Patents

Literature

105results about How to "Improve setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

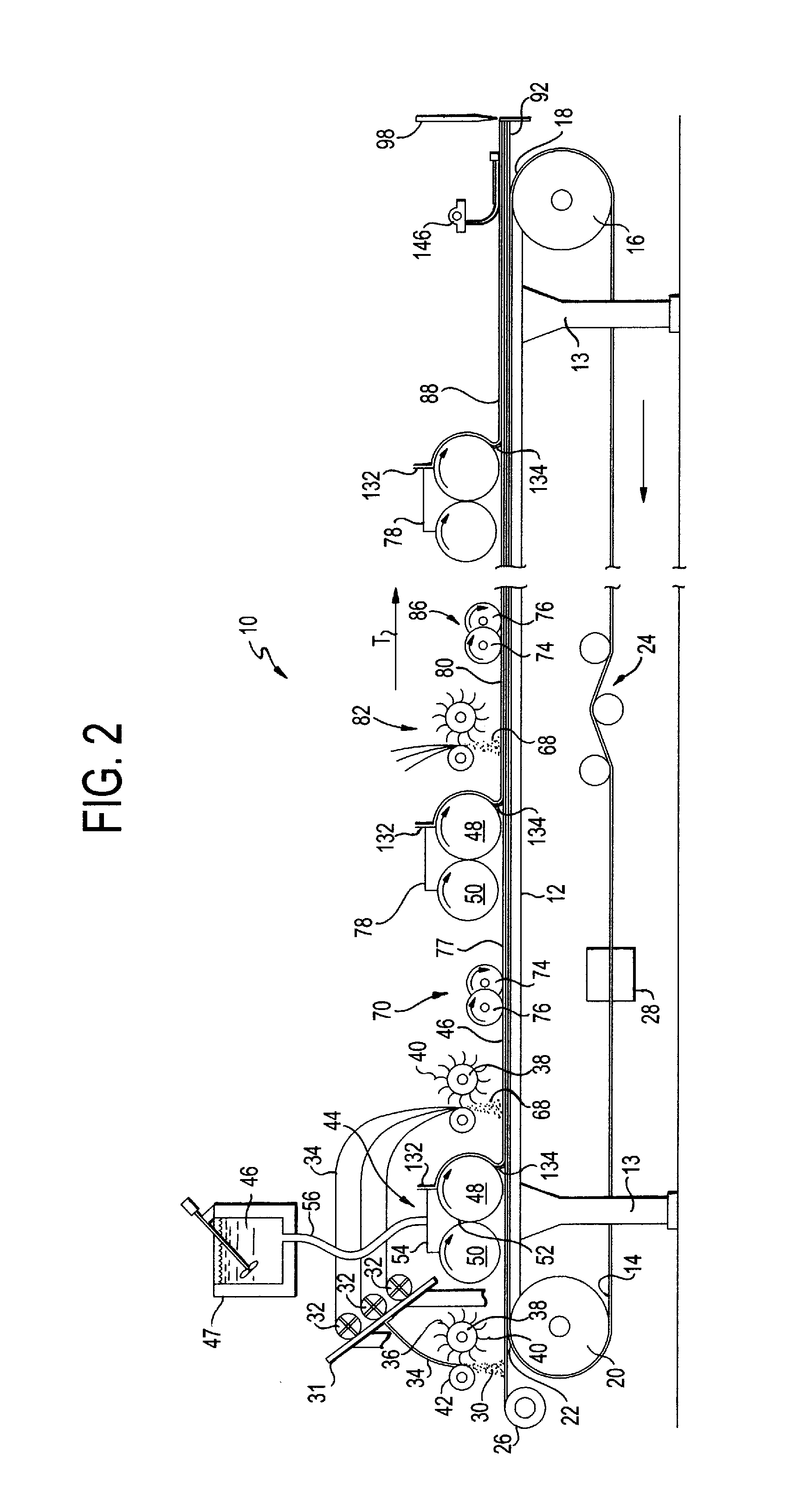

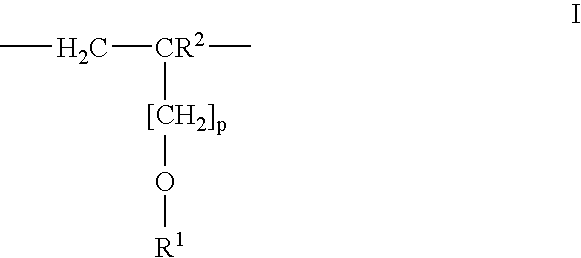

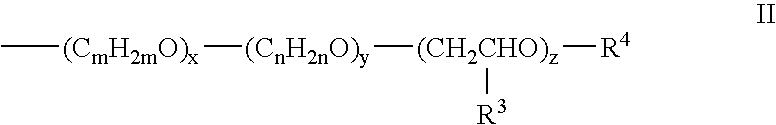

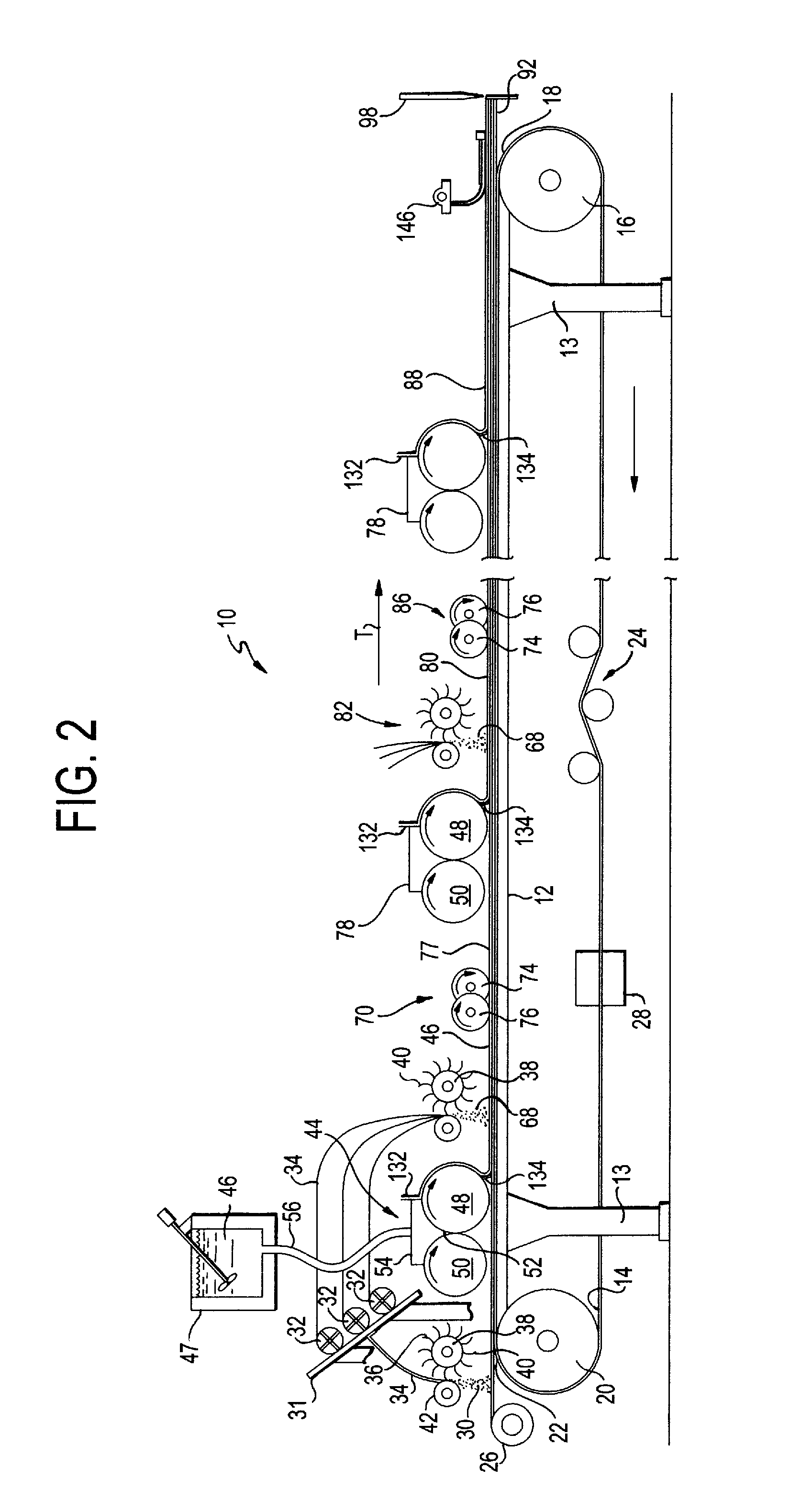

Method of making a gypsum slurry with modifiers and dispersants

InactiveUS20060280899A1Improved product set timeSufficient fluidityLayered productsThin material handlingSlurryGypsum

