Patents

Literature

45results about How to "Reduce tin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

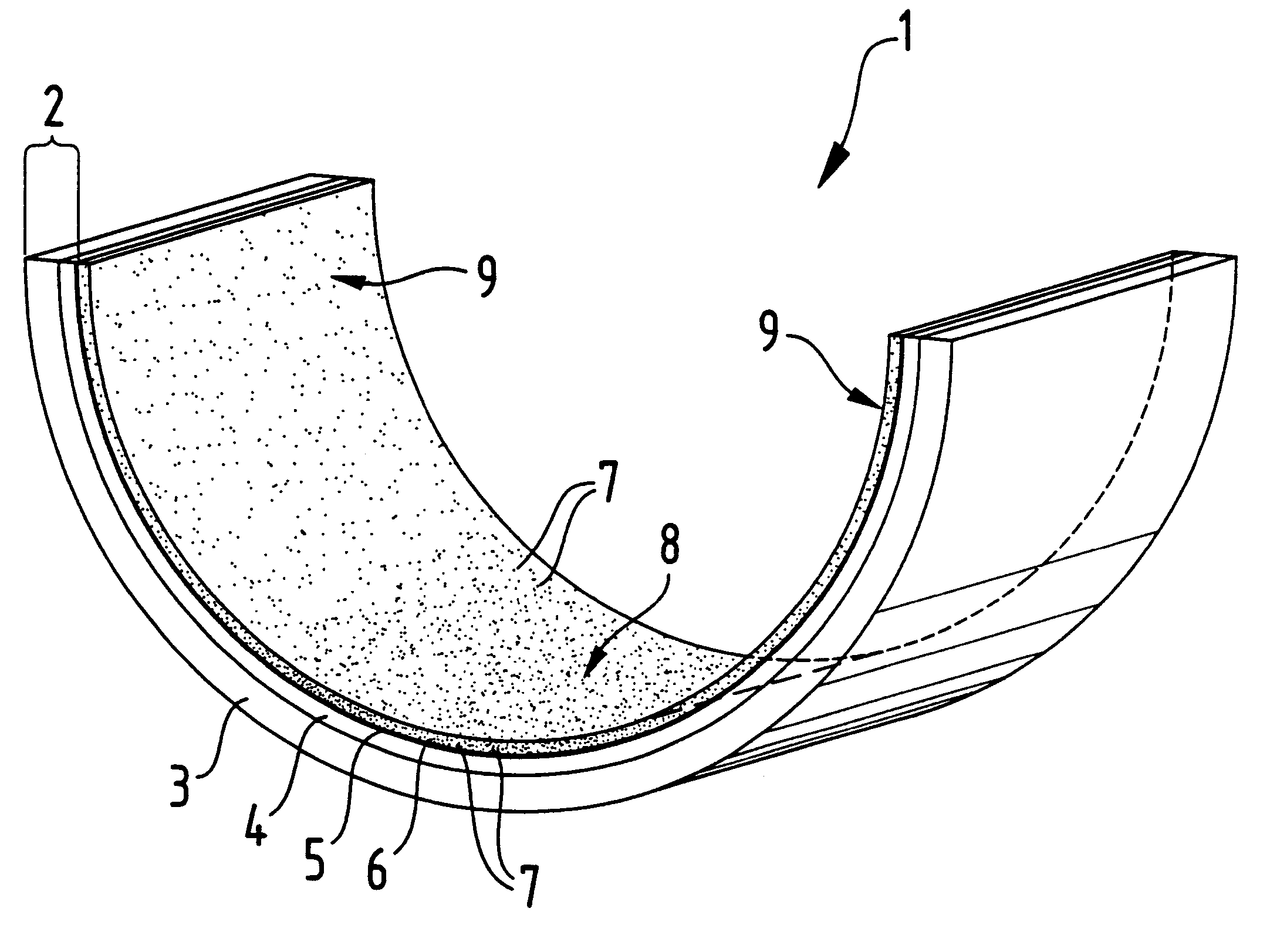

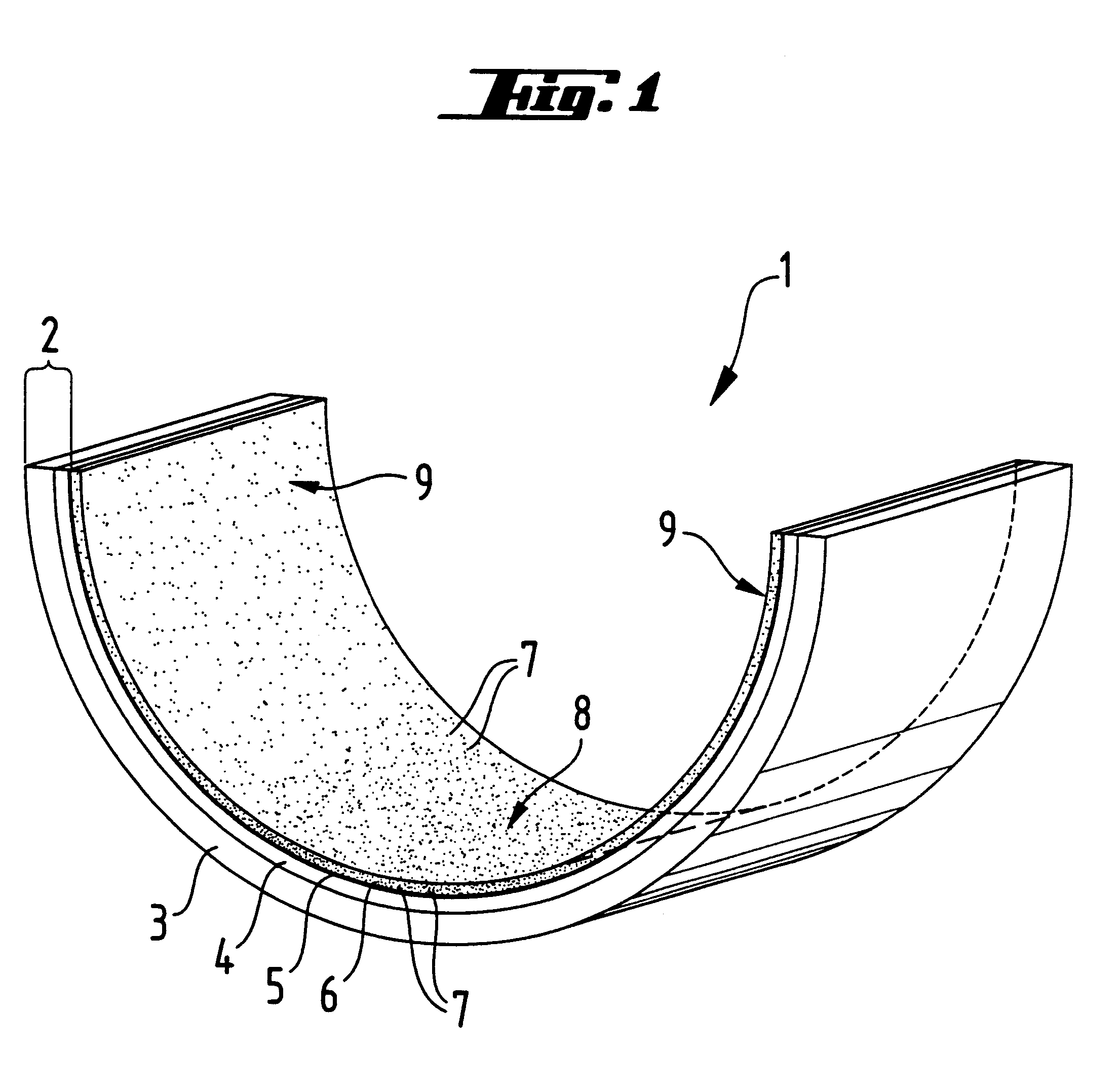

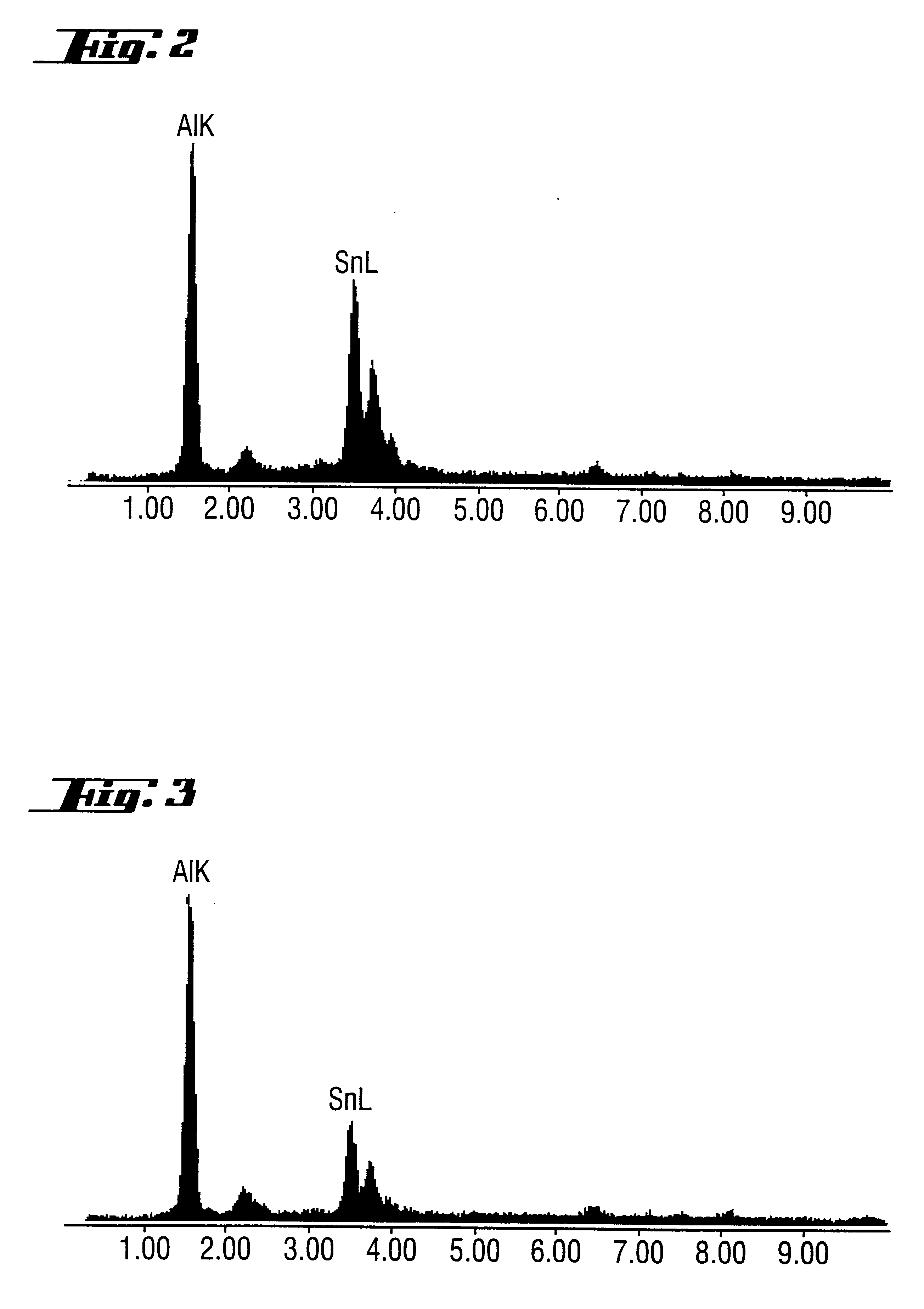

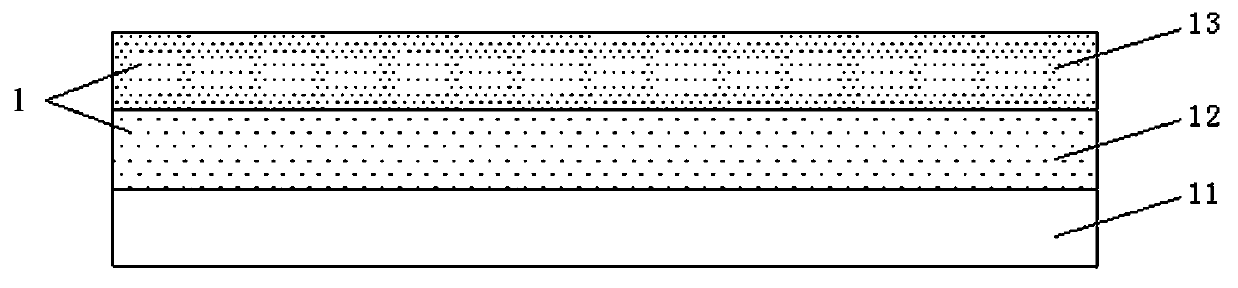

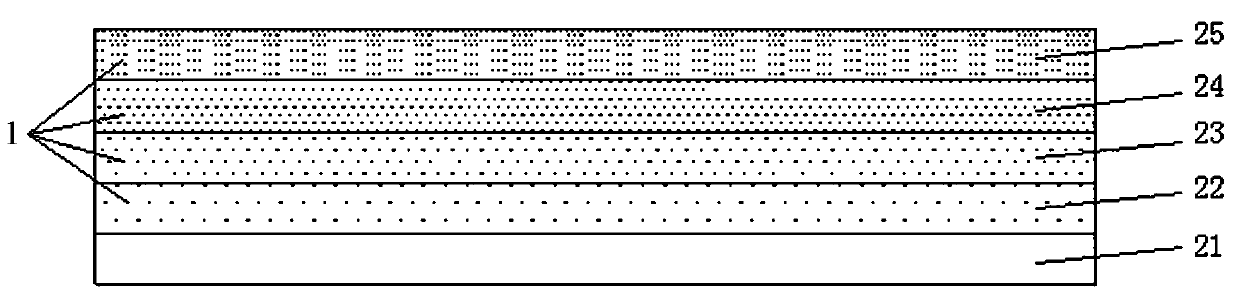

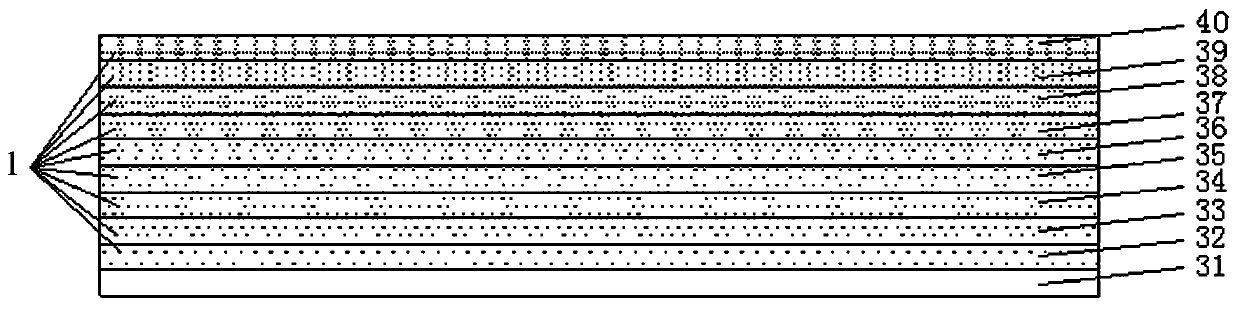

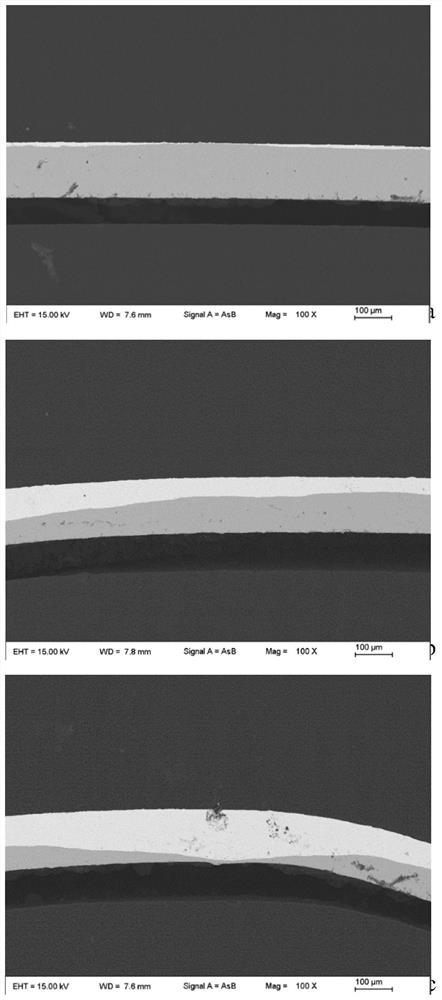

Half bearing and method for the production thereof

InactiveUS6316061B1Good emergency runningGood running-in behaviorShaftsVacuum evaporation coatingGas phaseElectron

