Flexible solid-state battery containing electron conduction interface layer and preparation method thereof

An electronic conduction and solid-state battery technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of slow self-diffusion, poor interface contact between lithium and electrolyte, and reduced cycle life of half-cells and full-cells. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Weigh 0.375g LiFePO respectively 4 , 0.05g super-P, 0.075g PEO-LiTFSI electrolyte, stirred by a slurry machine, mixed evenly, coated on a 4×5cm carbon-coated aluminum foil with a spatula, and dried at 60°C for 24h before use. Then dissolve 0.44g PEO and 0.1435g LiTFSI in 10mL of anhydrous acetonitrile, stir for 24h, apply it on the positive electrode layer with a spatula, place it in a drying room with a dew point of -60°C for 3h at room temperature, and volatilize at 50°C for 12h to remove the solvent , forming a polymer electrolyte layer. Then, in a drying room with a dew point of -60°C, using a magnetron sputtering apparatus, by controlling the sputtering current and sputtering time, a 5nm metal platinum layer was deposited on the polymer layer as an electron-conducting interface layer. On the electron-conducting interface layer, a metal lithium strip is placed, and a pressure of 8 MPa is applied to ensure good contact at the interface (observed by scanning the cros...

Embodiment 2

[0052] The flexible pouch battery was prepared according to the operation of Example 1, except that the thickness of the electron conducting interface layer-metal platinum layer was changed to 2nm, 8nm and 11nm.