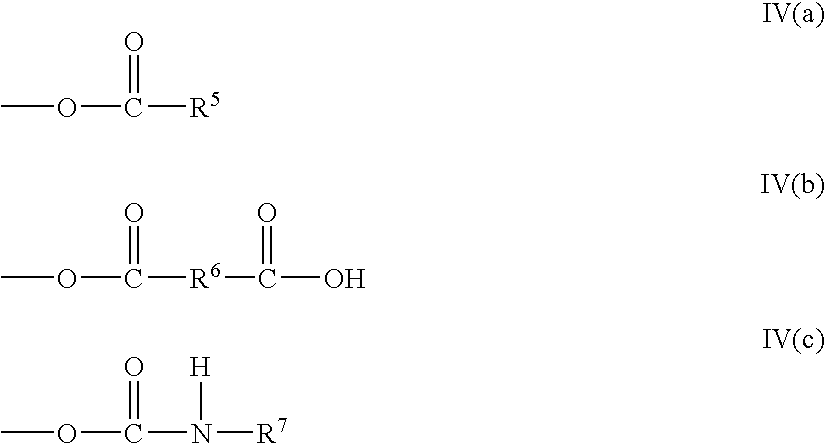

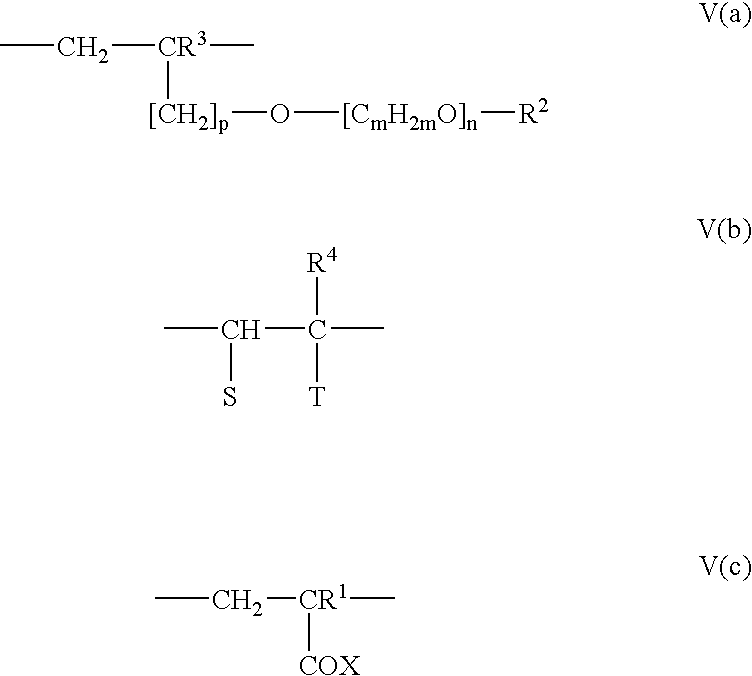

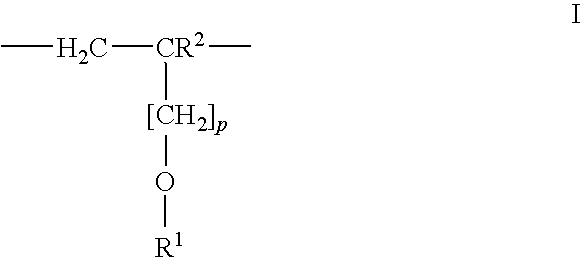

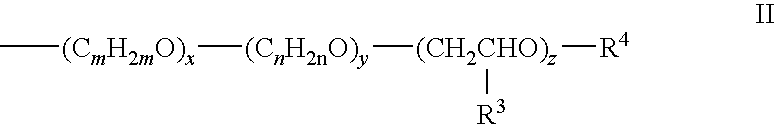

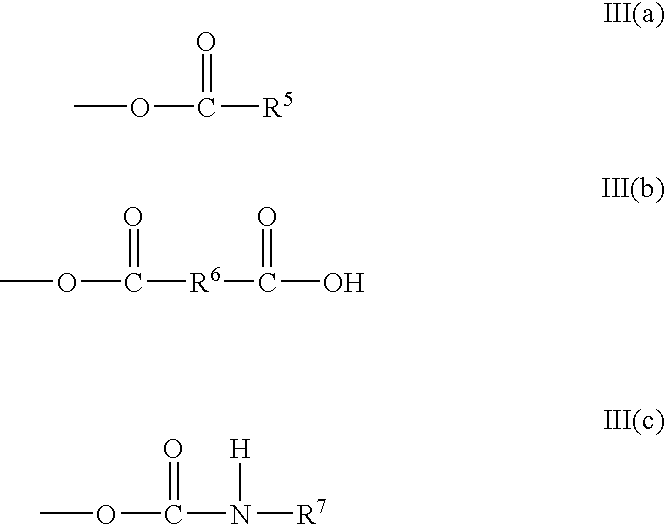

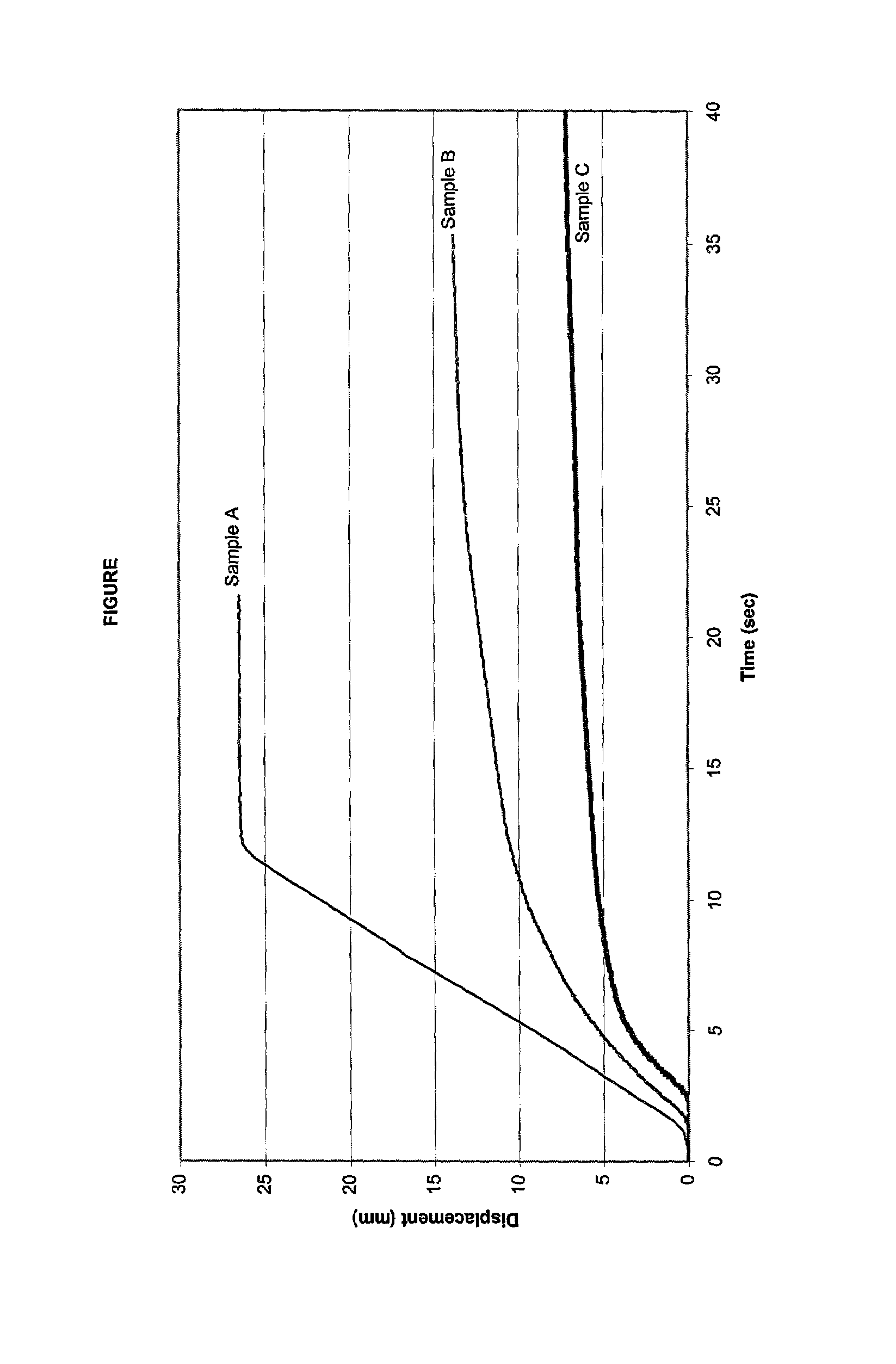

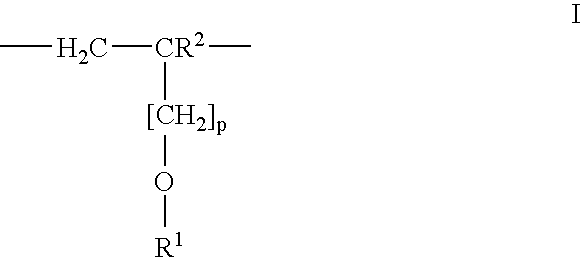

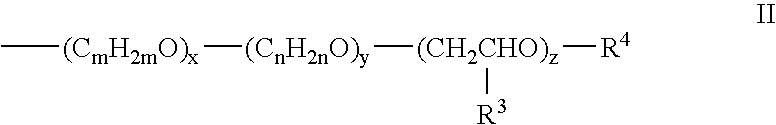

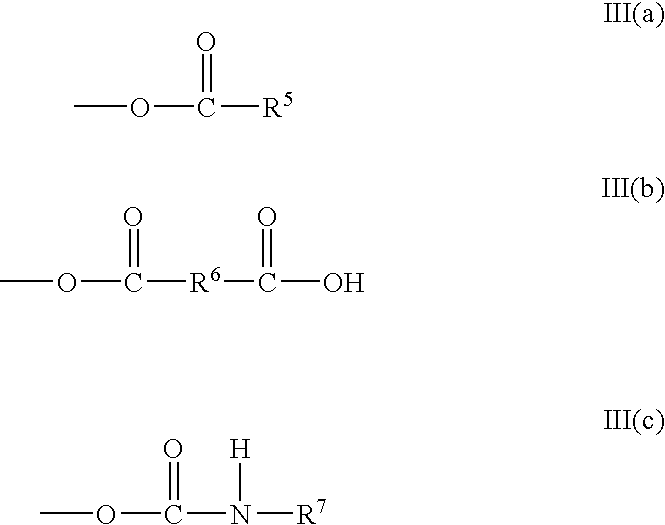

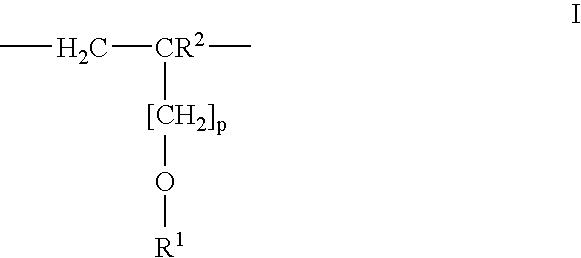

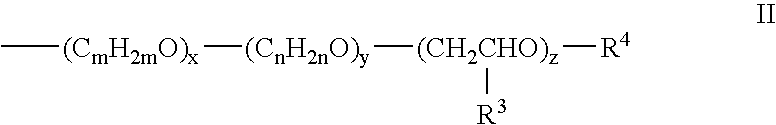

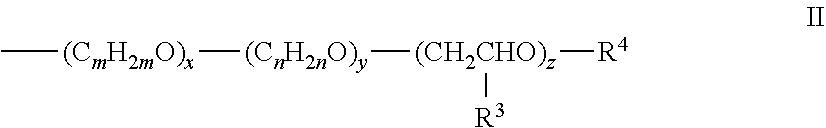

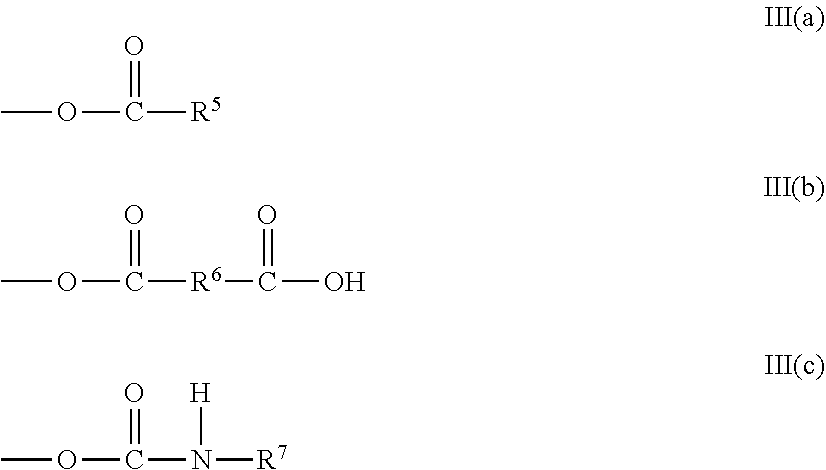

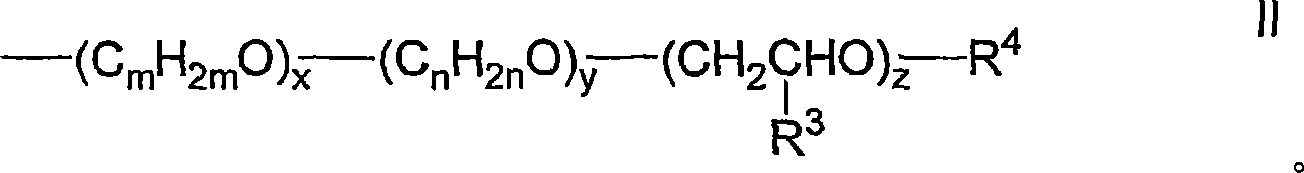

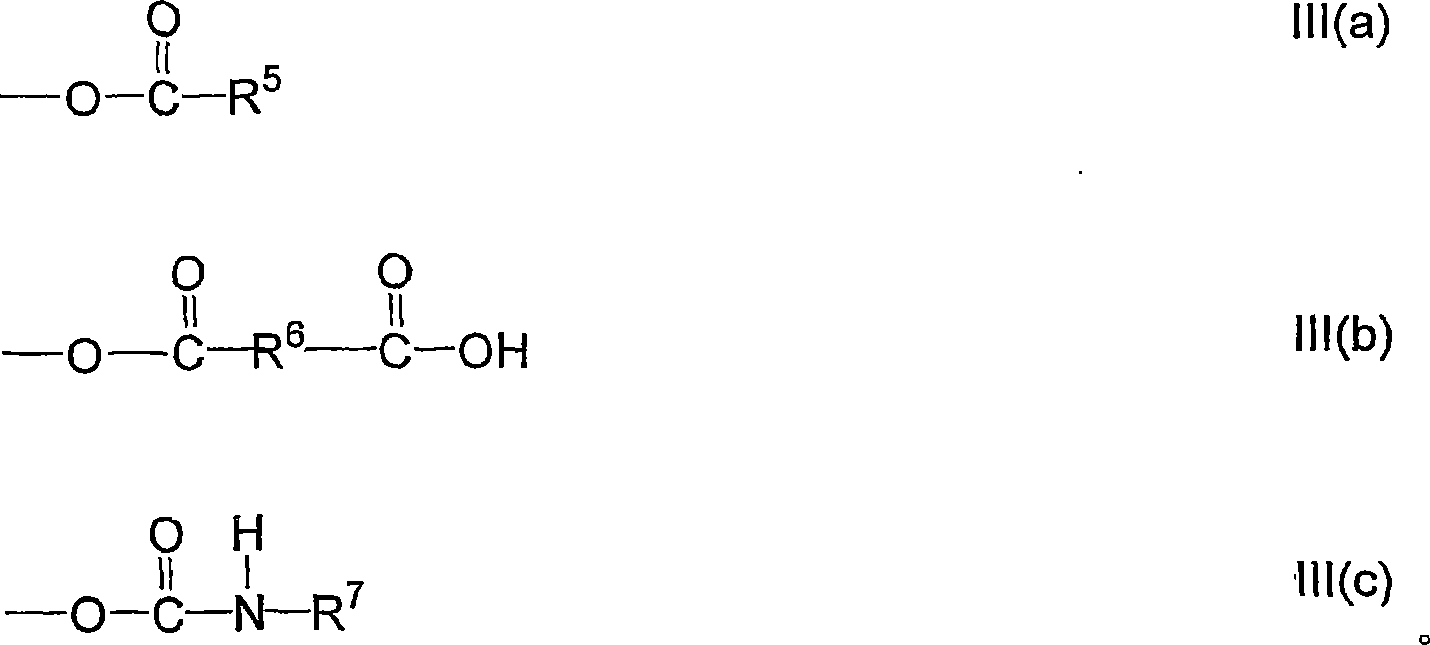

In a method of making a gypsum slurry, a polycarboxylate dispersant, a modifier and a hydraulic material comprising stucco are selected for use in the slurry. These components are then combined with water to form a slurry, where the modifier is added to the slurry prior to formation of a slurry phase by the water, the stucco and the dispersant. The modifier has been shown to be less effective when added after the dispersant and stucco have been contacted in an aqueous slurry. In a preferred embodiment, an amount of stucco is obtained and the modifier and dispersant are selected. A predissolved solution of a dispersant and modifier is prepared in water to form a solution prior to the addition of the stucco. After mixing the solution, the stucco is added to form the slurry. Optionally, the slurry is then shaped into a product and allowed to set.

Owner:UNITED STATES GYPSUM CO

Method of making a gypsum slurry with modifiers and dispersants

ActiveUS7572329B2Sufficient fluidityReduced dispersant dosagesCeramic shaping apparatusThin material handlingSlurryGypsum

In a method of making a gypsum slurry, a polycarboxylate dispersant, a modifier and a hydraulic material comprising stucco are selected for use in the slurry. These components are then combined with water to form a slurry, where the modifier is added to the slurry prior to formation of a slurry phase by the water, the stucco and the dispersant. The modifier has been shown to be less effective when added after the dispersant and stucco have been contacted in an aqueous slurry. In a preferred embodiment, an amount of stucco is obtained and the modifier and dispersant are selected. A predissolved solution of a dispersant and modifier is prepared in water to form a solution prior to the addition of the stucco. After mixing the solution, the stucco is added to form the slurry. Optionally, the slurry is then shaped into a product and allowed to set.

Owner:UNITED STATES GYPSUM CO

Bone graft substitute composition

ActiveUS7371409B2Overcome the lack of robustnessImprove setting timeBiocideBone implantDemineralized bone matrixCancellous bone

A bone graft substitute composition can include essentially of calcium sulfate, a mixing solution, and a plasticizing substance. A bone graft substitute composition can include calcium sulfate, demineralized bone matrix, cancellous bone, a plasticizing substance, and a mixing solution.

Owner:WRIGHT MEDICAL TECH

Metakaolin-based polymer foam concrete and preparation method thereof

The invention relates to metakaolin-based polymer foam concrete and a preparation method thereof. Metakaolin, coal ash and a coagulation accelerating agent are added into a mixing machine in proportion to be mixed to be uniform, an alkali excitant and water are added in proportion, and mixing is carried out to prepare slurry; while the slurry is prepared, a foaming agent is diluted with water in proportion of 1: 15, a high-speed mixing machine or a vacuum foaming machine is adopted for preparing fine and stable foam; and according to density design requirement, the prepared foam is blended into the uniformly mixed slurry in volume ratio to be mixed and foamed, wherein the volume ratio of the foam to the slurry is (1-4):1, and mixing is carried out for 2.5-3min until the foam is uniformly dispersed in the slurry, thus freshly blended metakaolin-based polymer foam concrete is prepared. Compared with the traditional cement-based foam concrete taking silicate cement as a main cementing material, the metakaolin-based polymer foam concrete has the characteristics of environmental friendliness, higher strength, low thermal conductivity, good heat insulating property and the like, and can be used for producing various foam concrete products.

