Patents

Literature

30results about How to "Sufficient fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of making a gypsum slurry with modifiers and dispersants

InactiveUS20060280899A1Improved product set timeSufficient fluidityLayered productsThin material handlingSlurryGypsum

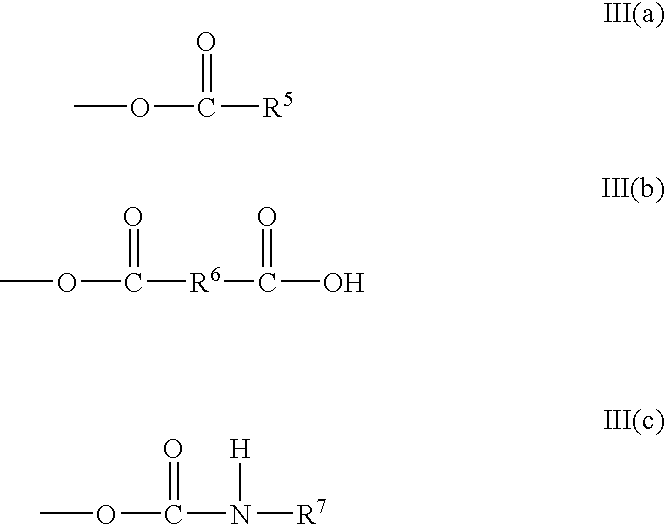

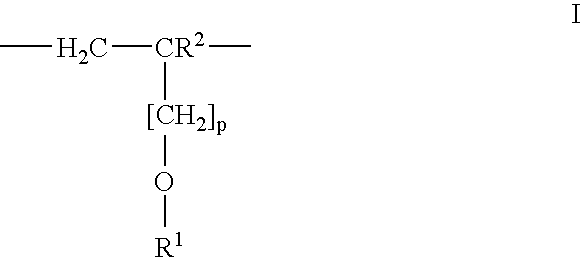

In a method of making a gypsum slurry, a polycarboxylate dispersant, a modifier and a hydraulic material comprising stucco are selected for use in the slurry. These components are then combined with water to form a slurry, where the modifier is added to the slurry prior to formation of a slurry phase by the water, the stucco and the dispersant. The modifier has been shown to be less effective when added after the dispersant and stucco have been contacted in an aqueous slurry. In a preferred embodiment, an amount of stucco is obtained and the modifier and dispersant are selected. A predissolved solution of a dispersant and modifier is prepared in water to form a solution prior to the addition of the stucco. After mixing the solution, the stucco is added to form the slurry. Optionally, the slurry is then shaped into a product and allowed to set.

Owner:UNITED STATES GYPSUM CO

Method of making a gypsum slurry with modifiers and dispersants

ActiveUS7572329B2Sufficient fluidityReduced dispersant dosagesCeramic shaping apparatusThin material handlingSlurryGypsum

In a method of making a gypsum slurry, a polycarboxylate dispersant, a modifier and a hydraulic material comprising stucco are selected for use in the slurry. These components are then combined with water to form a slurry, where the modifier is added to the slurry prior to formation of a slurry phase by the water, the stucco and the dispersant. The modifier has been shown to be less effective when added after the dispersant and stucco have been contacted in an aqueous slurry. In a preferred embodiment, an amount of stucco is obtained and the modifier and dispersant are selected. A predissolved solution of a dispersant and modifier is prepared in water to form a solution prior to the addition of the stucco. After mixing the solution, the stucco is added to form the slurry. Optionally, the slurry is then shaped into a product and allowed to set.

Owner:UNITED STATES GYPSUM CO

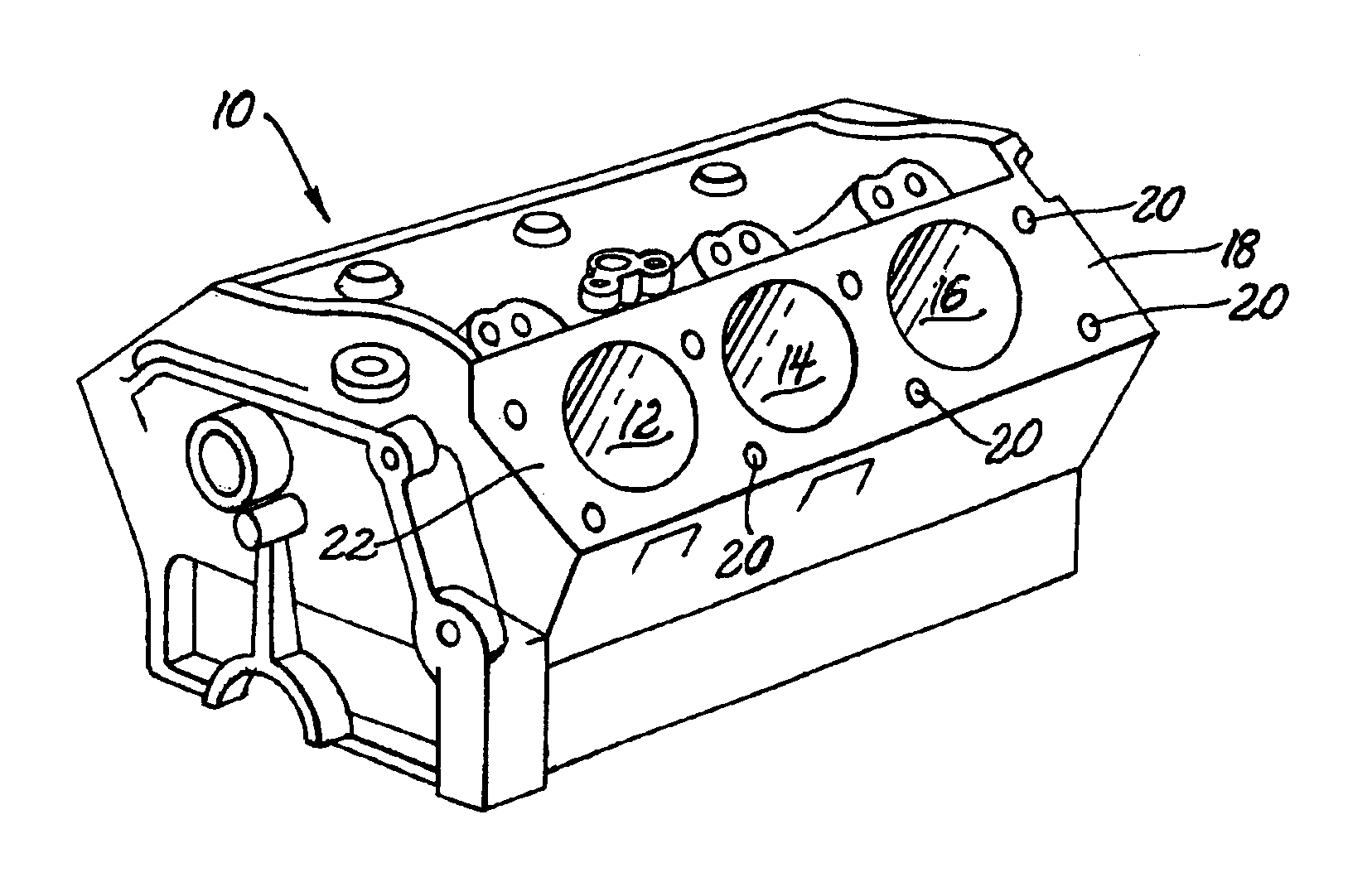

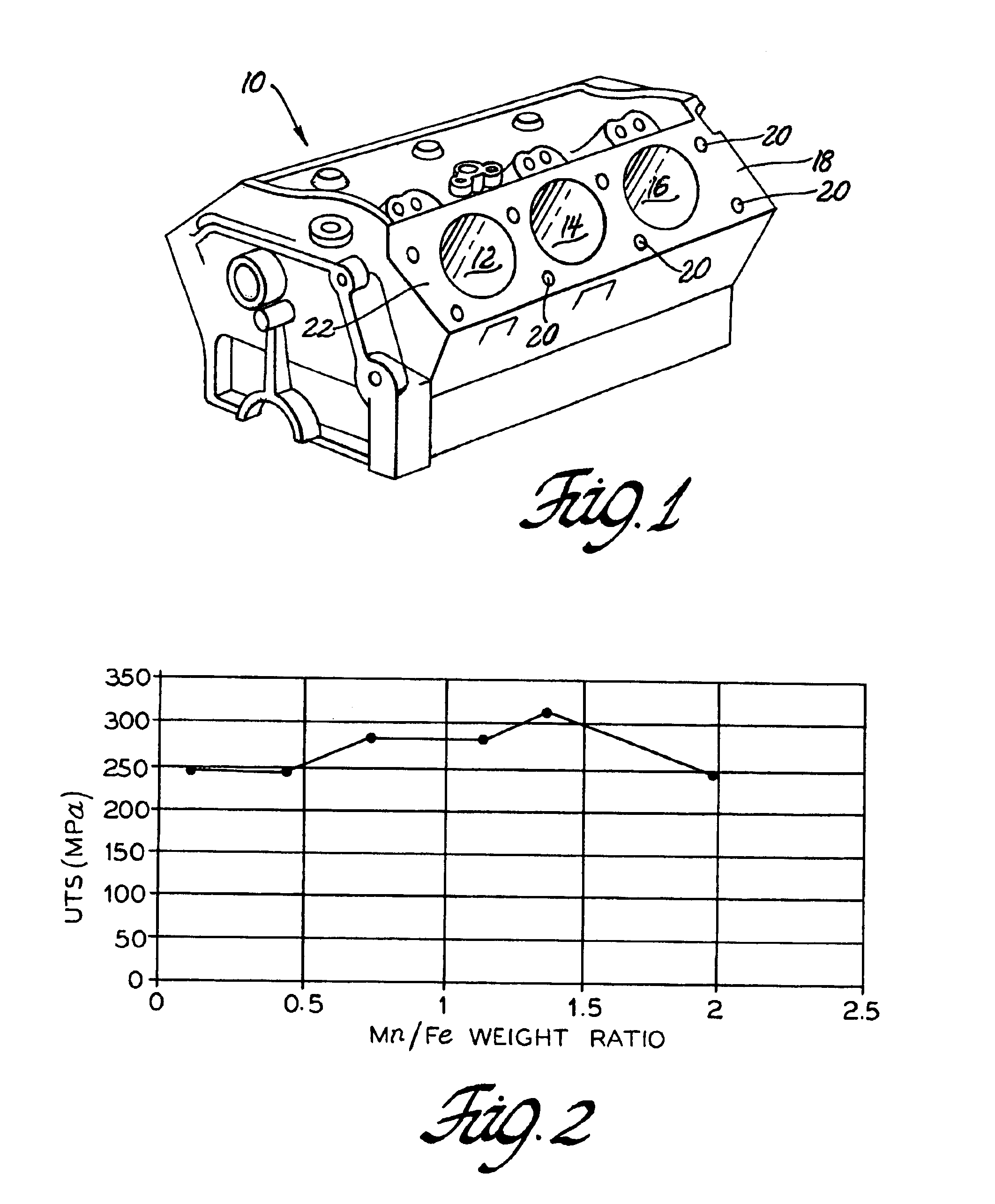

Aluminum alloy for engine blocks

An aluminum alloy is disclosed that is suitable for casting and machining cylinder blocks for engines, especially gasoline fuel engines for automotive vehicles. The casting has the strength and wear resistance to piston / seal scuffing for such engines. The alloy comprises, by weight, 9.5 to 12.5% silicon, 0.1 to 1.5% iron, 1.5 to 4.5% copper, 0.2 to 3% manganese, 0.1 to 0.6% magnesium, 2.0% max zinc, 0 to 1.5% nickel, 0.25% maximum titanium, up to 0.05% strontium and the balance aluminum, where the weight ratio of manganese to iron is 1.2 to 1.75 or higher when the iron content is equal to or greater than 0.4% and the weight ratio of manganese to iron is at least 0.6 to 1.2 when the iron content is less than 0.4% of the alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method of making a gypsum slurry with modifiers and dispersants

ActiveUS20060278135A1Improved product set timeSufficient fluidityCeramic shaping apparatusThin material handlingSlurryGypsum

In a method of making a gypsum slurry, a polycarboxylate dispersant, a modifier and a hydraulic material comprising stucco are selected for use in the slurry. These components are then combined with water to form a slurry, where the modifier is added to the slurry prior to formation of a slurry phase by the water, the stucco and the dispersant. The modifier has been shown to be less effective when added after the dispersant and stucco have been contacted in an aqueous slurry. In a preferred embodiment, an amount of stucco is obtained and the modifier and dispersant are selected. A predissolved solution of a dispersant and modifier is prepared in water to form a solution prior to the addition of the stucco. After mixing the solution, the stucco is added to form the slurry. Optionally, the slurry is then shaped into a product and allowed to set.

Owner:UNITED STATES GYPSUM CO

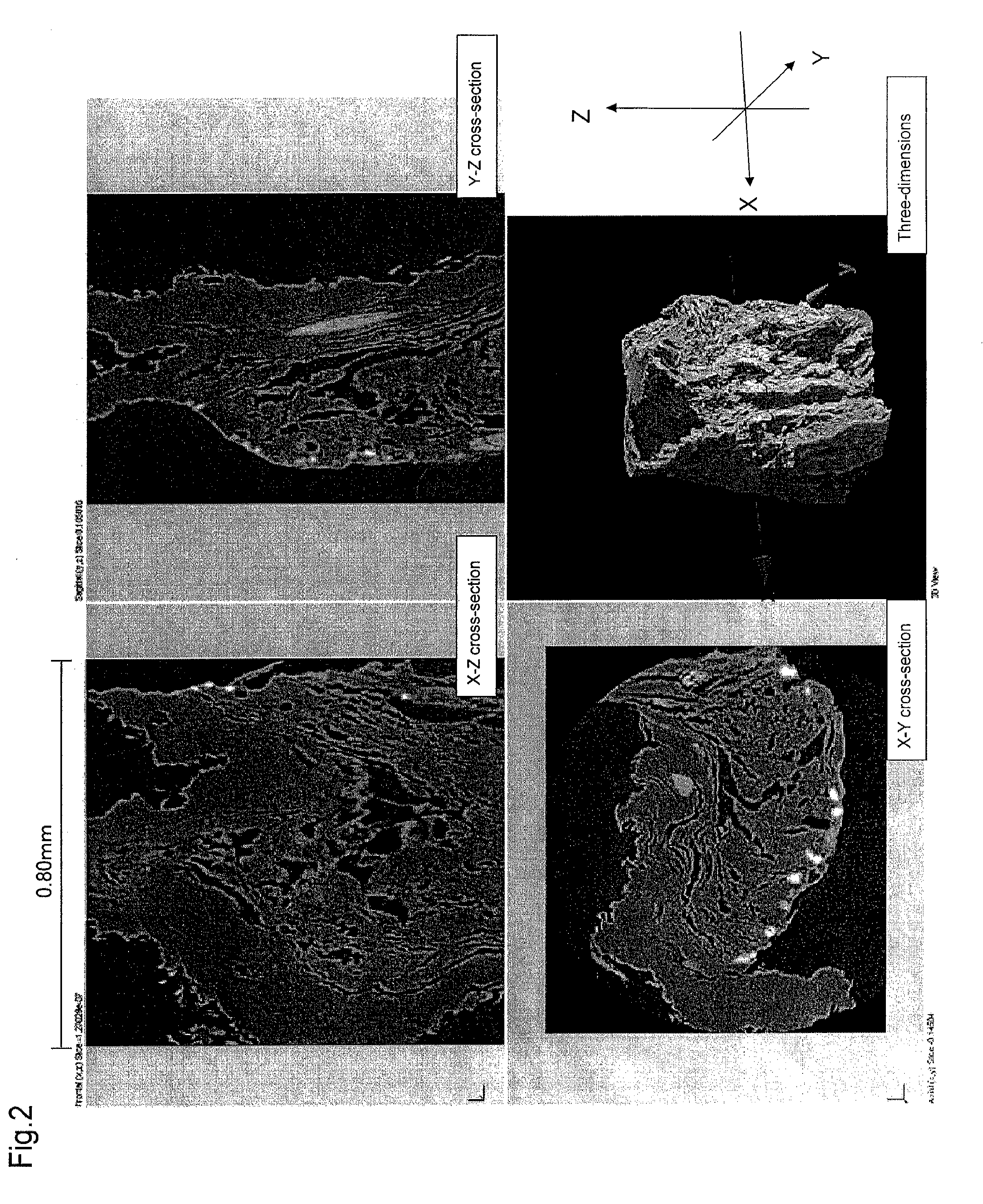

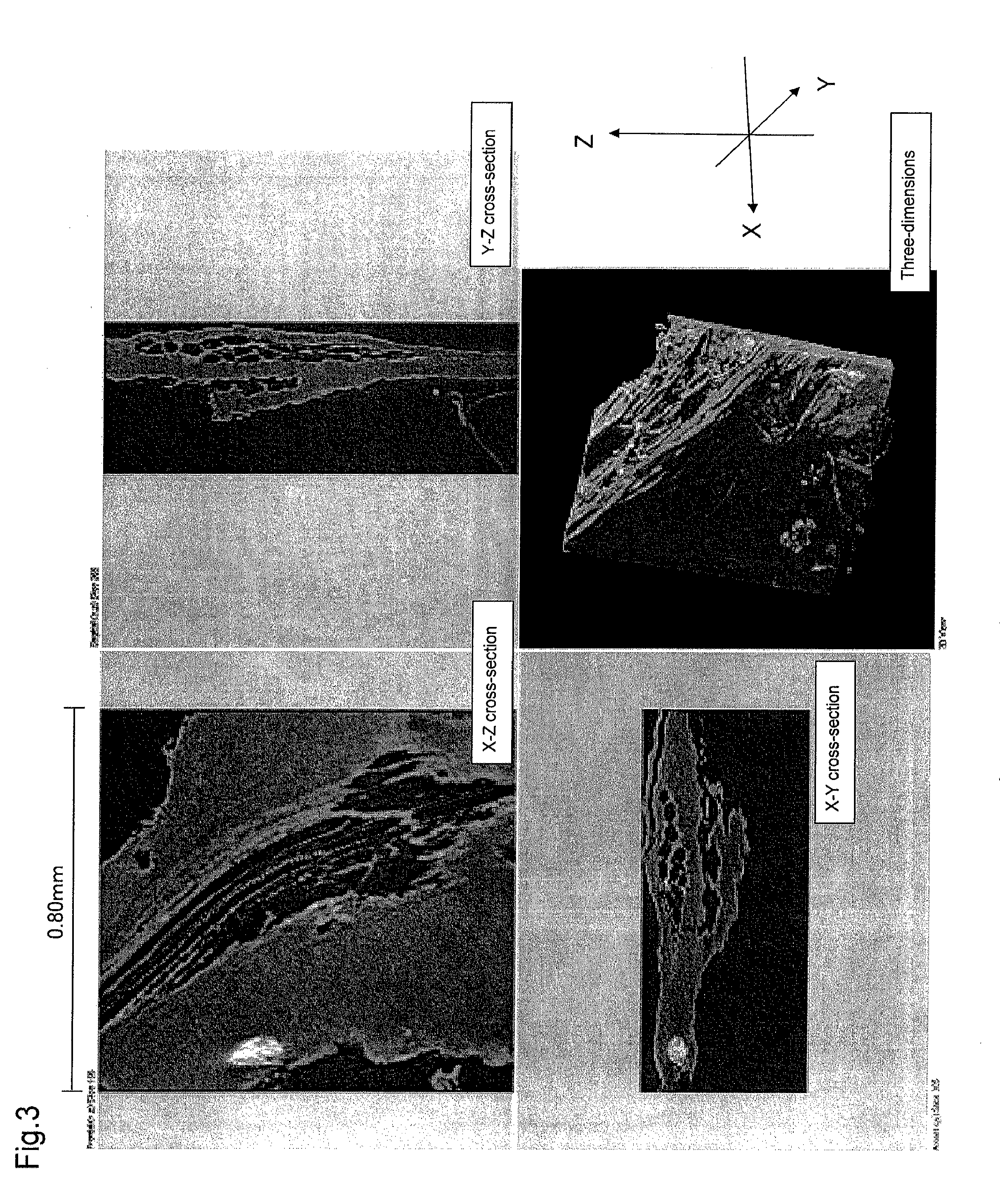

Three-dimensional periodic structure, three-dimensional periodic porous structure, and method for producing these

