0030] a. Weigh 30 parts of raw material organosilicon-modified acrylic resin, 20 parts of modified styrene-acrylic emulsion, 4 parts of modified polytetrafluoroethylene wax emulsion, 1 part of modified nano-silicon nitride, and modified mica in the following parts by weight 1 part of powder, 2 parts of modified nano-hydrated silica, 0.5 parts of aluminum borate whiskers, 0.5 parts of nano-microcrystalline cellulose, 1 part of glass microspheres, 2 parts of methyl tributylketoximosilane, 30 parts of ethyl acetate share;

[0031] Among them, the modification method of silicone-modified acrylic resin is: dissolve 10g of orthosilicate in 4mL of ethanol, add 0.01mL of dilute acid, hydrolyze at 70°C for 3 hours; Polycondensate for 2 hours to obtain a silicone oligomer; combine 5 g o...

Embodiment 2

[0041] A method for preparing a spherical pollution-resistant pin insulator, comprising the following steps:

[0042] S1. Prepare the insulator body;

[0043] S2, prepare antifouling coating, comprise:

[0044] a. Weigh 40 parts of raw material organosilicon-modified acrylic resin, 25 parts of modified styrene-acrylic emulsion, 6 parts of modified polytetrafluoroethylene wax emulsion, 2 parts of modified nano-silicon nitride, and modified mica in the following parts by weight 2 parts of powder, 3 parts of modified nano-hydrated silica, 2 parts of aluminum borate whiskers, 1 part of nano-microcrystalline cellulose, 3 parts of glass beads, 4 parts of methyl tributylketoxime silane, 35 parts of ethyl acetate share;

[0045] Among them, the modification method of silicone-modified acrylic resin is as follows: dissolve 10g of orthosilicate in 4mL of ethanol, add 0.01mL of dilute acid, and hydrolyze it at 80°C for 2 hours; Polycondensate for 1.5 hours to obtain a silicone oligome...

Embodiment 3

[0055] A method for preparing a spherical pollution-resistant pin insulator, comprising the following steps:

[0056] S1. Prepare the insulator body;

[0057] S2, prepare antifouling coating, comprise:

[0058] a. Weigh 50 parts of raw material organosilicon modified acrylic resin, 30 parts of modified styrene-acrylic emulsion, 8 parts of modified polytetrafluoroethylene wax emulsion, 3 parts of modified nano-silicon nitride, and modified mica in the following parts by weight 3 parts of powder, 4 parts of modified nano-hydrated silica, 2.5 parts of aluminum borate whiskers, 1.5 parts of nano-microcrystalline cellulose, 5 parts of glass microspheres, 6 parts of methyl tributylketoxime silane, 40 parts of ethyl acetate share;

[0059] Among them, the modification method of silicone-modified acrylic resin is as follows: dissolve 10g of orthosilicate in 4mL of ethanol, add 0.01mL of dilute acid, and hydrolyze at 90°C for 1 hour; Polycondensate for 1 hour to obtain a silicone ol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com