Owner:CHONGQING UNIV

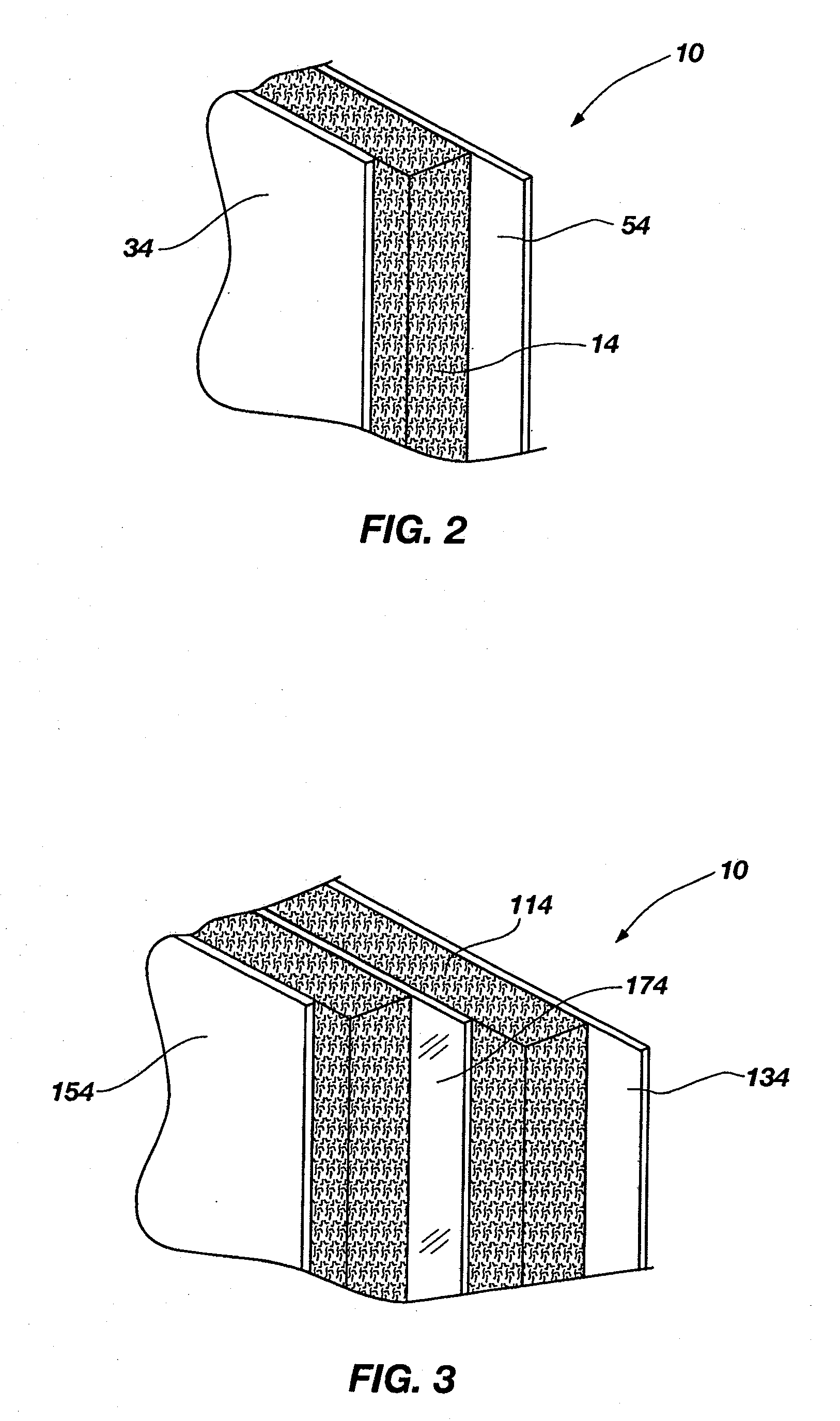

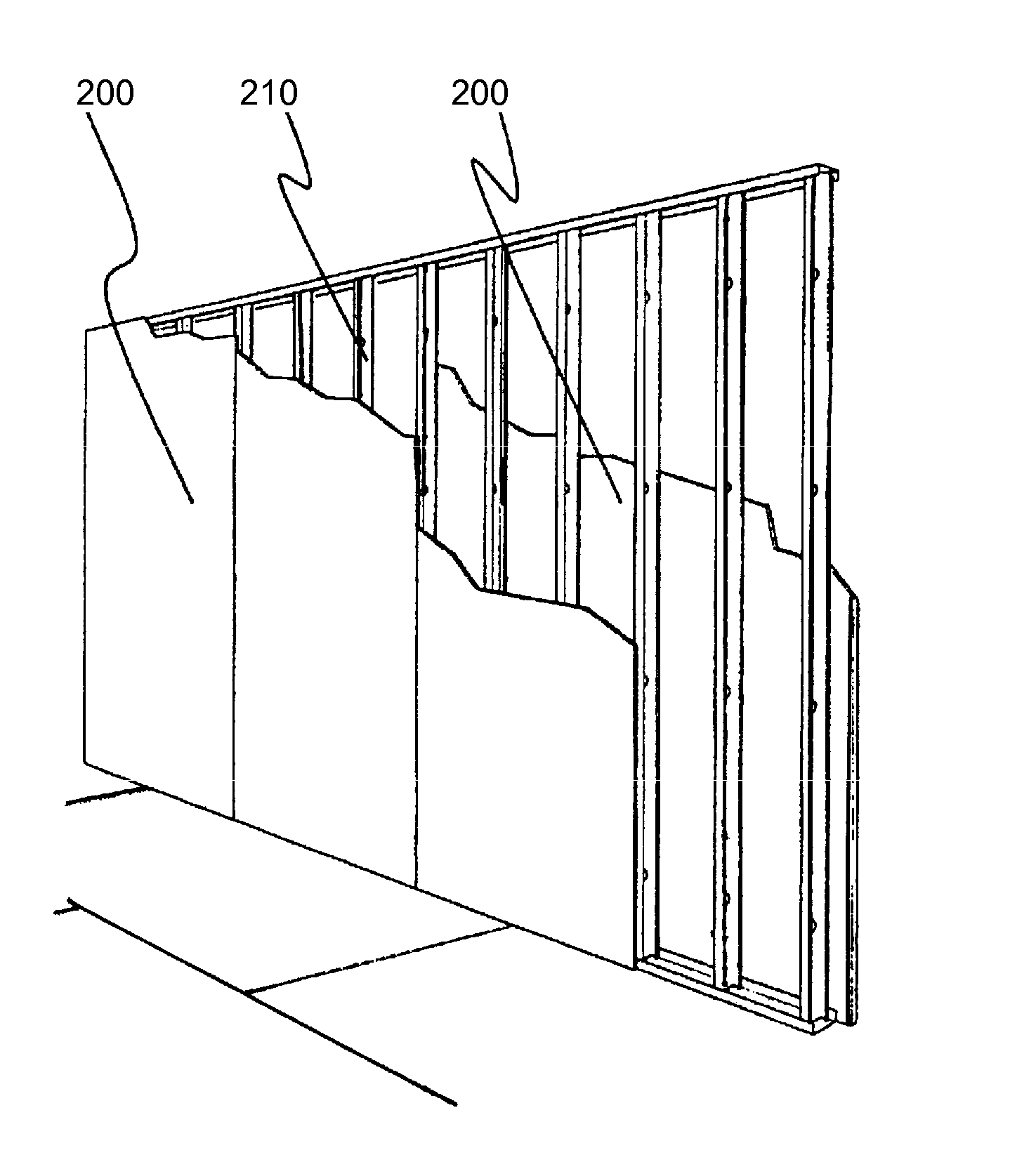

Cement based armor panel system

ActiveUS20100229715A1Improve liquidityUltra-high compressive strengthDoor/window protective devicesSolid waste managementFiberSuperplasticizer

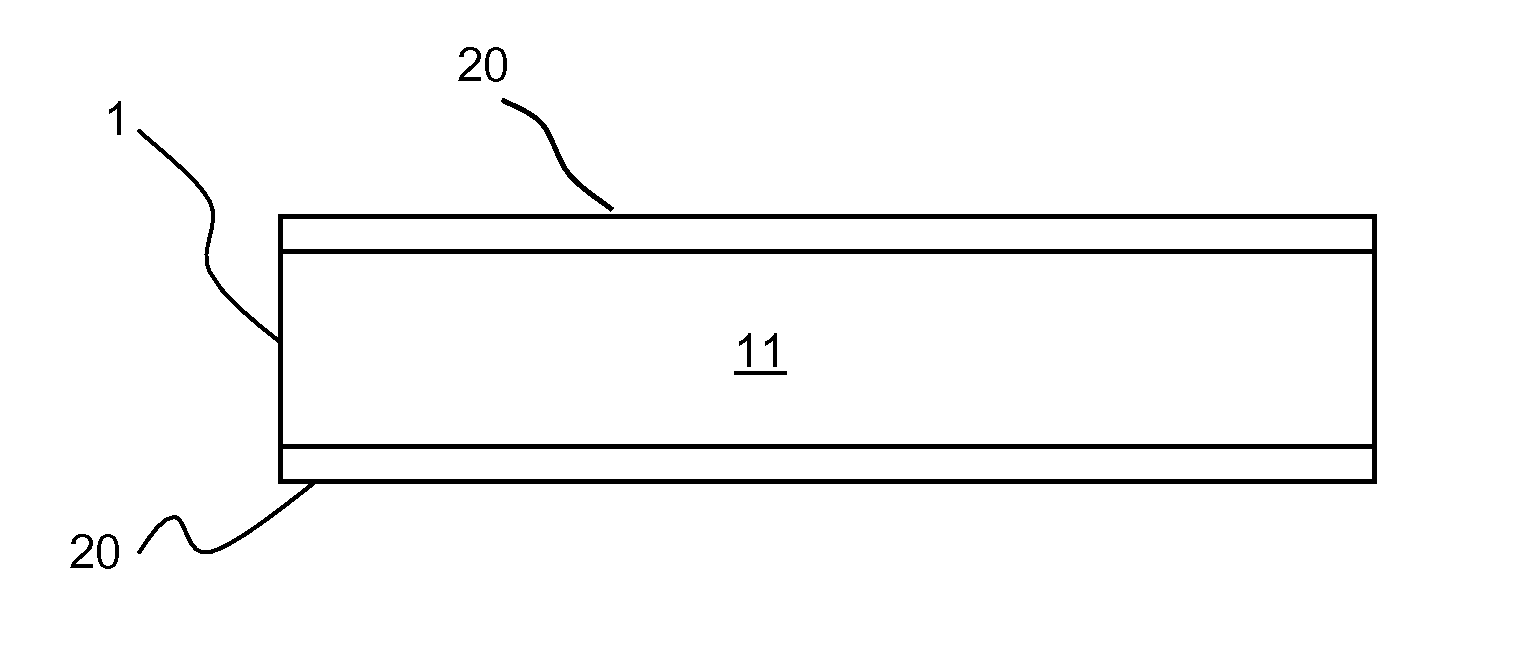

A cementitious armor panel assembly including cementitious armor panel with ballistic and blast resistant properties attached to a frame structure to produce a protective structure. The cementitious armor panels have a continuous phase resulting from the curing of an aqueous mixture of an inorganic cement binder, an inorganic mineral filler having a particle size of about 150-450 microns, a pozzolanic mineral filler, a polycarboxylate based superplasticizer self-leveling agent, and water. The mixture may also contain alkanolamine, and acid or acid salt. Prior to curing, the continuous phase is reinforced with fiber uniformly distributed in the continuous phase before it is cured to form the panel. The panel may be reinforced with a skin attached to at least one surface of the panel.

