Patents

Literature

33results about How to "Extend fire resistance time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

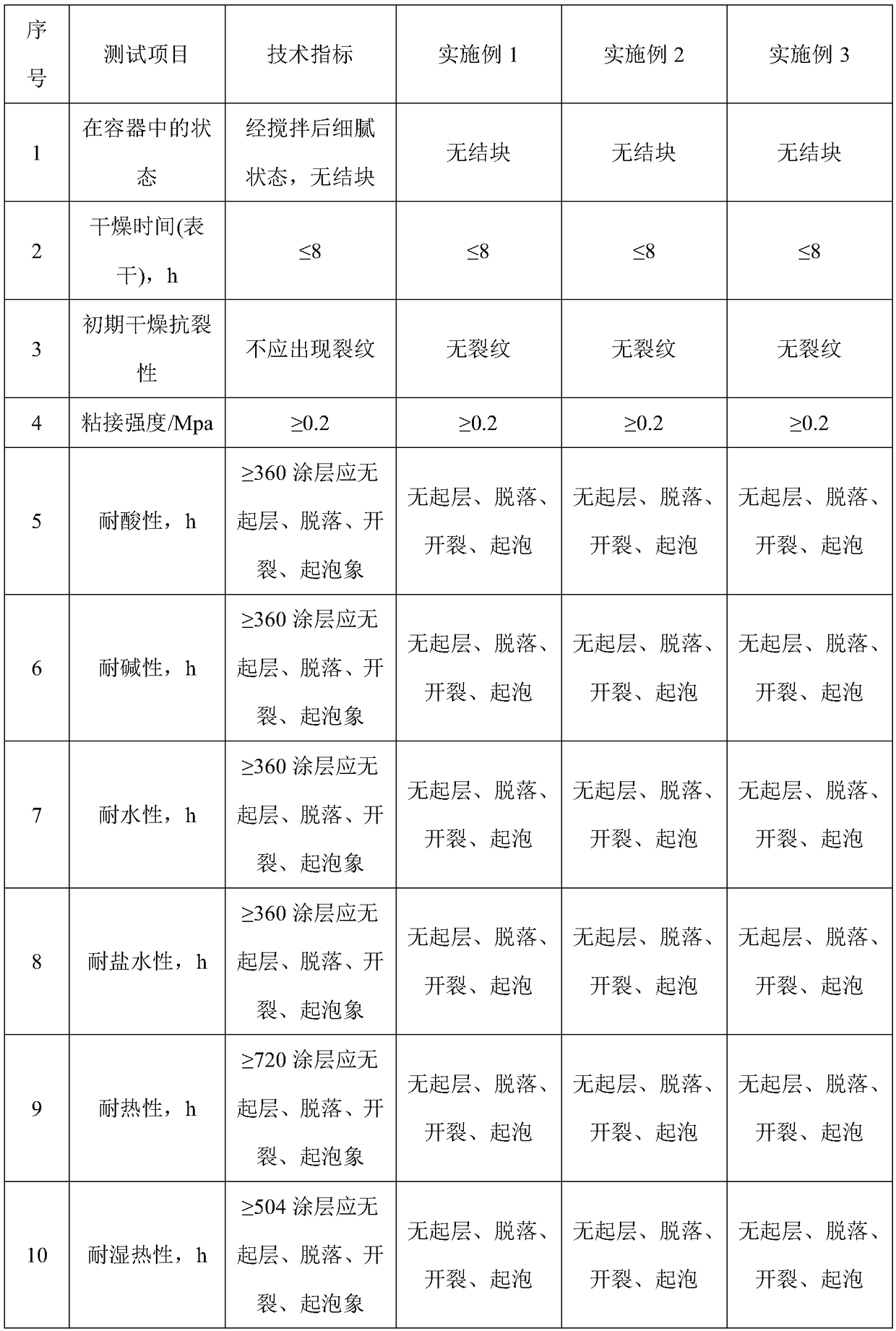

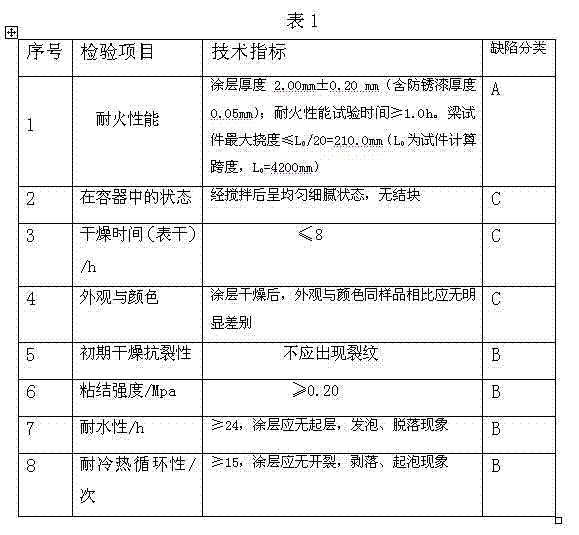

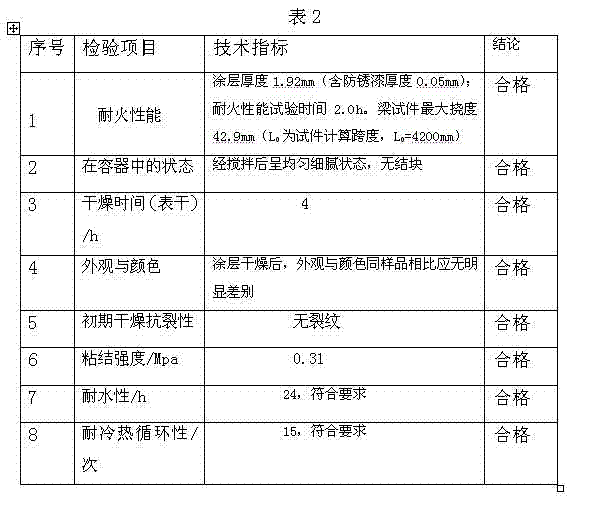

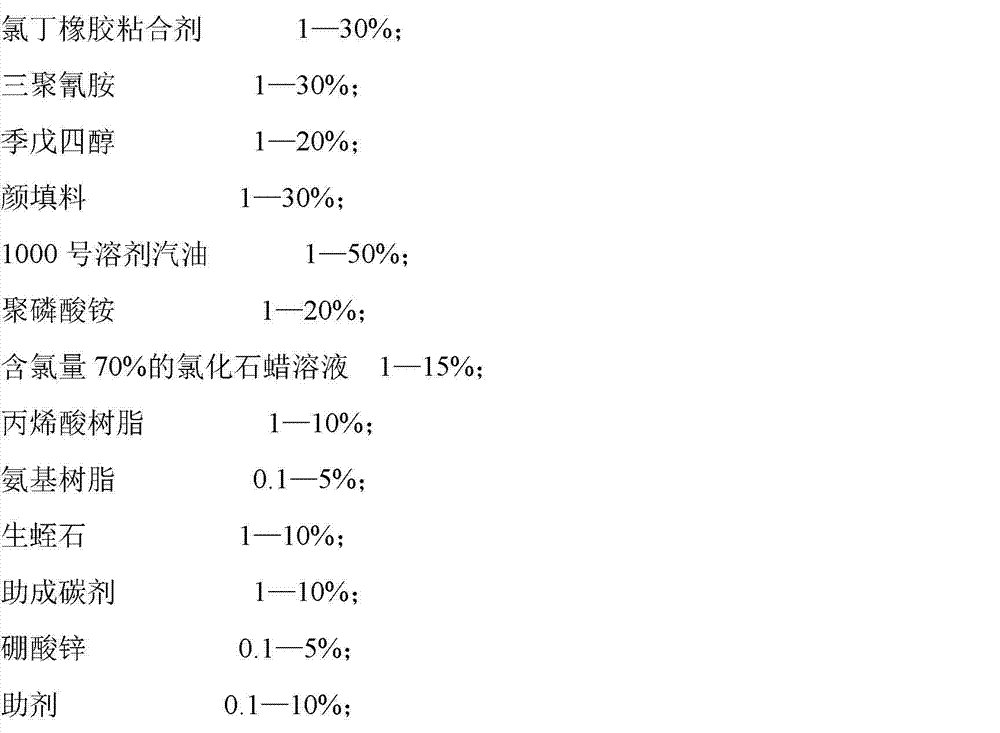

Fireproof and anti-corrosion bifunctional ultra-thin steel structure coating and preparation method thereof

InactiveCN102241925AHigh foaming rateImprove fire resistanceFireproof paintsChloropene polymer coatingsAdhesiveAcrylic resin