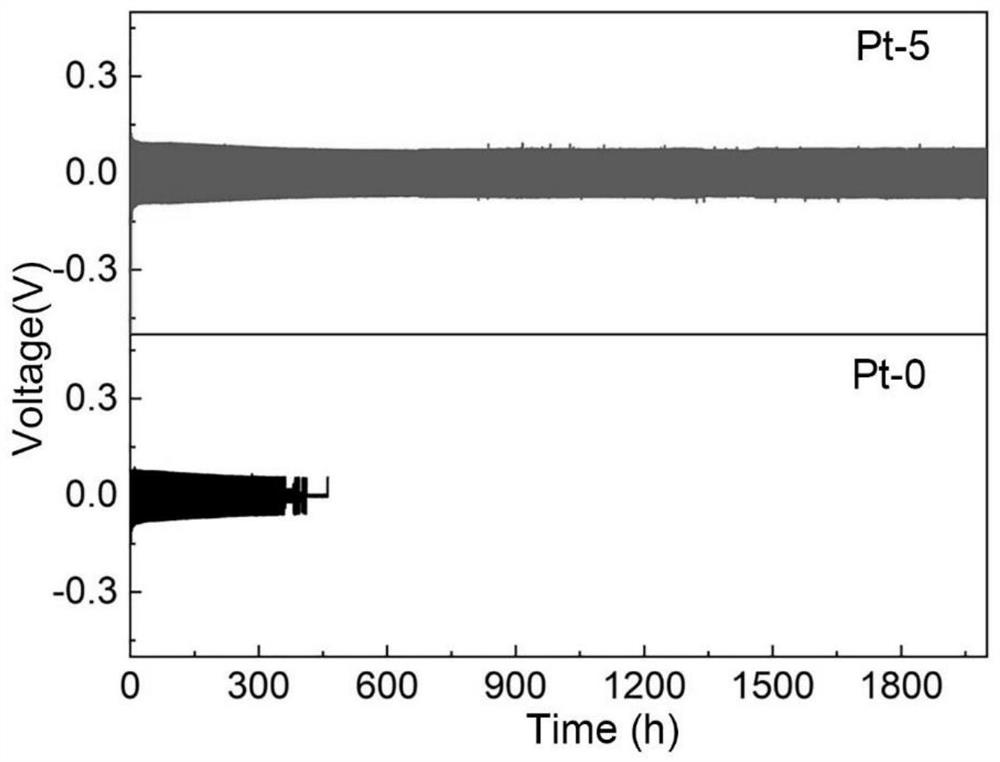

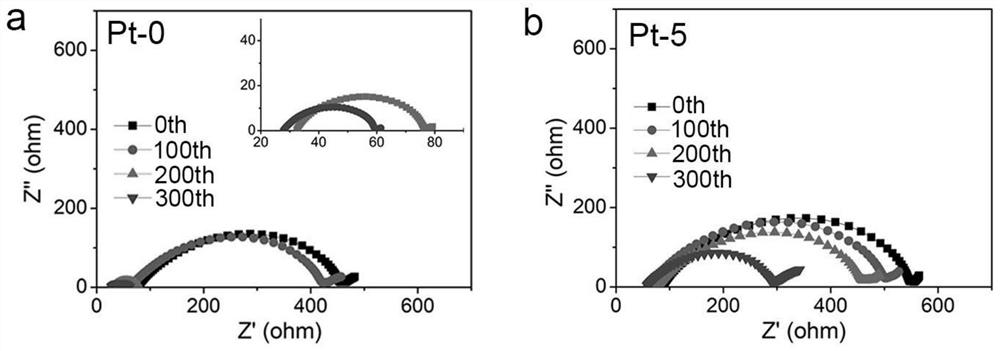

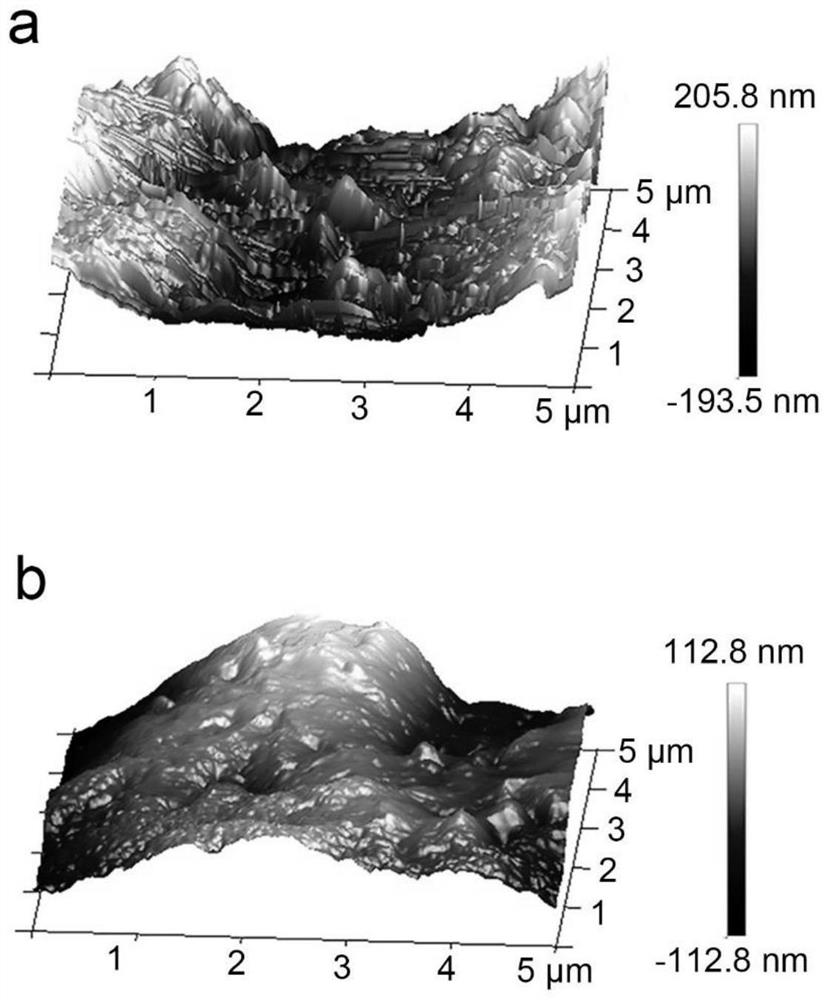

[0053] In order to test the effect of different thicknesses of the electronic conduction interface layer-metal platinum layer on the stable interface, at 50°C, 0.1mAcm -2 At current density, 0.1mAh cm -2 Charge and discharge test under capacity. like Figure 5 As shown, the modification of different platinum layers (Pt-2, Pt-5, Pt-8, Pt-11 electrolyte) makes the cycle life of lithium-lithium half-cells respectively 1200, 2000, 1600, 1300h, and no platinum layer Compared with the modified (Pt-0 electrolyte), there is a significant improvement, showing the role of the platinum layer in stabilizing the interface. Similarly, it shows that the thickness of the electron-conducting interface layer has a great influence on the cycle life. As the thickness increases, the p...

Embodiment 3

[0055] Weigh 0.375g LiCoO 2 , 0.05g Ketjen Black, 0.075g PAN-LiClO 4 The electrolyte was stirred and mixed evenly with a slurry machine, coated on a 4×5cm carbon-coated aluminum foil with a spatula, and dried at 80°C for 24 hours for use. Then 0.44g PAN and 0.08gLiClO 4 Dissolve in 10mL dimethylformamide solution, stir for 24 hours, apply it on the positive electrode layer with a spatula, place it in a drying room with a dew point of -60°C, and volatilize at 80°C for 24 hours to remove the solvent to form a polymer electrolyte layer. Then, in a drying room with a dew point of -60° C., a 5 nm metallic silver layer was deposited on the polymer layer as an electron-conducting interface layer by controlling the time by atomic layer deposition. On the electron-conducting interface layer, a metal lithium strip is placed, and a pressure of 8 MPa is applied to ensure the contact of the interface. Finally, it is sealed with aluminum-plastic film, and the tabs are welded to assemble ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com