Owner:UNITED STATES GYPSUM CO +1

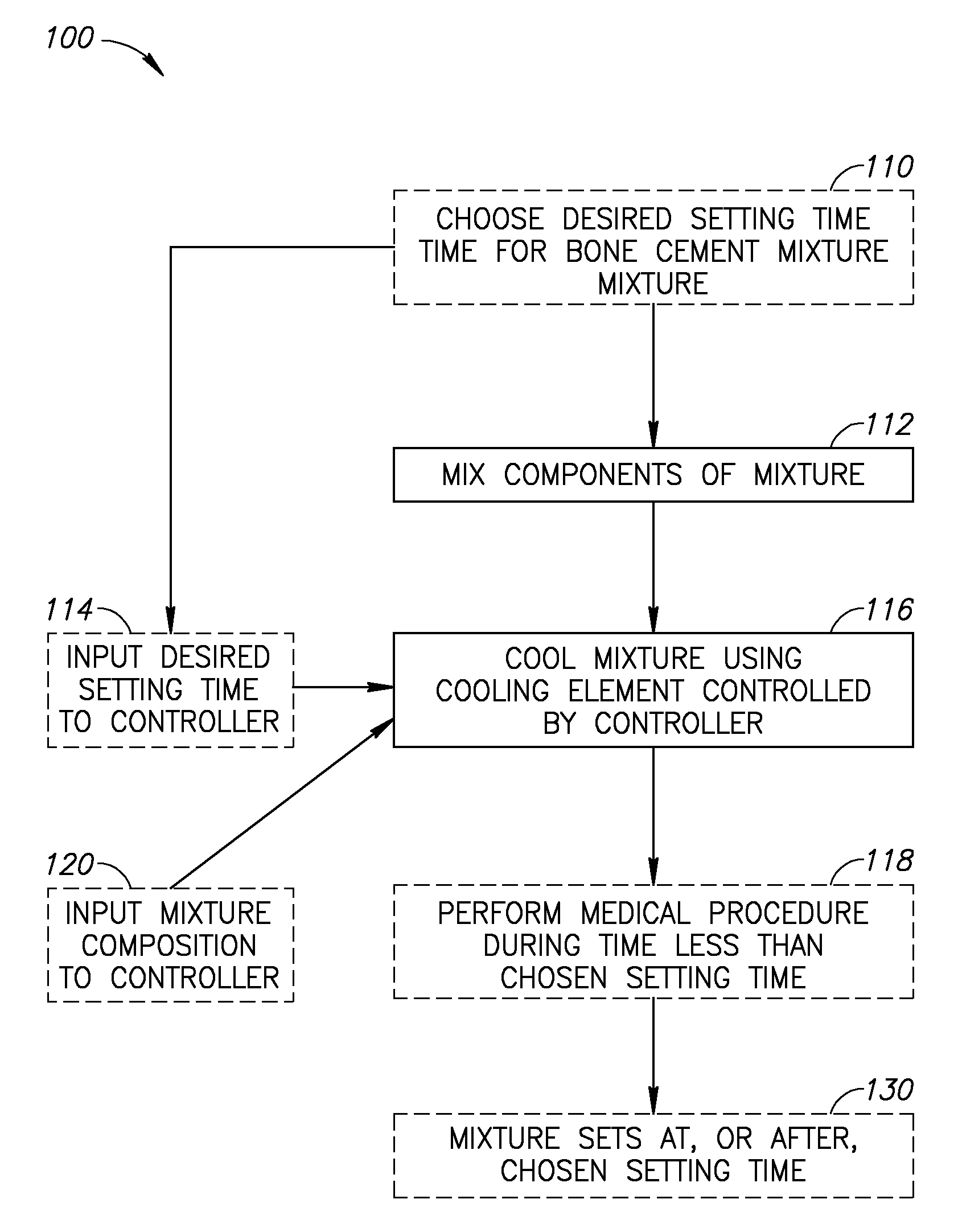

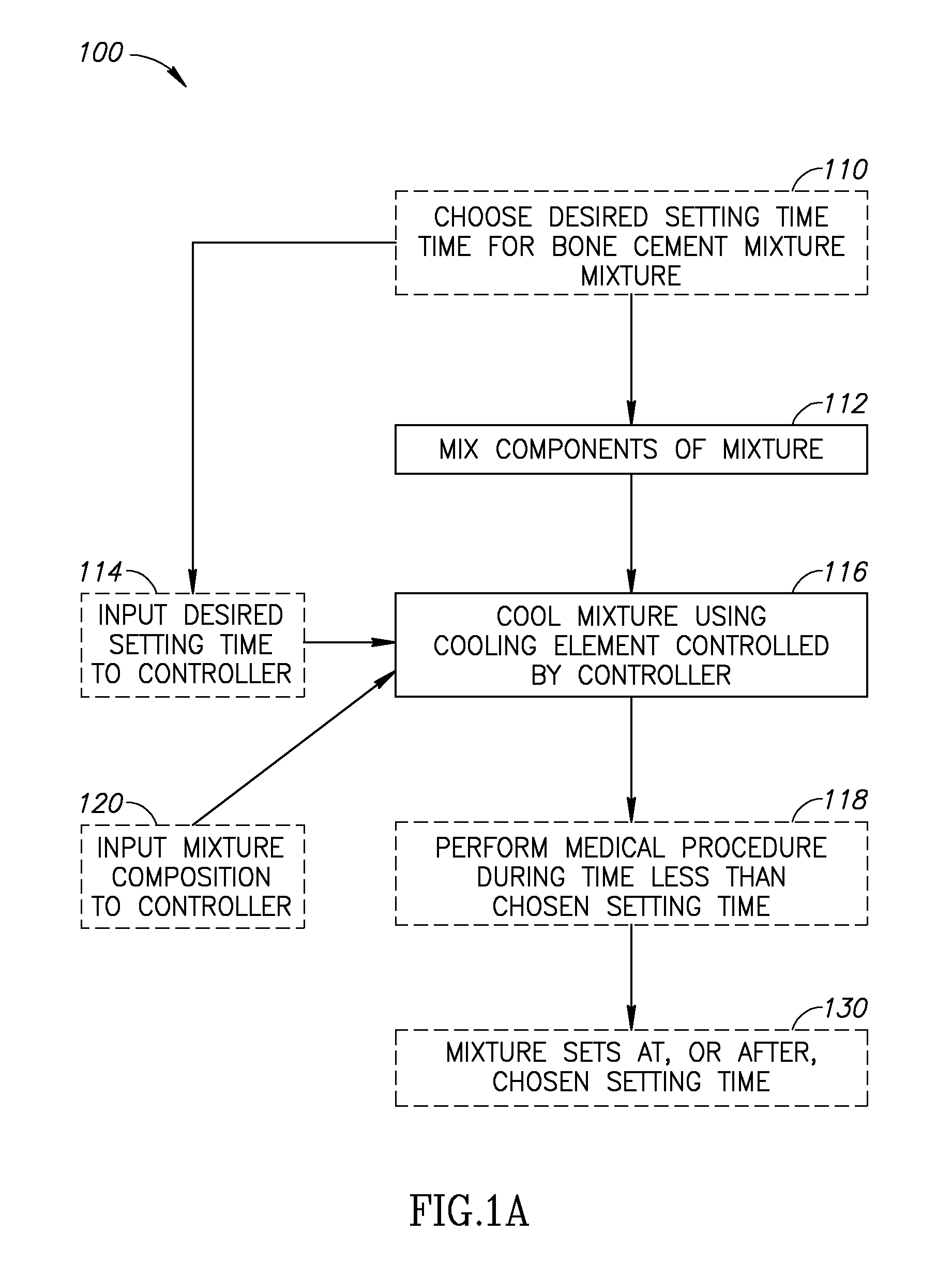

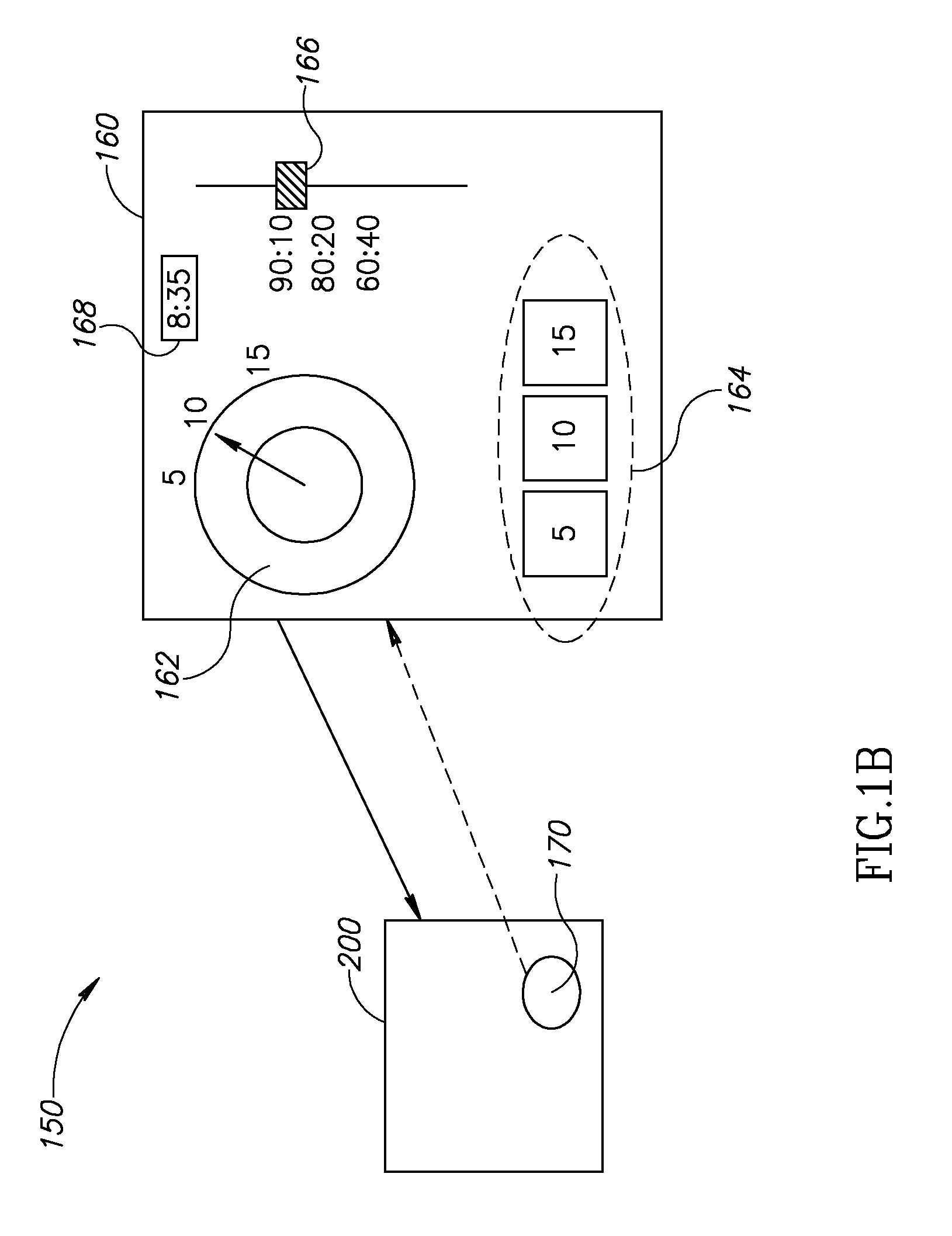

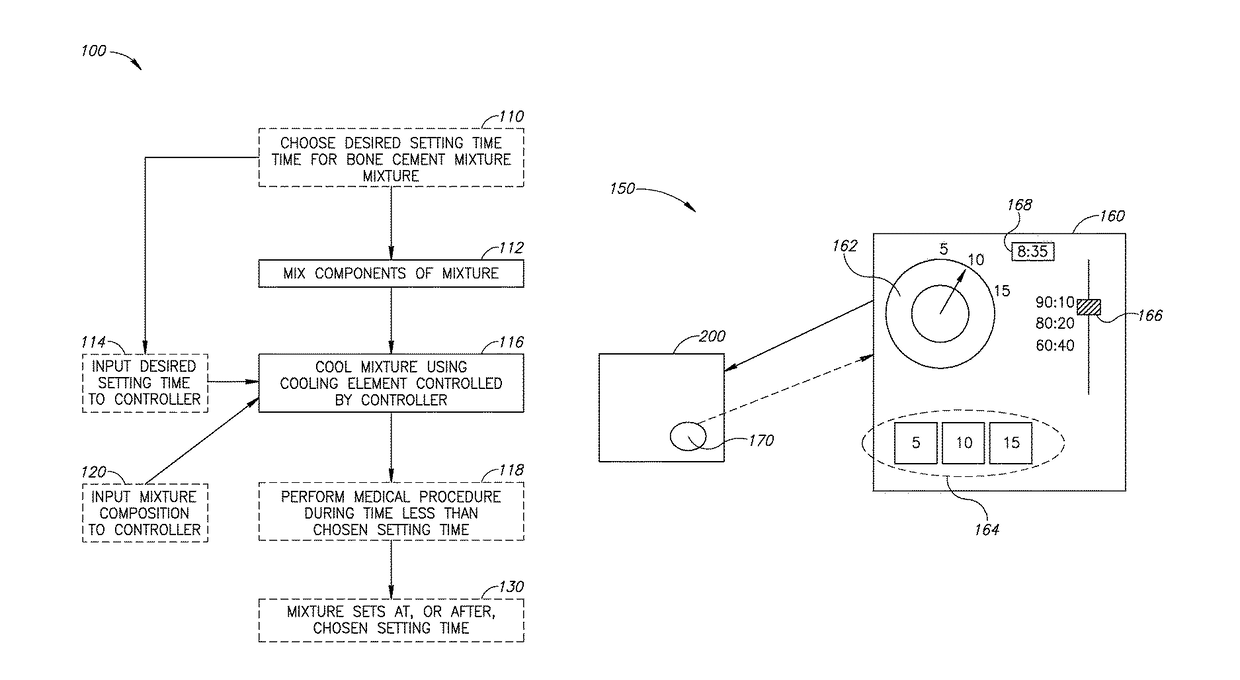

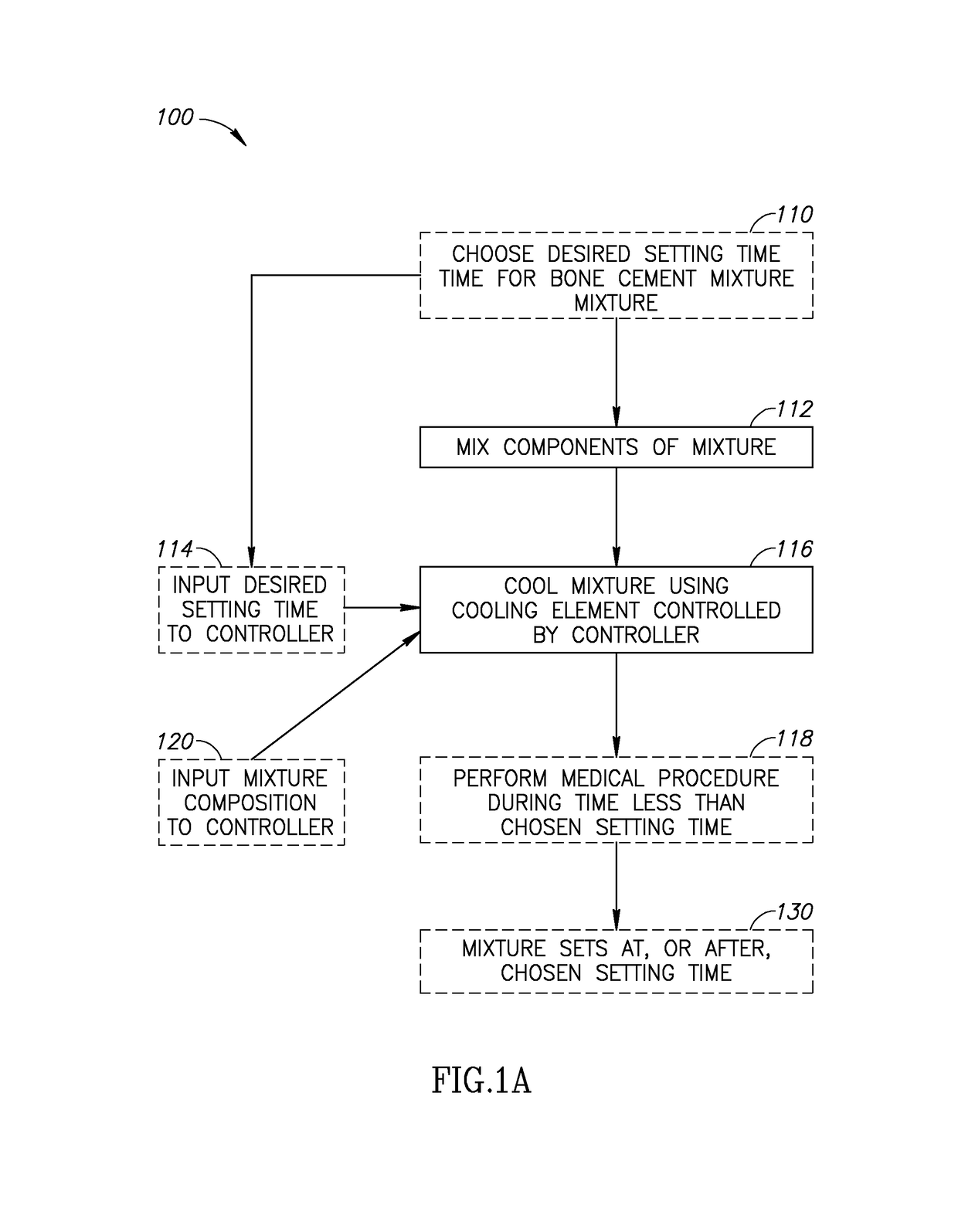

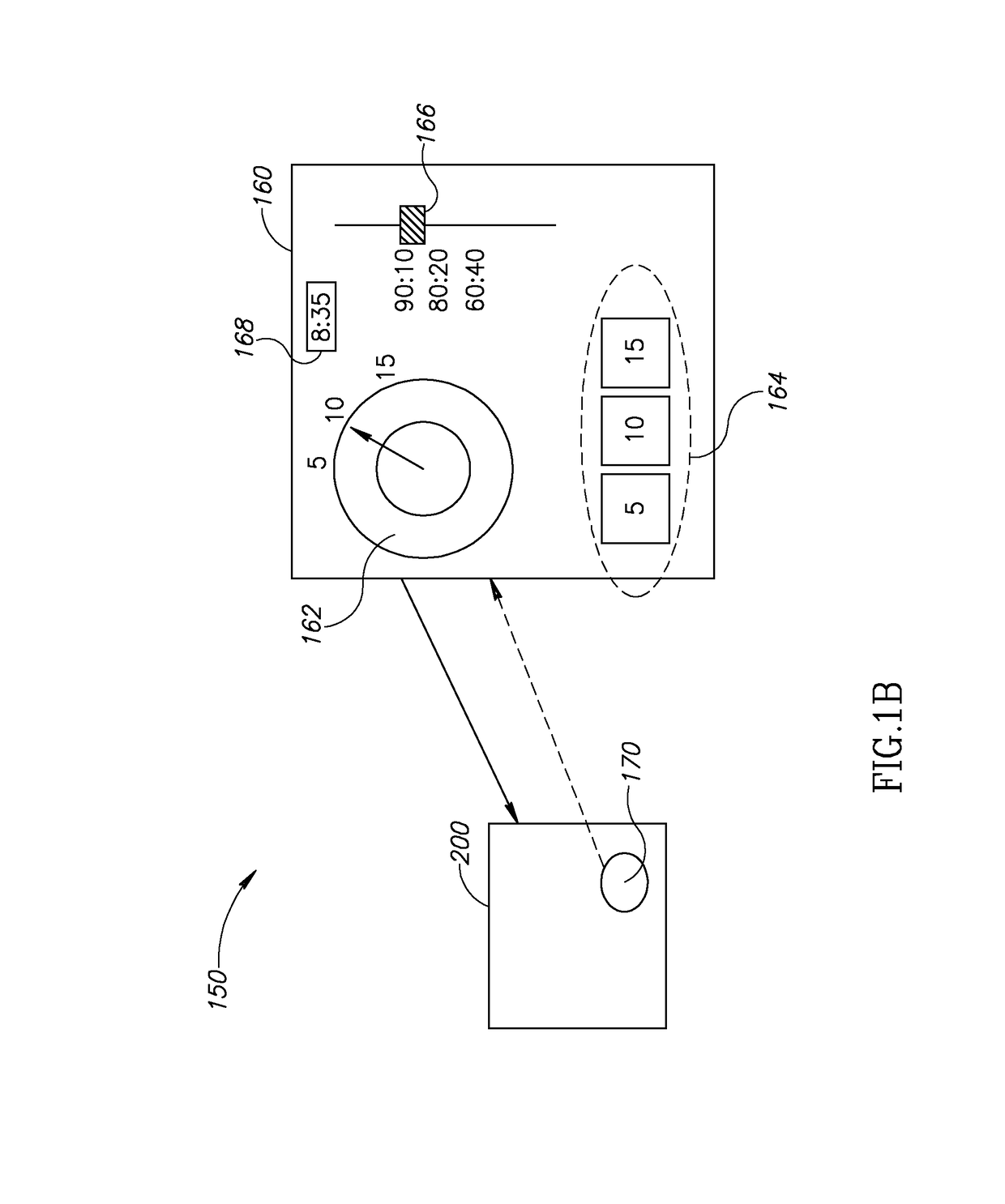

Temperature Control System

ActiveUS20140148866A1Improve securityReduce riskImpression capsJoint implantsTemperature controlFilling materials

A method of regulating a setting time of a bone filler material, the method comprising: (a) combining at least two filler material components to form a biocompatible mixture; (b) choosing a setting time for the mixture; and (c) regulating a temperature of the mixture to influence reaction kinetics so that the mixture does not set before the chosen setting time.