A half bearing has a backing member and at least one metallic overlay, which is applied by electron beam vapour deposition and which comprises at least one finely dispersed component in a matrix material, the atomic weight of which component is greater than that of the matrix material, wherein the concentration of the finely dispersed component (7) decreases continuously from the apex area (8) of the half bearing (1) towards the area (9) of the partial surfaces. The method is characterised in that, during the coating process, an inert gas pressure of 0.1 to 5 Pa is set in the apex area of the bearing shell.

Owner:FEDERAL MOGUL WIESBADEN

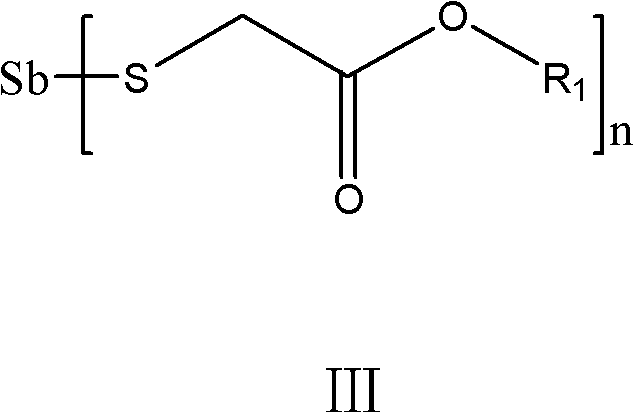

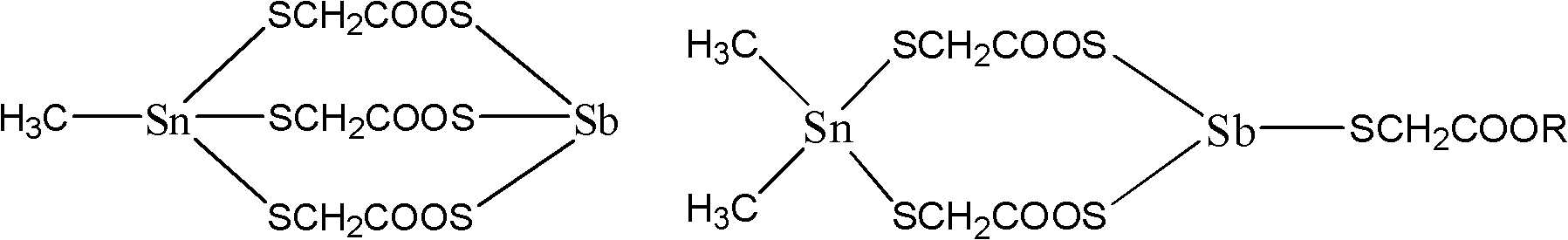

Sn-Sb-Zn composite heat stabilizer for polyvinyl chloride (PVC) sheets and preparation method and application thereof

InactiveCN102675770AReduce consumptionImproves initial and long-term thermal stabilityOrganic acidChemistry

The invention discloses a Sn-Sb-Zn composite heat stabilizer for polyvinyl chloride (PVC) sheets. The Sn-Sb-Zn composite heat stabilizer comprises, by weight, 10-20 parts of thioglycolic acid methyl tin, 40-60 parts of thioglycolic acetic ester antimony and 5-15 parts of organic acid zinc salt. The invention further discloses the preparation method of the Sn-Sb-Zn composite heat stabilizer and application of the Sn-Sb-Zn composite heat stabilizer as a PVC stabilizer. The composite heat stabilizer is high in product quality, low in toxicity, environment-friendly, less in tin content in a formula and applicable to various PVC hard sheet materials, has good initial and long-term heat stability, and is high in product transparency.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

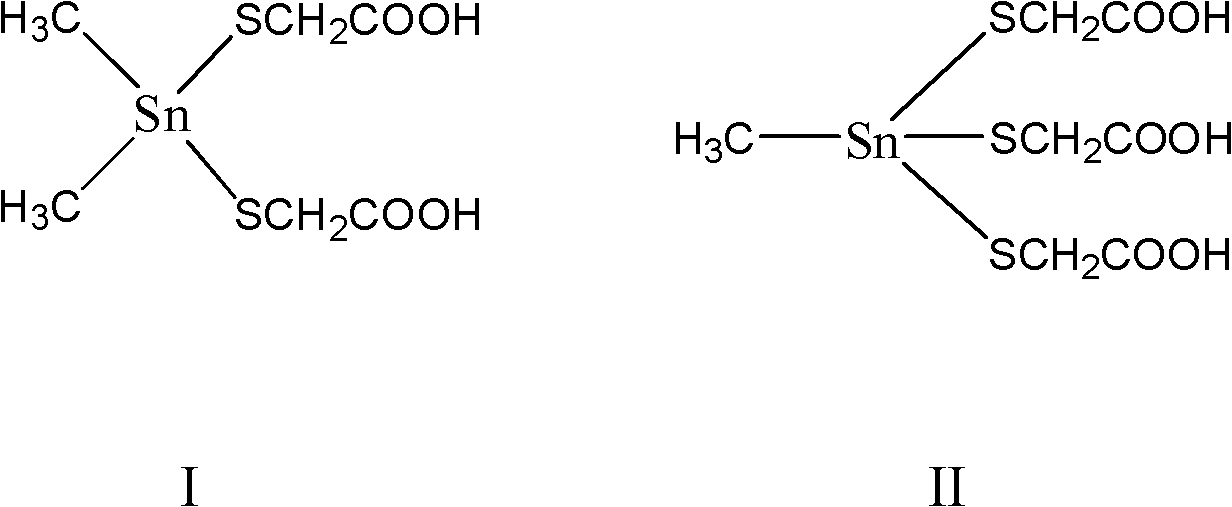

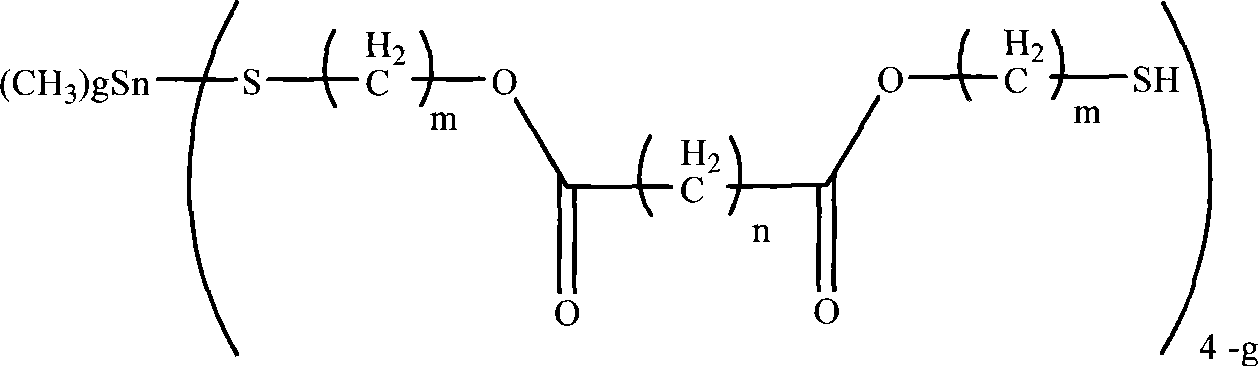

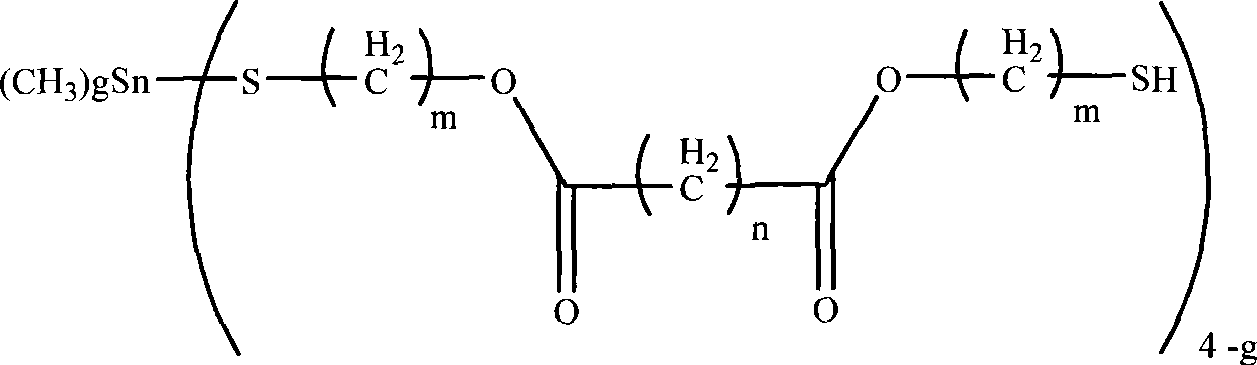

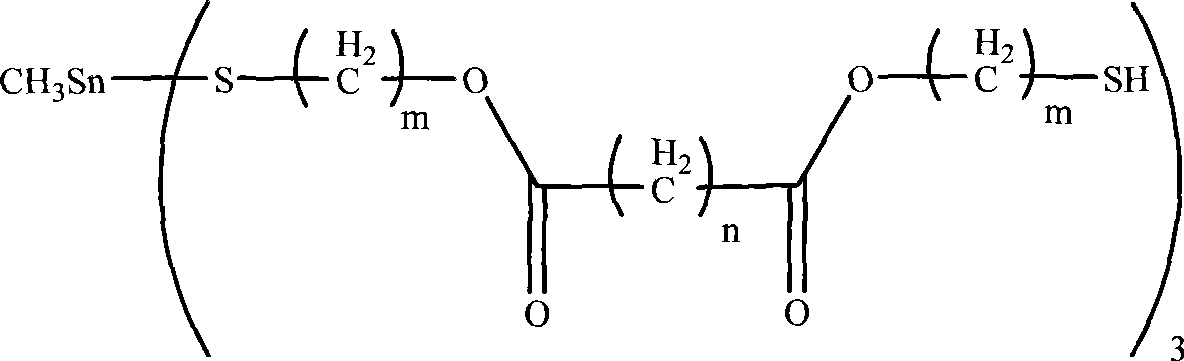

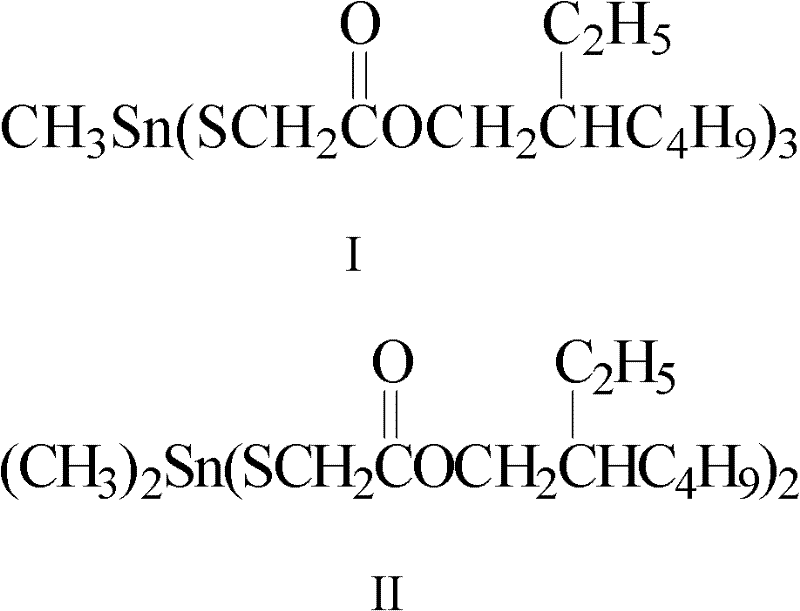

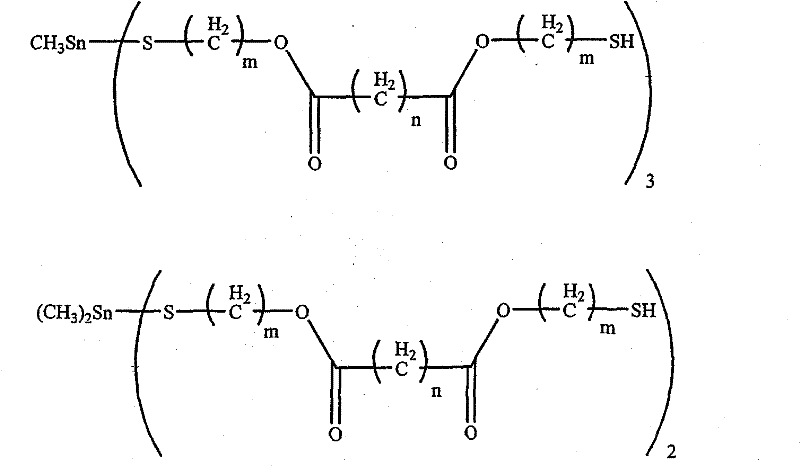

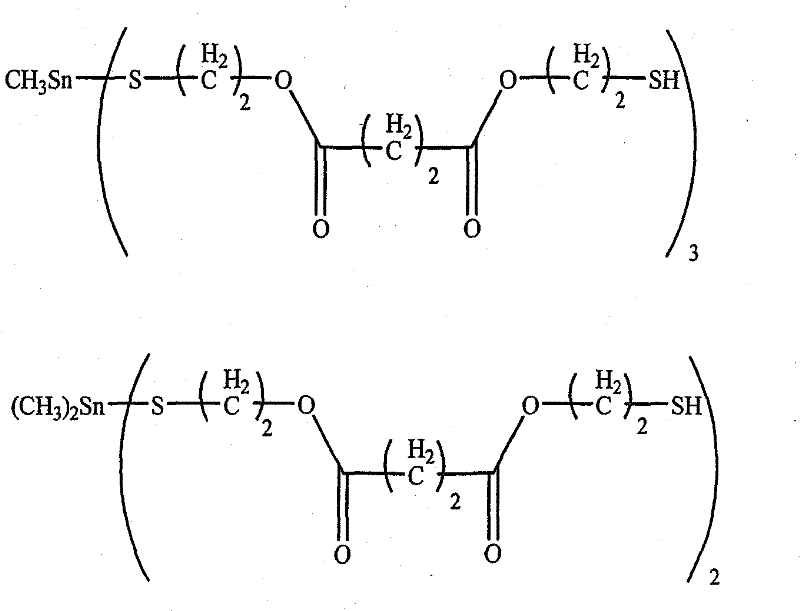

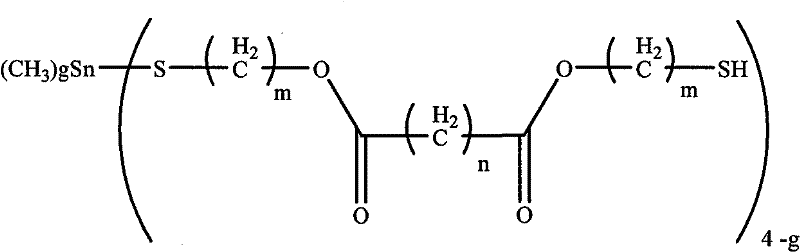

Methyltin stabiliser and preparation thereof

ActiveCN101475584AReduce tin contentImprove thermal stabilityTin organic compoundsNon toxicityWeather resistance

