Manufacturing methods for decorative paper with silver-flash effect on surface and for reinforced wood floor

A technology of laminated wood flooring and manufacturing methods, applied in the field of interior decoration materials, can solve the problems of dry flowers, foaming, etc., and achieve good effects of flashing silver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

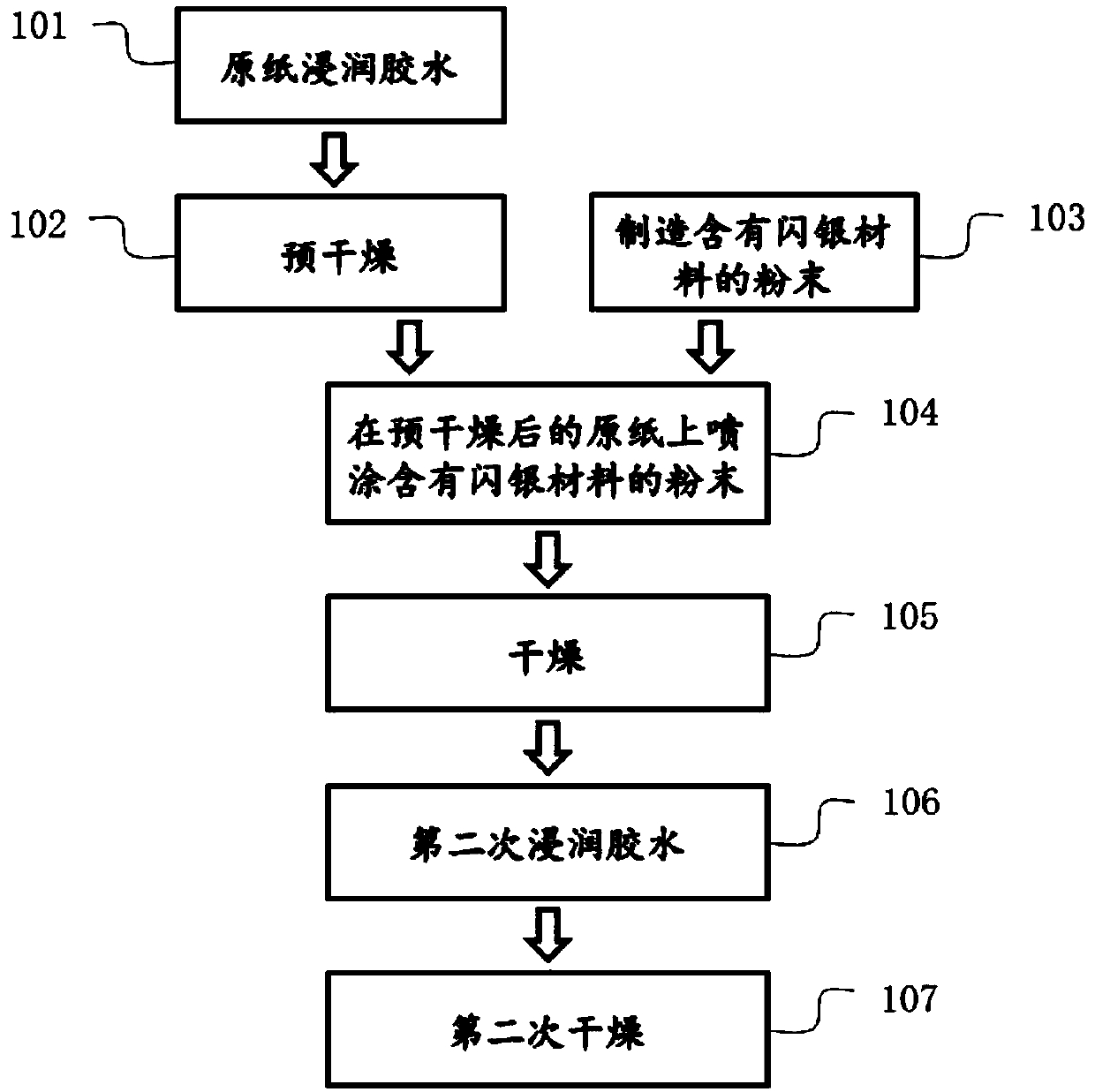

[0029] figure 1 It is a schematic flow chart of the manufacturing method of decorative paper with silver glitter effect according to Example 1 of the present invention, and the decorative paper according to the present invention can be obtained through this method. see figure 1 , the steps of this embodiment are as follows:

[0030] 101: soak both sides of the base paper with glue, the glue is melamine glue or other suitable liquid glue, and the dipping amount is kept within the range of 140.0% to 180.0%. For example, the dipping amount can be set at 140.0%, 180.0%, preferably 160.0%.