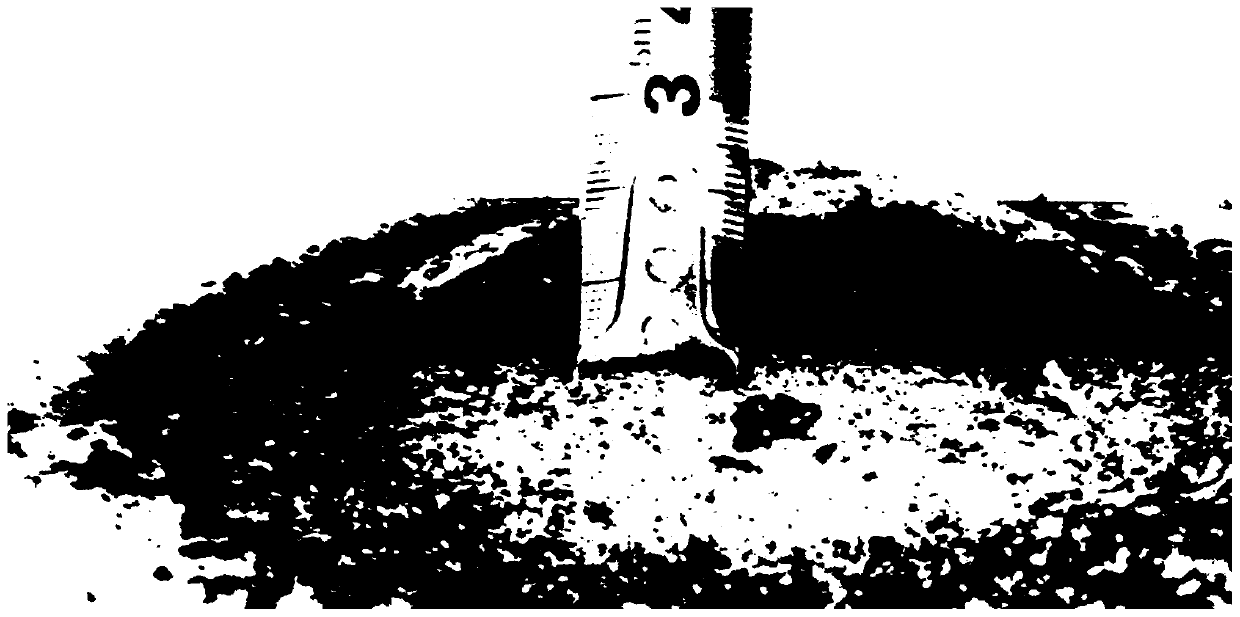

The invention discloses a fireproof and anti-corrosion bifunctional ultra-thin steel structure coating and a preparation method thereof. The fireproof and anti-corrosion bifunctional ultra-thin steel structure coating is prepared from the following raw materials by weight percentage: 1-30% of chloroprene rubber adhesive, 1-30% of melamine, 1-20% of pentaerythritol, 1-30% of pigment and filler, 1-50% of 1000# solvent gasoline,1-20% of ammonium polyphosphate, 1-15% of chlorinated paraffin solution with a chlorine content of 70%, 1-10 % of acrylic resin, 0.1-5% of amino resin, 1-10% of raw vermiculite, 1-10% of charring aid, 0.1-5% zinc borate and 0.1-10% of auxiliary agent. The fireproof and anti-corrosion bifunctional ultra-thin steel structure coating has the advantages of greatly improved maximum flexibility, fire resistance limit, binding strength and fire resistance time, good flame retardance, corrosion resistance, water resistance and weather resistance and low cost; and more importantly, the coating is safe and environmentally-friendly, and the coating layer formed by the coating is light and thin, thus truly embodying the fireproof and anti-corrosion dual functions and ultrathin characteristic.

Owner:浙江川科防保材料发展有限公司

Gypsum-based pre-mixed mortar and preparation method thereof

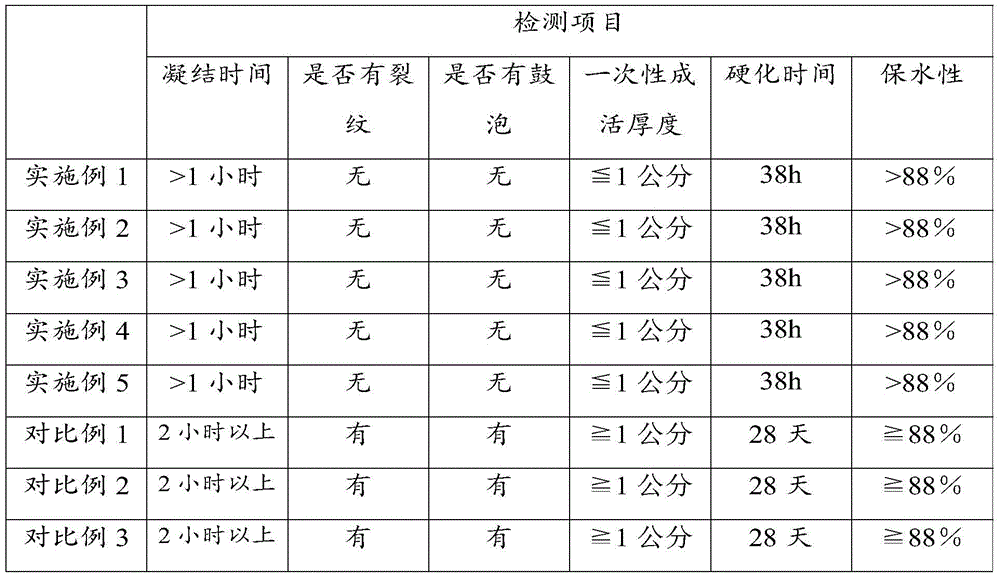

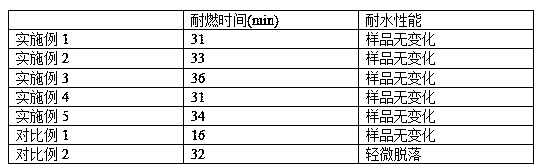

The invention provides a gypsum-based ready-mixed mortar and a preparation method thereof. The ready-mixed mortar comprises 450-500 parts of hemihydrate gypsum, 550-600 parts of aggregate, 0.7-1.5 parts of compound modification additive, 0.2-1.0 part of foaming agent and 1-10 parts of setting retarder. The preparation method includes the following steps: mixing hemihydrate gypsum, aggregate, compound modification additive, foaming agent and retarder to obtain ready-mixed mortar. The gypsum-based ready-mixed mortar has strong adhesion to the substrate, which overcomes the shortcomings of easy cracking and hollowing in the use of traditional cement-based ready-mixed mortar; the one-time survival thickness is 4mm-2cm, which is smooth to the wall surface The requirements for the degree of strength are not high, and the construction requirements are greatly reduced; the hardening is fast, which can speed up the construction progress; the cost is low, and at the same time, it also has the advantages of good fire resistance, automatic temperature adjustment function, and light weight.

Owner:GUIZHOU TENGFENG TECH CO LTD

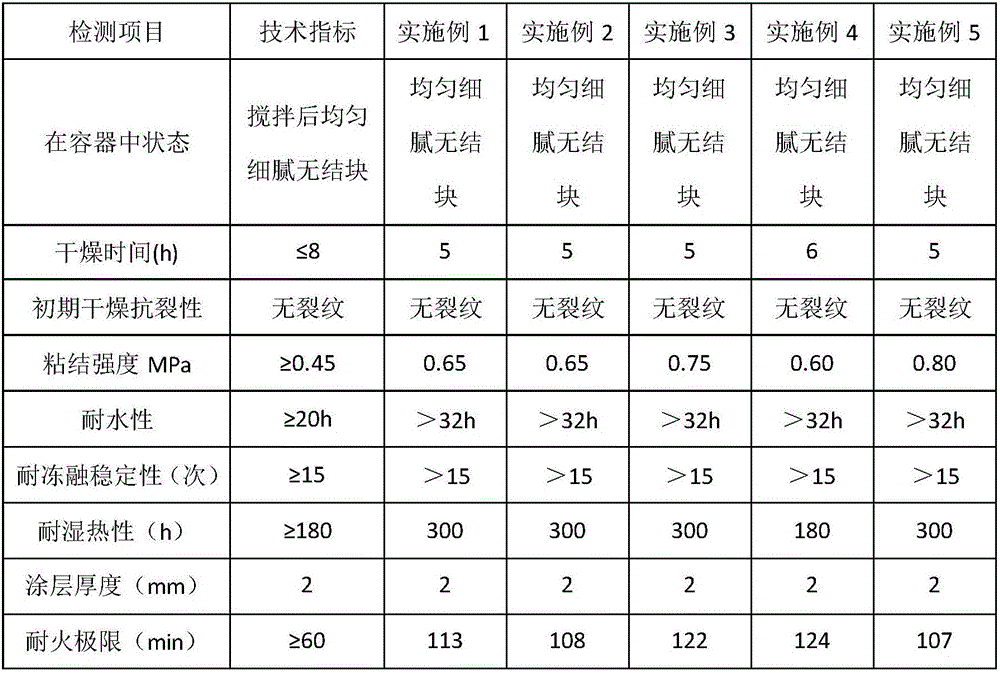

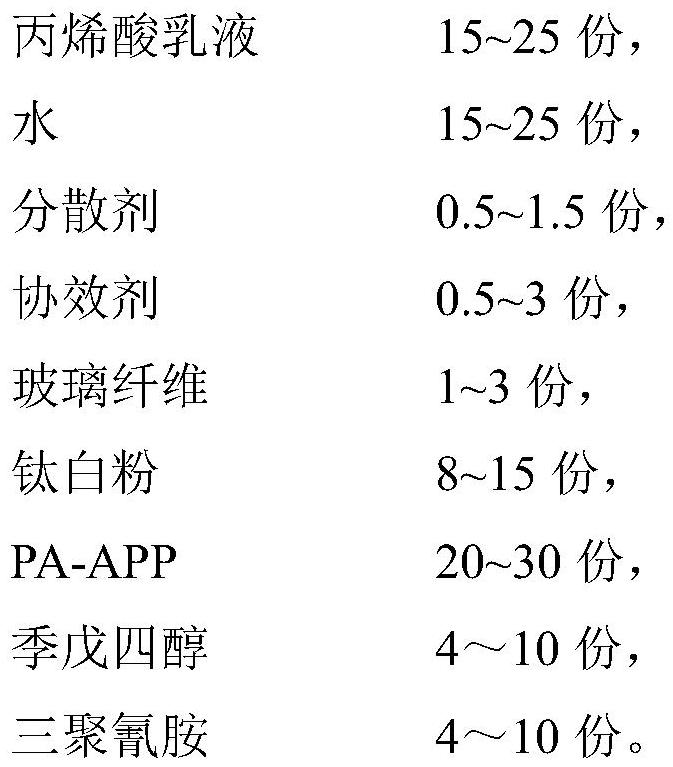

Intumescent fireproof paint and preparation method thereof

InactiveCN109929345AHigh strengthImprove fire performanceFireproof paintsDiphenyl phosphateCarbon layer

The invention provides an intumescent fireproof paint, which at least comprises the following components by weight: 20-50 parts of water, 5-30 parts of an emulsion, 3-20 parts of a pigment, 3-10 partsof isodecyl diphenyl phosphate, 20-60 parts of a composite intumescent flame retardant, 0.1-1 part of a dispersant, 0.1-1 part of a defoamer, 0.1-1 part of a thickener, 0.1-0.4 part of a pH regulator, 0-0.5 part of a bactericide, and 0-2 parts of a film-forming assistant. Through the synergistic effect of all the components, the obtained intumescent fireproof paint has the performance of environmental protection, decorativeness, color adjustability, dense and high density carbon layer, good adhesion and storage stability.