The invention provides a methyl tin stabilizer and a method for preparing the same and relates to the technical field of organic chemistry. The method comprises: in the presence of a catalyst, mixing and refluxing an alkyl diacid, mercaptoethanol and a solvent; after the reaction finishes, washing the solution with water and obtaining a dimercaptoester; and adding the obtained dimercaptoester into an aqueous solution of methyltin trichloride or / and dimethyltin dichloride, adjusting the pH value of the system by using an alkaline solution, carrying out an pre-esterification reaction before heat preservation, heating for carrying out a post-esterification reaction, washing an organic phrase after the reaction finishes, separating the organic phrase from a water phrase, carrying out vacuum water removal and obtaining the methyl tin stabilizer. The methyl tin stabilizer has high transparency, weather resistance, compatibility, pressure analysis, non-toxicity, excellent high-temperature stability and low tin content. The low tin-content methyl tin has higher thermal stability than the prior methyl tin, so final PVC products can achieve the same stability with even smaller amount of added methyl tin stabilizer, the use of tin is reduced and the production costs of terminal clients are reduced at last.

Owner:YANGZHOU HATAIKE TECH

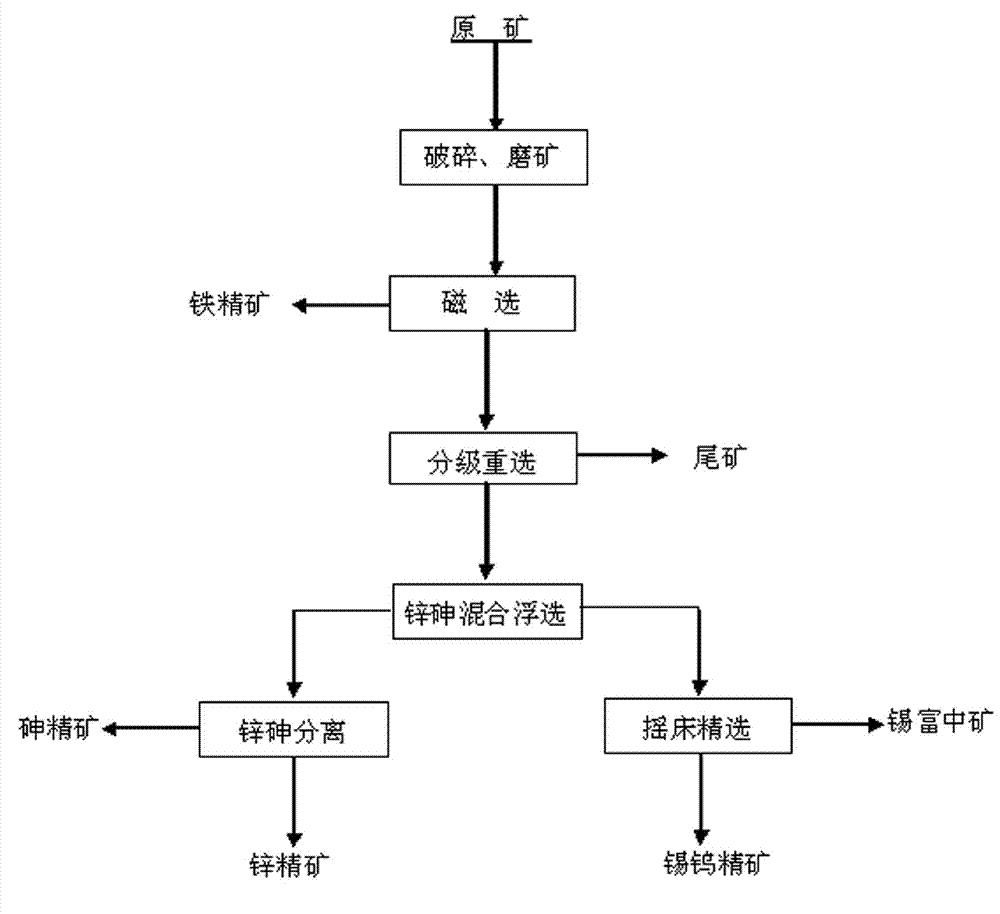

Polymetallic (iron, tin and zinc) ore comprehensive recovery beneficiation method

The invention relates to a polymetallic (iron, tin and zinc) ore comprehensive recovery combined beneficiation method, which belongs to the technical field of nonferrous metals ore beneficiation. The method comprise the steps of: smashing, grinding, magnetically separating ores to obtain iron ore concentrate; reselecting non-magnetic ore directly to obtain a tin, zinc, arsenic and tungsten heavy concentrate product; carrying out zinc and arsenic bulk flotation for the heavy concentrate product to obtain zinc and arsenic bulk concentrate; further separating the zinc and arsenic bulk concentrate to obtain zinc concentrate and arsenic concentrate, wherein floated tailings are tin and tungsten concentrates; then concentrating by a swing table to further separate high grade tin concentrate, tungsten concentrate, and tin-richened middlings. The polymetallic (iron, tin and zinc) ore comprehensive recovery combined beneficiation method provided by the invention is short in process flow, simple in method, simple to operate, energy-saving, small in occupied area, low in comprehensive cost of beneficiation, and high in recovery yield of associated metals such as iron, tin and the like.

Owner:YUNNAN TIN GROUP HLDG

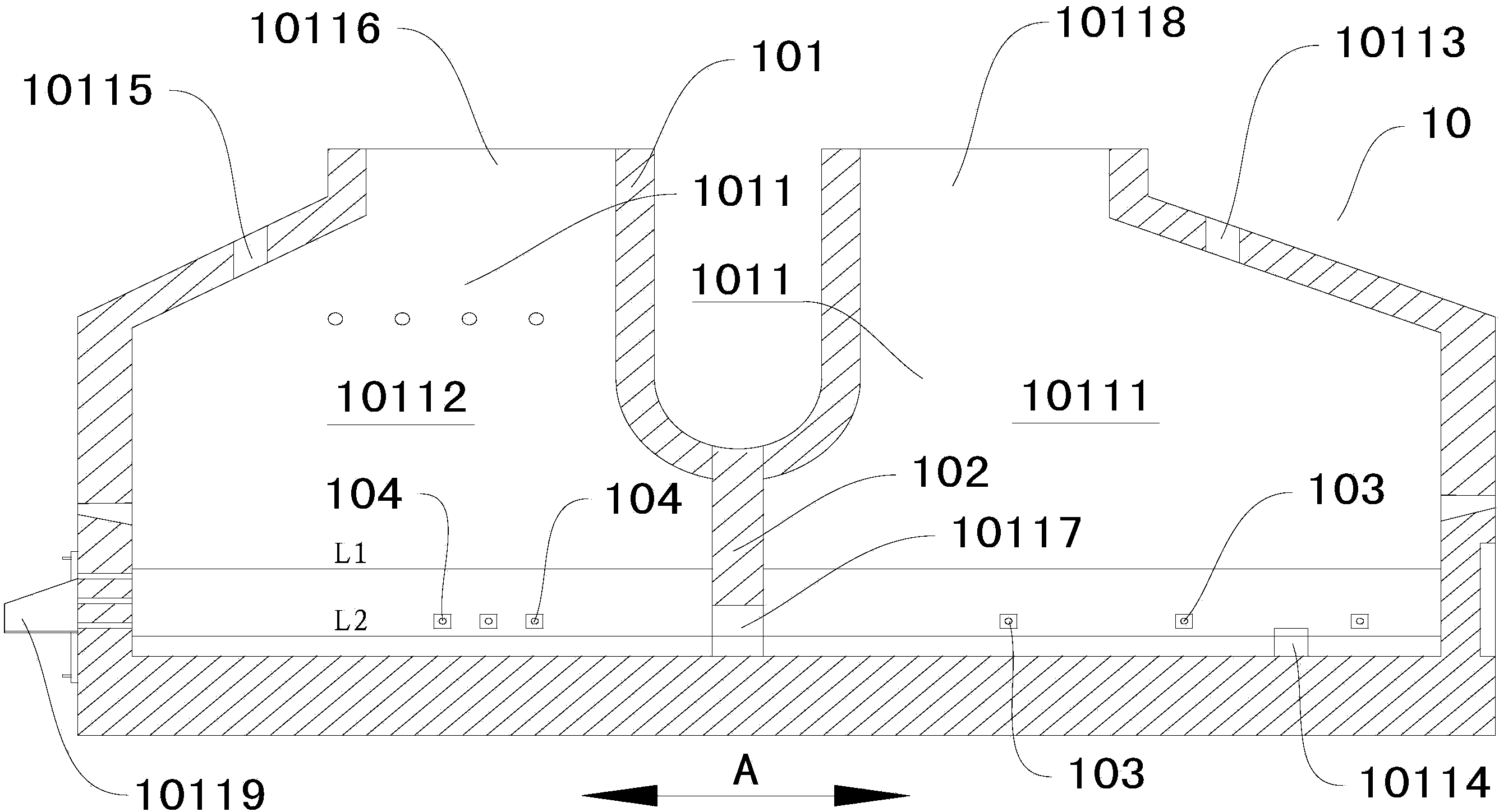

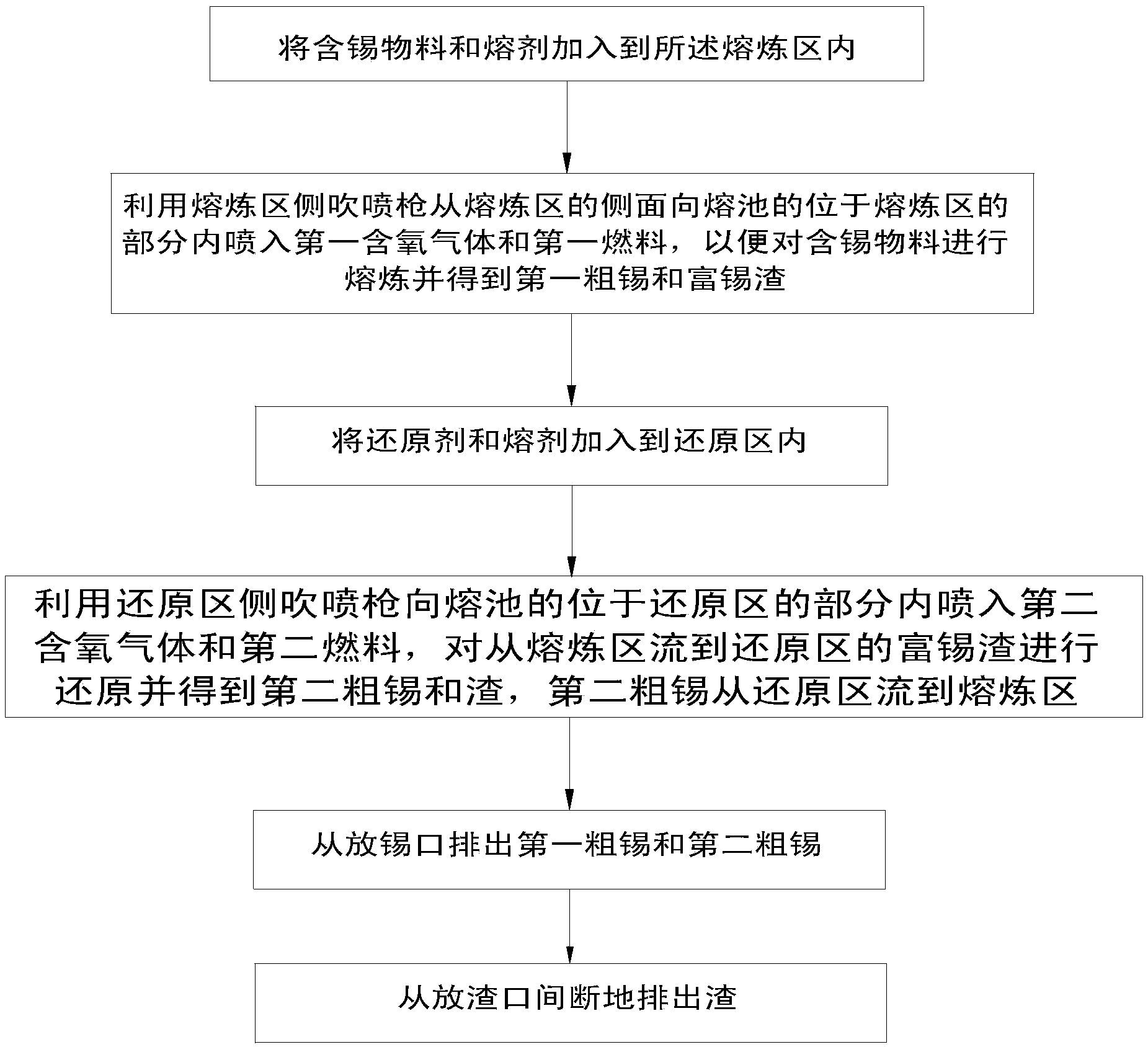

Continuous lateral blowing tin smelting device

The invention relates to a continuous lateral blowing tin smelting device, comprising a reacting furnace, a lateral blowing spray gun of a smelting zone, and a lateral blowing spray gun of a reducing zone, wherein a furnace chamber is formed inside the reacting furnace; a molten pool for containing slag and tin liquor is arranged at the lower part of the furnace chamber; a partition wall is arranged inside the furnace chamber and extends into the molten pool, so as to divide the furnace chamber into a smelting zone and a reducing zone; the molten pool in the smelting zone is communicated with the molten pool in the reducing zone; a charge door and a tin discharge hole are formed in the wall of the smelting zone; a reducing agent inlet and a slag discharge hole are formed in the wall of the reducing zone; a smoke outlet communicated with each of the smelting zone and the reducing zone is formed in the top wall of the furnace chamber; the lateral blowing spray gun of the smelting zone is arranged on the lateral wall of the smelting zone; the lateral blowing spray gun of the reducing zone is arranged on the lateral wall of the reducing zone. The continuous lateral blowing tin smelting device has the advantages of low energy consumption, good sealing property, high environmental protection property, simple structure, easy operation and the like.

