Transparent fireproof rubber plate, laminated fireproof glass and preparation method thereof

A fireproof rubber sheet and transparent technology, which is applied in the field of transparent fireproof rubber sheet, laminated fireproof glass and its preparation, can solve the problems affecting the fireproof performance and loss of fireproof glass, and achieve the advantages of small weight, variable properties and large area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

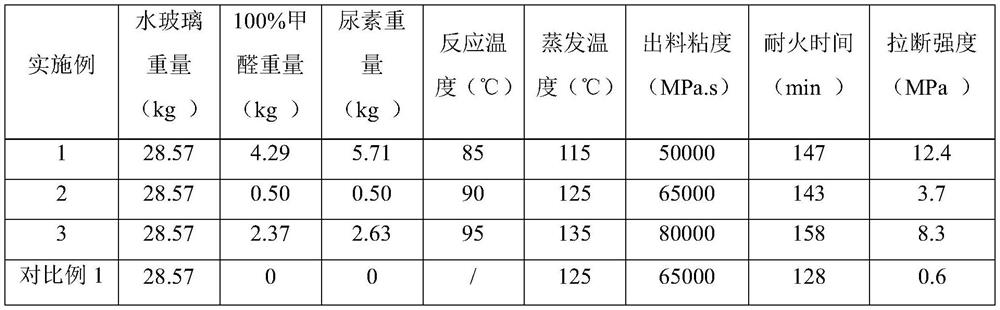

[0029] Embodiment 1, (molar ratio: formaldehyde: urea=1.5: 1; Weight ratio: urea-formaldehyde resin: water glass solid content=1: 1)

[0030]The formaldehyde (formaldehyde of 11.59kg37%) of 4.29kg is dissolved in the water glass (solid content 5kg) of 14.29kg equably under stirring, the urea of 5.71kg is dissolved in the water glass (solid content 5kg) of 14.29kg equably under stirring Content 5kg). Then mix the two parts of water glass solution and stir well. Under stirring, heat to 85°C to react for 1 hour, then heat to 115°C to evaporate water, stop heating when the viscosity of the composite solid solution reaches 50000MPa.s, discharge, and extrude into a 5mm thick plate. After cooling, cut it into a 300mm×300mm rubber sheet, laminate it to two 5mm thick, 300mm×300mm glass plates, and then become the test sample 1 of “laminated fireproof glass” with a size of 300mm×300mm.

Embodiment 2

[0031] Embodiment 2, (molar ratio: formaldehyde: urea=2.0: 1; Weight ratio: urea-formaldehyde resin: water glass solid content=0.1: 1)

[0032] The formaldehyde of 0.5kg (1.35kg37% formaldehyde) is dissolved in the water glass of 14.29kg (solid content 5kg) under stirring uniformly, the urea of 0.5kg is dissolved in 14.29kg (solid content 5kg) of water glass. Then mix the two parts of water glass solution and stir well. Under stirring, heat to 90°C to react for 2 hours, then heat to 125°C to evaporate water, stop heating when the viscosity of the composite solid solution reaches 65000MPa.s, discharge, and extrude into a 5mm thick plate. After cooling, cut it into a 300mm×300mm rubber sheet, laminate it to two 5mm thick, 300mm×300mm glass plates, and then become the test sample 2 of “laminated fireproof glass” with a size of 300mm×300mm.

Embodiment 3

[0033] Embodiment 3, (molar ratio: formaldehyde: urea=1.8: 1; Weight ratio: urea-formaldehyde resin: water glass solid content=0.5: 1)

[0034] The formaldehyde of 2.37kg (6.41kg37% formaldehyde) is dissolved in the water glass of 14.29kg (solid content 5kg) under stirring, the urea of 2.63kg is dissolved in 14.29kg (solid content 5kg) of water glass. Then mix the two parts of water glass solution and stir well. Under stirring, heat to 95°C to react for 3 hours, then heat to 135°C to evaporate water, stop heating when the viscosity of the composite solid solution reaches 80000MPa.s, discharge, and extrude into a 5mm thick plate. After cooling, cut it into a 300mm×300mm rubber sheet, laminate it to two 5mm thick, 300mm×300mm glass plates, and then become a 300mm×300mm “laminated fireproof glass” test sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com