Owner:上海中南建筑材料有限公司

Flame retardant coating for cars and preparation method thereof

InactiveCN104231890AExtend fire resistance timeImprove flame retardant performanceFireproof paintsPolyester coatingsMelamine phosphateAcrylic resin

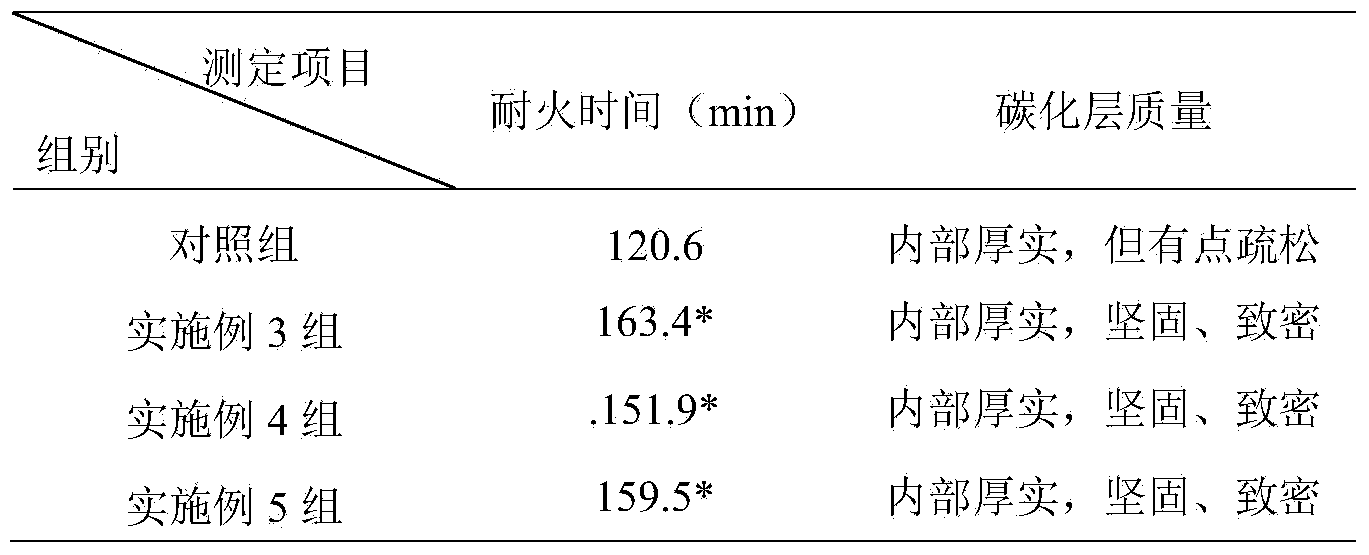

The invention discloses flame retardant coating for cars. The flame retardant coating for cars is prepared from the following raw materials in parts by weight: 20 parts of hydroxy acrylic resin, 10-30 parts of alkyd resin, 10-20 parts of trimethylolpropane triacrylate, 5-15 parts of etherified fluorocarbon resin, 5-20 parts of melamine polyphosphate, 5-15 parts of pentaerythritol, 5-15 parts of a foaming agent, 1-5 parts of pigments and 2-8 parts of pigments. The invention further discloses a preparation method of the flame retardant coating for cars. Compared with the prior art, the flame retardant coating for cars has relatively long fire-resistant time; and the internal structure of a carbide layer formed during combustion is thick, firm and compact, so that the flame retardant effect is obviously improved. And moreover, the discharge of the VOC (volatile organic compounds) is very small, and the environmental pollution is effectively reduced.

Owner:南京市荣达树脂有限公司

Calcium silicate board and preparation method thereof

ActiveCN111470811AImprove temperature resistance and fire resistance timeGood qualityMineralogyCement Material

The invention relates to a calcium silicate board and a preparation method thereof. The calcium silicate board is prepared from the following raw materials: 47-50 parts of quartz sand, 15-18 parts ofcement, 12-16 parts of fly ash, 15-18 parts of ultrafine ceramic fibers and 3-7 parts of paper fibers. According to the calcium silicate board, quartz sand is used as a main raw material; fly ash is taken as an auxiliary material, under the synergistic effect of cement, the superfine ceramic fibers and the paper fibers, the effects of all the raw materials can be fully played, the refractory temperature of the superfine ceramic fibers can be 1300 DEG C or above, and when the superfine ceramic fibers are applied to the calcium silicate board, the temperature resistance and the refractory time of the calcium silicate board are improved through the synergistic effect of all the raw materials; the fly ash and the paper fibers are added, so that the crack rate of the calcium silicate board canbe reduced; the preparation method of the calcium silicate board is simple, easy to operate, low in production cost and easy for industrial production.

Owner:唐山华纤科技有限公司

Smoke suppressant type indoor ultrathin fire-resistant paint for steel structure and preparation process thereof

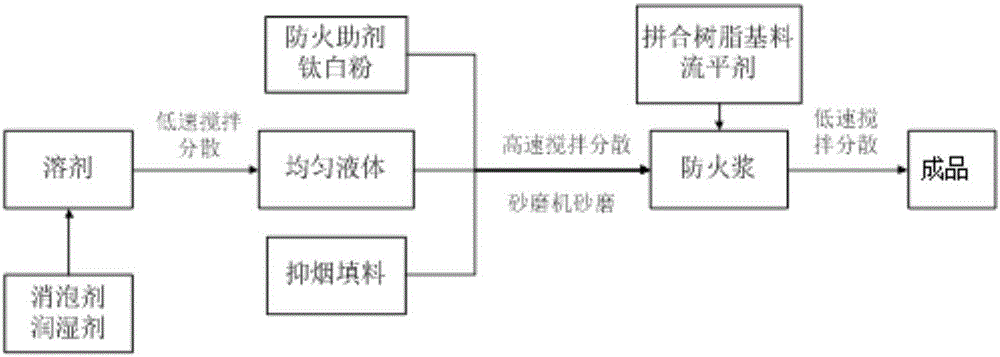

ActiveCN106833208AExtend fire resistance timeImprove fire performanceFireproof paintsPolyester coatingsWeather resistanceArray data structure

The invention discloses a smoke suppressant type indoor ultrathin fire-resistant paint for a steel structure. The fire-resistant paint is composed of the following components in parts by weight: 20-35 parts of synthetic resin base material, 25-45 parts of fire-resistant aid, 3-10 parts of titanium white, 5-15 parts of smoke suppressant filler, 1-3 parts of aid and 16-28 parts of solvent. Meanwhile, the invention also discloses a preparation process of the smoke suppressant type indoor ultrathin fire-resistant paint for a steel structure. According to the invention, the synthetic resin base material and the smoke suppressant filler are used, so that the prepared paint has very good fire resistance and excellent water resistance and weather resistance; and almost no toxic irritative gas is discharged in case of fire-induced expansion.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

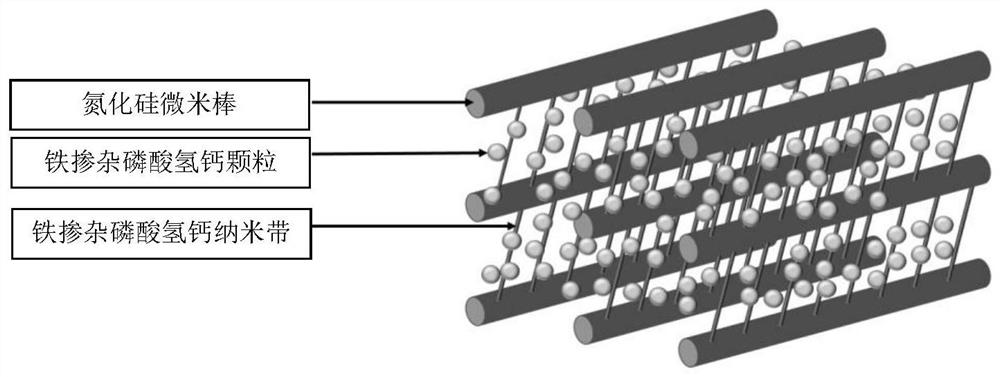

Bio-based fire-resistant paper capable of resisting fire for 1200 seconds and preparation method

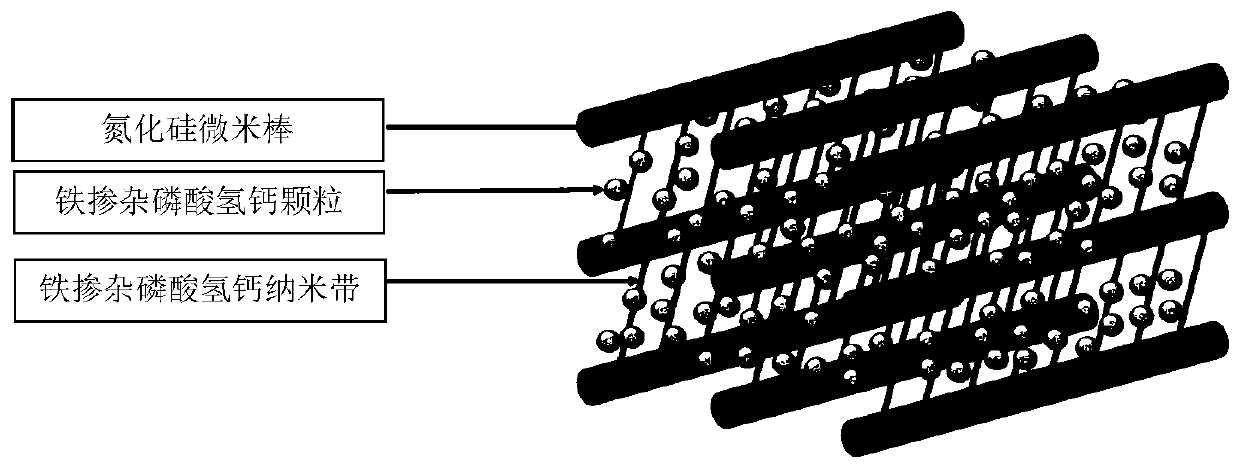

ActiveCN110713381AExtended tolerance timeImprove fire resistanceCalcium biphosphatePhysical chemistry