Owner:CHINA ENFI ENGINEERING CORPORATION

Micro-nanoparticle reinforced high-indium copper-based active solder and preparation method thereof

ActiveCN110640351ALower melting temperatureDiffusion strengtheningWelding/cutting media/materialsSoldering mediaMicro nanoIndium

The invention relates to a micro-nanoparticle reinforced high-indium copper-based active solder. The active solder comprises the following raw materials of, in parts by weight, 85 - 95 parts of base component, 2.5 - 9 parts of active component, 0.1 - 1 part of micro-component and 2 - 5 parts of micro-nano reinforced particles. A preparation method of the micro-nanoparticle reinforced high-indium copper-based active solder comprises the following steps of weighing and preparing the materials, high-frequency induction melting an intermediate alloy, vacuum smelting a solder, and conventional processing the solder into a filamentous or ribbon-shaped active solder. According to the micro-nanoparticle reinforced high-indium copper-based active solder, the formula is reasonable in design and highin cost performance; the basic component comprises the following components of, in parts by weight, 5 - 15 parts of indium, 3 - 8 parts of tin, 1 - 3 parts of manganese, 1 - 5 parts of phosphorus, 0.5 - 3 parts of antimony, 0.5 - 5 parts of silicon, 0.5 - 5 parts of germanium and the balance copper, through a method of replacing the tin with the indium and the phosphorus compositely, not only isthe melting temperature of the copper-based active solder reduced, but also the plasticity of the solder is improved and the processability of the solder is improved; and by adding the micro-nanoparticles, the strength of the solder and a soldered joint is improved.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

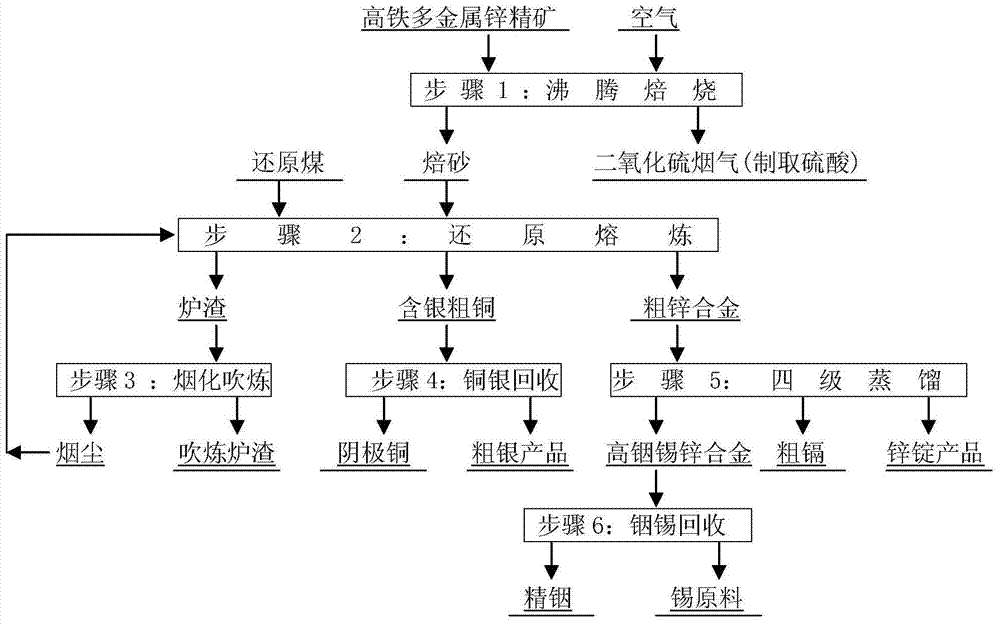

Method for treating high-iron and multi-metal zinc concentrate

ActiveCN103695635AEfficient recyclingAdvanced technical indicatorsPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention discloses a method for treating high-iron and multi-metal zinc concentrate. The method comprises the following steps of: boiling and roasting zinc concentrate containing 14-20 percent of Fe, 0.03-0.10 percent of In, 0.2-0.6 percent of Cu, 0.2-0.6 percent of Cd, 0.005-0.02 percent of Ag. 0.1-0.2 percent of Sn and 40-50 percent of Zn to produce flue gas and a roasted product; preparing sulfuric acid by using the flue gas; blending the roasted product in a reducing agent to be reduced and smelted to produce a crude zinc alloy, crude silver-containing copper and furnace cinder; blowing the furnace cinder to obtain soot and blown furnace cinder, returning the soot to be reduced and smelted, and selling the blown furnace cinder; extracting copper and silver from crude silver-containing copper; enabling the crude zinc alloy to enter a conventional distillation tower for performing four stages of distillation to produce a pyrogenic process distilled zinc product, a crude cadmium product and a high-indium, tin and zinc alloy; extracting indium and tin from the high-indium, tin and zinc alloy. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in product cost, and clean and environment-friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

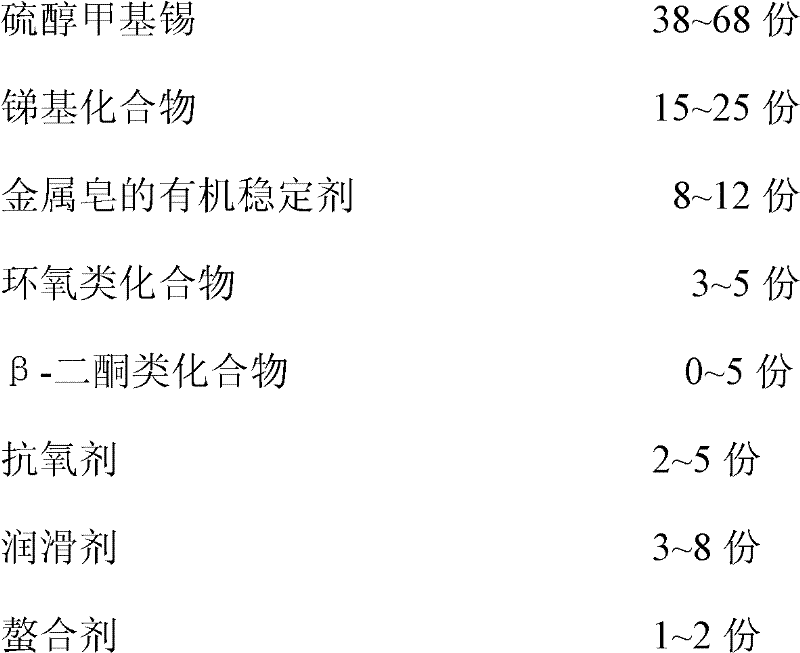

Efficient composite PVC (polyvinyl chloride) heat stabilizer and production method thereof

ActiveCN105218973AImprove the lubrication effectReduce heat dwell timePhosphoric Acid EstersPolyvinyl chloride

The invention belongs to the field of plastic additives and particularly relates to an efficient composite PVC (polyvinyl chloride) heat stabilizer. The heat stabilizer is prepared from 80-98 parts of methyl tin mercaptide, 2-20 parts of a liquid calcium-zinc stabilizer, 0.1-5 parts of phosphite ester and 0.1-5 parts of epoxidized soybean oil. According to characteristics of the methyl tin mercaptide and the liquid calcium-zinc stabilizer, the heat stabilizer taking the methyl tin mercaptide and the liquid calcium-zinc stabilizer as main materials and the phosphite ester and the epoxidized soybean oil as auxiliary materials is formed. The heat stabilizer has the characteristics that the lubrication property of PVC melts is improved, the heat retention time of the melts is shortened, and the consumption of the heat stabilizer is reduced; the tin content of the methyl tin mercaptide heat stabilizer is decreased, and the consumption of rare metal tin is reduced; the PVC is low in smell and low in toxicity during processing; the heat stabilizer is easy to prepare, low in processing cost and convenient to popularize industrially.

Owner:云南锡业锡化工材料有限责任公司

Copper-based brazing filler metal with gradually-changing coefficient of thermal expansion and preparing method of copper-based brazing filler metal

ActiveCN110549032AReduce tin contentLower melting temperatureWelding/cutting media/materialsSoldering mediaActive agentHot isostatic pressing

The invention discloses a copper-based brazing filler metal with a gradually-changing coefficient of thermal expansion and a preparing method of the copper-based brazing filler metal. The copper-basedbrazing filler metal is prepared from metal powder, thermal expansion coefficient adjusting powder, an active agent and a dispersing agent. The preparing method of the copper-based brazing filler metal comprises the steps that the mechanical alloying metal powder and the active agent are mixed to obtain mixed powder A, the mixed powder A is equally divided into n parts, the thermal expansion coefficient adjusting powder and the dispersing agent are mixed to obtain mixed powder B, and the mixed powder B is equally divided into n(n-1) / 2 parts; the first part of the mixed powder A and 0 mixed powder B are mixed to obtain mixed powder AB1, and the nth part of the mixed powder A and the (n-1)th part of the mixed powder B are mixed to obtain mixed powder ABn; and the mixed powder AB1 is evenlyscattered into a hot-pressed sintering grinding die to obtain a first powder layer, the rest can be done in the same manner, the nth powder layer is prepared, and the n layers of powder is subjected to vacuum hot isostatic pressing to obtain a static pressed blank, multi-pass cold rolling is carried out on the static pressed blank, and the copper-based brazing filler metal is obtained. By means ofthe copper-based brazing filler metal with the gradually-changing coefficient of thermal expansion and the preparing method of the copper-based brazing filler metal, joint residual stress is reduced,the joint strength is improved, and the problem that the reliability is poor when traditional brazing filler metal and ceramic-metal are brazed is solved.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Green and safe methyl tin mercaptide preparation method

InactiveCN105924467AGood stabilization effectImprove stabilityTin organic compoundsWeather resistanceAqueous solution

The invention relates to a preparation method for organic tin type materials, in particular to a green and safe methyl tin mercaptide preparation method. The green and safe methyl tin mercaptide preparation method comprises the following steps: (1), tin processing: putting metal tin and a first catalyst into a reaction kettle, halogenating after charging methyl chloride, adding a redistribution agent to perform a tin reaction, distilling, receiving fractions with gas temperature of 150-230 DEG C, and using pure water to absorb, thereby obtaining a methyl tin chloride water solution; (2), synthesizing: adding the obtained methyl tin chloride water solution into isooctyl thioglycolate, adding a second catalyst, stirring to react at 5-15 DEG C for 0.2-0.4 hour, adding alkali liquid, continuously stirring to react till a pH value of a reaction system reaches 7-9, heating to 60-70 DEG C, reacting for 1-1.5 hours, standing, cooling down, and layering; (3), rinsing; (4) distilling. According to the green and safe methyl tin mercaptide preparation method, a product has high transparency, weather resistance, compatibility and volatilization precipitation resistance, and has good heat stability and low tin content.

Owner:ANHUI SHENGHUA XINAOTE CHEM CO LTD

Indium tin oxide electrochemiluminescence reaction electrode regeneration cleaning method

InactiveCN104931568AStrong elution abilityReduce adsorptionMaterial electrochemical variablesIndium tin oxideElectrochemiluminescence

The invention relates to an indium tin oxide electrochemiluminescence reaction electrode regeneration cleaning method in the technical field of electrochemiluminescence biology detection and aims to enable an indium tin oxide electrochemiluminescence reaction electrode to be capable of being used repeatedly for multiple times. The technical scheme includes that that indium tin oxide electrochemiluminescence reaction electrode regeneration cleaning method includes the steps of aqueous-solution cleaning liquid soaking and cleaning, absolute ethyl alcohol soaking and cleaning, electrode surface activating treatment, drying and the like.

