Preparation method of super cementitious cement for 3D printing and super cementitious cement for 3D printing

A 3D printing and super-gelling technology, applied in the field of building materials, can solve the problems of low economic benefit, low grinding efficiency, and complex dosage, and achieve the effects of increasing hydration rate, excellent buildability, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

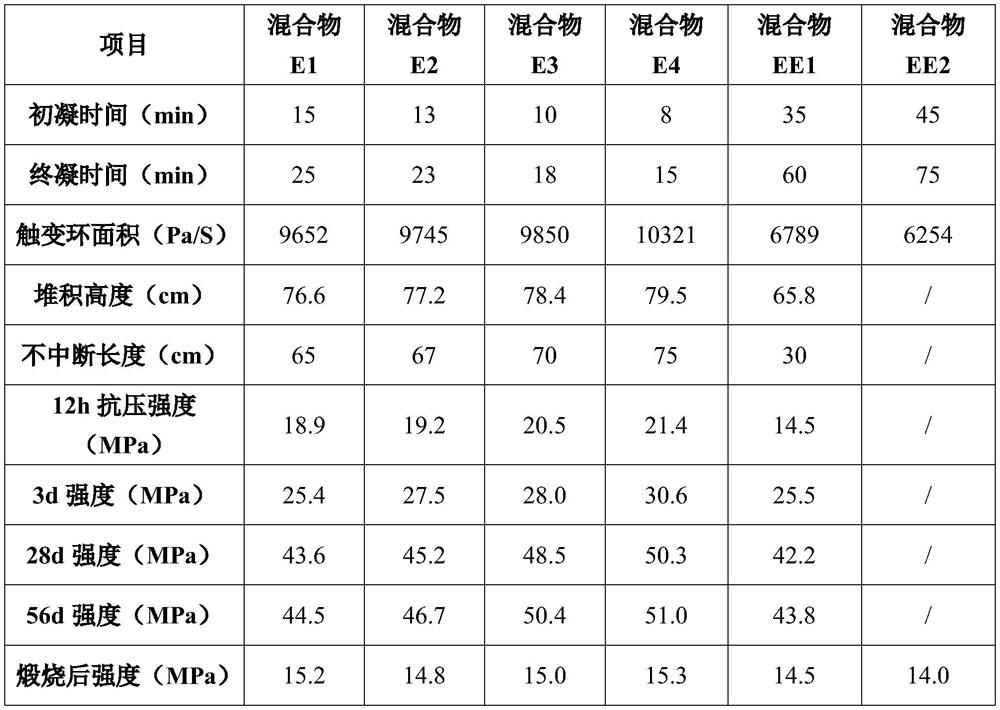

Examples

preparation example Construction

[0019] The invention provides a preparation method of super cementitious cement for 3D printing, the method comprising:

[0020] Step 1: put 100-150 parts by weight of aluminate cement, 400-600 parts by weight of water, and 2-8 parts by weight of grinding aid into a ball mill, and wet-grind to obtain nano-slurry A;

[0021] Step 2: Pass 380-475 parts by weight of Portland cement clinker, 20-25 parts by weight of gypsum, 120-180 parts by weight of water, 10-30 parts by weight of ultrafine ceramic fibers, and 1-5 parts by weight of water reducing agent through the liquid Phase grinding to obtain slurry B;

[0022] Step 3: adding the nano-slurry A, 1-10 parts by weight of interface enhancer, and 15-40 parts by weight of basalt fiber into the slurry B, and mixing to obtain a super cementitious cement for 3D printing.

[0023] Wherein, the aluminate cement used in step 1 can be aluminate cement commonly used in the field. Generally speaking, aluminate cement is prepared by calcini...

Embodiment 1

[0037] Step 1: Take 100 parts of aluminate cement, 400 parts of water, and 2 parts of triethanolamine-based high-efficiency grinding aid, and perform liquid phase grinding at a rotational speed of 400 r / min for 60 minutes to obtain a slurry A with a median particle size of 300 nm;

[0038] Step 2: Put 380 parts of Portland cement clinker, 20 parts of gypsum, 120 parts of water, 10 parts of ultra-fine ceramic fibers, and 1 part of polycarboxylate superplasticizer into a planetary ball mill, at 400 r / min. Slurry B was obtained by wet grinding for 20 minutes under the rotating speed, and the median particle size was 5 μm;

[0039] Step 3: Add slurry A, 2 parts of interface enhancer, and 15 parts of basalt fiber to slurry B, and mix them evenly to obtain the super cementitious cement C1 for 3D printing in Example 1;

[0040] Step 4: Mix the super cementitious cement C1 with 80 parts of water and 750 parts of river sand evenly to obtain a mixture E1 for 3D printing, which is then p...

Embodiment 2

[0042] Step 1: Take 120 parts of aluminate cement, 450 parts of water, and 4 parts of triethanolamine-based high-efficiency grinding aid, and liquid-phase grinding Slurry A with a median particle size of 200 nm for 80 minutes at a rotational speed of 600 r / min;

[0043] Step 2: Put 428 parts of Portland cement clinker, 22 parts of gypsum, 140 parts of water, 15 parts of ultra-fine ceramic fibers, and 2 parts of polycarboxylate superplasticizer into a planetary ball mill, at 500 r / min. Wet-milling for 20 minutes at a rotating speed obtains slurry B with a median particle size of 4 μm;

[0044] Step 3: Add slurry A, 4 parts of interface enhancer, and 25 parts of basalt fiber to slurry B, and mix evenly to obtain super cementitious cement C2 for 3D printing;

[0045] Step 4: Mix the super cementitious cement C2 with 80 parts of water and 750 parts of river sand evenly to obtain the mixture E2 for 3D printing, and then print it with a printer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com