The invention relates to bio-based fire-resistant paper capable of resisting fire for 1200 seconds. The bio-based fire-resistant paper is characterized by comprising silicon nitride nanorods, iron-doped calcium hydrophosphate nanoribbons and iron-doped calcium hydrophosphate particles, wherein the iron-doped calcium hydrophosphate nanoribbons are designed among silicon nitride nanorods with a directional three-dimensional network structure, iron-doped calcium hydrophosphate particles are distributed on the surfaces of the iron-doped calcium hydrophosphate nanoribbons and the surfaces of the silicon nitride nanorods; in addition, the iron-doped calcium hydrophosphate particles are further distributed among pores of a composite structure. The bio-based fire-resistant paper has the beneficialeffects that by constructing a construction rod-belt-particle multi-scale directional composite structure, the paper is not combusted in 1200 s without damage on shape; the iron-doped calcium hydrophosphate nanoribbons and the iron-doped calcium hydrophosphate particles endow the paper with biological safety and do not cause allergy or induce lesion and other reactions, so that the iron-doped calcium hydrophosphate nanoribbons and the iron-doped calcium hydrophosphate particles can be applied to wallpaper, interior architecture decoration and other application occasions in long-term contact with human bodies.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fireproof material taking gypsum as base material and construction method thereof

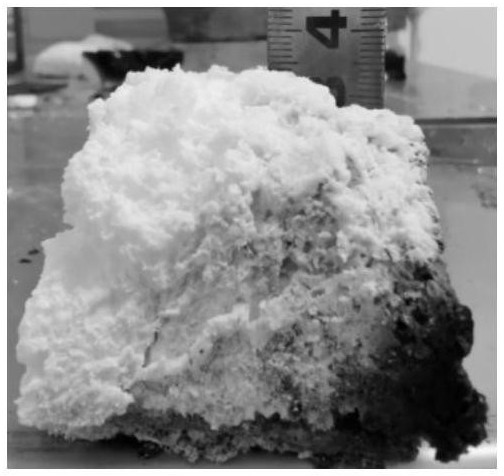

The invention relates to a fireproof material taking gypsum as a base material and a construction method thereof, and belongs to the technical field of building materials. The fireproof material taking gypsum as a base material is a two-component system, wherein the component A is prepared from the following materials in parts by weight: 30-80 parts of gypsum, 0-30 parts of polystyrene particles,0-30 parts of vermiculite, 1-15 parts of fiber, 50-100 parts of sodium carbonate, 1-5 parts of graphite, 1-5 parts of alpha-olefin sodium sulfonate, 1-10 parts of gypsum retarder, 1-3 parts of fillerand 1-3 parts of dicalcium silicate; and the component B is modified aluminum hydroxide and accounts for 5-30% of the weight of the component A. By means of the fireproof material, the one-time spraying thickness of a base material can reach 50 mm, and the problem caused by the fact that the thickness requirement is met only when workers conduct spraying on the base material many times is avoided.

Owner:河南中柏防火涂料科技有限公司

Fire-retardant glue for composite fireproof glass and preparation method of fire-retardant glue

InactiveCN106147666AIncrease the degree of cross-linkingFacilitate cross-linkingNon-macromolecular adhesive additivesAmide/imide polymer adhesivesPotassiumFire retardant

The invention discloses fire-retardant glue for composite fireproof glass. The fire-retardant glue is prepared from raw materials in parts by weight, 53-56 parts of N-hydroxymethyl acrylamide, 43-46 parts of N-(1, 1-dimethyl-3-oxobutyl) acrylic amide, 58-62 parts of potassium alum, 75-78 parts of magnesium chloride, 42-45 parts of potassium chloride, 2-3 parts of aminopropyltriethoxysilane, 4-6 parts of methyl triethoxysilane, 2.5-3.5 parts of phosphoric-oxygenic compound, 4-5 parts of diethylamine, 1.5-2.5 parts of ammonium persulfate, 0.8-1.5 parts of ferrous sulfate, 5-8 parts of absolute ethyl alcohol and 490-500 parts of water. The invention further discloses a preparation method of the fire-retardant glue for the composite fireproof glass. The fire-retardant glue for the composite fireproof glass has excellent fireproof, heat-resistant and heat insulation performances, fire-resistant time is greatly improved, bubbles and impurities in the curing process are avoided, and light transmission is excellent.

Owner:蚌埠市鑫民包装材料有限公司

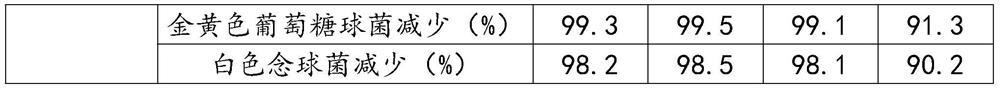

Flame-retardant antibacterial fabric

ActiveCN112160155AImprove the limitations of insolubility in water and difficulty in spinningImprove antibacterial effectFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentCotton fibreAnti bacterial

The invention discloses a flame-retardant antibacterial fabric which comprises the following raw materials including, by weight, 60-70 parts of antibacterial flame-retardant fibers, 30-40 parts of cotton fibers, 50-70 parts of a 10%-12% sodium hydroxide solution, 10-12 parts of fatty alcohol polyoxyethylene ether, 2-4 parts of nano barium oxide, 100-200 parts of treating fluid and 10-20 parts of shaping fluid. By preparing the antibacterial flame-retardant fibers and utilizing physical antibiosis, it can be guaranteed that a textile is antibacterial, the surrounding environment is not affected, viruses cannot reproduce in the textile, and therefore the textile cannot cause self-infection of the human body and cannot become a cross infection medium; and for the antibacterial flame-retardantfibers, compared with a dissolution type antibacterial additive, physical antibiosis is adopted, so that drug resistance of the human body cannot be caused, permeation into the human body like the dissolution type antibacterial additive through the skin is avoided, the immunity of the human body cannot be reduced, and an accumulated toxic reaction cannot be generated.

Owner:杭州远峰纺织原料制造有限公司

Heat insulation type composite fireproof glass and preparation method thereof

InactiveCN107935385AImprove fire performanceExtend fire resistance timeLaminationLamination apparatusLithium oxideAdhesive

The invention discloses heat insulation type composite fireproof glass and a preparation method thereof. The composite fireproof glass is made of two layers of monolithic glass bonded by an adhesive,wherein each of the two layers of monolithic glass comprises the following raw materials in part by weight: 60-90 parts of silicon dioxide, 1-15 parts of aluminum oxide, 1-15 parts of sodium oxide, 1-15 parts of calcium oxide, 0.01-10 parts of germanium dioxide, 0.1-10 parts of potassium oxide, 0.2-10 parts of sodium chloride, 0.1-10 parts of zirconium dioxide, 20-80 parts of magnesium chloride, 5-40 parts of potassium chloride, 0.3-10 parts of an organophosphorus flame retardant, 1-10 parts of ferrous sulfate, 1-25 parts of gadolinium oxide, 1-25 parts of lithium oxide and 1-30 parts of cerium dioxide. The heat insulation type composite fireproof glass and the preparation method thereof, disclosed by the invention, have the beneficial effects that all the raw materials are made into a mixture, and each of the two layers of monolithic glass is made by high temperature forming, annealing, cooling and physical toughening; when the composite fireproof glass formed by the combination of the two layers of monolithic glass prepared by adopting the raw materials and the process through the adhesive is in a high-temperature environment and even a fire, the fireproof performance is excellent, the fire resistance time of the heat insulation type composite fireproof glass is greatly prolonged, and the heat insulation property is excellent.

Owner:滕州市耀海玻雕有限公司

A kind of bio-based fire-resistant paper with fire resistance of 1200 seconds and its preparation method

The invention relates to a bio-based fire-resistant paper with a fire resistance of 1200 seconds, which is characterized in that it includes silicon nitride nanorods, iron-doped calcium hydrogen phosphate nanobelts and iron-doped calcium hydrogen phosphate particles; silicon nitride with an oriented three-dimensional network structure Iron-doped calcium hydrogen phosphate nanobelts are designed between the nanorods, and the iron-doped calcium hydrogen phosphate particles are distributed on the surface of the iron-doped calcium hydrogen phosphate nanobelts and the surface of the silicon nitride nanorods. In addition, the iron-doped calcium hydrogen phosphate The particles are also distributed between the pores of the composite structure. The benefit is that by constructing a rod-ribbon-particle multi-scale directional composite structure, it can withstand 1200 seconds without burning and maintain its shape without damage; iron-doped calcium hydrogen phosphate nanoribbons and iron-doped calcium hydrogen phosphate particles endow paper It has excellent biological safety and will not cause allergies or induce lesions and other reactions, so it can be used for long-term applications such as wallpapers, interior architectural decorations, etc. that are in contact with the human body for a long time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ultra-thin section steel structure weather-resistant fireproof paint, and preparation method thereof

ActiveCN108753020AGood weather resistanceImprove corrosion resistanceFireproof paintsAntifouling/underwater paintsPolyesterMelamine phosphate

The invention relates to an ultra-thin section steel structure weather-resistant fireproof paint, and a preparation method thereof. The ultra-thin section steel structure weather-resistant fireproof paint is composed of, by weight, 20 to 35 parts of modified acrylic resin, 10 to 18 parts of a nonsaturated polyester, 5 to 15 parts of alkyd resin, 10 to 20 parts of melamine phosphate, 4 to 10 partsof hydrated zinc borate, 5 to 10 parts of nanometer calcium carbonate, 3 to 7 parts of vermiculite, 25 to 40 parts of a solvent, 1 to 10 parts of modified barium metaborate, 1.5 to 3.6 parts of bentonite, 1 to 3 parts of a plasticizer, 0.5 to 3 parts of a levelling agent, and 1 to 5 parts of an ultraviolet ray absorber. The preparation process is simple; energy consumption is low; production costis low; the ultra-thin section steel structure weather-resistant fireproof paint possesses excellent flame resistance, weather resistance, bonding performance, sealing performance, is friendly to theenvironment, is wide in application range, and shedding is not easily caused.