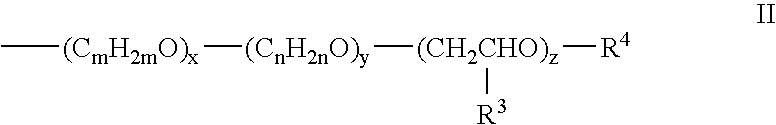

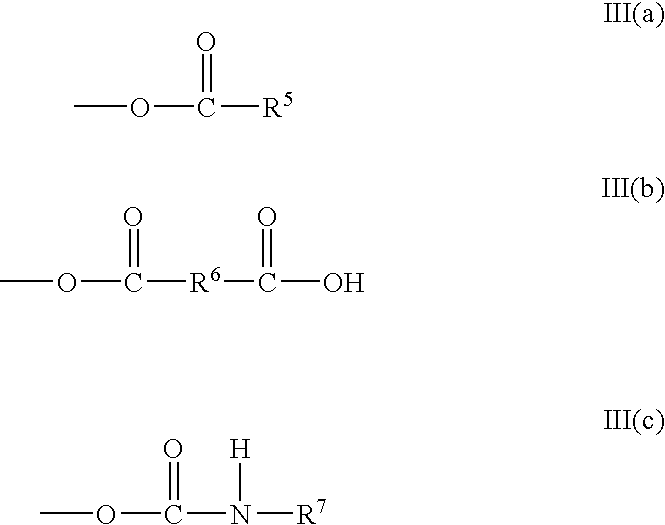

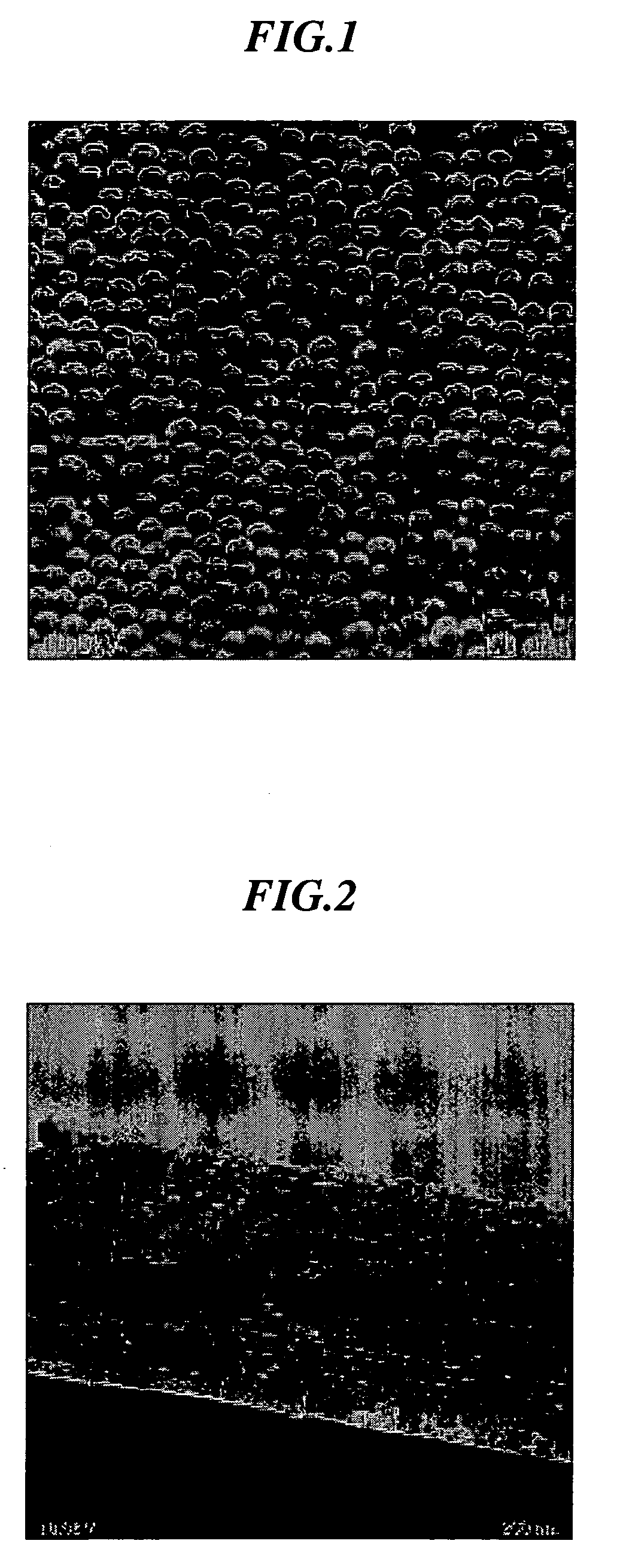

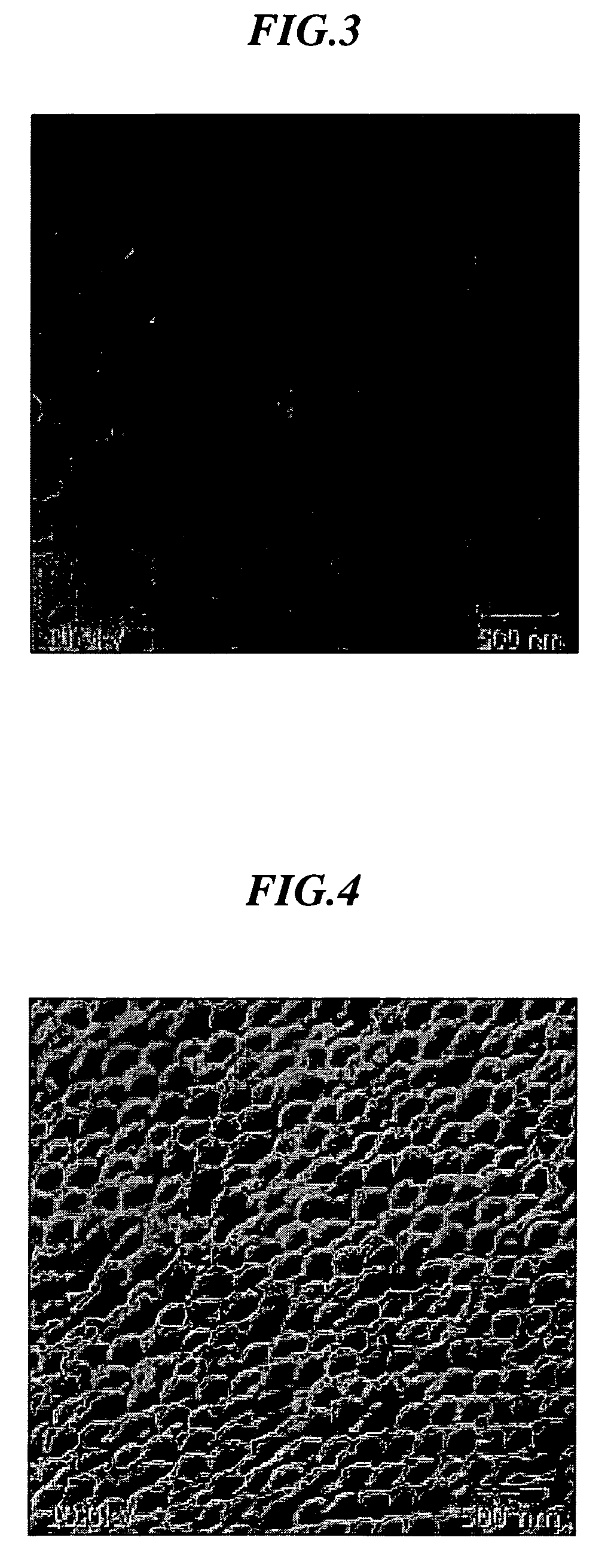

InactiveUS20060078736A1Robust and stableSimple designOptical filtersSynthetic resin layered productsBackbone chainCore shell

The three-dimensional periodic structure of the present invention comprises a matrix made of an inorganic oxides in which core-shell particles are disposed so as to contact with each other, the core-shell particles each comprising a core portion made of a fine particle and a shell portion made of a crosslinked hydrophilic organic polymer backbones, wherein the hydrophilic organic polymer backbones and the inorganic oxides hybridize into an organic / inorganic a composite.

Owner:KAWAMURA INST OF CHEM RES

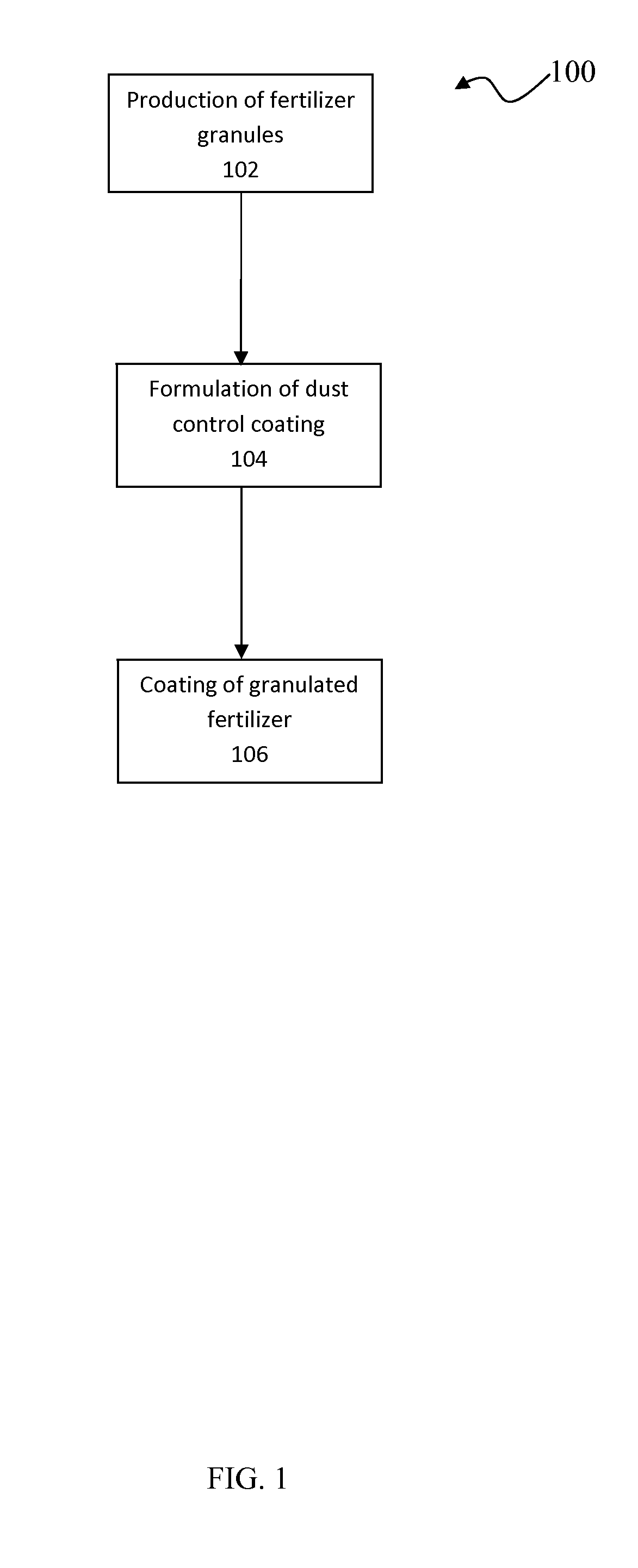

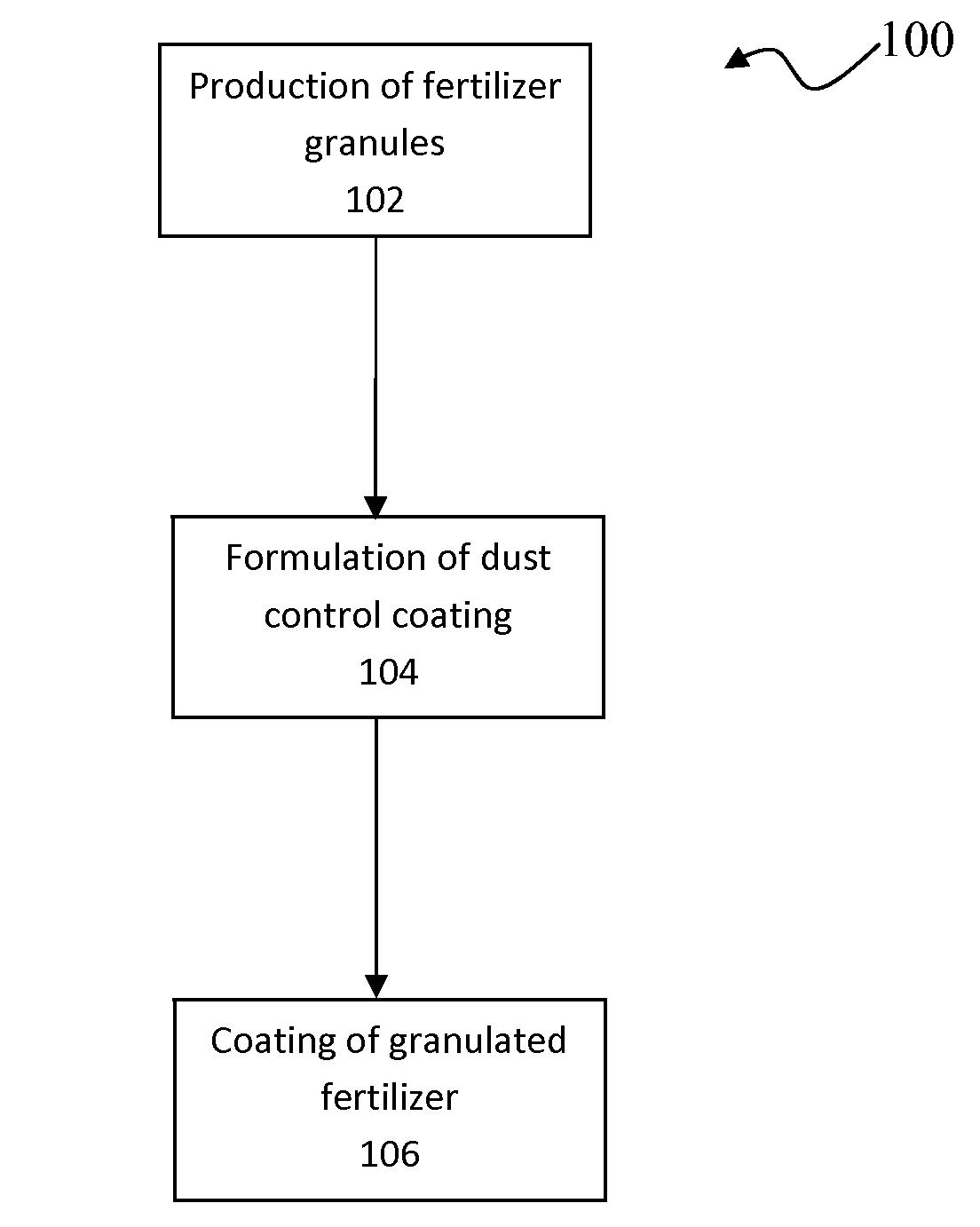

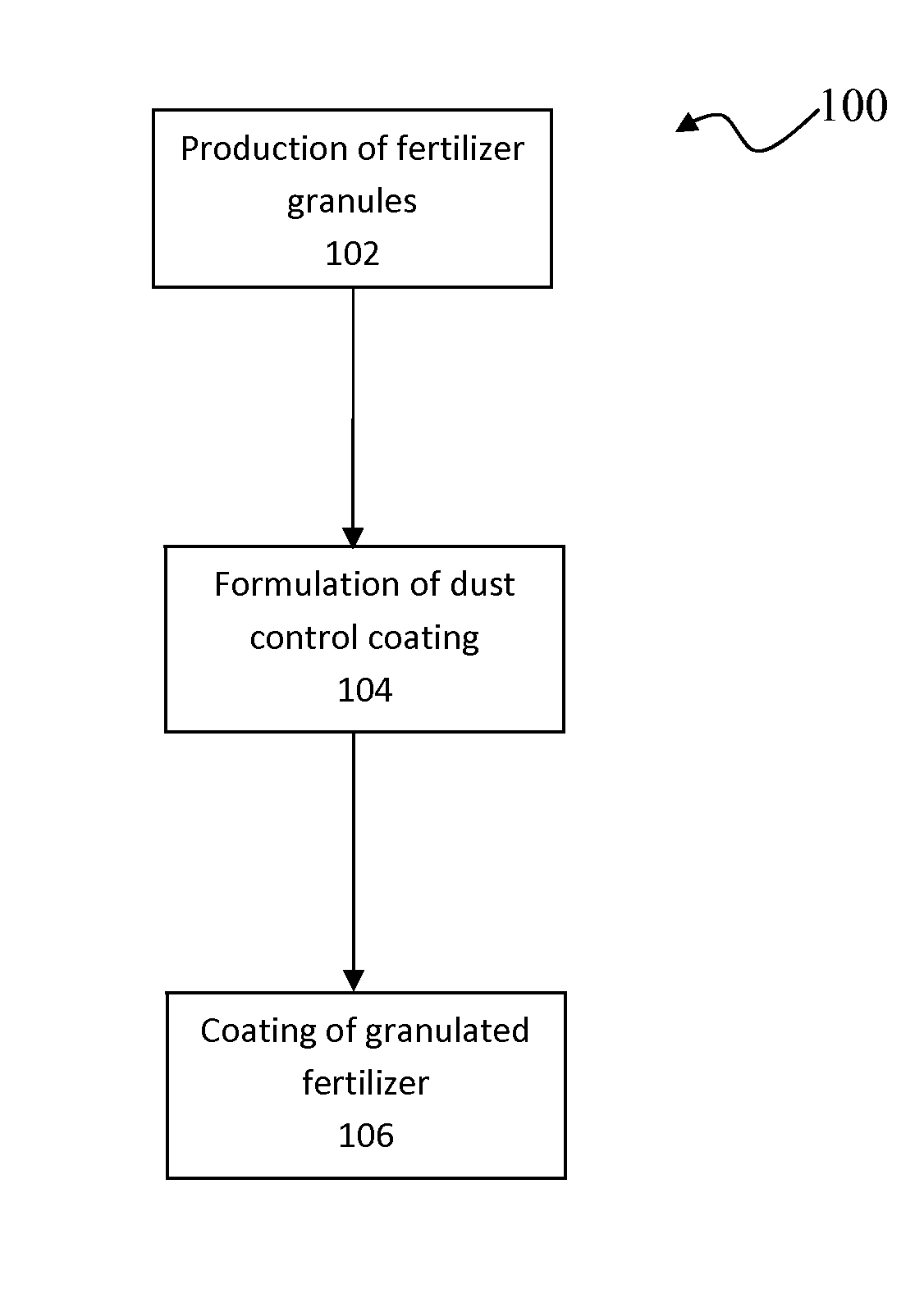

Granular fertilizers having improved dust control

InactiveUS20140137616A1Adequate dust controlHigh viscositySewage/sludge fertilisersUrea compound fertilisersParticulatesPolymer science

An oil-based coating for fertilizer granules impregnated with a polymer additive and related methods of applying the oil-based coating. The polymer additive can comprise homopolymers, copolymers, or combinations thereof, including polyethylene homopolymers. The polymer additive increases the viscosity of the oil-based coating, thereby increasing the duration for which the coating is capable of controlling or inhibiting the formation of dust particulates from the fertilizer granules.