Owner:彭梓 +1

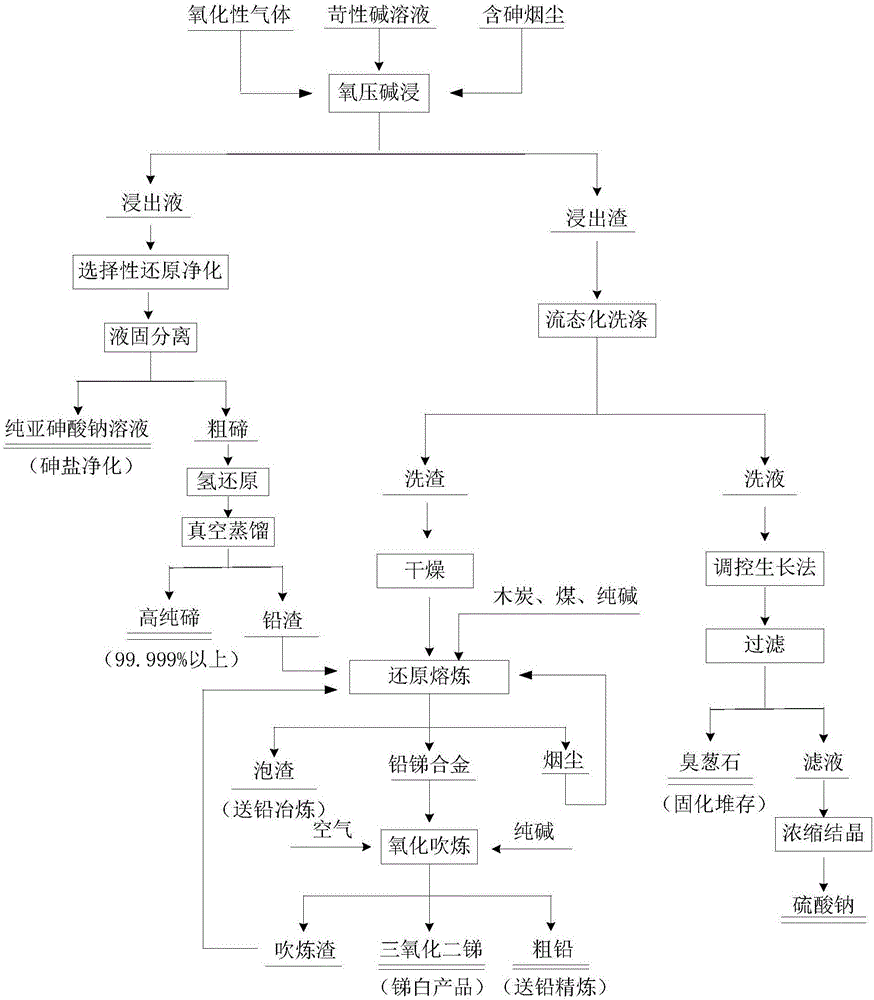

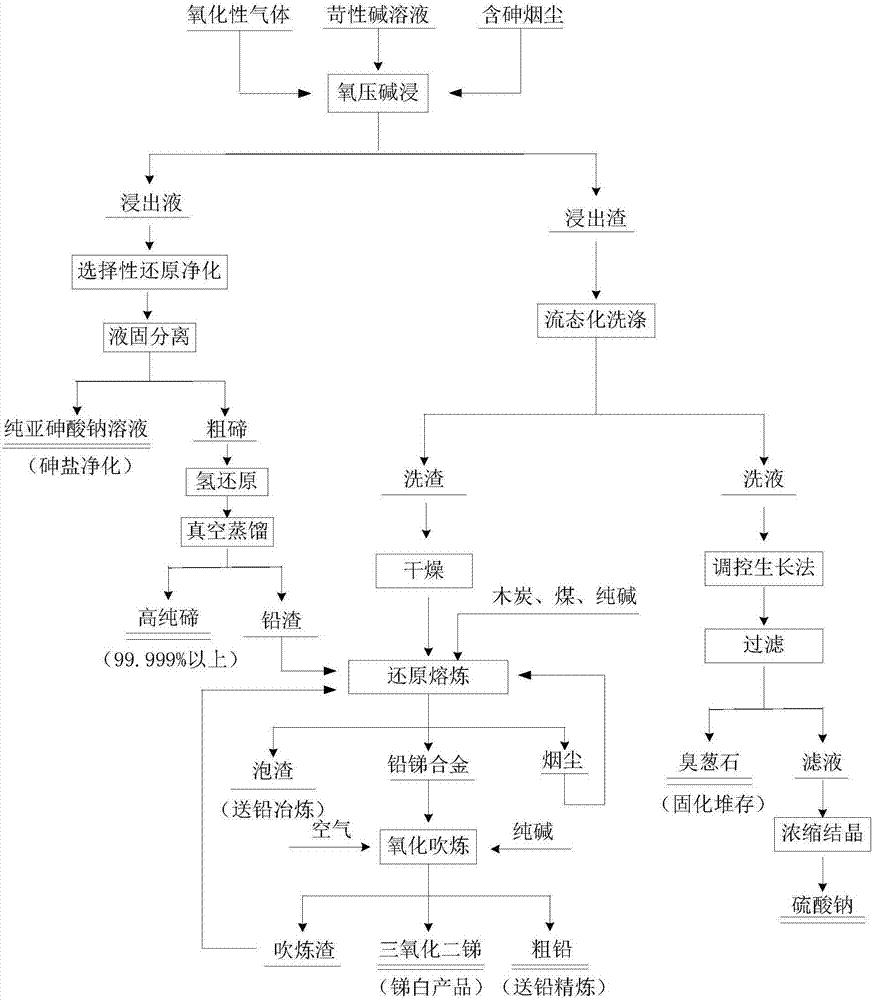

Harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke

The invention provides a harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke. All valuable elements are recycled and utilized through the procedures of carrying out oxygen pressure leaching via caustic alkali; carrying out selective reduction purification on leachate; during purification, carrying out hydrogen reduction and vacuum distillation on obtained crude tellurium so as to obtain high-purity tellurium; after purification, obtaining a pure sodium arsenite solution, and using the solution for the arsenic salt purification of a zinc sulfate solution so as to remove cobalt and nickel; carrying out fluidization washing on leaching residues; after washing, solidifying arsenic in the solution, and carrying out reduction smelting on the residues; and carrying out oxidization blowing and the like. The arsenic is removed from the smoke, stibium, lead, bismuth, stannum and the like are kept in the residues from which the arsenic is removed as much as possible, and the deep separation of the arsenic and the stibium is realized. The obtained pure sodium arsenite solution is used for the arsenic salt purification of the zinc sulfate solution used for wet-process zinc smelting so as to remove the cobalt and nickel raw materials, part of sodium arsenate with high impurity content is solidified, the arsenic is precipitated, the harmless recycling of the arsenic resource is realized, and the valuable elements, such as the tellurium, the stibium, the lead and the bismuth are recycled. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved.

Owner:CENT SOUTH UNIV

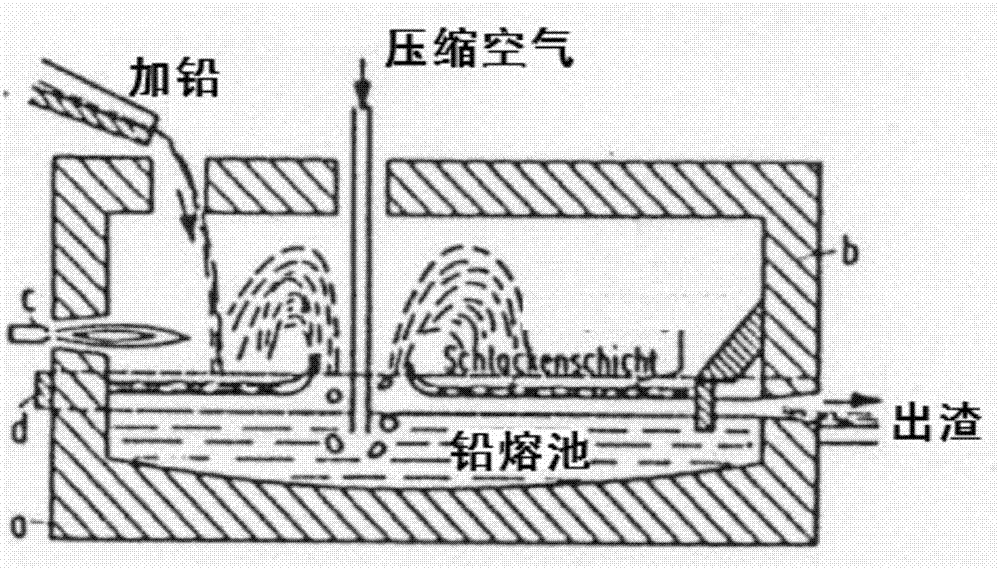

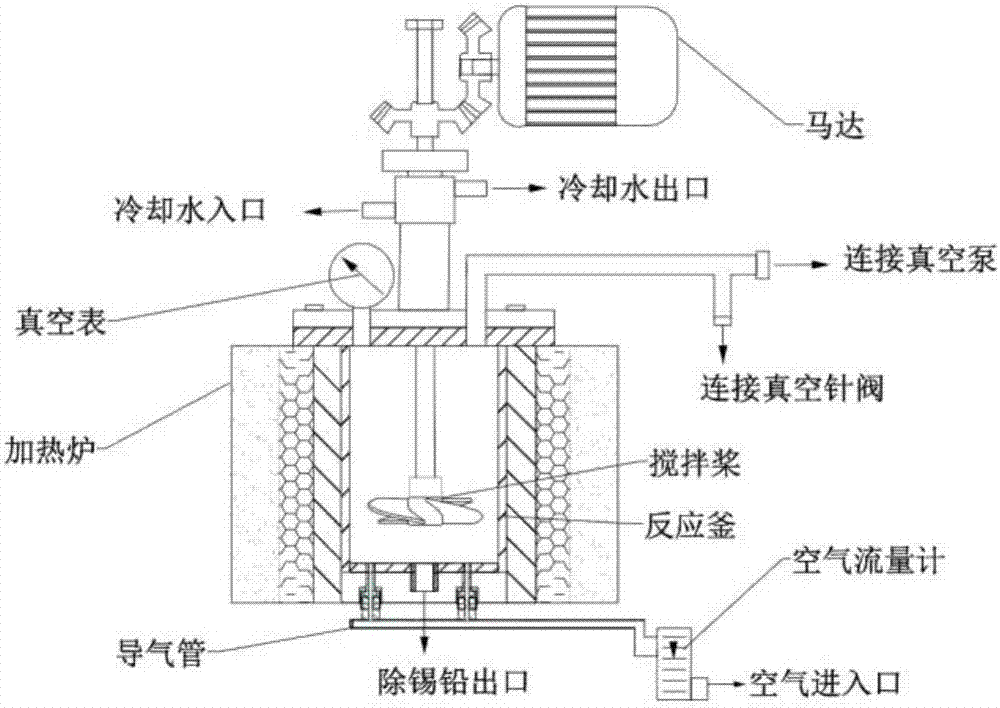

Crude lead oxidizing and refining process and device

The invention discloses a crude lead oxidizing and refining detinning process and device. The process comprises the steps that under a sealed vacuum condition, temperature is raised to enable crude lead to be molten, air and / or oxygen are / is sucked from air inlets at the bottom of a reaction kettle to form small bubbles, stirring is conducted to be uniform, an oxidizing reaction is conducted, and detinned lead is obtained. According to the crude lead oxidizing and refining process and device, the oxygen content on the surface of molten lead can be decreased, oxidation of a large amount of lead on the surface of a melt can be reduced, and metallic lead losses caused by local overoxidation inside the melt lead can be avoided. When the process is applied for treating crude lead with the tin content ranging from 0.1% to 0.2%, the detinned lead with the tin content lower than 5 ppm can be obtained, and the tin content in the detinned lead reaches the tin content standard of national refined-lead first-grade products; and meanwhile, the lead loss is lower than 5%, the tin content in the slag phase is about 8%, and some defects in an existing detinning process are overcome.

Owner:CENT SOUTH UNIV

Lead-free golden-plating materials

InactiveCN1818110ALow costSmall loss angleThin/thick film capacitorStacked capacitorsMetallic materialsCopper

A lead-free metal spraying stuff includes the Sn, Sb, Cu, Zn and so on. The weight percentage of the composition is Sn 20-90%, Sb 0.1-1%, Cu 0.01-0.1%, the impurity is less than 0.05%, the residue is Zn; the weight percentage of the impurity is Fe<=0.01%, Si<=0.01%, Pb<=0.03%, the cadmium<=0.002%.the invention can decrease the electrical resistivity and improve the strength by decreasing the content of the Cu and Ti, also it can decrease the content of Sn to 20%, so it can save the cost.

Owner:戴国水

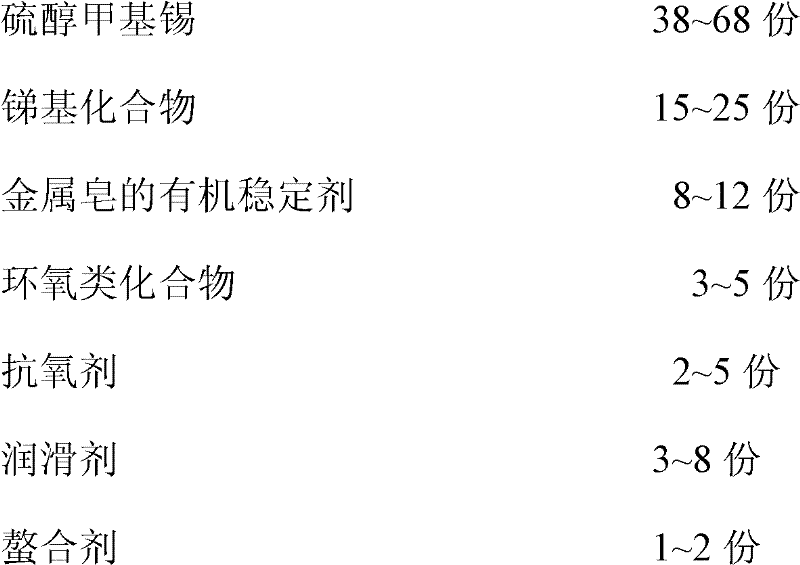

Methyltin composite heat stabilizer and preparation method thereof

The invention discloses a methyltin composite heat stabilizer, which comprises the following components in part by weight: 38 to 68 parts of methyl tin mercaptide, 15 to 25 parts of antimonide based compound, 8 to 12 parts of organic stabilizer of metallic soap, 3 to 5 parts of epoxy compound, 2 to 5 parts of antioxidant, 3 to 8 parts of lubricating agent and 1 to 2 parts of chelant, wherein the methyl tin mercaptide is a composite in which the mass ratio of S,S',S''-tris(isooctyl thioglycollate)-methyltin to S,S'-bis(isooctyl thioglycolate) dimethyltin is 20:80. The methyltin composite heat stabilizer has the advantages of high quality, low toxin, environmental protection, low tin content in the formula, strong practicability and wide application range; and materials prepared from the methyltin composite heat stabilizer, such as PVC sheets, pipes and blown films have the advantages of excellent initial and long-term heat stability, good lubrication system, no precipitation and good oxidation resistance, wherein the sheets and the blown films have good transparency.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

Method for obtaining sponge iron by treating high-iron low-tin ore by sulfurizing volatilization direct-reduction process

ActiveCN103088181AAchieve recyclingSolve the problem of high tin contentFluidised-bed furnacesFlue gasHot Temperature

The invention provides a method for obtaining sponge iron by treating high-iron low-tin ore by a sulfurizing volatilization direct-reduction process. The method comprises the steps of: respectively drying and grinding the high-iron low-tin raw ore, a sulfurizing agent and a reducing agent; adding the sulfurizing agent and the reducing agent in the raw ore and evenly mixing; putting the mixture obtained from the former step at the temperature of 1000-1300 DEG C simultaneously introducing inert gas with a flow rate of 0.2-1L / min, and preserving the temperature for 20-80minutes for carrying out sulfurizing volatilization treatment; and then introducing oxide gas with a flow rate of 0.2-1L / min and preserving the temperature for 20-80minutes for direct reduction; conventionally cooling high temperature flue gas generated in reaction, carrying out dust collection treatment for recovering tin resources in the high temperature flue gas, and cooling the remaining materials, thus obtaining the sponge iron. The high-iron low-tin ore is treated by utilizing the easy sulfurizing-volatilization property of tin, the content of tin can be reduced, tin is recovered and the comprehensive recovery rate of the tin resource is improved. Simultaneously, a coal-based direct reaction is carried out for producing the high-grade sponge iron, the technical flow is shortened and the comprehensive utilization rate of an iron resource is improved.