Owner:DEPUY SYNTHES PROD INC

Ecotypic cementing material

ActiveCN102515588AIncreases hydration activityImprove grinding efficiencyCement productionSodium metasilicateBrick

The invention relates to an ecotypic cementing material, which comprises the components of: 40-60 parts of building waste brick powder, 15-30 parts of slag, 10-20 parts of steel plant semi-dry sintering flue gas desulfurization ash, and 10-15 parts of a composite grinding aid activator, which is prepared by raw materials in the following weight ratio: 70-85 parts of calcination modified desulfurization gypsum, 5-10 parts of sodium metasilicate pentahydrate, 5-10 parts of sodium aluminate, 1-5 parts of a naphthalene-based water reducer, 0.1-0.5 part of triethanolamine, 0.05-0.1 part of potassium humate, and 0.05-0.1 part of glycerol. The cementing material of the invention utilizes the synergetic and complementary effects of component materials, realizes resource utilization of building waste brick powder and semi-dry desulphurization ash as well as other solid wastes, thus making waste profitable.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Phosphogypsum-base self-leveling material and preparation method thereof

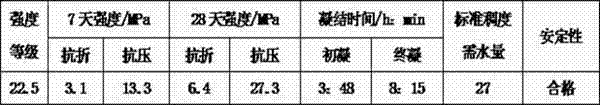

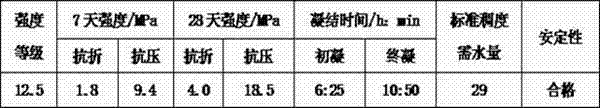

ActiveCN104692755AImprove product qualityImprove flexural strengthPhosphogypsumUltimate tensile strength

The invention relates to a phosphogypsum-base self-leveling material and a preparation method thereof. The phosphogypsum-base self-leveling material is composed of the following raw materials in percentage by weight: 10-20% of beta-gypsum powder, 20-30% of high-strength gypsum powder, 30-40% of aggregate, 5-15% of phosphogypsum crystal whisker, 2-4% of ore powder, 3-8% of cement, 0.1-0.3% of retarder, 0.05-0.10% of water retention agent and 0.1-0.5% of water reducing agent. Compared with the existing gypsum-base self-leveling material, the phosphogypsum-base self-leveling material utilizes abundant industrial waste phosphogypsum. Compared with the existing phosphogypsum-base self-leveling material, the product provided by the invention has the advantages of high quality, higher folding strength and lower production cost.

Owner:山东新大地环保建材股份有限公司

Method of making a gypsum slurry with modifiers and dispersants

ActiveUS20060278135A1Improved product set timeSufficient fluidityCeramic shaping apparatusThin material handlingSlurryGypsum

In a method of making a gypsum slurry, a polycarboxylate dispersant, a modifier and a hydraulic material comprising stucco are selected for use in the slurry. These components are then combined with water to form a slurry, where the modifier is added to the slurry prior to formation of a slurry phase by the water, the stucco and the dispersant. The modifier has been shown to be less effective when added after the dispersant and stucco have been contacted in an aqueous slurry. In a preferred embodiment, an amount of stucco is obtained and the modifier and dispersant are selected. A predissolved solution of a dispersant and modifier is prepared in water to form a solution prior to the addition of the stucco. After mixing the solution, the stucco is added to form the slurry. Optionally, the slurry is then shaped into a product and allowed to set.

Owner:UNITED STATES GYPSUM CO

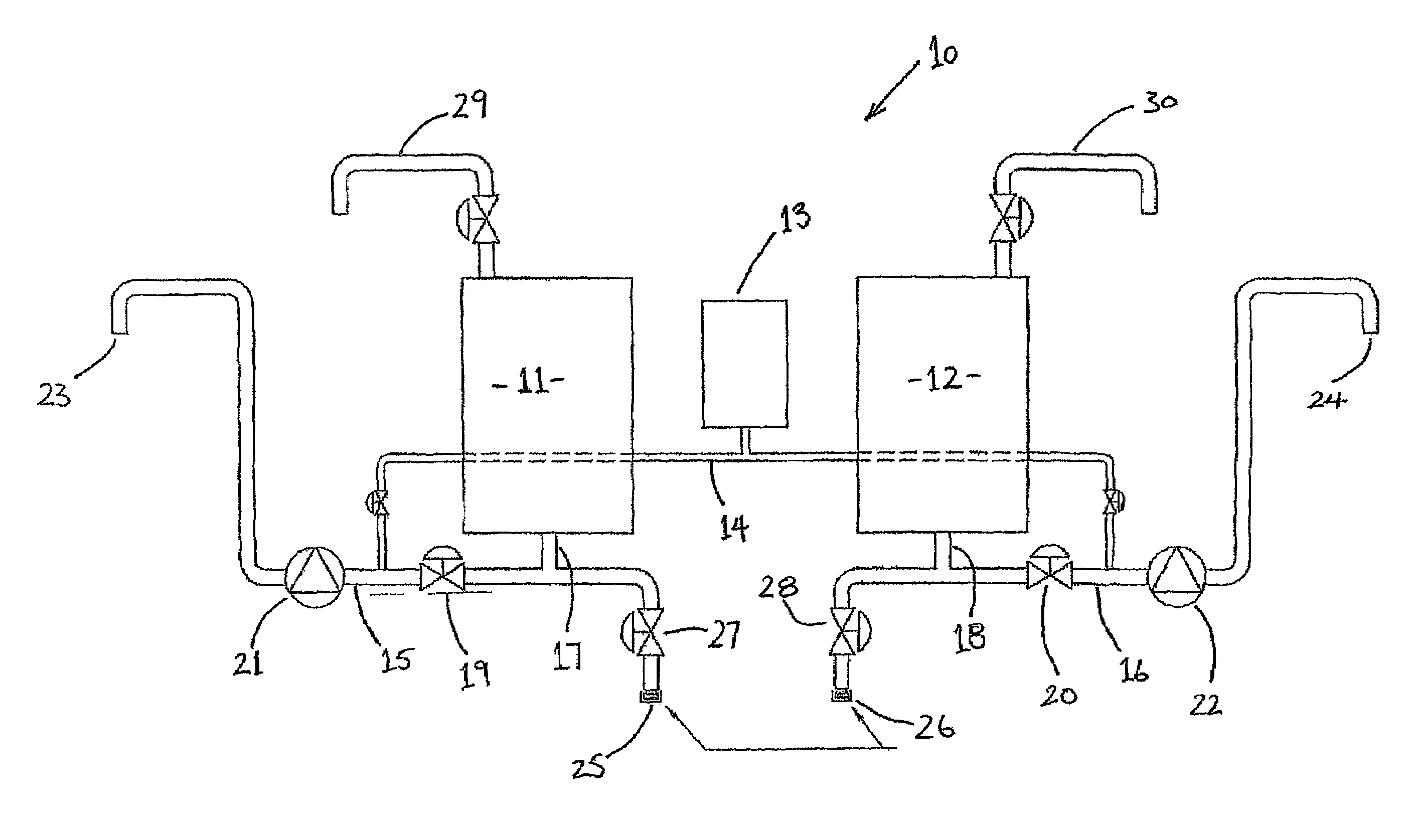

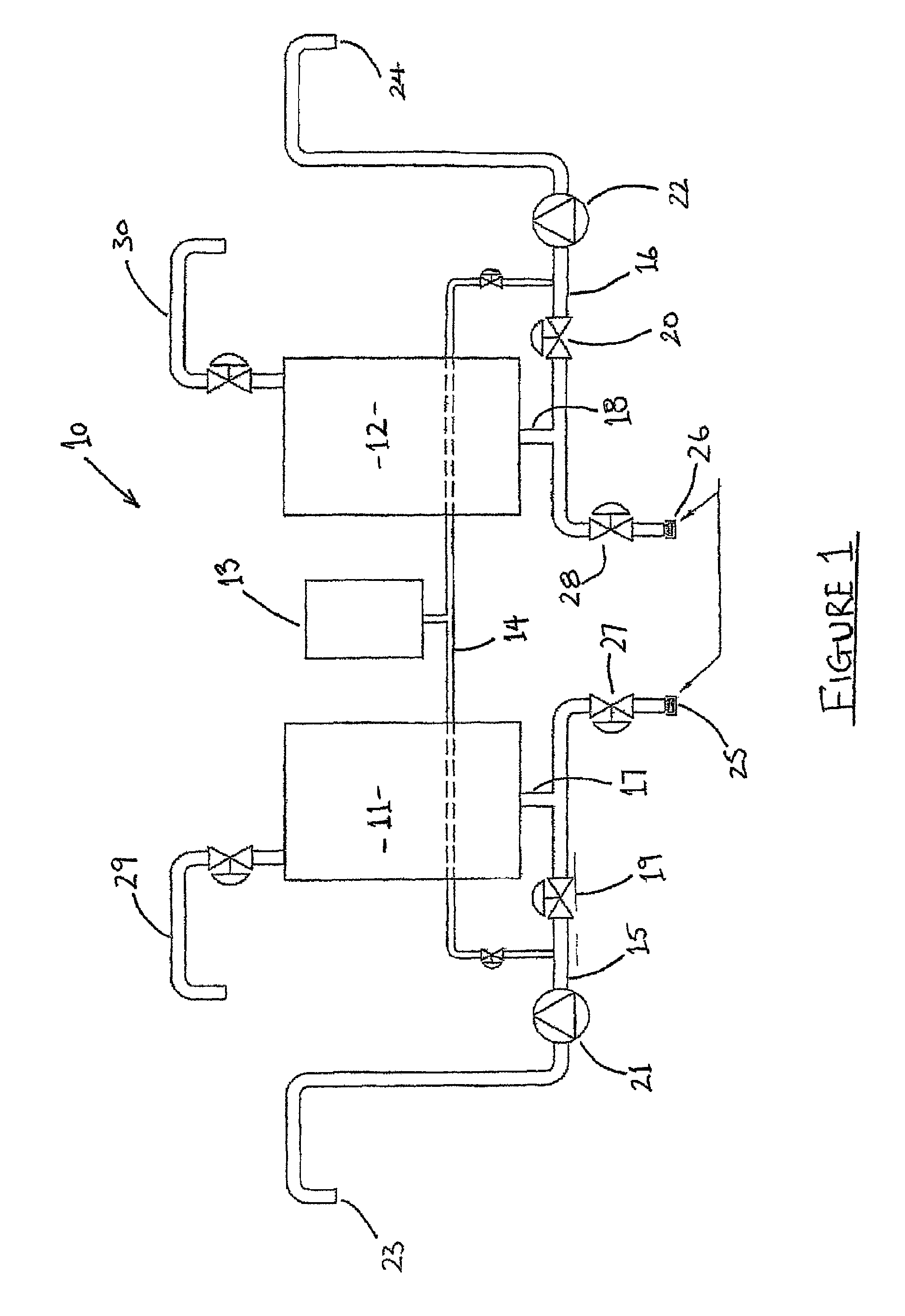

Effective use of dispersants in wallboard containing foam

Owner:UNITED STATES GYPSUM CO

Effective use of dispersants in wallboard containing foam

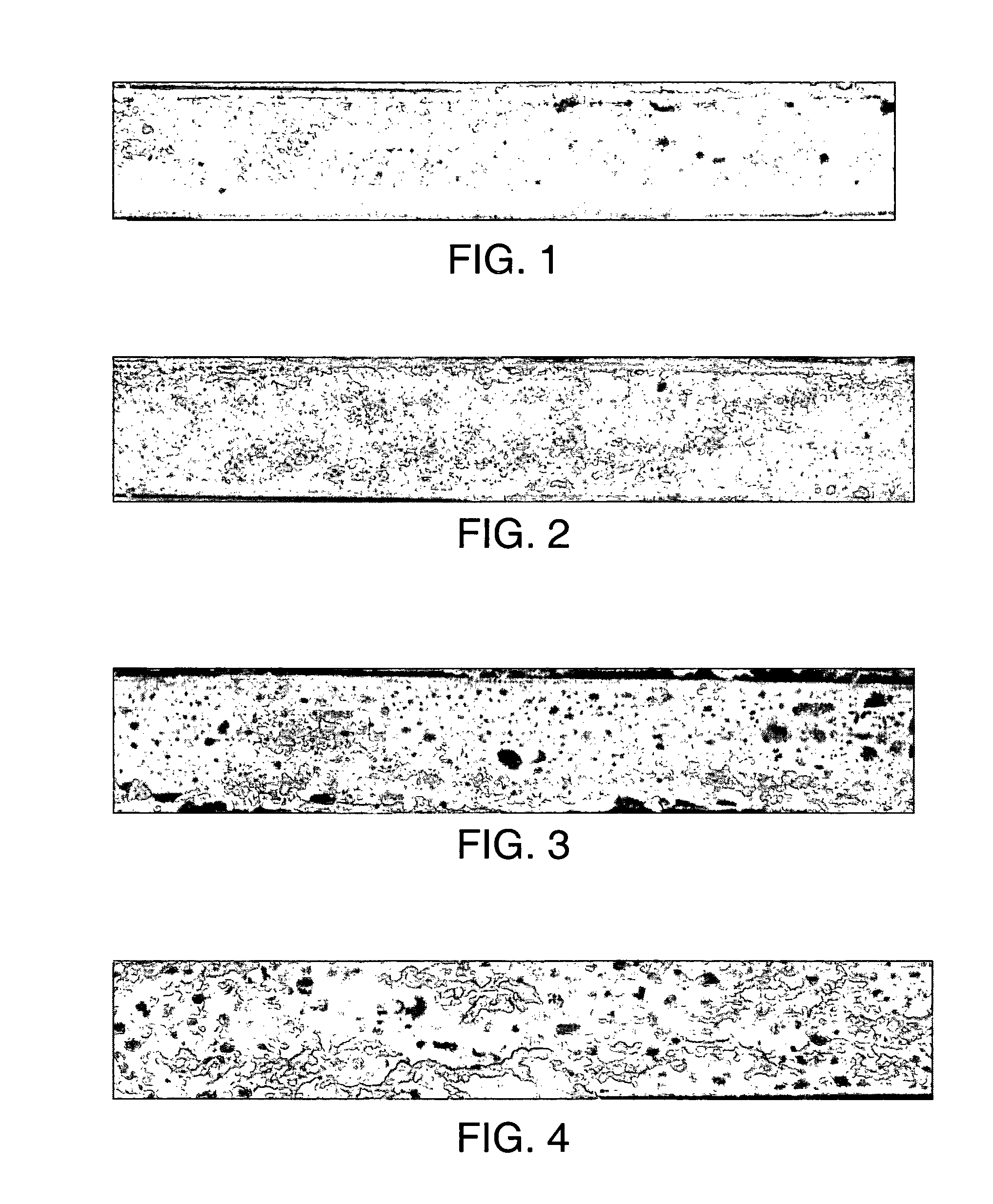

InactiveUS20060278129A1Without decreasing slurry fluidityImprove setting timeCeramicwareSlurryGypsum

Effective use of dispersants in wallboard containing foam results from a method where stucco is mixed with a first dispersant and a first quantity of water to form a gypsum slurry. A soap is blended with a second dispersant and a second quantity of water to make a foam. Subsequently, the foam is combined with the slurry. Choice of different first and second dispersants and their relative amounts allows control of the size distribution of the foam bubbles in the slurry and the resulting voids in the gypsum core. Use of the same dispersant in both the mixer and the foam water provides a boost in efficacy of the dispersant.