Owner:THE MOSAIC COMPANY

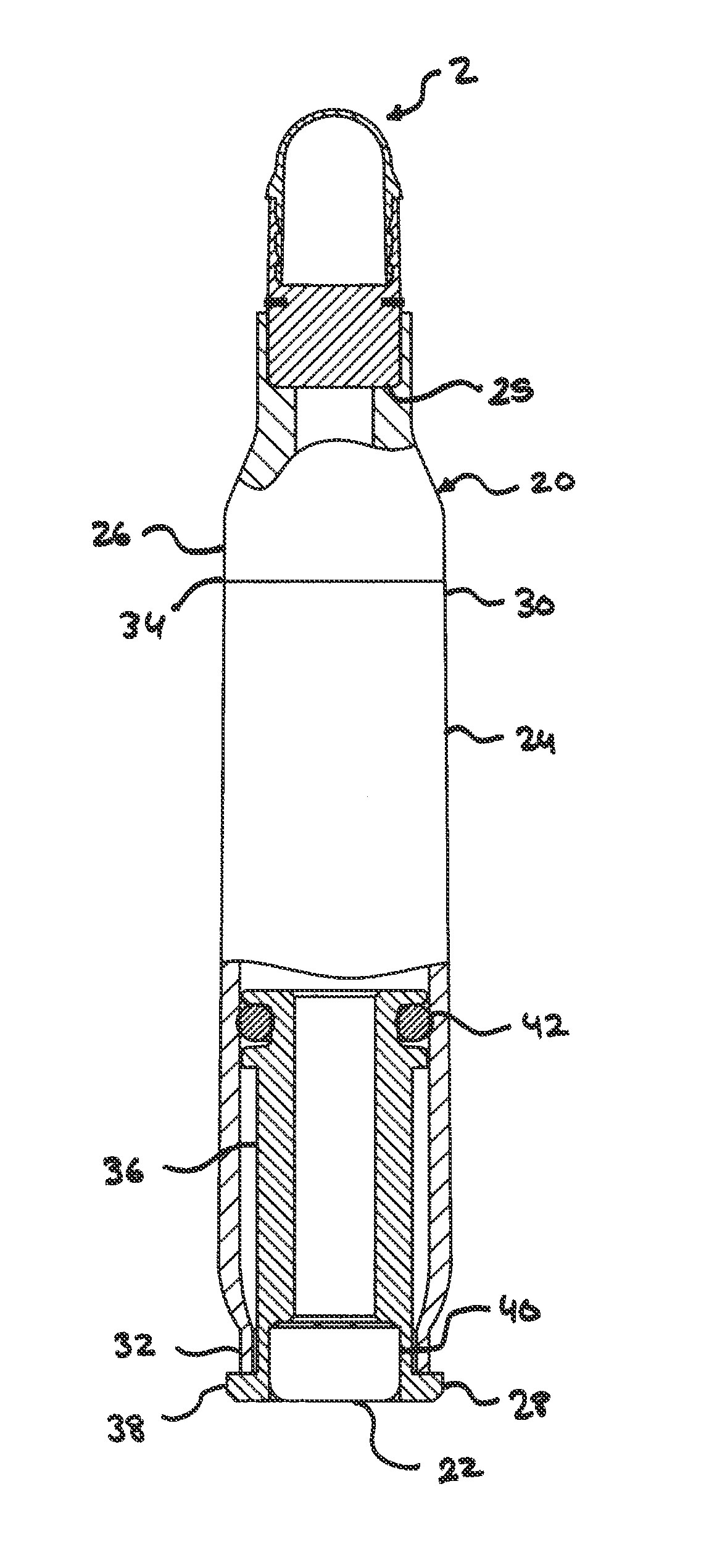

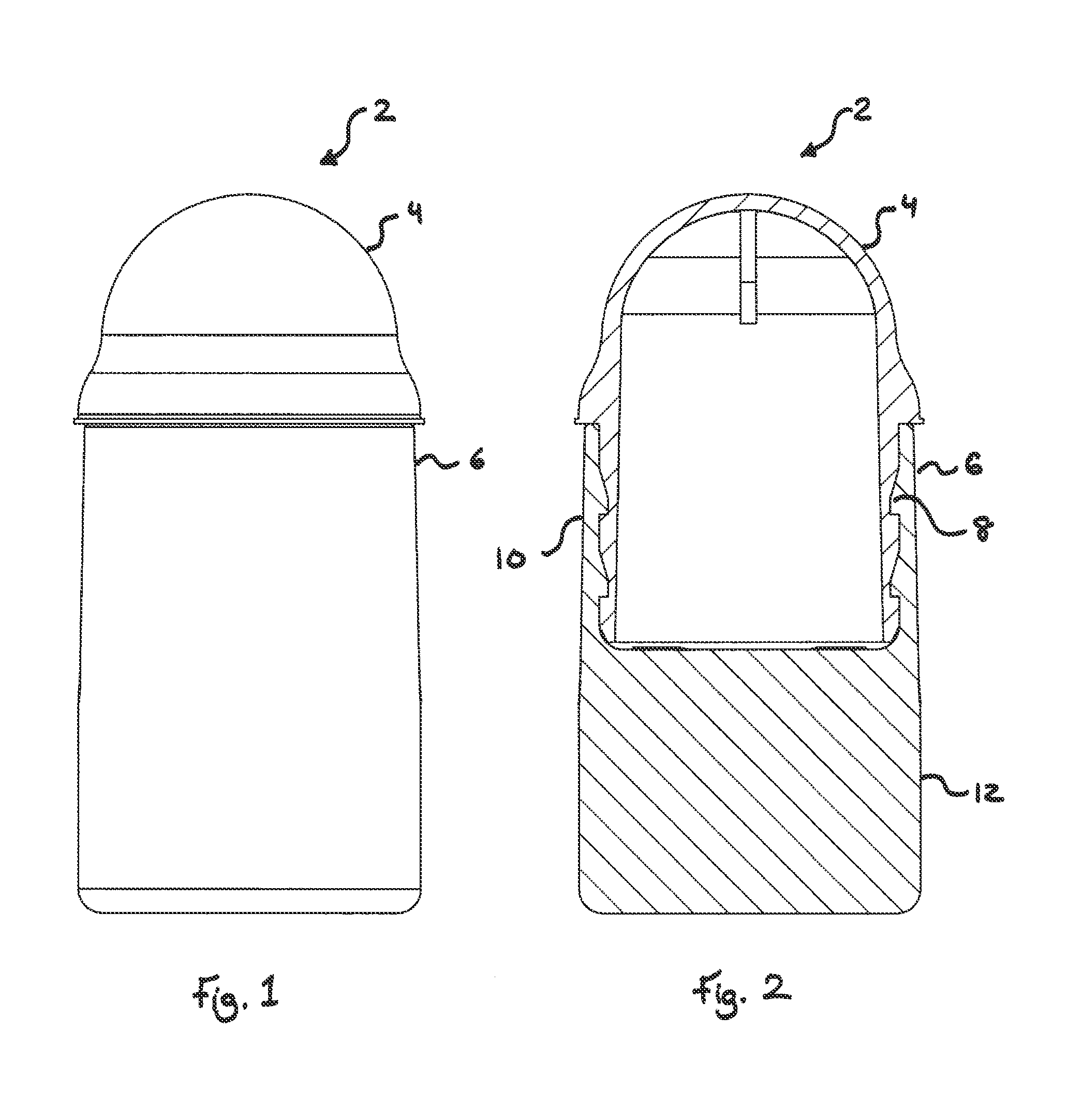

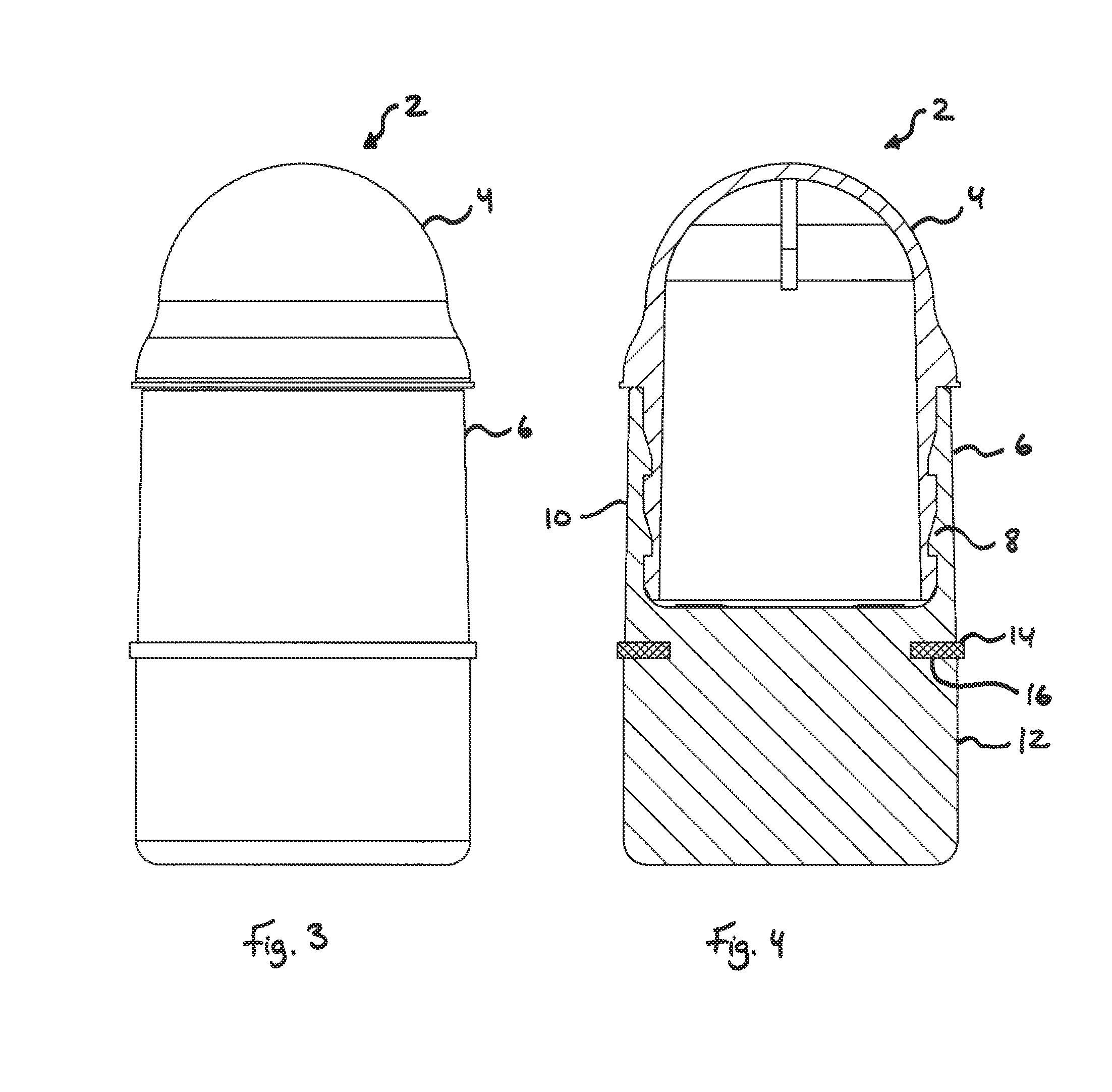

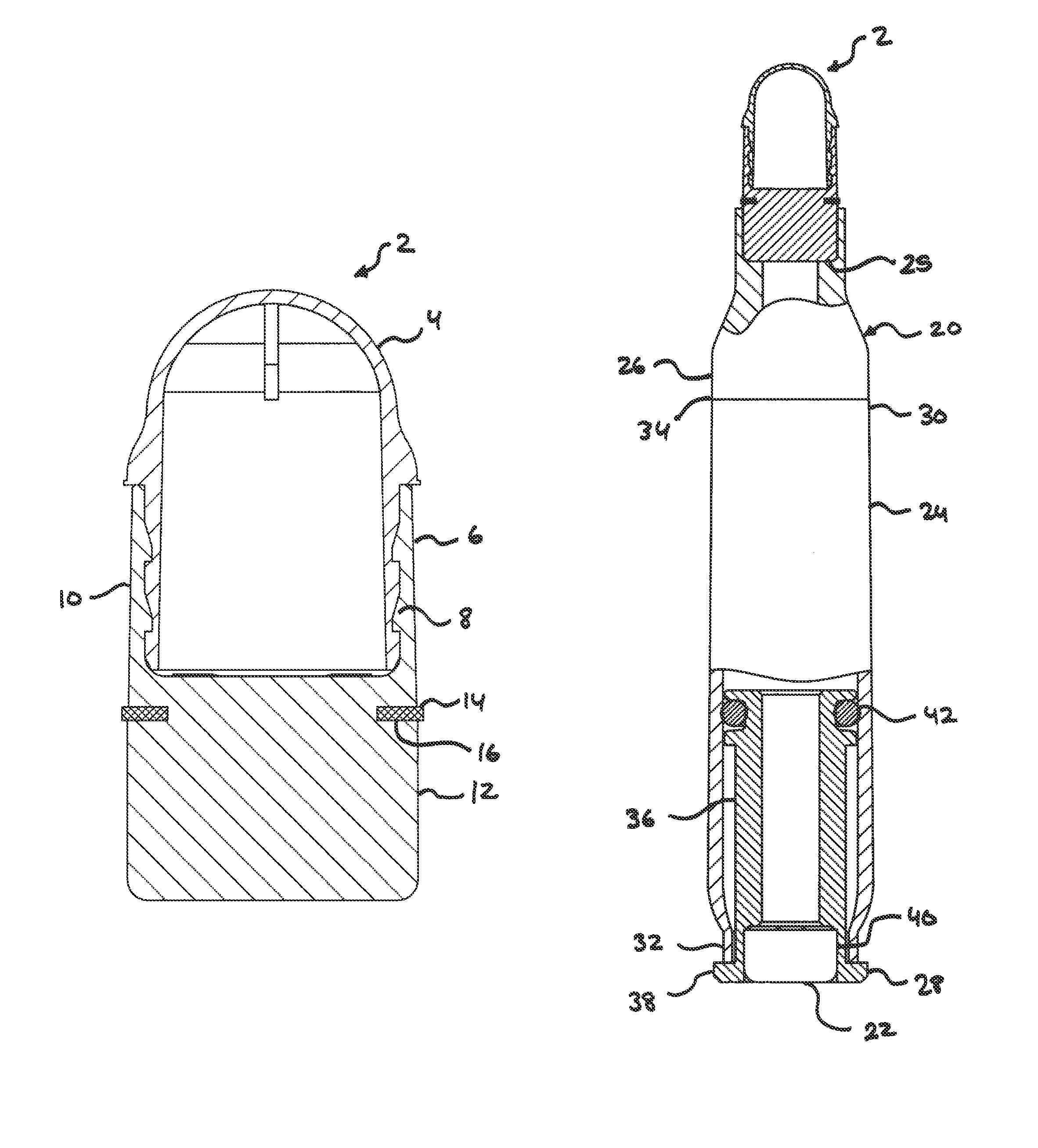

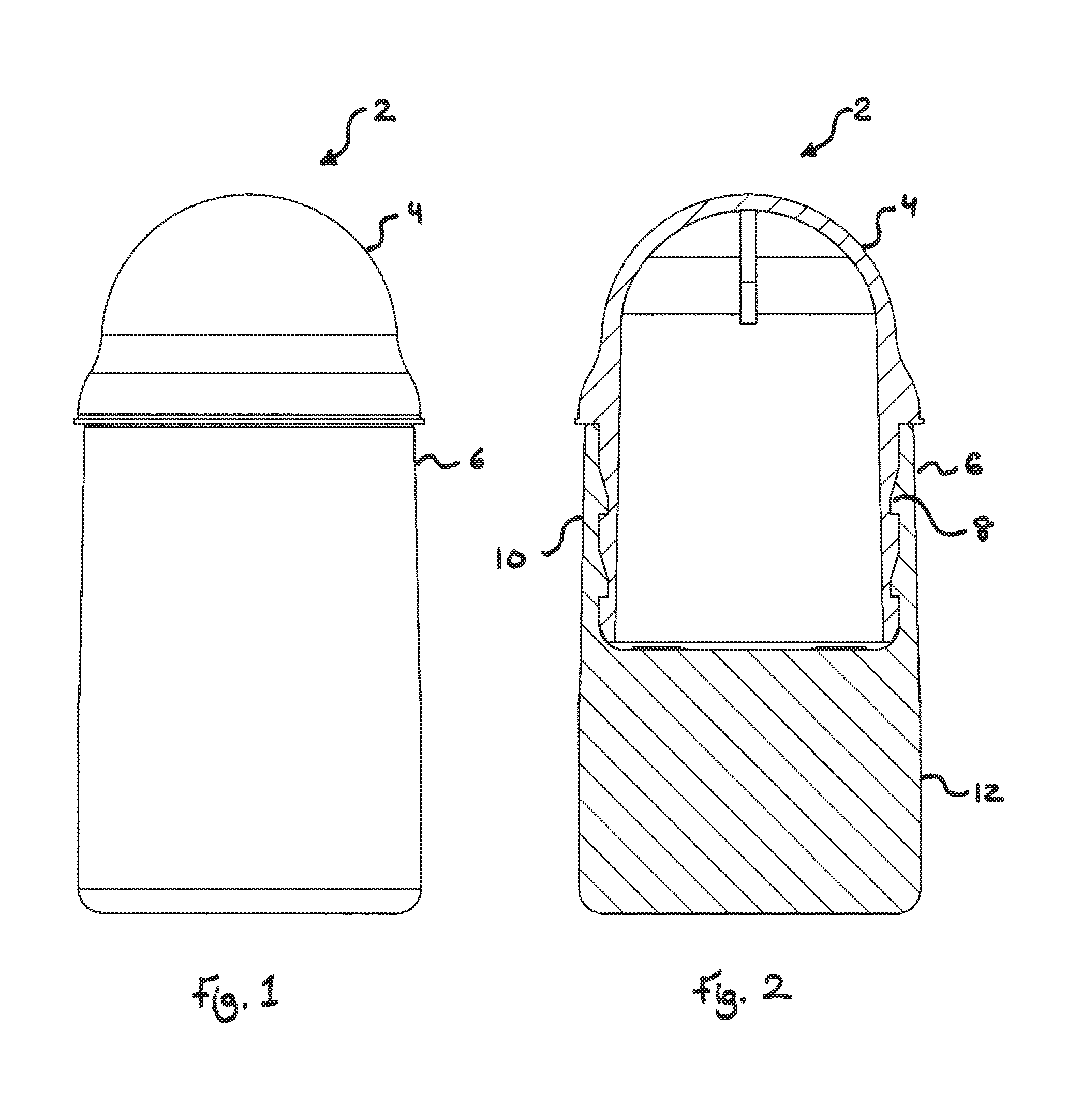

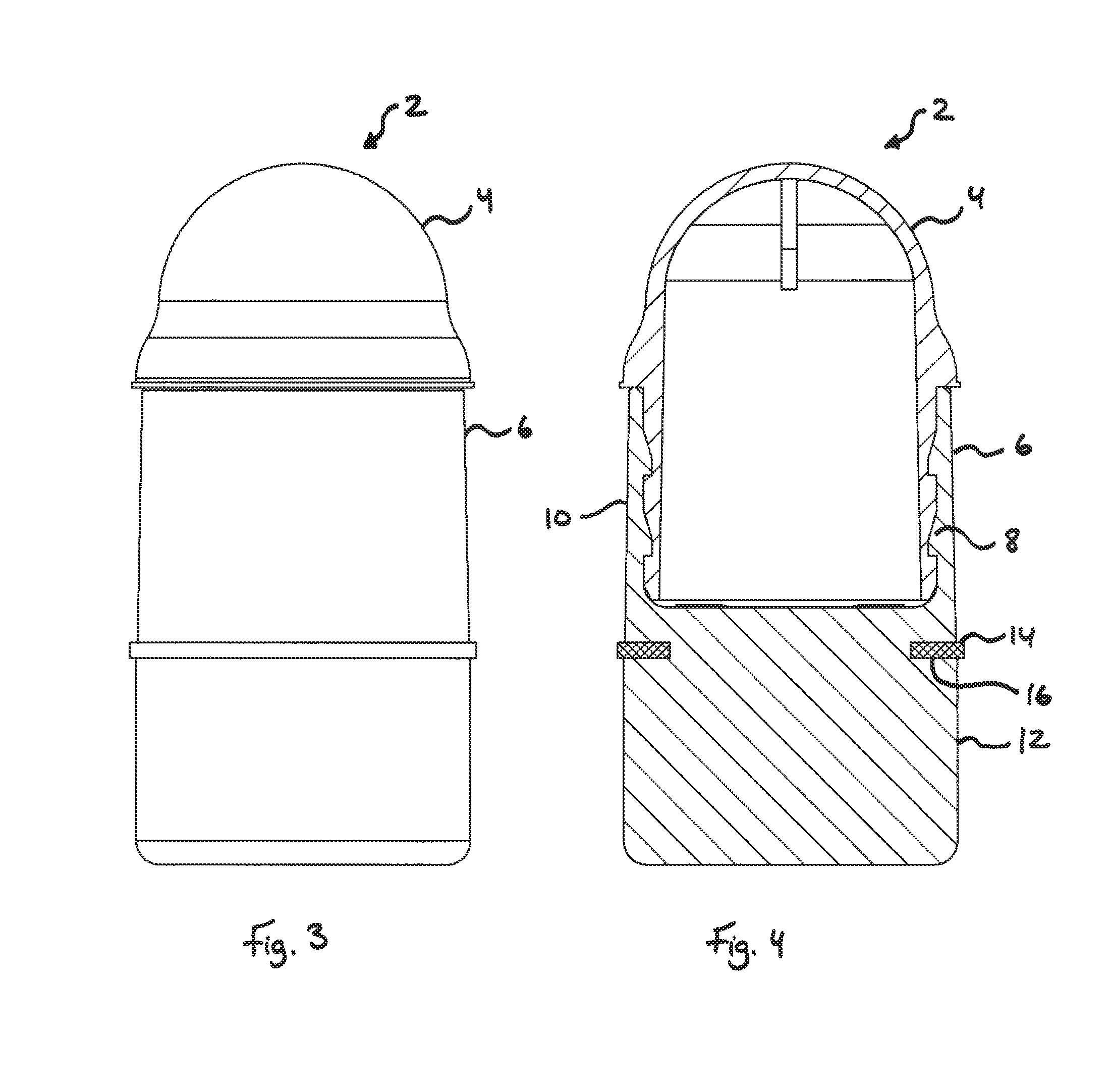

Spin-stabilized non-lethal projectile with a shear-thinning fluid

ActiveUS20140373745A1Reduce the amount requiredReduce momentumAmmunition projectilesTraining ammunitionEmulsionApparent viscosity

A non-lethal projectile having a shear-thinning fluid within an interior cavity. The shear-thinning fluid having a greater apparent viscosity at low shear rates to spin-stabilize the non-lethal projectile during flight and a lower apparent viscosity at a high shear rate corresponding with the shear-thinning fluid shearing against the frangible cap upon the non-lethal projectile striking the target, with the low viscosity of the shear-thinning fluid allowing proper dispersal upon impact with the target. The shear-thinning fluid can comprise a marking media and be in the form of an emulsion with less than about 50% liquid by volume to effectively disperse upon impact with the target.

Owner:GEN DYNAMICS ORDNANCE & TACTICAL SYST

High strength insulating metal-to-metal joints for solid oxide fuel cells and other high temperature applications and method of making

InactiveUS20060063057A1Sufficient fluidityDurable bondCooking-vessel materialsFinal product manufactureOperating environmentOxide

A seal formed between a metal part and a second part that will remain gas tight in high temperature operating environments which experience frequent thermal cycling, which is particularly useful as an insulating joint in solid oxide fuel cells. A first metal part is attached to a reinforcing material. A glass forming material in the positioned in between the first metal part and the second part, and a seal is formed between the first metal part and the second part by heating the glass to a temperature suitable to melt the glass forming materials. The glass encapsulates and bonds at least a portion of the reinforcing material, thereby adding tremendous strength to the overall seal. A ceramic material may be added to the glass forming materials, to assist in forming an insulating barrier between the first metal part and the second part and to regulating the viscosity of the glass during the heating step.