Owner:CHANGZHOU UNIV

Water-based heavy anti-corrosion flame-retardant coating material for metal base material, and preparation method thereof

InactiveCN110982373AExtend your lifeNot easy to yellowFireproof paintsAnti-corrosive paintsFirming agentFire resistance

The invention belongs to the field of water-based coating materials, and particularly relates to a water-based heavy anti-corrosion flame-retardant coating material for a metal base material, and a preparation method thereof. The water-based heavy anti-corrosion flame-retardant coating material comprises a component A and a component B according to a weight ratio of 100:(20-30), wherein the component A comprises 50-60 parts of a modified epoxy resin emulsion, 10-15 parts of functionalized modified graphene, 12-18 parts of a filler, 5-10 parts of a cosolvent, 0.5-1 part of an antifoaming agent,0.5-1 part of a leveling agent, 1-2 parts of an anti-settling agent, 0.5-1 part of an anti-freezing agent, 1-1.5 parts of a thickener, 1-2 parts of a wetting agent, 1-2 parts of a dispersant and 35-45 parts of deionized water, and the component B comprises 35 to 50 parts of a curing agent and 20 to 35 parts of a cosolvent. According to the invention, the water-based heavy anti-corrosion flame-retardant coating material has the advantages of good film-forming property, high coating adhesive force, good stability, greatly improved fire resistance limit, greatly improved bonding strength, greatly improved fire resistance time, good flame retardancy, good corrosion resistance, good water resistance, good weather resistance, low cost, safety and environmental protection; and the preparation method disclosed by the invention is simple, easy to operate, high in production efficiency, available in raw materials, low in energy consumption and capable of realizing large-scale production.

Owner:CHANGZHOU UNIV

Building coating and preparation method thereof

The invention discloses a building coating and a preparation method thereof. The building coating comprises the following components in parts by weight: 100 parts of polyvinyl butyral (PVB) resin, 30-50 parts of ammonium polyphosphate, 20-35 parts of titanium dioxide, 15-40 parts of amino resin, 15-30 parts of nano calcium carbonate, 25-40 parts of etherified melamine resin, 6-20 parts of hydroxyethyl cellulose, 15-30 parts of pentaerythritol, 4-20 parts of chlorinated paraffin, 6-20 parts of ethylene glycol monobutyl ether and 5-10 parts of sodium tripolyphosphate; and the building coating further comprises 20-30 parts of a styrene-acrylate copolymer emulsion, 4-10 parts of aluminum silicate fibers and 10-15 parts of a defoaming agent. The coating is applied to wall surfaces of building pipelines. The beneficial effects are as the follows that the PVB resin is adopted in the components, so that compared with an existing coating applied to building pipelines, the coating has improved adhesion capability on a pipeline, and the problem that the coating falls off and is stripped from the pipeline is reduced. The foaming rate of the coating provided by the invention is reduced, and thefire resistance time is prolonged.

Owner:陈泽威

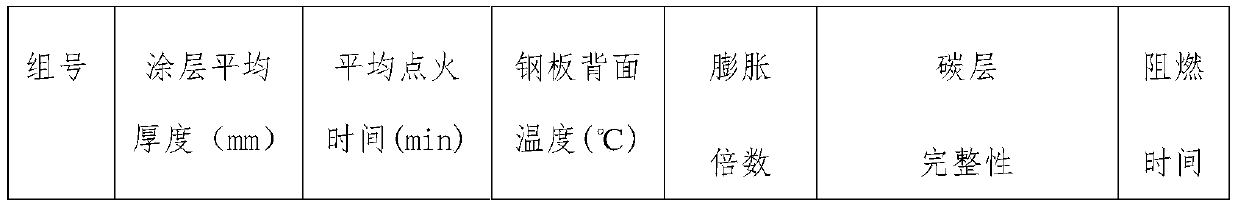

High-hardness heat-resistant intumescent fireproof coating and preparation method thereof

InactiveCN110183890AExtend fire resistance timeReduce viscosityFireproof paintsCarbon layerPolymer science

The invention belongs to the technical field of flame retardants, and provides a high-hardness heat-resistant intumescent fireproof coating and a preparation method thereof. The preparation method comprises the following steps: (1) preparing modified aluminum dihydrogen phosphate: adding a silane coupling agent hydrolyzed by an alcohol into aluminum dihydrogen phosphate; performing heating and stirring for a reaction; adding hydrogen-containing silicone oil dropwise; and performing heating and stirring for a reaction; and 2) preparing the fireproof coating: adding a dispersant, titanium dioxide, a levelling agent and a composite flame retardant into distilled water under stirring, wherein the composite flame retardant comprises a ternary system and modified aluminum dihydrogen phosphate; improving a stirring speed, performing stirring, reducing the stirring speed, adding an acrylic emulsion and an antifoaming agent, and performing stirring. According to the method provided by the invention, the high-hardness heat-resistant intumescent fireproof coating prepared by adopting the method has a larger foaming ratio and a hard foaming layer after being burned, ensures the complete performance of a carbon layer, and improves the fire-resistant time of the coating layer.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

Fire-retardant paint with steel structure

ActiveCN101857756BExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

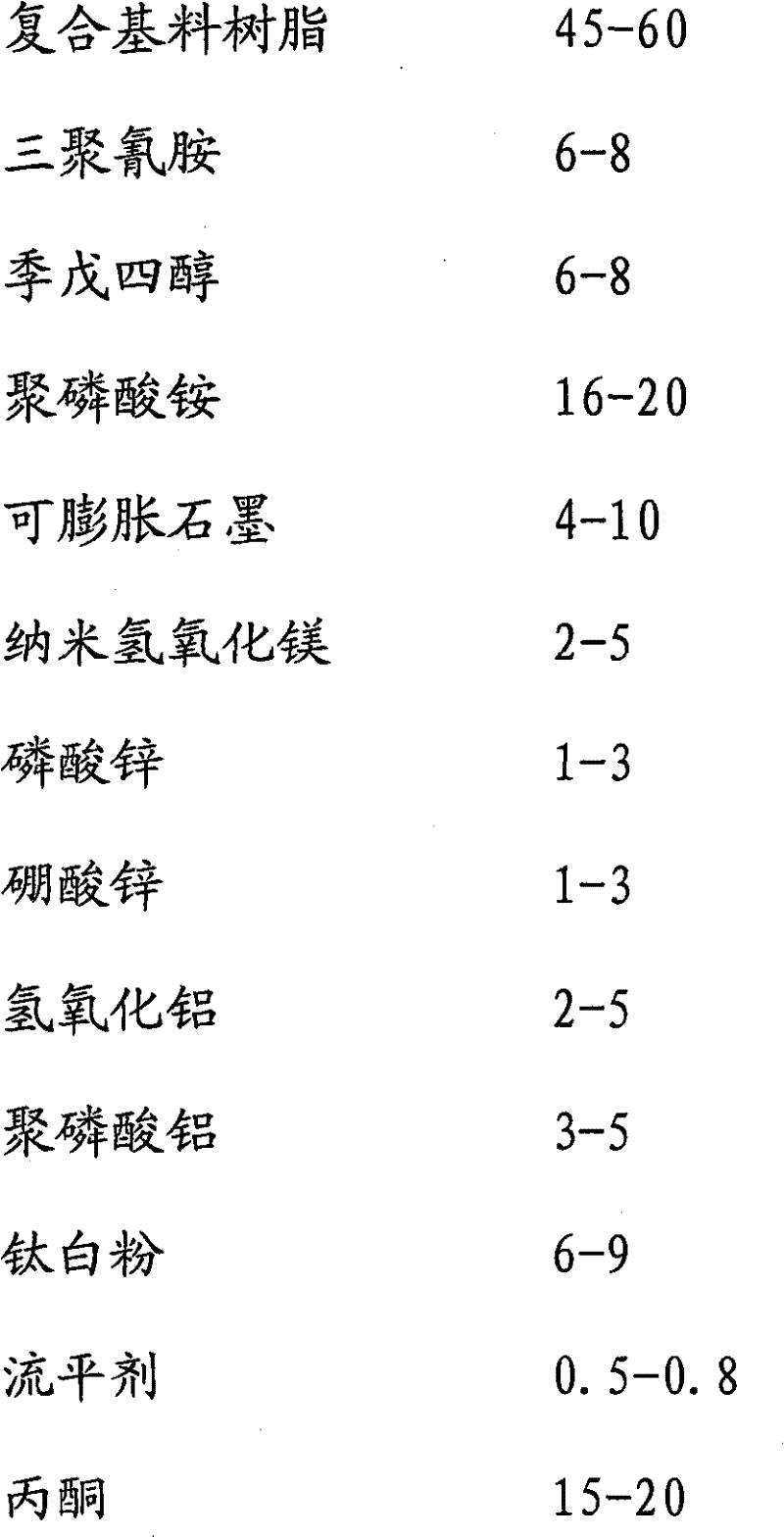

Preparation method of super cementitious cement for 3D printing and super cementitious cement for 3D printing

ActiveCN113149579BImprove plasticityImprove adhesionAdditive manufacturing apparatus3d printAluminate

The invention provides a preparation method of super cementitious cement for 3D printing and super cementitious cement for 3D printing prepared by the method. The preparation method of the super cementitious cement for 3D printing provided by the present invention comprises: step 1: take 100-150 parts by weight of aluminate cement, 400-600 parts by weight of water, and 2-8 parts by weight of grinding aid into a ball mill, Wet milling obtains nano slurry A; Step 2: 380-475 parts by weight of Portland cement clinker, 20-25 parts by weight of gypsum, 120-180 parts by weight of water, 10-30 parts by weight of ultrafine ceramic fibers, 1- 5 parts by weight of water reducer are ground into slurry B by liquid phase grinding; step 3: adding the nano slurry A, 1-10 parts by weight of interface enhancer, and 15-40 parts by weight of basalt fiber to the slurry B, And mix to get super cementitious cement for 3D printing. The super cementitious cement for 3D printing provided by the present invention is easy to mass-produce, has high wet grinding efficiency, and enables 3D printing to have quick setting and easy printing, high compressive strength and excellent post-processing performance.