Owner:KUNMING UNIV OF SCI & TECH

Method for decreasing impurity element tin in complex multi-element brass alloys

The invention discloses a method for decreasing impurity element tin in complex multi-element brass alloys and belongs to the technical field of melt purification in the copper smelting process. A main treatment technology comprises the steps of sorting pretreatment, feeding and melting, smelting, and casting treatment. Complex multi-element scrap brass raw materials are subjected to sorting pretreatment firstly, after melting in an induction furnace, 2-20% (in percentage by weight) of a copper-calcium alloy (Cu-Cu 10) is added, smelting and heat preservation are conducted for 5-20 minutes, then 1% of slag conglomeration agent (sodium fluoride) is added, and heat preservation is conducted for 15-30 minutes, and casting is conducted until ingots are formed. Thecontent of tin in the treatedbrass alloys is decreased by 20-50%, so that the content of the impurity element tin in the complex multi-element brass alloys is decreased to the beneficial element range, and the quality of the alloys is improved.

Owner:UNIV OF SCI & TECH BEIJING

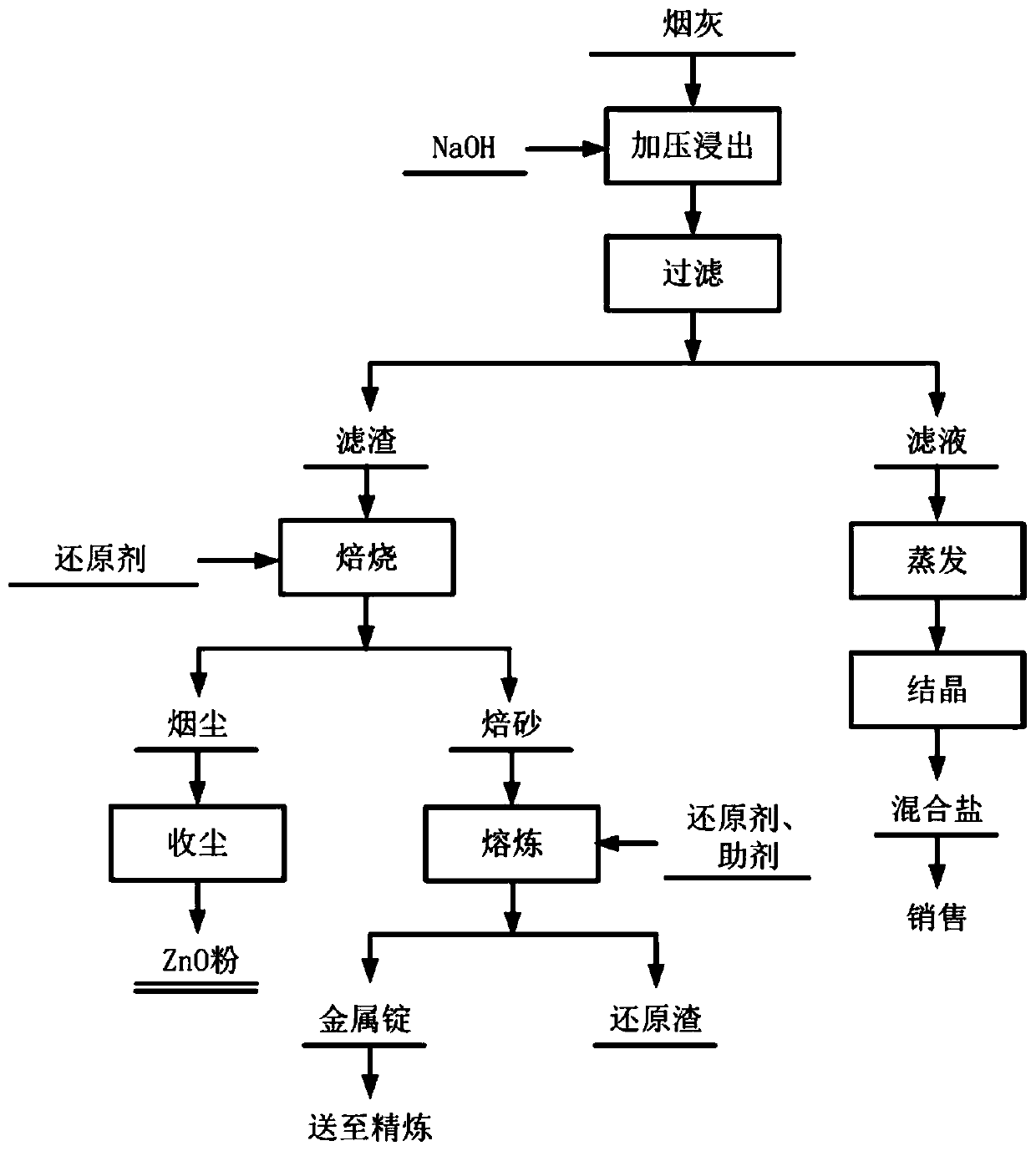

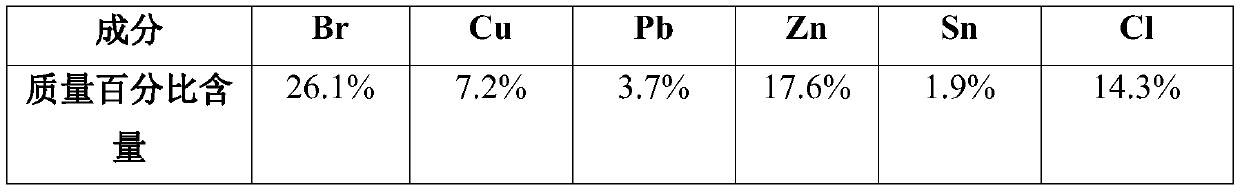

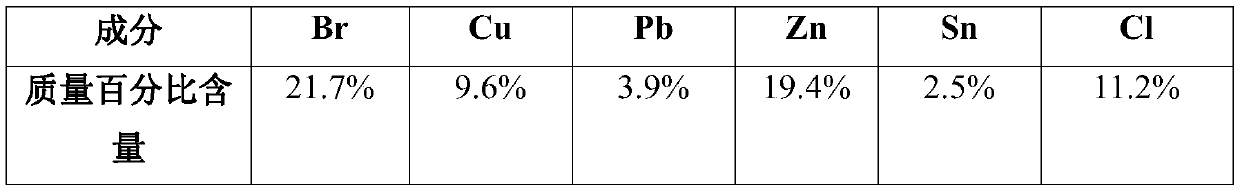

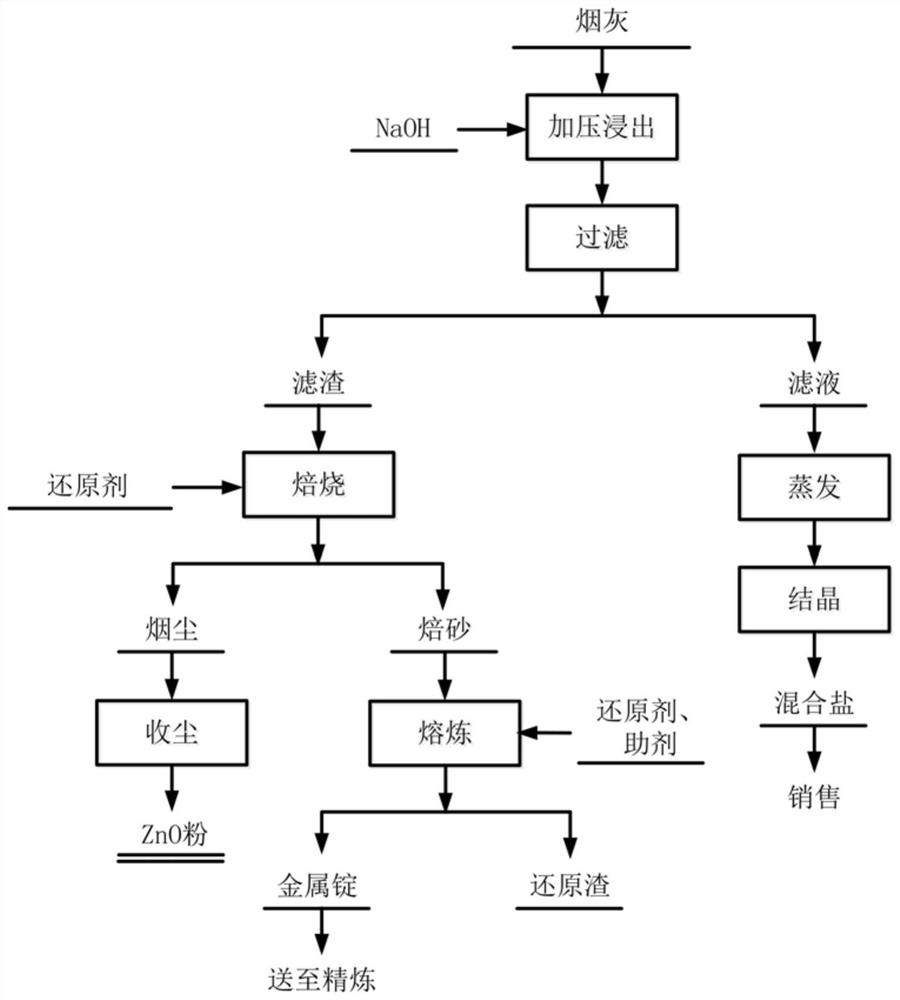

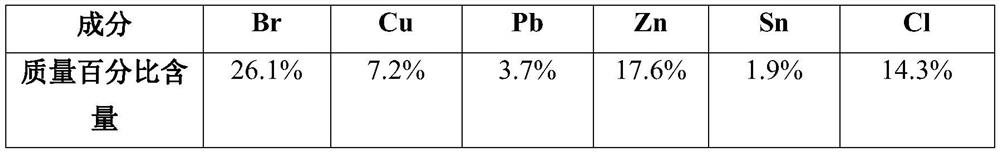

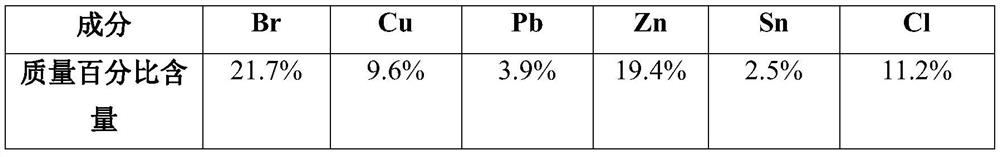

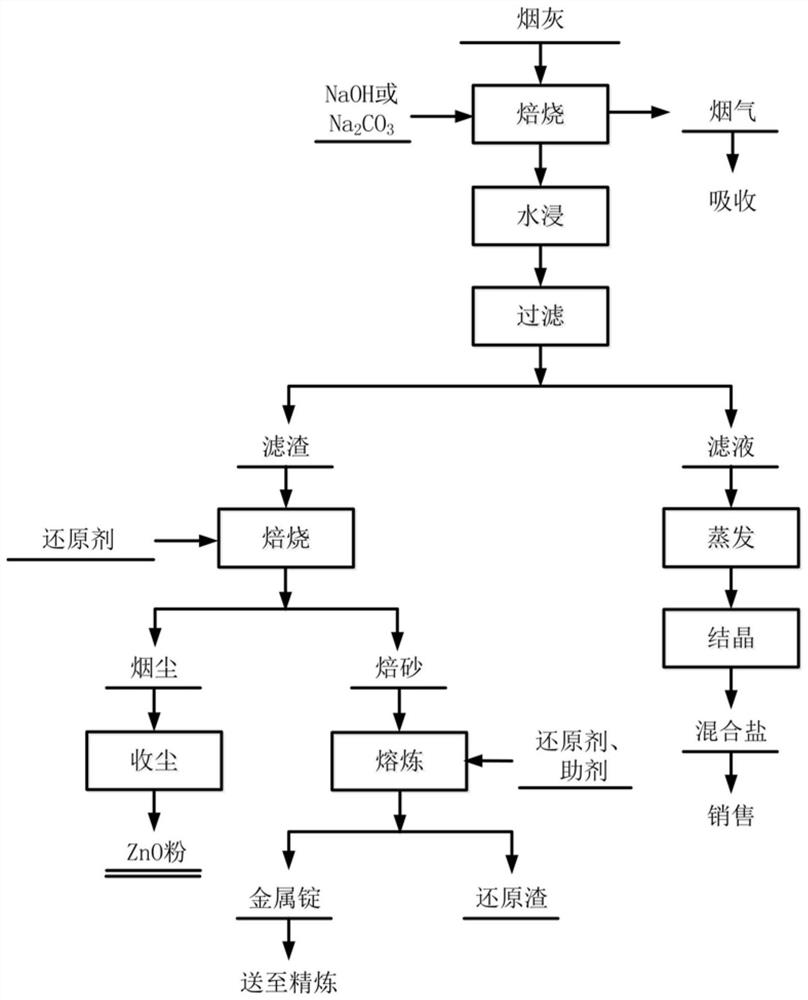

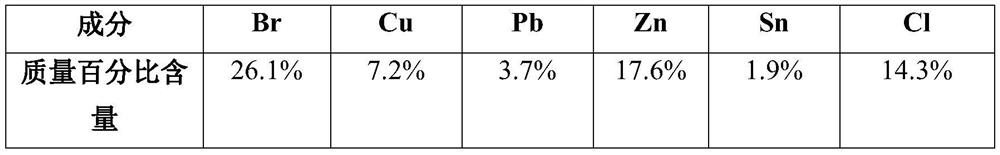

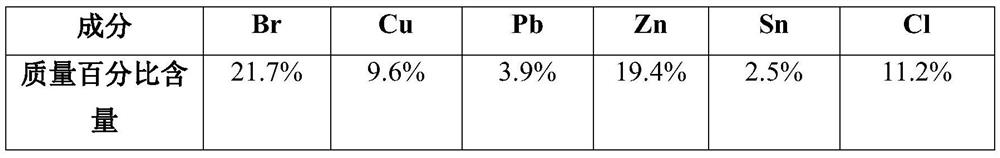

Waste circuit board smelting soot comprehensive recycling method

The invention belongs to the technical field of solid waste treatment, and particularly discloses a waste circuit board smelting soot comprehensive recycling method. According to the recycling method,alkali is added into smelting soot firstly for pressurized leaching, metal bromine and chlorine salt in the soot are converted into hydroxide precipitate, bromine and chlorine are converted into solvable NaBr and NaCl correspondingly, separation of bromine and chlorine from valuable metal can be achieved, filter liquor is evaporated and crystallized to obtain a coarse salt product, filter residueis reduced and roasted, through volatilization, zinc in slag can be recycled, a high-purity zinc oxide product is obtained, then a roasted product is further subjected to temperature rise smelting, and ingot metal and harmless reducing slag can be obtained. The waste circuit board smelting soot comprehensive recycling method effectively recycles bromine, chlorine and valuable metal in the waste circuit board smelting soot.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