Owner:BATTELLE MEMORIAL INST

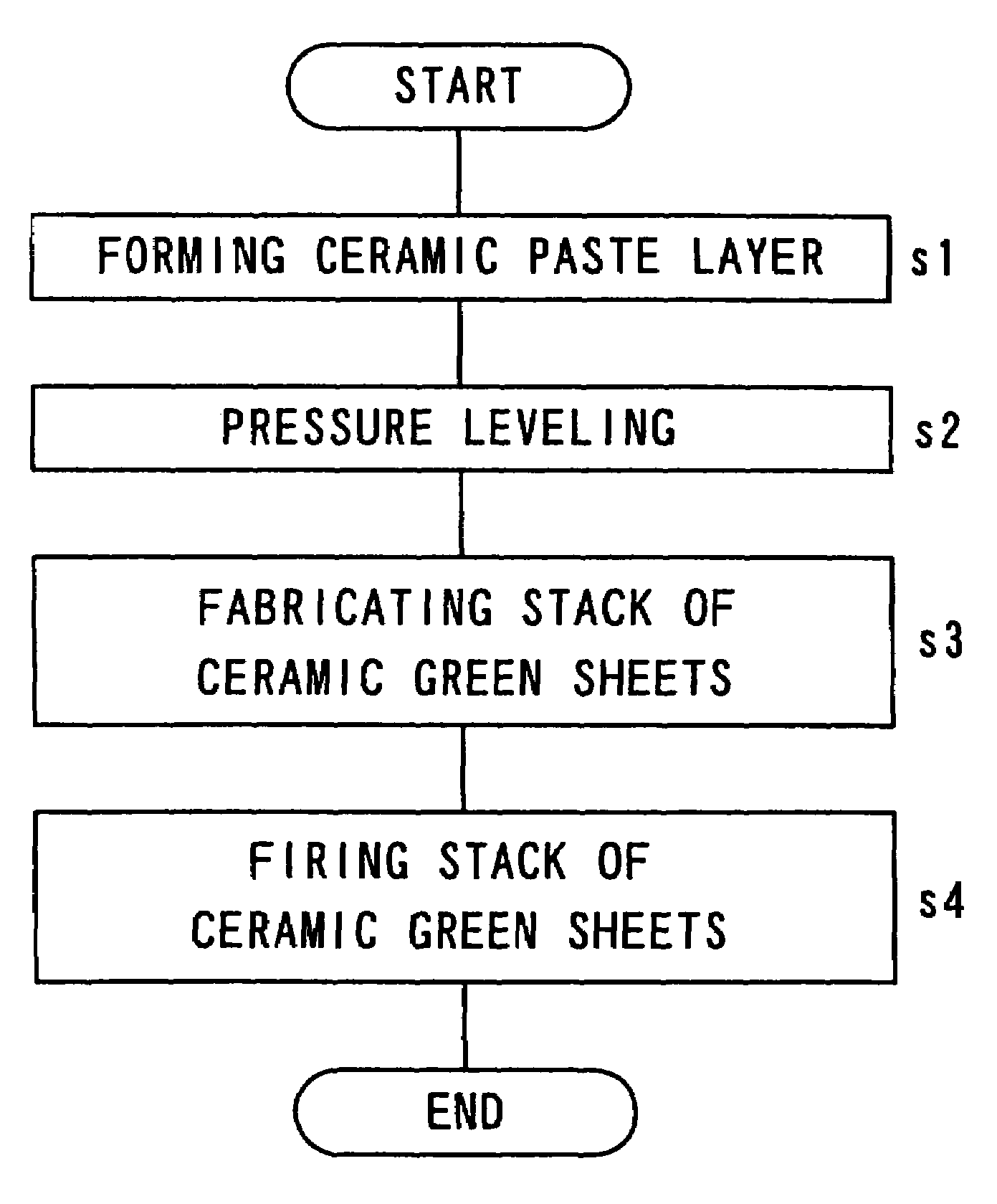

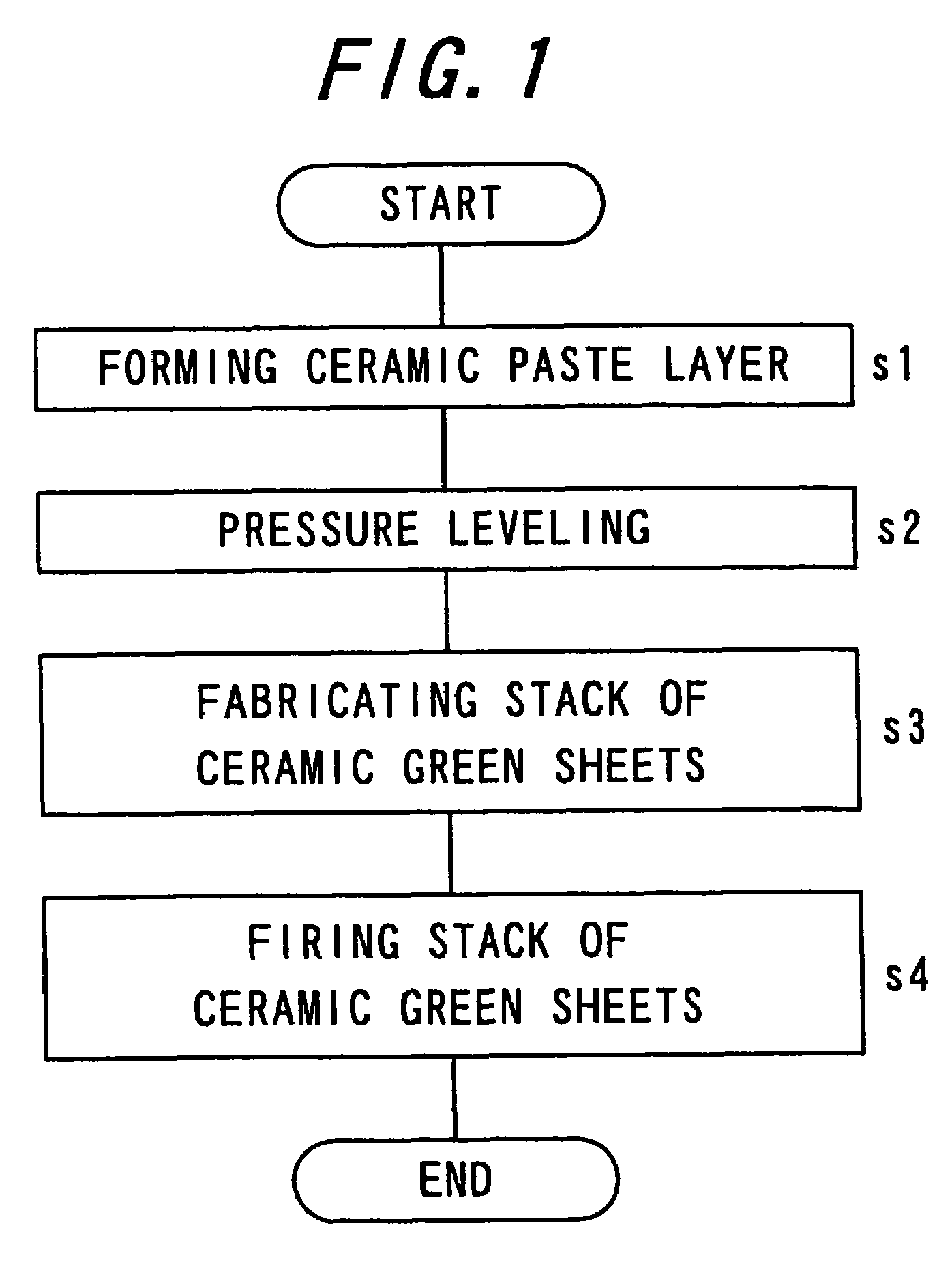

Method of manufacturing ceramic paste and ceramic multi-layer wiring substrate utilizing the same

InactiveUS7507682B2Sufficient fluidityAvoid deformationSemiconductor/solid-state device detailsPrinted circuit aspectsScreen printingCellulose

Owner:KYOCERA CORP

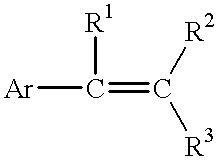

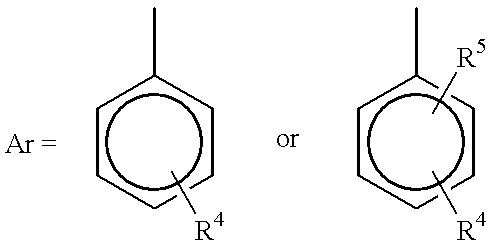

Process for reducing mono-functional and non-functional by-products during aralkylation of phenolics

Phenol aralkyistion polymers can be prepared by reaction among a phenolic monomer, at least one styrenic monomer and an aryl diolefin. A phenolic monomer can be initially aralkylated in the presence of an acid catalyst with a first portion of at least one styrenic monomer to obtain an aralkylated phenol. The aralkylated phenol thereafter can be reacted with an aryl diolefin to obtain a phenol aralkylation polymer. Optionally, (though preferably) the phenol aralkylation polymer is further aralkylated with a second portion of at least one styrenic monomer. By employing specific catalyst concentrations, reactant concentrations, reaction temperatures, and reaction times, the formation of mono-functional and non-functional by-products is substantially reduced.

Owner:GEORGIA PACIFIC CHEM LLC

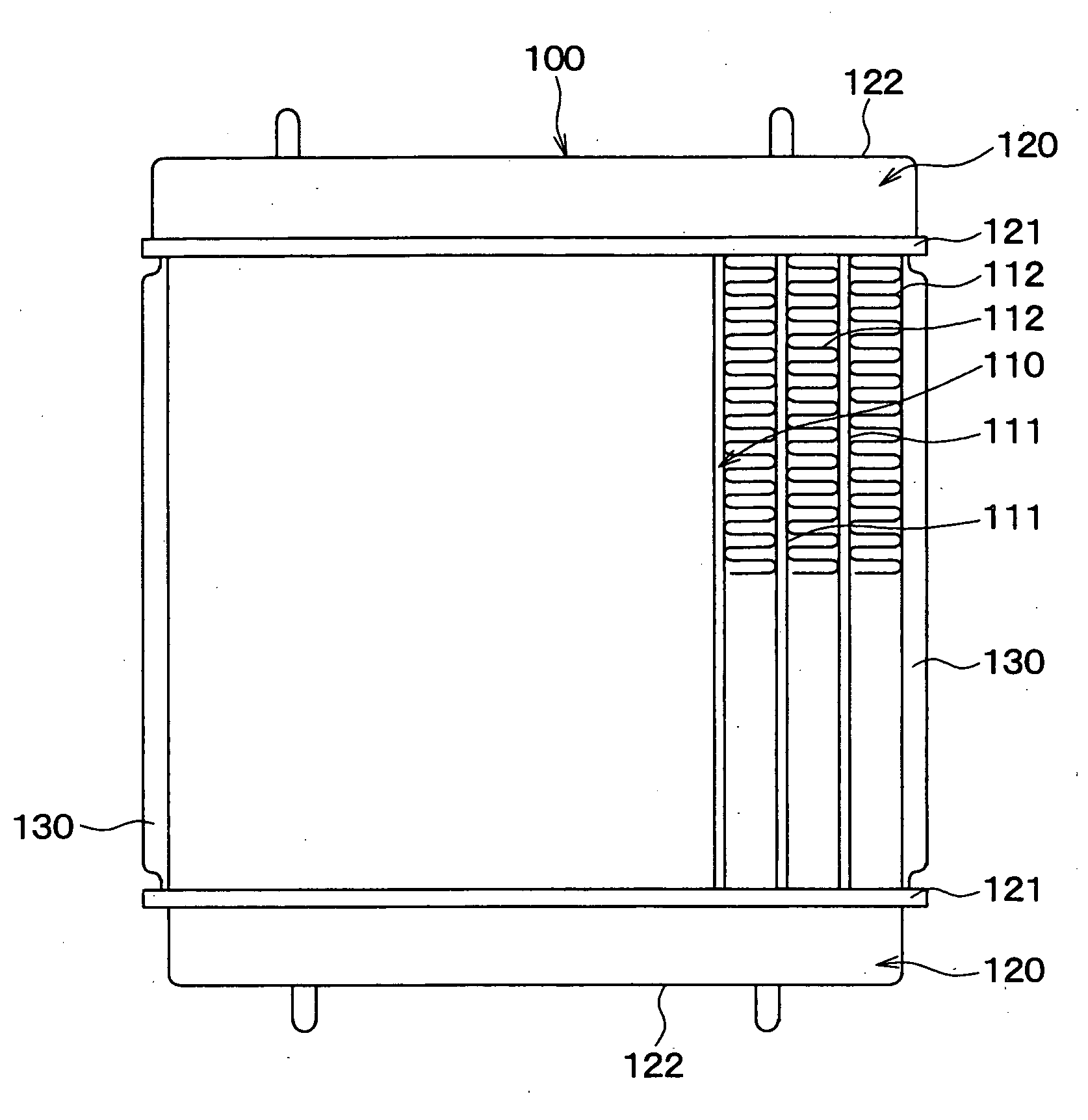

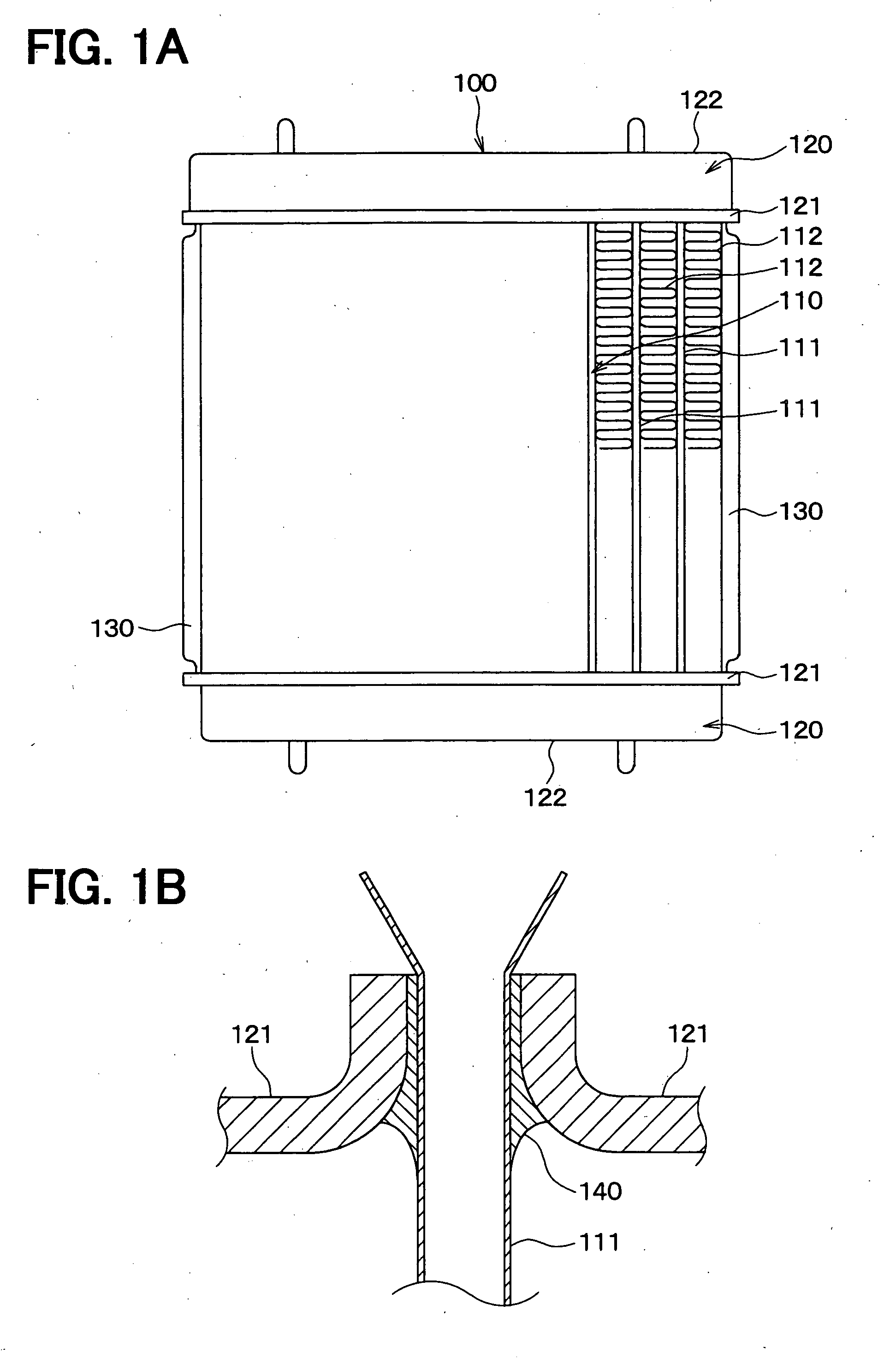

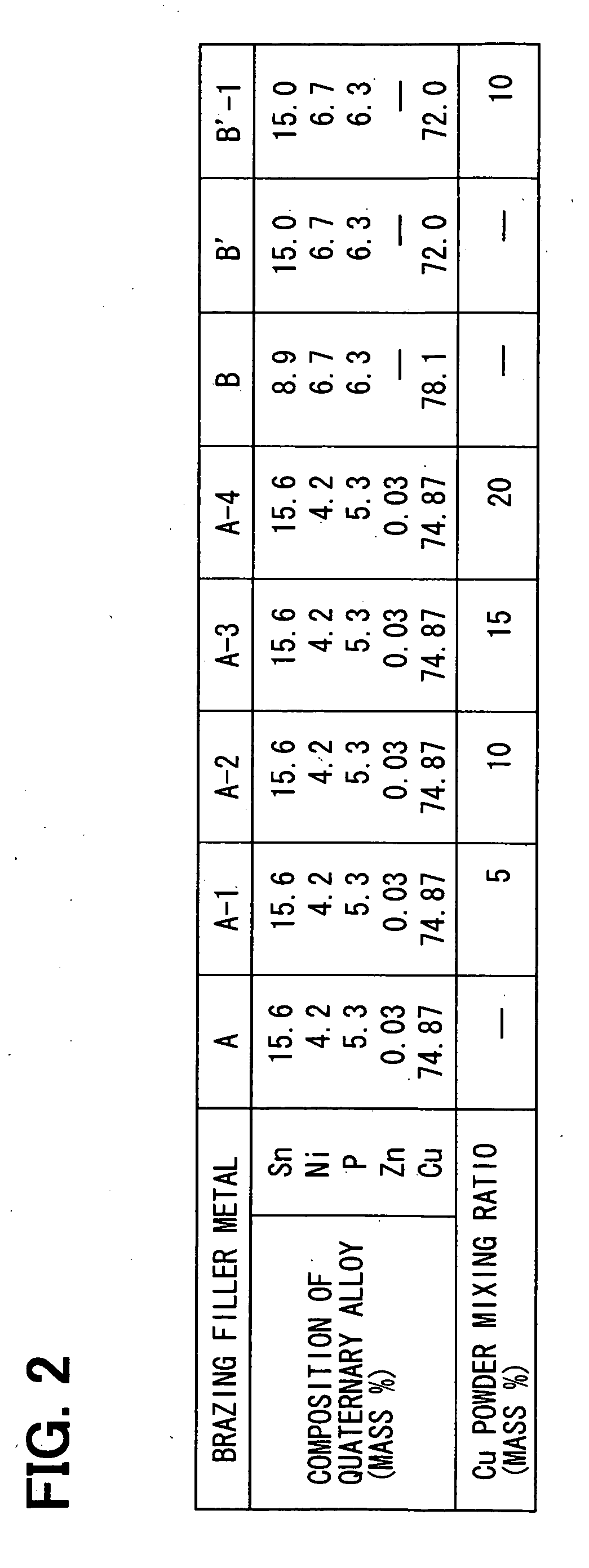

Brazing filler metal, brazing filler metal paste, and heat exchanger

InactiveUS20090297882A1Reduce tin contentImprove joint strengthWelding/cutting media/materialsThin material handlingOrganic solventPlate heat exchanger

A brazing filler metal includes quaternary alloy powder and copper powder. The quaternary allow powder consists of from 0.1 to 27.4 mass percent tin, from 0.8 to 5.1 mass percent nickel, from 2.2 to 10.9 mass percent phosphorous and a balance including copper and any unavoidable impurity. The brazing filler metal can be used in a form of paste by being mixed with an organic binder and an organic solvent. The brazing filler metal and the brazing filler metal can be used for joining members made of copper or copper alloy, such as members of a heat exchanger.

Owner:DENSO CORP +1

Spin-stabilized non-lethal projectile with a shear-thinning fluid

ActiveUS9470492B2Improve shelf-stability and performance characteristicImproves ballistic characteristicAmmunition projectilesTraining ammunitionEmulsionApparent viscosity

A non-lethal projectile having a shear-thinning fluid within an interior cavity. The shear-thinning fluid having a greater apparent viscosity at low shear rates to spin-stabilize the non-lethal projectile during flight and a lower apparent viscosity at a high shear rate corresponding with the shear-thinning fluid shearing against the frangible cap upon the non-lethal projectile striking the target, with the low viscosity of the shear-thinning fluid allowing proper dispersal upon impact with the target. The shear-thinning fluid can comprise a marking media and be in the form of an emulsion with less than about 50% liquid by volume to effectively disperse upon impact with the target.

Owner:GEN DYNAMICS ORDNANCE & TACTICAL SYST

Liquid resin composition, semi-conductor device, and process of fabricating the same

ActiveUS8106523B2Reduce wearEasy to handleSemiconductor/solid-state device detailsSolid-state devicesEngineeringPorous particle

A liquid resin composition for use as a sealing resin which reduces wear on a dicing blade or grinder employed for signularization or grinding. The liquid resin composition includes hollow and / or porous particles as a filler, and is adapted in use to be applied on a substrate constituting a semi-conductor device or electronic part.

Owner:MATSUSHITA ELECTRIC WORKS LTD

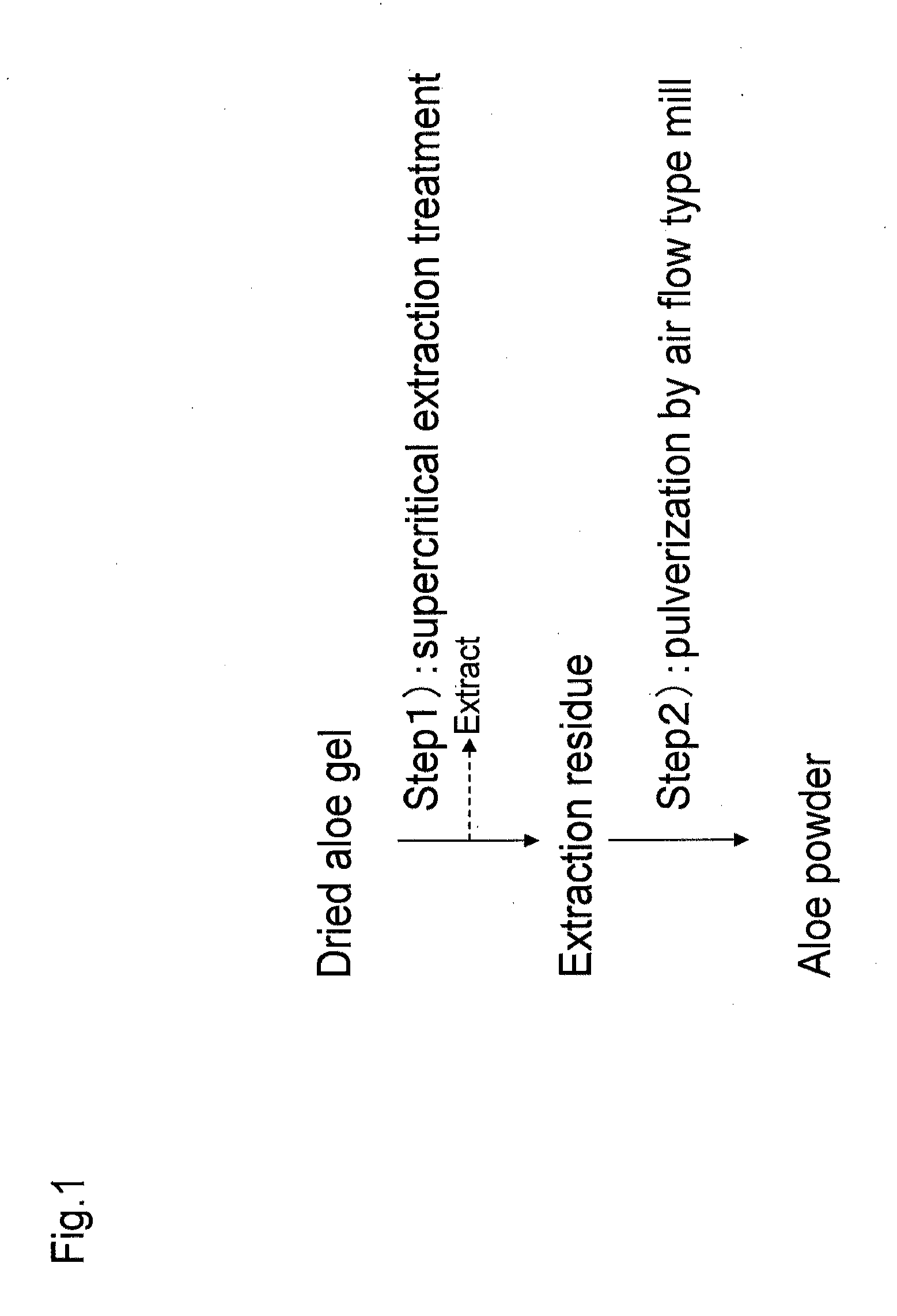

Method for manufacturing aloe powder

InactiveUS20120294913A1Efficient crushingEfficient productionCosmetic preparationsBiocideOrganic chemistryChemical engineering

A technique for efficiently performing pulverization of a dried aloe gel using an air flow type mill is provided. 1) A dried aloe gel is treated by supercritical extraction, an extract is removed from the dried aloe gel to obtain an extraction residue, and then 2) the extraction residue is pulverized with an air flow type mill to produce an aloe powder.

