A kind of plastic nano coating and preparation method thereof

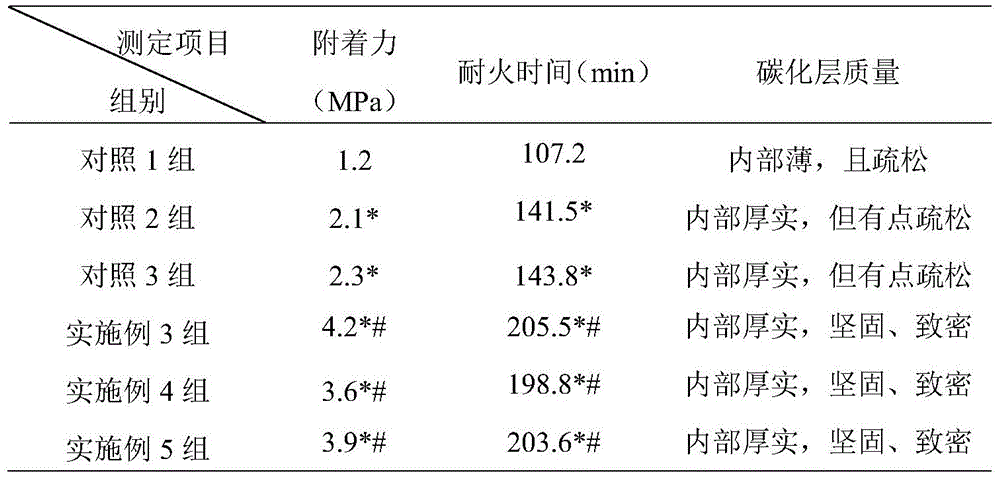

A nano-coating and plastic technology, applied in fireproof coatings, polyester coatings, coatings, etc., can solve the problems of insufficient coating adhesion, poor flame retardancy, and short service life, and achieve low cost, excellent adhesion, and internal chunky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Party:

[0019] Water-based acrylic resin 10g, polylactate 2g, pigment 0.5g, nano titanium dioxide 5g, nano silicon dioxide 100g, pentaerythritol 6g, talcum powder 8g, mica 15g.

[0020] The degree of polycondensation of the water-based acrylic resin is 30

[0021] Preparation:

[0022] (1) Take nano-titanium dioxide and nano-silicon dioxide and place them in a container, add a certain amount of deionized water, fully stir and mix to obtain primary emulsion;

[0023] (2) Fully pulverize mica and talcum powder, add pigment, and disperse at a high speed of 5000r / min for 40 minutes to obtain a color paste;

[0024] (3) Make an emulsion of water-based acrylic resin and polylactic acid ester, mix it with pentaerythritol, the above-mentioned primary emulsion and color paste, and disperse it with 300W ultrasonic wave for 2 hours.

[0025] The average particle diameter of the plastic nano coating is 50nm.

Embodiment 2

[0027] Party:

[0028] Water-based acrylic resin 10g, polylactate 12g, pigment 0.9g, nano titanium dioxide 15g, nano silicon dioxide 20g, pentaerythritol 12g, talcum powder 14g, mica 25g.

[0029] The degree of polycondensation of the water-based acrylic resin is 50

[0030] Preparation:

[0031] (1) Take nano-titanium dioxide and nano-silicon dioxide and place them in a container, add a certain amount of deionized water, fully stir and mix to obtain primary emulsion;

[0032] (2) Fully pulverize mica and talc powder, add pigment, and disperse at a high speed of 7000r / min for 60 minutes to obtain a color slurry;

[0033] (3) Make an emulsion of water-based acrylic resin and polylactic acid ester, mix it with pentaerythritol, the above-mentioned primary emulsion and color paste, and disperse it by ultrasonic wave at 500W for 4 hours.

[0034] The average particle diameter of the plastic nano coating is 90nm.

Embodiment 3

[0036] Party:

[0037] Water-based acrylic resin 10g, polylactate 7g, pigment 0.7g, nano-titanium dioxide 10g, nano-silicon dioxide 15g, pentaerythritol 9g, talcum powder 11g, mica 20g.

[0038] The degree of polycondensation of the water-based acrylic resin is 40

[0039] Preparation:

[0040] (1) Take nano-titanium dioxide and nano-silicon dioxide and place them in a container, add a certain amount of deionized water, fully stir and mix to obtain primary emulsion;

[0041] (2) Fully pulverize mica and talcum powder, add pigment, disperse at 6000r / min high speed for 50 minutes, and obtain color slurry;

[0042] (3) Make an emulsion of water-based acrylic resin and polylactic acid ester, mix it with pentaerythritol, the above-mentioned primary emulsion and color paste, and disperse it by ultrasonic wave at 400W for 3 hours.

[0043] The average particle diameter of the plastic nano coating is 70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com