Owner:UNITED STATES GYPSUM CO

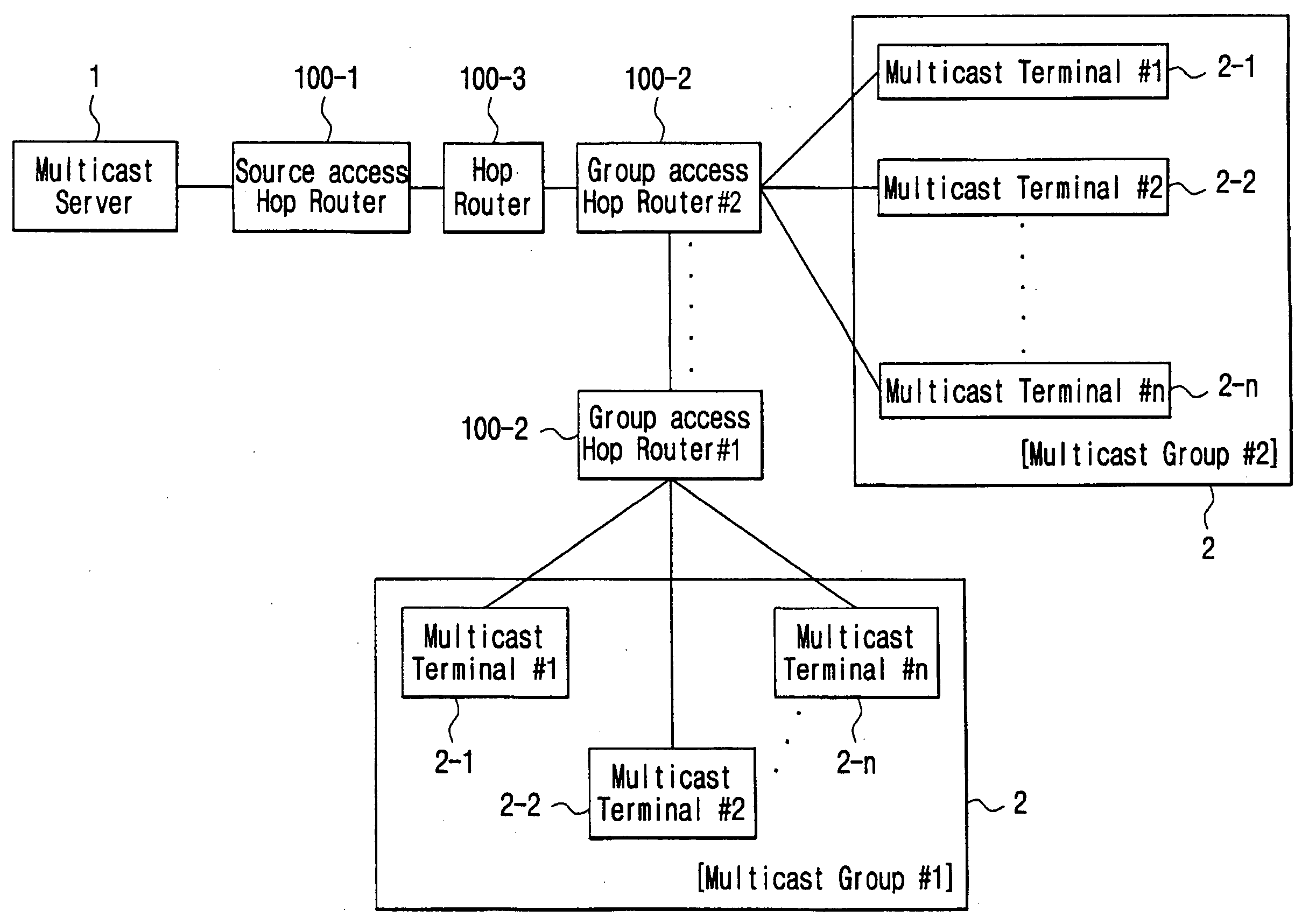

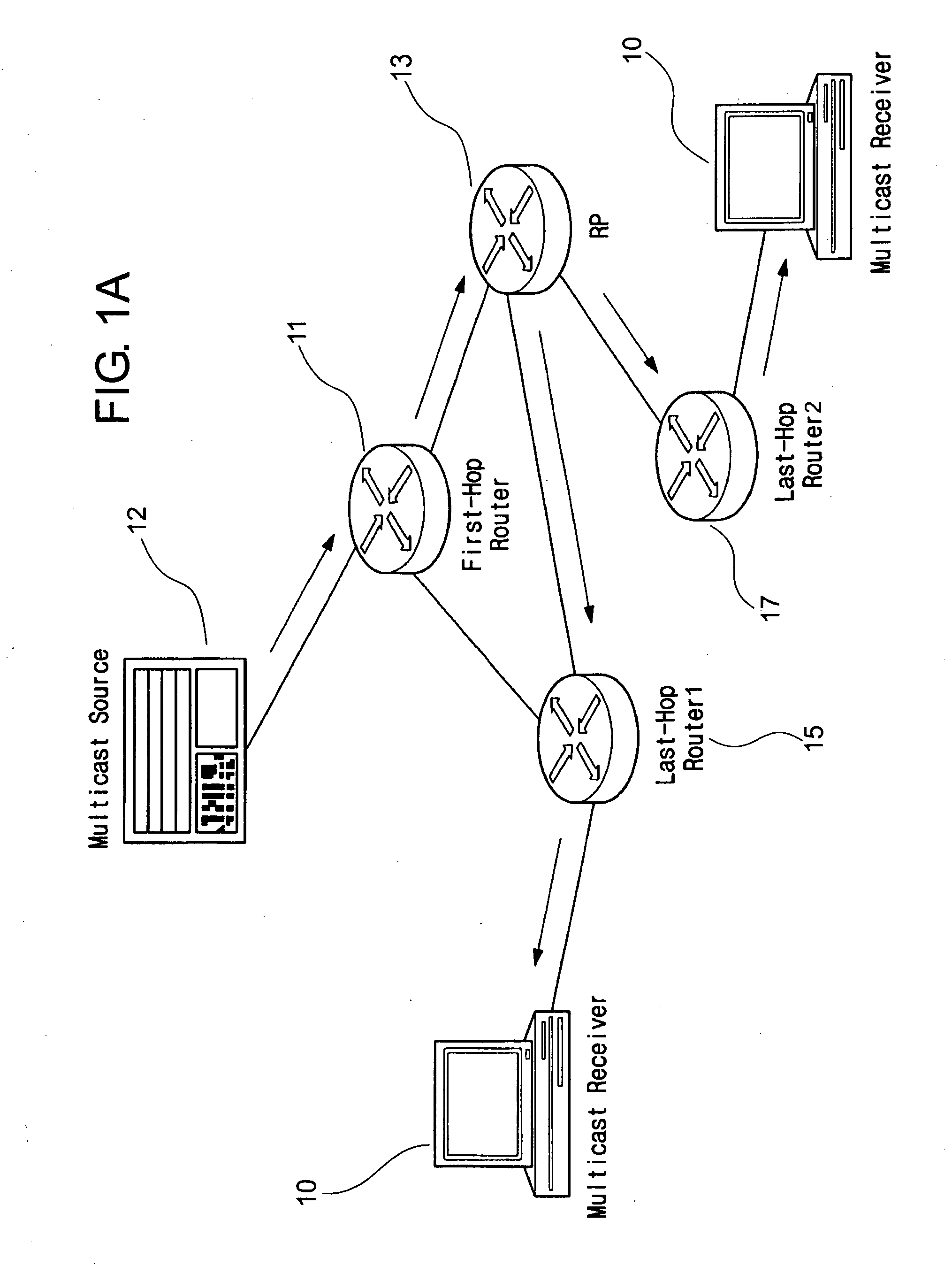

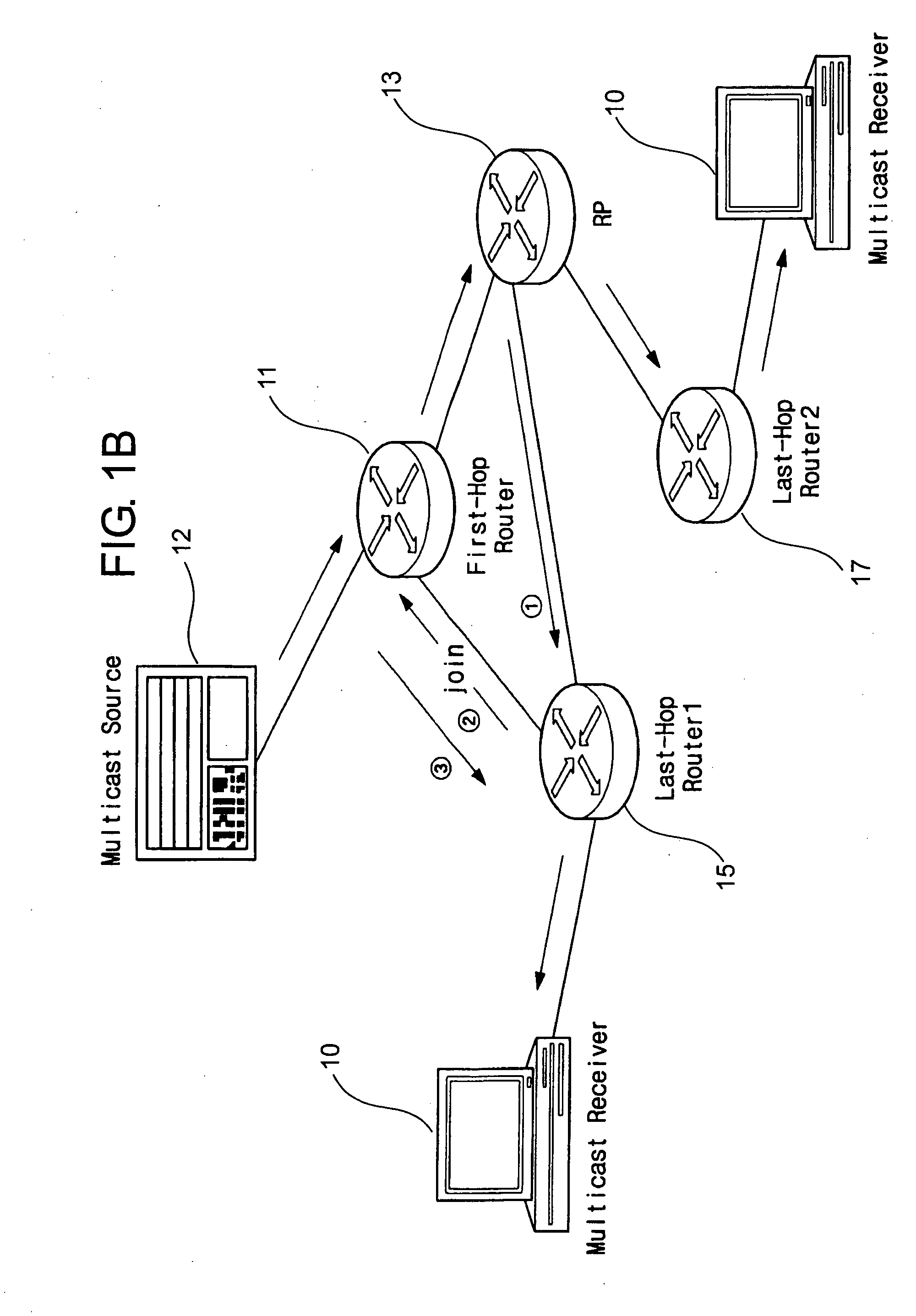

Join message load control system and method in network using PIM-SSM

InactiveUS20090067426A1Reduce unnecessary transmissionImprove setting timeSpecial service provision for substationData switching by path configurationTraffic capacityControl system

A Join message load control system in a network using a Protocol Independent Multicast-Source Specific Multicast (PIM-SSM) protocol, the Join message load control system including a source access hop router creating a SOURCE-INACTIVE message and transmitting the created SOURCE-INACTIVE message when a multicast traffic is not received from the multicast server during a set Keep-Alive Time (KAT), and the SOURCE-INACTIVE message including information on an update set time of a PIM Join message; and a group access hop router resetting the update set time of the PIM Join message when the SOURCE-INACTIVE message is received from the source access hop router. Accordingly, it is possible to reduce the periodical transmission of unnecessary Join(S, G) messages and thereby reduce traffic load in a network by adjusting a JP timer of the Join(S, G) message depending on whether a channel(S, G) is active or inactive.

Owner:SAMSUNG ELECTRONICS CO LTD

Utility materials incorporating a microparticle matrix formed with a setting agent

A composition, utility material, and method of making a utility material is disclosed. A composition having an improved setting time may include a plurality of microparticles mixed with a sodium silicate binder and an isocyanate setting agent, where the microparticle composition has a setting time of less than or equal to one hour. A utility material may be a wallboard that includes the composition.

Owner:MICROSPHERE LABS LLC

Dry mix cement composition, methods and systems involving same

InactiveUS7691198B2Modifies strengthEnhances polymerisationSolid waste managementAlkali metal silicate coatingsMulti phaseMaterials science

A dry mix cement composition including an alkaline multi-phase aluminosilicate material, wherein the alkaline multi-phase aluminosilicate material provides a source of alkaline and soluble silicate to the cement composition.

Owner:ZEOBOND RES

Green rapid-hardening early-strength magnesium phosphate-based healant and preparation method thereof

ActiveCN104909709AImprove compactnessHigh impermeability levelSolid waste managementSilica fumeMagnesium orthophosphate

The invention discloses a green rapid-hardening early-strength magnesium phosphate-based healant and a preparation method thereof. The green rapid-hardening early-strength magnesium phosphate-based healant is composed of a material A and a material B; the material A is prepared via mixing of a phosphate, borax, a toughening ingredient, an accelerating component, a water retention ingredient, a water reducing ingredient, and a grinding aid dispersing agent; and the B material is prepared via mixing of magnesium oxide, flyash, silica fume, ground steel slag, chromium iron tailing slag powder, anhydrite, an expanding agent, and a grinding aid dispersing agent. According to the preparation method, industrial supplementary cementious materials (flyash, silica fume, and ground steel slag) are added into cement, so that cement fluidity and early strength are improved; industrial chromium iron tailing slag powder is added into the green rapid-hardening early-strength magnesium phosphate-based healant as a filling material, so that it is beneficial for cement hydration reaction, set cement compaction rate is increased, and at the same time heavy metal waste solidification is realized. The green rapid-hardening early-strength magnesium phosphate-based healant is capable of achieving balance between magnesium phosphate cement setting time and high early strength, and solving problems that shrinking percentage is large and bonding strength is low.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Multifunctional expandable fiber anti-cracking waterproof agent and preparation method

The invention discloses a multifunctional expandable fiber anti-cracking waterproof agent. The multifunctional expandable fiber anti-cracking waterproof agent comprises the following components in parts by weight: 8-27.3 parts of calcium sulphoaluminate, 4-9 parts of calcium oxide, 5-9 parts of magnesium oxide, 14.7-23.5 parts of fly ash, 4-9 parts of an iron powder expanding agent, 1.5-7.8 partsof a modified sepiolite fabric, 1-4.5 parts of modified polypropylene fibers, 1.5-4 parts of sodium methyl silicate, 0.5-1.5 parts of sodium fluosilicate and 1-4 parts of a polycarboxylic acid effective water reducing agent, wherein the modified sepiolite fabric is modified through diluted hydrochloric acid and a silane coupling agent, the modified polypropylene fibers are modified through potassium dichromate, concentrated sulfuric acid and a silane coupling agent, thus, mutually cross-linked net-shaped structures are formed in concrete, compared with an existing anti-cracking waterproof agent which takes common sepiolite, sepiolite fibers and polypropylene fibers as raw materials, the anti-cracking waterproof agent is better in anti-cracking property and expanding property, shorter in time of coagulation and higher in concrete performance. The invention further provides a preparation method of the anti-cracking waterproof agent, and the raw materials are blended by a two-step method.