Owner:MORINAGA MILK IND CO LTD

Internal-Olefin Composition and Base Oil Comprising the Composition for Oil Drilling

ActiveUS20070270315A1Good choicePromote degradationFluid removalDrilling compositionOil drillingBase oil

The present invention provides an internal olefin composition comprising a mixture of 60 to 80% by mass of an olefin having 16 carbon atoms and 40 to 20% by mass of an olefin having 18 carbon atoms wherein a content of an α-olefin in the mixture is 10% by mass or less, and a content of a branched olefin in the mixture is 10% by mass or less, which has a good biodegradability even when discharged into the environments, a less toxicity against marine organisms, etc., and a sufficient fluidity when used as a base oil for oil drilling, etc.

Owner:IDEMITSU KOSAN CO LTD

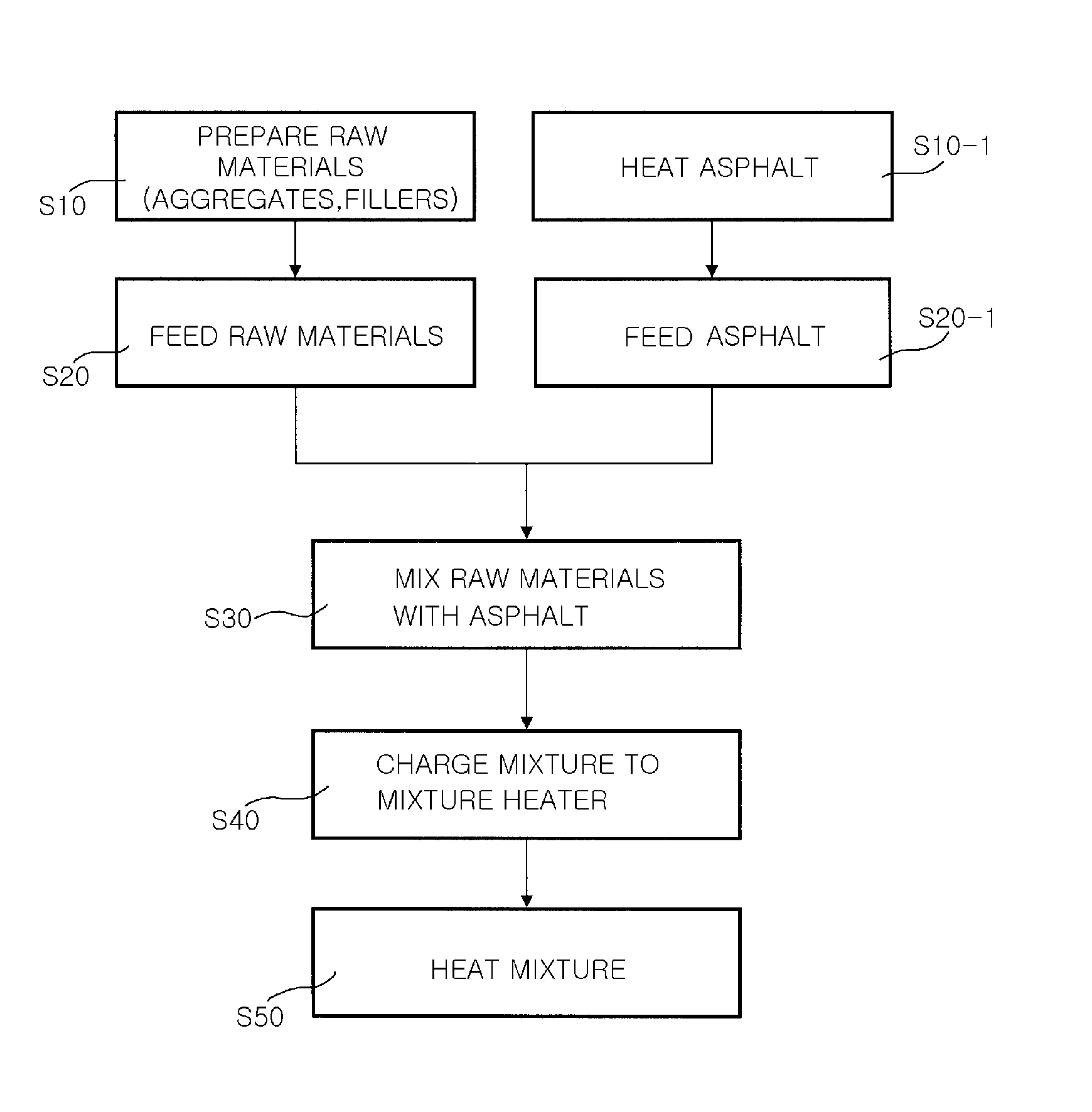

High Strength Ascon Composition Comprising Slag Ball and Method for Producing the Same

InactiveUS20070240611A1Easy to implementSufficient fluiditySolid waste managementBuilding insulationsSlagHigh intensity

Provided are ASCON utilizing atomized slag as fine aggregates and a method for producing the same. More particularly, provided are ASCON composition that is improved in strength by substituting all or part of fine aggregates for atomized slag and a method for producing the same. ASCON composition includes coarse aggregates, fine aggregates, fillers, and asphalt. When the fine aggregates is 100 parts by weight, the fine aggregates include 0-70 parts by weight of atomized slag balls having a diameter of less than 5mm. Accordingly, it is possible to obtain the ASCON composition that has large strength and can greatly reduce a heating temperature in the mixing operation.

Owner:UNECO CO LTD

Internal-olefin composition and base oil comprising the composition for oil drilling

ActiveUS7718580B2Promote degradationLess toxicityFluid removalDrilling compositionOil drillingBase oil

The present invention provides an internal olefin composition comprising a mixture of 60 to 80% by mass of an olefin having 16 carbon atoms and 40 to 20% by mass of an olefin having 18 carbon atoms wherein a content of an α-olefin in the mixture is 10% by mass or less, and a content of a branched olefin in the mixture is 10% by mass or less, which has a good biodegradability even when discharged into the environments, a less toxicity against marine organisms, etc., and a sufficient fluidity when used as a base oil for oil drilling, etc.

Owner:IDEMITSU KOSAN CO LTD

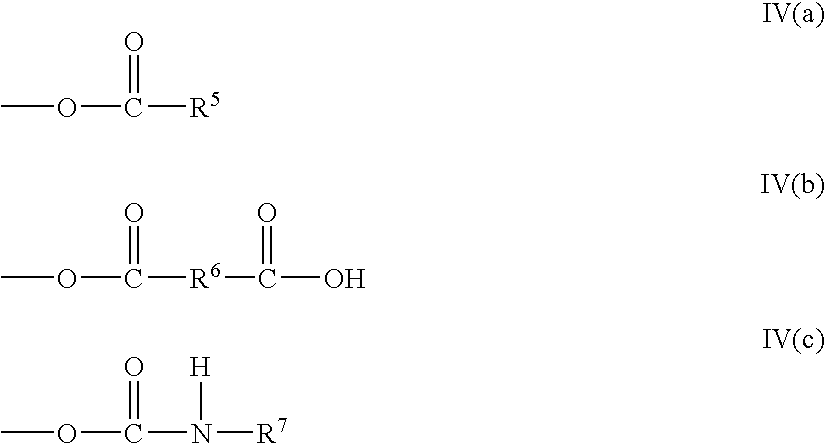

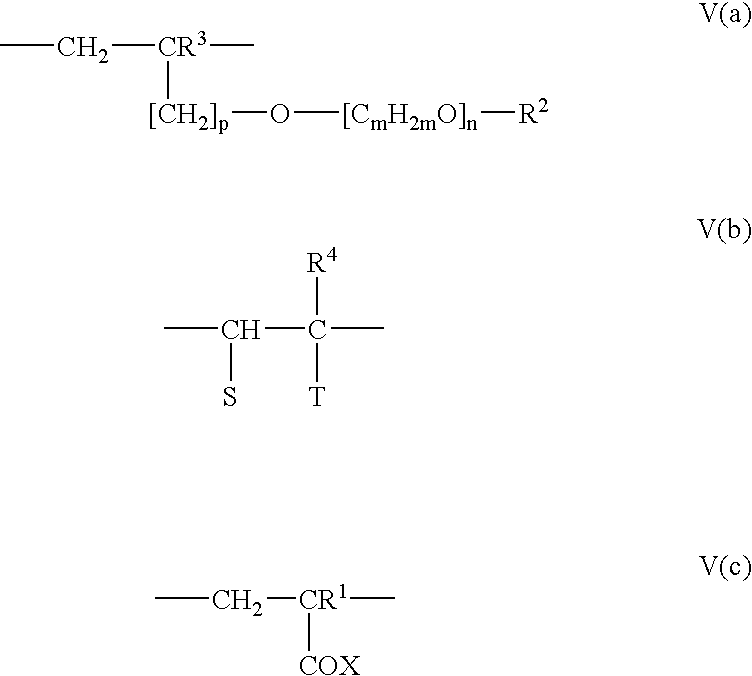

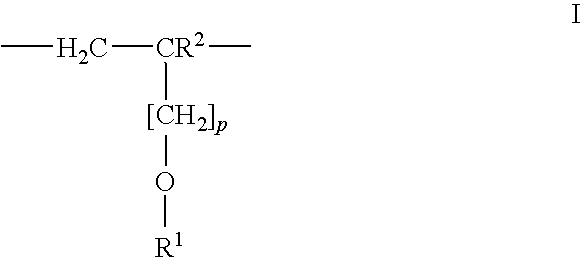

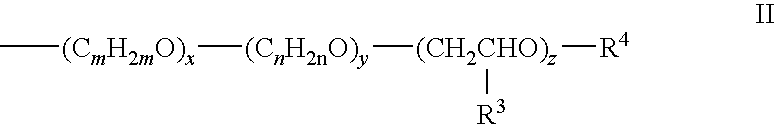

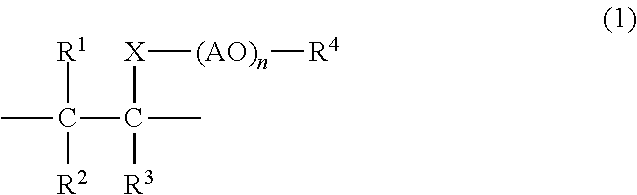

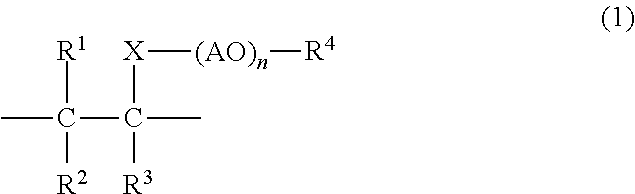

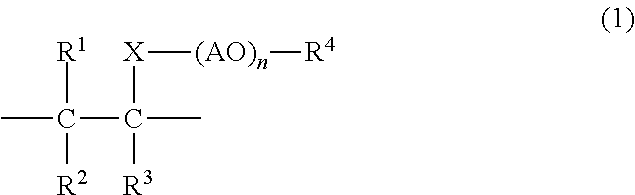

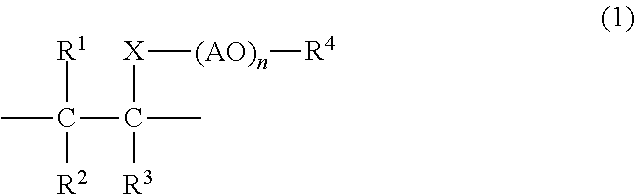

Gypsum dispersant

There is provided a gypsum dispersant and a gypsum additive that improve the fluidity of gypsum slurry even if gypsum raw materials used are different in quality and that do not induce delay of curing of gypsum slurry. A gypsum dispersant, including: (A) a polycarboxylic acid polymer; and (B) a polyamide polyamine obtained by a reaction of a polyalkylene polyamine and a dibasic acid as essential components, and / or an alkylene oxide adduct of the polyamide polyamine.