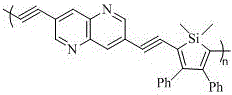

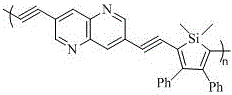

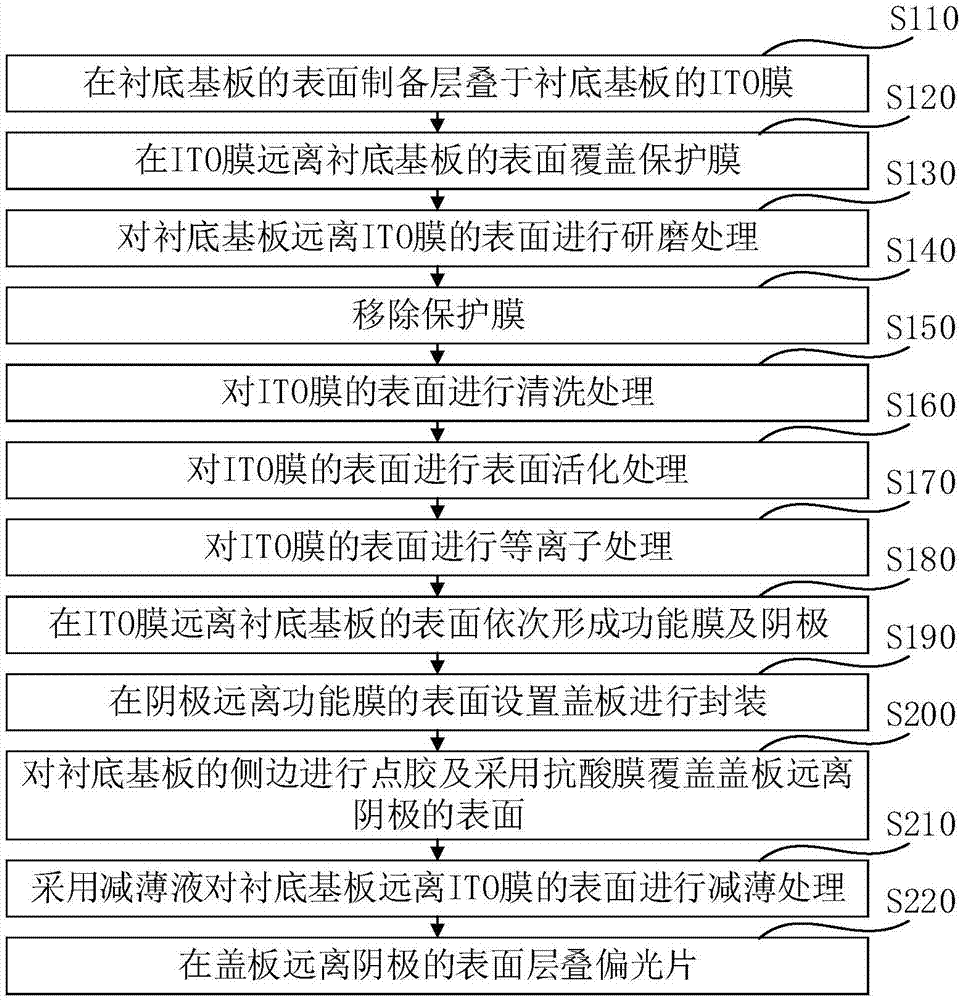

Preparation method of organic light-emitting display panel

ActiveCN108011053AIncrease brightnessImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerWorking life

The invention relates to a preparation method of an organic light-emitting display panel. The preparation method of the organic light-emitting display panel comprises the following steps of preparingan ITO film stacked on a substrate on the surface of the substrate; carrying out cleaning treatment on the surface of the ITO film; carrying out surface activation treatment on the surface of the ITOfilm; carrying out plasma treatment on the surface of the ITO film until a work function of the surface of the ITO film is 5.2-5.6eV; sequentially forming a functional film and a cathode on the surface of the ITO film, wherein the functional film comprises a hole injection layer; and arranging a cover plate on the surface, far away from the functional film, of the cathode for carrying out packaging. According to the preparation method of the organic light-emitting display panel, the potential-energy difference between ITO and the hole injection layer can be effectively reduced, hole injectionis facilitated, the work function of the surface of the ITO film can be improved and the smoothness of the surface of the ITO film can be improved, so that the light-emitting efficiency of the organiclight-emitting display panel is further improved and the working life of the organic light-emitting display panel is further prolonged.

Owner:WGTECH JIANGXI

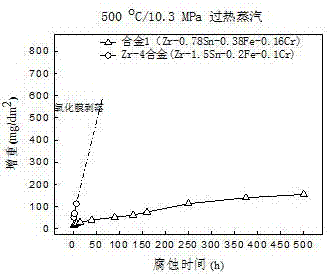

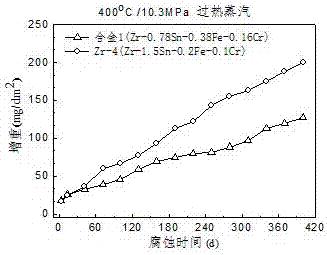

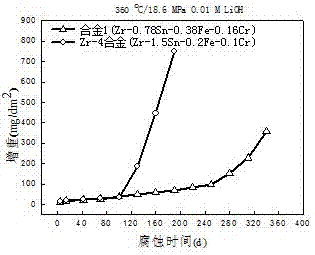

Zirconium alloy for cladding material of nuclear fuel element in non-hydrogenated deoxidization pressurized water reactor

InactiveCN107034385AImprove corrosion resistanceExcellent boil-like corrosion resistanceOptical rangefindersNuclear energy generationPressurized water reactorNiobium

The invention relates to zirconium alloy for a cladding material of a nuclear fuel element in a non-hydrogenated deoxidization pressurized water reactor, and belongs to the technical field of zirconium alloy materials. The zirconium alloy comprises, by weight, 0.73%-1.1% of Sn, 0.25%-0.6% of Fe, 0.1%-0.25% of Cr and the balance Zr and inevitable impurities. The zirconium alloy does not contain niobium and thus is insensitive to dissolved oxygen in corrosive media, and meanwhile, the alloy has extremely excellent corrosion resistance and is obviously superior to Zr-4 alloy under the corrosive condition of superheated steam at the temperature of 500 DEG C and under the pressure of 10.3 Mpa, the corrosive condition of superheated steam at the temperature of 400 DEG C and under the pressure of 10.3 Mpa, the corrosive condition of a LiOH water solution at the temperature of 360 DEG C and under the pressure of 18.6 Mpa / 0.01 M and the corrosive condition of deionized water at the temperature of 360 DEG C and under the pressure of 18.6 Mpa. The zirconium alloy is used for the cladding material of the nuclear fuel element in the non-hydrogenated deoxidization pressurized water reactor.

Owner:SHANGHAI UNIV

Biodegradable medical zinc-tin alloy as well as preparation method and application thereof

InactiveCN112410615AOvercome the defect of loss of mechanical propertiesOvercoming non-degradable weaknessesSurgeryProsthesisHemolysisIngot

The invention relates to the technical field of medical materials, in particular to a biodegradable medical zinc-tin alloy and a preparation method and application thereof. The biodegradable medical zinc-tin alloy comprises zinc and tin, wherein tin accounts for 0-10wt%, excluding 0, of the zinc-tin alloy, a total content of the zinc and the tin is 0-99.95wt% excluding 0, and the balance is impurities. According to the preparation method, homogenization heat treatment is conducted on an alloy ingot in a casting state, and compared with pure zinc, the biodegradable zinc-tin alloy has the advantages that the mechanical property is good, processing is easy, the corrosion resistance is good, the hemolysis rate is lower than 5%, the surface adhesion morphology is good, and the blood compatibility is good, and the alloy can be used as a material for preparing various degradable medical implants.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

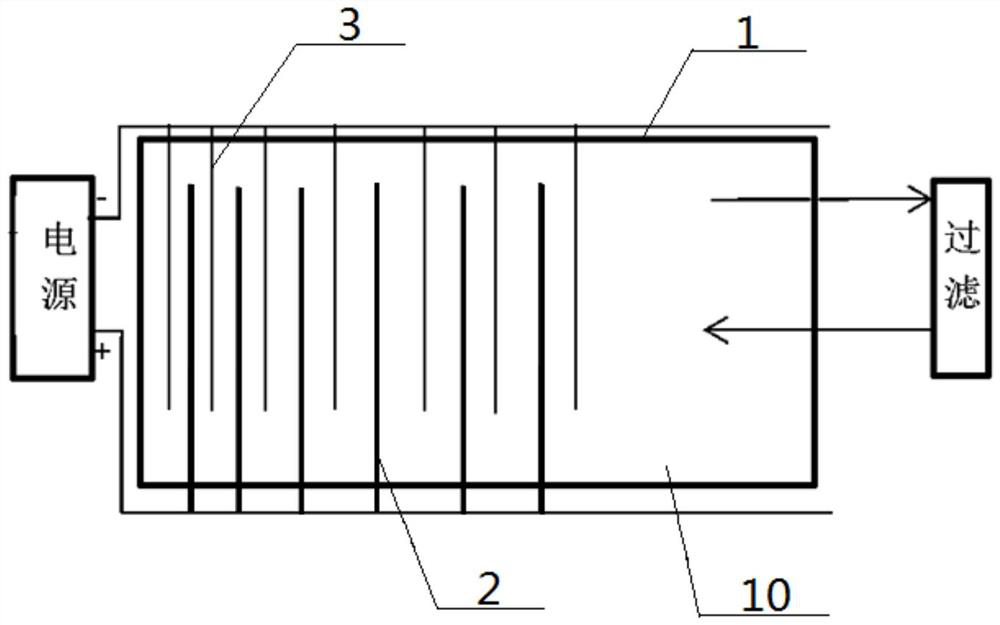

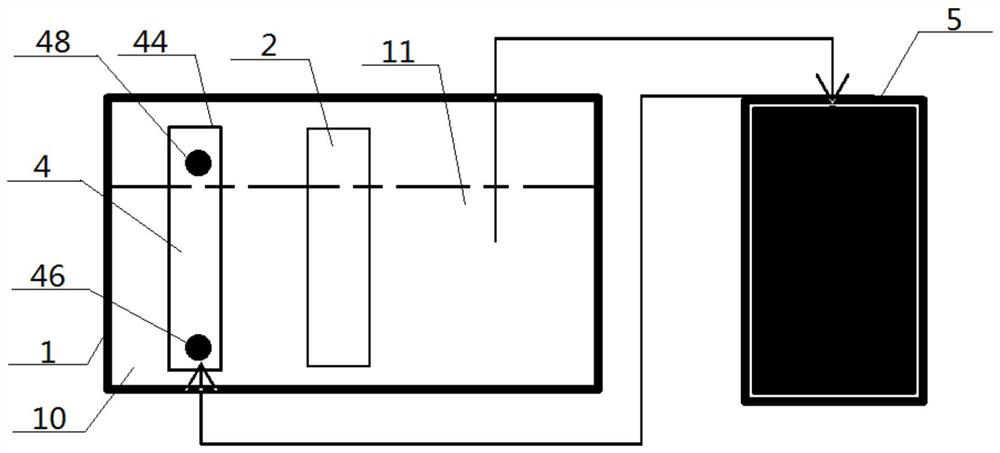

Recovery process of ITO waste target material

ActiveCN113652717AWon't happenAvoid enteringPhotography auxillary processesProcess efficiency improvementElectrolytic agentOrganic acid

The invention provides a recovery process of an ITO waste target material. The recovery process comprises the following steps: firstly, an electrolyte is prepared in an electrolytic tank, wherein the PH value of the electrolyte is 0.5-2, solutes in the electrolyte are 0.01-5mol / l of organic acid radicals and 0.01-5mol / l of inorganic acid radicals, and a solvent in the electrolyte is ultrapure water; then, the ITO waste target material is put in an anode basket; then, a cathode plate and the anode basket are both put in the electrolyte, and the internal of the anode basket communicates with the electrolyte; cathode lugs on the anode basket and the cathode plate are connected to a circuit; then, the circuit with the anode lugs and the cathode lugs is started to start electrolysis; the electrolysis temperature is 10-50 DEG C; the electrolysis current is 30-100A / m<2>; and indium elementary substances are generated on the surface of the cathode plate, and preferably, the indium elementary substances generated on the cathode plate are wholly flaky for wholly taking indium. The recovery process generates no waste gas and waste liquid, and is lower in pollution, free of loss and lower in cost.

Owner:ENSHI ZHICHUN ELECTRONIC MATERIAL CO LTD

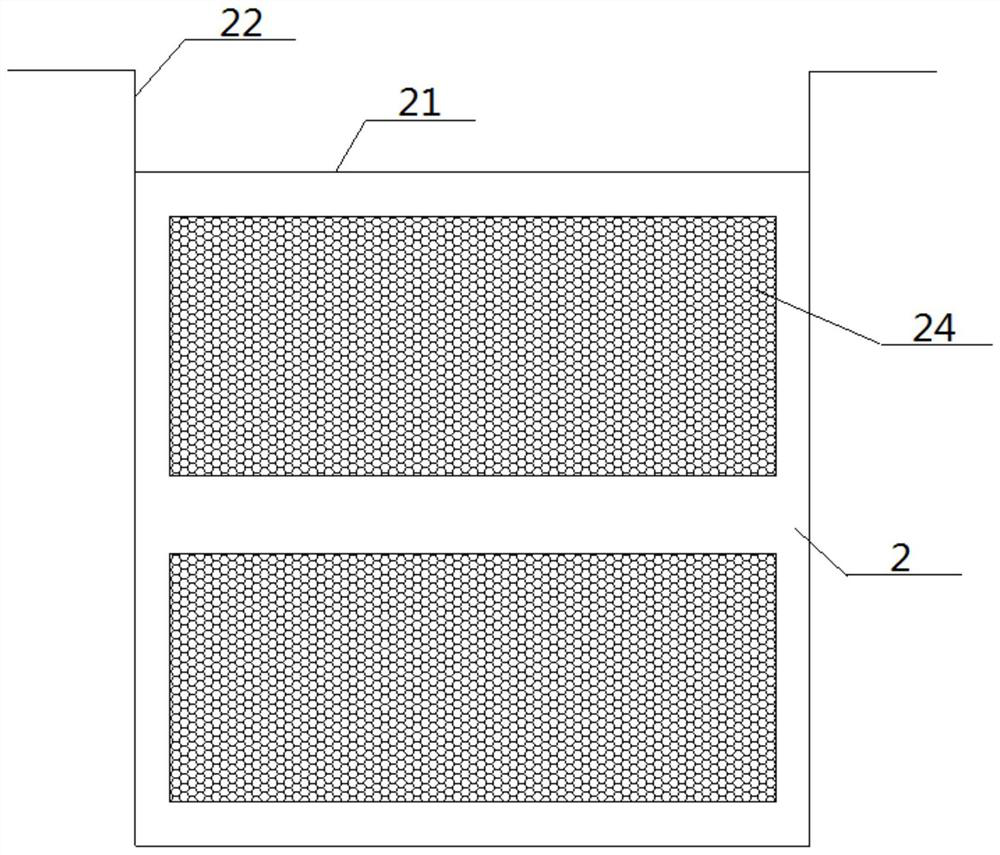

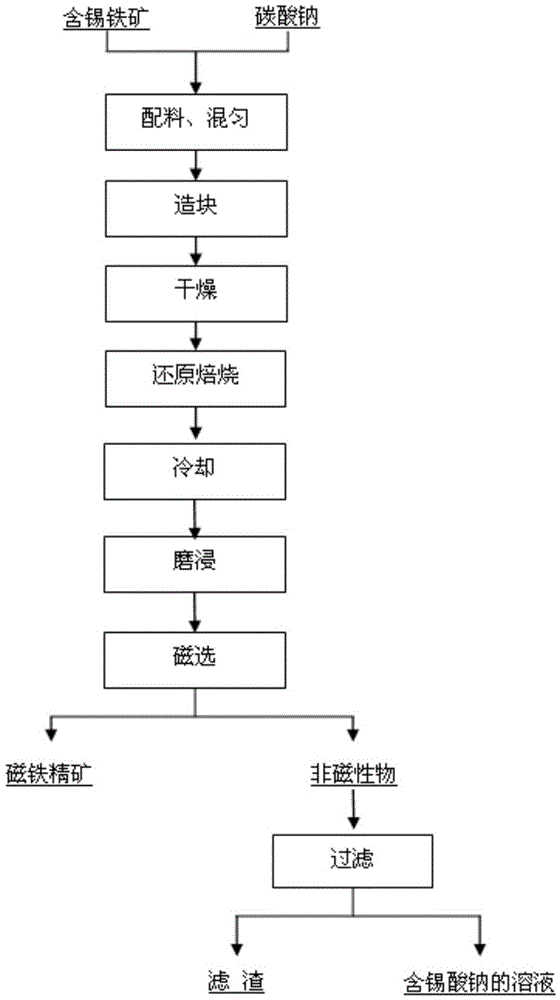

A method for preparing iron concentrate for ironmaking from tin-containing iron ore