[0031] 102: Pre-dry the base paper soaked with glue on both sides. The pre-drying equipment can be an oven or other suitable drying equipment that can maintain a constant temperature. The temperature range of the oven is 60 to 80 degrees Celsius, and the drying time is 30 to 45 seconds. For example, the drying temperature can be set at 60 degrees Celsius, 80 degrees Celsius, preferably 70 d...

Embodiment 2

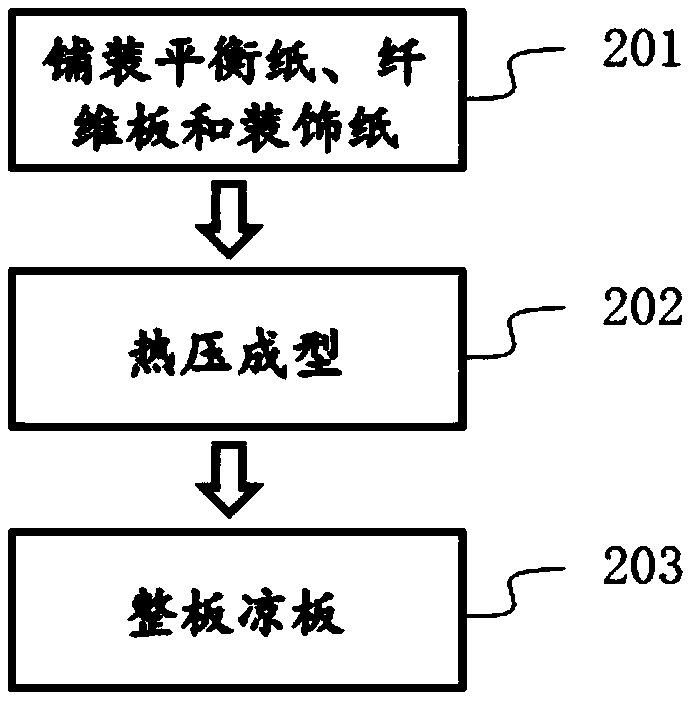

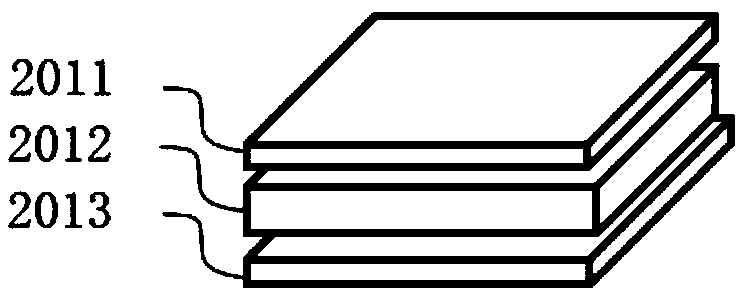

[0041] Figure 2A It is a schematic flow chart of the floor manufacturing method according to Embodiment 2 of the present invention, Figure 2B It is a schematic diagram of the floor stacking structure according to Example 2 of the present invention, through which the laminated wood flooring with silver flash effect according to the present invention can be obtained. The steps of the manufacturing method are as follows:

[0042] 201: stack and pave the silver-colored decorative paper 2011, MDI high-density fiberboard 2012 and moisture-proof balance paper 2013 manufactured in Example 1 in sequence from top to bottom to obtain a laminated structure;

[0043] 202: Carry out thermocompression molding on the laminated structure, using a Wenconer continuous press machine for thermocompression, wherein the pressing temperature is kept in the range of 180 to 190 degrees Celsius, the pressure is kept at 50 to 70 kilograms per square centimeter, and the time is set at 19 to the range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com