Owner:YOSHINO GYPSUM CO LTD

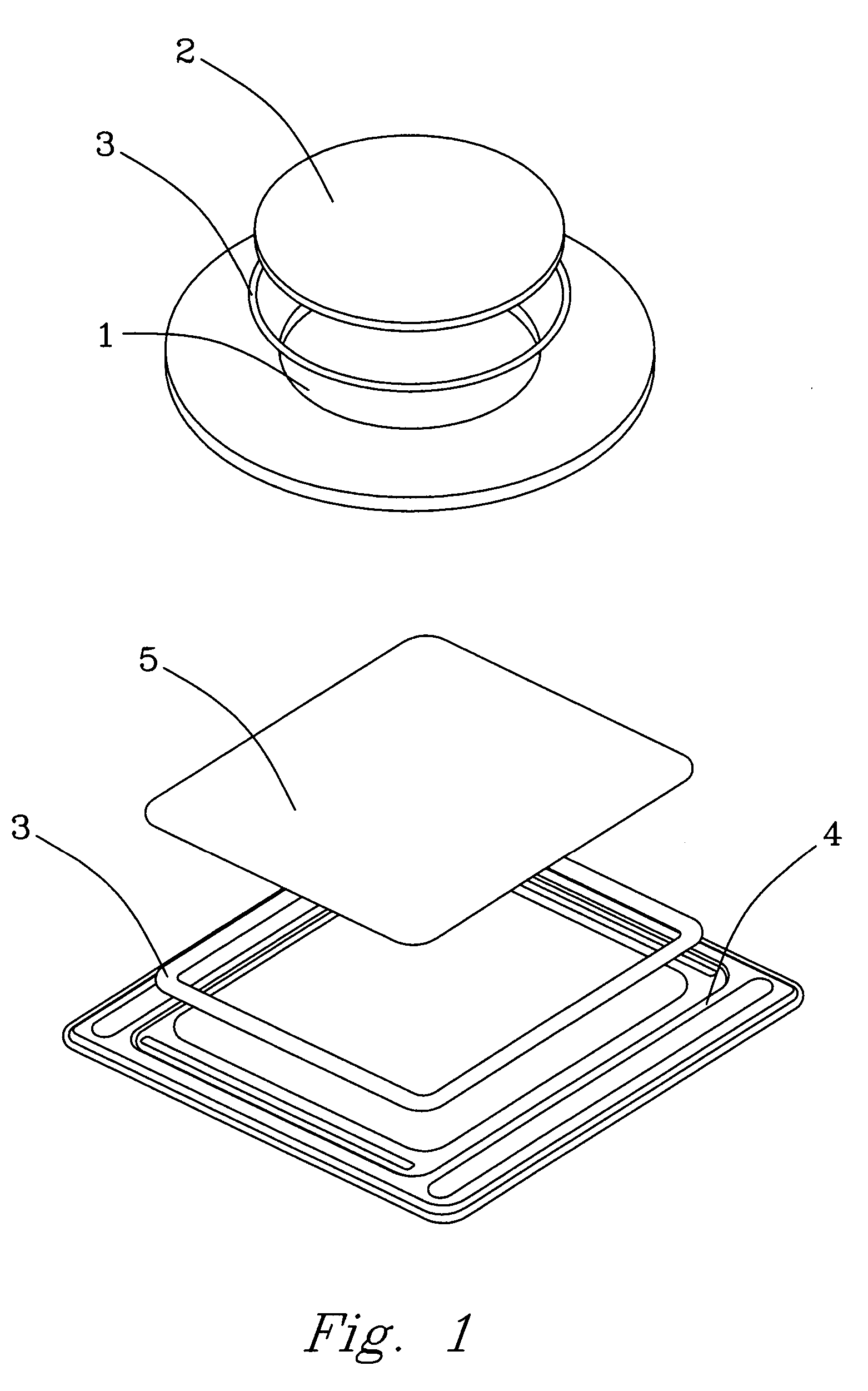

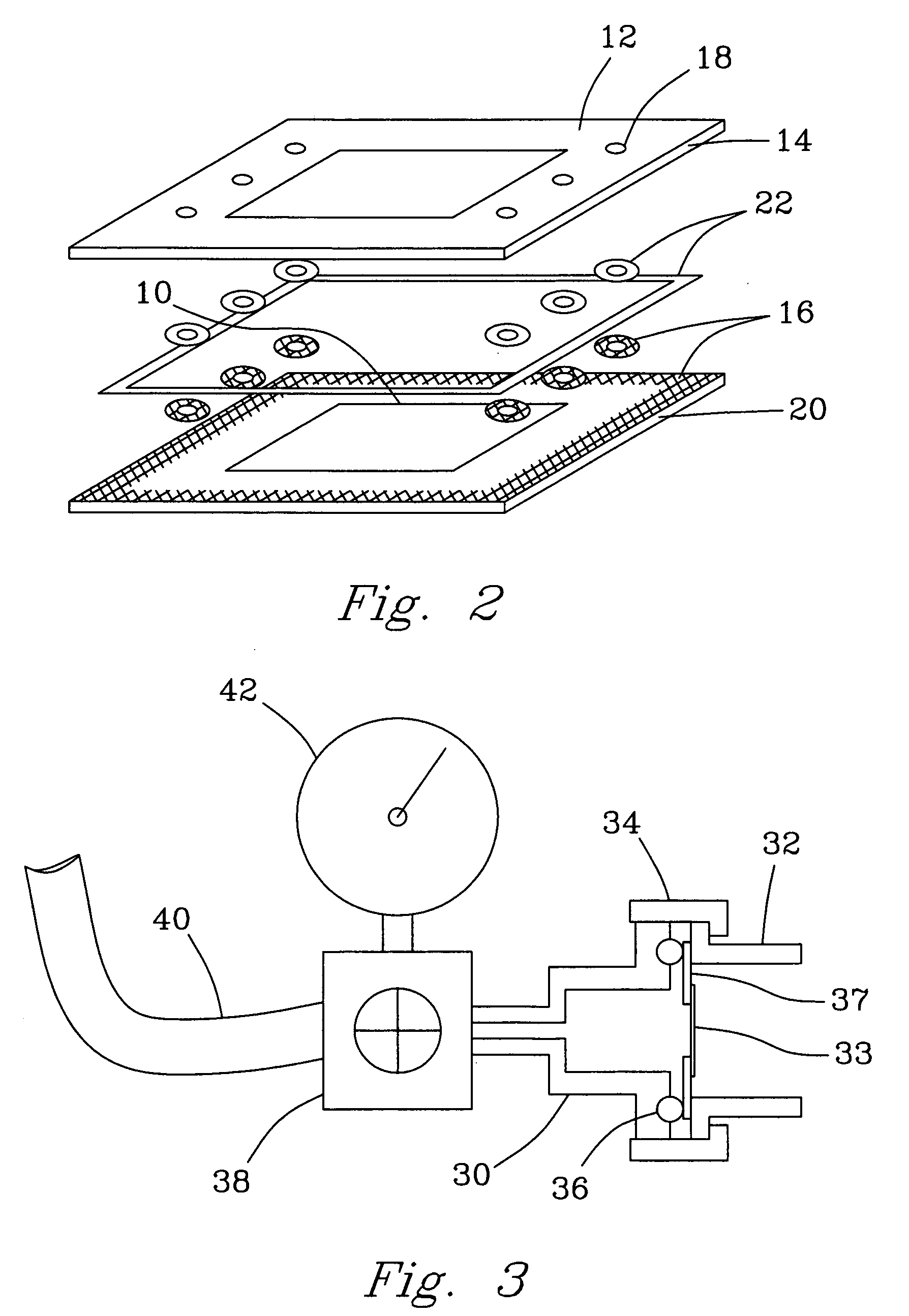

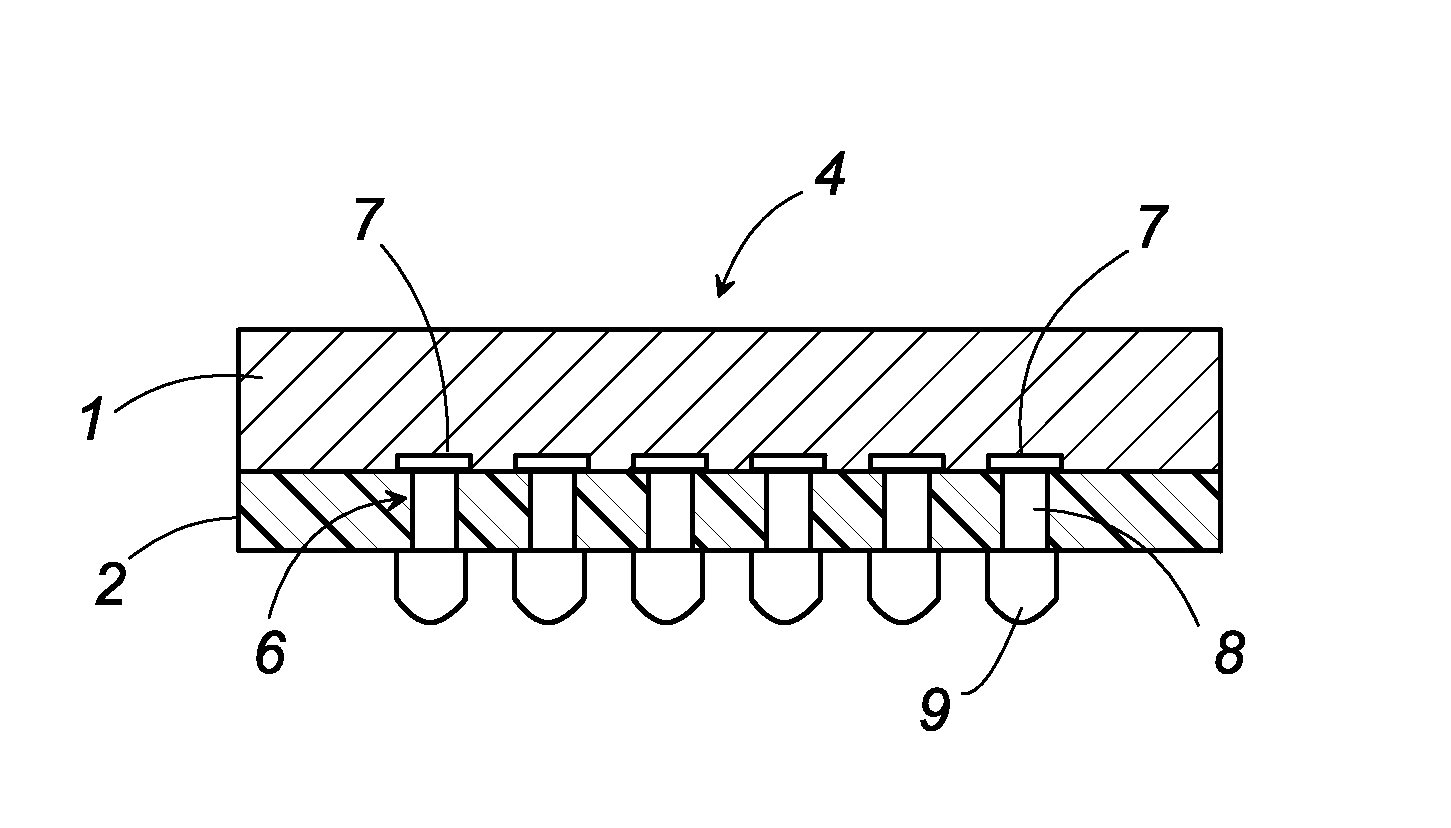

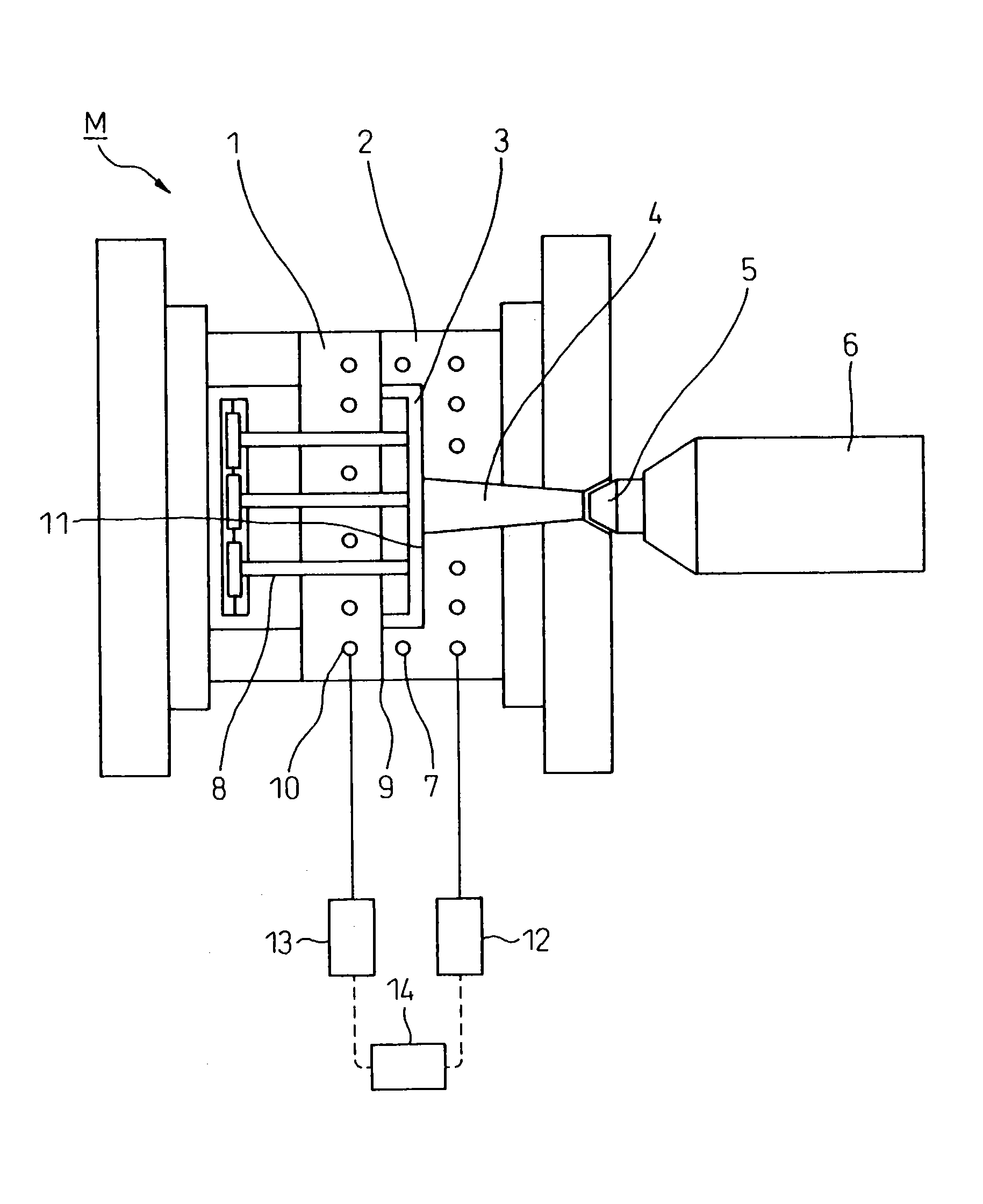

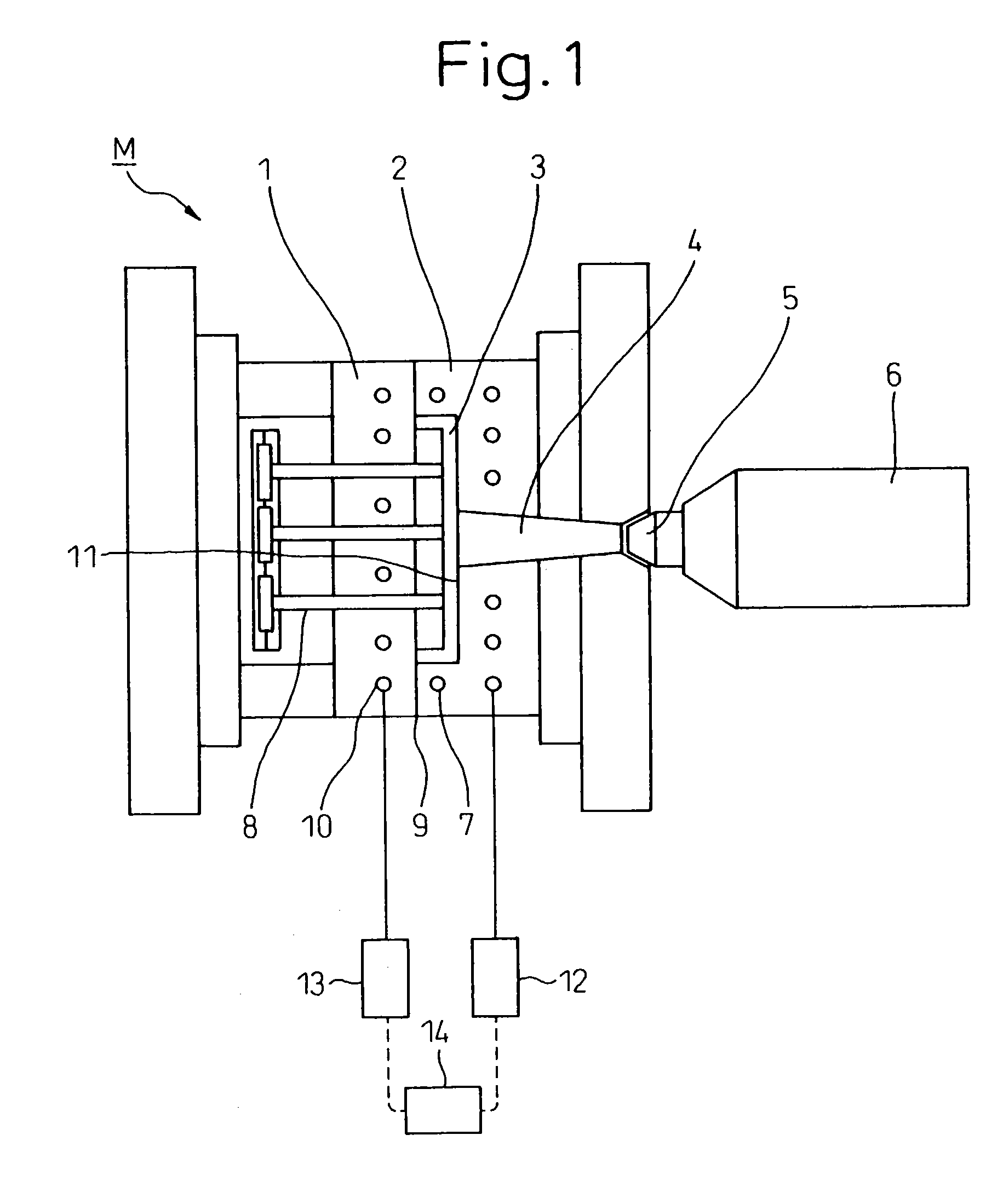

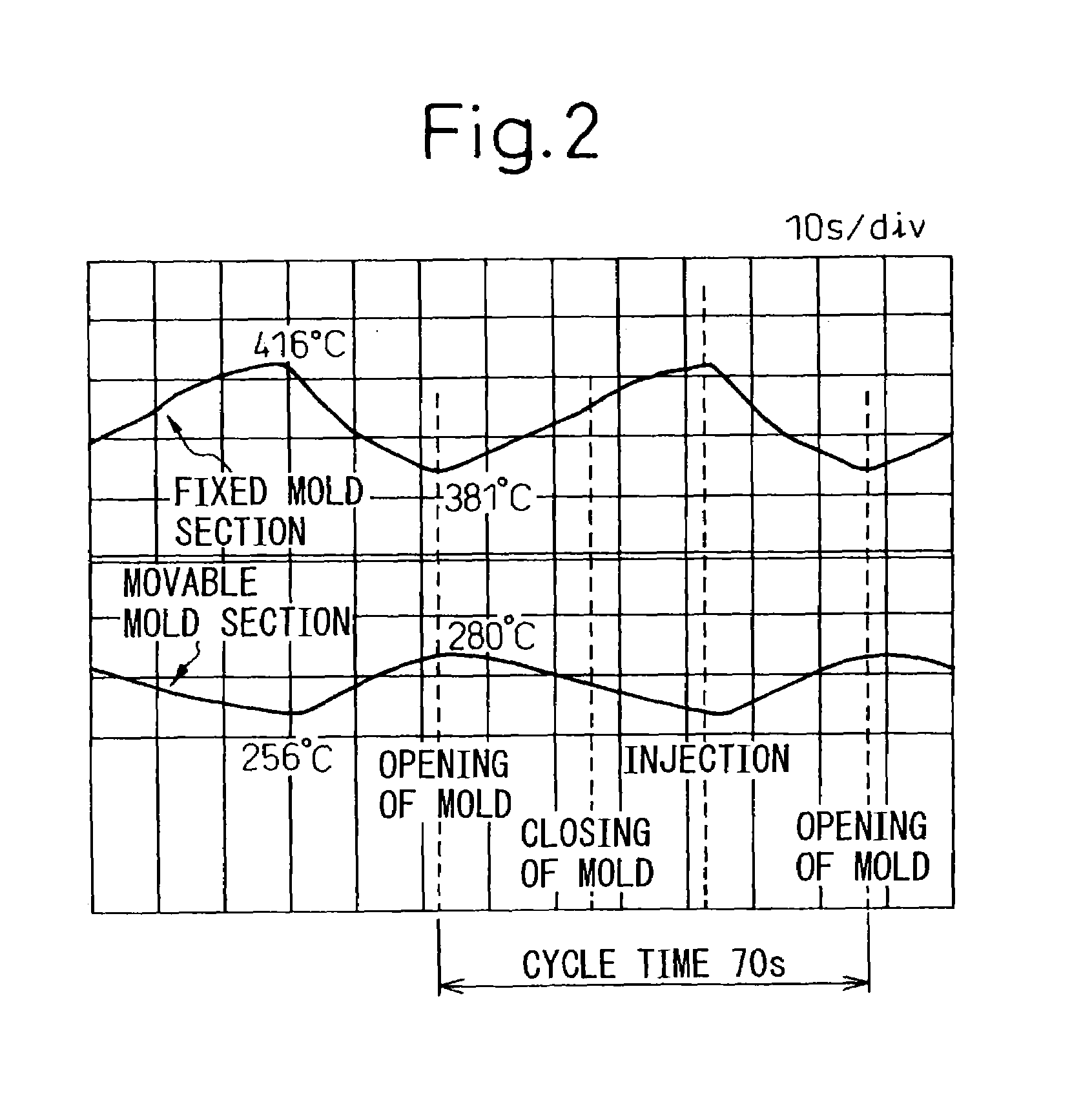

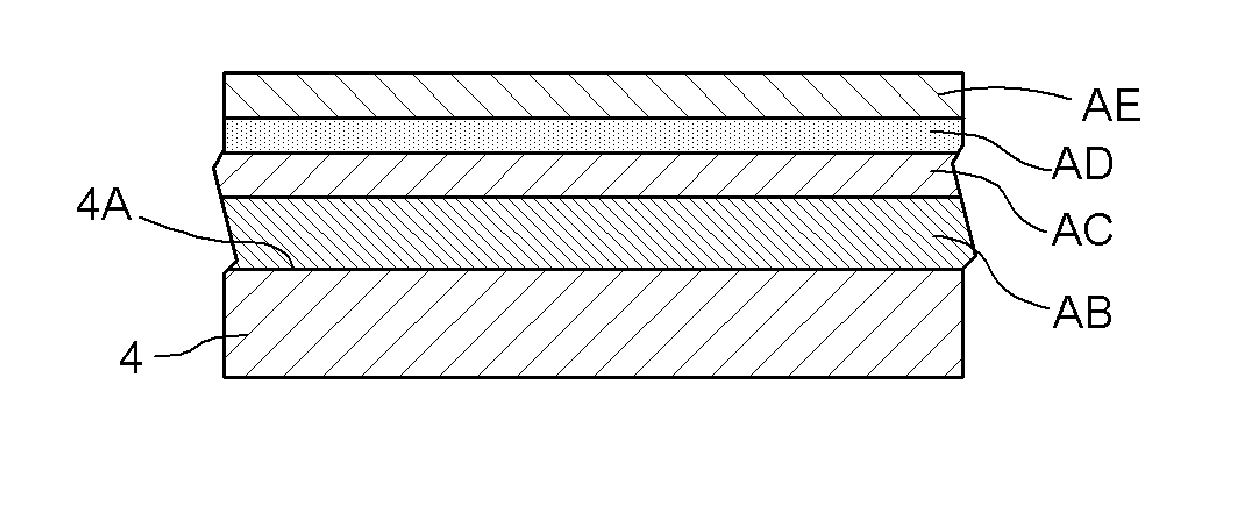

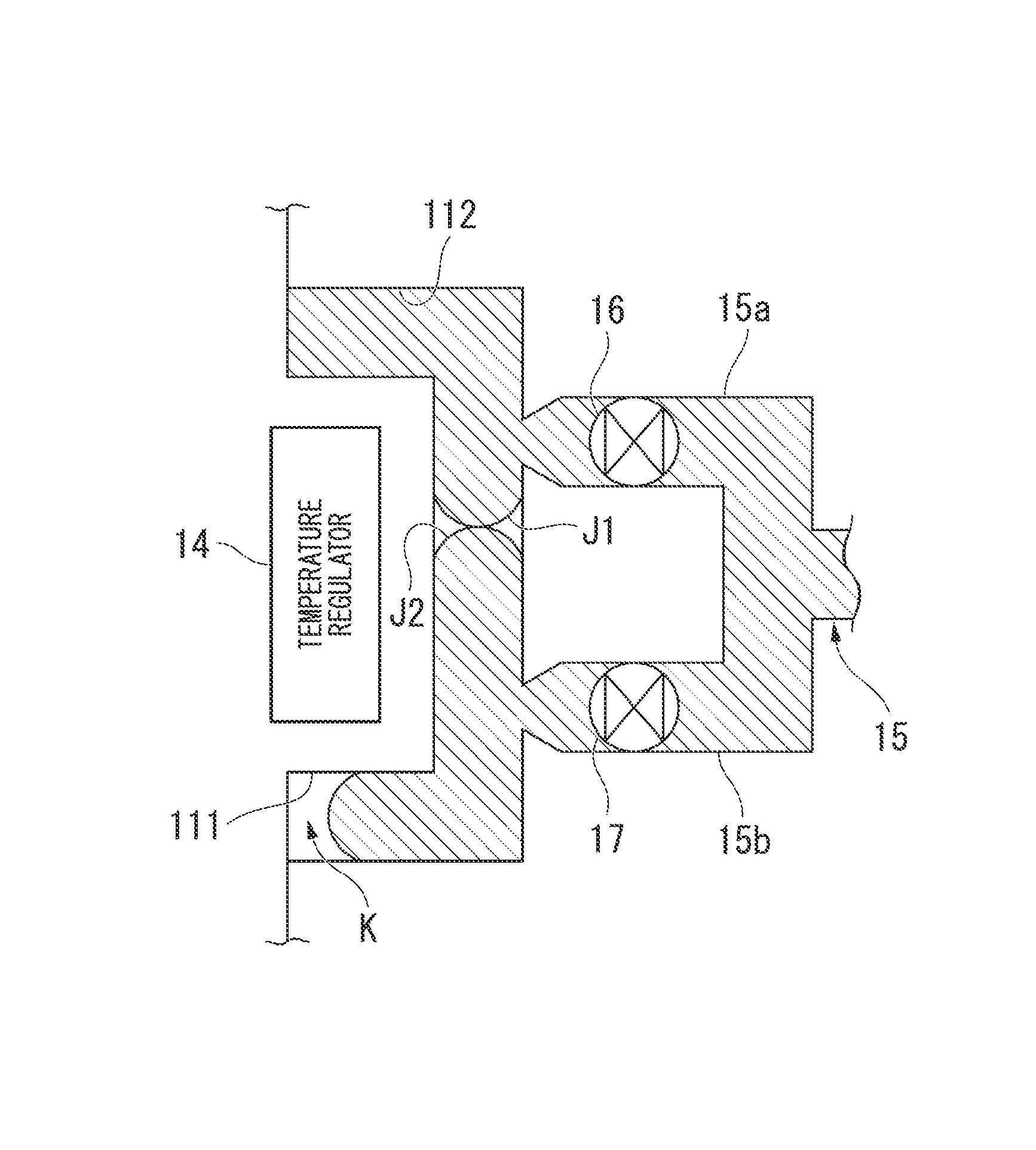

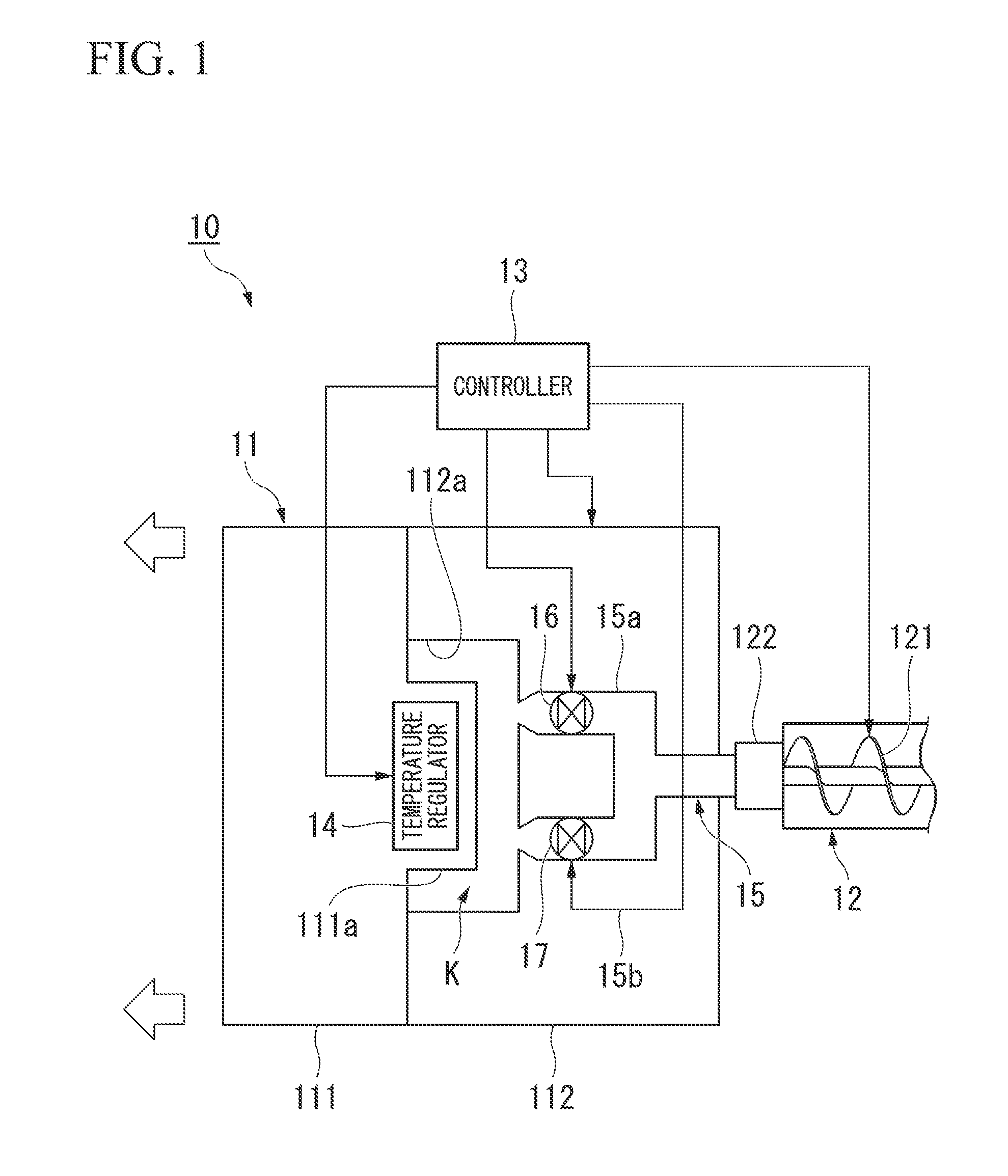

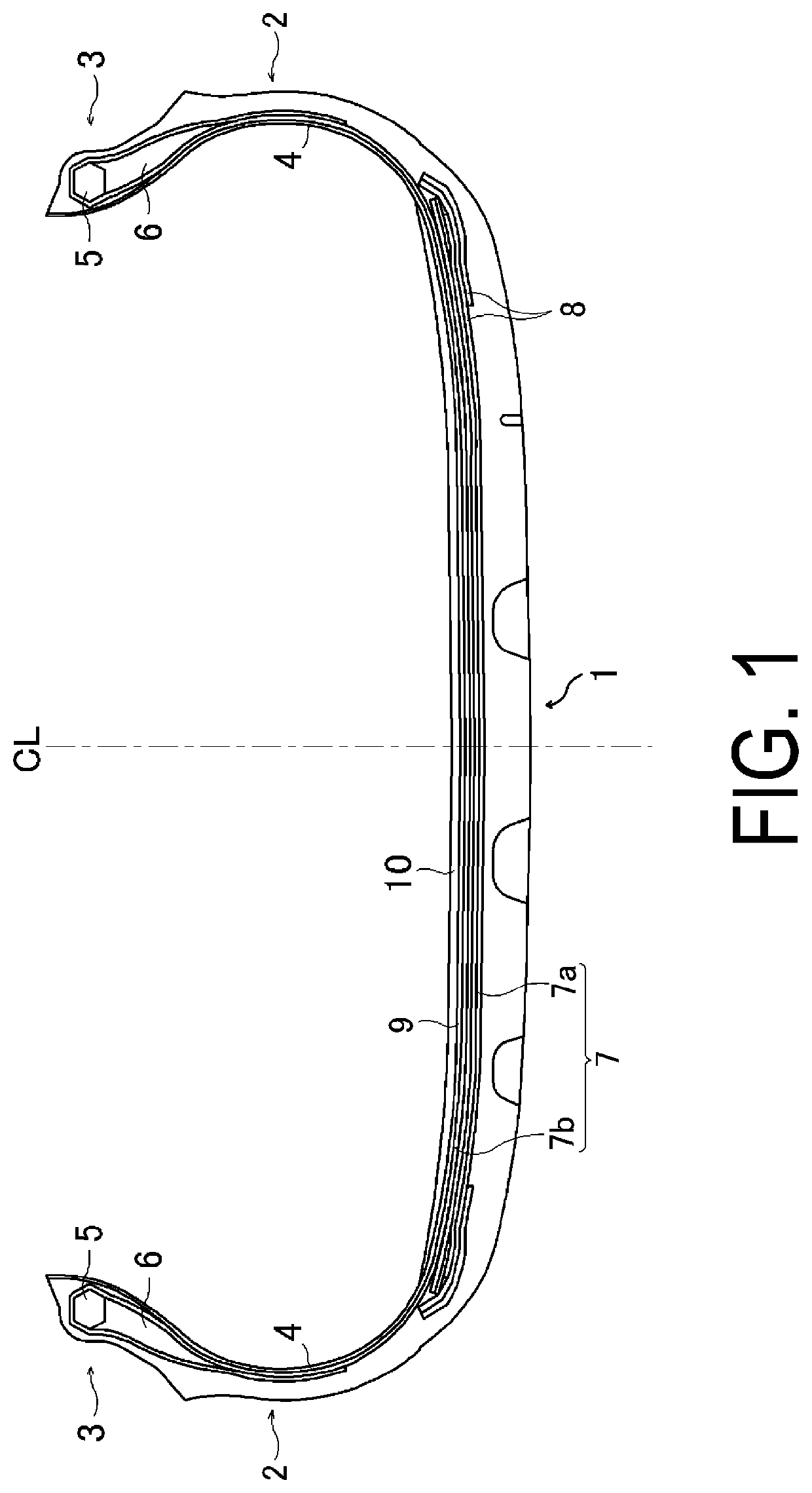

Mold and method of molding metallic product

InactiveUS7025116B2Limitation for transferRaise transfer toMelt-holding vesselsTemperature controlMetallurgy

A mold M for molding a metallic product including a fixed mold section 2 and a movable mold section 1, wherein heating means 7 is provided in the fixed mold section and cooling means 10 is provided in the movable mold section, which means are controlled by a temperature control device 14 so that any desired temperature is obtainable. Also, as the heating and the cooling of the mold are not repeated, but the fixed mold section is always heated and the movable mold section is always cooled, it is possible to shorten the cycle times.

Owner:DENSO CORP

High-energy and protein-enriched nutritional composition

InactiveUS20180228196A1Low viscositySufficient fluidityFood scienceEnvironmental healthAdditive ingredient

This application relates to a high-protein and high-calorie, ready-to-use, heat-sterilized, oral enteral nutritional composition.

Owner:EVEN SANTE IND

Surface ornament composition for part of fishing tackle or bicycle

ActiveUS20140178676A1Solve the lack of corrosion resistanceAvoid lack of toughnessRodsReelsEpoxyCarbamate

A surface ornament composition for a fishing tackle or a bicycle is provided. An inner coating layer is laminated on a part made of fiber reinforced plastics, a silver thin film coating layer is laminated on the inner coating layer and an outer coating layer is laminated on the silver thin film coating layer. The inner and outer coating layers are formed by use of one selected from resin paint of two-part type formed by urethane reaction of isocyanate group and hydroxyl group, resin paint of two-part type formed by reaction of resin having amino group and silicon compound having epoxy group and resin paint of two-part or three part type in which the above two reactions are simultaneously generated. The silver thin film coating layer is formed of metal complex of silver with amine as ligand that is heated after having been applied.

