Smoke suppressant type indoor ultrathin fire-resistant paint for steel structure and preparation process thereof

A fire-resistant coating, ultra-thin technology, applied in the direction of fire-resistant coatings, polyester coatings, coatings, etc., can solve the problems of insufficient smoke suppression and weather resistance, and release of irritating gases, so as to improve the fire resistance limit time and reduce irritation Inert gas, the effect of improving the fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

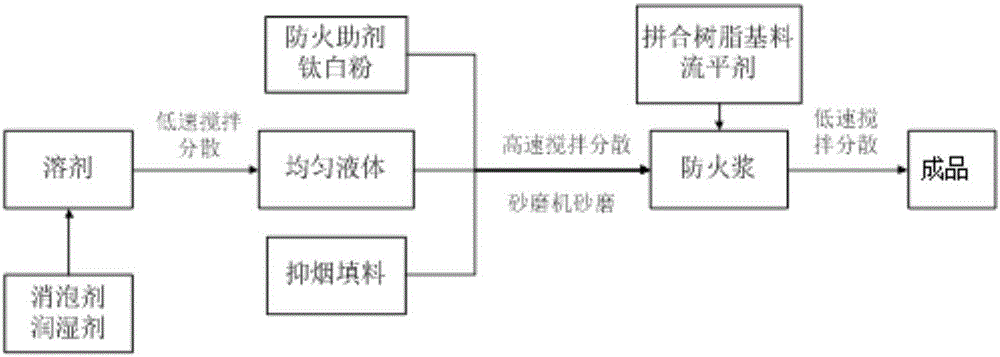

[0029] combine figure 1 , a smoke-suppressing indoor ultra-thin steel structure fireproof coating, the preparation process is as follows:

[0030] (1) Add 0.6kg of BYK141 defoamer and 0.8kg of BYK104S wetting agent to 19kg of 200# solvent oil and disperse at a low speed of 500r / min to form a uniform liquid;

[0031] (2) Respectively, the fireproof additives composed of ammonium polyphosphate 18kg, melamine 8kg, pentaerythritol 8kg, titanium dioxide 7kg and antimony trioxide 0.3kg, zinc oxide 0.5kg, talcum powder 5.5kg, calcium carbonate 4kg, perlite 2kg The smoke-suppressing filler is added to the homogeneous liquid described in step (1), first dispersed by 1500r / min high-speed stirring for 10 minutes, then inhaled into a sand mill, and sand-milled to a fineness of less than 80 microns to obtain a fireproof slurry;

[0032] (3) After adding 0.6kg of BYK306 leveling agent and 0.6kg of BYK306 leveling agent to the fire-proof slurry described in step (2), the combined resin base...

Embodiment 2

[0034] combine figure 1 , a smoke-suppressing indoor ultra-thin steel structure fireproof coating, the preparation process is as follows:

[0035] (1) Add 0.6kg of BYK052 defoamer and 0.8kg of BYK104S wetting agent to 17.5kg of 150# solvent and disperse at a low speed of 500r / min to form a uniform liquid;

[0036] (2) Fireproof additives composed of ammonium polyphosphate 22kg, melamine 9kg, dipentaerythritol 6kg, titanium dioxide 8kg and antimony trioxide 0.3kg, zinc oxide 1kg, talcum powder 5kg, calcium carbonate 4kg, perlite 2kg respectively The smoke-suppressing filler is added into the homogeneous liquid described in step (1), firstly inhaled into a sand mill after being dispersed by 1500r / min high-speed stirring for 10 minutes, and sand-milled to a fineness of less than 80 microns to obtain a fireproof slurry;

[0037] (3) After adding 11kg of acrylic resin, 11kg of acrylic modified alkyd resin, and 5.5kg of amino resin to the combined resin base material, and 0.6kg of ...

Embodiment 3

[0039] combine figure 1 , a smoke-suppressing indoor ultra-thin steel structure fireproof coating, the preparation process is as follows:

[0040] (1) Add 0.6kg of BYK141 defoamer and 0.7kg of BYK104S wetting agent to 17.5kg of s-1000# solvent and stir at a low speed of 500r / min to form a uniform liquid;

[0041] (2) Fireproof additives consisting of ammonium polyphosphate 18kg, melamine 8kg, pentaerythritol 8kg, titanium dioxide 8kg and antimony trioxide 0.3kg, zinc oxide 0.5kg, talcum powder 4.5kg, calcium carbonate 5kg, perlite 3kg respectively The smoke-suppressing filler is added to the homogeneous liquid described in step (1), first dispersed by 1500r / min high-speed stirring for 12 minutes, then inhaled into a sand mill, and sand-milled to a fineness of less than 80 microns to obtain a fireproof slurry;

[0042] (3) After adding 0.7kg of BYK306 leveling agent and 0.7kg of BYK306 leveling agent into the fireproof pulp described in step (2) by adding the combined resin ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com