Owner:CENT SOUTH UNIV

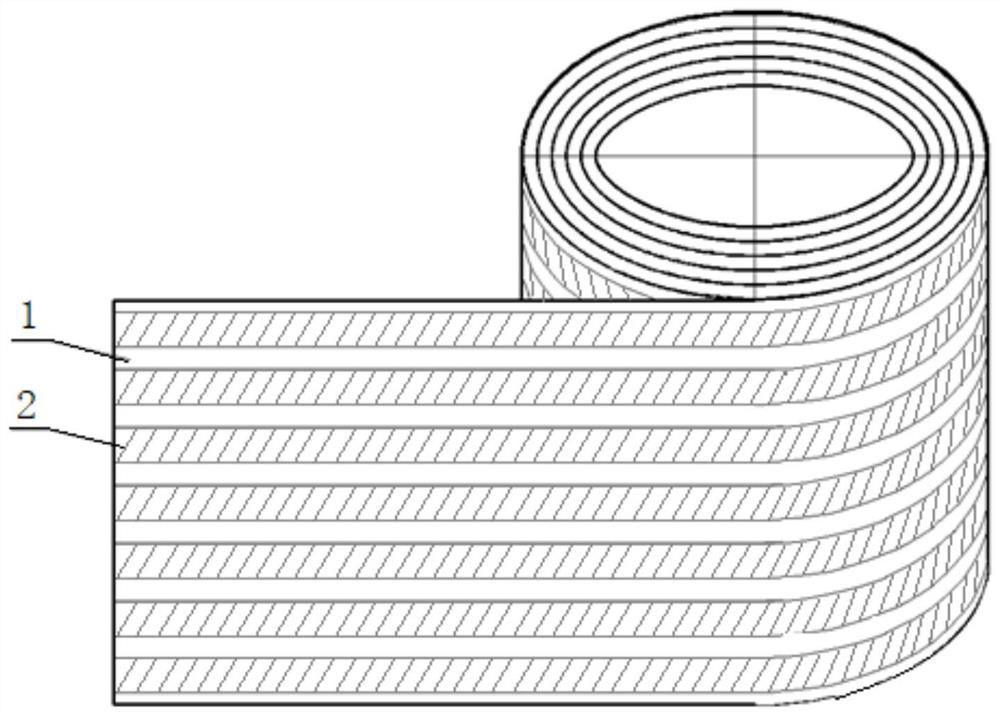

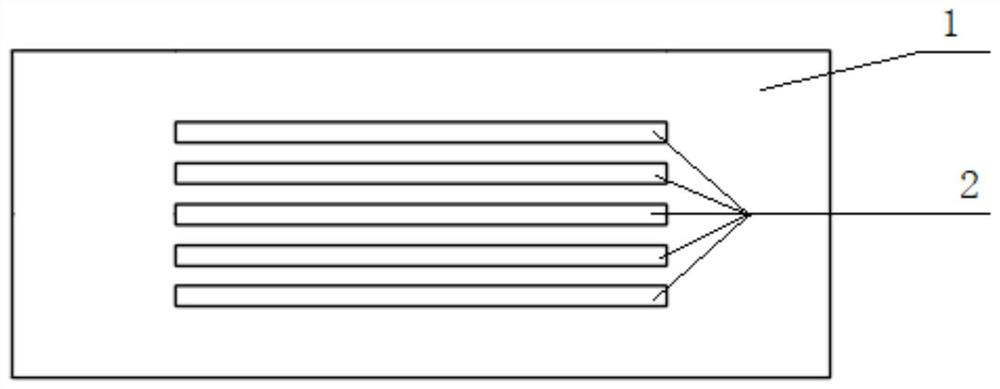

High-tin-content copper-tin brazing filler metal grid-shaped composite strip and preparation method thereof

ActiveCN113941797AIncrease soldering temperatureLow soldering temperatureWelding/cutting media/materialsSoldering mediaCopperFiller metal

The invention discloses a high-tin-content copper-tin brazing filler metal grid-shaped composite strip. The tin content is 10wt%-60wt%; the high-tin-content copper-tin brazing filler metal grid-shaped composite strip comprises a strip-shaped copper base body, a plurality of grooves which are arranged in parallel at intervals are formed in one surface of the strip-shaped copper base body, the grooves are filled with tin to form tin bars, and the tin bars and copper around the grooves are connected into a whole. The invention further discloses a preparation method of the high-tin-content copper-tin brazing filler metal grid-shaped composite strip. According to the method, the influence of the tin adding amount on the machining forming performance can be avoided, when the tin content reaches 10wt%-60wt%, the high-tin-content copper-tin brazing filler metal strip can still be obtained through a conventional pressure machining method, and the brazing temperature is reduced.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

A kind of comprehensive recovery method of waste circuit board smelting soot

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

A method for recovering valuable metals from arsenic-containing fumes and harmless disposal of arsenic resources

ActiveCN106834676BEasy to separateReduce tin contentProcess efficiency improvementSodium arseniteCobalt

Owner:CENT SOUTH UNIV

A method for harmless recovery of waste circuit board smelting soot

The invention belongs to the technical field of solid waste treatment, and specifically discloses a harmless recycling method for smelting soot from waste circuit boards. The recovery method first adds alkali to the smelting soot for roasting, and converts the metal bromide and chloride salts in the soot into water-insoluble metal oxides, and the bromine and chlorine elements form water-soluble sodium bromide and sodium chloride, and the soot after roasting After water immersion and filtration, the separation of bromine, chlorine and valuable metals is realized. Bromine and chlorine mainly enter the solution, and then the crude salt product is obtained through evaporation and crystallization, and then the filter residue is reduced and roasted, and the zinc element in the residue is recovered by volatilization. , to obtain a higher purity zinc oxide product, and then the calcine is further heated and smelted, and the metal oxide is reduced to produce metal ingots and harmless reduction slag. The waste circuit board smelting soot treatment method provided by the invention can effectively separate bromine and chlorine in the waste circuit board smelting soot, and can simultaneously remove organic matter in the soot, and effectively recover bromine, chlorine and valuable metals.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Preparation of methyltin stabiliser

ActiveCN101475584BReduce tin contentImprove thermal stabilityTin organic compoundsAlkaneNon toxicity

The invention provides a methyl tin stabilizer and a method for preparing the same and relates to the technical field of organic chemistry. The method comprises: in the presence of a catalyst, mixing and refluxing an alkyl diacid, mercaptoethanol and a solvent; after the reaction finishes, washing the solution with water and obtaining a dimercaptoester; and adding the obtained dimercaptoester into an aqueous solution of methyltin trichloride or / and dimethyltin dichloride, adjusting the pH value of the system by using an alkaline solution, carrying out an pre-esterification reaction before heat preservation, heating for carrying out a post-esterification reaction, washing an organic phrase after the reaction finishes, separating the organic phrase from a water phrase, carrying out vacuum water removal and obtaining the methyl tin stabilizer. The methyl tin stabilizer has high transparency, weather resistance, compatibility, pressure analysis, non-toxicity, excellent high-temperature stability and low tin content. The low tin-content methyl tin has higher thermal stability than the prior methyl tin, so final PVC products can achieve the same stability with even smaller amount of added methyl tin stabilizer, the use of tin is reduced and the production costs of terminal clients are reduced at last.

Owner:YANGZHOU HATAIKE TECH

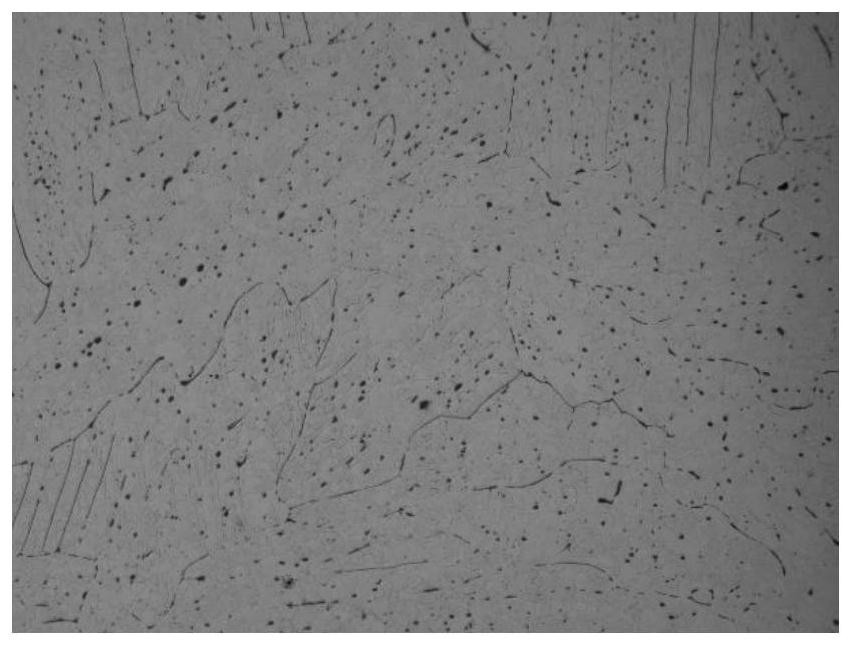

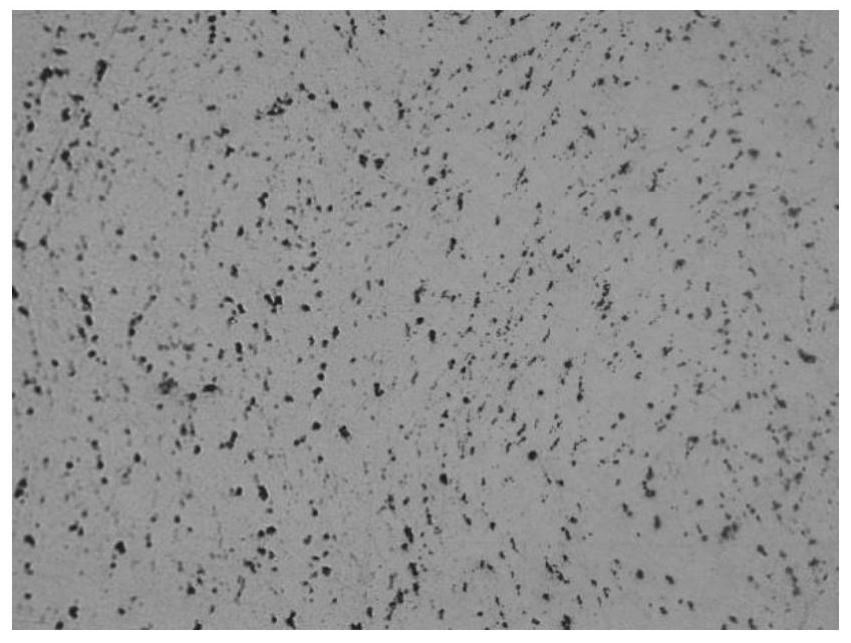

Extruded aluminum alloy for oil-free bearing and preparation method of extruded aluminum alloy

The invention discloses an extruded aluminum alloy for an oil-free bearing and a preparation method of the extruded aluminum alloy, and belongs to the field of aluminum alloy materials. The extruded aluminum alloy for the oil-free bearing is composed of the following element components in percentage by weight: 2%-3% of Sn, 4%-5% of Cu, 0.1%-0.3% of Fe, 0.05%-0.1% of Si and 0.01%-0.04% of Zn. According to the extruded aluminum alloy, copper is added on the basis of an aluminum-tin bearing alloy, the copper element can be dissolved into a solid solution to reinforce a base body, the surface strength and hardness of the alloy are enhanced under the condition that the good abrasion resistance, fatigue resistance, seizure resistance and embedment performance of the alloy are kept, and thereforethe bearing can be used under the high-speed, high-load and high-temperature conditions; and in addition, according to the alloy, on the basis of the aluminum-tin bearing alloy, the tin content is greatly reduced, the production and manufacturing cost is greatly reduced, the plasticity of the alloy is greatly improved, meanwhile, the reduction amplitude of the yield strength and the tensile strength of the alloy is very small, meanwhile, the time for the alloy to reach the peak hardness is greatly shortened compared with single-stage aging, and the effect of saving energy is achieved.

Owner:广东深美特种铝合金股份有限公司

A kind of aluminum base-steel bimetal bearing material and its preparation process

ActiveCN105626695BMeet the requirements of environmental performanceImprove carrying capacityBearing componentsAlloyPollution

The invention belongs to the technical field of bearing pad materials, and specifically discloses an aluminum-based-steel bimetallic bearing pad material and a preparation process thereof. The material is composed of an aluminum covering layer, an aluminum-based alloy layer, an aluminum transition layer and a low-carbon steel layer; among them, the aluminum-based alloy layer is an endogenous TiB2 with endogenous TiB2 particles as a reinforcement and an aluminum-tin-copper alloy as a matrix alloy. Particle-reinforced aluminum-tin-copper alloy. The preparation method comprises the following steps: (1) preparing materials; (2) preparing an aluminum-based alloy layer; (3) rolling with aluminum cladding; (4) manufacturing steel strips; (5) cold rolling and compounding. The interface bonding strength between the aluminum base alloy layer and the steel plate of the aluminum base-steel bimetallic bearing material of the present invention is high, the bearing capacity of the aluminum base-steel bimetallic bearing material is strong and the anti-friction property is good, the bearing pad works stably, has a long service life, and produces Low cost, environmental protection and no pollution.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com