Owner:SHIMANO INC

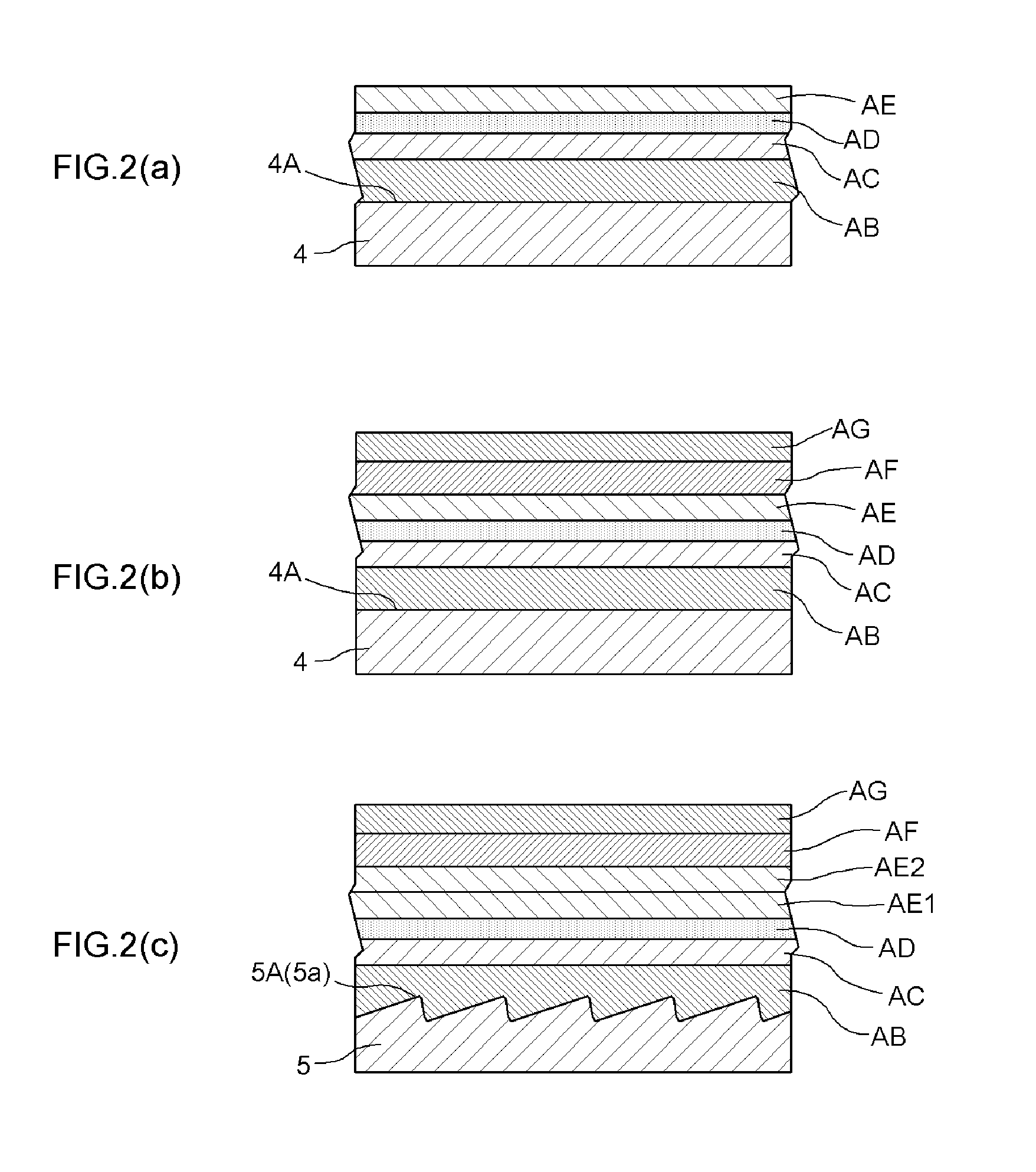

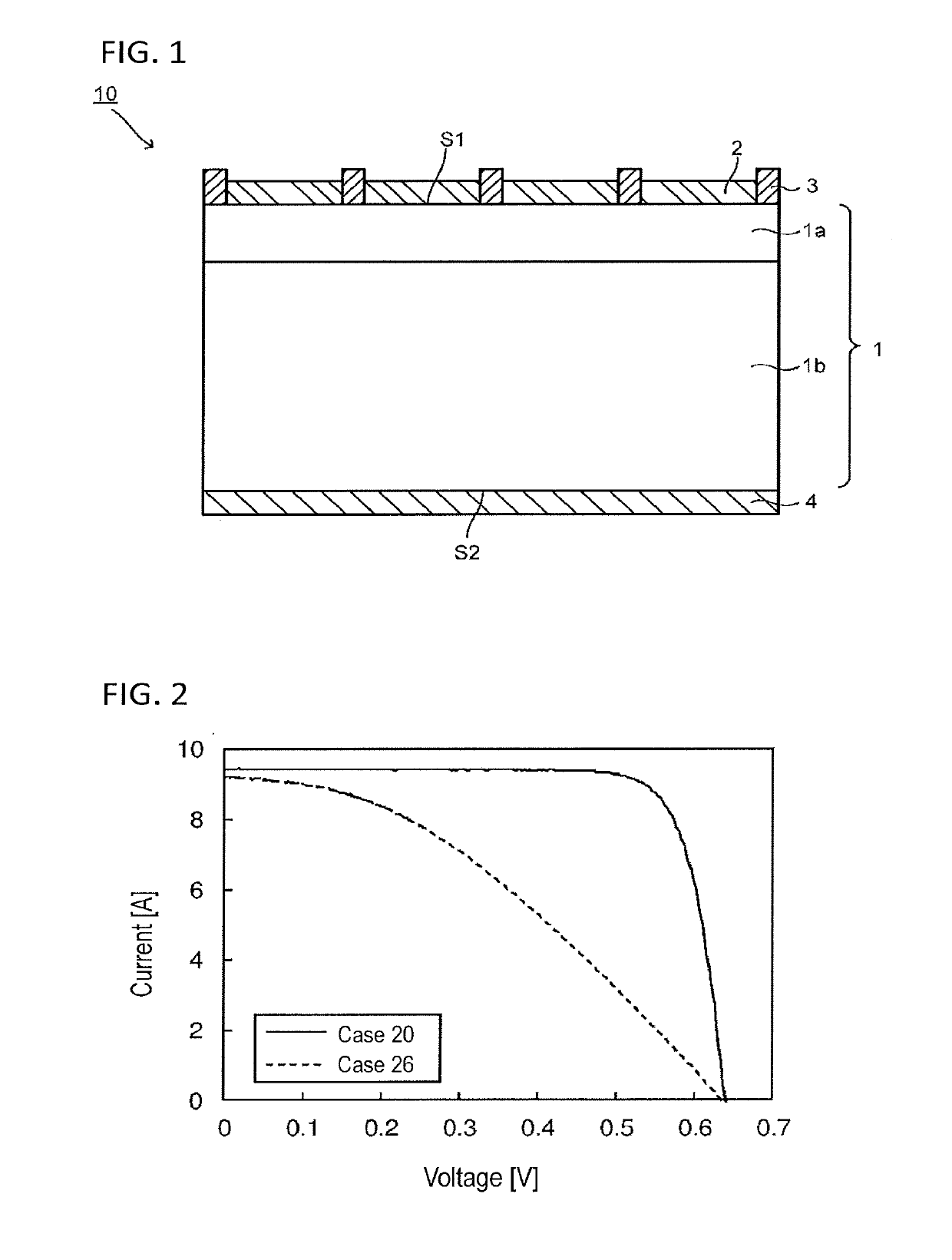

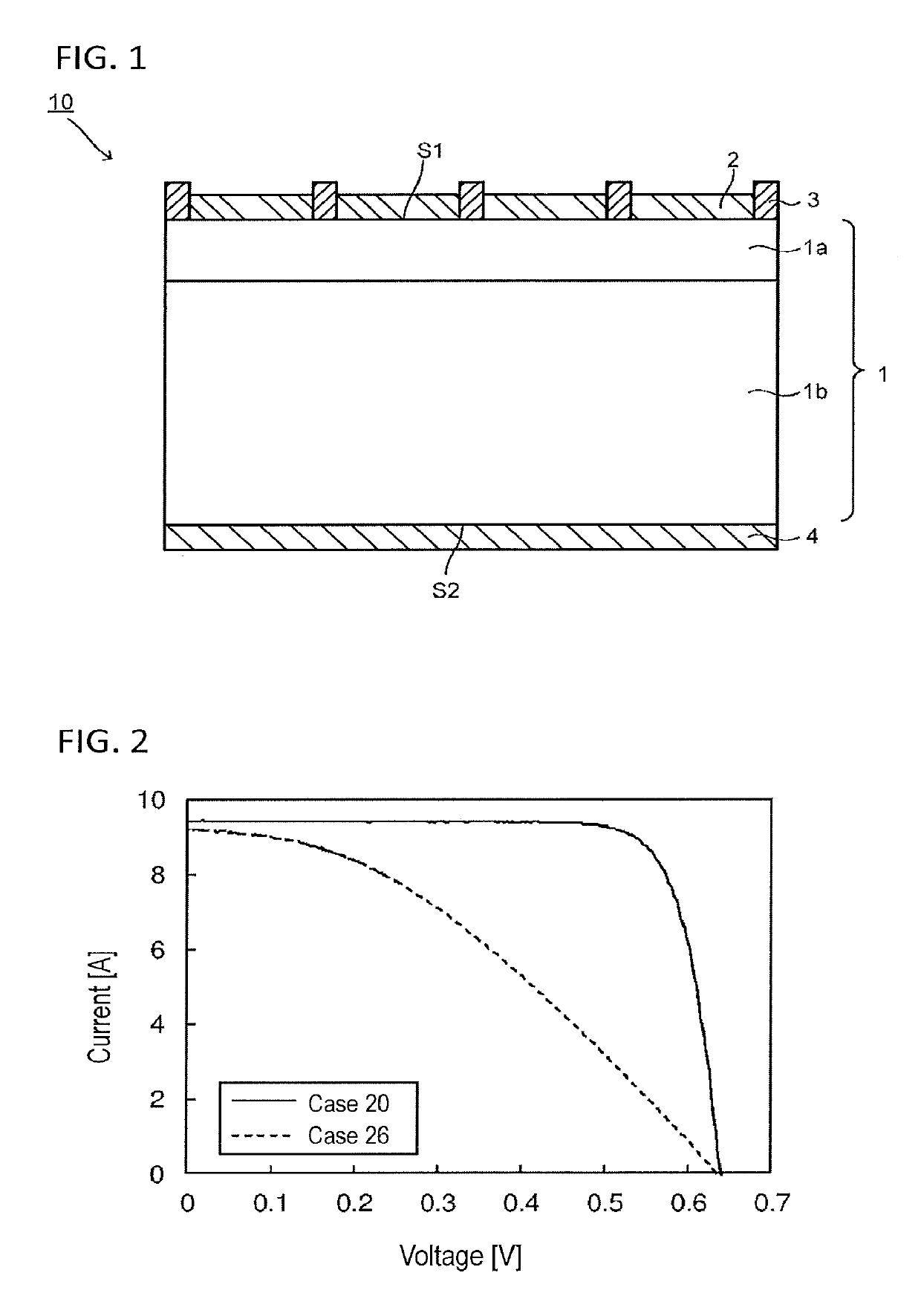

Glass composition, glass powder, conductive paste, and solar cell

ActiveUS20190135682A1Lower resistanceImprove conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteSolar cell

A glass composition includes, as expressed by mol % in terms of oxide, from 15 to 40% of PbO, from 25 to 50% of MoO3, from 5 to 25% of P2O5 and from 7 to 15% of ZnO. A glass powder includes the glass composition. The glass powder has D50 of from 0.3 to 2.0 μm, where D50 is a 50% particle diameter in a volume-based cumulative particle size distribution.

Owner:ASAHI GLASS CO LTD

Granular fertilizers having improved dust control

InactiveUS9321699B2High viscosityExtended durationLayered/coated fertilisersFertilizer mixturesParticulatesPolymer science

An oil-based coating for fertilizer granules impregnated with a polymer additive and related methods of applying the oil-based coating. The polymer additive can comprise homopolymers, copolymers, or combinations thereof, including polyethylene homopolymers. The polymer additive increases the viscosity of the oil-based coating, thereby increasing the duration for which the coating is capable of controlling or inhibiting the formation of dust particulates from the fertilizer granules.

Owner:THE MOSAIC COMPANY

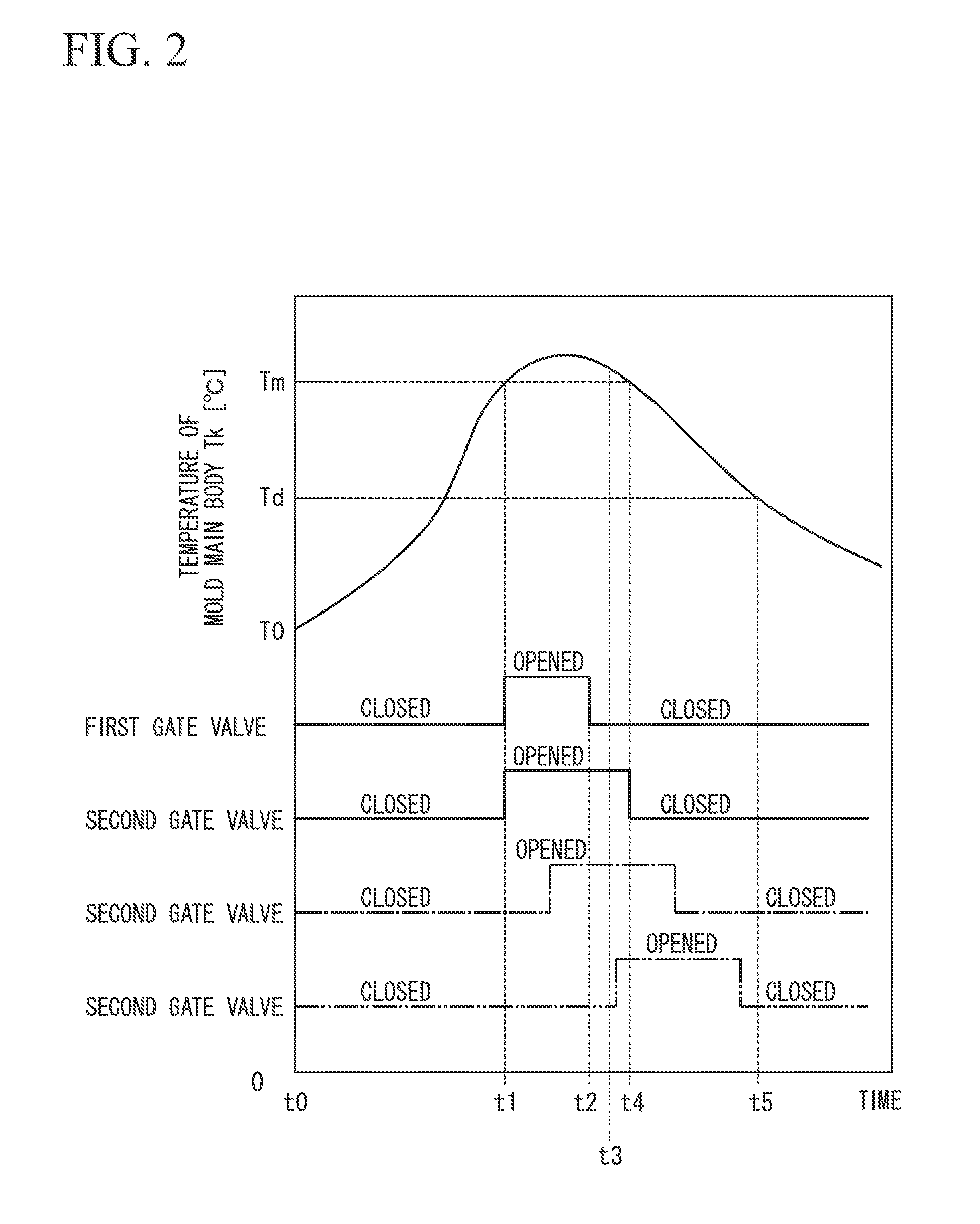

Resin injection molding method

The resin injection molding method of the present invention is a method for molding resins inside a cavity formed within a mold. The method comprises injecting resins into the cavity through a plurality of paths installed so as to be openable and closable and optionally maintaining the resin inside the cavity at a pressure; closing each of the plurality of paths such that the resins injected from each path converge, there being a time difference between when a first path and a second path of the plurality of paths are closed; and solidifying at least the resin which is injected from the path closed earliest with a crystallinity greater than or equal to a predetermined crystallinity degree.