Owner:HUBEI UNIV OF TECH

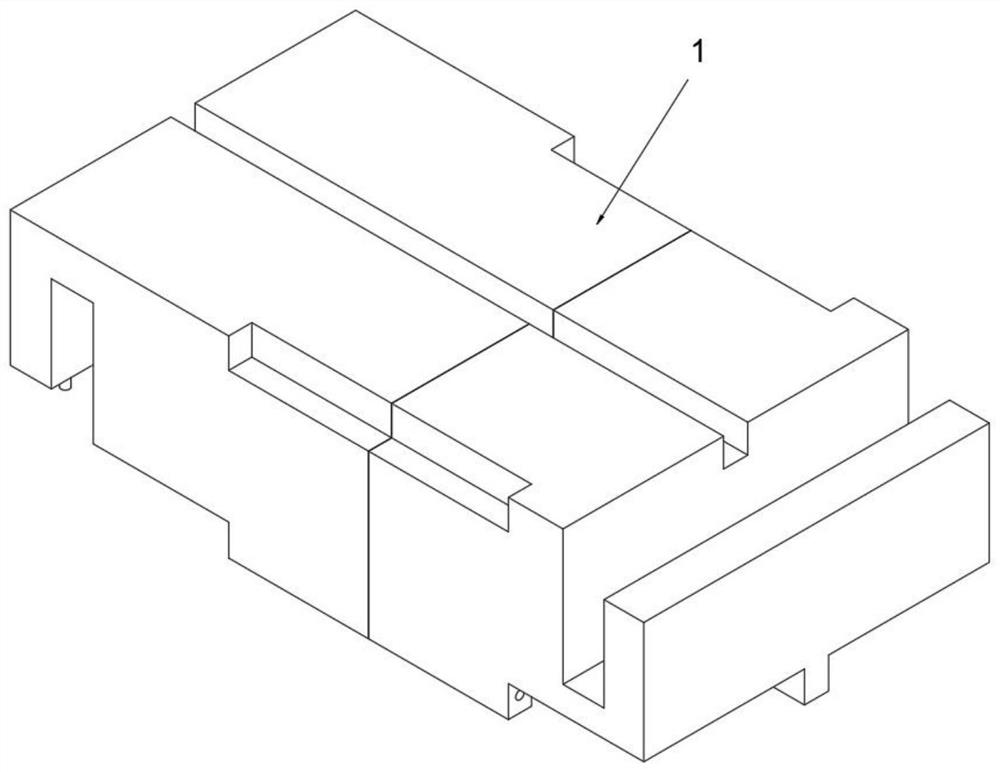

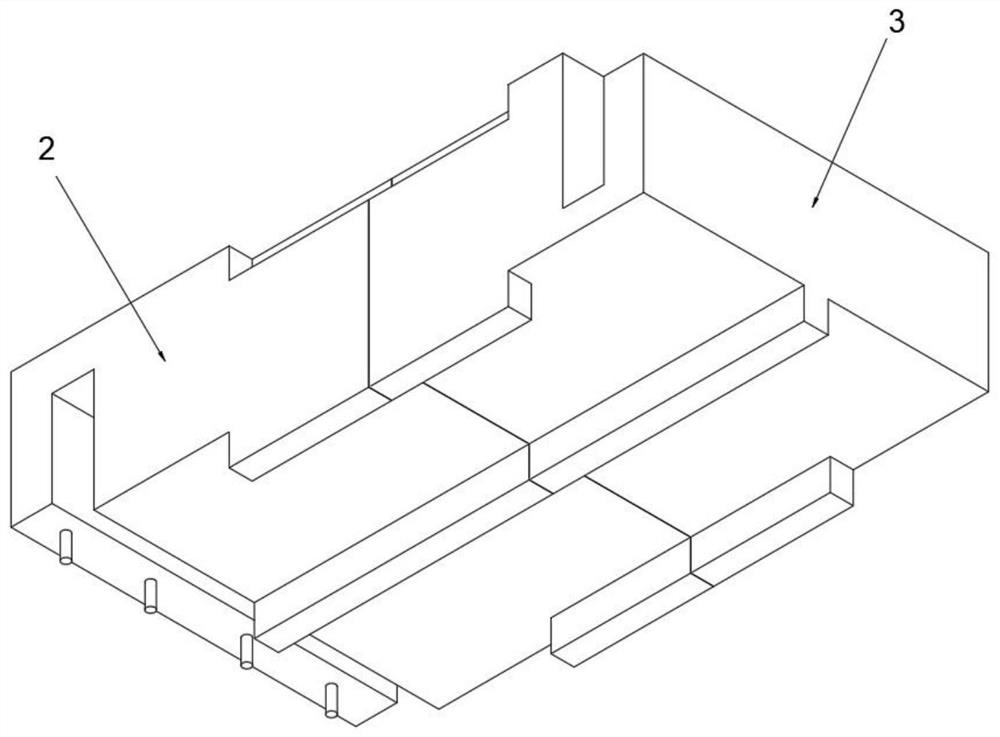

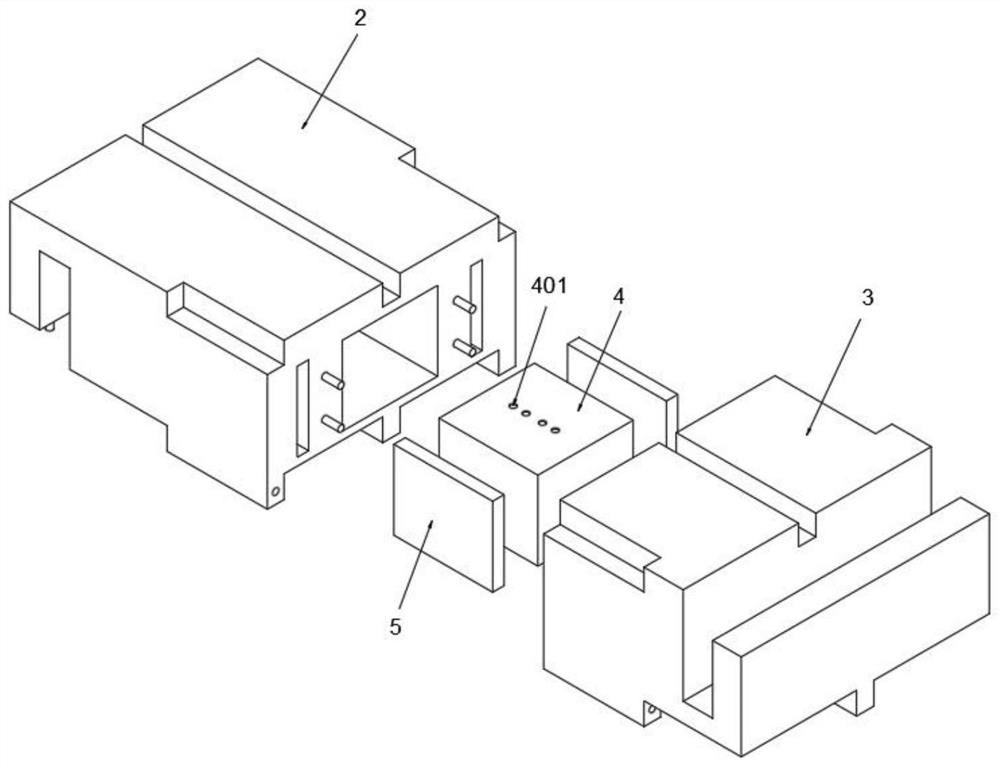

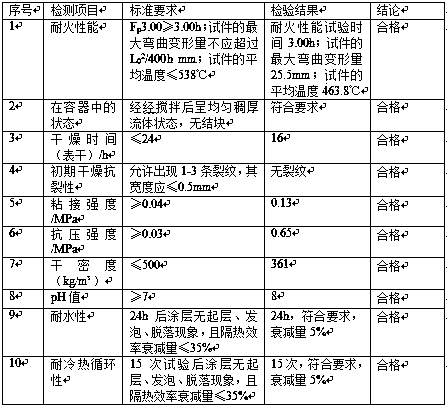

Refractory brick prepared on the basis of refractory material

ActiveCN112833671ARealize personalized stacking and splicingAchieve replacementFurnace componentsFire brickRefractory

The invention relates to the technical field of refractory brick structures, in particular to a refractory brick prepared on the basis of a refractory material. The refractory brick prepared on the basis of the refractory material comprises a main brick which at least comprises a first shell inside; a first limiting groove is formed in the center of the upper surface of the first shell; a groove is formed in the position, close to the right side edge, of the upper surface of the first limiting groove; a first clamping wall is integrally formed in the position, close to the left side edge, of the upper surface of the first shell; a connecting rod is fixedly connected to the lower surface of the first clamping wall; a lower groove is reserved between the first clamping wall and the first shell; a first core groove is formed in the center of the surface of the right side wall of the first shell; and first heat insulation grooves are formed in the front side and the rear side of the first core groove. Through an arranged brick core and an arranged heat insulation plate, the structural stability of the brick body is improved through the brick core; the problem of expansion and cracking of the brick body caused by continuous high temperature of the refractory brick is effectively relieved; through the heat insulation plate, the heat transfer efficiency can be reduced and the refractory effect can be effectively enhanced; and through the brick core and the heat insulation plate, the overall refractory performance of the brick body can be improved.