Owner:TIANJIN JINSHENGYUAN SPECIAL BUILDING MATERIALS

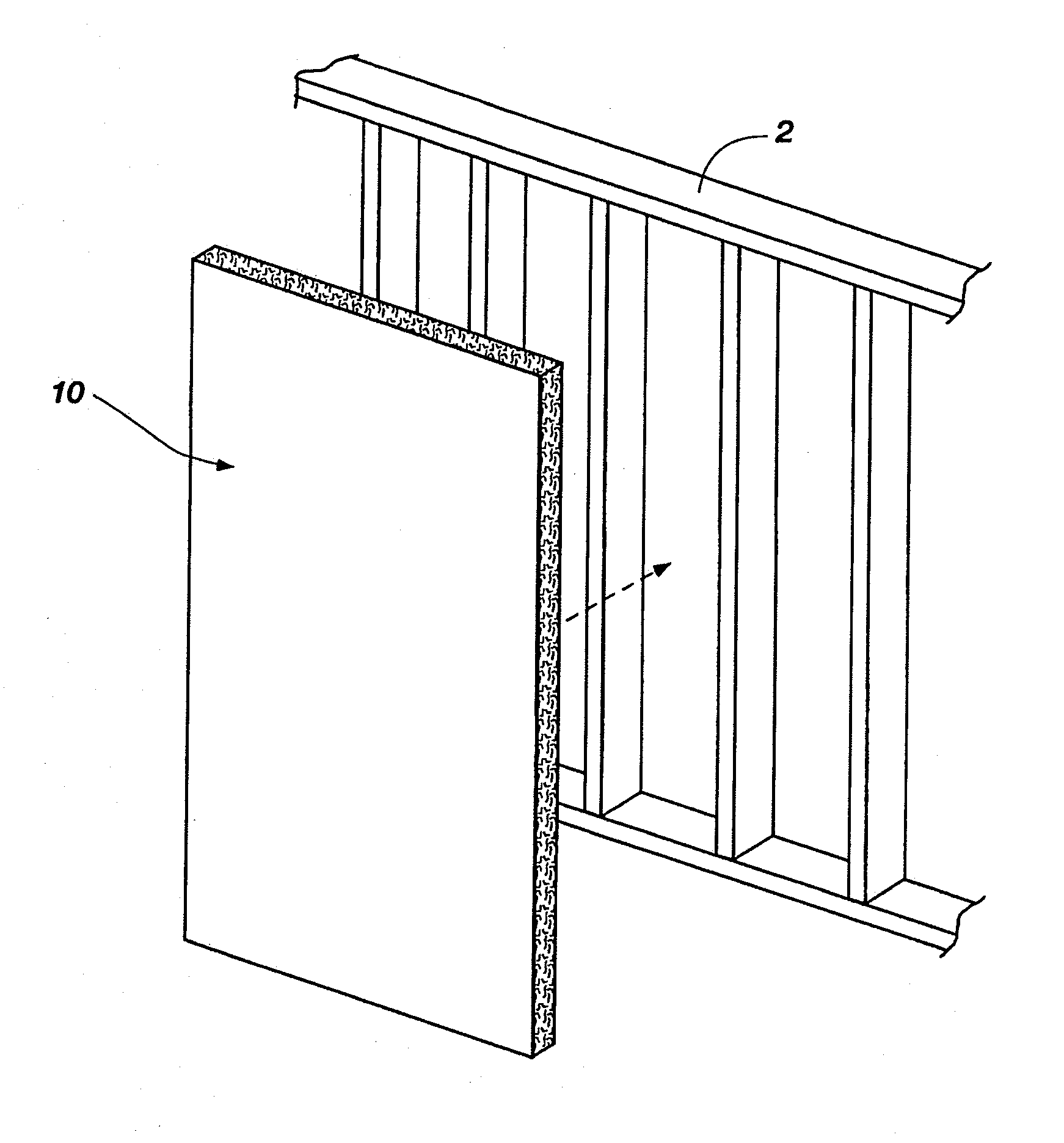

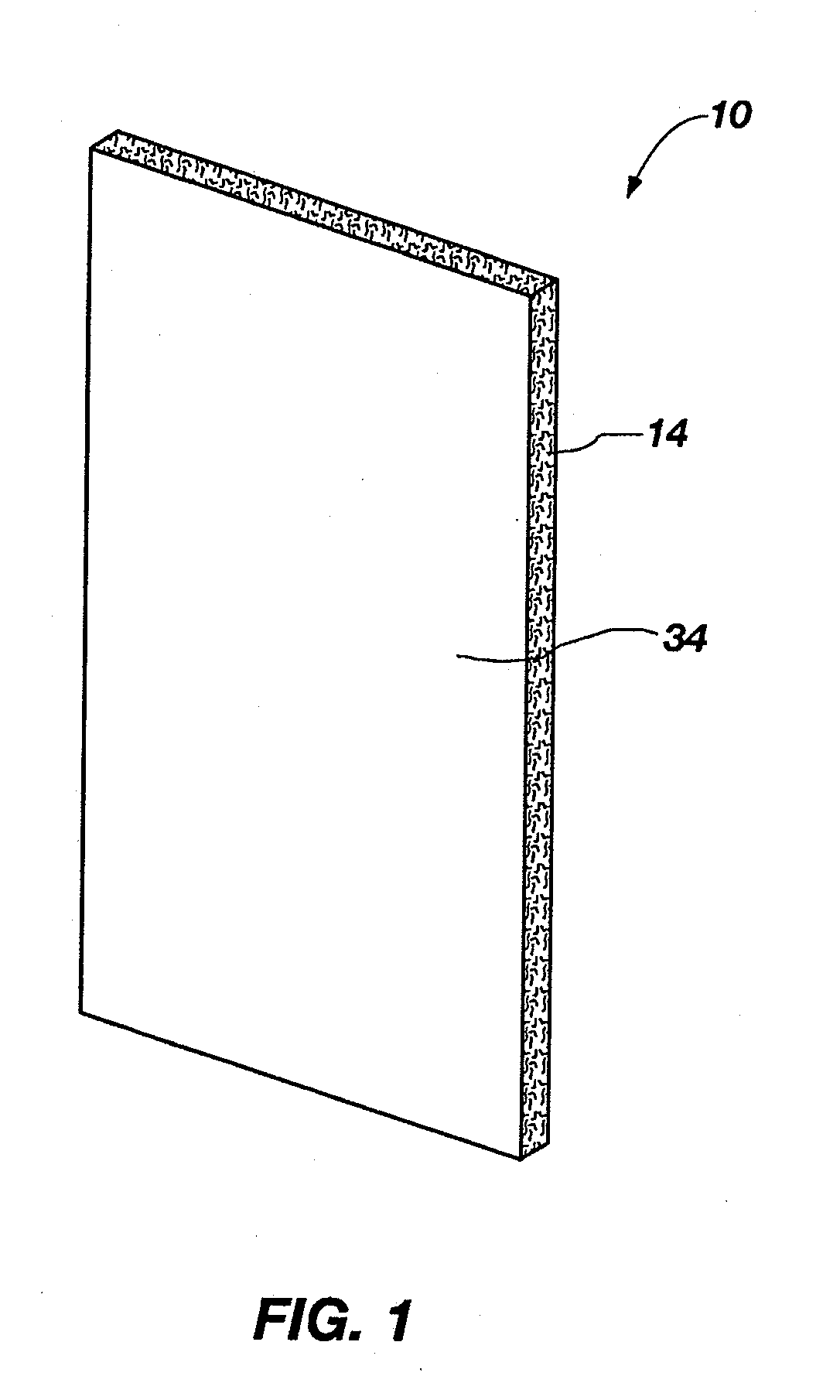

Cement based armor panel system

ActiveUS8061257B2Improve liquidityUltra-high compressive strengthDoor/window protective devicesSolid waste managementFiberSuperplasticizer

A cementitious armor panel assembly including cementitious armor panel with ballistic and blast resistant properties attached to a frame structure to produce a protective structure. The cementitious armor panels have a continuous phase resulting from the curing of an aqueous mixture of an inorganic cement binder, an inorganic mineral filler having a particle size of about 150-450 microns, a pozzolanic mineral filler, a polycarboxylate based superplasticizer self-leveling agent, and water. The mixture may also contain alkanolamine, and acid or acid salt. Prior to curing, the continuous phase is reinforced with fiber uniformly distributed in the continuous phase before it is cured to form the panel. The panel may be reinforced with a skin attached to at least one surface of the panel.

Owner:UNITED STATES GYPSUM CO +1

Novel architecture gypsum powder and its preparation method

The invention relates to a new building gypsum powder and method for paper-faced gypsum board prepared by industrial waste. Wherein, mixing ardealite and desulfurized gypsum with wt% ratio as 50~90%í†10~50%, drying, calcining, cooling, aging, and removing free and crystal water in mixed material. This product has well-improved properties with low cost, and also benefits to environmental protection.

Owner:TAISHAN GYPSUM CO LTD

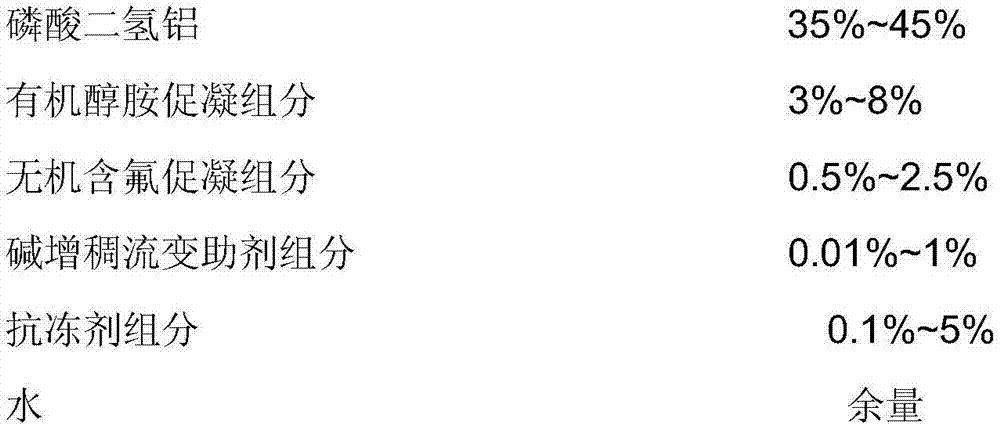

Alkali-free chloride-free sulfate-free liquid accelerator

The invention discloses an alkali-free chloride-free sulfate-free liquid accelerator applicable to a sulfate corrosion environment. The liquid accelerator is composed of aluminum dihydrogen phosphate,an organic alcohol amine coagulating component, an inorganic fluorine-containing coagulating component, an alkali thickening rheological agent component, an antifreeze agent component and water. Theliquid accelerator disclosed by the invention does not contain sodium, potassium, chlorine and sulfate, has an excellent coagulating effect, is short in coagulation time during construction, high in strength and low in resilience rate, has excellent low-temperature storage and application functions, and is particularly suitable for application of sprayed concrete and stoppage and rush-repair engineering in inland and coastal sulfate environments.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