Owner:MITSUBISHI HEAVY INDS PLASTIC TECH

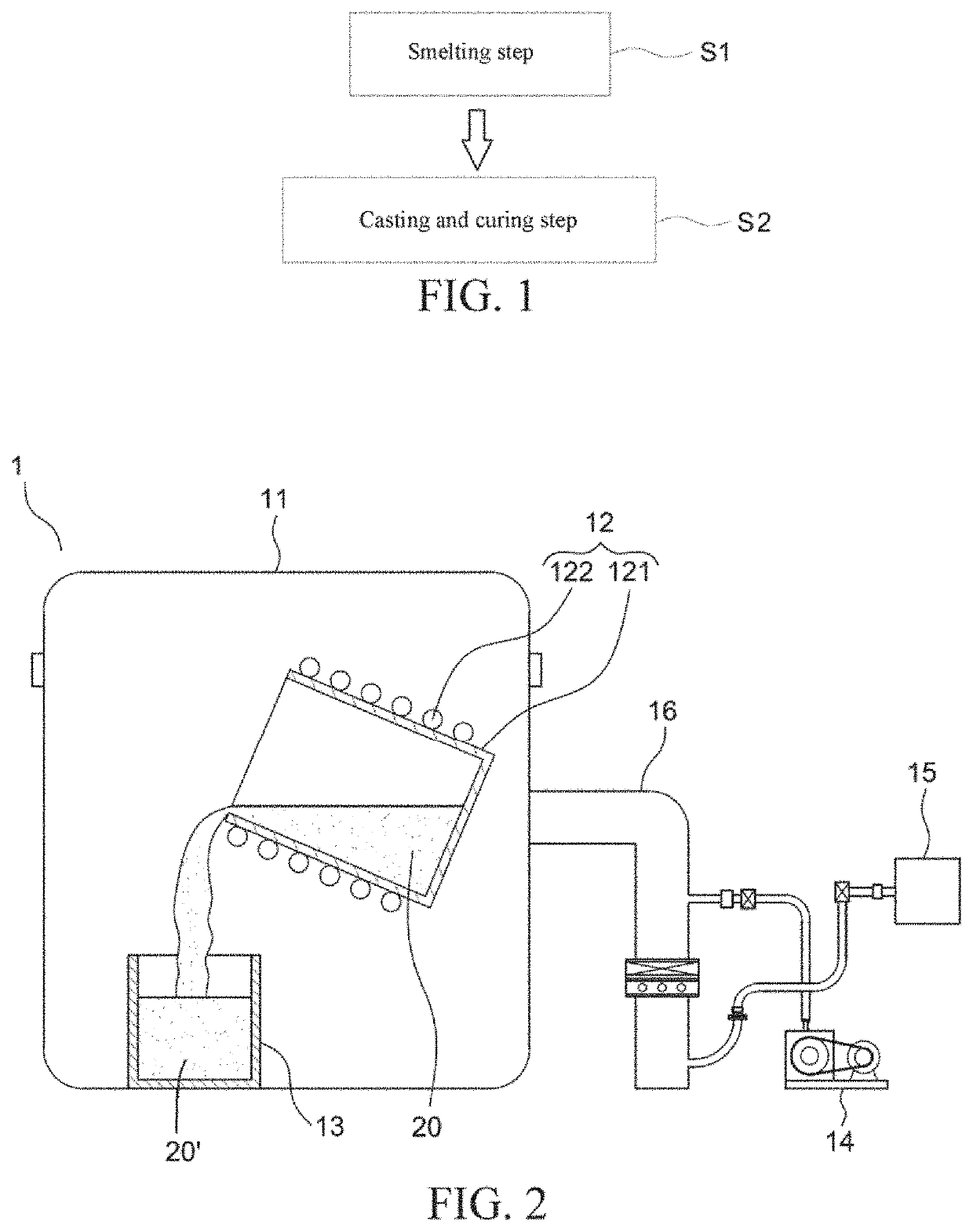

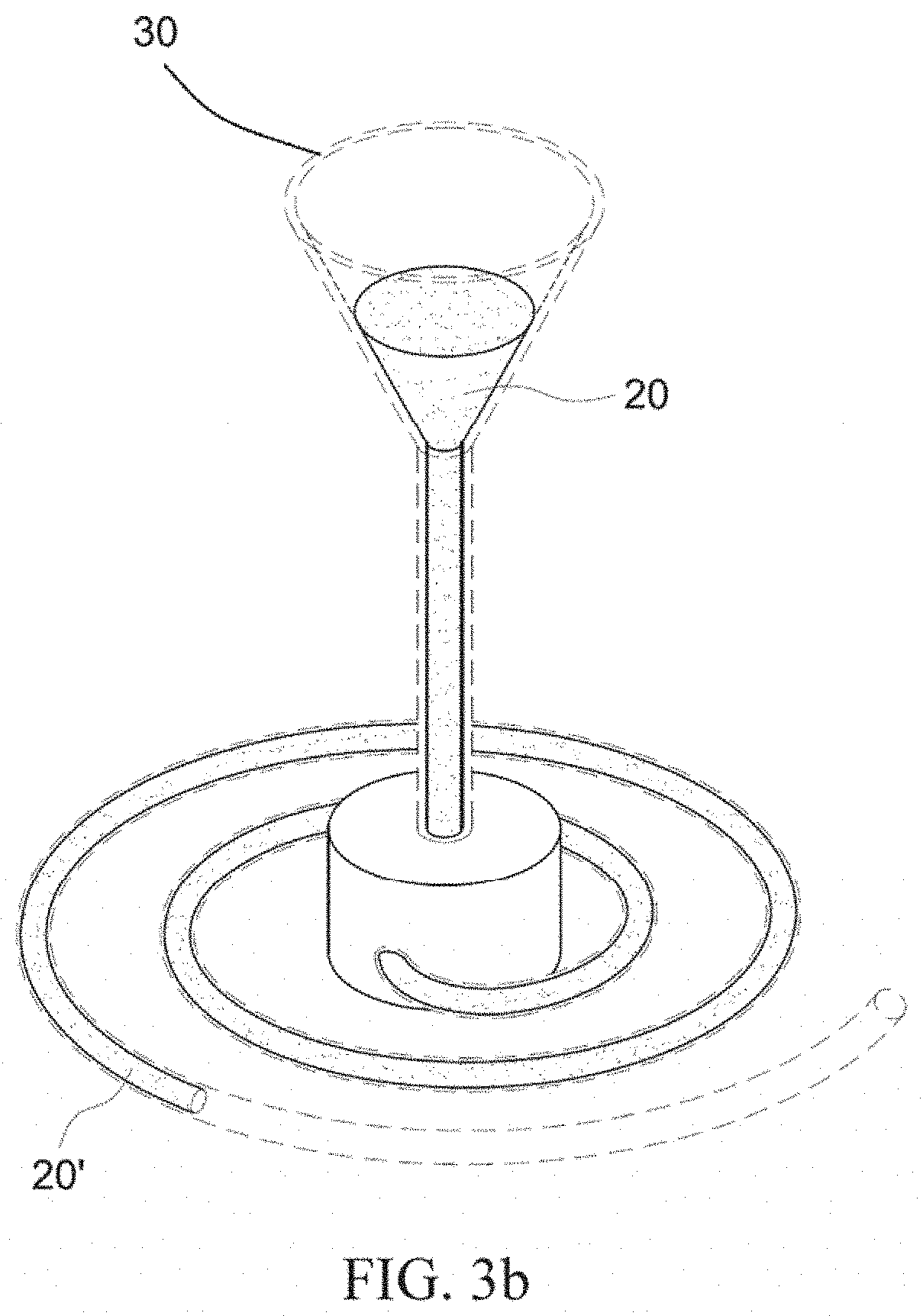

Titanium-aluminum intermetallic and manufacturing method thereof for improving casting fluidity

ActiveUS20220178006A1Adequate casting fluidityImproving casting fluidityInternal combustion piston enginesCastabilityFerrosilicon

A titanium-aluminum intermetallic for improving casting fluidity includes the following elements in atomic percentage: Al: 40 at % to 50 at %, Cr: 1 at % to 8 at %, Nb: 1 at % to 8 at %, Mo: 1 at % to 5 at %, Mn: 1 at % to 6 at %, Ni+Si+Fe: 1 at % to 15 at %, B: 0.05 at % to 0.8 at %, and the balance of Ti and inevitable impurities. The titanium-aluminum intermetallic in the present disclosure has more adequate casting fluidity, that is, has better castability.

Owner:METAL INDS RES & DEV CENT

Glass composition, glass powder, conductive paste, and solar cell

ActiveUS10407340B2Lower resistanceImprove conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteSolar cell

A glass composition includes, as expressed by mol % in terms of oxide, from 15 to 40% of PbO, from 25 to 50% of MoO3, from 5 to 25% of P2O5 and from 7 to 15% of ZnO. A glass powder includes the glass composition. The glass powder has D50 of from 0.3 to 2.0 μm, where D50 is a 50% particle diameter in a volume-based cumulative particle size distribution.

Owner:ASAHI GLASS CO LTD

Sealant material composition

PendingUS20220325155A1Improve sealingSufficient viscosityOther chemical processesWithout separate inflatable insertsPolymer scienceButyl rubber

Provided is a sealant material composition that makes it possible to ensure good sealing properties and to suppress sealant flow due to traveling. As a sealant material composition forming a sealant layer disposed on an inner surface of a pneumatic tire, a sealant material composition comprising from 1 part by mass to 40 parts by mass of an organic peroxide and from 0.1 parts by mass to 40 parts by mass of a crosslinking agent, being blended, per 100 parts by mass of a rubber component containing a chlorinated butyl rubber, is used.

Owner:YOKOHAMA RUBBER CO LTD

Gypsum dispersant

InactiveUS20160244365A1Sufficient fluidityWithout decreasing productivityMining engineeringPolyamide

There is provided a gypsum dispersant and a gypsum additive that improve the fluidity of gypsum slurry even if gypsum raw materials used are different in quality and that do not induce delay of curing of gypsum slurry. A gypsum dispersant, characterized by comprising: (A) a polycarboxylic acid polymer; and (B) a polyamide polyamine obtained by a reaction of a polyalkylene polyamine and a dibasic acid as essential components, and / or an alkylene oxide adduct of the polyamide polyamine.

Owner:TOHO CHEM IND

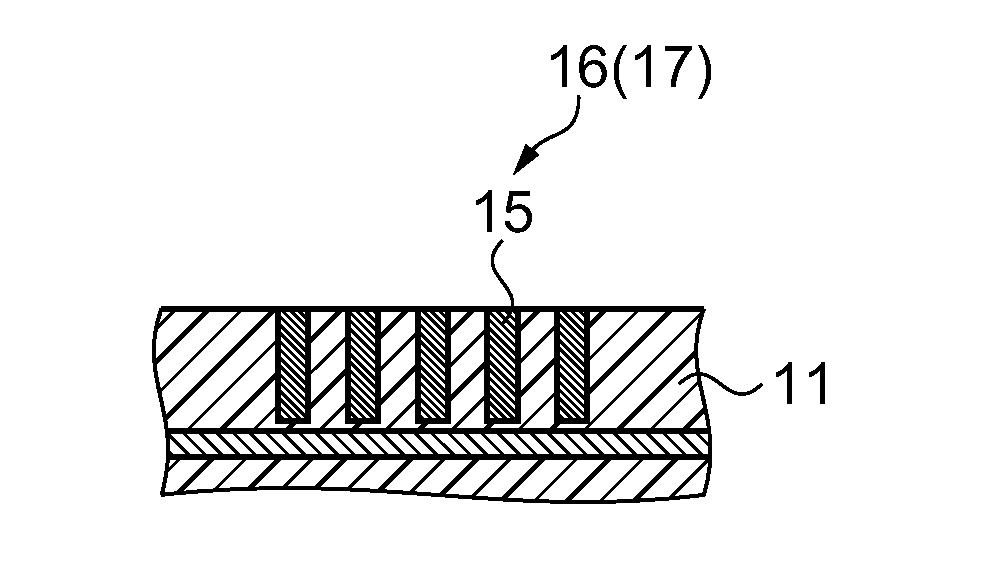

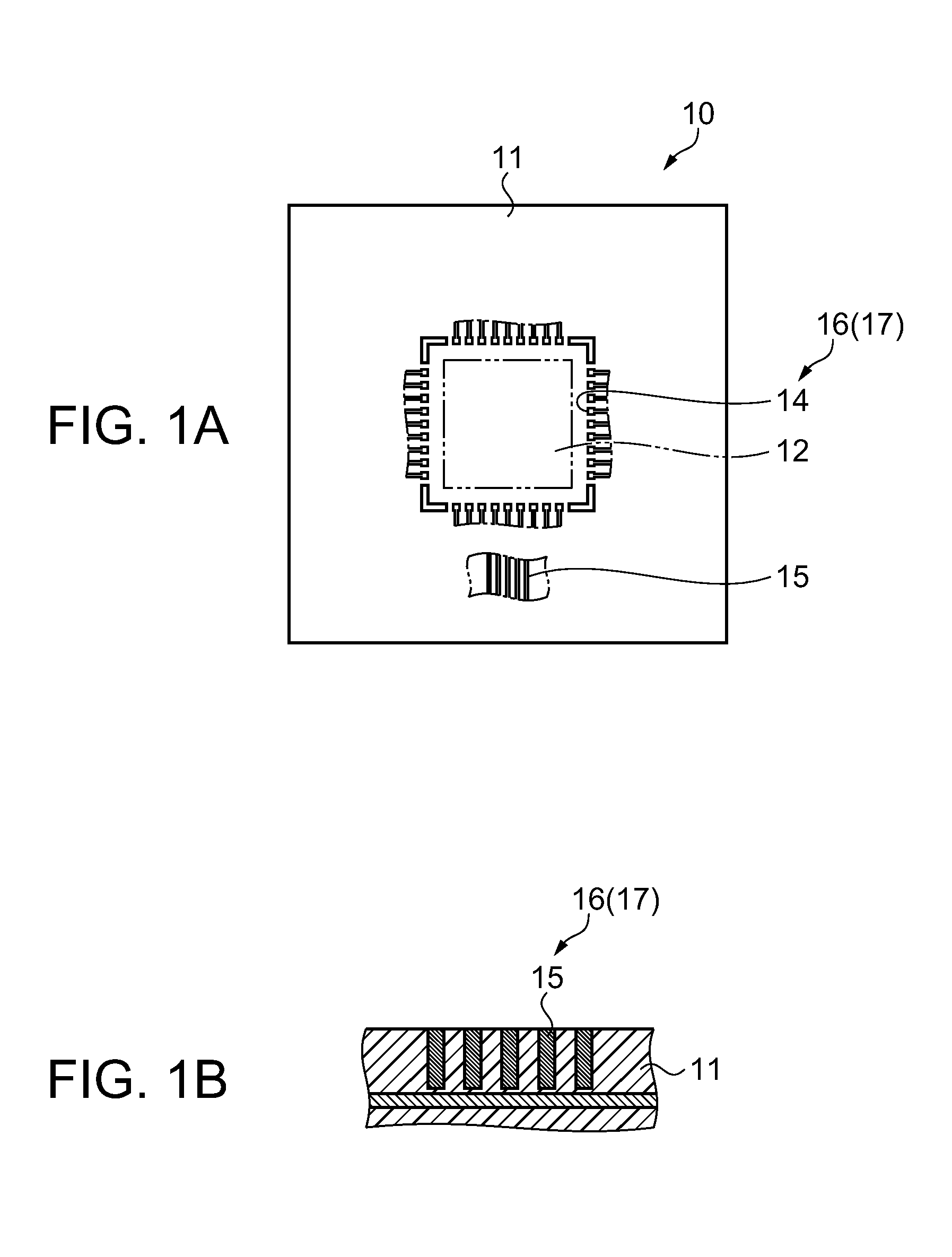

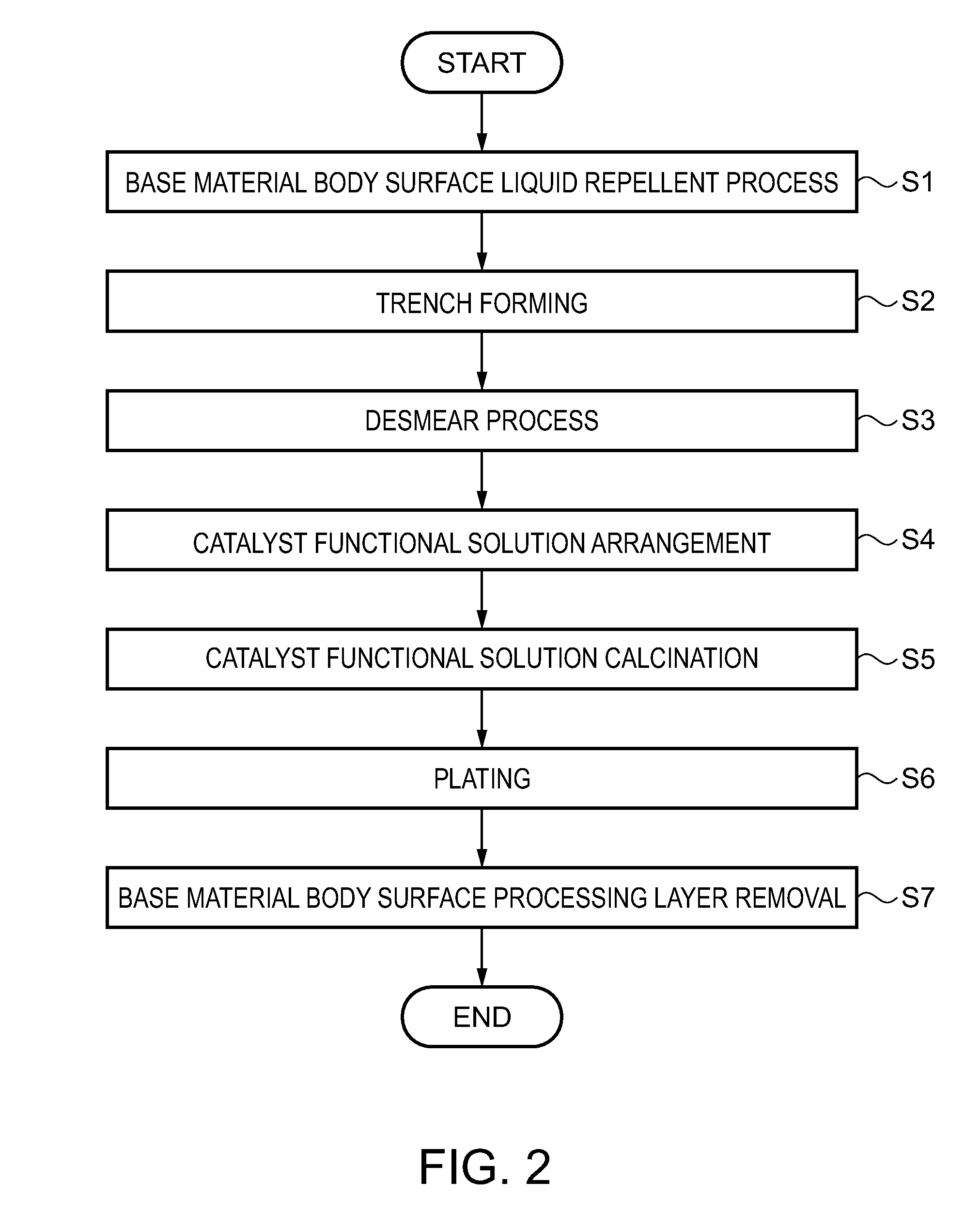

Method of forming circuit interconnection, circuit board, and circuit interconnection film having film thickness larger than width thereof

InactiveUS20110174528A1Improve distributionWell formedNon-insulated conductorsRadiation applicationsEngineeringConductive materials

A method of forming a circuit interconnection on a circuit board includes: forming a trench that corresponds to a shape of the circuit interconnection on an interconnection base material that forms the circuit interconnection; distributing a catalyst for forming a conductive layer on the trench; and forming a conductive circuit interconnection film that forms the circuit interconnection by distributing a plating solution in a range that includes the trench and depositing a conductive material from the plating solution through the catalyst for forming the conductive layer.

Owner:SEIKO EPSON CORP

Gypsum dispersant

ActiveUS9382155B2Sufficient fluidityWithout decreasing productivitySolid waste managementSlurryCarboxylic acid

Owner:TOHO CHEM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com