Owner:辽宁铭轩新材料科技有限公司

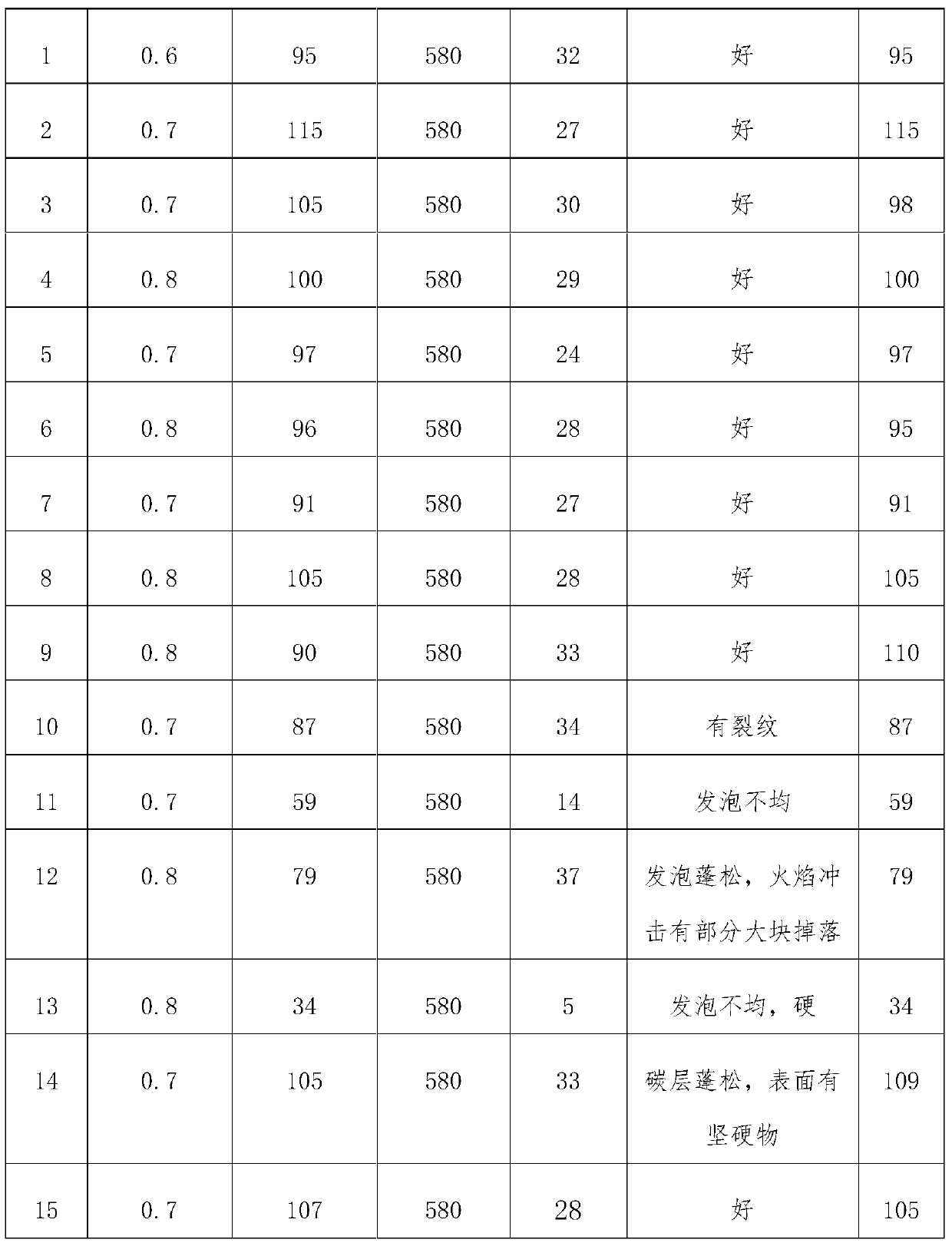

Expansion-type fireproof paint used for lost foam

InactiveCN104690217AImprove fire resistanceExtend fire resistance timeFoundry mouldsFoundry coresPotassiumResin-Based Composite

The invention discloses an expansion-type fireproof paint used for lost foam, which comprises the following components by weight: 35-45 parts of composite resin, 8-12 parts of n-butyl acetate, 6-9 parts of ammonium polyphosphate, 4-6 parts of chlorinated terphenyls, 3-5 parts of glass wool, 0.6-0.8 parts of potassium ammonium polyphosphate, 2-4 parts of nano-sized magnesium hydroxide, 1.2-1.5 parts of charring agent, 3-5 parts of hydroxyethyl cellulose and 0.5-0.7 parts of sodium fluosilicate. The composite resin prepared by the components with specific proportion can effectively increase the fireproof limitation, compared with a single resin, the fireproof time is increased by 6-8 minutes; the prepared paint has excellent stability can be used for coating on the surface of the lost foam, expandable graphite and nano-sized magnesium hydroxide in the components have cooperation flame retardation effect, and can bear the high / low temperature cycle influence.

Owner:QINGDAO DAYUN MACHINERY

Composite material with decorative and flame retardant functions and construction method thereof

InactiveCN111233418ALong fire resistanceGood insulation performanceBuilding constructionsGraphiteCompositermes

The invention relates to a composite material with decorative and flame retardant functions and a construction method thereof, and belongs to the technical field of building materials. The composite material is a two-component system, and is composed of a component A and a component B. The component A is prepared from the following materials in parts by weight: 30 to 100 parts of gypsum, 0 to 30 parts of polystyrene particles, 0 to 30 parts of vermiculite, 1 to 15 parts of fiber, 50 to 100 parts of sodium carbonate, 1 to 5 parts of graphite, 1 to 5 parts of alpha-olefin sodium sulfonate, 1 to10 parts of a gypsum retarder, 1 to 3 parts of a filler, 1 to 3 parts of dicalcium silicate and 1 to 5 parts of pigments. The component B is modified aluminum hydroxide and accounts for 5-30% of the weight of the component A. The composite material has the advantages of long fire-resistant time and good heat insulation performance. The composite material also has a decorative property, and reflective and decorative effects by adding the nano scale pigments, and the added modified pigments are high in saturation degree, strong in tinting strength, good in dispersing property, high in covering power and high in opaqueness.

Owner:河南梵迦德涂料有限公司

Coating technology of fire retardant

ActiveCN106243817AImprove water resistanceExtend fire resistance timeFireproof paintsPigment treatment with macromolecular organic compoundsMaterials preparationWax

The invention relates to the technical field of fire retardant pretreatment, and especially relates to a coating technology of a fire retardant. The technology comprises the steps of material preparation, coating wax preparation, fire retardant coating and post-treatment. The technology has the advantages of simplicity and low cost, and is suitable for coating general powdery or granular fire retardants; and the coated fire retardant obtained through the technology has good waterproof property, and has no dissolving phenomenon in an aqueous fireproof coating system, so the foaming rate of ultrathin aqueous fireproof coatings containing the coated fire retardant can reach 30 times, the fireproof period and the coating layer waterproofing performance of the coatings are effectively improved, and the coatings are suitable for being further promoted and applied.

Owner:JIANGSU ZHAOHUI CHEM

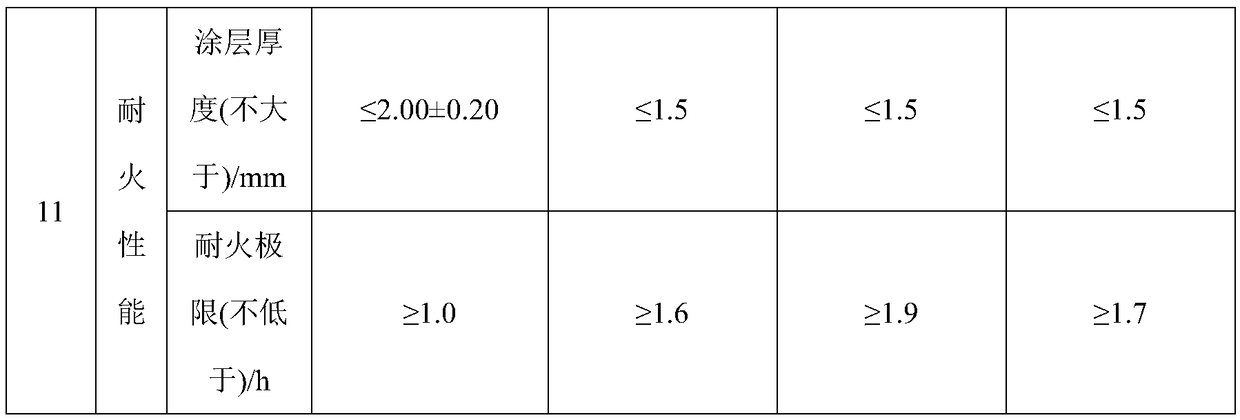

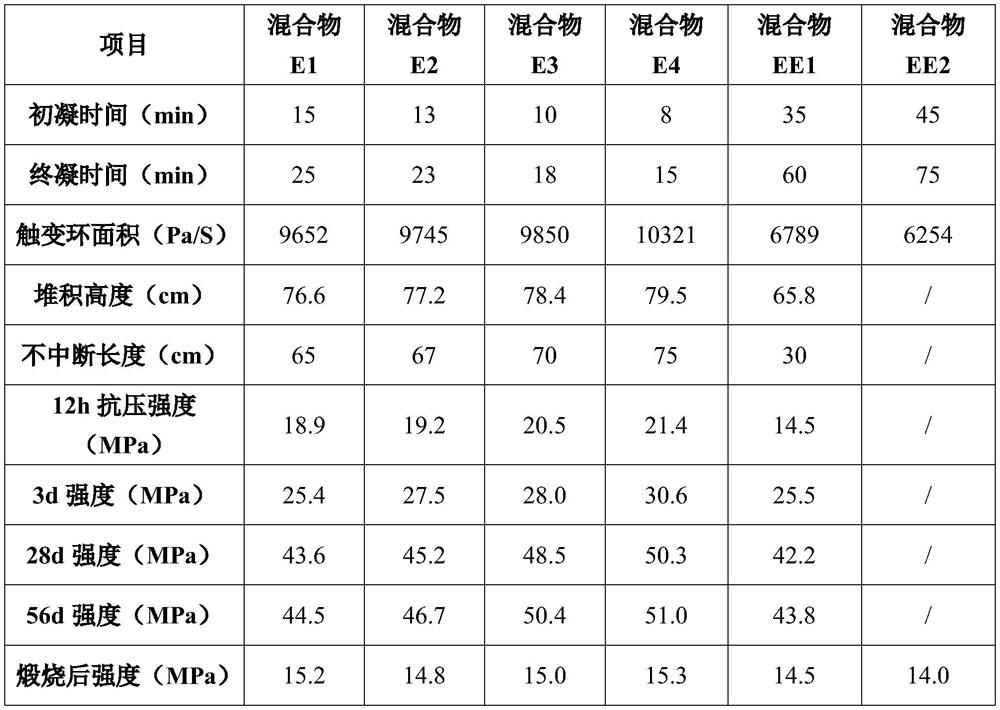

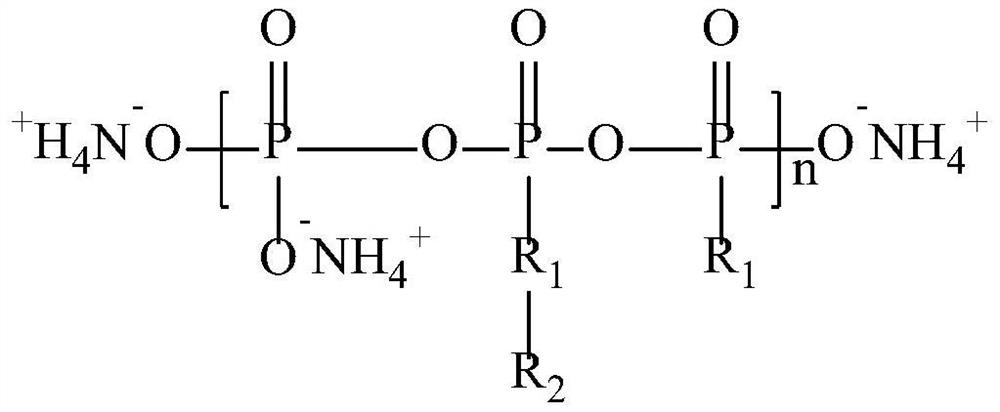

A kind of organosilicon-modified phytate-coupled ammonium polyphosphate and fire-retardant coating prepared therefrom