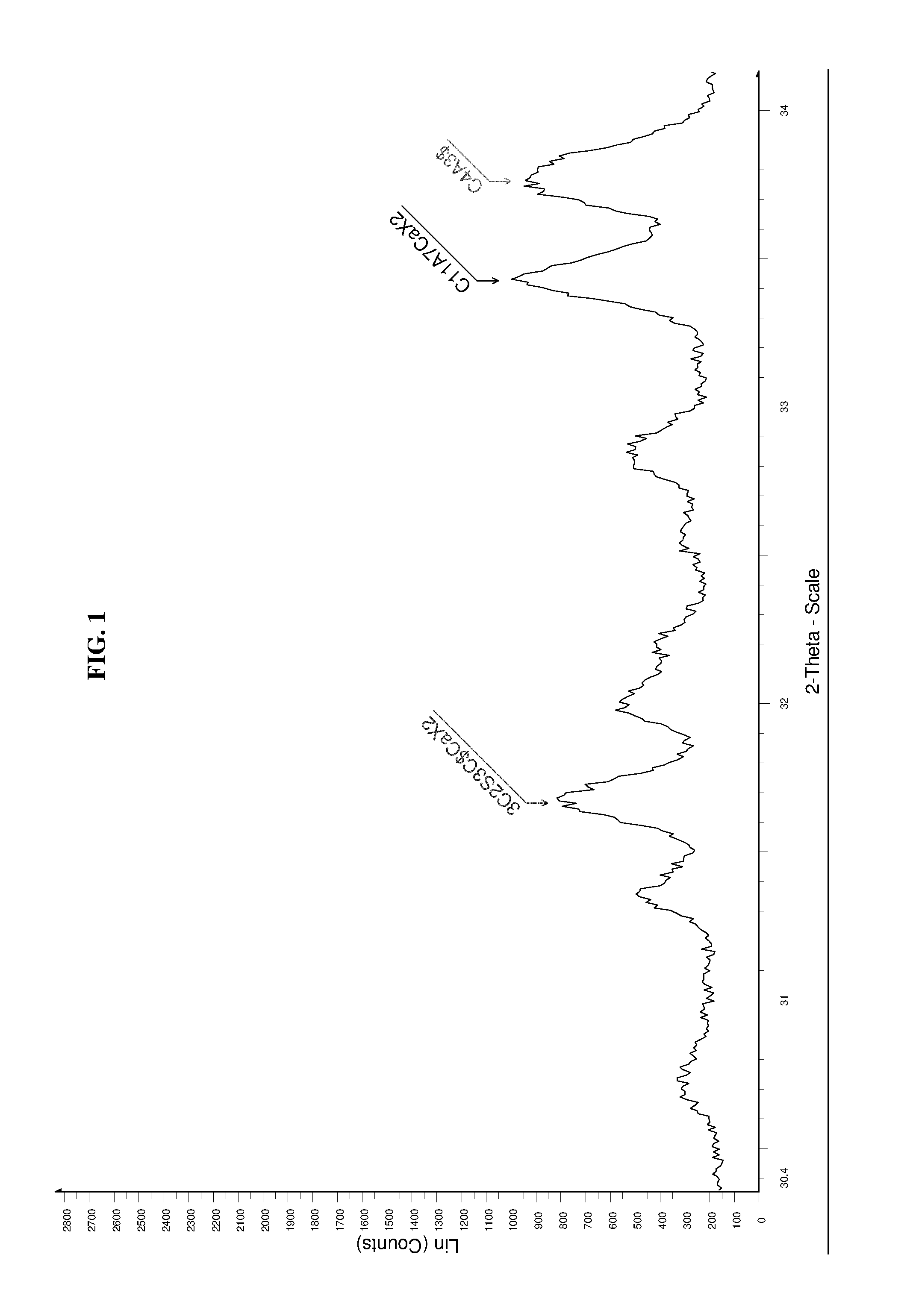

High performance sulfo-aluminous clinker

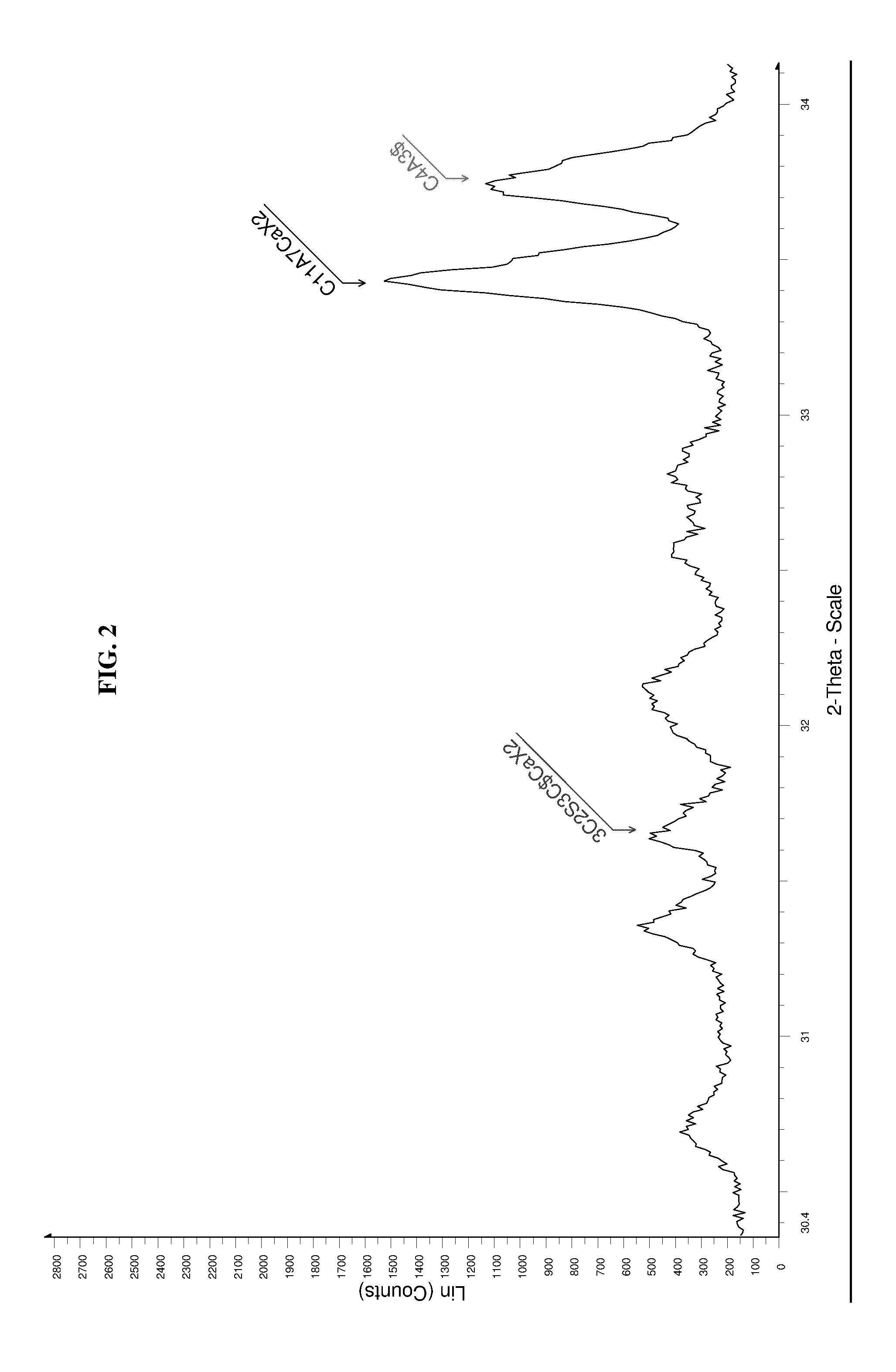

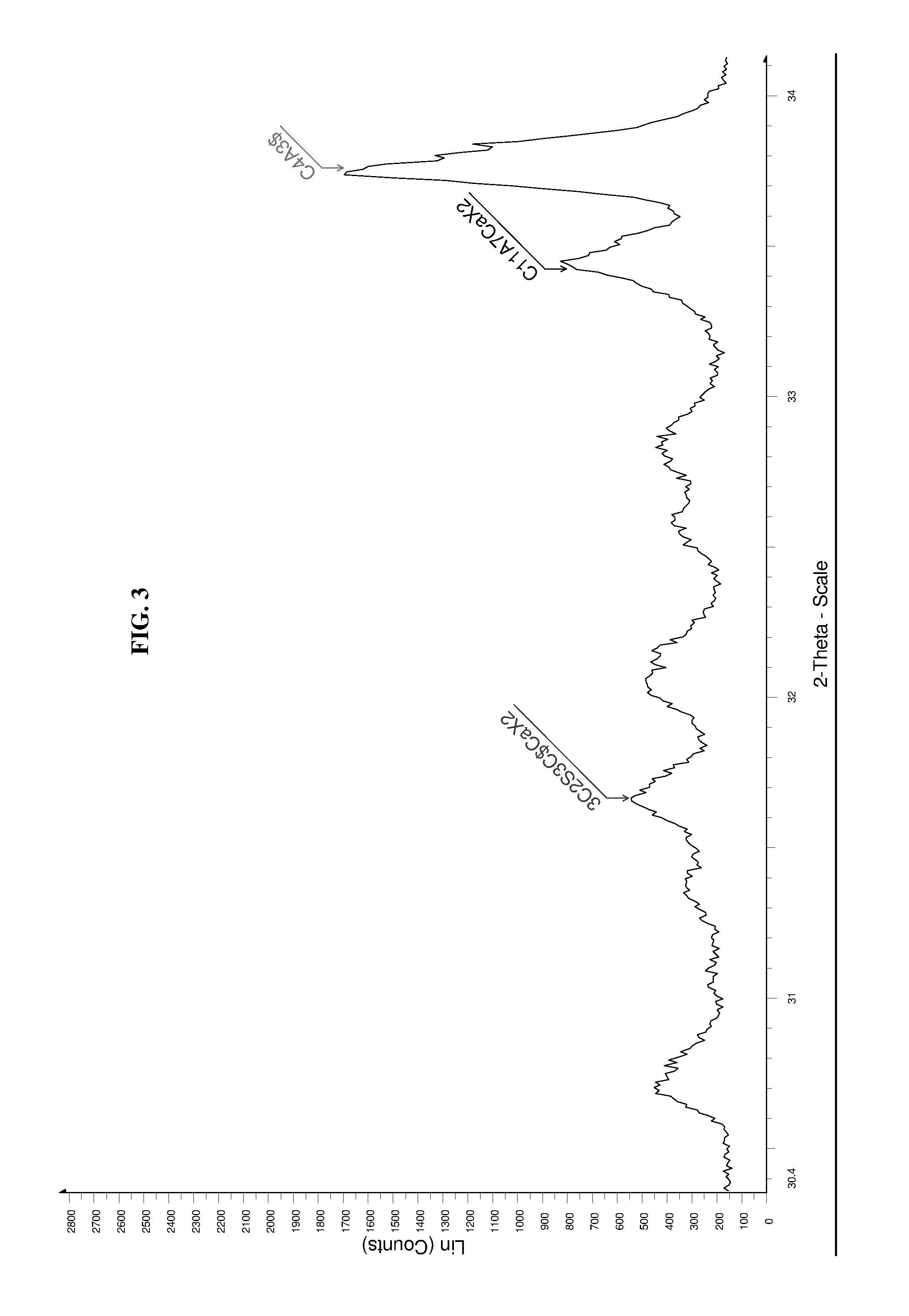

The invention relates to a sulfo-aluminous clinker with optimal setting time and short term compressive strengths, comprising a mixture of the following phases: —calcium sulfoaluminate, or C4A3$, in amounts higher than 50% by weight of the mixture, —belite, or C25, in amounts between 2 and 23%, —3C25 3C$ CaX2, X being fluorine or chlorine, between 3 and 15% —C11A7CaX2, X being fluorine or chlorine, between 2 and 12%, both fluorine and chlorine being altogether present in the mixture, and phase C5S2$ being absent. The invention also relates to a method for preparing this sulfo-aluminous clinker, and hydraulic binders comprising this clinker.

Owner:ITALCEMENTI

Effective use of melamine sulfonate condensate dispersants in wallboard containing foam

Effective use of dispersants in wallboard containing foam results from a method where stucco is mixed with a first dispersant and a first quantity of water to form a gypsum slurry. A soap is blended with a second dispersant and a second quantity of water to make a foam. Subsequently, the foam is combined with the slurry. Choice of different first and second dispersants and their relative amounts allows control of the size distribution of the foam bubbles in the slurry and the resulting voids in the gypsum core. Melamine sulfonate condensate and polycarboxylate dispersants are preferred dispersants.

Owner:UNITED STATES GYPSUM CO

Autoclaved aerated concrete plate repairing agent

InactiveCN104926258AIncrease late strengthRealize comprehensive utilizationSolid waste managementFiberBuilding product

The invention discloses an autoclaved aerated concrete plate repairing agent and belongs to the technical field of building materials. The autoclaved aerated concrete plate repairing agent is composed of, by mass, 40-60% of coal ash, 10-30% of gypsum, 5-15% of cement, 10-30% of sand, 0.01-2.0% of fiber, 0.01-1.05 of water retaining agent and 0.01-1.5% of setting retarder. The coal ash is coal ash for silicate building products meeting JC / T, the gypsum is semi-hydrated gypsum, and the cement is universal silicate cement meeting GB. By the autoclaved aerated concrete plate repairing agent, the problem that an existing repairing agent and an autoclaved aerated concrete plate have chromatic aberration and are low in binding strength and long in setting time.

Owner:SHANDONG TIANYU WALL MATERIAL

Calcium phosphate composition and method of preparing same

InactiveUS6849275B2Improve setting timeEasy to controlBiocidePowder deliveryCelluloseCalcium biphosphate

A method for controlling the formation of a hydroxyapatite bone filler from dry calcium phosphate precursors in an aqueous solution uses coated sodium phosphate powder. The sodium phosphate powder is coated with a water soluble cellulose. Until the cellulose dissolves in the aqueous solution setting of the calcium phosphate cements proceeds slowly but when the exposed sodium phosphate particles start to solubilize in the aqueous solution the setting rate increases.

Owner:HOWMEDICA OSTEONICS CORP

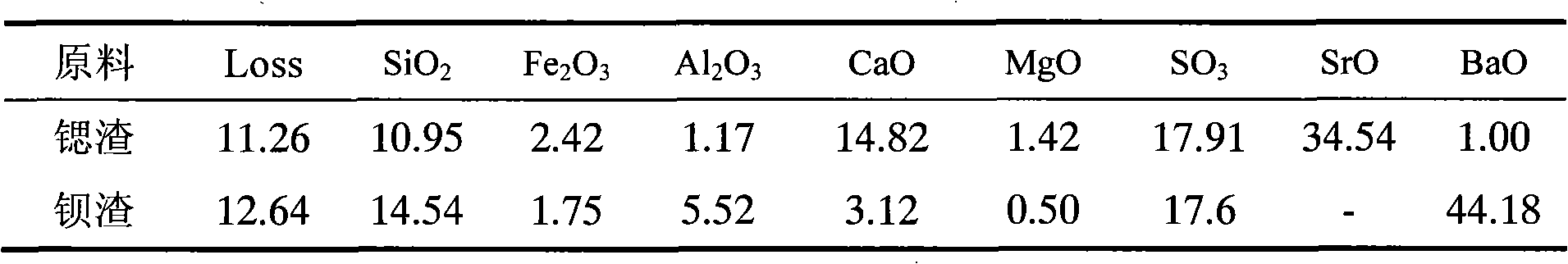

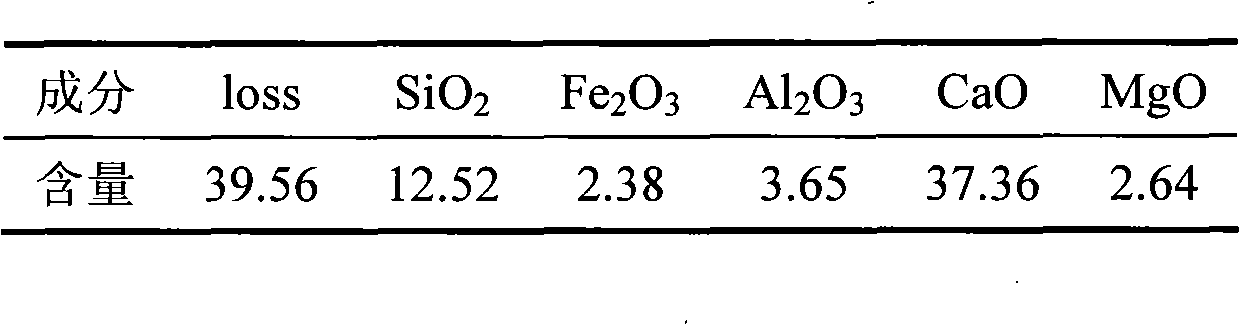

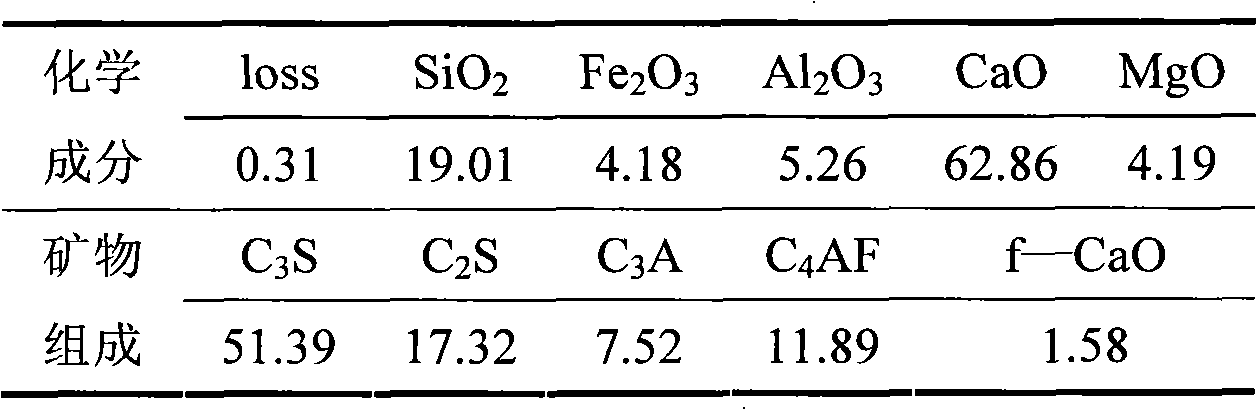

Strontium-barium cement calcination composite mineralizer

The invention relates to a strontium-barium cement calcination composite mineralizer, which is mainly made of strontium slag and barium slag, wherein both the weight percentage of the strontium slag and the weight percentage of the barium slag are 15 to 85 percent; the strontium slag is waste residue for producing strontium carbonate, and the weight percentage of SrO is required to be 25 to 40 percent; and the barium slag is waste residue for producing barium carbonate, and the weight percentage of BaO is required to be 20 to 50 percent. The invention utilizes the strontium slag and the barium slag as raw materials to synthesize the composite mineralizer, and achieves the aims of improving the cement strength, accelerating the hydrating and hardening of cement, improving the yield of kilns, reducing the cement cost, saving energy and resources, and reducing environmental pollution through the activation and mineralization of the composite mineralizer during the calcination of cement clinker.

Owner:UNIV OF JINAN

Temperature control system

ActiveUS9918767B2Reduce riskImprove securityImpression capsDomestic refrigeratorsTemperature controlFilling materials

A method of regulating a setting time of a bone filler material, the method comprising: (a) combining at least two filler material components to form a biocompatible mixture; (b) choosing a setting time for the mixture; and (c) regulating a temperature of the mixture to influence reaction kinetics so that the mixture does not set before the chosen setting time.

Owner:DEPUY SYNTHES PROD INC

Concrete admixture and use in low temperatures

A novel admixture including an accelerator and a corrosion inhibitor, that accelerates the time required to set a concrete mixture at low temperature even in concrete containing a pozzolan such as fly ash. A suitable accelerator includes a mixture of a non-chloride type accelerator and a nitrite-based corrosion inhibitor.

Owner:TERZO LAWRENCE J

Self-consolidating geopolymer compositions and methods for making same

ActiveUS20200231503A1Improve liquidityImprove performanceSolid waste managementCement productionSulfatePhysical chemistry

Self-consolidating geopolymer compositions utilizing fly ash and inorganic mineral including alkaline earth metal oxide as cementitious reactive components and include cement set retarder. The alkaline earth metal oxide is preferably calcium oxide (also known as lime or quicklime) and / or magnesium oxide. The inorganic minerals including alkaline earth metal oxide have an alkaline earth metal oxide content preferably greater than 50 wt. %, more preferably greater than 60 wt. %, even more preferably greater than 70 wt. %, and most preferably greater than 80 wt. %, for example greater than 90 wt. %. The cementitious reactive powder may optionally also include one or more aluminous cements and one or more source of calcium sulfates. The cementitious reactive powders are activated with an alkali metal chemical activator selected from alkali metal salt and / or alkali metal base. Methods for making the compositions are also disclosed.

Owner:UNITED STATES GYPSUM CO

Method of making a gypsum slurry with modifiers and dispersants

In the method of making a gypsum slurry, a polycarboxylate-based dispersant, a modifier, and a hydraulic material including stucco are selected for use in the slurry. These components are then combined with water to form a slurry, wherein the modifier is added to the slurry before the slurry phase is formed from the water, the stucco, and the dispersant. It has been shown that the modifier will have less efficacy when added after the dispersant and the stucco have been contacted in the aqueous slurry. In a preferred embodiment, a quantity of stucco is obtained and the modifier and the dispersant are selected. A pre-dissolved solution of dispersant and modifier is prepared in water to form a solution prior to addition to the stucco. After mixing the solutions, the stucco is added to form the slurry. Optionally, the slurry is then shaped into a product and allowed to set.

Owner:USG CORP

Road engineering base course and soil road base polymer grouting material

The invention provides a road engineering base course and soil road base polymer grouting material. The material is characterized by comprising the following components in parts by weight: 100 parts of metallurgical slag, 30 parts of high-lime fly ash, 10 parts of metakaolin, 1-3 parts of thickening water-retaining agent, 30 parts of alkaline exciting agent and 2-4 parts of additive. The material has the advantages of quick setting, early strength, large fluidity and good permeability.

Owner:上海城西城建工程勘测设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com