The invention discloses an organosilicon-modified phytate-coupling ammonium polyphosphate and a fireproof coating prepared therefrom. An epoxy silane coupling agent and a phytic acid metal salt are respectively added to the ammonium polyphosphate in proportion to mix uniformly. , modified reaction at high temperature for a period of time, pulverized to obtain phytate-coupled ammonium polyphosphate with high phosphorus content and good fluidity. Storage time, the fire resistance time measured under the fire resistance limit test can reach up to 120min, the carbon layer after combustion is dense and continuous, the bonding force with the bottom plate is good, and it does not fall off, and its performance is better than that of the existing commercially available APP. coating.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

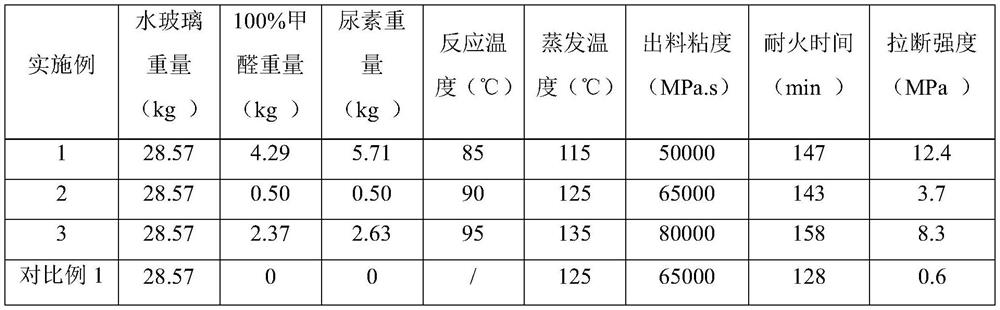

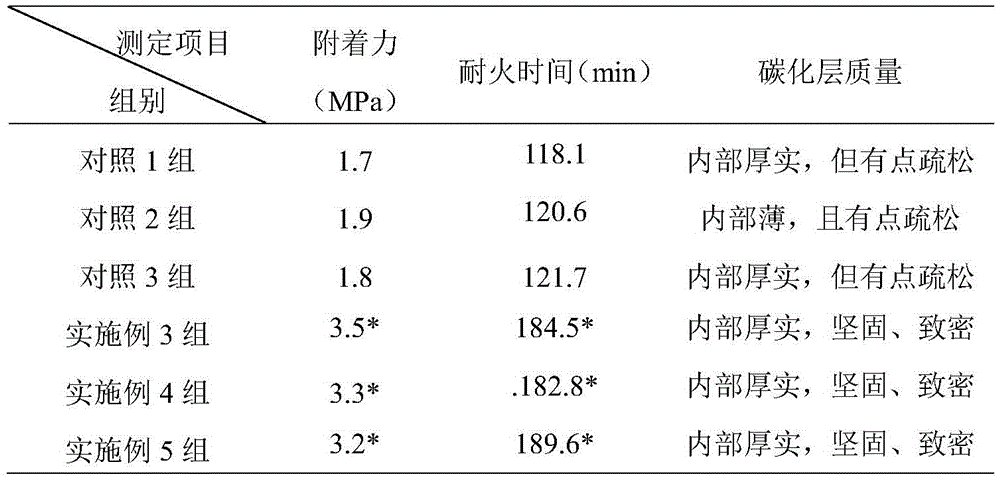

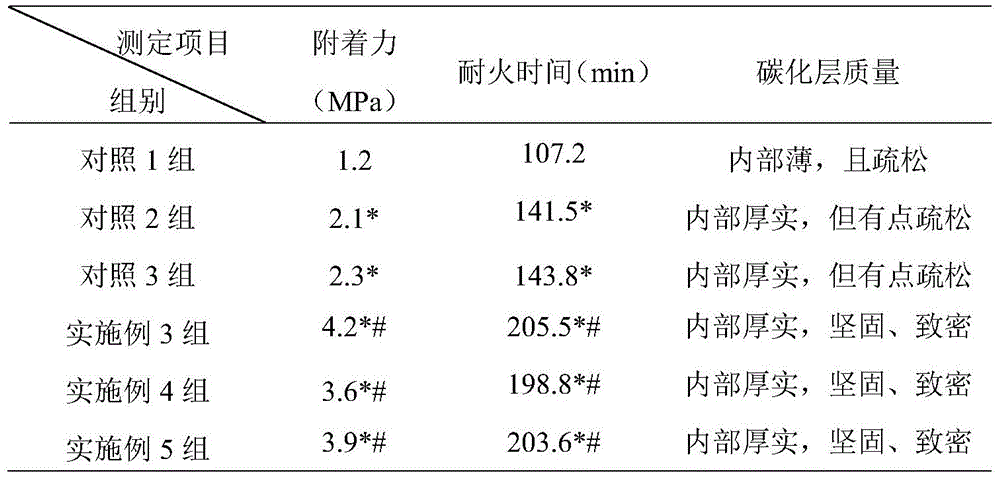

Transparent fireproof rubber plate, laminated fireproof glass and preparation method thereof

The invention provides a transparent fireproof rubber plate which is prepared by the following steps: reacting formaldehyde, urea and water glass at 85-95 DEG C for 1-3 hours, carrying out in-situ polymerization to prepare urea resin, then raising the temperature, evaporating and dehydrating, stopping heating after the viscosity of the prepared composite solid solution reaches 50000-80000 MPa.s, discharging, and extruding the composite solid solution into a plate while the composite solid solution is hot, thereby obtaining the transparent fireproof rubber plate. The transparent fireproof rubber plate provided by the invention can be used for preparing laminated fireproof glass, the prepared fireproof glass is light in weight and large in area, the fireproof rubber plate can keep good adhesiveness and mechanical strength at high temperature, and the fireproof time of the fireproof glass is greatly prolonged.

Owner:嘉兴柯程科技有限责任公司

A kind of flame-retardant plastic coating and preparation method thereof

InactiveCN104263144BLow costSimple processFireproof paintsPolyester coatingsWater basedAcrylic resin

The invention discloses a flame-retardant plastic paint which mainly is prepared from the following raw materials in parts by weight: 20 parts of water-based acrylic resin, 10-20 parts of polystyrene, 2-12 parts of polylactate, 4-10 parts of zinc stearate, 1-5 parts of sodium dodecylsulfate, 2-8 parts of dibutyl phthalate, 6-12 parts of pentaerythritol, 0.5-0.9 part of pigment and 1-7 parts of inorganic filler. The invention also discloses a preparation method of the flame-retardant plastic paint. Compared with the prior art, the flame-retardant plastic paint has the advantages of low cost, simple technique, high adhesive force, excellent adhesiveness and longer fire resistance time; and the carbonization layer formed during combustion has thick inside, is firm and compact, and has obviously higher flame-retardant effect.

Owner:南京市荣达树脂有限公司

A kind of plastic nano coating and preparation method thereof

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Fireproof and anti-corrosion bifunctional ultra-thin steel structure coating and preparation method thereof

InactiveCN102241925BHigh foaming rateImprove fire resistanceFireproof paintsChloropene polymer coatingsAcrylic resinAdhesive

The invention discloses a fireproof and anti-corrosion bifunctional ultra-thin steel structure coating and a preparation method thereof. The fireproof and anti-corrosion bifunctional ultra-thin steel structure coating is prepared from the following raw materials by weight percentage: 1-30% of chloroprene rubber adhesive, 1-30% of melamine, 1-20% of pentaerythritol, 1-30% of pigment and filler, 1-50% of 1000# solvent gasoline,1-20% of ammonium polyphosphate, 1-15% of chlorinated paraffin solution with a chlorine content of 70%, 1-10 % of acrylic resin, 0.1-5% of amino resin, 1-10% of raw vermiculite, 1-10% of charring aid, 0.1-5% zinc borate and 0.1-10% of auxiliary agent. The fireproof and anti-corrosion bifunctional ultra-thin steel structure coating has the advantages of greatly improved maximum flexibility, fire resistance limit, binding strength and fire resistance time, good flame retardance, corrosion resistance, water resistance and weather resistance and low cost; and more importantly, the coating is safe and environmentally-friendly, and the coating layer formed by the coating is light and thin, thus truly embodying the fireproof and anti-corrosion dual functions and ultrathin characteristic.

Owner:浙江川科防保材料发展有限公司

A coating process of fire retardant

ActiveCN106243817BImprove water resistanceExtend fire resistance timeFireproof paintsPigment treatment with macromolecular organic compoundsWaxMaterials preparation

Owner:JIANGSU ZHAOHUI CHEM

Fire resistant glazings

ActiveUS9346962B2Improve fire performanceIncrease volumeFireproof paintsSolid waste managementBoron containingGlass-ceramic

An aqueous mixture for the production of fire resistant glazings comprising: at least one alkali metal silicate, at least one glass, glass-ceramic and / or ceramic additive, and water, wherein the at least one glass, glass-ceramic and / or ceramic additive has at least one boron containing moiety directly or indirectly attached to a surface thereof by covalent or ionic bonding.

Owner:PILKINGTON GROUP LTD

A kind of calcium silicate board and preparation method thereof

Owner:唐山华纤科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com